Abstract

Ca0.92(Li,Ce)0.04Bi2Nb2−x W x O9 (x = 0.01–0.06) high-temperature piezoceramics were prepared by a conventional solid-state sintered method, and effects of W content on their piezoelectric properties were studied. All samples possess a pure Aurivillius-type structure, showing that Li, Ce, and W dopants have well diffused into the CaBi2Nb2O9 lattice to form a solid solution. The doping with W slightly decreases the Curie temperature (T C) of the ceramics. In addition, the excellent electrical properties (e.g., d 33 ~ 16.1 pC/N, k p ~ 9.58 %, Q m ~ 4,767) and a high Curie temperature (e.g., T c ~ 925 °C) are simultaneously obtained in the ceramics with x = 0.04, together with an enhanced thermal stability of <900 °C. As a result, the investigated material system provides the promising potential applications in ultra-high-temperature environments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

High-temperature piezoelectric sensors are of major importance for the chemical and material processing, automotive, aerospace, and power-generating industries [1]. Aurivillius-type bismuth layer-structured ferroelectrics (BLSFs) [2] have attracted significant attention because of their potential applications in nonvolatile ferroelectric random-access memory and high-temperature piezoelectric devices [3–5].

CaBi2Nb2O9 (CBNO) material consisting of (CaNb2O7)2− between (Bi2O2)2+ layers is a typical two-layered Aurivillius-type compound, possessing a very high Curie temperature (T c ~ 943 °C). Nevertheless, the piezoelectric coefficient (d 33) of a pure CBNO ceramic was found to be only about 5.8 pC/N [6, 7], which hinders its practical applications. Therefore, many investigations have been carried out to improve its piezoelectric properties, such as texturing techniques [4, 8] and chemical modifications [9–11]. Among those, an effective way to improve the piezoelectric properties of CBNO ceramics is doping the rare earth elements and alkali metal elements [8–10], and unfortunately their T c quickly decreases. Recently, Wang et al. and Yin et al. have reported that the W6+-doped BLSFs ceramics possess the enhanced remanent polarization, reduced coercive field, and improved fatigue property [12, 13]. Moreover, Saito et al. [14] have reported that the d33 value of (K0.44Na0.52Li0.04)(Nb0.84Ta0.lSb0.06)O3 ceramics could significantly improved by Li+- , Ta5+- , Sb5+-co-doped A- and B-sites of the (K0.5Na0.5)NbO3(KNN) ceramics. However, there are few reports on the ion substitutions for A- and B-sites of CBNO ceramics. As a result, it is of great interest to study the effects of ion substitutions for A- and B-sites on piezoelectric properties of CBNO compounds.

In the present paper, the (Li,Ce,W)-co-modified Ca0.92(Li,Ce)0.04Bi2Nb2−x W x O9 ceramics were prepared by the conventional solid-state sintered method, and we emphasized the effects of W content on their piezoelectric properties. We simultaneously attained a large d 33 and a high T c by refining W content. In addition, such a ceramic possesses an enhanced thermal stability. The underlying physical mechanisms were also given.

2 Experimental procedure

The Ca0.92(Li,Ce)0.04Bi2Nb2−x W x O9 (x = 0.01, 0.02, 0.03, 0.04, 0.05, 0.06; abbreviated as CLCBN-W100x) ceramics were prepared by conventional solid-state reaction with metal oxides or carbonate powders consisting of Bi2O3 (99 %), CaCO3 (99 %), Nb2O5 (99.99 %), Li2CO3 (99.99 %), CeO2 (99.99 %), and WO3 (99 %). All the powders were weighed according to the stoichiometric compositions and subsequently ball-mixed for 24 h. The milled powders were dried and calcined at ~850 °C for 2 h, and then, these mixtures were milled again in the same condition. The milled powders were dried, ground, and then granulated with a polyvinyl alcohol (PVA) binder. The granulated powders were pressed into disks with a diameter of 10 mm and a thickness of 0.9 mm at a pressure of 150 MPa. After burning out the PVA at ~550 °C, these disks were sintered at 1,070–1,090 °C for 2–3 h and then cooled down to room temperature. The detail preparation process can be found in the patent [15]. The phase structure of these ceramics was determined by X-ray diffraction (XRD) employing the CuK α lines (DX2700, Dandong, China). Microstructure characterization of the sintered ceramics was conducted by scanning electron microscopy (SEM, S-3400 N, Hitachi, Japan). For the room-temperature electrical and dielectric measurements, the Pt paste electrodes were fixed on both surfaces of these sintered pellets at 1,000 °C for 10 min in air. The dielectric behavior as a function of temperatures was determined using a precision LCR analyzer (HP4980A, Agilent, USA) connecting with a programmable furnace. Those samples were poled in a silicon oil bath at 180 °C under a dc electric field of 10–15 kV/mm for 15 min. Their piezoelectric coefficient d 33 was measured using a quasi-static d 33 meter (ZJ-3A, Institute of Acoustics, Academia Sinca, China). Their thermal depoling experiments were conducted by holding the poled samples for 2 h at each temperature, cooling to room temperature, measuring the d 33 value, and repeating the procedures up to 950 °C. The electromechanical coupling factor k p of the sintered ceramics was characterized by an impedance analyzer (HP 4294A, Agilent, USA) according to IEEE standard, and the mechanical quality factor Q m was measured by an impedance analyzer (PV70A, Beijing Band ERA Co. Ltd., Beijing, China).

3 Results and discussion

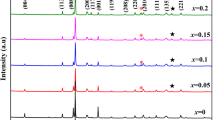

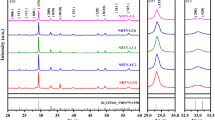

Figure 1 shows the XRD patterns of (Li,Ce,W)-substituted CBNO ceramics. The diffraction peaks were indexed according to the Joint Committee on Powder Diffraction Standards No. 49-608 (CaBi2Nb2O9), as shown in Fig. 1. All samples have a single phase of two-layered Aurivillius-type structure, and no secondary phases were found, indicating that (Li,Ce,W) dopants have diffused into the CBN lattice to form a solid solution. The highest intensity of the diffraction peak of CLCBN-W100x ceramics is (115) in all the XRD patterns, which is consistent with the fact that the most intense reflection of the Aurivillius phase is all of the type of [11(2 m + 1)] [16, 17].

The SEM surface micrographs of (Li,Ce,W)-substituted CBNO ceramics are shown in Fig. 2. As shown in Fig. 2, the grain is plate-like structure, which is also a characteristic of Aurivillius phase ceramics [18]. In addition, the grain growth is anisotropic owing to the high grain growth rate in the direction perpendicular to the c-axis of the Aurivillius phase crystal [19, 20]. From Fig. 2, (Li,Ce,W)-substituted CBNO ceramics have uniform grain size, less porosity, and dense structure, showing that the doping with W does not change the microstructure dramatically. In addition, the CLCBN-W4 ceramics show the better microstructure.

Figure 3a, b shows temperature dependence of permittivity and dielectric loss of CLCBN-W100x ceramics, measured at 1 MHz and 30–970 °C. When the x concentration is less than 0.04, the T C value slightly decreases to ~925 °C as compared with that of a pure CBNO ceramic (~943 °C) [6, 7]. When the x concentration is >0.04, there are no obvious T C peaks due to the sharp decrease in the resistivity and the more involved flaw in (Li, Ce, W)-substituted CBNO ceramics under a high measurement temperature. Generally speaking, high T C values have been attained in the (Li, Ce, W)-modified CBNO ceramics, providing its potential applications in ultra-high-temperature environments. As shown in Fig. 3, the permittivity and loss of the ceramics are relatively flat below 800 °C, indicating the good thermal stability of dielectric properties.

Figure 4 shows the d 33 against x of the ceramics, measured at room temperature. It can be clearly seen that the d 33 value increases with the increase in W content (x < 0.04), and then, the d 33 value decreases with further increase in W content. The d 33 value of CLCBN-W4 ceramics is 16.1 pC/N, which is nearly three times of a pure CBN ceramic (~5.8 pC/N) [6] and also higher than the reported A-site-substituted CBN ceramics (~13 pC/N) [6–10]. This improved piezoelectric activity originates from the substitution of B-site Nb5+ ions by W6+ ions. Firstly, if the oxide octahedron B-site ion radius is small, the ion can leave its equilibrium position and produce greater deviation, which improve the spontaneous polarization. Secondly, the tungsten ion is suggested to be a donor substitution, which decreases the amount of oxygen vacancies; moreover, the oxygen vacancies restrain the movement of domain walls, so the tungsten doping can enhance the piezoelectric activity in the CNBNT-100x ceramics.

Figure 5 shows the thermal depoling behavior of d 33 of the ceramics. The poled samples were insulated 2 h at each annealing temperature, and the d 33 was measured at room temperature. The d 33 value decreases slightly at low temperature regions due to the thermally activated reverses switching of the non-180° domains [11, 21]. When the annealing temperature is above T C, the d 33 value of all compounds decreases rapidly to zero or near zero, exhibiting the nature of the ferro-paraelectric phase transitions. Even if the annealing temperature reaches 900 °C, the d 33 value of CLCBN-W4 ceramics still retains ~13.4 pC/N (83 % of its initial values). This result demonstrates that the CLCBN-W100x ceramics possess the enhanced thermal stability of piezoelectric properties.

Figure 6 shows the electromechanical coupling factor k p and the mechanical quality factor Q m of the ceramics. It can be clearly seen that the k p and Q m values increase with the increase in W content (x < 0.04) and then decrease with further increase in W content. As compared with d 33, the k p and Q m values have the similar trend, and the optimal kp and Q m values of the ceramic with x = 0.04 reach to 9.58 % and 4,767, respectively.

4 Conclusions

The Aurivillius-type Ca0.92(Li,Ce)0.04Bi2Nb2−x W x O9 ceramics were prepared via the conventional mixed oxide routes. A single two-layered Aurivillius-type structure was observed in all ceramics. The piezoelectric coefficient d 33 value of the ceramics was dramatically increased by the addition of (Li,Ce,W), and the optimal electrical properties (e.g., d 33 ~ 16.1 pC/N, k p ~ 9.58 %, Q m ~ 4,767) and a high T c (~925 °C) were simultaneously attained when the x value is 0.04. In addition, the dielectric and piezoelectric properties of the ceramics exhibit good thermal stability. These results indicate that the ceramics of this work are one of the promising candidates for high-temperature applications.

References

R.C. Turner, P.A. Fuierer, R.E. Newnham, T.R. Shrout, Appl. Acoust. 41, 299–324 (1994)

B. Aurivillius, Arkiv. Kemi 1, 499–512 (1949)

H.X. Yan, C.E. Li, J.G. Zhou, W.M. Zhu, L.X. He, Y.X. Song, Jpn. J. Appl. Phys. 39, 6339–6342 (2000)

H.X. Yan, H.T. Zhang, R. Ubic, M.J. Reece, J. Liu, Z.J. Shen, Z. Zhang, Adv. Mater. 17, 1261–1265 (2005)

D.J. Gao, K.W. Kwok, D.M. Lin, Curr. Appl. Phys. 11, S124–S127 (2011)

X.D. Zhang, H.X. Yan, M.J. Reece, J. Am. Ceram. Soc. 91, 2928–2932 (2008)

C.M. Wang, J.F. Wang, S.J. Zhang, T.R. Shrout, Phys. Status Solidi RRL 3, 49–51 (2009)

X.X. Tian, S.B. Qu, B.K. Wang, W.S. Zhang, J.F. Zhao, Sci. China Chem. 54, 1552–1557 (2011)

C.M. Wang, S.J. Zhang, J.F. Wang, M.L. Zhao, C.L. Wang, Mater. Chem. Phys. 118, 21–24 (2009)

X.X. Tian, S.B. Qu, H.L. Du, Y. Li, Z. Xu, Chin. Phys. B 21, 037701 (2012)

Z.H. Peng, Q. Chen, Y.D. Wang, D.Q. Xin, D.Q. Xian, J.G. Zhu, Mater. Lett. 107, 14–16 (2013)

X. Wang, H. Ishiwara, Appl. Phys. Lett. 82, 2479–2481 (2003)

Y. Yin, D. Su, J. Lou, J. Ma, W. Li, X.M. Lu, J.S. Zhu, Y.N. Wang, Integr. Ferroelectr. 65, 69–80 (2004)

Y. Saito, H. Takao, T. Tani, Nature 432, 84–87 (2004)

J.G. Zhu, Y.D. Wang, Q. Chen, Z.H. Peng, D.Q. Xiao, Sichuan University, China Patent 201410128596.3, 1 Apr 2014

H.X. Yan, Z. Zhang, W.M. Zhu, L.X. He, Y.H. Yu, C.G. Li, J.G. Zhou, Mater. Res. Bull. 39, 1237–1246 (2004)

C.M. Wang, L. Zhao, J.F. Wang, L.M. Zheng, J. Du, M.L. Zhao, C.L. Wang, Mater. Sci. Eng. B 163, 179–183 (2009)

D.Y. Sua′rez, I.M. Reaney, W.E. Lee, J. Mater. Res. 16, 3139–3149 (2001)

C.M. Wang, J.F. Wang, S.J. Zhang, T.R. Shrout, J. Appl. Phys. 102, 094110 (2009)

X.Y. Huang, Z.G. Chen, X.L. Zheng, C.H. Gao, C.H. Guan, C. Zhao, J. Rare Earths 25(Supp. L), 158–162 (2007)

H.X. Yan, H.T. Zhang, M.J. Reece, X.L. Dong, Appl. Phys. Lett. 87, 082911 (2005)

Acknowledgments

Authors gratefully acknowledge the supports of the National Natural Science Foundation of China (NSFC Nos.61201064 and 51332003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Wu, J., Peng, Z. et al. Piezoelectric properties and thermal stability of Ca0.92(Li,Ce)0.04Bi2Nb2−x W x O9 high-temperature ceramics. Appl. Phys. A 119, 337–341 (2015). https://doi.org/10.1007/s00339-014-8972-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8972-4