Abstract

Environmental considerations coupled with fossil fuel depletion encouraged research community to implement green protocol by partially or fully replacing petrochemicals. This is valid in case of adhesive research and development, where partial replacement of colloidal stabilizer, polyvinyl alcohol (PVA), is replaced by an abundant and sustainable material, corn starch (S). The work here investigates the effect of adding PVA and S blends formulated for polyvinyl acetate (PVAc)-white glue for wood adhesives. To enhance overall properties, boric acid, citric acid, glyoxal, and glutaraldehyde were employed as crosslinkers at a low concentration (0.1 wt.%). The presence of free hydroxy groups of PVA-S blend provides a site for the crosslinkers. Crosslinked blends are formulated with PVAc binder, plasticizer, and preservatives forming a wood adhesive. Various characterization techniques were employed for measuring physical and thermo-mechanical properties. Crosslinking was proved with dynamic mechanical analysis. Enhancement in performance properties was shown by the increase in tensile shear strength on bonded wood substrates and wet tack analysis. Tensile strength of bonded wood after 8 h. showed 16% increment for citric acid-incorporated sample, 13% for glutaraldehyde, 8% for boric acid, and ~ 7% for glyoxal crosslinked wood adhesive. Moreover, crosslinking consolidated polymer chains, which resulted in enhanced thermo-mechanical properties. Overall, the crosslinked samples showed better physical, mechanical, and thermal properties when compared to the non-crosslinked adhesive. Hence, this study can be a potential in the further development of sustainable white glue for wood bonding applications.

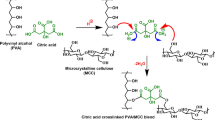

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

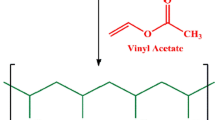

Reliability on fossil fuels and petrochemicals has been constantly debated with the growing population [1]. There has been an intriguing quest for alternative systems which can function as a candidate for sustainable economy [2,3,4]. Researchers have found a huge potential on biopolymers as they are abundantly available and can be tailored for any particular application [5]. Adhesive sector also has witnessed such a change from formaldehyde-based binders for wood consolidation to systems which consists of biopolymers and organic solvent-free adhesives [6]. As water being an environmentally benign solvent, water-based wood adhesives, such as polyvinyl acetate (PVAc) emulsion wood adhesives, commonly known as ‘white glue’ or ‘white adhesive’ have gained much momentum [7]. Polyvinyl alcohol (PVA) itself is used as adhesive and a protective colloid for PVAc emulsion [8]. However, PVA being a petrochemical is not a complete solution considering the sustainability and green adhesive fulfillment. One potential candidate which has similar structure of PVA and can be a fully/partially substitutable candidate is starch (S) [9,10,11]. Starch belongs to polysaccharide family and is the second most abundant naturally occurring biopolymer [12]. Starch-incorporated wood adhesives have shown biodegradability, cost-effectiveness, and enhanced binding on various substrates, thus finding application in commercial-grade adhesives [13, 14]. Furthermore, starch has free hydroxyl groups in its structure, which acts as a site for further chemical modification [15]. Apart from this, starch can be blended with other similar polymers, which can show synergistic property [16].

As mentioned, starch alone as a colloidal stabilizer for PVAc has been proposed by researchers. However, there are many bottleneck challenges of starch which limits themselves as a lone colloidal stabilizer. Blending PVA and starch (PVA/S) is an approach where the properties of colloidal stabilization of PVA and binding attributes of starch can be tailored together [16, 17]. Singha et al. reported the biodegradable nature of starch and PVA blends with enhanced mechanical and thermal properties [18]. In another work, Chen et al. modified starch and PVA blend by crosslinking and showed its biodegradable nature [19]. Moreover, blending naturally abundant biopolymer, starch, with PVA is a green approach to reduce the dependency on fossil fuel based polymers [20, 21]. There has been a series of work by Gadhave et al., where modification of PVA/S blends by crosslinking approach has been shown potential applicability as wood adhesives [16, 22]. Various crosslinkers have been successfully evaluated as crosslinkers for PVA/S blend, thereby exhibiting enhanced adhesive performance properties. Namely, the crosslinkers reported by the group are dialdehydes [11], complex of dialdehyde (glutaraldehyde sodium bisulfite) [12], boric acid [23], citric acid [5], and silane [24] and its incorporation has enhanced thermo-mechanical and performance properties with respect to wood adhesion.

Although there are various works on PVAc wood adhesives, greener approach to reduce dependency on PVA as colloidal stabilizer for PVAc emulsion remains scant. Starch has been shown as a potential candidate which can partially or fully replace PVA in PVAc emulsion-based adhesive. However, as starch has many limitations, an attempt to investigate the applicability of PVA blended starch as a candidate for PVAc emulsion is presented here. Limited number of works have been reported in PVA/S blend-incorporated PVAc white glues. In the present work, instead of PVA alone as stabilizer, we have formulated PVAc emulsion wood adhesive with crosslinked PVA/S blend system. Various classes of crosslinkers such as inorganic acid (boric acid), an organic acid (citric acid), and two dialdehydes of different chain lengths, namely glutaraldehyde and glyoxal, have been formulated with PVAc. Incorporation of the crosslinkers is at a very low concentration (0.1 wt.%) in PVA/S, as higher concentration affects storage stability of adhesives [16]. The effect on various properties such as viscosity and change in viscosity relating to time by accelerated stability test was compared and studied. The performance properties of the adhesive were further studied by measuring the wet tack and tensile shear strength of wood joints bonded with these systems at various intervals, hence making the work as a holistic and a comprehensive investigation. Hence, the work is an attempt and a step forward aiming for green, sustainable, and environmentally benign adhesive for wood consolidation, thereby fueling the green protocol.

Materials and methods

Materials

PVA (CAS No. as 9002-89-5, % degree of hydrolysis as 87–89%, molecular weight in the range of 99,000– 1,05,000 g/mol) was supplied by Kuraray Co. Ltd. Corn starch (CAS No. as 9002-25-8, % moisture content of 5–7%, and amylose content as 25–30%) purchased from Sanstar Bio-polymer Ltd. PVAc emulsion (CAS No. as 9003-20-7, PVA stabilized, with 55% solid, and viscosity as 3500 cp and pH of 4.5), formaldehyde (CAS No. as 50-00-0, molecular biology grade, ≥ 36.0% in H2O), boric acid (CAS No. 10043-35-3, 98% pure), citric acid (CAS No. 77-92-9, 99%), glyoxal (CAS No. 107-22-2, ∼40% in water), glutaraldehyde (CAS No. 111-30-8, 25% solution), and di-butyl phthalate (CAS No. 84-74-2, DBP) were obtained from Sigma-Aldrich.

Preparation method

Corn starch and PVA blends were prepared and formulated as per the procedure described in [16]. The preparation method involved two-step process where first step focused on the preparation of colloidal solution. PVA and corn starch were blended followed by reaction with various crosslinkers. In the second step, modified PVA/S blend samples were formulated by mixing various additives mentioned in Table 1 at 175 rpm for 1.5 h [9]. For comparison, a blank sample (ML-Standard) was prepared without crosslinkers. As the crosslinkers were added and reacted with the blend, and PVAc was added later, an assumption is made that the changes in properties are developed by the presence of crosslinkers. This final product was then labeled as in Table 1 and stored in plastic containers.

Characterization and testing

Viscosity and pH

Viscosity was measured at 20 rpm using Brookfield DV1 Viscometer as per ASTM D1084. A digital pH meter, CL 54 + Toshcon Industries, India, was employed for measuring pH. The measurement was performed according to ASTM E70. Both the tests were conducted at a temperature of 28 °C.

Dynamic mechanical analysis (DMA)

Analysis was performed using DMA Q-800 from TA Instruments, Mumbai, India; 200-micron-thick samples were casted on a polytetrafluoroethylene (PTFE) using an applicator and films were solidified at 28 °C. The analysis was performed at temperature ranging from − 30 °C to 150 °C, with five-minute hold time, as it reaches programmed temperature. Ramp rate of 5 °C/min was given; frequency of 1 Hz and a strain 0.1% were the inputs given.

Pencil hardness test

Adhesive samples were casted over a glass plate using an applicator of 1000 microns and made to dry at 28 °C for 1 day and tested using QHQ-A portable pencil hardness tester following ASTM D 3363 standard.

Wet tack

A probe tack analyzer from Rohit Instruments, Pidilite R & D lab, Mumbai, was employed for testing. 2–3 mg of adhesives was placed between a metal cylinder and surface. The cylinder squeezes sample as it approaches surface at 5 mm/min. Resistive force exerted on the cylinder as it moves up after being in contact with the adhesive was noted as wet tack value (unit in gram-force (gf)), to minimize error test repeated for 3 times and data represented with error value.

Tensile strength

Tensile lap shear strength of wooden specimen (plywood and laminate (ply-lam)) was measured using UTM Tinius Olsen H25KT, Mumbai, India, at 28 °C and 65–70% relative humidity, according to ASTM D 906. The white glue was applied to 50 mm × 50 mm area of wooden specimens, then placed in sample holder of the apparatus, and pulled apart at 5 mm/min. For measuring the tensile strength development over time, testing was done for 2, 4, 6, and 8 h. For all the compositions, five specimens were analyzed, and standard deviations were reported.

Stability test

For studying the stability of white glue over time, viscosity was monitored using Brookfield DV1 Viscometer at 20 rpm at various intervals keeping samples at 50 °C in an oven. The test was conducted at 28 °C on the 15th, 21st, and 30th day after its preparation.

Results and discussion

The result obtained from various test is shown in Tables 2, 3, and 4.

Viscosity and pH

From the results of viscosity analysis (Fig. 1), all the samples showed increment in viscosity except the standard sample. The presence of free polar hydroxyl (-OH) groups in PVA/S blend acts as a location for the crosslinking reaction [23]. Boron atom, with an empty p orbital, attracts nucleophilic OH groups in PVA/S blend forming crosslinks [20, 25]. As crosslinks created consolidates the polymeric chains, viscosity increment can be correlated with the crosslinking reactions. In the case of citric acid-incorporated sample, although citric acid forms crosslinks with the hydroxyl groups by ester linkages [26, 27], increment in viscosity was least. Temperature and pH influence the effect of citric acid, depending on the two factor it can crosslink or hydrolyze the starch molecules [28]. Structurally, citric acid has a 3-dimensional anatomy, which can function as a spacer, thereby promoting the mobility of blend polymer chains [29]. In addition, gelatinization and retrogradation of starch by citric acid in acidic conditions (from pH value shown in Table 2) support for decreasing the viscosity [30, 31]. Hence, although crosslinks are created, plasticizing effects overrule in the viscosity data, resulting in least increment of viscosity for citric acid sample, compared to the other samples.

For the samples with dialdehydes (glutaraldehyde and glyoxal), acidic condition (shown in Table 2) catalyzes the formation of acetal linkages with free -OH of PVA/S blend [32]. This contributes to the enhancement in the viscosity of the samples. Furthermore, crosslinking increases the chain length of PVA/S blend and hence increases chances of entanglement, contributing to rise in viscosity compared to blank samples. Based on the aforementioned mechanism of crosslinking, possible crosslinked PVA/S blend structures are depicted in Fig. 2. In general, by adding 0.1% of crosslinker in the system, there is a significant rise in the viscosity of the adhesive, which could be advantageous the applicability and spread ability of white adhesive.

Dynamic mechanical analysis (DMA)

DMA analysis relates to the thermos-mechanical properties of polymeric materials. In the present investigation, it is observed that all the sample films exhibited major transitions above glassy temperature. Moreover, it can be seen that there are two transitions at 45 °C and 90 °C relating to glass transition temperature (Tg) of PVAc and PVA, respectively [16, 22]. Figure 3 shows storage modulus (E’) curves and loss modulus (E”), and Fig. 4 represents tan delta for all the adhesive samples. Table 3 consolidates values of E’, E”, and tan delta for all the adhesive samples. ML-5 (glutaraldehyde sample) showed maximum shift in E’, E” and tan delta value. Formation of acetal bonds with PVA and starch contributed to the enhancement, and hence, thermo-mechanical properties have been boosted [18, 33]. It is worth mentioning that the boric acid-containing sample also showed enhancement in E’, E”, and tan delta value. However, for the rest, value remains closer to the standard. Also, ML-3 sample containing citric acid showed the lowest values for storage and loss modulus. Although citric acid acted as crosslinker for PVA/S blend as observed by an increase in tan delta, citric acid with its 3D structure promotes the mobility of chains by acting as a spacer [29]. Also while preparing the blend, temperature was at 92–95 °C; possible chances of unreacted citric acid in the polymer matrix contributed to gelatinization in starch rather than crosslinking [30, 34]. Hence, better chain mobility occurs, resulting in lowering of storage and loss modulus for citric acid containing sample. Overall, DMA analysis also showed the possibility of crosslinking reaction which is in line with the observations from the viscosity data.

Pencil hardness test

Pencil hardness analysis correlates with the mechanical properties of polymer film samples. As crosslinkers are expected to increase the hardness of adhesive films [11], the results shown in Table 2 are in line with the assumption. Crosslinking reaction contributes to reduction in voids between the polymeric chains; this makes the tip of pencils hard to penetrate. Boric acid-incorporated sample showed the maximum value, whereas citric acid containing sample showed the minimum. 3-D network formed as boric acid reacted with PVA, starch, and PVAc [35] consolidates thereby reducing the intermolecular distance; hence, film hardness increases. Although for the citric acid sample, hardness value slightly enhanced, the possibility of plasticizing nature of unreacted citric acid can be observed. Dialdehyde crosslinkers (glyoxal and glutaraldehyde) containing samples showed good strength, as acetal bonding enhanced the stiffness of films, thus contributed to the enhancement [36]. Hence, introduction of crosslinkers contributed to a positive shift of hardness values.

Wet tack

From the results shown in Table 2, modified samples showed enhanced wet tack property. Crosslinking consolidates the polymer chains and restricts mobility and results in better cohesion between the chains. Boric acid-crosslinked sample, ML-1, forms a complex 3-dimensional network structure [35]. Hence, following the similar observations from viscosity data, DMA graphs, and pencil hardness data, the same trend is shown here. The plasticizing nature of unreacted citric acid [22] is clear from wet tack analysis, although there is a small increment for ML-3; the data are almost comparable to ML-Standard. Dialdehyde-crosslinked blends showed similar increment in wet tack. The formation of acetal bonds enhanced the internal cohesion, and hence, improvements are reflected in the wet tack data.

Tensile strength (ply to lam)

For the analysis of tensile shear strength of bonded wood substrates, the substrates were placed in single lap adhesive joint, as shown in Fig. 5 a and b. It is noteworthy to mention that presence of pores in the surface of laminate led to good wetting of adhesives, while plywood showed poor wetting [16]. It was noted that all the samples showed failure at the adhesive applied area and not failure at substrate, as shown in Fig. 5c, d. The test was conducted as per calculated time intervals, and its results are shown in Fig. 6a and Table 4. The time wise analysis enabled understanding of bond development in wooden specimen, and results are in accordance with wet tack analysis. Although, test conducted after 2 h. of bonding showed no significant bond development, but results for 4, 6 and 8 h. showed indication of enhanced bonding. Boric acid-crosslinked sample showed the maximum improvement in tensile strength. Complex formation and effective crosslinking of boric acid consolidated the chains, enhancing viscosity and wet tack; due to this, the adhesion on wooden substrates increased; especially, the enhancement of bonding strength at 4 and 6 h. is advantageous in the development of wood adhesives with high initial grab and enhanced handling strength properties. ML-3 sample showed improvement in tensile strength, although citric acid showed plasticizing effect, the spread-ability, and wetting properties of the white glue on wooden pieces being improved. ML-5 and ML-2 samples with dialdehydes also showed enhancement in bonding strength. Crosslinking by acetal bond formation led to cohesion as shown in the wet tack analysis, with good film hardness made a positive effect on the bonding strength. Tensile strength of bonded wood substrates after 8 h. showed clear evidence on the crosslinking effect. 16% increment in tensile strength was observed for citric acid-incorporated sample, 13% for glutaraldehyde, 8% for boric acid, and ~ 7% for glyoxal-crosslinked wood adhesive. Hence, the modified white glue formulation has a significant role in enhancing the tensile strength for adhesive bonded with plywood to laminate wooden specimen.

Stability test

The changes in viscosity upon storage of adhesive are an important parameter for studying its storage stability [16]. Generally, viscosity of adhesive increases upon storage as secondary forces builds up viscosity, and with the passage of time, polymer chains orients to its lower energy [22]. Polar hydroxyl groups in PVA/S form hydrogen bonds; hence, after an initial rise viscosity becomes almost stable. The results shown in Fig. 6b follow similar pattern. ML-5 sample showed initial increment in viscosity (Fig. 1) as glutaraldehyde acts as a crosslinker for PVA/S blend by acetal bonding [37]. However, after 15 days of storage in 50 °C, the sample was found gelled. The presence of acidic hydrogen must have contributed to its gelation. Although ML-5 sample gets gelled, the enhancements in hardness of film, wet tack, and bonding strength can be advantageous. Hence, ML-5 white glue sample can be made as a two-pack system, where glutaraldehyde and the other formulation can be separately packed. Steep increment in viscosity after 15 days of storage shown by boric acid sample, ML-1, is due to the complex 3-D network formation [22, 35]. ML-2 sample with glyoxal as crosslinker showed increase in viscosity with respect to time, but after 30 days, lump formation was observed. The increment in viscosity is sharp, and possibility for gelation after 30 days cannot be neglected. From the literature, it is studied that citric acid acts as a good additive for PVA/S blend [22, 34]; similar observations are also noted. Citric acid-incorporated adhesive, ML-3, showed stable viscosity profile without lump formation, discoloration, and odor, showing the stability. The sample can be comparable to the stability of ML-Standard, since both the samples showed similar viscosity profile and are almost same after 30 days. Hence, on comparison, although boric acid sample showed high viscosity without gelling even after 30 days, the higher value of viscosity compared to standard can be an issue on spread-ability in wooden substrates. On the other hand, citric acid-incorporated white glue formulation showed a more stable viscosity with respect to time.

Conclusion

The study investigated the effect of various crosslinkers on PVA/S blend and its incorporation in PVAc emulsion-based adhesive. Physical, thermal, mechanical, and performance properties were analyzed comprehensively. Results from DMA analysis proved the proposed crosslinking mechanism, as samples showed increase in Tg by shift of tan delta peak, on addition of crosslinkers. Moreover, enhanced storage modulus denoted the rise in mechanical property. Viscosity enhancement for the sample with crosslinked blends can be equated to the spread ability and better surface application of white adhesive. Various analysis concluded the pronounced effect of plasticization over crosslinking for citric acid sample. All the crosslinked samples showed profound enhancement in adhesion property evidenced from tensile test on wooden specimens and wet tack analysis. Although boric acid sample reflected its crosslinking effects in various analysis, viscosity rise after 30 days of storage at 50 °C can be a limitation on its ease of application on wood substrate. Gel formation in dialdehyde samples can be resolved by making it as a two-pack system. In conclusion, the study successfully investigated the incorporation of various crosslinkers of PVA/S into PVAc-based formulation, and the so prepared white adhesive samples showed better physical, mechanical, and thermal properties when compared to the standard adhesive. Hence, this study can be potential in further development of PVAc adhesive with starch blended PVA system for wood bonding applications.

References

Vineeth SK, Tebyetekerwa M, Liu H et al (2022) Progress in the development of solid-state electrolytes for reversible room-temperature sodium–sulfur batteries. Mater Adv 3:6415–6440. https://doi.org/10.1039/D2MA00428C

Vineeth SK, Gadhave RV (2020) Sustainable raw materials in hot melt adhesives : a review. Open J Polym Chem 10:49–65. https://doi.org/10.4236/ojpchem.2020.103003

Vineeth SK, Gadhave RV, Gadekar PT (2019) Nanocellulose applications in wood adhesives—review. Open J Polym Chem 09:63–75. https://doi.org/10.4236/ojpchem.2019.94006

Dhawale PV, Vineeth SK, Gadhave RV, Mahanwar PA (2021) Cellulose stabilized polyvinyl acetate emulsion: review. Open J Org Polym Mater 11:51–66. https://doi.org/10.4236/ojopm.2021.112002

Vineeth SK, Gadhave RV, Gadekar PT (2022) Polyvinyl alcohol–cellulose blend wood adhesive modified by citric acid and its effect on physical, thermal, mechanical and performance properties. Polym Bull. https://doi.org/10.1007/s00289-022-04439-0

Dhawale PV, Vineeth SK, Gadhave RV et al (2022) Tannin as a renewable raw material for adhesive applications: a review. Mater Adv 3:3365–3388. https://doi.org/10.1039/D1MA00841B

de Souza GO, Pimenta AS, Trianoski R et al (2020) Production of edge-glued panels with wood from three Brazilian dry forest tree species and five types of adhesives. Int Wood Prod J. https://doi.org/10.1080/20426445.2020.1721041

Qiao L, Coveny PK, Easteal AJ (2002) Modifications of poly(vinyl alcohol) for use in poly(vinyl acetate) emulsion wood adhesives. Pigment Resin Technol 31:88–95. https://doi.org/10.1108/03699420210420378

Gadhave RV, Vineeth SK (2022) Synthesis and characterization of starch stabilized polyvinyl acetate-acrylic acid copolymer-based wood adhesive. Polym Bull. https://doi.org/10.1007/s00289-022-04558-8

Vineeth SK, Gadhave RV, Gadekar PT (2019) Chemical modification of nanocellulose in wood adhesive: review. Open J Polym Chem 09:86–99. https://doi.org/10.4236/ojpchem.2019.94008

Vineeth SK, Gadhave RV, Gadekar PT (2020) Glyoxal cross-linked polyvinyl alcohol-microcrystalline cellulose blend as a wood adhesive with enhanced mechanical, thermal and performance properties. Mater Int 2:0277–0285

Gadhave RV, Vineeth SK, Gadekar PT (2020) Cross-linking of polyvinyl alcohol/starch blends by glutaraldehyde sodium bisulfite for improvement in thermal and mechanical properties. J Mater Environ Sci 11:704–712

Cheng L, Guo H, Gu Z et al (2017) Effects of compound emulsifiers on properties of wood adhesive with high starch content. Int J Adhes Adhes 72:92–97. https://doi.org/10.1016/j.ijadhadh.2016.10.001

Wang P, Cheng L, Gu Z et al (2015) Assessment of starch-based wood adhesive quality by confocal Raman microscopic detection of reaction homogeneity. Carbohydr Polym 131:75–79. https://doi.org/10.1016/j.carbpol.2015.05.044

ud Din Z, Chen L, Xiong H et al (2020) Starch: an undisputed potential candidate and sustainable resource for the development of wood adhesive. Starch/Staerke. https://doi.org/10.1002/star.201900276

Vineeth SK, Gadhave RV, Gadekar PT (2022) Investigation of crosslinking ability of sodium metabisulphite with polyvinyl alcohol–corn starch blend and its applicability as wood adhesive. Indian Chem Eng 64:197–207. https://doi.org/10.1080/00194506.2021.1887769

Jishnu NS, Vineeth SK, Das A et al (2021) Electrospun PVdF and PVdF-co-HFP-based blend polymer electrolytes for lithium ion batteries. In: Balakrishnan NTM, Prasanth R (eds) Electrospinning for advanced energy storage applications, 1st edn. Springer Singapore, Singapore, pp 201–234. https://doi.org/10.1007/978-981-15-8844-0_8

Singha AS, Priya B, Pathania D (2015) Cornstarch/poly(vinyl alcohol) biocomposite blend films: mechanical properties, thermal behavior, fire retardancy, and antibacterial activity. Int J Polym Anal Charact 20:357–366. https://doi.org/10.1080/1023666X.2015.1018491

Chen L, Imam SH, Gordon SH, Greene RV (1997) Starch-polyvinyl alcohol crosslinked film—performance and biodegradation. J Environ Polym Degrad 5:111–117. https://doi.org/10.1007/BF02763594

Gadhave RV, S.K. V, Dhawale P V, Gadekar PT, (2020) Effect of boric acid on poly vinyl alcohol- tannin blend and its application as water-based wood adhesive. Des Monomers Polym 23:188–196. https://doi.org/10.1080/15685551.2020.1826124

Singh HK, Patil T, Vineeth SK et al (2020) Isolation of microcrystalline cellulose from corn stover with emphasis on its constituents: corn cover and corn cob. Mater Today Proc 27:589–594. https://doi.org/10.1016/j.matpr.2019.12.065

Gadhave RV, Mahanwar PA, Gadekar PT, Kasbe PS (2019) A study on the effect of starch–polyvinyl alcohol blends by addition of citric acid and boric acid for enhancement in performance properties of polyvinyl acetate-based wood adhesive. J Indian Acad Wood Sci 17:9–20. https://doi.org/10.1007/s13196-019-00249-6

Gadhave RV, S. K. V, Mahanwar PA, Gadekar PT, (2021) Effect of addition of boric acid on thermo-mechanical properties of microcrystalline cellulose/polyvinyl alcohol blend and applicability as wood adhesive. J Adhes Sci Technol 35:1072–1086. https://doi.org/10.1080/01694243.2020.1832775

Gadhave RV, Mahanwar PA, Gadekar PT (2019) Effect of vinyl silane modification on thermal and mechanical properties of starch-polyvinyl alcohol blend. Des Monomers Polym 22:159–163. https://doi.org/10.1080/15685551.2019.1678223

Yin Y, Li J, Liu Y, Li Z (2005) Starch crosslinked with poly(vinyl alcohol) by boric acid. J Appl Polym Sci 96:1394–1397. https://doi.org/10.1002/app.21569

Reddy N, Yang Y (2010) Citric acid cross-linking of starch films. Food Chem 118:702–711. https://doi.org/10.1016/j.foodchem.2009.05.050

Kusumah SS, Umemura K, Yoshioka K et al (2016) Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard I: Effects of pre-drying treatment and citric acid content on the board properties. Ind Crops Prod 84:34–42. https://doi.org/10.1016/j.indcrop.2016.01.042

Olsson E, Menzel C, Johansson C et al (2013) The effect of pH on hydrolysis, cross-linking and barrier properties of starch barriers containing citric acid. Carbohydr Polym 98:1505–1513. https://doi.org/10.1016/j.carbpol.2013.07.040

Teodorescu M, Bercea M, Morariu S (2018) Biomaterials of poly(vinyl alcohol) and natural polymers. Polym Rev 58:247–287. https://doi.org/10.1080/15583724.2017.1403928

Shi R, Bi J, Zhang Z et al (2008) The effect of citric acid on the structural properties and cytotoxicity of the polyvinyl alcohol/starch films when molding at high temperature. Carbohydr Polym 74:763–770. https://doi.org/10.1016/j.carbpol.2008.04.045

Hirashima M, Takahashi R, Nishinari K (2004) Effects of citric acid on the viscoelasticity of cornstarch pastes. J Agric Food Chem 52:2929–2933. https://doi.org/10.1021/jf0347867

Park J-S, Park J, Ruckenstein E (2001) On the viscoelastic properties of poly(vinyl alcohol) and chemically crosslinked poly(vinyl alcohol). J Appl Polym Sci 82:1816–1823. https://doi.org/10.1002/app.2023

Kumar GCM, Jeyaraj P, Nagamadhu M (2019) Dynamic mechanical analysis of glutaraldehyde cross linked polyvinyl alcohol under tensile mode. In: Advances in polymer composites: mechanics, characterization and applications. AIP conference proceedings, p 020017

Park H-R, Chough S-H, Yun Y-H, Yoon S-D (2005) Properties of starch/PVA blend films containing citric acid as additive. J Polym Environ 13:375–382. https://doi.org/10.1007/s10924-005-5532-1

Prosanov IY, Abdulrahman ST, Thomas S et al (2018) Complex of polyvinyl alcohol with boric acid: structure and use. Mater Today Commun 14:77–81. https://doi.org/10.1016/j.mtcomm.2017.12.012

Tanpichai S, Oksman K (2016) Cross-linked nanocomposite hydrogels based on cellulose nanocrystals and PVA: Mechanical properties and creep recovery. Compos Part A Appl Sci Manuf 88:226–233. https://doi.org/10.1016/j.compositesa.2016.06.002

Gadhave RV, Mahanwar PA, Gadekar PT (2019) Effect of glutaraldehyde on thermal and mechanical properties of starch and polyvinyl alcohol blends. Des Monomers Polym 22:164–170. https://doi.org/10.1080/15685551.2019.1678222

Acknowledgements

We would like to thank Institute of Chemical Technology, Mumbai, India, for the support throughout this work.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vineeth, S.K., Gadhave, R.V. Corn starch blended polyvinyl alcohol adhesive chemically modified by crosslinking and its applicability as polyvinyl acetate wood adhesive. Polym. Bull. 81, 811–825 (2024). https://doi.org/10.1007/s00289-023-04746-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04746-0