Abstract

Polylactic acid (PLA)/starch acetate (SA) base film was prepared by scraping film method with PLA as the base film material, modified SA as the filling phase and polyethylene glycol (PEG) as plasticizer. Chitosan (CS)/tea polyphenol (TP) antibacterial agent was coated on the surface of PLA/SA base film by coating method. The morphology and structure of the composite film were characterized by FTIR, XRD, SEM and thermogravimetric analysis, and the mechanical, optical and antibacterial properties were tested and analyzed. The results showed that CS/TP compound antibacterial agent was well combined with PLA/SA base film. Compared with the PLA/SA base film, when the content of TP (based on the mass of PLA/SA base film, the same below) was 0.4%, the tensile strength of the composite film increased by 29.33%, had good mechanical strength (24.96 ± 0.65 MPa), and the elongation at break increased by 29.34%; There was no obvious change in transparency, the light transmittance decreased by 0.86%; At the same time, the antibacterial composite film had good antibacterial effect on Escherichia coli, Staphylococcus aureus and Bacillus subtilis. PLA/SA/CS/TP antibacterial composite film could be used in food packaging, especially those designed to protect food from light and microbial decay.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the improvement of living standards, plastic had entered every industry of human life. The packaging industry was one of the most important applications of plastics, accounting for nearly 40% of global plastic production [1, 2]. The widespread use of petroleum-based plastic food packaging had caused great harm to the environment. In contrast, the use of biodegradable plastic packaging had the advantages of ordinary plastic, while they did not leave any negative environmental impact and greatly reduce the cost of waste disposal systems [3]. Therefore, people had paid more and more attention to the development and use of biodegradable materials to meet the requirements of green packaging [4].

In recent years, the use of natural biopolymers to produce biodegradable packaging film, edible film and coating materials had increased significantly in the literature [5]. In these natural biological polymer, starch preparation of biodegradable film or edible packaging film was one of the most commonly used materials, because of their low cost, good film forming, good biocompatibility, wide sources, as well as good reproducibility and biodegradability by the attention of people, biodegradability of starch film had become a research hotspot in recent years [6, 7]. However, poor properties, such as low water vapor barrier, relatively low mechanical properties and processing difficulty, and strong hydrophilicity, had greatly limited the application of starch [8, 9]. In contrast to the high hydrophilicity of starch, polylactic acid (PLA) had a strong hydrophobicity, and its performance as a food film could be improved by applying starch to the hydrophobic PLA layer [10]. PLA was an environmentally friendly biodegradable thermoplastic polyester with great research potential [11]. It had been reported that when discarded into the environment, pure PLA could degrade slowly over a period of several months to 2 years, while petroleum-based plastics could take more than 500–1000 years [12]. At the same time, packaging materials made from PLA raw materials could be composted after use without producing any substances harmful to the environment [13]. Ye et al. found that the degradation rate of pure polylactic acid film could reach 16.43% after eight weeks of burial, while that of polylactic acid–tea polyphenol–chitosan composite film could reach 38.44% [4]. In addition, PLA had other interesting properties such as high mechanical strength, thermal stability, barrier properties, processing properties, biocompatibility and low environmental impact. PLA was classified as GRAS (generally considered safe) by the US Food and Drug Administration (FDA). Therefore, PLA could be used for food packaging (bags, bottles, containers, etc.) [14]. Starch had good resistance to oxygen [15] and polylactic acid to water vapor[16]. Similarly, PLA had higher mechanical resistance and more brittle than starch, and the combination of the two could improve the mechanical properties of the film [16]. The combination of polylactic acid and starch might be an effective method to improve the functional properties of starch film [17]. Mixing PLA with low-cost biodegradable polymers (such as starch) could alleviate the above disadvantages and combine its advantages, while reducing the material cost and improving the degradation performance of composite materials, so as to partially replace petroleum-based plastics [18]. However, starch was a hydrophilic substance while polylactic acid was a hydrophobic substance, and the two were incompatible in thermodynamic properties. Therefore, starch needed to be modified to increase the compatibility between starch and polylactic acid [19].

At present, starch could be modified by a variety of physical or chemical methods to achieve desired properties. One of the most common methods was to use external plasticizers [6]. Commonly used plasticizers include polyethylene glycol, citric acid and its esters, glycerin, formamide, etc. [20]. Starch could also be modified [21] to enhance the compatibility of the two and improve the performance of composite materials. Among them, hydrophilic polyethylene glycol (PEG) could preferentially associate firmly with starch [22] and promote the biodegradation of starch/polylactic acid composite [20], which could be used to plasticize starch or make starch composite compatible [20, 23, 24]. In addition, chemical modification of starch was necessary to improve the mechanical properties of natural polymers. The esterification of starch gave the product good thermoplastic properties, enhanced mechanical properties and increased hydrophobicity. Acetylation was one of these methods, which had attracted extensive attention in recent years. Even at low degree of substitution [25], acetylation could significantly improve the physicochemical properties and functional properties of starch with relative ease [26]. Acetic anhydride was a commonly used acetylation agent of organic substrates, and starch acetate could be obtained by esterification of starch with acetic anhydride or vinyl acetate [27]. Its swelling power, solubility and light transmittance were all higher than natural starch, and increase with the increase in the concentration of acetic anhydride, and its light transmittance was always higher than the corresponding natural starch in the storage process [25], which had the characteristics of reduced backgrowth trend, high clarity, low viscosity, high swelling power and low gelatinization temperature and time [28]. Compared with natural starch, acetate starch and Polylactic acid had better compatibility, and the properties of the mixture could be improved accordingly. Rasool et al. found that starch acetylation was an effective means to improve the compatibility between starch and PLA. Compared with the blend containing pure starch, the PLA blend containing 2.5-degree acetylated starch had higher tensile strength (26%) and toughness (29%), and the temperature of the blend increased by 3.2% at the maximum degradation rate [29].

As we all know, chitosan (CS) and tea polyphenols (TP) had become research hotspots due to their excellent antibacterial properties, renewable resources, degradability and easy processing [30]. CS was the second most abundant polysaccharide after cellulose. It was insoluble in water or organic solvents, but soluble in organic acid aqueous solution and inorganic acid [31]. It had good properties, such as biocompatibility, biodegradation and non-toxicity, and had antibacterial activity to different microbial communities [19, 32]. Meanwhile, it had the characteristics of enhancing the absorption of bioactive compounds such as tea polyphenols [33]. There had been many reports on the antibacterial activity of chitosan. Bonilla et al. [34] showed that PLA/CS composite had significant antibacterial activity against aerobic microorganisms and coliform microorganisms, especially when the chitosan powder particle size was reduced. However, it was known from a large number of literatures that bacteriostatic effect of CS was very limited when it was used alone, and even some studies showed that chitosan did not show antibacterial effect without any supplement [35,36,37]. Therefore, in order to improve its mortality to bacteria, it was necessary to combine chitosan with other bacteriostatic agents to achieve synergistic effect.

Tea polyphenols (TP) was a new type of antioxidant, which showed good antioxidant activity and non-toxic properties in various food model systems and had good application prospects [38]. It had been widely used in food preservation [39]. Its mechanism of action was achieved by inhibiting the generation and scavenging of free radicals. Haoxiang Gao et al. [40] prepared the polysaccharide membrane by adding TP to pectin and chitosan matrix by blending method. The study found that chitosan had strong biological adhesion ability, which could slow down the release of active components in the membrane, regulate the release rate of TP, and prolong its active time and effect. Jingsong Ye et al. [4] prepared polylactic acid (PLA)-tea polyphenol (TP)-chitosan (CS) composite membrane with different concentrations by using the stretch membrane method and applied it to the preservation of strawberry. When the mass of composite membrane compared with that of chitosan: When tea polyphenol was 7:3, the rot rate and quality loss rate of strawberry were significantly reduced, the retention time of soluble solids and vitamin C was improved, and the shelf life of strawberry was greatly prolonged.

In this paper, the blending of starch and polylactic acid was not only to enrich the utilization of agricultural resources, but also to improve the added value of agricultural products. The greater significance was to significantly reduce the production cost of polylactic acid materials while taking into account the comprehensive performance of materials, and to solve the problem of the slow degradation of polylactic acid in the natural environment, which was of great significance to alleviate the current situation of oil resource shortage and environmental pollution. The effect of CS/TP composite antimicrobial coating on film properties, especially on the antimicrobial activity of the film, was still unclear. Therefore, the purpose of this study was: (1) to develop an antibacterial film with PLA and SA as the main raw materials. (2) to evaluate the morphology, structure and mechanical, optical properties of the composite film after coating. (3) to evaluate the effect of antibacterial activity of composite film. (4) the effects of different concentrations of chitosan (CS) and tea polyphenol (TP) on the antibacterial activity of the film were investigated. As far as we know, there was no research on CS/TP composite reinforced PLA/SA film, and our research might be the first time.

Experimental

Materials

Polylactic acid, MW = 10,000, Shenzhen Guanghua Weiye Co., Ltd; Soluble starch, polyethylene glycol (PEG400), dichloromethane, glacial acetic acid, acetic anhydride, glycerol (AR), Tianjin Guangfu Technology Development Co., Ltd; Chitosan, deacetylation degree ≥ 95%, Aladdin Industrial Corporation; Tea polyphenols, ≥ 98%, Shanghai Piper Biotechnology Co., Ltd; Beef extract, peptone, agar (BR), Beijing Aoboxing Biotechnology Co., Ltd; Escherichia coli, Staphylococcus aureus, Bacillus subtilis, Microbiology Laboratory of Harbin Commercial University.

Equipment

Nicolette 6700 Fourier Transform Infrared Spectrometer, Thermo Fisher, USA; X, pert3 Powedr X-ray diffractometer, Panaco, the Netherlands; QUANTA200 scanning electron microscope, Fidecam, USA; STA449 F3 thermogravimetric differential thermal synchronous analyzer, NETZSCH, Germany; LD-05 computer-controlled tensile testing machine, Changchun Yueming Small Testing Machine Co., Ltd; WGT-S type transmittance/haze tester, Shanghai Instrumental Electrical Physics Optical Instrument Co., Ltd.

Material preparation

Preparation of starch acetate

Starch (SC) was dried in vacuum at 70 °C for 5 h, and acetic anhydride was cooled at 4 °C for standby. 20 g dry starch and 25 mL glacial acetic acid were mixed and stirred evenly, and 10% (based on the mass of starch) acetic anhydride was added dropwise within 5 min, and the reaction was conducted at 90 °C for 3 h. Centrifuge and collect the precipitate, the precipitate was repeatedly washed with distilled water until the pH test paper showed neutral color, then was filtered, and dried at 60 °C to constant weight to obtain starch acetate (SA).

Preparation of coating solution

The preservative film was prepared by coating method, and different concentrations of antibacterial coating liquid were prepared for coating. Chitosan acetic acid solution was used as the template and tea polyphenols were added as the compound to enhance the efficacy of the antibacterial compound. Firstly, different concentrations of template solution (chitosan, CS) (1%, 2%, 3%) were prepared for coating. After selecting the appropriate concentration of chitosan solution (3%), tea polyphenols (TP) of different concentrations (0.1%, 0.4%, 0.7%) were combined for compound.

Preparation of polylactic acid base film

10% polylactic acid (PLA, based on the mass of dichloromethane) was dissolved in dichloromethane, stirred until completely dissolved, and well mixed PLA film solution was prepared. The film solution was treated with ultrasonic for 10 min to remove bubbles. The PLA film solution was laid on the glass plate use a 500 µm film scraper to form a PLA wet film. After the dichloromethane volatilizes, PLA wet film was dried at 55 °C for 24 h to obtain PLA base film.

Preparation of PLA/SC-based film

10% SC and PEG400 (based on the mass of dichloromethane) were dissolved in dichloromethane, ultrasonic treatment was used for 20 min under the protection of ice water bath to obtain SC solution. Proper amount of PLA was added to dissolve in SC solution, stirred until completely dissolved, and well mixed PLA/SC film solution was prepared. The film solution was treated with ultrasonic for 10 min to remove bubbles. The PLA/SC film solution was laid on the glass plate use a 500 µm film scraper to form a PLA/SC wet film. After the dichloromethane volatilizes, PLA/SC wet film was dried at 55 °C for 24 h to obtain PLA/SC base film.

Preparation of PLA/SA base film

10% SA and PEG400 (based on the mass of dichloromethane) was dissolved in dichloromethane, ultrasonic treatment was used for 20 min under the protection of ice water bath to obtain SA solution. Proper amount of PLA was added to dissolve in SA solution, stirred until completely dissolved, and well-mixed PLA/SA film solution was prepared. The film solution was treated with ultrasonic for 10 min to remove bubbles. The PLA/SA film solution was laid on the glass plate use a 500 µm film scraper to form a PLA/SA wet film. After the dichloromethane volatilizes, PLA/SA wet film was dried at 55 °C for 24 h to obtain PLA/SA base film.

Preparation of PLA/SA Antibacterial Composite film

The composite film was prepared by coating method, PLA/SA film was used as the base film and antibacterial coating solutions of different concentrations was prepared for coating. Chitosan acetic acid solution was used as the template and tea polyphenol was added as the compound agent to enhance the antibacterial compound coating solution. The PLA/SA/CS/TP antibacterial composite film was obtained by coating antibacterial solution on the surface of PLA/SA base membrane with 200 µm coating roller and drying at 25 °C for 10 h (Scheme 1). The proportion of base film and antibacterial composite film was shown in Table 1.

Testing and characterization

Test of Fourier transform infrared spectrometry (FTIR)

The Nicolette 6700 Fourier transform infrared spectrometer of Thermo Fisher Company was used. The sample was determined by potassium bromide pressing method. The scanning speed was 0.2 cm/s, the scanning times were 10 times, and the wavenumber range was 600–4000 cm−1.

Test of X-ray diffraction analysis (XRD)

X, pert3 Powedr X-ray diffractometer was used, acceleration voltage was 40 kV, electric current was 30 mA. The scanning diffraction angle 2θ rotates from 5° to 50°, the scanning step was 0.2°/2θ, the scanning speed was 2°/min, and the crystallization of the film was analyzed.

Test of SEM

The morphology and characteristics of film were observed by QUANTA200 scanning electron microscope. The cross-sectional structure was observed by gold-plating after the drying film was cooled in liquid nitrogen, broken and re-dried in vacuum. The surface structure of the sample was directly gold-plated.

Test of thermogravimetric (TG)

The thermal stability of film was analyzed by STA449F3 thermogravimetric differential thermal synchronous analyzer. The temperature range was 30–600 °C and the heating rate was 10 °C/min in nitrogen environment under dynamic TGA mode.

Test of mechanical properties

According to GB/T 1040.2-2006, 150 mm × 10 mm film sample was cut and balanced 48 h in standard environment. Tensile properties were tested by computer measuring and controlling tensile testing machine. Each kind of film was measured in 5 groups, respectively. The tensile speed was set as 5 mm/min, and the standard distance was set as 40 mm. The maximum load and fracture displacement of each film were recorded, and the tensile strength (TS), elongation at break (EAB) and elastic modulus (EM) of the film samples were calculated according to formulas 1–3.

where: P—maximum load (N); b, d—sample width and thickness (mm); x—fracture displacement (mm); L0—standard distance (mm).

Test of optical properties

According to GB/T 2410-2008 and ASTM D1003-61 (1997), 50 mm × 50 mm square film sample was cut and placed at the light transmittance/haze tester under constant temperature (25 °C), constant humidity (50%) and normal pressure (0.1 MPa) to measure the light transmittance and haze of the film in 5 groups, respectively.

Test of antimicrobial properties

The disk-diffusion assay was used to verify the antibacterial activity of the films. First, the films were cut into 6 mm diameter disks under aseptic conditions. Next, they were placed on Petri dishes previously seeded with beef extract peptone medium containing Escherichia coli, Staphylococcus aureus and Bacillus subtilis. There were four disks on each plate, one corresponds to control group while the other three comprised three replicates of different concentration. The plates were incubated at 37 °C for 24 h. Following incubation, the bacterial growth around the film was watched, the diameter of the inhibition zone was measured by digital caliper.

Data statistics and analysis

SPSS 25.0 software (IBM SPSS Statistics) was used to perform ANOVA on the data obtained. The significance test method was Duncan multiple tests, and the significance level was 0.05.

Results and discussion

FTIR analysis of composite film

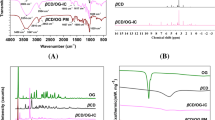

Figure 1 shows the FTIR spectra of the base film and composite film, Fig. 2 shows the local FTIR spectra of starch and starch acetate, and Fig. 3 shows the local FTIR spectra of the antibacterial composite film.

As shown in Figs. 1 and 2, at 3460, 1640, 1160 and 990 cm−1 in the SC and SA spectrograms were the characteristic absorption peaks of starch such as O–H stretching vibration, O–H bending stretching vibration, C-H bending vibration, C–O stretching vibration and C–O–C asymmetric stretching vibration. It can be clearly seen from the enlarged picture with the wavelength of 2000–1500 cm−1 that there was a new characteristic peak at 1730 cm−1, which was the carbonyl infrared absorption peak of the ester generated by the reaction between the acid and the starch hydroxyl, indicating that the starch modification was successful.

In PLA spectrogram, 2995, 2929, 2849 cm−1 was C–H stretching vibration of CH and CH3, 1750 cm−1 was C =O stretching vibration of ester structure, 1457 and 1381 cm−1 were bending vibration of CH3, 1186 cm−1 was asymmetric stretching vibration of C–O–C group in PLA, 1076 cm−1 was C–O–C symmetric stretching vibration, 1040 cm−1 was C–CH3 stretching vibration.

In PLA/SC, PLA/SA and antibacterial composite film spectrogram, near 2900, 1750, 1457 and 1381 cm−1, 1186 cm−1 were the C–H stretching vibration of –CH and –CH3 of PLA, the stretching vibration of ester carbonyl C =O, the bending vibration of –CH3, and the asymmetric stretching vibration of C–O–C. There was no obvious starch absorption peak or new peak in PLA/SC and PLA/SA base film spectrogram, SC, SA and PLA were physically combined. A new characteristic peak appears at 803 cm−1 in the spectrum of PLA/SA/CS/TP antibacterial composite film (Fig. 3), which was the out of plane bending vibration absorption of C–H on the aromatic ring. It is the main component of catechins and flavonoids in tea polyphenols. It showed that the antibacterial agent was successfully coated on the surface of the base film.

XRD analysis of composite film

Figure 4 was the XRD diagram of the base film and composite film. As shown in Fig. 4, in the XRD spectrum of PLA film, there was an obvious characteristic peak of PLA crystal form at 15.2º, which belongs to the (200) and (100) crystal planes. The wide hump type indicated that the PLA crystallinity was not high. The crystal diffraction peak intensity of PLA/SC film and PLA film had little difference, and there was an obvious characteristic peak of PLA crystal form at 16.5º. The addition of SC did not change the crystal form of PLA. Due to the addition of SA, PLA/SA has a new peak at 22.2 º, which is the reflection of PLA (015) crystal surface. The intensity of the characteristic diffraction peak of 16.5º PLA had been enhanced, indicating that the addition of SA affected the crystalline state of PLA, and better promoted the crystallization of PLA. After the addition of CS and CS/TP composite antibacterial agent, the XRD peak of the composite film was sharp and the diffraction peak was strong. The diffraction peaks appeared at 16.5º, 19.0º and 22.2º, representing the reflection of stable PLA crystals (200)/(100), (203) and (015). It may be that the addition of an appropriate amount of CS and CS/TP formed a certain intermolecular interaction with PLA/SA, which helped the composite to better crystallize, indicating that the addition of an appropriate amount of CS and CS/TP could effectively promote the crystallization of PLA, improve material stability.

SEM analysis of composite film

Figures 5 and 6 were the SEM images of the surface of the base film and the antibacterial composite film respectively. Figures 7 and 8 were the SEM images of section of the base film and the antibacterial composite film respectively.

As shown in Fig. 5 and Fig. 7, the surface of PLA film was flat, and some hollow structures in the membrane were clearly visible. From the section image (Fig. 7b), it could be seen that the cross section of PLA membrane was uneven, with stratification, and there were gaps and cavities at the cross section. The flatness of the PLA/SC film surface decreased. It was obvious that there were agglomerates on the film surface (Fig. 5c), which was rougher than the PLA film. It was predicted that the addition of SC failed to blend evenly with the PLA film substrate. From the section image (Fig. 7c), it could be seen that there were large particles of agglomerates on the fracture surface of the film, indicating that the PLA/SC system still existed incompatibility, which would form structural defects on the film, leading to reduced mechanical properties of the film material. The surface of PLA/SA film was dense, without obvious large starch aggregates (Fig. 5d). The addition of SA improved the compatibility between SA and PLA to a certain extent. The PLA/SA film was more uniform and denser. From the section image (Fig. 7d), it could be seen that the large aggregates were reduced, and the cross-linking inside the base film was more tighter an firmer, indicating that the compatibility between SA and PLA base film had been significantly improved, achieving the desired purpose of modification.

As shown in Figs. 6 and 8, the PLA/SA/CS film surface was coated with CS, and the PLA/SA/CS/TP antibacterial composite film surface was coated with CS/TP antibacterial compound solution. The antibacterial film surface was partially uneven but dense and uniform due to the coating of antibacterial agent, indicating that the antibacterial agent and cellulose film were successfully compounded, and the composite film surface was no void, disorder or irregularity. It could be seen from the section image (Fig. 8) that the antibacterial agent was uniformly coated on the surface of PLA/SA base film to form a layer of dense structure. With the increase of the concentration of the antibacterial agent, the gap between the antibacterial substance and the base film became smaller and smaller, and the combination between them became closer and closer (Fig. 8b–d). This might be because the addition of the antibacterial agent CS and TP increased, and more hydrogen bonds were formed between antibacterial agent and the base film, so that the combination between them was better, with better mechanical property, thermal stability and antibacterial effect.

TG analysis of composite film

Figure 9 showed the TG curve of base film and antibacterial composite film. Table 2 showed the temperature of base film and antibacterial composite film at 5, 10, 30 and 50% weight loss.

As shown in Fig. 9, PLA, PLA/SC, PLA/SA and PLA/SA/CS films had an obvious weight loss stage, which was between 350 and 400 °C, due to the degradation of PLA, SC and SA in the composite membrane. The PLA film began to lose weight at about 120 °C, which might be caused by the volatilization of small lactic acid molecules (boiling point 122 °C) in the PLA film. The weight loss was 5, 10, 30 and 50% at 324.53, 339.90, 361.13 and 370.54 °C, respectively (Table 2). The weight loss of PLA/SC film at 306.47, 323.65, 348.13, 362.32 °C and PLA/SA film at 309.13, 325.57, 351.83, 365.9 °C are 5, 10, 30 and 50%, respectively. Because the thermal stability of plasticizer PEG400 was relatively poor compared with PLA, the addition of PEG400 increased the dispersion of starch in the PLA matrix, increased the distance between starch molecules in the system, weakened the force between starch molecules, and decreased the thermal stability of the composite film. Due to the interaction between SA and ester groups in PLA molecules, the stability of PLA/SA films was increased compared with PLA/SC films, and the initial thermal decomposition temperature of PLA/SA films was 2.66 °C higher than that of PLA/SC films. At 301.59, 316.02, 335.24 and 345.85 °C, the PLA/SA/CS film lost 5, 10, 30 and 50% of its weight. The initial thermal decomposition temperature was lower than that of the PLA/SA film, mainly due to the degradation of CS components in the composite film. PLA/SA/CS/TP antibacterial composite film had two stages of obvious weight loss, the first stage was between 250 and 280 °C, which might be caused by the degradation of CS components in the composite film and the volatilization of polyphenols in TP, the second stage was between 350 and 400 °C, which was caused by the degradation of PLA in the composite film. PLA/SA/CS/TP antibacterial composite film had good thermal stability at 248.43, 277.71, 352.82, 364.74 °C, with weight loss of 5, 10, 30, 50%.

Figure 10 showed the DTG curve of base film and antibacterial composite film. As shown in Fig. 10, the maximum weight loss rate temperatures of PLA, PLA/SC, PLA/SA, PLA/SA/CS and PLA/SA/CS/TP antibacterial composite film were 376.98, 371.68, 376.22, 354.38 and 369.99 °C respectively, indicating that the pyrolysis process was mainly the decomposition of the base film. The maximum weight loss rate temperature of PLA/SA/CS/TP antibacterial composite film was higher than that of PLA/SA/CS film. It might be that the thermal degradation of the base film was inhibited by the strong hydrogen bonding between the composite antibacterial agent and PLA, SA due to the strong hydrogen bonding between components, so the system had better thermal stability.

Mechanical properties analysis of composite film

Tensile strength and elongation at break were the most common mechanical parameters in food packaging applications, which meant that the integrity and performance of packaged products could be maintained [41]. Figure 11 showed the mechanical properties curve of the base film and the antibacterial composite film, and Table 3 showed the mechanical and optical properties parameters of the base film and the antibacterial composite film.

As shown in Fig. 11, PLA film had a good tensile strength (TS) of 35.49 ± 0.31 MPa, which was higher than the packaging film circulating in the market. The elongation at break (EAB) was 3.39 ± 0.24%, and the elastic modulus (EM) was 1052.25 ± 77.63 MPa, indicating that PLA film was hard and brittle, lacking flexibility and elasticity. After PEG400 and SC were added, TS of PLA/SC membrane decreased, and EAB increased significantly by 114.75%, indicating that the addition of PEG400 weakened the force between polymer molecular chains, making the polymer chains easier to move, and small molecular plasticizers could penetrate into the starch granules to destroy the hydrogen bond effect within the starch molecules, thus increasing EAB of the composite film. TS of PLA/SA film modified by SA was reduced to 19.30 ± 2.50 MPa, and EAB was significantly increased by 244.84% compared with PLA film, indicating that the existence of similar molecular structure between SA and PLA increased the interfacial adhesion. In addition, the addition of PEG400 reduced the hydrogen bond force between polymers, making the polymer chain easy to move. EAB of PLA/SA film was much higher than that of PLA/SC film with the same proportion. At the same time, due to the presence of ester groups in SA, the solubility in dichloromethane organic solvent was better, which contributed more to enhancing the compatibility between the two phases. The composite membrane became more flexible. The introduction of SA was superior to SC in improving the brittleness and flexibility of PLA film. After CS was coated on the surface, TS of PLA/SA/CS composite film increased with the increase of CS coating amount, and EAB increased significantly (Table 3), which indicated that the viscosity of CS itself will form physical crosslinking with PLA molecules to a certain extent. At the same time, there were a lot of amino and hydroxyl groups on the CS molecular chain, which would form hydrogen bonds with the hydroxyl groups in PLA molecules and SA molecules, the adhesive force between the blends was improved, and then the mechanical properties of the blends were improved. TS and EAB of PLA/SA/CS/TP antibacterial composite film coated with CS/TP composite antibacterial agent were little affected by the change of TP concentration, mainly because the addition amount of TP was less, and it was attached to the surface of the composite film through the viscous medium of CS solution, which had little impact on the mechanical properties of the composite film. EAB of PLA/SA/CS/TP antibacterial composite film with 0.4% TP concentration was 15.12 ± 0.54%, increased by 346.02%, and EM was 165.10 ± 4.93 MPa, indicating that the toughness and elasticity of the composite film were significantly improved, while maintaining good mechanical strength (24.96 ± 0.65 MPa).

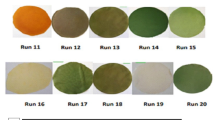

Optical properties analysis of composite film

Figure 12 showed the light transmittance and haze of the base film and antibacterial composite film. As shown in Fig. 12, the light transmittance and haze of PLA film were 93.16 ± 0.05 and 2.14 ± 0.65% respectively, which were characterized by excellent light transmittance and gloss performance. The transmittance of PLA/SC, PLA/SA and PLA/SA/CS (CS coating amount of 3%) films were 83.20 ± 0.72, 87.90 ± 0.77 and 86.58 ± 0.45%, respectively, which had decreased to varying degrees. The haze had increased to 22.84 ± 0.61, 20.19 ± 0.61 and 28.48 ± 5.78%, respectively, indicating that the addition of SC and SA and the coating of CS had an impact on the transmittance of PLA films, mainly because SC and SA particles increased the absorption, reflection and refraction of light after entering the interior of the films, at the same time, the coating of CS blocked the transmission of light. With the addition of CS/TP composite antibacterial agent, the transmittance of PLA/SA/CS/TP antibacterial composite film decreased with the increase of TP addition. At the same time, TP had its own color, which affected the optical properties of the composite film. The haze of the composite film was significantly improved, and the color of the antibacterial composite film changed.

Antimicrobial properties analysis of composite film

TP could inhibit bacteria by destroying the cell membrane structure, interfering with the normal function of cell DNA, and hindering the synthesis and expression of cell proteins. The antibacterial properties of the prepared antibacterial composite film were tested by inhibition zone method for the gram-negative Escherichia coli (E. coli), gram-positive Staphylococcus aureus (S. aureus) and Bacillus subtilis (B. subtilis). The results were shown in Table 4.

It could be seen from Table 4 that the PLA/SA film alone had no bacteriostatic effect. Since the PLA/SA/CS and PLA/SA/CS/TP films were coated with CS and CS/TP composite antibacterial agents, they had a certain bacteriostatic effect. The addition of CS increased the antibacterial activity of films, indicating that PLA/SA/CS film with different concentration of CS all had certain bacteriostatic effect of 3 test microorganisms, and 3% CS coating film antibacterial performance was best, the diameters of the bacteriostatic zones against E. coli, S. aureus and B. subtilis were 7.44 ± 0.07, 7.69 ± 0.20 and 9.11 ± 0.10 mm, respectively. The results showed that the bacteriostatic effect of 3% CS concentration on these three kinds of bacteria was better than 1 and 2% concentration. CS was soluble only in acidic environment, under certain acidic conditions, the molecule becomes polycation [42]. When the positive charge density of CS is increased, the antibacterial properties would be enhanced [43], and the cationic properties of CS could have a certain antibacterial effect on E. coli and S. aureus [44]. Although there were differences between the cell walls of Gram-negative bacteria represented by E. coli and Gram-positive bacteria represented by S. aureus and B. subtilis, the antibacterial mode of chitosan against them all starts from the interaction of cell surface and first damages the cell wall or outer membrane [43].The antibacterial properties of the antibacterial composite films after adding TP gradually increased with the increase of TP content, it had more significant bacteriostatic effect. The diameter of bacteriostatic zones of PLA/SA/CS/TP antibacterial composite film with 0.7% addition amount reached 10.52 ± 0.63 mm, 9.50 ± 0.15 mm and 11.13 ± 0.12 mm, respectively. The inhibitory effect of TP on E. coli, S. aureus and B. subtilis might be the direct bacteriostatic effect of catechin by destroying bacterial cell membrane, inhibiting fatty acid synthesis and inhibiting enzyme activity. The use of composite antibacterial agents could exert their own bacteriostatic effect and have better bacteriostatic performance.

Conclusions

In this study, PLA/SA/CS/TP antibacterial composite film was prepared by coating method with PLA/SA as base membrane and CS/TP as antibacterial agent. The results of FTIR, XRD and SEM showed that CS/TP and PLA/SA base film were well compounded; TG results showed that the composite film had good thermal stability. The mechanical, optical and bacteriostatic properties of PLA/SA/CS/TP antibacterial composite film were evaluated. The results showed that the tensile strength and elongation at break of the composite film increased significantly, while the transparency decreased. At the same time, it had good bacteriostatic effects on E. coli, S. aureus and B. subtilis. The antibacterial composite film coated with CS/TP had good mechanical, optical and bacteriostatic properties, it had a good reference significance for the preparation of green antibacterial packaging materials.

References

Żołek-Tryznowska Z, Holica J (2020) Starch films as an environmentally friendly packaging material: printing performance. J Clean Prod, 276.

Wang B et al (2021) Antibacterial activity, optical, and functional properties of corn starch-based films impregnated with bamboo leaf volatile oil. Food Chem 357:129743

Pirsa S et al (2022) Nano-biocomposite based color sensors: Investigation of structure, function, and applications in intelligent food packaging. Food Packag Shelf Life. p. 31.

Ye J et al (2018) Preparation and properties of polylactic acid-tea polyphenol-chitosan composite membranes. Int J Biol Macromol 117:632–639

Rhim J-W et al (2013) Bio-nanocomposites for food packaging applications. Prog Polym Sci 38(10–11):1629–1652

Wang B et al (2021) Physicochemical properties and antibacterial activity of corn starch-based films incorporated with Zanthoxylum bungeanum essential oil. Carbohydr Polym 254:117314

Sani IK et al (2021) Composite film based on potato starch/apple peel pectin/ZrO2 nanoparticles/ microencapsulated Zataria multiflora essential oil; investigation of physicochemical properties and use in quail meat packaging. Food Hydrocolloids, p. 117.

Qin Y et al (2016) Effects of chitin nano-whiskers on the antibacterial and physicochemical properties of maize starch films. Carbohydr Polym 147:372–378

Wang X et al (2020) Research advances in chemical modifications of starch for hydrophobicity and its applications: a review. Carbohydr Polym 240:116292

Muller J et al (2017) Antimicrobial properties and release of cinnamaldehyde in bilayer films based on polylactic acid (PLA) and starch. Eur Polymer J 96:316–325

Ncube LK et al (2020) Environmental impact of food packaging materials: a review of contemporary development from conventional plastics to polylactic acid based materials. Materials (Basel) 13(21).

Kumar N et al (2017) Advances in bio-nanocomposite materials for food packaging: a review. Nutrition Food Sci 47(4):591–606

Siakeng R et al (2018) Natural fiber reinforced polylactic acid composites: a review. Polym Compos 40(2):446–463

Coltelli MB et al (2020) Properties and skin compatibility of films based on Poly(Lactic Acid) (PLA) bionanocomposites incorporating Chitin nanofibrils (CN). J Funct Biomater 11(2).

Ortega-Toro R et al (2015) Active bilayer films of thermoplastic starch and polycaprolactone obtained by compression molding. Carbohydr Polym 127:282–290

Muller J et al (2016) Influence of plasticizers on thermal properties and crystallization behaviour of poly(lactic acid) films obtained by compression moulding. Polym Int 65(8):970–978

Zhou X et al (2021) Biodegradable sandwich-architectured films derived from pea starch and polylactic acid with enhanced shelf-life for fruit preservation. Carbohydr Polym 251:117117

Li G et al. (2020) Synthesis and biological application of polylactic acid. Molecules 25 (21).

Meng L et al (2019) Preparation, microstructure and performance of poly (lactic acid)-Poly (butylene succinate-co-butyleneadipate)-starch hybrid composites. Composites Part B: Eng 177.

Rogovina SZ et al (2018) Influence of PEG on mechanical properties and biodegradability of composites based on PLA and starch. Starch Stärke 70(7–8).

Meng L et al (2019) Improvement of interfacial interaction between hydrophilic starch film and hydrophobic biodegradable coating. ACS Sustain Chem Eng 7(10):9506–9514

Ortega-Toro R et al (2016) Improvement of properties of glycerol plasticized starch films by blending with a low ratio of polycaprolactone and/or polyethylene glycol. Food Hydrocolloids 56:9–19

Henise J et al (2015) Biodegradable tetra-PEG hydrogels as carriers for a releasable drug delivery system. Bioconjug Chem 26(2):270–278

Zhang K et al (2020) Effect of sodium citrate/polyethylene glycol on plasticization and retrogradation of maize starch. Int J Biol Macromol 154:1471–1477

Singh N et al (2004) Influence of acetic anhydride on physicochemical, morphological and thermal properties of corn and potato starch. Food Chem 86(4):601–608

Diop CI et al (2011) Effects of acetic acid/acetic anhydride ratios on the properties of corn starch acetates. Food Chem 126(4):1662–1669

Subaric D et al (2014) Modification of wheat starch with succinic acid/acetic anhydride and azelaic acid/acetic anhydride mixtures I. Thermophysical and pasting properties. J Food Sci Technol 51(10):2616–2623.

Ali TM, Hasnain A (2015) Physicochemical, morphological, thermal, pasting, and textural properties of starch acetates. Food Rev Intl 32(2):161–180

Nasseri R et al (2020) Poly(lactic acid)/acetylated starch blends: effect of starch acetylation on the material properties. Carbohydr Polym 229:115453

Soni B et al (2016) Transparent bionanocomposite films based on chitosan and TEMPO-oxidized cellulose nanofibers with enhanced mechanical and barrier properties. Carbohydr Polym 151:779–789

Srinivasa PC, Tharanathan RN (2007) Chitin/Chitosan—safe, ecofriendly packaging materials with multiple potential uses. Food Rev Intl 23(1):53–72

Raafat D, Sahl HG (2009) Chitosan and its antimicrobial potential—a critical literature survey. Microb Biotechnol 2(2):186–201

Liang J et al (2017) Applications of chitosan nanoparticles to enhance absorption and bioavailability of tea polyphenols: a review. Food Hydrocolloids 69:286–292

Bonilla J et al (2013) Effects of chitosan on the physicochemical and antimicrobial properties of PLA films. J Food Eng 119(2):236–243

Sani IK et al (2019) Preparation of chitosan/zinc oxide/Melissa officinalis essential oil nano-composite film and evaluation of physical, mechanical and antimicrobial properties by response surface method. Polymer Test 79.

Abdollahi M et al (2012) A novel active bionanocomposite film incorporating rosemary essential oil and nanoclay into chitosan. J Food Eng 111(2):343–350

Ojagh SM et al (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122(1):161–166

Wang Y et al (2021) Preparation, characterization, and 3D printing verification of chitosan/halloysite nanotubes/tea polyphenol nanocomposite films. Int J Biol Macromol 166:32–44

López de Dicastillo C et al (2013) Immobilization of green tea extract on polypropylene films to control the antioxidant activity in food packaging. Food Res Int 53(1):522–528

Gao HX et al (2019) A functional polysaccharide film forming by pectin, chitosan, and tea polyphenols. Carbohydr Polym 215:1–7

Zhang W, Jiang W (2020) Antioxidant and antibacterial chitosan film with tea polyphenols-mediated green synthesis silver nanoparticle via a novel one-pot method. Int J Biol Macromol 155:1252–1261

Lim SH, Hudson SM (2004) Synthesis and antimicrobial activity of a water-soluble chitosan derivative with a fiber-reactive group. Carbohydr Res 339(2):313–319

Kong M et al (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144(1):51–63

Wei D et al (2009) The synthesis of chitosan-based silver nanoparticles and their antibacterial activity. Carbohydr Res 344(17):2375–2382

Acknowledgements

This project was supported by “the Fundamental Research Funds for the Central Universities” (2572019BL01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Q., Zhai, W., Cui, L. et al. Physicochemical properties and antibacterial activity of polylactic acid/starch acetate films incorporated with chitosan and tea polyphenols. Polym. Bull. 80, 13319–13341 (2023). https://doi.org/10.1007/s00289-023-04691-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04691-y