Abstract

Polymer blend films consisted of poly(vinylidene fluoride) (PVDF) and poly(methyl methacrylate) (PMMA) (compositional ratios of PVDF/PMMA = 100/0, 80/20, 60/40, 40/60, 20/80, and 0/100 wt/wt%) were prepared by solution casting method. These PVDF/PMMA blend films were characterized by employing an X-ray diffractometer, Fourier transform infrared spectroscopy, scanning electron microscope, differential scanning calorimeter, and broadband dielectric relaxation spectroscopy. The PVDF crystal phases formed in these polymer blends were explained and their crystallite sizes, degree of crystallinity, and melting temperatures were determined. The dielectric dispersion study over the broadband frequency range of 20 Hz–1 GHz confirmed the decrease in dielectric permittivity with increased frequency of the applied harmonic electric field and it changed anomalously when the PVDF/PMMA blend compositional ratio varied. Dielectric loss tangent spectra illustrated the blend composition-dependent PVDF chain segmental relaxation process in these polymer blends which appeared in the radio frequency region. The alternating current electrical conductivity spectra revealed the increase in conductivity with increased frequency, and at a fixed frequency, the conductivity showed a variation in one order of magnitude with the variation in the blend composition ratio over the entire range. The experimental results highlighted that these PVDF/PMMA blend films could be used as frequency tunable dielectrics and insulating materials for advances in next-generation flexible device technologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, flexible-type polymeric dielectric materials, having poly(vinylidene fluoride) (PVDF) as one of the constituents, attracted considerable attention in research due to their promising properties suitable for widespread technological applications [1,2,3,4,5]. The polymorphs of semicrystalline PVDF matrix and this matrix-based hybrid nanocomposites play an important role to be used as a dielectric, electric insulator, and functional materials in the design and development of the desired dimension advanced flexible-type energy generator and storage devices [2, 5]. Furthermore, the polymeric materials that have controllable dielectric and electrical insulation properties over wide-range radio frequencies are credited to enormous industrial and technological applications, especially in the development of tunable capacitors, electromagnetic interference shielders, high-performance radio frequency antennas, microwave integrated circuits, etc. [6,7,8,9,10,11]. However, to date, limited work is available on the dielectric properties of polymers, their blends, and nanocomposites over the broadband radio frequency range from 1 MHz to 1 GHz [7, 8, 10,11,12,13] which is more needed and to be carried out to meet the industrial demands for advances in high-frequency device technologies. Among the synthetic polymers, poly(vinylidene fluoride) (PVDF), poly(methyl methacrylate) (PMMA), poly(ethylene oxide) (PEO), polyaniline (PANI), polypyrrole (PPy), polyamide (PA), polyacrylonitrile (PAN), polyethylene terephthalate (PET), poly(tetrafluoroethylene) (PTFE), polyacrylate (PC), poly(vinyl alcohol) (PVA), etc., are largely investigated to be used as dielectrics for the advances in flexible types variety of electronic and electrical devices [1, 3, 4, 10, 11, 14,15,16].

The PVDF is credited as an electroactive polymer due to its appreciable thermoplastic and electroactive properties [2, 3, 5]. It is extensively used as a dielectric material for energy storage because of its several useful properties like high mechanical strength, lightweight, good thermal stability, elevated dielectric strength, appropriate dielectric properties, good chemical inertness, high plasticity, sensible optical transparency, and also piezoelectric and pyroelectric properties [2, 5, 17,18,19,20,21]. In particular, the semicrystalline PVDF matrix may exist in a variety of polar and non-polar crystal phases denoted by α, β, γ, δ, and ε [2, 3]. Among these polymorphs, the α-phase is non-polar and most commonly observed in the PVDF matrix-based films when prepared by all the established methods, whereas the polar β-phase is highly appreciated for technological advances, and therefore, it is created by various treatments of the prepared films (e.g. mechanical, electrical, thermal, etc.) [2, 3, 5, 21, 22]. The polar γ-phase in the solution-cast PVDF film can be introduced by its annealing at an appropriate high temperature [22]. Detailed characteristics of a unit cell, conformation, and dipole moment of these polymorphs and their formation in PVDF are summarized in the review articles [3, 22].

The α-phase of PVDF material exhibits low-dielectric permittivity due to its non-polar character. A thermodynamically stable electroactive polar β-phase exhibits high polarizability due to effectively arranged dipoles of repeat units (CH2–CF2) that are oriented in a parallel direction to the applied harmonic alternating current (AC) electric field, and hence resulted in high dielectric permittivity as compared to the other crystal phases of the PVDF matrix [2, 17, 20]. The β-phase credited appreciable dielectric, piezo-, pyro-, and ferroelectric characteristics of PVDF matrix which have a high significance in the fabrication of advanced energy storage and harvesting devices (viz. supercapacitors, nanogenerators, actuators, transducers, sensors, and high energy rechargeable batteries) [3, 5, 8, 17,18,19,20,21,22,23,24]. A literature survey revealed that the dielectric permittivity of the PVDF film at low frequencies and ambient temperature may be in the range of 4–12 depending on the relative amount of various crystal phases developed in the prepared film and additionally its state-of-the-art treatments with mechanical stretching, electrospinning, irradiating, etc. [2, 3, 5, 20,21,22]. For the investigation of PVDF material properties, its films are formed through various established methods like melting under high pressure, electrospinning, heat-controlled spin-coating, and solution casting using the solvents like dimethylformamide or dimethylacetamide [2, 3, 5, 13, 21, 22].

In the last decade, numerous studies established that the structural, thermal, optical, and dielectric properties of a PVDF matrix can also be modified and tailored with the state-of-the-art by blending with non-polar or polar polymers and further making its matrix-based nanocomposites with a variety of nanofillers through suitable film fabrication routes [12, 13, 18, 19, 21, 23,24,25,26]. Previous studies also concluded that the PVDF forms miscible blends over the entire composition range with some of the polymers such as poly(methyl methacrylate) (PMMA), polyacrylate (PC), chitosan, and polyketone which is a result of heterogeneous interactions developed between the functional fluorocarbon group of the PVDF and the carbonyl groups of these blended polymers [18, 25, 27,28,29]. The polymer blends consisted of semicrystalline PVDF and amorphous PMMA are immensely studied for confirmation of the blend miscibility, crystallization, and dielectric polarization [23, 24, 28, 30,31,32]. The PMMA is important transparent plexiglass of low permittivity over a wide frequency and temperature range [11, 33,34,35,36]. Therefore, it is frequently used as a dielectric in the preparation of microelectronic devices and also the multifunctional composites for their promising electronic and optoelectronic applications [33,34,35,36]. But high brittleness of the PMMA film is one of the major drawbacks to the realization of dimensional design flexibility of modern electronic devices [11, 25, 33,34,35,36]. In contrast to the PMMA film, the PVDF film bears appreciable flexibility, and therefore, the designed PVDF/PMMA blend film can serve as a better flexible dielectric and insulating material for advances in polymer technologies. With this point of view, a detailed study of varying compositional ratio engineered PVDF/PMMA blend films is needed over a broadband frequency range to highlight their possible dielectric applications in next-generation microelectronic devices.

Therefore, in consideration of above-mentioned facts, the present study deals with the detailed characterization of varying composition PVDF/PMMA blend films. For this purpose, different compositional ratios PVDF/PMMA blend films (i.e. PVDF/PMMA = 100/0, 80/20, 60/40, 40/60, 20/80, 0/100 wt/wt%) were prepared by the solution casting method. These films are characterized to their morphological, structural, thermal, dielectric, and electrical properties by employing advanced techniques. The dielectric and electrical measurements are performed over nine orders of magnitude broadband frequency range which is its kind of the first study on these polymer blend materials. The in-depth analysis of the experimental data with the composition variation in the PVDF/PMMA blends revealed some structure-property relationships and also explained the suitability of these polymer blend films for polymer engineering and technologies-based next-generation flexible devices.

Experimental

Materials

The powder samples of PVDF (average molecular weight Mw ~ 5.34 × 105 g/mol) from Sigma-Aldrich, France, and the PMMA (average molecular weight Mw ~ 3.50 × 105 g/mol) from Sigma-Aldrich, Germany were used for the preparation of PVDF/PMMA blend films. N,N-dimethyl formamide (DMF) for HPLC and UV spectroscopy grade from Loba Chemie, India was used as a common solvent for the PVDF and the PVDF/PMMA blend powders, whereas tetrahydrofuran (THF) for HPLC grade from SD Fine-Chem Limited, India was used as a solvent for pure PMMA powder.

Preparation of PVDF/PMMA blend films

The PVDF/PMMA blend films of different compositional ratios (i.e. PVDF/PMMA = 100/0, 80/20, 60/40, 40/60, 20/80, 0/100 wt/wt%) were prepared by solution casting film preparation method. Initially, the required amounts of PVDF and PMMA powders for a fixed compositional ratio were taken into the stoppered conical glass bottle for the preparation of the blend solution in the DMF solvent. The homogeneous solution of the PVDF/PMMA blend was obtained in DMF with a continuous magnetic bar stirring at 500 rpm and simultaneous heating at 60 °C using a thermostated hot plate magnetic bar stirrer. Different compositional ratios of PVDF/ PMMA blend solutions were prepared by the same procedure in separate glass bottles. After that, these homogeneous polymeric solutions were cast onto the glass Petri dishes and heated at about 70 °C on the thermostated hot plate till the DMF solvent was completely evaporated and turned the dissolved polymers into the films. The pure PMMA film was formed by casting its solution at room temperature, which was prepared in THF solvent. These solution-cast prepared films of PVDF/PMMA blend and also the pristine PVDF and PMMA were dried overnight at 45 °C in a vacuum oven to remove the solvent traces.

Characterization techniques

The microimages of the pure PVDF film, PVDF/PMMA (80/20 wt/wt%) blend film, and the pure PMMA film were recorded with Zeiss EVO 18 scanning electron microscope (SEM) at 10 μm scale and 1.0 KX magnification.

The X-ray diffraction (XRD) patterns of all the polymeric films were recorded by using an X’pert Pro multipurpose powder diffractometer (MPD) of Malvern PANalytical, The Netherlands. The X-ray radiations of wavelength 1.5406 Å were generated from Cu-Kα target of the X-ray tube biasing it at the voltage of 45 kV with a current of 40 mA. The XRD patterns of the films were recorded by fixing the films, one after another, on the power sample holder. These XRD measurements of the films at ambient temperature were performed in the reflection mode operation of the diffractometer with an angular sweep speed of 0.05 deg/s over the 2θ range from 10° to 42°.

The Fourier transform infrared (FTIR) transmittance spectra of the films in the wavenumber range from 650 to 4000 cm−1 were recorded in attenuated total reflectance (ATR) mode by employing the FTIR spectrometer (Agilent Technologies; Cary 630).

The thermograms of the samples were recorded in the temperature range from 55 to 200 °C with a heating rate of 10 °C/min by employing the differential scanning calorimeter (DSC) of Netzsch (Polyma 214), Germany. For the DSC measurements, the required amount of the sample (about 7 mg) was filled into an aluminium pan covered with a pierced lid and it was placed into the Arena® furnace having a nitrogen flow at a rate of 40 mL/min. These DSC measurements were controlled with Netzsch Proteus® software.

The frequency-dependent electrical measurements (capacitance Cp, resistance Rp, and dielectric dissipation factor D (dielectric loss angle tangent tanδ)) of the polymer films were carried out using the precision inductance–capacitance–resistance (LCR) meter of 1-V signal amplitude with frequency variation in the range from 20 Hz to 1 MHz. The precision LCR meter of Agilent Technologies, Model: 4284A, and a parallel circular plates solid dielectric test fixture of 38 mm diameter active electrode (Model: 16451B) were used for these electrical measurements. The frequency-dependent complex permittivity \(\varepsilon^{*} (\omega ) = \varepsilon^{\prime} - \varepsilon^{\prime\prime}\) values of the samples were determined from the measured electrical quantities Cp, Rp, and D. The real part of permittivity εʹ and dielectric loss tangent (\(\tan \delta = \varepsilon^{\prime\prime}/\varepsilon^{\prime}\)) in the frequency range of 1 MHz–1 GHz of the PVDF/PMMA blend films were measured by employing radio frequencies impedance/material analyzer (IMA of Keysight Technologies, Model: E4991B, equipped with a solid test fixture of 15 mm diameter electrodes Model: 16453A). The test fixture was calibrated with short, open, and standard load (teflon), before the sample measurements. Thereafter, the εʹ and tanδ values of the samples, appropriately mounted between the electrodes were measured directly by sweeping the frequency from 1 MHz to 1 GHz which was controlled by material measurement firmware of Keysight Technologies (E499B-002). The dielectric test fixtures used with the LCR meter and IMA equipment have a special design that meets the ASTM D150 standard of measurements. The provision of springs attached to the electrodes provides the balance and pressure to establish their proper contact with the loaded dielectric sample for precision measurements. These electrical and dielectric measurements of the films were made at a fixed temperature of 27 °C using both the equipments which covered the broadband frequency range of 20 Hz–1 GHz.

Results and discussion

Physical and morphological properties

The digital pictures of these films are provided in Fig. 1a for having a look at the transparency and surface smoothness, and also the manual test of flexibility and bending. The PMMA film has excellent transparency which is slightly less for the PVDF film, and it seems to a little decrease for the blend films when the amount of PVDF increases. The manual touch realizes the highly smooth surfaces of the films. The bending test infers that these polymer blend films are slightly hard showing their compact packing and reasonable flexibility but not stretchable. Figure 1b depicts the SEM images of pure PVDF film, pure PMMA film, and PVDF/PMMA blend (80/20 wt/wt%) film. The PVDF film has characteristic spherulites of micro-sized separated by fibril-like textures representing its polymorphs, and there are no micro-pores that show its highly compact surface [21]. The SEM image of pristine PMMA film confirms the highly smooth surface which is attributed to the amorphous structure and tight molecular packing because the micro-pores are not noticeable [37]. The SEM image of the PVDF/PMMA blend also exhibited spherulite structures of less number but bigger sizes and less imperfect which are surrounded by the smooth regions revealing the formation of a miscible blend with at least the development of some PVDF-rich domains. Additionally, the absence of micro-pores also reveals the formation of a tightly packed surface of the PVDF/PMMA blend film.

XRD traces and structural analysis

To examine the influence of the amorphous PMMA on the polymorphs of semicrystalline PVDF, the diffractograms of the different compositional ratios PVDF/PMMA blend films (PVDF/PMMA = 100/0, 80/20, 60/40, 40/60, 20/80, and 0/100 wt/wt%) are provided one above another in Fig. 2a. The PANalytical X’pert data viewer and analyzer software is used to determine the Bragg angle (2θ), intensity (I), and full width at half maximum (FWHM) of various diffraction peaks that appeared in XRD patterns of the PVDF/PMMA blend films. Additionally, the overlapped diffraction peaks are separated through a deconvolution procedure using OriginLab 8.5 software, and the FWHM values of deconvoluted peaks fairly support that obtained from the X’pert data analyzer software. The obtained values of these structural parameters along with Miller indices (hkl) corresponding to reflection planes of the assigned crystal phases of the PVDF in these polymer blend films are listed in Table 1. The values of interlayer spacings (d) and crystallite sizes (L) of the various crystals developed in the PVDF/PMMA blend films were evaluated, respectively, by using the Bragg’s law Eq. (1) and the Debye–Scherrer relationship Eq. (2) demonstrated previously [21, 38], and these values are listed in Table 1.

where λ = 1.5406 Å denotes the wavelength of Cu-Kα X-ray radiation, θ represents the Bragg’s angle, k is the crystallites shape factor (also known as Scherrer constant) and its value is most commonly taken as 0.94 for the semicrystalline polymers, and β is the full width at half maximum (FWHM) of the diffraction peaks of PVDF/PMMA blend films. Although the determination of L by the Scherrer equation gives rather a lower bound on the coherently scattering domain size which may or may not be equal to the crystal size. But the study of L gives valuable information, especially about the trends of changes in crystallite shapes with the variation in the amount of the constituents of the composition which we have considered and explained for the PVDF/PMMA blends. Figure 2a illustrates that the XRD pattern of the pristine PVDF film (labelled by 100/0) exhibits different intensities diffraction peaks at 2θ values of 19.22°, 20.67°, and 39.67° confirming its semicrystalline behaviour which is also supported by the spherulite morphology of this film (Fig. 1b). According to the previous literature [21, 22, 24, 39,40,41,42,43], the shoulder peak appeared at 19.22° can be assigned to the γ-phase of the reflection plane (022). Additionally, the main intense peak and another mild peak were observed, respectively, at 20.67° and 39.67° attributed to the β-crystal phase of reflection planes (110), (200) and (201), (111) revealing its polymorphic character. In the case of PVDF film, the assignments of crystal phases to the exhibited diffraction peaks are still controversial [22]. Here, the main intense peak assigned to β-phase could also have some proportion of α-phase and the same in the case of 19.22° peak. The XRD pattern of pristine PMMA film (labelled as 0/100) exhibited a broad diffraction hump centred around 13.17° confirms the amorphous nature of the PMMA matrix [31, 37] which is also revealed from the highly smooth surface morphology of the solution-cast PMMA film (Fig. 1b).

The XRD patterns of the various compositional ratios PVDF/PMMA blend films (labelled by 80/20, 60/40, 40/60, and 20/80 in Fig. 2a) show that the blending of PMMA with the PVDF modifies the structural characteristics of the γ- and β-crystal phases as evidenced from the shift in their peaks positions which also reflects from an altered morphology of the 80/20 wt/wt% blend film (Fig. 1b). Further, the intensities of these low angle side shifted diffraction peaks gradually decrease with the increase in PMMA amount in the PVDF/PMMA blend which reveals alteration in the amount of dominance phase to that of another merged phase. It can be noted from Fig. 2a that the γ-phase diffraction peak disappeared and a new diffraction peak appeared at 2θ = 15.12° when the compositional ratio was varied and the relative content of amorphous PMMA reaches 40 wt% in the PVDF/PMMA blend. Furthermore, when the content of PMMA raised to 80 wt% in the blend, it seems that the polar β-phase largely reduced and a non-polar α-phase appeared in dominance mode as revealed from the mild peak that was noted at 19.87° belonging to the reflection plane (110) [21, 22]. The decrease in XRD peaks intensities also evidenced that the crystalline content of the PVDF/PMMA blend films decreases with the increasing relative content of amorphous PMMA in the blends that means during film formation, these blends PMMA act as a disturbing factor for the better order of PVDF crystallization.

Figure 2b illustrates the variation in crystallite size L of the β- and γ-crystal phases with the PMMA (wt%) for these PVDF/PMMA blend films. It is noted from this figure that the value of L decreased slightly (from 19.15 to 17.79 nm) for the γ-crystal phase but it increased almost linearly from 6.99 to 9.15 nm for the β-crystal phase (probably the merged α-phase with dominant β-phase) when the amount of PMMA increased in these blend films. This result establishes that the PMMA amount acts as a disturbing factor for the development of smaller sizes dense crystallites of the PVDF and promotes to form of bigger sizes crystallites with lesser density in the PVDF/PMMA blends and simultaneously reduces the size of γ-crystals. This finding also supports the bigger sizes of spherulite morphology that appeared in the PVDF/PMMA blend film. Additionally, from Fig. 2c, one can see that the value of interlayer spacing d increased linearly (from 0.462 to 0.480 nm) for the γ-crystal phase and a little increase for the β-crystal phase (from 0.430 to 0.441 nm) with increased the content of PMMA in the PVDF/PMMA blend films. This finding suggests the increase in the intercalated amount of the PMMA between the layers of PVDF crystallites and reveals the formation of a miscible blend.

FTIR spectra and confirmation of crystal phases of PVDF

FTIR spectroscopy is a most established versatile technique to identify the occurrence of different bondings and the interactions in the polymer blend and composite materials and the alteration in structures with the variation in blend compositional ratios [16, 21, 38, 44]. Additionally, this technique is frequently used for the identification and assignment of polymorphs in the ferroelectric PVDF polymer matrix [21, 22, 44, 45]. Therefore, the FTIR measurements on PVDF/PMMA blend films are performed to support the XRD results on the structural properties of these blend films. The FTIR transmittance spectra over a wavenumber range of 650–4000 cm−1 for the PVDF/PMMA blend films are shown in Fig. 3. The reported FTIR spectra of the studied samples exclude the wavenumber range of 2100–4000 cm−1 because in this range, vibrational modes of PVDF and PMMA are not exhibited. The wavenumbers of various infrared (IR) bands corresponding to structural vibration modes for the PVDF and the PMMA chains are marked by vertical dotted lines in the figure and the same with their assignments are listed in Table 2. The nature of polymer–polymer interactions in these PVDF/PMMA blend materials is explored noting a shift in positions of the various IR bands (i.e. change in bands wavenumbers) and alterations in the bands intensities, and also the shapes as compared to that of the characteristic IR bands of the pristine PVDF and PMMA materials.

The FTIR spectrum of pristine PVDF (denoted by 100/0 in the figure) identifies the presence of polar β- and γ-phases and also non-polar α-phase. Low intensity IR bands exhibited at 769 cm−1 and 1455 cm−1 correspond to the skeletal bending and in-plane bending (scissoring) of the CF2 and CH2 functional groups, respectively, which attribute to the PVDF α-phase [21, 42, 46]. An intense IR band appeared at 835 cm−1, representing the stretching and wagging of the CH2 and CF2 functional groups, also evidenced by the overlapped β- and γ-phases [21, 22, 44, 45]. The bands displayed at 872 cm−1 and 1230 cm−1 correspond to stretching of the CF2 and C–F functional groups, respectively, which can be assigned to the γ-phase of PVDF [22, 44, 45]. Furthermore, the other intense or weak IR bands displayed at 1070, 1167, and 1402 cm−1 can be assigned to the wagging and symmetric stretching of the CH2 and CF2 functional groups of the PVDF repeat unit, respectively. The IR bands appeared at 1070 cm−1 and 1402 cm−1 can be assigned to the overlapped α- and β-phases, while another band at 1167 cm−1 can be attributed to the β-phase [22, 44, 45]. According to a comparative survey of the literature, FTIR results may cause some confusion in the assignment of the α-, β- and γ-crystal phases, and therefore, their comparison is a must with the phases identified by XRD and DSC results [22] which we have performed in this study. The FTIR spectrum of PMMA is shown in the upper layer of Fig. 3. This spectrum displayed the intense or weak bands at 749, 840, 909 and 964, 986, 1062, 1140 and 1189, 1240, 1434, 1483, and 1722 cm−1 corresponding to the C–C stretching/CH3 wagging, CH2 rocking, O–CH3 rocking, O–CH3 in-phase bending, C–O–C asymmetric stretching, C–O stretching, C–C–O symmetric stretching, C–CH3 asymmetric bending, C–CH2 asymmetric bending, and C=O stretching vibration of carbonyl groups, respectively, as demonstrated in earlier literature [47, 48].

Figure 3 shows that the characteristic vibrational modes of PVDF which belongs to its various crystals phase are significantly altered due to the addition of PMMA and that these vibrational modes showed further change as the PVDF/PMMA blend compositional ratio is varied. It is observed that the IR bands of the PVDF in the PVDF/PMMA blends relatively shifted to higher wavenumbers in comparison with the pristine PVDF bands with some uneven variations in their intensities indicating some alteration in the amount of crystal phases. Also, some new IR bands appeared in the FTIR spectra of the blends which are consistent with PMMA. The bands of PVDF in the 80/20 wt/wt% PVDF/PMMA blend are slightly altered. But increasing the PMMA concentration to 80 wt% in the blend considerable changes in the positions of the IR bands of PVDF and PMMA could be observed, and some new IR bands of PMMA appeared at 909, 1062, and 1189 cm−1. The weak IR band of PVDF at 769 cm−1 disappeared when the PMMA concentration increased to 60 wt% in the blend films. However, the intensity of the IR band at 1455 cm−1 slightly increases with increased concentration of PMMA, which suggested the presence of α-phase in all PVDF/PMMA blend films. The co-existence of most of the PVDF and PMMA of the characteristic IR bands in the FTIR spectra of PVDF/PMMA blends evidence the formation of a miscible blend that is owing to hydrogen bond interactions between the functional groups of these polymers [46]. In the PVDF/PMMA blend films, the IR bands for pristine PMMA at 1140 cm−1and 1722 cm−1 correspond to stretching vibration of C–O and C=O polar functional groups and are shifted to the higher wavenumber side in all the PVDF/PMMA blend compositions. This shift is caused by the interaction between the ester and carbonyl groups of the PMMA with the CH2 groups of the PVDF chain, which also indicates the formation of compatible blends of these two constituents [45, 47].

DSC thermograms

Thermal transition and degree of crystallinity of the PVDF crystallites in the different compositional ratios PVDF/PMMA blend films were explained from analysis of their DSC thermograms of temperature range from 55 to 200 °C (Fig. 4a). The thermogram of pristine PVDF film exhibited two endothermic peaks. A weak endothermic peak observed at 81.3 °C can be assigned to the β-phase recrystallization temperature Tβr as explained in the literature [49] because its glass transition is exhibited at about − 40 °C [50]. The intense complex endothermic peak at 166.4 °C belongs to a melting temperature Tm of the dominant β-phase crystal of the PVDF [13, 22,23,24, 32, 42] but its asymmetric distribution indicates the involvements of α-phase also. This finding from the DSC trace also favours the XRD results on the existence of both the phases (a small amount of α-phase merged with dominant β-phase) in the pristine PVDF film which was also revealed from the FTIR results and morphological analysis. The pristine PMMA film exhibited a narrow peak at 80.6 °C which is attributed to its glass transition temperature Tg [51]. The pristine PMMA structure is less flexible thus leading it relatively high value of glass transition temperature [52].

a DSC thermograms of various compositional ratios PVDF/PMMA blend films (PVDF/PMMA = 100/0, 80/20, 60/40, 40/60, 20/80, and 0/100 wt/wt%), and plots of b Xc (%) and c Tm (°C) versus PMMA (wt%) for the PVDF/PMMA blend films. Solid lines represent b exponential fit of data and c B-spline fit of data points

It can be noted from Fig. 4a that the glass transition temperature peak related to PMMA in the PVDF/PMMA blend films largely changes in shape and intensity when the blend composition ratio varied from 20/80 to 80/20 wt/wt% in the step of 20. For the PMMA-rich blend having 20/80 wt/wt% composition, the Tg of PMMA appeared, but the blends 40/60 and 60/40 wt/wt% have this broader peak with the signature of overlapping the PMMA glass transition peak with the β-phase recrystallization peak of PVDF (marked with the vertical down arrow in the figure). The fact that we don’t see it at 80/20 wt/wt% blend might be because it is simply too weak and masked by the PVDF β-phase recrystallization phenomenon. The Tg values of PMMA and Tβr of PVDF noted from the DSC traces of these PVDF/PMMA blend films are listed in Table 3.

The degree of crystallinity Xc (%) of PVDF/PMMA blend films which represents the amount of PVDF crystallites in the blend can be determined by the melting enthalpy-based relationship given in Eq. (3) [24, 31]:

The \(\Delta H_{{\text{m}}}\) values of the PVDF/PMMA blend films are taken equal to the area under the endothermic peak in the DSC traces and \(\Delta H_{{\text{m}}}^{ * }\) is the melting enthalpy for a 100% crystalline PVDF [104.5 (J g−1)] [24]. The onset melting temperature Tm(O), peak melting temperature Tm or Tm(P), end melting temperature Tm(E), melting temperature range ΔTm = Tm(E) − Tm(O), melting enthalpy ΔHm, and the degree of crystallinity Xc (%) of the PVDF crystallites in these PVDF/PMMA blend films were obtained from DSC traces and listed in Table 3.

It is explored that when a relative amount of PMMA increases (≥ 40 wt%) in the PVDF/PMMA blend films, the value of Tm(O) decreases at a greater rate than the Tm(E) (Table 3). Thus, the value of ΔTm increases and consequently the range of the melting process of the PVDF crystallites expands largely. These results are obtained due to the formation of more imperfect PVDF crystals with the increased amount of PMMA in the formulated blend compositions as argued earlier [24, 53]. The obtained Xc (%) values are plotted in Fig. 4b which confirmed that the degree of crystallinity of the PVDF decreases exponentially with the increase in PMMA amount in the blend films. The pristine PVDF crystallinity is 34.9% and it drops to 2.2% when the PVDF/PMMA blend was prepared with a 40/60 wt/wt% compositional ratio. The XRD pattern of PVDF/PMMA (labelled by 20/80) blend film has a little peak showing its almost amorphous character, and this fact is also favoured by its DSC thermogram. Such a large decrease in the degree of crystallinity of these blend films with the increase in PMMA amount (especially for PMMA-rich blends) is simply the fact that PMMA chains disturb the order formation of PVDF chains structures.

Figure 4c shows that the melting temperature Tm of PVDF crystallites also decreases when the amount of PMMA increases in the PVDF/PMMA blend films. A drop of about 24 °C is found in the Tm value for 40/60 wt/wt% compositional ratio PVDF/PMMA blend film in comparison with that of the pristine PVDF film (Table 3). This decrease in the melting temperature is associated with a decrease in the chemical potential of PVDF when it is blended with amorphous PMMA [31]. From this result and also detailed discussion on the glass transition temperature, melting temperature, and degree of crystallinity of the PVDF/PMMA blend films over the entire compositional ratio, we also suggest a miscible blend formation of the blended semicrystalline PVDF and amorphous PMMA which favours the earlier findings [24, 31, 49, 54,55,56,57]. The results of this work and the previous studies on these blends evidenced that the PVDF and PMMA miscibility arises due to the intermolecular chain interactions which are either through the oxygen atoms of the carbonyl groups of PMMA and the hydrogen atoms of PVDF or the dipole–dipole interaction between the CH2 groups of the PMMA chain and the CF2 groups of the PVDF chain [32, 58]. Besides this interpretation and reported facts about the formation of miscible PVDF/PMMA blend, the presented structural results on the PVDF crystallites also evidenced that there is always the possibility of the formation of a quite pure PVDF phase in all these different composition blends.

Dielectric dispersion and relaxation processes

Dielectric dispersion behaviour of a dielectric material as a function of harmonic electric field frequency is concerned with the electric energy storage ability and the dielectric loss (energy dissipation) by the material at a fixed temperature [1, 3, 7, 11, 15, 21, 38], and it is defined by complex dielectric permittivity function ε* given in Eq. (4) [3, 20]:

where the real part εʹ refers to dielectric permittivity which is a measure of the energy storage capacity of a dielectric material and the imaginary part εʺ is the dielectric loss which identifies the amount of stored electromagnetic energy converted into the heat per cycle by Joule heating effect. This loss part is related to different physical processes that occurred in the dielectric like electrical conduction, dielectric relaxation, dielectric resonance, etc., whereas the energy storage part represents the magnitude of dielectric polarization processes which are mostly the applied harmonic electric field frequency-dependent. For identification of the suitability of dielectric material in the development of energy storage devices, it must have an appreciably high value of εʹ and a reasonably low value of εʺ [1, 4, 5]. Furthermore, the εʹ values must remain stable over a broader frequency window to work the device satisfactorily under the influence of different frequency harmonic fields [4, 8, 11, 12]. The \(\varepsilon^{\prime}\) values for the PVDF/PMMA blend films were determined by the capacitive measurement method using the relation given in Eq. (5) [4, 59]:

where tg is the film thickness, A is the surface area of the active electrode of the test fixture, Cp is the capacitance of the test fixture loaded with the dielectric sample, and \(\varepsilon_{0} = 8.854 \times 10^{ - 12}\) F m−1 is the dielectric permittivity in a vacuum. The εʺ values for these films were determined from their frequency-dependent εʹ and tanδ values using the following relationship given in Eq. (6) [3, 15, 38, 59]:

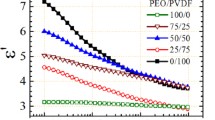

Figure 5 shows the εʹ, εʺ, and tanδ spectra of the PVDF/PMMA blend films covering a broader frequency range from 20 Hz to 1 GHz of the applied harmonic electric field at a fixed temperature of 27 °C. One can understand from this figure that the values of all these dielectric functions change with the variation in frequency and also the polymers compositional ratio in the PVDF/PMMA blends. These blends exhibited a decrease in εʹ values in various characteristic steps when the frequency increases, and finally attained the study state. Furthermore, the εʹ values of these blend films change anomalously in the range of about 4–9, at 20 Hz, with the variation in blend compositional ratio which leads to their appropriateness as dielectric materials in power frequency devices, whereas observed values in the range of about 2.8–3.8 at 1 GHz confirm their suitability as a flexible dielectric substrate for the development of microwave devices. The structural parameters established that there is significant variation in the polar β-phase and also the signature of α-phase merged with β-phase which changes irregularly with the variation in constituents composition of these polymer blends which causes anomalous variation in their εʹ values at a fixed frequency. This behaviour of εʹ values with structural changes establishes a structure-property relationship for the varying composition PVDF/PMMA blend materials. According to previous literature on dielectric materials [1, 4, 6, 7, 9, 13, 39, 60, 61], dispersion behaviour of εʹ values reveals that among these polymer blends of high εʹ and low ε″ could be potential candidates for the development of energy storage devices. Additionally, low εʹ blends can be used as dielectric substrates in high-frequency OFETs, integrated microelectronic devices, and flexible-type microwave devices. The high-loss blend materials (high ε″ in the relaxation frequency range) also suggest their appropriateness for electromagnetic interference (EMI) shielders.

Several characteristic features of dielectric dispersion related to broadband frequency range εʹ spectra of the PVDF/PMMA blend films can be noted in Fig. 5a. The decrease in εʹ values at a lower range of frequencies is associated with the Maxwell–Wagner–Sillars (MWS) type interfacial polarization (IP) process which in general exhibited in the semicrystalline polymers, polymer blends, and the polymer matrices-based composites having different conductivity constituents as defined in detail in the literature [14, 15, 26, 39, 62, 63]. The magnitude of the IP process (MWS) is strongly ruled by the type of dielectric material which means its formation is mild for non-polar dielectrics which enhances when some charge carriers are available in the dielectric to displace some short distances and it appears very strong in the dielectric having ion-dipole complexes. The interfacial polarization in the PVDF and PVDF/PMMA blends is caused due to the accumulation of displaced charges at the interfaces of the crystalline and amorphous domains or the domains of different types of crystallites in these polymeric dielectric materials [15, 38, 39, 62].

A small dispersion of εʹ values at low experimental frequencies for the PVDF and its blends with PMMA infers that the contribution of the MWS process in these dielectrics is small. The variation in εʹ values of the PMMA film is noted relatively low (from 4.1 to 3.2) with a wide range of frequency variation (over a nine orders of magnitude) confirming it as a low-dielectric material of almost frequency independent polarization performance [37, 50]. This dielectric dispersion behaviour makes the pristine PMMA film the most appropriate dielectric material for applications as a gate insulator in organic thin-film transistors (OTFTs) and low-dielectric material as a substrate in the fabrication of microelectronic devices [33, 34, 37, 50, 60]. The relatively high εʹ values of the PVDF film in comparison with that of the PMMA film are owing to the formation of the polar β-phase of the PVDF which was thoroughly discussed in the previous sections “XRD traces and structural analysis–DSC thermograms”. The appreciable decrease in εʹ values of the PVDF and PVDF/PMMA blend films with an increasing frequency above 1 MHz is attributed to molecular polarization that explains the existence of the chain segmental relaxation process (α-relaxation) of the PVDF as demonstrated in the literature [8, 12, 13, 61, 64]. The dielectric studies on a variety of polymers and nanocomposites also demonstrated the dielectric dispersion and occurrence of structural relaxations in such materials in the 1 MHz–1 GHz range [7, 10, 11, 65, 66]. For the benefit of readers and also to the technocrats and industrial users, the εʹ values of all the PVDF/PMMA blends at 100 Hz, 10 kHz, 1 MHz, 100 MHz, and 1 GHz are provided in Table 4, which may also be interesting for dielectric modelling of these polymer blend materials.

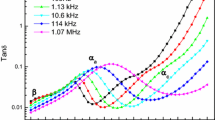

The εʺ and tanδ spectra shown in Fig. 5b, c reveal that the PVDF/PMMA blend films have the chain segmental relaxation process (α-relaxation) in the higher experimental frequency region. The characteristic features of this peak that appeared in the PVDF/PMMA blend seem identical to that of the PVDF film which suggests that in the miscible blend, some PVDF-rich PVDF/PMMA domains exist and the dynamics of the PVDF α-relaxation process in these domains is largely influenced by the existed small PMMA amount in the domains. The assumption of PVDF-rich dynamical domains in the miscible PVDF/PMMA blend is with the consideration of its SEM image given in Fig. 1b. The pristine PVDF film exhibited a highly intense α-relaxation peak around 15 MHz, and its intensity is reduced significantly for the PVDF/PMMA blend films which further shows some variation in intensity and the position on the frequency scale with the variation in polymer blend compositional ratio. The position of this relaxation peak on the frequency scale anomalously changes with the variation in constituents composition in these PVDF/PMMA blend films revealing that the hindrance to this process alters in presence of PMMA and also changes with its blended amount. In comparison with the PVDF and PVDF/PMMA blend films, the pristine PMMA film displayed two relaxation peaks of very low intensities around 100 Hz and 5 MHz which can be assigned to its high rigid chain segmental motion (α-relaxation) and the dipolar rotational motion (β-relaxation), respectively [37, 50, 60, 67]. The β-relaxation peak is obtained due to the rotation of the ester functional group (–COOCH3) around the C–C bond of the repeat unit that connects it to the main PMMA chain [60, 67]. The values of the relaxation time τs (also denoted by τα) for the PVDF, PMMA, and the PVDF/PMMA blend films and the τD (τβ) for pure PMMA film were determined using Eq. (7) [21]:

where fp is the frequency value of the peak that appeared in tanδ spectrum representing the relaxation process and it is marked for the PVDF film as a representative sample in Fig. 5c. The calculated values of τs of these PVDF/PMMA blend films are listed in Table 5. The variation in the τs values confirms a huge alteration in the segmental motion of the PVDF chains with the variation in blended PMMA amount for various compositional ratios of the PVDF/PMMA blend materials.

Figure 6 explains the variation in εʹ values of the PVDF/PMMA blend films with PMMA (wt%) amount at fixed frequencies of 100 Hz, 10 kHz, 1 MHz, 100 MHz, and 1 GHz and temperature of 27 °C. The obtained plots confirm that the trend in change of εʹ values of different compositional ratios PVDF/PMMA blend films at all these fixed frequencies is almost identical. This figure also identifies that the εʹ values change anomalously with the relatively increased amount of PMMA in the blend films. An initial blending of 20 wt% PMMA reduced the εʹ values, but enhances again with an increase in PMMA amount and exhibited the maximum εʹ values for the PVDF/PMMA blend of 40/60 (wt/wt%). After this concentration, the εʹ values decrease for the PVDF/PMMA film of 20/80 (wt/wt%) and then for pristine PMMA film. These results evidence that the εʹ values can be tailored with the frequency variation as well as the polymer compositional ratio of the PVDF/PMMA blends. It is further revealed that the PVDF/PMMA blend exhibited maximum εʹ values at all the frequencies when its degree of crystallinity turned close to zero. This finding explains that the PVDF in an amorphous state has better polarizability in the formulated PVDF/PMMA blends.

AC electrical conductivity

The frequency-dependent AC electrical conductivity (real part σʹ) of dielectric material is associated with its dielectric loss εʺ as defined in Eq. (8) [11, 14, 38, 39]:

Figure 7 illustrates the dispersion behaviour of σʹ with frequency variation from 20 Hz to 1 GHz for the PVDF, PMMA, and their blends. On the log–log scale, σ′ values of these polymer blend films increase linearly with the increase in frequency in the lower experimental frequency region and then turned slightly nonlinear from the onset frequency range of the α-relaxation process. It may be noted that the σʹ values are very low (< 10−11 S cm−1) for the PVDF/PMMA blend materials at 20 Hz confirming their high insulation behaviour. The MWS-type interfacial polarization is responsible for the low value of σʹ at the lower frequency region in such types of polymer dielectric materials [68, 69]. The interfaces between the segments and/or domains of the PVDF and PMMA in their blends behave like potential barriers for the charge carriers at the lower frequencies reducing the probability of the carriers overcoming these potential barriers, and hence, the conduction is poor. However, in the high-frequency region, the charge carriers have enough energy to overcome such types of potential barriers, and hence, the value of σʹ increases. The σ′ values also exhibited anomalous behaviour, at a fixed frequency, when the PMMA content increased in the PVDF/PMMA blend films.

Conclusions

This paper reported the morphology, crystalline phases of the PVDF and their degree of crystallinity and melting temperatures, along with the broadband frequency range (20 Hz–1 GHz) dielectric and electrical dispersion behaviour of the different compositional ratios PVDF/PMMA blend films. The XRD and FTIR results confirm the distinguishable or co-existence of α-, β- and/or γ-crystal phases of the PVDF and their amounts largely change with the variation in PVDF/PMMA blend compositional ratio. The SEM images explain the spherulite morphology of the PVDF and the highly smooth surface of PMMA with the tight molecular packing which also appeared in their blends. It is explored that the initial addition of 20 (wt%) PMMA amount with the 80 (wt%) PVDF, and then further increase in PMMA amount over the entire compositional ratio enhanced the PVDF amorphous phase and turned the PVDF/PMMA blend of 40/60 wt/wt% almost amorphous. DSC thermograms demonstrated that the melting temperature Tm, melting enthalpy ΔHm, and degree of crystallinity Xc (%) of the PVDF crystallites decreased due to the initial addition of PMMA and then further increase in its concentration in the PVDF/PMMA blends. A comparative analysis of XRD, FTIR, and SEM results explains that the PVDF/PMMA blends are miscible over the entire compositional ratio but there is also the existence of PVDF-rich domains. The morphological, structural, and controllable thermal properties demonstrate that these flexible polymeric blend materials may be promising host matrices for the development of advanced polymeric nanocomposites.

The analysis of broadband dielectric dispersion confirmed that the εʹ values of these PVDF/PMMA blend films at 20 Hz can be achieved in the range of 4–9 with the adjustment of polymer compositional ratios whereas from 2.8 to 3.8 at 1 GHz when they are used at 27 °C. Furthermore, the interfacial polarization has some contribution to the dielectric permittivity at lower frequencies, whereas the dipolar polarization largely ruled the permittivity values at higher radio frequencies. The chain segmental relaxation process is identified in the radio frequency range for the PVDF and PVDF/PMMA blends, and this relaxation is largely influenced by the PMMA amount in the PVDF-rich domains of the blends. All these blends have low electrical conductivity suggesting their suitability for electrical insulators in the design and development of wider frequency AC field operative microelectronic devices. These polymeric blend materials of characteristic structural, thermal, dielectric, and electrical properties could be potential candidates for use as dielectric substrates and insulators in the manufacturing of a variety of flexible-type microelectronic devices, energy storage tunable capacitors workable up to microwave frequencies, flexible-type high radio frequency antenna, and EMI shielders.

References

Tan DQ (2020) The search for enhanced dielectric strength of polymer-based dielectric: a focused review on polymer nanocomposites. J Appl Polym Sci 137:49379

Rajeevan S, John S, Georage SC (2021) Polyvinylidene fluoride: a multifunctional polymer in supercapacitor applications. J Power Sour 504:230037

Prateek TVK, Gupta RK (2016) Recent progress on ferroelectric polymer-based nanocomposites for high energy density capacitors; synthesis, dielectric properties, and future aspects. Chem Rev 116:4260–4317

Zha JW, Zheng MS, Fan BH, Dang ZM (2021) Polymer-based dielectrics with high permittivity for electric energy storage: a review. Nano Energy 89:106438

Behera R, Elanseralathan K (2022) A review on polyvinylidene fluoride polymer based nanocomposites for energy storage applications. J Energy Storage 48:103788

Olariu MA, Hamciuc C, Neacsu OM, Hamciuc E, Dimitrov L (2019) Microwave dielectric properties of polyimide composites based on TiO2 nanotubes and carbon nanotubes. Dig J Nanomater Biostruct 14:37–44

Singha S, Thomas MJ (2008) Permittivity and tan delta characteristic of epoxy nanocomposites in the frequency range of 1 MHz−1 GHz. IEEE Trans Dielectr Electr Insul 15:2–11

Zhou W, Li T, Yuan M, Li B, Zhong S, Li Z, Liu X, Zhou J, Wang Y, Cai H, Dang ZM (2021) Decoupling of inter-particle polarization and intra-particle polarization in core–shell structured nanocomposites towards improved dielectric performance. Energy Storage Mater 42:1–11

Jeon H, Jin S, Shin KY (2022) Highly flexible, high-performance radio-frequency antenna based on free-standing graphene/polymer nanocomposite film. Appl Surf Sci 582:152455

Sengwa RJ, Dhatarwal P (2021) PVA/MMT and (PVA/PVP)/MMT hybrid nanocomposites for broad-range radio frequency tunable nanodielectric applications. Mater Lett 299:130081

Sengwa RJ, Dhatarwal P (2022) Toward multifuctionalilty of PEO/PMMA/MMT hybrid polymer nanocomposites: promising morphological, nanostructural, thermal, broadband dielectric, and optical properties. J Phys Chem Solids 166:110708

Sengwa RJ, Dhatarwal P (2022) Crystalline phases thermal behaviour and radio frequencies dielectric properties of PVDF/PEO/metal oxides hybrid polymer nanocomposites films. J Polym Res 29:186

Dhatarwal P, Sengwa RJ (2022) Crystalline phases thermal behaviour, optical energy band gap, and broadband radio wave frequency dielectric properties of PEO/PVDF blend films. Macromol Res 30:460–469

Chen S, Chen S, Qiao R, Xu H, Liu Z, Luo H, Zhang D (2021) Enhanced dielectric constant of PVDF-based nanocomposites with one dimensional core-shell polypyrrole/sepiolite nanofibers. Compos A Appl Sci Manuf 145:106384

Sengwa RJ, Dhatarwal P (2021) Nanofiller concentration-dependent appreciably tailorable and multifunctional properties of (PVP/PVA)/SnO2 nanocomposites for advanced flexible device technologies. J Mater Sci Mater Electron 32:9661–9674

Dhatarwal P, Sengwa RJ (2019) Impact of PVDF/PEO blend composition on the β-phase crystallization and dielectric properties of silica nanoparticles incorporated polymer nanocomposites. J Polym Res 26:196

Brunengo E, Conzatti L, Schizzi I, Buscaglia MT, Canu G, Curecheriu L, Costa C, Castellano M, Mitoseriu L, Stagnaro P, Buscaglia V (2021) Improved dielectric properties of poly(vinylidene fluoride)–BaTiO3 composites by solvent-free processing. J Appl Polym Sci 138:50049

El-Sayed S, Farag ZR, Saber S (2020) Dielectric relaxations and optical properties of polyvinylidene fluoride/chitosan films. AIP Adv 10:095127

Kumar N, Sengwa RJ, Dhatarwal P, Saraswat M (2022) Effectively polymer composition controllable optical properties of PVDF/PMMA blend films for advances in flexible devices technologies. Indian J Eng Mater Sci 29:169–180

Tsonos C, Zois H, Kanapitsas A, Soin N, Siores E, Peppas GD, Pyrgioti EC, Sanida A, Stavropoulos SG, Psarras GC (2019) Polyvinylidene fluoride/magnetic nanocomposites: dielectric and thermal response. J Phys Chem Solids 129:378–386

Dhatarwal P, Sengwa RJ (2019) Polymer compositional ratio-dependent morphology, crystallinity, dielectric dispersion, structural dynamics, and electrical conductivity of PVDF/PEO blend films. Macromol Res 27:1009–1023

Martins P, Lopes AC, Lanceros-Mendez S (2014) Electroactive phases of poly(vinylidene fluoride): determination, processing and applications. Prog Polym Sci 39:683–706

Chiu FC, Chen CC, Chen YJ (2014) Binary and ternary nanocomposites based on PVDF, PMMA, and PVDF/PMMA blends: polymorphism, thermal, and rheological properties. J Polym Res 21:378

Zhao X, Chen S, Zhang J, Zhang W, Wang X (2011) Crystallization of PVDF in the PVDF/PMMA blends precipitated from their non-solvents: special “orientation” behavior, morphology, and thermal properties. J Cryst Growth 328:74–80

Qiu J, Gu Q, Sha Y, Huang Y, Zhang M, Luo Z (2022) Preparation and application of dielectric polymers with high permittivity and low energy loss: a mini review. J Appl Polym Sci 139:52367

Liu Y, Gao J, Yao R, Zhang Y, Zhao T, Tang C, Zhong L (2020) Enhanced energy storage performance in a PVDF/PMMA/TiO2 blending nanodielectric material. Mater Chem Phys 250:123155

Mishra J, Tiwari SK, Abolhasani MM, Azimi S, Nayak GC (2017) Fundamental of polymer blends and its thermodynamics. In: Thomas S, Mishra R, Kalarikkal N (eds) Micro and nano fibrillar composites (MFCs and NFCs) from polymer blends. Woodhead Publishing, Sawston, pp 27–55

Shi Z, Ma X, Zhao G, Wang G, Zhang L, Li B (2020) Fabrication of high porosity nanocellular polymer foams based on PMMA/PVDF blends. Mater Des 195:109002

Abolhasani MM, Arani AJ, Nazockdast H, Guo Q (2013) Poly(vinylidene fluoride)-acrylic rubber partially miscible blends: crystallization within conjugated phases induce dual lamellar crystalline structure. Polymer 54:4686–4701

Weng Z, Wu M, Ren Q, Li W, Zhu X, Wang L, Li H, Zheng W (2022) Achieving low-thermal conductivity and high β phase in PVDF/PMMA blend foams via low-pressure microcellular foaming. J Appl Polym Sci 139:52338

Aid S, Eddhahak A, Khelladi S, Ortega Z, Chaabani S, Tcharkhtchi A (2019) On the miscibility of PVDF/PMMA polymer blends: thermodynamics, experimental and numerical investigations. Polym Test 73:222–231

Yang JH, Zhang YS, Xue F, Liu DF, Zhang N, Huang T, Wang Y (2021) Structural relaxation and dielectric response of PVDF/PMMA blend in the presence of graphene oxide. Polymer 229:123998

Mohammed MI, Khafagy RM, Hussien MSA, Sakr GB, Ibrahim MA, Yahia IS, Zahran HY (2022) Enhancing the structural, optical, electrical, properties and photocatalytic applications of ZnO/PMMA nanocomposite membranes: towards multifunctional membranes. J Mater Sci Mater Electron 33:1977–2002

Sengwa RJ, Dhatarwal P (2021) Polymer nanocomposites comprising PMMA matrix and ZnO, SnO2, and TiO2 nanofillers: a comparative study of structural, optical, and dielectric properties for multifunctional technological applications. Opt Mater 113:110837

Zhou Y, Liu Q, Chen F, Sun X, Li S, Guo J, Zhao Y, Yang Y, Xu J (2021) Gradient dielectric constant sandwich-structured BaTiO3/PMMA nanocomposites with strengthened energy density and ultralow-energy loss. Ceram Int 47:5112–51222

Muller O, Hege C, Guerchoux M, Merlat L (2022) Synthesis, characterization and nonlinear optical properties of polylactide and PMMA based azophloxine nanocomposites for optical limiting applications. Mater Sci Eng B 276:115524

Dhatarwal P, Choudhary S, Sengwa RJ (2021) Dielectric and optical properties of alumina and silica nanoparticles dispersed poly(methyl methacrylate) matrix-based nanocomposites for advanced polymer technologies. J Polym Res 28:63

Dhatarwal P, Sengwa RJ (2020) Tunable β-phase crystals, degree of crystallinity, and dielectric properties of three-phase PVDF/PEO/SiO2 hybrid polymer nanocomposites. Mater Res Bull 129:110901

Xia J, Zheng Z, Guo Y (2022) Mechanically and electrically robust, electro-spun PVDF/PMMA blend films for durable triboelectric nanogenerators. Compos Par A 157:106914

Li Y, Zhang G, Song S, Xu H, Pan M, Zhong GJ (2017) How chain intermixing dictates the polymorphism of PVDF in poly(vinylidene fluoride)/polymethylmethacrylate binary system during recrystallization: a comparative study on core–shell particles and latex blend. Polymers 9:448

Cui Z, Hassankiadeh NT, Zhuang Y, Drioli E, Lee YM (2015) Crystalline polymorphism in poly(vinylidene fluoride) membranes. Prog Polym Sci 51:94–126

Meng Q, Li W, Zheng Y, Zhang Z (2010) Effect of poly(methyl methacrylate) addition on the dielectric and energy storage properties of poly(vinylidene fluoride). J Appl Polym Sci 116:2674–2684

Afonso E, Gómez AM, Tiemblo P, Garcia N (2021) Industrially viable method for producing all-polymer hydrophobic surfaces apt for slippery liquid-infused substrates. Appl Surf Sci 535:147728

Cai X, Lei T, Sun D, Lin L (2017) A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv 7:15382–15389

Elashmawi IS, Hakeem NA (2008) Effect of PMMA addition on characterization and morphology of PVDF. Polym Eng Sci 48:895–901

Satapathy S, Pawar S, Gupta PK, Varma KBR (2011) Effect of annealing on phase transition in poly(vinylidene fluoride) films prepared using polar solvent. Bull Mater Sci 34:727

Namouchi F, Smaoui H, Fourati N, Zerrouki C, Guermazi H, Bonnet JJ (2009) Investigation on electrical properties of thermally aged PMMA by combined use of FTIR and impedance spectroscopies. J Alloys Compd 469:197–202

Rai VN, Mukherjee C, Jain B (2017) UV-Vis and FTIR spectroscopy of gamma irradiated polymethylmethacrylate. Indian J Pure Appl Phys 55:775–785

Veitmann M, Chapron D, Bizet S, Devisme S, Guilment J, Royaud I, Poncot M, Bourson P (2015) Thermal behavior of PVDF/PMMA blends by differential scanning calorimetry and vibrational spectroscopies (Raman and Fourier transform infrared). Polym Test 48:120–124

Gregorio RG, Nociti NCPDS (1995) Effect of PMMA addition on the solution crystallization of the alpha and beta phases of poly(vinylidene fluoride) (PVDF). J Phys D 28:432–436

Dhatarwal P, Sengwa RJ (2021) Superior optical and dielectric properties of ultrasonic-assisted solution-cast prepared PMMA/MMT nanocomposite films. Funct Compos Struct 3:025008

Koseki Y, Aimi K, Ando S (2012) Crystalline structure and molecular mobility of PVDF chains in PVDF/PMMA blend films analysed by solid-state 19F MAS NMR spectroscopy. Polym J 44:757–763

Mazuki NF, Nagao Y, Kufian MZ, Samsudin AS (2022) The influences of PLA into PMMA on crystallinity and thermal properties enhancement-based hybrid polymer in gel properties. Mater Today Proc 49:3105–3111

Freire E, Bianchi O, Monteiro EEC, Nunes RCR, Forte MC (2009) Processability of PVDF/PMMA blends studied by torque rheometry. Mater Sci Eng C 29:657–661

Pawde SM, Deshmukh K (2009) Investigation of the structural, thermal, mechanical, and optical properties of poly(methyl methacrylate) and poly(vinylidene fluoride) blends. J Appl Polym Sci 114:2169–2179

Zhang Y, Liu Y, Tang C, Yao R, Fan Y, Gao J, Zhong L (2020) Enhanced thermal stability of electrical properties in PVDF/PMMA blend. In: IEEE conference on electrical insulation dielectric phenomena, 188−191

Lei C, Wang X, Tu D, Wang H, Du Q (2009) Charge distribution in PVDF/PMMA blends under DC field. Mater Chem Phys 114:272–278

Song H, Yang S, Sun S, Zhang H (2013) Effect of miscibility and crystallization on the mechanical properties and transparency of PVDF/PMMA blends. Polym Plast Technol Eng 52:221–227

Abaci U, Guney HY, Yilmazoglu M (2021) Plasticizer effect on dielectric properties of poly(methyl methacrylate)/titanium dioxide composites. Polym Polym Compos 29:S565–S574

Lavina S, Negro E, Pace G, Gross S, Depaoli G, Vidali M, Noto VD (2007) Dielectric low-k composite films based on PMMA, PVC and methylsiloxane-silica: synthesis, characterization and electrical properties. J Non-Cryst Solids 353:2878–2888

Yu K, Wang H, Zhou Y, Bai Y, Niu Y (2013) Enhanced dielectric properties of BaTiO3/poly(vinylidene fluoride) nanocomposites for energy storage applications. J Appl Phys 113:034105

Wang HQ, Wang JW, Wang XZ, Gao XH, Zhuang GC, Yang JB, Ren H (2022) Dielectric properties and energy storage performance of PVDF-based composites with MoS2@MXene nanofiller. Chem Eng J 437:135431

Feng Y, Deng Q, Peng C, Wu Q (2019) High dielectric and breakdown properties achieved in ternary BaTiO3/MXene/PVDF nanocomposites with low-concentration fillers from enhanced interface polarization. Ceram Int 45:7923–7930

Clark AG, Montero MS, Govinna ND, Lounder SJ, Asatekin A, Cebe P (2020) Relaxation dynamics of blends of PVDF and zwitterionic copolymer by dielectric relaxation spectroscopy. J Polym Sci 58:1311–1324

Dhatarwal P, Sengwa RJ, Choudhary S (2022) Broadband radio frequency dielectric permittivity and electrical conductivity of dispersed tin oxide and silica nanoparticles in poly(ethylene oxide)/poly(methyl methacrylate) blend matrix-based nanocomposites for nanodielectric applications. J Macromol Sci B Phys 61:111–120

Sengwa RJ, Dhatarwal P (2022) Thermally improved crystalline phase and intercalated PEO/OMMT nanocomposites for high to ultrahigh radio frequency range low-permittivity nanodielectrics. J Appl Polym Sci 139:51599

Sengwa RJ, Choudhary S (2014) Dielectric properties and fluctuating relaxation processes of poly(methyl methacrylate) based polymeric nanocomposites electrolytes. J Phys Chem Solids 75:765–774

Alrooqi A, Al-Amshany ZM, Al-Harbi LM, Altalhi TA, Refat MS, Hassanien AM, Atta AA (2022) Impact of charge transfer complex on the dielectric relaxation processes in poly(methyl methacrylate) polymer. Molecules 27:1993

Fahmy T, Elzanaty H (2019) AC conductivity and broadband dielectric spectroscopy of a poly(vinyl chloride)/poly(ethyl methacrylate) polymer blend. Bull Mater Sci 42:220

Acknowledgements

The University Grants Commission, New Delhi, is gratefully acknowledged for the experimental grant through SAP DRS-II Project Grant [No. F.530/12/DRS-II/2016(SAP-I)].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, N., Sengwa, R.J. Broadband dielectric dispersion (20 Hz–1 GHz) and relaxation, crystalline structure, and thermal characterization of PVDF/PMMA blend films. Polym. Bull. 80, 12021–12046 (2023). https://doi.org/10.1007/s00289-022-04632-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04632-1