Abstract

Photo-luminescent water-soluble nitrogen-doped carbon dots (N-CDs) were prepared based on the gum tragacanth polysaccharide and triethylenetetramine (TETA) by one-step hydrothermal carbonization method. The prepared N-CDs showed high fluorescence emission at λem = 460 nm with high quantum yield (QY = 74.69%) at the excitation wavelength λex = 335 nm. Various amounts of the N-CDs as a curing agent were mixed homogenously with diglycidyl ether of bisphenol A (DGEBA) epoxy resin and cured at 60 °C at different times. The films prepared from the nanocomposite were transparent, photo-luminescent with high emission at 460 nm. The prepared N-CDs and epoxy resin@N-CDs nanocomposites were characterized by Fourier-transform infrared spectroscopy (FT-IR), x-ray powder diffraction, scanning electron microscope, Thermogravimetric analysis, Differential scanning calorimetry, Ultraviolet–visible spectroscopy, fluorescence spectroscopy, and Dynamic mechanical analysis. The nanocomposite showed good thermal stability up to 350 °C with a relatively high glass transition temperature at Tg = 105 °C. The storage modulus (Gʹ) of the nanocomposite with 20 wt% N-CDs was more than twice of the storage modulus of the pristine epoxy resin cured with TETA alone.

Graphical abstract

New epoxy resin@N-CDs nanocomposite was prepared with epoxy resin and N-CDs. The prepared nanocomposite showed good optical property and thermal stability. The prepared N-CDs played as a good curing agent and improved the glass transition temperature (Tg) of the nanocomposite.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Compared to the semiconductor quantum dots and among many other kinds of nanoparticles, recently carbon dots (CDs), which was initially discovered by Xu and et al. [1], have attracted the attention of many researchers due to their interesting properties including chemical inertness, biocompatibility, fluorescent, low photobleaching, environment-friendliness, and low cytotoxicity [2,3,4,5,6,7]. Among many techniques for preparation of CDs such as microwave-assisted synthesis, electrochemical etching, treatment of graphite, laser ablation of graphite, and electrochemical oxidation and treatment of graphite [3,4,5,6,7,8,9,10,11], the hydrothermal carbonization method is a simple green, low level of air pollution, low energy consumption, and effective method [12,13,14,15]. However, although CDs can be simply obtained, their low fluorescence quantum yield (< 10%) can be overcome effectively by the practical approach of doping CDs with nitrogen and/or sulfur atoms [16]. Doping is an optimal method to improve optical features and surface chemical properties of nanomaterials [17,18,19]. Also, CDs application in the polymer is limited due to their aggregation and weak interactions with the polymer matrix [20,21,22]. Agricultural wastes and polysaccharides are biocompatible, easy to use, and safe which have been used for the preparation of CDs [23, 24]. Gum Tragacanth (GT) is a natural polysaccharide and is obtained from the stems and branches of Astragalus gummifer growing mainly in the semi-desert and mountainous regions, which has been widely used in medical and food fields. The most attractive characteristics of GT are biocompatibility, non-toxic, acid and heat stability, emulsification ability, and stability over a wide range of pH [25,26,27,28,29]. The hydroxyl and carboxylic acid groups in the GT structure provide the desired positions for reacting with different functional groups [26, 30, 31]. Epoxy resins are one of the high-performance polymers that are widely used as thermoset materials with high mechanical strength, thermal stability, and chemical resistance [32,33,34]. The toughness and flexibility of the thermoset polymers can be improved by blending with the flexible polymers and the addition of nanoparticles [32, 35, 36]. Preparation of light-emitting polymer nanocomposites with CDs were reported in the literature including polysaccharide-based CDs in poly(methyl methacrylate) and poly(vinyl alcohol) [11], N-CDs with poly(methyl methacrylate), amido group functionalized CDs in epoxy nanocomposites, and CDs in hyperbranched epoxy nanocomposite, CDs in poly(ethylene glycol) nanocomposite film [37]. Application of N-CDs is more superior to CDs and other nanomaterials due to their compatibility with many polymer matrices, water- solubility, highly fluorescent, biocompatibility, and nontoxicity. Following our previous work [38], a low-cost method via selecting GT as carbon and triethylenetetramine (TETA) as nitrogen source was constructed to synthesize nitrogen-doped carbon dots (N-CDs) through a simple hydrothermal route. Herein, we report for the first time, the fabrication, characterization, and evaluation of properties of epoxy resin@N-CDs nanocomposite as an advanced material for future optical devices with strong application potential. The optical and mechanical properties of epoxy resin nanocomposite cured with N-CDs are compared with the epoxy resin cured with TETA alone. The prepared nanocomposite is characterized by different techniques such as FT-IR, XRD, SEM, DMTA, TGA, DSC, UV–vis spectrometer, and fluorescence spectroscopy.

Experimental

Materials

The high-quality Gum Tragacanth (GT) of Zagros Mountains region has been purchased from the local pharmaceutical shop in Sanandaj (Iran). GT flakes were purified by sieving to remove dust and small particles, purifying with ethanol extraction, and drying under vacuum for 48 h, and kept in desiccators before use. Ethylene glycol monoethyl ether, Tetrahydrofuran, and n-Hexane were purchased from Merck (Germany), triethylenetetramine (TETA) from Fluka (Germany), and diglycidyl ether of bisphenol A (DGEBA) epoxy resin equivalent epoxy weight of 185 and solid content of 99% from a representative agency of Shell Company. All these compounds were used as received without further purification.

Synthesis of N-CDs

2.0 g purified GT was dissolved in 100 mL ultra-pure water and then precipitated in ethanol (~ 50 mL) and dried in the vacuum oven at 40 °C. Nitrogen-doped carbon dots (N-CDs) were prepared according to our previous reported procedure [38] by using TETA as the nitrogen source. The stoichiometric amount of TETA for the preparation of the N-CDs was obtained using an acid–base titration of a solution of 1.0 g GT in 100 mL of distilled water with 0.01 M NaOH solution in the presence of phenolphthalein as an indicator [38]. 1.0 g purified GT was dissolved in 70 mL ultra-pure water and stirred for 3 h to acquire a homogenous solution. Then, the obtained stoichiometric amount of TETA (7.4 mL) was added into the GT solution and stirred for 30 min. The resulting solution was transferred into a 100 mL Teflon-lined autoclave and heated at 180 °C for 8 h. The autoclave was cooled down gradually and the obtained light brown solution was centrifuged at 20,000 rpm for 15 min, the solution was filtered by CA syringe filter to remove deposits. The supernatant solution was collected and the N-CDs were obtained by freeze-drying for 48 h. Finally, the nanoparticles were washed with organic solvents such as THF, n-Hexane, ethanol to make sure that there is no extra TETA sitting on the surface of N-CDs.

Quantum yield measurement

The fluorescent quantum yield (QY) value of the N-CDs was determined at the excitation wavelength of 335 nm using the following equation:

where Qx is the QY of N-CDs, A is the optical density and F is the intensity of luminescent spectra, η is the refractive index of used solvent. Quinine sulfate (quantum yield 54%) in 0.1 M H2SO4 (ƞ = 1.33) [39] solution was used as the reference. The subscripts of std and x refer to the reference standard and the unknown sample, respectively.

Preparation of epoxy resin@N-CDs nanocomposite

Different amounts of N-CDs as the curing agent (5, 10, and 20 weight%) were added to 1.0 g epoxy resin in the presence of 0.5 mL ethylene glycol monoethyl ether and stirred mechanically for 30 min at room temperature to obtain a uniform mixture. The mixture was uniformly coated on the polyethylene film and cured in a vacuum oven at 60 °C for 20, 90, and 150 min, respectively. For comparison, the epoxy resin was also cured by mixing homogeneously with an epoxy equivalent amount of TETA (13.53 wt%). Then the cured thin films (thickness of 0.4–0.6 mm) were peeled off from the plates after their immersion in hot water (50 °C), and the films were dried under vacuum at room temperature. The nanocomposites were named resin@N-CDs.1, resin@N-CDs.2, resin@N-CDs.3, corresponding to 5, 10, and 20 wt% N-CDs, respectively. The pristine epoxy thermoset without N-CDs was named resin@N-CDs0. The prepared films were used for the measurement of the nanocomposite properties.

Thermal properties of nanocomposite

The thermal properties of nanocomposite were investigated by thermogravimetric analysis (TGA) with a temperature program from 25 to 600 °C through a heating rate of 10 °C/min under nitrogen atmosphere (20 cm3/min). For this purpose, a 20 mg cured sample was put in the sample chamber of TGA, and then was heated according to the temperature program.

Optical properties of N-CDs and epoxy resin@N-CDs nanocomposite

Optical properties of the prepared N-CDs in a dilute aqueous solution and the nanocomposite film were measured by UV–visible and fluorescence spectroscopy. Fluorescence spectra were recorded at the excitation wavelength of λex = 335 nm. The fluorescence spectra of dilute aqueous solutions of N-CDs in different concentrations (15, 30, 50, 80, 100, 200, and 250 ppm) were recorded. The epoxy resin@N-CDs nanocomposite transparent and unconventional films were prepared on the quartz glass using N-CDs (5, 10, and 20 wt%) as curing agents. The fluorescence spectra of the epoxy resin@N-CDs nanocomposite films were attained using an excitation wavelength of λex = 360 nm.

Characterization

The Fourier transform infrared (FTIR) spectra of N-CDs and epoxy resin@N-CDs nanocomposites were recorded on a Bruker FTIR spectrophotometer (vector 22 system) using KBr pellets. Raman spectra of N-CDs were recorded using Raman spectrometer device Teksan (Takram N1-541, laser wavelength = 532 nm). The UV–visible spectra were recorded using a UV–vis spectrophotometer (Cecile 5503 UV–visible). The fluorescence spectra were recorded using the FP-8300 JASCO fluorescence spectrophotometer (Japan). The fluorescence color image of the N-CDs solution and the epoxy resin@N-CDs transparent thin films (thickness 0.5 mm) were obtained by using a UV fluorescence spectrophotometer (Camag UV Cabin, mercury lamp, power of 8 W, λ = 254, 365 nm). The x-ray diffraction (XRD) graphs of GT, N-CDs and epoxy resin@N-CDs nanocomposite were recorded using Philips x-ray diffractometer (PW1730, Netherlands) with Cu Kα radiation (λ = 0.154 nm) at a scan rate of 10 °C/min. The elemental composition of the GT and prepared N-CDs were confirmed by EDX-mapping images (FESEM TESCAN apparatus, MIRA II,France). The transmission electron microscopy (TEM) images were studied by a Filips TEM device (M120, Netherland). The Surface morphology of the N-CDs and epoxy resin@N-CDs nanocomposite film was studied using field emission scanning electron microscopy (FE-SEM) (TESCAN MIRA Π, Czech). Thermogravimetric analysis (TGA) curves were attained under the nitrogen atmosphere at the heating rate of 10 °C/min from room temperature to 600 °C using STA 504 (Germany). Differential scanning calorimetric (DSC) study of the nanocomposite was performed using TA, model: Q600 (US) from 25 to 300 °C under Argon gas. Dynamic mechanical thermal analyses (DMTA) were performed using the DMTA-TRITON model: TRITEC 2000 DMA (England) over a temperature range of 25–150°C. The static contact angle values of the epoxy resin@N-CDs nanocomposite were measured at room temperature using CAG-20, Jikan Co. To obtain an equilibrium contact angle, the measurements were performed by using three drops of distilled water on the nanocomposite film.

Results and discussion

Preparation of N-CDs and epoxy resin@N-CDs nanocomposite

Nitrogen-doped carbon dots (N-CDs) were prepared from gum tragacanth (GT) polysaccharide as a raw carbon source and triethylenetetramine (TETA) as a nitrogen doping source using a one-pot hydrothermal carbonization technique in a Teflon-lined autoclave at 180 °C for 10 h. By surface functionalization of CDs with nitrogen, the bridge is generated between CDs and the polymer matrix, which increases their interactions with the polymer matrix. Thus this practical approach strengthens the interface and improves the homogeneous dispersion of nitrogen-doped carbon dots. This will also decrease the light scattering and increase the intensity of fluorescence and the transparency of the nanocomposite [40,41,42]. At the beginning of the thermal process, the carboxylic acid groups in the macromolecular chains of GT react with the amine groups of TETA. In the later stage and at the higher temperature (180 °C), the formed precursor undergoes hydrothermal carbonization into the N-doped graphitic structure containing various functional groups including amine and oxygen-containing groups on the surface. It is believed that the quantum yield and chemical stability of carbon nanoparticles are increased by doping with heteroatoms such as nitrogen. It has been suggested that the highly efficient fluorescent emission and increase in the quantum yield can be related to the N-doping-induced modulation of the chemical and electronic properties of the CDs [43]. The prepared N-CDs were completely soluble in water which can be due to the formation of hydrogen bonding on the surface between the functional groups such as COOH, C–OH, and C–N with water molecules. The amine groups in the carbonized structure in the N-CDs can act as a curing agent and react with the epoxide groups in the resin.

Therefore, the epoxy resin@N-CDs nanocomposites were prepared using epoxy resin and different amounts of N-CDs as curing/reinforcing agents in a vacuum oven at 60 °C. Figure 1 schematically illustrates the preparation of N-CDs and epoxy resin@N-CDs nanocomposite. The reaction between amine groups in the N-CDs curing agent with the strained epoxide ring of the epoxy resin is the fastest reaction occurring during the curing process. However, there are other functional groups such as hydroxyl, carboxylic, and epoxide ring in the N-CDs structure that can also contribute in the curing reaction to the longer times and higher temperatures. Also the optical emission of different sizes of N-CDs in the polymer matrix may lead to useful materials for optical devices like light-emitting diodes and UV light detector systems as well as in anti-counterfeiting applications.

Characterization of N-CDs and epoxy resin@N-CDs nanocomposite

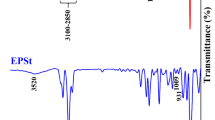

The FT-IR spectra of the samples of GT, N-CDs, pure epoxy resin, and the epoxy resin@N-CDs nanocomposite (resin@N-CDs.3) are shown in Fig. 2a. The absorption bands in the spectrum of GT appeared at 3100–3700, 2924, 1747, and 985–1220 cm−1 which are attributed to the stretching vibrations of O–H, aliphatic C–H, C=O, and C–O, respectively. Also, the absorption bands in the region 1431–1645 cm−1 and at 1035 cm−1 can be assigned to the symmetrical and asymmetrical stretching vibrations of the carboxylate and asymmetric stretching vibration of C–O–C, respectively [44]. The absorption bands in the spectrum of the N-CDs in the region of 3290 and 3340 cm−1 are related to N–H and O–H stretching vibration, respectively. There are also absorption bands at 2800–3000, 1640, 1566, 1419, and 1104 cm−1 due to the C–H, C=O, C=C, C–N, and C–O stretching vibrations, respectively [38, 45]. In the spectrum of pure epoxy resin, the characteristic absorption bands of the stretching vibrations appeared at 3450 (O–H), 3000–2830 (aliphatic C–H), 1607 (aromatic C=C) and1400–1450 cm−1 (aliphatic C–H bending and rocking). Additionally, the presence of the epoxide group is exhibited by the characteristic absorption bands at 1250, 940 cm−1 which are related to stretching of C–O–C and C–O of oxirane [34, 46, 47]. In the spectrum of the epoxy resin@N-CDs nanocomposite, the characteristic absorption bands appeared at 3410 (O–H), 3390 (N–H), 1721 (C=O), 2800–3000 (C–H), 1036 (end epoxy group), and 1119 cm−1 (C–O) [48]. The absorption band of the C=O in the N-CDs has shifted from 1640 to 1721 cm−1 due to the formation of amide linkage as a result of the reaction between carboxylic acid/ester groups and amine groups [49]. Also, the complete disappearance of the oxirane absorption band (at 940 cm−1) of the epoxy resin confirms its participation in the curing reaction and formation of the network structure. Raman spectroscopy is one of the best tools for describing the carbon nanomaterials. The Raman spectra of the synthesized N-CDs in the range of 500–4000 cm−1 in Fig. 2b clearly shows two different bands at 1350 and 1575 cm−1 related to the vibration of sp2 carbon atoms (G-band) in a two-dimensional hexagonal lattice and to the vibrations of sp3 carbon atoms (D-band) in the termination plane of disordered graphite, respectively [48]. The peak strengths of the G-band and D-band were represented as IG and ID, respectively. The ID/IG (a D:G intensity ratio) for the synthesized N-CDs was measured to be 0.89. Generally, (ID < IG) ratio less than 1 indicates that the synthesized carbon materials are well graphitized [50, 51]. Therefore, the Raman spectrum suggests that the synthesized N-CDs have a graphitic structure without major surface faults. Furthermore, XRD was utilized to explore crystallinity of N-CDs (Fig. 2c), the diffraction peaks located at 2θ = 20.15°, which represents the partial graphitization of the N-CDs (d-spacing ~ 0.44 nm for the C (002) peak). The XRD pattern of GT shows a broad peak around 2θ = 24.63° corresponding to an amorphous carbon phase. The epoxy resin@N-CDs nanocomposite (resin@N-CDs.3) exhibited one intense peak at 2θ = 18.1° corresponding to d-spacing of ~ 0.48 nm and a less intense peak at 2θ = 45° which can be due to the contained semicrystalline and amorphous regions [52]. The basal reflection peak (002) of N-CDs at 2θ = 20.15° has shifted to 2θ = 18.1° in the epoxy resin@N-CDs nanocomposite due to the intercalation of epoxy chains with N-CDs particles.

The UV–vis absorption and fluorescence (FL) spectroscopy were utilized to explore optical the properties of the N-CDs and epoxy resin@N-CDs nanocomposite. The prepared N-CDs showed UV–vis absorption bands at 280 and 335 nm due to the π → π* and n → π* transition of C=C and N=C bonds, respectively, as shown in Fig. 3a. The fluorescence emission spectra of the N-CDs was recorded at various excitation wavelengths (λex) from 300 to 385 nm, as shown in Fig. 3b. The maximum fluorescence intensity was observed at λem = 460 nm with a high quantum yield (QY = 74.69%) at λex = 335 nm. This is also comparable with QY = 73% at λem = 450 nm reported for N-CDs prepared from porous copper fibers and ethylenediamine [53] and much higher than QY = 14% reported for N-CDs at λem = 450 nm prepared from ascorbic acid (AA) and β-alanine (BA) [54] and also QY = 28.46% reported for N-CDs at λem = 445 nm prepared from natural peach gum polysaccharide and ethylenediamine [45]. Also, the fluorescence intensity decreased at the excitation wavelengths below and above 335 nm. Figure 3c shows the dependence of the photoluminescence (PL) intensity on the concentration of the N-CDs. At the excitation wavelength of λex = 335 nm, a relatively narrow fluorescence spectra with the maximum intensity at λem = 460 nm was observed. The emission spectra also showed a small shoulder above 500 nm. As can be seen in Fig. 3c, the fluorescent intensity increased from 100 units to ~ 3000 units when the concentration of the N-CDs increased from 15 to 250 ppm. The light yellow solution of N-CDs displayed strong blue fluorescence under 365 nm UV light and strong green fluorescence under 254 nm UV light, as shown in Fig. 3d. The reason for the color change at different excitation wavelengths is suggested due to the different sizes of carbon dots and their band gaps [49].

a UV–vis absorption of N-CDs, b PL spectra of the N-CDs with different excitation wavelengths, c PL spectra with different N-CDs concentrations; d Images of transparent N-CDs aqueous solution under visible light and emission of green and blue fluorescence under 254 and 365 nm excitation wavelength, respectively

Figure 4a shows the UV–vis absorption of epoxy resin@N-CDs nanocomposite film. The nanocomposite film shows absorption bands at 280 and 335 nm due to the π → π* and n → π* transition of C=C and N=C bonds, respectively.

a UV–vis absorption of epoxy resin@N-CDs nanocomposite film (20 wt% N-CDs), b PL spectra of the nanocomposite with different excitation wavelengths, c PL spectra of nanocomposite film with various amounts of N-CDs, d Transparent nanocomposite film under visible light and under 254 and 365 nm excitation wavelength with emission of green and blue fluorescence, respectively

The fluorescence emission spectra of the nanocomposite sample containing 20 wt% N-CDs was recorded at various excitation wavelengths (λex) from 300 to 380 nm, as shown in Fig. 4b. The maximum fluorescence intensity of the nanocomposite was observed under λex = 360 nm excitation wavelength at λem = 460 nm the same as the reported for the N-CDs. As shown in Fig. 4c, the PL intensity of epoxy resin@N-CDs nanocomposite is dependent on the content of the N-CDs in the nanocomposite. In comparison with the pristine cured sample of epoxy resin which does not exhibit fluorescence emission (Fig. 4b), the epoxy resin@N-CDs nanocomposite showed strong fluorescence emission with a narrow and symmetrical peak at λem = 465 nm upon excitation at λex = 360 nm. The PL intensity which depends on the number of particles excited at a particular wavelength increases with increasing the concentration of the N-CDs in the nanocomposite.

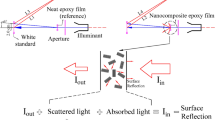

The transparency and photoluminescence are the unique optical characteristics of CDs-based polymer nanocomposites, which are difficult to achieve with other carbon-based nanocomposites. The transparency of the prepared epoxy resin@N-CDs nanocomposite (Fig. 4d) can be due to the quantum size (< 10 nm) of the N-CDs, their homogeneous dispersion in the polymer matrix, and contribution in the chemical cross-linking and formation of the network. At the short wavelength of the visible light, the transmittance of the film slightly decreases which can be due to the absorption of the light source by the N-CDs. The color change of the epoxy resin@N-CDs nanocomposite film under different illuminated lights is shown in Fig. 4d. The light brownish color of the prepared film in the visible light changed to the green under UV light at λex = 254 nm and to the blue color under UV light at λex = 365 nm. These color changes are due to transitions of the π-π* and n − π*, which can be related to the absorption bands of the C=C, C=O, and N=C bonds in the epoxy resin@N-CDs nanocomposite, respectively. The color changes are due to the presence of different sizes of the N-CDs in the nanocomposite, and the maximum fluorescence emission was observed at λem = 460 nm upon the excitation wavelength of λex = 360 nm. The inset of Fig. 5a shows the N-CDs particle size distribution histogram. There are particles with different sizes in the range of 1–4 nm with the most particles are in the region of 2.5–3 nm. The internal morphology of the synthesized N-CDs was further investigated by TEM analysis to verify the characteristics of nanoparticles. As presented in Fig. 5b and c, the N-CDs with spherical shape and narrow size distribution are dispersed well.

Figure 6a, b and c shows the elemental mapping of the N-CDs, indicating the presence of C, N, and O in the synthesized N-CDs. Also, the results of the EDX analysis for GT and N-CDs in Fig. 6d and 6e, as listed in Table 1, show the ratio of atomic and weight percent’s of elements for carbon 43.59: 38.73%, oxygen 19.15: 22.67%, and nitrogen 37.26: 38.60% nitrogen. This result indicates that nitrogen is successfully doped into the structure of CDs.

The FE-SEM images of the sample surface of GT, N-CDs, and epoxy resin@N-CDs nanocomposite unconventional thin film (thickness 0.5 mm) (resin@N-CDs.3) are shown in Fig. 7. As compared with the smooth and continuous surface of GT (Fig. 7a), the prepared N-CDs (Fig. 7b) are spherical nanoparticles with a narrow size distribution in the range of 10–15 nm and with high colloidal stability. The N-CDs were incorporated homogeneously in the epoxy resin and then cured. The surface morphology of the epoxy resin@N-CDs nanocomposite (Fig. 7c) showed rough and folded which can be due to the interaction of N-CDs with epoxy resin and porous surface of the nanocomposite.

Thermo-mechanical properties of epoxy resin@N-CDs nanocomposite

TGA curves of GT, N-CDs, Epoxy resin + TETA and epoxy resin@N-CDs nanocomposite are shown in Fig. 8a. The GT weight loss is observed at temperatures below 200 °C, 230–350 °C, and 400–600 ºC related to the evaporation of water molecules, the loss of side groups such as acid and ester groups, and decomposition of the main chain, respectively. The N-CDs weight loss at temperatures below 100 °C and 150–310 °C is due to the evaporation of water molecules and the loss of the surface functional groups. The TGA curve of the control film (epoxy Resin + TETA) showed weight loss at the temperature range of 350–450 °C due to the breakdown of the epoxy network. In the case of the epoxy resin@N-CDs nanocomposite, the initial weight loss at the temperature 350–450 °C and − 600 °C is attributed to the breakdown and decomposition of the main backbone. The residual weight (char yield) of the neat GT, N-CDs, control sample and epoxy resin@N-CDs nanocomposite are about 5 wt%, 10 wt%, 12 wt% and 30 wt% at 600 °C, respectively.

Figure 8b indicates the DSC thermogram of the curing epoxy resin with N-CDs from 20 to 300 °C under N2 atmosphere at a heating rate of 2 °C/min. A small peek at 40 °C can be related to the evaporation of ethylene glycol monoethyl ether solvent and a large exothermic peak at around 125 °C due to the curing of epoxy resin. There is not exothermic peak during the second heating step from room temperature up to 300 °C. The fast curing of the epoxy resin indicates the reaction between amine groups in the N-CDs and the strained epoxide ring in the resin. However, an endothermic step was observed around 105 °C during the second heating which can be related to the glass transition temperatures (Tg) of the cured nanocomposite. These results confirm that the incorporation of N-CDs in the epoxy resin leads to the formation of a cross-linked network. In the dynamic mechanical thermal analysis (DMTA), the material under continuous change of temperature is exposed to oscillatory shear force and the elastic and viscous properties of a material such as the elastic modulus (G′), the loss modulus (G″), and the damping factor tanδ = G″/G′ are measured. Some fundamental characteristics of polymeric materials such as crystallization, melting, and glass transition temperature (Tg) can be obtained from the DMTA test. Figure 8c and d shows the tan δ and the storage modulus (G′) of the epoxy resin@N-CDs nanocomposite as a function of the temperature from the glassy state to the rubbery plateau region. As can be seen, the initial G′ of the nanocomposite sample with 20 wt% N-CDs is much higher (two folds) than the G′ sample with wt% N-CDs and the control sample cured with the stoichiometric amount of TETA. The storage modulus of all samples decreased with increasing temperature due to the increase in chain mobility. The maximum peak of the damping factor (tan δ) (in Fig. 8c) indicates the Tg of the control sample and nanocomposite with 10 and 20 wt% N-CDs and are 75, 80, and 85 °C, respectively. As these results show, in comparison with TETA, the N-CDs as a curing and reinforcing agent increased Tg and the storage modulus of the epoxy nanocomposite.

Measurement of static contact angle

The static contact angle of distilled water drop on solid film epoxy resin@N-CDs nanocomposite was measured to obtain an equilibrium contact angle. The average contact angle obtained from three drops of distilled water on the nanocomposite film are shown in Table 2. Epoxy resin chains can interact with the water molecules via hydrogen bonding force. The contact angle values measured for the epoxy resin@N-CDs nanocomposite film with a thickness of (45 nm) are very close to the results reported for the cured epoxy resin [55, 56]. The results of the contact angle in Table 2 show that the nanocomposite film has a hydrophilic surface. The previous reported results [56] also showed that the nature of the epoxy film surface change to more hydrophobic state as its thickness increases.

Conclusions

In this study, highly fluorescent N-doped CDs (N-CDs) with a high quantum yield (74.69%) emission at λem = 465 nm upon excitation at λex = 360 nm and excellent water-solubility have been synthesized from a cheap and readily available GT polysaccharide and triethylenetetramine (TETA) using a one-step hydrothermal carbonization method. The prepared N-CDs were used as a curing agent in the curing process of the epoxy resin to prepare epoxy resin@N-CDs nanocomposite. The epoxy resin was cured by the fast reaction between amine groups in the N-CDs and the strained epoxide ring of the epoxy resin at 60 °C. The maximum fluorescence intensity of the nanocomposite was observed, under λex = 360 nm excitation wavelength, at λem = 460 nm the same as the reported for the N-CDs. The optical properties of the prepared N-CDs and epoxy resin@N-CDs nanocomposites are an interesting topic that warrants further research in the field of design of optical catalysts and sensors systems. In summary, we have prepared epoxy nanocomposites by using N-CDs as curing and reinforcing agent that exhibited with better optical, fluorescence, thermal, and mechanical properties than films made from epoxy resin cured with an aliphatic curing agent (TETA). The results obtained with the N-CDs can be transferred to other polymers matrix providing optical devices like light-emitting diodes and UV light detection systems.

References

Xu X, Ray R, Gu Y et al (2004) Electrophoretic analysis and purification of fluorescent single-walled carbon nanotube fragments. J Am Chem Soc 126:12736–12737

Kang Y-F, Li Y-H, Fang Y-W et al (2015) Carbon quantum dots for zebrafish fluorescence imaging. Sci Rep 5:11835

Jia X, Li J, Wang E (2012) One-pot green synthesis of optically pH-sensitive carbon dots with upconversion luminescence. Nanoscale 4:5572–5575

Li Q, Ohulchanskyy TY, Liu R et al (2010) Photoluminescent carbon dots as biocompatible nanoprobes for targeting cancer cells in vitro. J Phys Chem C 114:12062–12068

Goh EJ, Kim KS, Kim YR et al (2012) Bioimaging of hyaluronic acid derivatives using nanosized carbon dots. Biomacromol 13:2554–2561

Hsu P-C, Shih Z-Y, Lee C-H, Chang H-T (2012) Synthesis and analytical applications of photoluminescent carbon nanodots. Green Chem 14:917–920

Li H, Kang Z, Liu Y, Lee S-T (2012) Carbon nanodots: synthesis, properties and applications. J Mater Chem 22:24230–24253

Luo PG, Sahu S, Yang S-T et al (2013) Carbon “quantum” dots for optical bioimaging. J Mater Chem B 1:2116–2127

Lai C-W, Hsiao Y-H, Peng Y-K, Chou P-T (2012) Facile synthesis of highly emissive carbon dots from pyrolysis of glycerol; gram scale production of carbon dots/mSiO2 for cell imaging and drug release. J Mater Chem 22:14403–14409

Zhao HX, Liu LQ, De Liu Z et al (2011) Highly selective detection of phosphate in very complicated matrixes with an off–on fluorescent probe of europium-adjusted carbon dots. Chem Commun 47:2604–2606

Zhou L, He B, Huang J (2013) Amphibious fluorescent carbon dots: one-step green synthesis and application for light-emitting polymer nanocomposites. Chem Commun 49:8078–8080

Yang Y, Cui J, Zheng M et al (2012) One-step synthesis of amino-functionalized fluorescent carbon nanoparticles by hydrothermal carbonization of chitosan. Chem Commun 48:380–382

Tang L, Ji R, Cao X et al (2012) Deep ultraviolet photoluminescence of water-soluble self-passivated graphene quantum dots. ACS Nano 6:5102–5110

Kwon W, Rhee S-W (2012) Facile synthesis of graphitic carbon quantum dots with size tunability and uniformity using reverse micelles. Chem Commun 48:5256–5258

Zhu S, Meng Q, Wang L et al (2013) Highly photoluminescent carbon dots for multicolor patterning, sensors, and bioimaging. Angew Chem Int Ed 52:3953–3957

Hu Y, Zhang L, Li X et al (2017) Green preparation of S and N co-doped carbon dots from water chestnut and onion as well as their use as an off–on fluorescent probe for the quantification and imaging of coenzyme A. ACS Sustain Chem Eng 5:4992–5000

Karthik KV, Raghu AV, Reddy KR et al (2022) Green synthesis of Cu-doped ZnO nanoparticles and its application for the photocatalytic degradation of hazardous organic pollutants. Chemosphere 287:132081. https://doi.org/10.1016/j.chemosphere.2021.132081

Kannan K, Radhika D, Reddy KR et al (2021) Gd3+ and Y3+ co-doped mixed metal oxide nanohybrids for photocatalytic and antibacterial applications. Nano Express. https://doi.org/10.1088/2632-959x/abdd87

Jonnalagadda M, Prasad VB, Raghu AV (2021) Synthesis of composite nanopowder through Mn doped ZnS-CdS systems and its structural, optical properties. J Mol Struct 1230:129875. https://doi.org/10.1016/j.molstruc.2021.129875

Ding C, Zhu A, Tian Y (2013) Functional surface engineering of C-dots for fluorescent biosensing and in vivo bioimaging. Acc Chem Res 47:20–30

Mohan S, Oluwafemi OS, Songca SP et al (2014) Facile synthesis of transparent and fluorescent epoxy–CdSe–CdS–ZnS core–multi shell polymer nanocomposites. New J Chem 38:155–162

Li Y-Q, Yang Y, Fu S-Y et al (2008) Transparent and light-emitting epoxy super-nanocomposites containing ZnO-QDs/SiO2 nanocomposite particles as encapsulating materials for solid-state lighting. J Phys Chem C 112:18616–18622

Thambiraj S, Shankaran R (2016) Green synthesis of highly fluorescent carbon quantum dots from sugarcane bagasse pulp. Appl Surf Sci 390:435–443

Kumar A, Chowdhuri AR, Laha D et al (2017) Green synthesis of carbon dots from ocimum sanctum for effective fluorescent sensing of Pb2+ ions and live cell imaging. Sens Actuators B Chem 242:679–686

Masoumi A, Ghaemy M (2014) Removal of metal ions from water using nanohydrogel tragacanth gum-g-polyamidoxime: isotherm and kinetic study. Carbohydr Polym 108:206–215

Hemmati K, Ghaemy M (2016) Synthesis of new thermo/pH sensitive drug delivery systems based on tragacanth gum polysaccharide. Int J Biol Macromol 87:415–425

Badakhshanian E, Hemmati K, Ghaemy M (2016) Enhancement of mechanical properties of nanohydrogels based on natural gum with functionalized multiwall carbon nanotube: study of swelling and drug release. Polymer (Guildf) 90:282–289

Hosseini MS, Hemmati K, Ghaemy M (2016) Synthesis of nanohydrogels based on tragacanth gum biopolymer and investigation of swelling and drug delivery. Int J Biol Macromol 82:806–815

Moradi S, Sadrjavadi K, Farhadian N et al (2018) Easy synthesis, characterization and cell cytotoxicity of green nano carbon dots using hydrothermal carbonization of gum tragacanth and chitosan bio-polymers for bioimaging. J Mol Liq 259:284–290

Sahraei R, Ghaemy M (2017) Synthesis of modified gum tragacanth/graphene oxide composite hydrogel for heavy metal ions removal and preparation of silver nanocomposite for antibacterial activity. Carbohydr Polym 157:823–833

Sahraei R, Pour ZS, Ghaemy M (2017) Novel magnetic bio-sorbent hydrogel beads based on modified gum tragacanth/graphene oxide: removal of heavy metals and dyes from water. J Clean Prod 142:2973–2984

De B, Karak N (2013) Novel high performance tough hyperbranched epoxy by an A 2+ B 3 polycondensation reaction. J Mater Chem A 1:348–353

Barua S, Dutta G, Karak N (2013) Glycerol based tough hyperbranched epoxy: synthesis, statistical optimization and property evaluation. Chem Eng Sci 95:138–147

Hsissou R, Berradi M, El Bouchti M et al (2019) Synthesis characterization rheological and morphological study of a new epoxy resin pentaglycidyl ether pentaphenoxy of phosphorus and their composite (PGEPPP/MDA/PN). Polym Bull 76:4859–4878. https://doi.org/10.1007/s00289-018-2639-9

Zhang D, Jia D (2006) Toughness and strength improvement of diglycidyl ether of bisphenol-A by low viscosity liquid hyperbranched epoxy resin. J Appl Polym Sci 101:2504–2511

Morell M, Erber M, Ramis X et al (2010) New epoxy thermosets modified with hyperbranched poly (ester-amide) of different molecular weight. Eur Polym J 46:1498–1509

Hao Y, Gan Z, Xu J et al (2014) Poly(ethylene glycol)/carbon quantum dot composite solid films exhibiting intense and tunable blue-red emission. Appl Surf Sci 311:490–497. https://doi.org/10.1016/j.apsusc.2014.05.095

Rahmani Z, Ghaemy M (2019) One-step hydrothermal-assisted synthesis of highly fluorescent N-doped carbon dots from gum tragacanth: Luminescent stability and sensitive probe for Au3+ ions. Opt Mater (Amst) 97:109356

Zhang R, Chen W (2014) Nitrogen-doped carbon quantum dots: Facile synthesis and application as a “turn-off” fluorescent probe for detection of Hg2+ ions. Biosens Bioelectron 55:83–90

Chen L, Zhang C, Du Z, et al (2015) Fabrication of amido group functionalized carbon quantum dots and its transparent luminescent epoxy matrix composites. J Appl Polym Sci. https://doi.org/10.1002/app.42667

Wu ZL, Zhang P, Gao MX et al (2013) One-pot hydrothermal synthesis of highly luminescent nitrogen-doped amphoteric carbon dots for bioimaging from Bombyx mori silk–natural proteins. J Mater Chem B 1:2868–2873

Dong Y, Pang H, Bin YH et al (2013) Carbon-based dots co-doped with nitrogen and sulfur for high quantum yield and excitation-independent emission. Angew Chem Int Ed 52:7800–7804

Zuo P, Lu X, Sun Z et al (2016) A review on syntheses, properties, characterization and bioanalytical applications of fluorescent carbon dots. Microchim Acta 183:519–542

Indana MK, Gangapuram BR, Dadigala R et al (2016) A novel green synthesis and characterization of silver nanoparticles using gum tragacanth and evaluation of their potential catalytic reduction activities with methylene blue and Congo red dyes. J Anal Sci Technol 7:19

Liao J, Cheng Z, Zhou L (2016) Nitrogen-doping enhanced fluorescent carbon dots: green synthesis and their applications for bioimaging and label-free detection of Au3+ ions. ACS Sustain Chem Eng 4:3053–3061

Kocaman S, Ahmetli G (2016) A study of coating properties of biobased modified epoxy resin with different hardeners. Prog Org Coat 97:53–64

Zhang C, Du L, Liu C et al (2016) Photostable epoxy polymerized carbon quantum dots luminescent thin films and the performance study. Results Phys 6:767–771

Wu W, Zhan L, Ohkubo K et al (2015) Photocatalytic H2 evolution from NADH with carbon quantum dots/Pt and 2-phenyl-4-(1-naphthyl)quinolinium ion. J Photochem Photobiol B Biol. https://doi.org/10.1016/j.jphotobiol.2014.10.018

De B, Kumar M, Mandal BB, Karak N (2015) An in situ prepared photo-luminescent transparent biocompatible hyperbranched epoxy/carbon dot nanocomposite. RSC Adv 5:74692–74704

Atchudan R, Pandurangan A, Joo J (2013) Synthesis of multilayer graphene balls on mesoporous Co-MCM-41 molecular sieves by chemical vapour deposition method. Microporous Mesoporous Mater. https://doi.org/10.1016/j.micromeso.2013.03.035

Shen R, Song K, Liu H et al (2012) Dramatic Fluorescence enhancement of bare carbon dots through facile reduction chemistry. ChemPhysChem. https://doi.org/10.1002/cphc.201200018

Raghu AV, Gadaginamath GS, Priya M et al (2008) Synthesis and characterization of novel polyurethanes based on N 1, N 4 -bis[(4-hydroxyphenyl)methylene]succinohydrazide hard segment. J Appl Polym Sci 110:2315–2320. https://doi.org/10.1002/app.27366

Rao L, Tang Y, Lu H et al (2018) Highly photoluminescent and stable N-doped carbon dots as nanoprobes for Hg2+ detection. Nanomaterials 8:900. https://doi.org/10.3390/nano8110900

Edison TNJI, Atchudan R, Sethuraman MG et al (2016) Microwave assisted green synthesis of fluorescent N-doped carbon dots: cytotoxicity and bio-imaging applications. J Photochem Photobiol B Biol 161:154–161. https://doi.org/10.1016/j.jphotobiol.2016.05.017

Liechti KM, Schnapp ST, Swadener JG (1997) Contact angle and contact mechanics of a glass/epoxy interface. Int J Fract 86:361–374

Abbasian A, Ghaffarian SR, Mohammadi N, Fallahi D (2004) The contact angle of thin-uncured epoxy films: thickness effect. Colloids and surfaces A: physicochem. Eng Asp 236:133–140

Acknowledgements

We wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salehtabar, F., Ghaemy, M. Preparation of strongly photoluminescent nanocomposite from DGEBA epoxy resin and highly fluorescent nitrogen-doped carbon dots. Polym. Bull. 80, 3247–3264 (2023). https://doi.org/10.1007/s00289-022-04207-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04207-0