Abstract

The aim of this work is to evaluate the effect of poly-ε-caprolactone addition and concentration on the gas permeability, tensile properties and biodegradation of PBAT/PCL blends prepared by extrusion in a bench scale single-screw extruder. The blends were characterized by scanning electron microscopy (SEM), tensile properties, permeability to oxygen (O2) and carbon dioxide (CO2) gas and biodegradation in soil. Our data indicate that PCL addition to poly(butylene adipate-co-terephthalate) (PBAT) increases its permeability to both O2 and CO2. The tensile properties of the blends are sensitive to PCL concentration and, particularly, their modulus is higher than that of PBAT. SEM images did not show changes in PBAT morphology upon PCL incorporation and content. Biodegradation (bio-disintegration) in soil was shown to increase with both the presence and content of PCL in the blends. Incorporation of up to 25% of PCL to PBAT can be suitable to develop materials with high potential of biodegradation with preserved tensile properties. The higher permeability upon blending with PCL can also be useful in applications such as cooking food coated with polymeric films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Environmental concerns about the management and disposal of solid waste has led to industrial and academic endeavors to develop materials with good properties during use and fast degradation after disposal. Therefore, the replacement of conventional and non-biodegradable plastics by polymers that degrade when composted under favorable conditions has been recognized for decades [1, 2].

Poly(butylene adipate-co-terephthalate) (PBAT) is a biodegradable copolymer with good processability, high deformability and mechanical properties similar to those of PE. It has a combination of characteristic properties derived from its aromatic and aliphatic components: butylene terephthalate and butylene adipate, respectively. PBAT is considered a promising material for agricultural packaging and after irradiation can also be used in more demanding areas, such as regenerative medicine or active packaging [3]. In addition, PBAT can be processed by conventional equipment (mixers, extruders, injection molding machines, etc.) and is stable during regular processing conditions [4]. Chaves and Fechine (2016) reported that increases in processing temperature contribute to chain scission reactions during PBAT processing in an internal mixer [5]. Al-Itry et al. (2012) proposed a mechanism of degradation of PBAT during processing based on hydrolysis of the ester bond, followed by β-scission [6]. However, aromatic rings can effectively protect the copolymer from radiation-induced processes while aliphatic ester segments can make the material susceptible to radiation crosslinking and/or degradation [3].

Several researchers [7,8,9,10] have investigated the incorporation of nanoparticles into PBAT by evaluating the properties and biodegradation of the polymer. The development of polymeric blends, as well as their association with nanotechnology, appears as another possible solution that can be adopted in different technological areas, aiming at improving the intrinsic properties of polymers.

The literature reports several studies on the use of PBAT in polymeric blends aiming to improve the toughness of brittle biodegradable polymers, such as PLA. Wang et al. (2016) [11] studied the PLA/PBAT blend using a solvent casting method for food packaging application. They concluded that PBAT reduced the brittleness and improved the flexibility of the PLA. The results of packaging tests with fresh green onions revealed that PBAT-containing films effectively maintain product freshness and prevent fogging on the surface of packaging film due to its high water vapor permeability. The authors evaluated the biodegradation of the PBAT/PLA blend under soil conditions. They concluded that after four months of degradation, the PBAT/PLA samples buried in soil, presented themselves in small fragile fragments, showing a lower degradation rate than when compared to the neat polymers. Further, the melting temperature and melting point changes of the various components in the PBAT/PLA blend before and after degradation basically followed the changing process of the respective single polymers.

PCL is a linear aliphatic semi-crystalline polyester, commonly used in pharmaceuticals and dressings for wounds. Due to its biodegradability, biocompatibility and environmental friendliness PCL have been used for packaging, agriculture and medical devices, as well as a substitute of non-biodegradable commodity polymers [12, 13].

Our research group has been investigating PBAT and its blends, evaluating their stability under processing and degradation conditions, and the properties required for packaging applications [14,15,16,17]. Sousa et al. (2018) [18] evaluated the rheological and thermal characteristics of PBAT in blends with polycaprolactone (PCL), processed in an internal laboratory mixer. It was observed that the PBAT/PCL blend is immiscible, with phase inversion at about 70% PCL. Crystallization data during cooling indicated a strong interaction between PBAT and PCL.

Even so, further studies are needed to elucidate the influence of PBAT composition on miscibility, mechanical properties, permeability, time and mechanism of degradation of polymers and their blends. Blends of PBAT/PCL can be interesting, because both polymers are biodegradable, commercially available and with important properties for packaging applications. Unless the PBAT is previously photo-oxidized, it degrades very slowly when buried in soil [15]. Therefore, the reason for incorporating PCL into PBAT is that, not only is PCL stiffer than PBAT, but its biodegradation rate is higher than that of PBAT. PBAT has important properties, such as high flexibility, for the production of packaging, but it degrades slowly when discarded under normal conditions. PCL is stiffness than PBAT and highly biodegradable and can also be used in packaging production. PBAT/PCL blends can be promising in the production of packaging, combining adequate mechanical properties with a high biodegradability.

Experimental

The polymers used were PBAT (polybutylene adipate-co-terephthalate), purchased from BASF, known commercially as ECOFLEX® F C1200 and PCL (poly-ε-caprolactone), purchased from MCassab and manufactured by PERSTORP under the trade name CAPA 6500®.

Samples of neat PBAT, PCL and PBAT/PCL blends were prepared in a Haake Rheomix 3000 laboratory internal mixer operating with roller type rotors at a nominal speed of 60 rpm, with a 150ºC chamber wall temperature processed during 15 min. The blends produced in the mixer were ground and fed to a 16-mm bench scale single screw extruder Lab-16 Chill-Roll from AX Plásticos (Brazil) with a flat die, operating in a range of 80–120ºC and 35–45 rpm, to prepare films for further characterization. Films specimens with thickness between 112 and 211 µm were obtained. Table 1 reports the compositions and film thicknesses obtained.

The gas permeability to oxygen and carbon dioxide of the films manufactured were determined according to ASTM D1434 and ISO 15,105/1 standards at 25 °C in a GPD-C Brugger equipment. Film specimens were tensile tested according to ASTM D882, in an EMIC DL1000 universal testing machine fitted with a 20 N load cell operating at 50 mm/min extension rate at ambient temperature. The Young’s modulus was calculated from the slope of the initial linear region of the load deformation curve. The maximum tensile strength was determined by dividing the maximum tensile load carried by the specimen during the test by the original sample cross-sectional area. Scanning electron microscopy images of gold sputtered cryogenically fractured surfaces were obtained in a Shimadzu SSX 500 equipment with 500 × − 2000 × magnification.

A composting soil prepared by manually mixing equal quantities of organic fertilizer, earthworm humus and fertile soil was used for biodegradation testing which took place in an incubator operating at 30–35 °C with air and soil relative humidity kept at 80 and 60%, respectively. The samples were buried in the prepared soil and weighted weekly, for 17 weeks, to determine sample mass loss (bio-disintegration) as a function of time, calculated by Eq. 1, where m0 is the initial mass and mf the final mass of the sample, according to ASTM G160 standard.

Results and discussion

Permeability

Oxygen and carbon dioxide gas permeability tests results are graphically shown in Fig. 1.

Results indicate that PCL is more permeable to both oxygen and carbon dioxide than PBAT. Oxygen and carbon dioxide permeabilities of PCL are 3.7- and 2.8-fold higher than that of PBAT, respectively. Therefore, increasing the PCL content in the blend increases the permeability values in both cases.

The increase in carbon dioxide permeability with higher PCL content in blends is more significant than oxygen permeability. Increasing from 10 to 25% and from 25 to 50% of PCL in the blend increases oxygen permeability by 51% and 27%, respectively, relative to 90PBAT/10PCL blend (Fig. 1a). Figure 1b shows a gradual increase in CO2 permeability with increasing PCL content, reaching increases of up to 114%.

Permeability is favored by the decrease in crystallinity, which leads to a higher diffusion coefficient, since diffusion is restricted to amorphous regions and the length of the diffusion path decreases in this condition [19]. However, despite the crystallinity of PCL being greater than that of PBAT [18], the low glass transition temperature (Tg) of PCL, far below ambient and test temperature, may have contributed to the increase in permeability to both O2 and CO2 gases compared to PBAT, since the packing density of the PCL chains may have been decreased due to increased mobility. Sousa et al. (2018) [18] also observed that increments above 50% of PCL in PBAT tend to decrease the total crystallinity of the blend, which can justify the observed behavior.

The permeability of films tends to increase as the gas molecule diameter decreases. Thus, contrary to what was experimentally observed, a higher permeability to oxygen molecules than to carbon dioxide molecules, was expected. It is possible that this effect was offset by the higher solubility of CO2 in the PBAT and PCL.

Tensile properties

Tensile results for PBAT, PCL and PBAT/PCL blends are shown in Figs. 2, 3, 4.

Tensile properties were affected by PCL incorporation and content into the PBAT matrix. Our results indicate that the Yong’s modulus of PCL is larger than that of PBAT and also led to an increase in the stiffness of systems containing up to 25% of PCL. This behavior was expected because of the higher modulus of PCL [15, 20]. However, further increase in PCL content in the blend, i.e., for the 50PBAT/50PCL blend, led to a decrease in modulus. It is believed that a change in blend morphology at high PCL concentrations is responsible for the observed decrease in modulus of the 1:1 PBAT/PCL blend.

The experimental data spread observed for the tensile strength of the different systems (Fig. 3) investigated makes it difficult to, non-equivocally, state the influence of PCL incorporation on the properties of PBAT/PCL blends. Apparently, a decrease in tensile strength with PCL concentration with up to 25% PCL was observed, followed by a slight increase at higher PCL content. This behavior is taken as indicative of a possible phase inversion in the system with higher PCL content. The occurrence of intermediate values of tensile strength lower than those of neat components shows a trend of strong contribution of the interface to the maximum strength. Values much lower than those of the individual components would indicate a state of incompatibility due to low interfacial adhesion. Further tests must be conducted before a conclusion is reached. The Young’s modulus and tensile strength values of neat polymers agree with those found in the literature [12, 20, 21] for PBAT (~ 55 MPa) and PCL (~ 15 MPa).

Elongation at break (Fig. 4) clearly decreased with increasing PCL content in the blend. Neat PBAT shows a significantly higher elongation at break than the neat PCL. This is associated to structure of PBAT which displays low crystallinity and high flexibility and toughness [22, 23]. PCL, on the other hand, is a rigid, brittle polymer. Thus, a decrease in elongation at break for the blends was expected and predicted by the rule of mixtures since the elongation at break of PCL (~ 19%) is much lower than that of PBAT (~ 780%). Approximately a 94% reduction in this property when 50% PCL was incorporated into neat PBAT.

The rule of the mixtures was applied for Young’s modulus to observe the expected values for this property, as shown in Fig. 5, and a positive–negative deviation was observed. Up to 25% PCL content in the blend, the Young’s Modulus values obtained are higher than those predicted while values below those predicted were observed for the 50PBAT/50PCL blend, which can be explained by the immiscibility and phase separation of the blends. A similar behavior was reported by Sousa et al. (2018) [18] when investigating degradation during processing of PBAT/PCL blends, which suggested that phase inversion leading to a co-continuous system in PBAT/PCL blends containing more than 30% of PCL was obtained.

Scanning electron microscopy (SEM)

Figure 6 shows the micrographs of the surfaces of the PBAT/PCL blends containing 10%, 25% and 50% of PCL.

Blends containing 10 and 25% PCL have a uniform, pore-free structure with some rounded particles dispersed on the matrix surface. It is believed that these particles result from condensation during cooling of the film in the chill-roll or incomplete melting of the blending components. Considering the PBAT and PCL melting temperatures, the processing temperatures employed and the small length of the extruder, it is possible that these are incompletely molten PBAT particles. The 50PBAT/50PCL blend surface is irregular and seems to point to increased phase separation.

Figure 7 shows the micrographs of the fractured surfaces of PBAT/PCL blends with 10%, 25% and 50% of PCL.

Figure 7 shows blends with ductile fracture characteristics, dense morphology and free of pores. In these compositions, it is not possible to distinguish the individual phases of the blends.

The increase in the concentration of PCL, apparently did not cause phase segregation as observed on fracture surfaces, which may indicate a partial miscibility between the components of the mixture.

Biodegradation

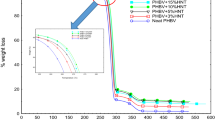

The mass loss curves of PBAT/PCL films are illustrated in Fig. 8.

The data show that: (a) mass loss increases with soil burial time for all investigated systems, (b) PCL degrades faster than PBAT and (c) the mass loss of the investigated systems increases with the PCL content. In other words, the loss mass order due to bio-disintegration is: PCL > PBAT50/PCL50 > PBAT 75/PCL25 > PBAT90/PCL10 > PBAT.

Average mass losses after 119 days (17 weeks) of soil burial were, respectively, 2.3% and 34.7% for PBAT and 50PBAT/50 PCL blend. Neat PCL lost 57% of its mass in 37 days of burial and completely disintegrated after 41 days of testing. Although the biodegradation of samples buried in soil in the laboratory is not as aggressive as the real conditions, especially regarding temperature, Weng et al. (2013) [2] observed that after 120 days of burial, only fragments of PBAT film obtained by casting were detected. In another study reported by Palsikowski et al. (2017) [1], the soil degradation time of neat PBAT was only 30 days, with only fragments of the polymer being observed. The differences in the literature for the degradation of PBAT can be attributed to the different composting conditions adopted.

Conclusions

Our data indicate both oxygen and carbon dioxide permeabilities increased with PCL content in the blends. When compared with neat PBAT, oxygen gas permeability initially decreases and carbon dioxide gas permeability increased with the PCL incorporation. The unexpected higher CO2 permeability than O2 permeability observed for all systems are thought to be due to higher solubility of CO2 in PCL and PBAT. Incorporation and increase in PCL content in the blends led to stiffer blends which little change in tensile strength when compared with PBAT. Additive mechanical properties (Young´s modulus) up to 25% of PCL and a negative deviation of these characteristics above this concentration were observed which was attributed to blend phase inversion. SEM analysis was unable to detect changes in morphology of the systems investigated as a function of PCL content. Biodegradation is significantly more pronounced with PCL incorporation and content. PBAT is a biodegradable polymer with important characteristics that allows it to be used in the packaging industry. However, compared with PCL, this polymer degrades very slowly. For fast disposal applications, the quick degradation of the polymer after use is interesting. Thus, blending PCL and PBAT is a viable solution as it increases its degradation without negatively affecting tensile strength, modulus and permeability characteristics. Adding up to 25% PCL to PBAT is a useful alternative for the environment, as it combines maintenance or improvement of properties combined with higher biodegradability.

References

Palsikowski PA, Kuchnier CN, Pinheiro IF, Morales AR (2017) Biodegradation in soil of PLA/PBAT blends compatibilized with chain extender. J Polym Environ 26:1–12

Weng Y-X, Jin Y-J, Meng Q-Y, Wang L, Zhang M, Wang Y-Z (2013) Biodegradation behavior of poly(butylene adipate-coterephthalate) (PBAT), poly(lactic acid) (PLA), and their blend under soil conditions. Polym Test 32:918–926

Razepna M, Przybytniak R, Sadło J (2018) Radiation degradation and stability of PBAT: copolymer of aromatic and aliphatic esters. J Appl Polym Sci 46682:1–8

Yamamoto M, Witt U, Skupin G, Beimborn D, Müller RJ (2002) Biodegradable aliphatic-aromatic polyesters:“Ecoflex®.” In: Steinbüchel A, Doi Y (eds) Biopolymers: polyesters III – Applications and commercial products, vol 4. Wiley, New York

Chaves RP, Fechine GJM (2016) Thermo stabilisation of poly (butylene adipate-co-terephthalate). Polímeros 26:102–105

Al-Ltry R, Lamnawara K, Maazouz A (2012) Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym Degrad Stab 97:1898–1914

Fukushima K, Rasyida A, Yang MC (2013) Biocompatibility of organically modified nanocomposites based on PBAT. J Polym Res 20:302

Chen JH, Chen CC, Yang MC (2011) Characterization of nanocomposites of poly (butylene adipate co-terephthalate) blending with organoclay. J Polym Res 18:2151–2159

Someya Y, Kondo N, Shibata M (2007) Biodegradation of poly(butylene adipate-co-butylene terephthalate)/layered-silicate nanocomposites. J App Polymer Sci 106:730–736

Someya Y, Sugahara Y, Shibata M (2005) Nanocomposites based on poly(butylene adipate-co-terephthalate) and montmorillonite. J App Polymer Sci 95:386–392

Wang L-F, Rhim J-W, Hong S-I (2016) Preparation of poly(lactide)/poly(butylene adipate-co-terephthalate) blend films using a solvent casting method and their food packaging application. Food Sci Technol 68:454–461

França DC, Morais DDS, Bezerra EB, Araújo EM, Wellen RMR (2018) Photodegradation mechanisms on poly(ε-caprolactone) (PCL). Mater Res 21(5):e20170837

Ludueña LN, Vázquez A, Alvarez VA (2012) Effect of lignocellulosic filler type and content on the behavior of polycaprolactone based eco-composites for packaging applications. Carbohyd Polym 87:411–421

Almeida TG, Silva Neto JE, Costa ARM, Silva AS, Carvalho LH, Canedo EL (2016) Degradation during processing in poly(butylene adipate-co-terephthalate)/vegetable fiber compounds estimated by torque rheometry. Polym Test 55:204–211

Falcão GAM, Almeida TG, Bardi MAG, Carvalho LH, Canedo EL (2019) PBAT/organoclay composite films — part 2: effect of UV aging on permeability, mechanical properties and biodegradation. Polym Bull 76:291–301

Marinho VAD, Pereira CAB, Vitorino MBC, Silva AS, Carvalho LH, Canedo EL (2017) Degradation and recovery in poly(butylene adipate-co-terephthalate)/thermoplastic starch blends. Polym Test 58:166–172

Santos TT, Almeida TG, Morais DDS, Magalhães FD, Guedes RM, Canedo EL, Carvalho LH (2020) Effect of filler type on properties of PBAT/organoclay nanocomposites. Polym Bull 77:901–917

Sousa FM, Costa ARM, Reul LTA, Cavalcanti FB, Carvalho LH, Almeida TG, Canedo EL (2018) Rheological and thermal characterization of PCL/PBAT blends. Polym Bull 76:1573–1593

Jost V (2018) Packaging related properties of commercially available biopolymers – An overview of the status quo. Express Polym Lett 12:429–435

Bezerra EB, França DC, Morais DDS, Rosa MF, Morais JPS, Araújo EM, Wellen RMR (2017) Processing and properties of PCL/cotton linter compounds. Mater Res 20(2):317–325

Falcão GAM, Vitorino MBC, Almeida TG, Bardi MAG, Carvalho LH, Canedo EL (2017) PBAT/organoclay composite films: preparation and properties. Polym Bull 74:4423–4436

Boonprasertpoh A, Pentrakoon D, Junkasem J (2017) Investigating rheological, morphological and mechanical properties of PBS/PBAT blends. J Metal, Material, Mineral 27:1–11

Fukushima K, Rasyida A, Yang MC (2013) Characterization, degradation and biocompatibility of PBAT based nanocomposites. Appl Clay Sci 80–81:291–298

Acknowledgements

The authors thank to Federal University of Campina Grande (UFCG) for support and are grateful for the fellowships provided by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) in favor of Morais (PNPD), Sousa (PhD), Marinho (PhD) and Cavalcanti (MSc) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) in favor of Carvalho (PQ) and Almeida (PDJ#160909/2019-8).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sousa, F.M., Cavalcanti, F.B., Marinho, V.A.D. et al. Effect of composition on permeability, mechanical properties and biodegradation of PBAT/PCL blends films. Polym. Bull. 79, 5327–5338 (2022). https://doi.org/10.1007/s00289-021-03745-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03745-3