Abstract

There is a myriad of ways to crosslink hydrogel wound dressings; however, they require additional steps to remove the residue of the crosslinking agents, or their byproducts in biological environments are toxic. In this study, we studied and characterized the crosslinking of the chitosan hydrogels by various dicarboxylic acids, including oxalic acid, adipic acid, and sebacic acid under vacuum at 90 °C. The concentrations of the crosslinkers in the crosslinked hydrogels are tolerable for the cells, and the membranes can be used after crosslinking without complicated additional steps to remove the unreacted residues. The molar ratio of the crosslinkers was calculated based on the stoichiometry of the chitosan amine groups. Attenuated total reflectance Fourier transform infrared spectroscopy revealed amide linkage formation between amine groups of the chitosan and carboxyl groups of the dicarboxylic acids at 90 °C. The results showed that the chitosan membranes crosslinked with oxalic acid had higher Young's modulus (~ 1042 N/mm2) and ultimate tensile strength (~ 75 N/mm2) in comparison with the other dicarboxylic acids. Moreover, the membranes crosslinked with oxalic acid showed a weight loss of ~ 5.4% after 24 h at double-distilled water, which was drastically lower than that of the others. Thus, oxalic acid was selected as the most effective crosslinker. Cell viability assay, using mouse fibroblast (L929) cells, was conducted on the mechanically optimized membranes. The fibroblast cells successfully attached and spread well on the surface of the membranes. In conclusion, the obtained results suggested oxalic acid as an effective and non-toxic crosslinker for chitosan-based membranes for wound dressing applications.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chitosan is a linear amino polysaccharide. It is the second most abundant natural biopolymer after cellulose. Chitosan is derived from the cell walls of fungi, crustacean shells, exoskeletons of invertebrates and arthropods [1,2,3,4,5]. Chitosan is available in various grades; they differ in the molecular weight and deacetylation degree [6, 7]. Owing to its intrinsic properties such as biocompatibility, biodegradability, and hemostatic, antibacterial, antitumor, and antioxidative activities, chitosan has received increasing attention as a unique biopolymer for widespread applications in drug delivery and tissue engineering [4, 8,9,10,11]. Besides the ability of chitosan in accelerating the wound healing process, its antibacterial and antimicrobial activities against a wide variety of pathogens make it suitable for wound dressing applications [12,13,14,15,16]. Antibacterial properties of chitosan are explained as: the chitosan has a positive surface charge in physiological pH; it effectively binds to the negatively charged membrane of various bacterial cells resulting in the rupture of the cell wall membrane and killing the bacteria [17, 18].

Bioadhesive properties of chitosan prevent fluid or air gap formation lessening the risk of infection and reducing pain and increasing the longevity of the wound dressing at the wound site [19]. In addition, chitosan shows excellent ability in film formation when dissolved in organic acids, which is another interesting feature of this polymer over other biopolymers used in the fabrication of wound dressings [20,21,22]. An ideal wound dressing should be biocompatible and should keep the wound adequately moist. It should also protect the wound against the invasion of pathogens, accelerate the healing process, and should be non-antigenic, hemostatic, and elastic [5, 23, 24]. Chitosan itself can satisfy most of the criteria for an ideal wound dressing material; however, the chitosan membranes have weak mechanical properties, which impede the chitosan in being a suitable material for wound dressing applications. Crosslinking is one of the methods that can improve the mechanical properties of the polymers [25]. Several reagents are available for the crosslinking of chitosan, including glutaraldehyde, ethylene glycol, genipin, tripolyphosphate, diglycidyl ether, diisocyanate, and dicarboxylic acids [26, 27]. Non-cytotoxic crosslinking agents, like most of the dicarboxylic acids, can be used in the crosslinking process without further specific steps to remove the residues of crosslinker. Dicarboxylic acids alone cannot dissolve chitosan, but they can be utilized in crosslinking reaction under certain conditions [27]. This study aimed to develop a membrane for wound dressing application with mechanical properties, cytocompatibility, and stability compared to plain chitosan. Here, we investigated different dicarboxylic acids, non-toxic reagents, to fabricate crosslinked chitosan membranes for wound dressing applications. To evaluate the efficacy of each crosslinker, the membranes were first characterized by ATR-FTIR spectroscopy, weight loss in water, and tensile strength test. We performed biological assessments like cell attachment and growth on the best candidate.

Material and methods

Materials

Chitosan (Mn = 810,000, DD > 85%) was purchased from Sigma-Aldrich (USA). Adipic acid, oxalic acid, sebacic acid, 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT), dimethyl sulfoxide (DMSO), ethanol, and glutaraldehyde were purchased from Merck (Germany) and used without any purification. RPMI 1640, fetal bovine serum (FBS), penicillin/streptomycin, l-glutamine, trypsin/EDTA, and phosphate buffer saline (PBS) were purchased from the GIBCO Company.

Preparation of crosslinked chitosan films

The chitosan solution was prepared by dissolving the polymer (1% w/v) in aqueous acetic acid solutions (1% v/v) and stirring for 12 h at room temperature. The mixture was filtered using Büchner funnel to separate undissolved particulates. Finally, the solution was mixed with crosslinkers, then cast into Petri dishes, and incubated at 25 ± 2 °C for 24 h. The ratios between the amine groups of chitosan, based on the degree of deacetylation (DD), and carboxyl groups of the acids were used to determine the quantity of dicarboxylic acids. The chitosan films were peeled off from the Petri dishes and were further dried in a vacuum for 12 h. Finally, the chemical crosslinking of the chitosan membrane was carried out by heating the specimens at 90 °C under vacuum for 2 h. The membranes were kept at room temperature in a desiccator without further treatment for the upcoming tests. A plain chitosan film was also prepared through the same procedure and used as control. Figure 1 shows the schematic illustration of the chemical structure of dicarboxylic acids and crosslinking reaction between amine groups of chitosan and carboxyl moieties of dicarboxylic acids.

ATR-FTIR spectroscopy

The chitosan films were characterized using ATR-FTIR spectroscopy (Bruker, Equinox 55, Germany) with a resolution of 20 scans cm−1, in transmission mode. The samples were analyzed in the wavenumber range of 400–4000 cm−1.

Mechanical properties

The mechanical properties of both crosslinked and non-crosslinked chitosan films were determined according to ASTM D882-12 [28] using a tensile strength instrument, GALDABINI (Sun 2500) with a load cell of 50 N capacity. The films were cut into 50 mm length and 10 mm width and placed in a vacuum oven at 60 ± 5 °C overnight. The specimens were fixed vertically on the grips of the instrument and pulled at a crosshead speed of 1 mm/s. The gauge length between the two clamps was set at 10 mm to determine Young's modulus (E), ultimate tensile strength (UTS), and elongation at break (εb) for each specimen.

Weight loss in an aqueous medium

The chitosan films were cut into square shapes, weighed (w1), immersed in double-distilled water, and incubated at 37 °C (± 2 °C) for 24 h. Next, the specimens were dried in a vacuum oven at 60 °C (± 5 °C) overnight and weighed again (w2). The weight loss value (Ws) was calculated using Eq. (1).

Cell adhesion study

The cell adhesion study was performed using the L929 cell line (supplied by national cell bank of Iran, Pasteur Institute of Iran) according to the same procedure as described by Jamalpoor et al. [29]. Briefly, the number of 4 × 104 cells was seeded on the chitosan membranes (non-crosslinked and crosslinked), with dimensions of 20 × 20 mm2 and sterilized with UV radiation for 30 min in advance. Cell-seeded films were incubated for 4 h at 37 ± 1 °C, allowing the cells to attach. Then, 400 µL of RPMI-1640 medium supplemented with 10% FBS was added to each well and incubated. To assess the morphology of the cells, we removed the culture medium and rinsed the membranes with the PBS solution. The attached cells were fixed with 4% GTA solution for 20 min and dehydrated in graded ethanol solutions (50%, 60%, 70%, 80%, 90%, and 100%), and finally dried at 25 ± 2 °C, for scanning electron microscopy (SEM) (AIS 2100, Seron Technology, Korea). In this study, tissue culture plate (TCP) was considered as the negative control.

Cytotoxicity

The cytotoxicity of the membranes was studied with the L929 cell line utilizing tetrazolium dye-based colorimetric (MTT) assay. The MTT assay was performed on the extracts of the films, according to Bonakdar et al. [30], with minimal modifications. Briefly, the extract of each sample was prepared according to the ISO 10993-12 standard test method [31] by incubating the specimens in RPMI 1640 culture medium for 24 h. The RPMI 1640 medium free of the sample was also incubated and used as a negative control. The L929 cells were seeded into a 96-well plate at the confluency of 1 × 104 cells per well and supplied by 90 μL RPMI 1640 medium and 10 μL FBS and incubated for 24 h. Then, the medium was removed and replaced with 90 μL of the prepared extract media plus 10 μL FBS and incubated for 24 h. Next, the media was removed, and 100 μL of MTT dye solution (0.5 mg/mL in PBS) was added to each well followed by incubation for 4 h. Finally, the MTT solution was aspirated out, and 100 μL of DMSO was added to each well and incubated for 15 min to dissolve the formazan crystals prior to the absorbance measurement. The optical density (OD) was performed by a microplate reader (ELX800, Biotech, USA) at 570 nm and normalized to the control OD.

Statistical analysis

All the results are expressed as mean ± standard deviations. Statistical comparisons were performed with one-way analysis of variance (ANOVA). The p value < 0.05 was considered as a statistical significance level.

Results and discussion

Characterization

ATR-FTIR spectra of both non-crosslinked and crosslinked chitosan films are shown in Fig. 2. The results are separated in different colors. To avoid overwriting the data of one sample on the others, we introduced gaps between the graphs; consequently, the vertical axis is representative of actual intensities of the peaks. The characteristic transmittance peak around 3450 cm−1 in each spectrum is attributable to the overlapping N–H and O–H stretching bands of chitosan, while the peaks seen at 1565 cm−1 are related to the C=O stretching vibration of the amide I group [32, 33]. Formation of ionic salts of chitosan with carboxylic acids is confirmed by the appearance of the NH3+ peaks around 1514 cm−1 and 1615 cm−1, and –COO− peak at about 1556 cm−1 [34, 35]. Intensities of the peaks of the carbonyl group (1500–1600 cm−1) and amine group (1400 cm−1) are influenced. The observation is due to the interactions of chitosan with the organic acids; the results are in good agreement with the published literature [36]. Also, similar observations have been reported for chitosan/glutamic acid and chitosan/succinic acid blend hydrogels [37]. The peak that appeared around 1300 cm−1 in the spectra of the oxalic acid-crosslinked specimens confirmed the formation of amide II as a result of the reaction of amine groups of the chitosan and carboxyl groups of the oxalic acid at 90 °C under vacuum, confirming the report of Cai et al. [25].

Mechanical properties

The primary purpose of using dicarboxylic acids for crosslinking of chitosan is to improve the mechanical properties and increase the durability of chitosan films for biomedical applications with high biocompatibility [36]. The results of the mechanical properties of the chitosan films are summarized in Table 1. The oxalic acid reagent enhanced both Young's modulus (from 726.9 to 1042.4 N/mm2) and the UTS (from 62.1 to 75.6 N/mm2) in the chitosan films. Crosslinking with oxalic acid, however, decreased the elongation at the break of the chitosan films from ~ 40 to ~ 15%. Thus, it could be considered as an effective crosslinking agent for chitosan. Crosslinking by the other dicarboxylic acids decreased the mechanical properties of the chitosan films (no statistical significance), which can be attributed to the lower reactivity of the carboxylic moiety as a result of their long carbon backbone. The long carbon chain, in general, leads to lower reactivity of the end chemical groups. As a fact, the mechanical properties (mainly, Young's modulus, UTS) of the crosslinked chitosan membranes will decrease in the wet condition, because water molecules act as a plasticizer in the polymeric matrix. Thus, it is rational to select the membrane with higher mechanical properties (membranes crosslinked with oxalic acid) as the best candidates.

Weight loss

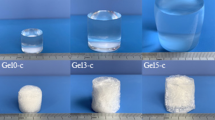

Chitosan-based biomaterials have poor stability in aqueous medium and thus need further treatments such as crosslinking for biomedical applications [38]. The results of the weight loss tests of the chitosan films are represented in Fig. 3. All the crosslinked chitosan films showed weight loss after 24 h immersion in double-distilled water, but there was significantly less weight loss in crosslinked membranes than plain chitosan films. Chitosan/oxalic acid represented the smallest change in weight. The results suggest that oxalic acid was the most effective crosslinking reagent for chitosan since it led to the lowest Ws compared to the others. According to the results of the mechanical properties and the weight loss percentages of the specimens, the oxalic acid-crosslinked chitosan membranes were selected as the optimized specimen for further studies.

Cell adhesion study

An ideal wound dressing material should not exhibit any cytotoxic effect during the time of exposure to the wound. Thus, evaluation of the cytocompatibility of a wound dressing material is critical. In this study, the L929 cell line was selected as the model cell line since the fibroblast cells play crucial roles in the wound healing process [39]. SEM images of the cultured fibroblast cells on the surfaces of the chitosan films are represented in Fig. 4. As seen, the fibroblast cells adhered well to the surface of the films and spread. No visible cell debris or changes in morphology, such as cell necrosis and loss of spindle shape, were observed, which certify the non-cytotoxicity of the prepared films. Proper attachment of the fibroblast cells on the surface was expected based on previous reports [40, 41], and our results delineated the same trend. The morphologies of the cells on the crosslinked membranes with 0.22% w/v oxalic acid appear to be diverted from the spindle shape of the healthy fibroblast. It could be ascribed to the surface properties of the membranes and the residual oxalic acid in the polymer matrix. This observation is in agreement with cytocompatibility results, indicating the optimum amount of the oxalic acid should be 0.11% w/v for the given chitosan substrate.

Cytocompatibility

Further confirmation of the non-cytotoxicity of the prepared films was conducted with MTT assay on the extracts of the specimens. Figure 5 demonstrates the viability of the fibroblast cells after 24 h contact with the extract of the samples. According to the results of MTT assay, the cell viabilities of the chitosan and chitosan/oxalic acid (0.11% w/v) films were close to the TCP. They did not show any significant difference (P > 0.05), translating in the nontoxicity of the membranes. The published scientific literatures [16, 42, 43] can support this observation.

Conclusion

In this study, the crosslinking effects of various dicarboxylic acids, including oxalic acid, adipic acid, and sebacic acid, on the properties of chitosan membranes were evaluated. The obtained results showed that the oxalic acid could significantly improve the mechanical properties and stability of the chitosan membranes. The water loss percentage data were a means of confirming the oxalic acid efficacy in the crosslinking of chitosan, which led to the minimum value of 5.4%, translating in a stable crosslinking reagent. Cell viability assay for the oxalic acid-crosslinked chitosan membrane showed the cytocompatibility of the membranes. The findings suggest that oxalic acid (with a concentration of 0.11% w/v) could be a promising crosslinking reagent of chitosan with almost no cytotoxicity for biomedical wound dressing applications.

References

Campos MG, Satsangi N, Rawls HR, Mei LH (2009) Chitosan cross‐linked films for drug delivery application. Paper presented at: macromolecular symposia

Zuo P-P, Feng H-F, Xu Z-Z et al (2013) fabrication of biocompatible and mechanically reinforced graphene oxide–chitosan nanocomposite films. Chem Cent J 7(1):39–39

Hsiao Y-C, Chen C-N, Chen Y-T, Yang T-L (2013) Controlling branching structure formation of the salivary gland by the degree of chitosan deacetylation. Acta Biomater 9(9):8214–8223

Chien R-C, Yen M-T, Mau J-L (2016) Antimicrobial and antitumor activities of chitosan from shiitake stipes, compared to commercial chitosan from crab shells. Carbohydr Polym 138:259–264

Tachaboonyakiat W, Sukpaiboon E, Pinyakong O (2014) Development of an antibacterial chitin betainate wound dressing. Polym J 46(8):505–510

Liu Z, Ge X, Lu Y, Dong S, Zhao Y, Zeng M (2012) Effects of chitosan molecular weight and degree of deacetylation on the properties of gelatine-based films. Food Hydrocolloids 26(1):311–317

Hattori H, Ishihara M (2015) Changes in blood aggregation with differences in molecular weight and degree of deacetylation of chitosan. Biomed Mater 10(1):015014

Dashtimoghadam E, Mirzadeh H, Taromi FA, Nyström B (2013) Microfluidic self-assembly of polymeric nanoparticles with tunable compactness for controlled drug delivery. Polymer 54(18):4972–4979

Majedi FS, Hasani-Sadrabadi MM, VanDersarl JJ et al (2014) On-chip fabrication of paclitaxel-loaded chitosan nanoparticles for cancer therapeutics. Adv Funct Mater 24(4):432–441

Meng X, Tian F, Yang J, He C-N, Xing N, Li F (2010) Chitosan and alginate polyelectrolyte complex membranes and their properties for wound dressing application. J Mater Sci Mater Med 21(5):1751–1759

Karbasi S, Khorasani SN, Ebrahimi S, Khalili S, Fekrat F, Sadeghi D (2016) Preparation and characterization of poly(hydroxy butyrate)/chitosan blend scaffolds for tissue engineering applications. Adv Biomed Res 5:177

Kojima K, Okamoto Y, Miyatake K, Kitamura Y, Minami S (1998) Collagen typing of granulation tissue induced by chitin and chitosan. Carbohydr Polym 37(2):109–113

Ueno H, Mori T, Fujinaga T (2001) Topical formulations and wound healing applications of chitosan. Adv Drug Deliv Rev 52(2):105–115

Benhabiles M, Salah R, Lounici H, Drouiche N, Goosen M, Mameri N (2012) Antibacterial activity of chitin, chitosan and its oligomers prepared from shrimp shell waste. Food Hydrocolloids 29(1):48–56

Dragostin OM, Samal SK, Dash M et al (2016) New antimicrobial chitosan derivatives for wound dressing applications. Carbohydr Polym 141:28–40

Moghadas B, Dashtimoghadam E, Mirzadeh H, Seidi F, Hasani-Sadrabadi MM (2016) Novel chitosan-based nanobiohybrid membranes for wound dressing applications. RSC Adv 6(10):7701–7711

Je J-Y, Kim S-K (2006) Chitosan derivatives killed bacteria by disrupting the outer and inner membrane. J Agric Food Chem 54(18):6629–6633

Helander IM, Nurmiaho-Lassila EL, Ahvenainen R, Rhoades J, Roller S (2001) Chitosan disrupts the barrier properties of the outer membrane of Gram-negative bacteria. Int J Food Microbiol 71(2):235–244

Kim S-K (2010) Chitin, chitosan, oligosaccharides and their derivatives: biological activities and applications. CRC Press, Boca Raton

López-Mata MA, Ruiz-Cruz S, Silva-Beltrán NP, Ornelas-Paz JJ, Zamudio-Flores PB, Burruel-Ibarra SE (2013) Physicochemical, antimicrobial and antioxidant properties of chitosan films incorporated with carvacrol. Molecules 18(11):13735–13753

Fernandez-Saiz P, Lagaron J, Ocio M (2009) Optimization of the film-forming and storage conditions of chitosan as an antimicrobial agent. J Agric Food Chem 57(8):3298–3307

Li Q, Dunn E, Grandmaison E, Goosen M (1992) Applications and properties of chitosan. J Bioact Compat Polym 7(4):370–397

Kamoun EA, Chen X, Eldin MSM, Kenawy E-RS (2015) Crosslinked poly(vinyl alcohol) hydrogels for wound dressing applications: a review of remarkably blended polymers. Arab J Chem 8(1):1–14

Elsner JJ, Shefy-Peleg A, Zilberman M (2010) Novel biodegradable composite wound dressings with controlled release of antibiotics: microstructure, mechanical and physical properties. J Biomed Mater Res B Appl Biomater 93(2):425–435

Cai M, Gong J, Cao J, Chen Y, Luo X (2013) In situ chemically crosslinked chitosan membrane by adipic acid. J Appl Polym Sci 128(5):3308–3314

Muzzarelli RA (2009) Genipin-crosslinked chitosan hydrogels as biomedical and pharmaceutical aids. Carbohydr Polym 77(1):1–9

Chen P-H, Kuo T-Y, Liu F-H et al (2008) Use of dicarboxylic acids to improve and diversify the material properties of porous chitosan membranes. J Agric Food Chem 56(19):9015–9021

ASTM D882-18 (2018) Standard test method for tensile properties of thin plastic sheeting. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D0882-18, www.astm.org.

Jamalpoor Z, Mirzadeh H, Joghataei MT, Zeini D, Bagheri-Khoulenjani S, Nourani MR (2015) Fabrication of cancellous biomimetic chitosan-based nanocomposite scaffolds applying a combinational method for bone tissue engineering. J Biomed Mater Res Part A 103(5):1882–1892

Bonakdar S, Emami SH, Shokrgozar MA, Farhadi A, Ahmadi SAH, Amanzadeh A (2010) Preparation and characterization of polyvinyl alcohol hydrogels crosslinked by biodegradable polyurethane for tissue engineering of cartilage. Mater Sci Eng C 30(4):636–643

ISO B. 10993-5 (1999) Biological evaluation of medical devices. Tests for in vitro cytotoxicity

Sadeghi D, Karbasi S, Razavi S, Mohammadi S, Shokrgozar MA, Bonakdar S (2016) Electrospun poly(hydroxybutyrate)/chitosan blend fibrous scaffolds for cartilage tissue engineering. J Appl Polym Sci. https://doi.org/10.1002/app.44171

Mansouri M, Nazarpak MH, Solouk A, Akbari S, Hasani-Sadrabadi MM (2017) Magnetic responsive of paclitaxel delivery system based on SPION and palmitoyl chitosan. J Magn Magn Mater 421:316–325

Yalçınkaya S, Demetgül C, Timur M, Çolak N (2010) Electrochemical synthesis and characterization of polypyrrole/chitosan composite on platinum electrode: its electrochemical and thermal behaviors. Carbohydr Polym 79(4):908–913

Ritthidej GC, Phaechamud T, Koizumi T (2002) Moist heat treatment on physicochemical change of chitosan salt films. Int J Pharm 232(1):11–22

Ghosh A, Ali MA (2012) Studies on physicochemical characteristics of chitosan derivatives with dicarboxylic acids. J Mater Sci 47(3):1196–1204

Tsao CT, Chang CH, Li YD et al (2011) Development of chitosan/dicarboxylic acid hydrogels as wound dressing materials. J Bioact Compat Polym 26(5):519–536

Szymańska E, Winnicka K (2015) Stability of chitosan—a challenge for pharmaceutical and biomedical applications. Mar Drugs 13(4):1819–1846

Güneş S, Tıhmınlıoğlu F (2017) Hypericum perforatum incorporated chitosan films as potential bioactive wound dressing material. Int J Biol Macromol 102:933–943

Tığlı RS, Karakeçili A, Gümüşderelioğlu M (2007) In vitro characterization of chitosan scaffolds: influence of composition and deacetylation degree. J Mater Sci Mater Med 18(9):1665–1674

Ma J, Wang H, He B, Chen J (2001) A preliminary in vitro study on the fabrication and tissue engineering applications of a novel chitosan bilayer material as a scaffold of human neofetal dermal fibroblasts. Biomaterials 22(4):331–336

Tyliszczak B, Drabczyk A, Kudłacik-Kramarczyk S, Bialik-Wąs K, Sobczak-Kupiec A (2017) In vitro cytotoxicity of hydrogels based on chitosan and modified with gold nanoparticles. J Polym Res 24(10):153

Tyliszczak B, Drabczyk A, Kudłacik-Kramarczyk S, Bialik-Wąs K, Kijkowska R, Sobczak-Kupiec A (2017) Preparation and cytotoxicity of chitosan-based hydrogels modified with silver nanoparticles. Colloids Surf B 160:325–330

Acknowledgements

The authors would like to express their sincere gratitude to Iran National Science Foundation (INSF) for supporting this research and Ms. Sama Ghalei for her openhanded support and assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moghadas, B., Solouk, A. & Sadeghi, D. Development of chitosan membrane using non-toxic crosslinkers for potential wound dressing applications. Polym. Bull. 78, 4919–4929 (2021). https://doi.org/10.1007/s00289-020-03352-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03352-8