Abstract

Preparation of associating multiblock copolymer electrolytes mediated by radical addition–fragmentation chain transfer (RAFT) technique has been evaluated and reported in this investigation. The synthesization of copolymers was performed at room temperature in 1,4-dioxane using redox catalyst: tert-butyl hydroperoxide and ascorbic acid as initiator. The copolymers are composed of a large hydrophilic block formed with acrylic acid and ethyl acrylate and a short hydrophobic segment of lauryl acrylate. A symmetrical RAFT chain transfer agent was used in order to incorporate a greater number of blocks by chain extension of macroagent, triblock and pentablock copolymers. Once obtained, the resultant polymers were thoroughly characterized by nuclear magnetic resonance, size exclusion chromatography, differential scanning calorimetry and rheometry with the aim to determine the structure–property relationship. The influence of hydrophobic length was demonstrated and played a significant role in the rheological properties of copolymers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the last five decades, the synthesis of associating water-soluble copolymer electrolytes has experienced an extraordinary upgrowth. This is particularly due to the interests for these polymers and their applications in specific areas such as: cosmetics, oil recovery, water treatments, coatings, paints and Li-ion battery [1,2,3,4,5,6]. These polymers are constituted with a large hydrophilic backbone and a short hydrophobic block (usually < 5%, mol) which can induce a physical cross-linking in aqueous solution and the resulting network displays significant rheological features [7,8,9]. The reversible physical cross-linking depends on the number and length of hydrophobic block inserted to the backbone polymer chains, and can produce two types of interactions: intramolecular (same chain) or intermolecular (different chains) [10, 11]. It is worth mentioning that the type of interactions in aqueous media is strongly attached to the critical aggregation concentration of the media and the concentration of polymer which lead to defined regimen: dilute (C < C*) and semi-dilute (C* < C) giving rise to the intra- or intermolecular interactions, respectively [12, 13].

In general, water-soluble-associating polymers are classified according to different parameters such as: nature of both hydrophobic and hydrophilic block, the topology of resulting polymer (i.e., the position of hydrophobic block in the backbone of polymer), origin of polymer and the preparation methods. With regard to the position of the hydrophobic groups, these are classified into three types: telechelic [14], multi-stickers [15] and combined polymers [16]. Considering the nature of each block, these polymers could be divided in three classes: thermo-responsive [17, 18], hydrophobically modified [19] and electrolytes [20]. Based on the ion content, associating polymer electrolytes are mainly governed by electronic static interactions without omitting their thermodynamic properties [21]. Associating polymer electrolytes are mainly characterized by their weak solubility at low pH (acidic media) and start to solubilize by increasing their ionization degrees [22]. Associating polymer electrolytes are obtained by both free radical polymerization (FRP) [23] and reversible deactivation radical polymerization (RDRP) techniques [24,25,26,27,28,29] and gained significant interest due to their potential applications in electrochemical systems [30], drug delivery and rheological modifiers or core–shell nanostructures for paints and coatings areas [31].

Recently, Yu et al. [32] reported the synthesis of a terpolymer made of acrylamide, sodium acrylate and dodecyl polyoxyethylene acrylate, and the resulting associative polymer exhibited interesting rheological properties and can be used in enhanced oil recovery as an antisalt oil displacement agent. Perrier et al. reported the synthesis of well-defined anionic multiblock copolymer of N-hydroxyethyl acrylamide (HEAm), 4-acryloylmorpholine (NAM) and 2-acrylamido-2-methylpropanesulfonic acid sodium salt (AMPS) via RAFT polymerization under thermal initiation with no mention of their rheological properties [33]. On the other side, they also prepared multiblock copolymer using acrylamide and acrylate monomers under redox initiation at room temperature (25 °C) but the authors did not provide any information in regard to the rheological properties of resulting polymers [34, 35]. Recently, we reported the synthesis of associating multiblock copolymer made of methacrylic acid, ethyl acrylate and octadecyl methacrylate under RAFT conditions at 70 °C, and rheological properties are studied after dissolution of polymer in basic media (pH ≈ 9.0) [36].

In spite of aforementioned advances, the preparation of associating multiblock copolymer electrolytes under redox RAFT polymerization condition has not been reported. In this manuscript, we describe the synthesis of associating multiblock copolymer electrolytes performed under redox RAFT polymerization at room temperature (25 °C) in organic solution media. The associating multiblock copolymers electrolytes with defined architectures made of long hydrophilic block of acrylic acid and ethyl acrylate (AA-co-EA) and short hydrophobic block of lauryl acrylate (LA) were prepared. The resultant copolymers withdrawn from each polymerization step were characterized by different techniques as SEC, NMR, UV, DSC and rheology in the aim to determine their structures and rheological properties.

Experimental section

Materials

Ethyl acrylate (EA, Sigma-Aldrich, 99%) was purified under vacuum pump to remove the inhibitor MEHQ and stored at 0 °C before using. Acrylic acid (AA, Sigma-Aldrich, Anhydrous, 99%), lauryl acrylate (LA, Sigma-Aldrich, 90%), tert-butyl hydroperoxide solution (TBHP, Luperox®, 70% in H2O), L-ascorbic acid (AcAs, Sigma-Aldrich, 99%), 1,4-dioxane (Sigma-Aldrich, anhydrous, 99.8%), trimethylsilyldiazomethane solution (TMSCHN2, Sigma-Aldrich, 2.0 M in hexane), sodium (Na, Sigma-Aldrich, 99.9%), benzophenone (Sigma-Aldrich, 99%), deuterated dimethyl sulfoxide (DMSO-d6, Sigma-Aldrich, 99.9%), ethyl ether (Jalmek, anhydrous, 99%), carbon disulfide (CS2, Sigma-Aldrich, 99.9%), hydrochloric acid solution (HCl, Sigma-Aldrich, 37%), chloroform (Riedel–de Haen, 99%), hexane (Macron Fine Chemical, 95%), tetrabutylammonium hydrogensulfate (Sigma-Aldrich, 97%), acetone (JT Baker, 99.6%) and sodium hydroxide (NaOH, Sigma-Aldrich, 98%) were used as received. Tetrahydrofuran (THF, Jalmek, 99%) was purified by distillation using a mixture of sodium benzophenone. RAFT chain transfer agent and S,S’-Bis (α,α′-dimethyl-α″-acetic acid)-trithiocarbonate (DMAT) were synthesized as reported elsewhere [37].

Synthesis of water-soluble associating polyelectrolytes

Synthesis of polyelectrolyte P(EA-co-AA) (RF)

In the first step, the macroagent (RF) was synthesized through a copolymerization of ethyl acrylate (EA) and acrylic acid (AA). In a typical experiment: EA (58.13 g, 0.58 mol), AA (41.85 g, 0.58 mol) and DMAT (1.128 g, 4 × 10−3 mol) of TBHP (0.0523 g, 5.8 × 10−3 mol) and 1,4-dioxane (405.15 g, 4.6 mol) were introduced to a vessel (three-neck glass jacketed reactor of 500 mL) equipped with mechanical agitation, condenser, septa, and adapted to a thermostated bath. The condenser was used to avoid the evaporation of monomer. The system was deoxygenated by bubbling nitrogen (N2) during 30 min. A deoxygenated solution of AsAc (0.05 g, 2.8 × 10−4 mol) dissolved in DMF was added (via a syringe) to the mixture for starting the polymerization. The reaction was carried out at a temperature of 25 °C during 24 h.

At the end of the predetermined time, the reactor was opened to the atmosphere and polymer was recovered by precipitation in ethyl ether (three times). The material was then dried under vacuum at 50 °C for 24 h, characterized using different techniques such as: SEC, 1H NMR, rheology and DSC. Conversion was determined by gravimetry and results are given in Table 1.

Synthesis of the Triblock P ((EA-co-AA)-b-LA-b-(EA-co-AA)) (RF2)

For the preparation of triblock copolymer electrolyte (second step-RF2), the chain extension was performed using a similar procedure than macroagent (RF). A solution of RF (30 g, 1.233 × 10−3 mol), LA (6.16 g of, 0.0256 mol), TBHP (3.17 × 10−4 g, 2.46 × 10−7 mol) was dissolved in 1,4-dioxane (144.6 g, 1.64 mol) and introduced to a three-neck glass jacketed reactor (250 mL) equipped with mechanical agitation, condenser, septa, and adapted to a thermostated bath. The mixture was deoxygenated using bubbling N2 during 30 min. A deoxygenated solution of AsAc (2.17 × 10−4 g, 1232 × 10−7 mol) diluted in DMF was withdrawn to a precursor solution and added to the mixture for starting the polymerization process. The reaction was carried out at a temperature of 25 °C during 24 h. Final polymer was recovered by precipitation in ethyl ether (three times) dried under vacuum at 50 °C for 24 h and characterized. Conversion was determined by gravimetry. Results from characterization are given in Table 1.

Synthesis of the Pentablock P((EA-co-AA)-b-LA-b-(EA-co-AA)-b-LA-b-(EA-co-AA)) (RF3)

In the third step, the chain extension of triblock copolymer (RF2) was performed by the copolymerization of EA and AA. RF2 (19 g, 7.26 × 10−4 mol), (EA 11.05 g, 0.11 mol), AA (7.72 g, 0.11 mol) and TBHP (5.71 × 10−5 g, 6.33 × 10−7 mol from a precursor solution) were dissolved in 1,4-dioxane (152 g, 1.72 mol) and introduced to a flask (three-neck glass jacketed reactor 250 mL) adapted to a thermostated bath. The mixture was deoxygenated by bubbling N2 during 30 min and kept under mechanical agitation. A deoxygenated solution of AsAc (5.58 × 10−5 g, 3.166 × 10−7 mol from a precursor solution) diluted in DMF was added to the mixture (via syringe) for starting the polymerization. The reaction was carried out at a temperature of 25 °C during 24 h.

After a predetermined time (24 h), the reactor was opened to atmosphere and the resultant polymer was recovered by precipitation in ethyl ether (three times) and dried under vacuum at 50 °C for 24 h. The conversion was then calculated by gravimetry, and the yellowish polymer was characterized by different techniques (aforementioned). Data from analyses are given in Table 1.

Synthesis of the Heptablock P((EA-co-AA)-b-LA-b-(EA-co-AA)-b-LA-b-(EA-co-AA)-b-LA-b-(EA-co-AA)) (RF4)

The heptablock copolymer (RF4) was obtained by chain extension of pentablock copolymer (RF3) by polymerization of LA (fourth step). RF3 (10 g, 1.66 × 10−4 mol), LA (0.833 g, 3.465 × 10−3 mol) and TBHP (3.0 × 10−5 g, 3.332 × 10−7 mol from a precursor solution) were dissolved in 1,4-dioxane (43.33 g, 0.5 mol) and introduced to a flask (three-neck glass jacketed reactor 100 mL) adapted to a thermostated bath. The mixture was kept under mechanical agitation and deoxygenated by bubbling N2 during 30 min. Forthwith, a deoxygenated solution of AsAc (2934 × 10−5 g, 1.66 × 10−7 mol from a precursor) diluted in DMF was added to the mixture for starting the polymerization. The reaction was carried out under agitation at 25 °C for 24 h. The reaction was carried out at a temperature of 25 °C during 24 h.

The resultant polymer was recovered by precipitation in ethyl ether (three times) and dried under vacuum at 50 °C for 24 h. The conversion of yellowish polymer was calculated by gravimetry. Final polymer was characterized by different techniques, and data are given in Table 1.

Characterization

1H NMR spectra of copolymers were recorded in a Bruker advance 500 MHz spectrometer in DMSO-d6 at room temperature, and chemical shift values (δ) are reported in ppm. The integral values of the δ were used to determine the composition molar of associating multiblock copolymer electrolytes. Ultraviolet (UV–visible) spectra were recorded using a Shimadzu 2401 UV–visible spectrophotometer, and samples are dissolved in DMSO. Size exclusion chromatography (SEC) was carried out on an Agilent technologies HPLC system equipped with ultraviolet and refractive index detectors. Before SEC analysis, samples were methylated as reported elsewhere [38] and latter was dissolved in dried THF and filtered in a 20 µm pore size. The system used consisted of a column series (103, 105 and 106 Å) and THF as the eluent at a flow rate of 1 mL min−1 at 40 °C. The molecular weights (Mn and Mw) and molecular weight distribution (Đ = Mw/Mn) were determined using polystyrene standards (from 162–3,900,000 g mol−1) for column calibration without Mark–Houwink corrections. Thermal analyses were carried out on a differential scanning calorimetry (DSC) instrument (TA instrument model Discovery Series) using N2 at a flow of 50 mL/min, a scanning rate of 10 °C/min and a temperature range from − 80 to 250 °C.

Preparation of samples for characterization

SEC

The samples were prepared by dissolution of methylated polymer in dried THF with a concentration of 1 mg × mL. The sample was passed through a 0.2 μm filter before analysis. The methylation process was performed as reported [38] using TMSCHN2 as methylating agent.

Rheology

Sample from each polymer reaction (RF, RF2, RF3 and RF4) was dissolved in distilled water for obtaining a solution of 20 wt%. The latter was diluted in order to prepare solutions with different concentrations from 0.1 to 20 wt%. The polymer RF displayed solubility in water, notwithstanding the copolymers (RF2, RF3 and RF4) were not soluble. For this reason, the solution of these samples was neutralized dropping a solution of ammonium hydroxide (30%). Solutions of all polymers exhibited a complete solubility at pH ca. to 9.0. The solutions were kept under agitation for 24 h.

Results and discussion

The RAFT polymerization is characterized by high livingness of thiocarbonyl end chain that is primordial for synthesizing well-defined architectures and good control of the molecular weight and molecular weight distribution of prepared polymers. Despite the advantages, McCormick et al. investigated and demonstrated the effect of thermal condition on RAFT end chain fidelity which could be involved in the chain extension process for obtaining complex copolymers [39]. For this reason, in the present manuscript, we report the preparation of associating multiblock copolymers using redox RAFT technique (Scheme 1) at room temperature. The polymerization reactions were carried out in 1,4-dioxane using redox initiation. Low concentration of redox initiators has been used with the aim to achieve a high livingness end chain and maintain the molecular weight distribution values below 1.5. The symmetric chain transfer agent S,S′-bis (α,α′-dimethyl-α″-acetic acid)-trithiocarbonate (DMAT) was selected in order to acquire as many block as possible with the minimum number of steps.

The polymerization reactions of both hydrophilic and hydrophobic blocks lead to high monomer consumption (> 80%) after 24 h. Nevertheless, it is worth mentioning that the synthesis of hydrophilic block using unpurified EA exhibits a low conversion (< 40%) and a poor control on the polymerization process under similar conditions. The polymerization reaction conditions and results are given in Table 1.

THF-SEC was used to measure the molecular weights and molecular weight distributions of resultant polymers after methylation using TMSCHN2. SEC trace of macroagent (RF) (PAA-co-PEA) displays a monomodal chromatogram showing a narrow dispersity (Đ = 1.2), whereas the copolymer RF2 exhibits a shoulder at low molecular weight which caused an increase in the molecular weight distribution. The copolymer RF3 and RF4 do not display a shoulder as clear as RF2, notwithstanding their molecular weight distributions are not as symmetrical as RF. Further, data from the molecular weights of the copolymers RF3 and RF4 mismatch with the targeted, and this discrepancy can be attributed to the following factors: (a) SEC analysis conditions using Mark–Houwink–Sakurada parameters α and k of polystyrene as calibration standard curve, (b) degradation of thiocarbonylthio group during the methylation process. (Figure 1).

In order to ascertain the effect of methylation on the molecular weight values, both methylated and original polymer RF2 were dissolved in DMSO and characterized by UV–visible. Result shows that the thiocarbonylthio group disappeared to methylated polymer, whereas a large signal was observed at 310 cm−1 in the UV–vis spectra of original polymer (Fig. 2) and confirms our recent investigation on the metamorphosis of thiocarbonylthio toward TMSCHN2 [40]. On the other hand, the SEC traces shown in Fig. 1 show a shift toward higher molecular weight after each chain extension reaction to form tri-, penta- and heptablock copolymers despite the molecular weights obtained by THF-SEC are widely lower than targeted. Notwithstanding, the increase in the molecular weight of polymers could confirm the presence of thiocarbonylthio end group and the insertion of new block to the backbone of polymer.

Spectroscopic analysis (NMR) was performed to determine the structure and molar composition of acquired associating copolymer electrolytes. 1H NMR analysis of associating copolymers electrolytes was carried out at room temperature (25 °C) in DMSO-d6 without further modification, and spectra are shown in Fig. 3. In the 1H NMR of RF corresponding to the macroagent PAA-co-PEA, the chemical shift (δ) of hydroxyl proton of acrylic acid is observed at 12.3 ppm. Two other signals related to residual solvent DMF and 1,4-dioxane were detected at 7.9 and 3.8 ppm, respectively. The methylene CH2 linked to the ester group of ethyl acrylate is observed at δ = 4.0 ppm. The methylene of acrylic acid and ethyl acrylate are overlapped and detected at 2.2 ppm ca. to the deuterated solvent DMSO-d6. The methylene of the backbone polymer is observed between 1.8 and 1.2 ppm, respectively. 1H NMR spectra of copolymers (RF2, RF3 and RF4) displayed similar δ than RF which confirm the presence of AA and EA. Moreover, a novel δ is observed at 0.8 ppm and ascribed to the methyl group (CH3) of lauryl acrylate. The presence of this signal plays an essential role and confirms the insertion of hydrophobic block to the backbone of associating copolymer electrolytes.

The integral values of selected chemical shifts allowed to determine the molar composition of each copolymer electrolytes. For calculating, the integral value of three specific chemical shifts is considered: the proton of acid group at 12.3 ppm, the methylene (two protons of CH2) linked to acrylate group (I/2) of both EA and LA and methyl group (three protons of CH3) of LA (I/3). As given in Table 1, the molar composition of EA/AA in the macroagent (RF) is 44 and 56%, respectively. This result presumes a major conversion of EA during the redox RAFT polymerization of both monomers. In the case of multibock copolymers (RF2, RF3 and RF4) featured by the incorporation PLA block, the molar composition percentage obtained for each polymer describes the formation of desired multiblock copolymers (Table 1). Based on the composition values obtained through NMR spectra, we conclude these values matched with the expected in the theoretical molecular weights.

Differential scanning calorimetry

To confirm the structure of resultant materials, DSC analysis was attentively performed. Figure 4 exhibits the DSC curves of all copolymers electrolytes. The DSC curve of macroagent (RF) shows only one Tg ca. to 26 °C (blue line), whereas the Tgs of homopolymers PAA and PEA is 105 and − 24 °C, respectively [41]. Then, the presence of one Tg presumes the formation of a random copolymer PAA-co-PEA. The thermogram of triblock copolymer (RF2) (red line) exhibits two transitions temperature at − 18 and 52 °C which confirm the incorporation of a new block to the copolymer structure. Despite the pentablock copolymer (RF3) holds in fact two PLA blocks, the thermogram of this copolymer (RF3) presents only one Tg at 20 °C. The presence of one transition temperature in RF3 can be attributed to the low molar composition (ca. to 2.7%) and/or chain length of PLA (shorter than RF2) which could inhibit the detection of any transition for the PLA segment in this polymer. Finally, the thermogram of heptablock copolymer (RF4) exhibits two transitions temperature at − 9 and 25 °C and confirms once again the insertion of a novel PLA block to the backbone of polymer. It is worth mentioning that the Tg of a homopolymer PLA is closed to − 3 °C and plays an important role in the transition temperature of synthesized associating copolymers [27]. The low Tg of PLA (between − 18 and − 9 °C) incorporated to the backbone may have also affected the hydrodynamic volume of polymers and THF-SEC analysis which was carried out at 40 °C.

Rheological properties of associating water-soluble polymers in aqueous solution

The rheological properties of synthesized copolymers were performed in aqueous solution at different concentration range from 0.1 to 20 wt%, and the findings allowed to determine the effect of hydrophobic block on the viscosity and the regime concentration of these copolymers. These analyses were carried out at room temperature (25 °C) using a thermostated recirculation bath. Depending on the viscosity of copolymers, two geometric instruments were used: cone plate (50 mm 2°) and double gap. The polymer RF is relatively soluble in deionized water and its pH is ca. to 3.5, while the copolymers RF2, RF3 and RF4 are entirely insoluble in deionized water. To solubilize the copolymers, hydroxide ammonium solution 2.0 M was added dropwise up until a total dissolution of polymer. The pH of solution was continuously monitored as well as the physical aspect of solution moves from translucent to a transparent solution by addition of basic solution and the pH shows a value near to 9.0. Despite the high solubility of RF in deionized water, his pH was also adjusted at 9.0 in the purpose to perform the rheological analyses under similar conditions than copolymers.

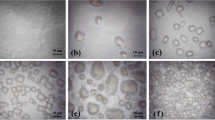

Figure 5 displays the viscosity versus shear rate of copolymer electrolytes in aqueous solution at different concentration using a shear rate range from 0.001 to 1000 s−1. For the polymer RF, the viscosity increases according to the concentration of solution growth up from 1 to 20 wt%, and data show a Newtonian motion whatever the measured concentration. This weak augmentation observed in the viscosity of MA (from 0.0015 to 0.033 Pa S) is generally assigned to the increase in the concentration which could induce to the steric hindrance of polymer in solution. In the case of the triblock copolymer electrolyte (RF2) featured by the incorporation of a hydrophobic block (8 units) of LA (Mn = 1900 g mol−1) in the polymeric chain, the result from the viscosity versus shear rate of this copolymer exhibits a substantial increase in the viscosity compared to his former polymer RF. The viscosity of RF2 shows a Newtonian motion at low concentration (1–8 wt%). By increasing the concentration from 10 to 20 wt%, the viscosity of RF2 displays two different behaviors: a Newtonian motion at low shear rate (0.1–60 s−1) and a shear-thinning behavior characterized by a shrinking on the viscosity when the shear rate increases, and this behavior is more pronounced at high concentration of polymer. Taking into account the viscosity values of both RF and RF2, we can observe that at a similar concentration (20 wt%), the viscosity of RF2 (1.5 Pa S) increases two magnitude orders in comparison with the viscosity of RF (0.033 Pa S) in spite of the insertion only on hydrophobic block PLA to the backbone polymer.

The pentablock copolymer, recognized in Fig. 4c as RF3, is made of three large hydrophilic block (PAA-co-PEA) and two short hydrophobic block (PLA). We tried to dissolve the polymer (RF3) at different concentration. However, 4 wt% represents the highest concentration where the resulting polymer becomes soluble in an aqueous solution. The viscosity of this copolymer was measured at different concentrations < to 4 wt % and result show a Newtonian motion at low shear rate then a pseudoplastic behavior at high shear rate. The sample RF3 dissolved at 4 wt% was also submitted to rheological analysis and result displays a rheo-thickener behavior at low shear rate (0.001–0.4 s−1) characterized by an increase in the viscosity of polymer. This behavior was previously reported [8] and is attributed to the breakdown of intramolecular interactions at low shear rate that give rise to the formation of additional intermolecular interactions which leads to the increase in the viscosity at low shear rate range. This unexpected increase observed on the viscosity of RF3 at a concentration of 4 wt% could also be ascribed to number and length of hydrophobic chain inserted to the backbone of polymer. Further, we observe that the viscosity of RF3 at 4 wt% (η = 10 Pa S) increase three magnitude order versus the viscosity of the former polymer RF2 (η = 0.013 Pa S) at the same concentration.

Regarding heptablock copolymer electrolyte (RF4) distinguished by incorporation of novel hydrophobic block to the polymeric chains of RF3, the solubility of solution decreases at 2 wt% and diluted samples were submitted to rheological analyses at a concentration range from 0.01 to 2 wt%. The viscosity data acquired for sample ranged from 0.01 to 1 wt% showed a Newtonian behavior at low shear rate with a significant increase in the viscosity values; further, the viscosity of polymer displays a pseudoplastic motion at higher shear rate. Based on the shear rate range used in the rheological analysis of previous polymer RF3, in the case of RF4, we do not observe a Newtonian nor rheo-thickener behavior for the polymer sample measured at a concentration of 2 wt%. Notwithstanding, the viscosity of this polymer displays a pseudoplastic behavior for this stated shear rate range with an increase in the viscosity of this polymer compared to the former polymer RF3. Considering the viscosity obtained both copolymer electrolytes RF3 and RF4 at same concentration (2 wt%), we observe that the viscosity value of RF4 (η = 100 Pa S) increases three magnitude order in comparison with the RF3 (η = 0.2 Pa s) and this higher viscosity value could be attributed to the number of hydrophobic block (three) incorporated to the backbone.

Concentration regimes

For a better understanding of the rheological properties of aforementioned associating multiblock copolymer electrolytes, a series of rheological studies were performed considering a definite concentration range for each water-soluble associating multiblock copolymer electrolytes. The most important finding acquired in this study is the ability to determine the concentration regimes of each polymer which correspond to the entanglement level of studied polymer at different concentration. This information plays an important role in the rheological behavior of polymer since the concentration regime describes the correlation between polymeric chains and the hydrophobic interactions into the system.

Considering the concentration value of polymer associating namely (C), this latter fundamentally describes two potential interactions: (1) the presence of intramolecular interactions when concentration of polymer is lower than the critical aggregation concentration (C*) which leads to unentangle between polymeric chains. (2) formation of the intermolecular interactions when the concentration of polymer is higher than C* and the intermolecular interactions generally come from the interactions between hydrophobic segment of different macromolecule chains and leads to entanglement therefore an increase in the viscosity of polymer.

Before any discussions about the results from the concentration regimes of associating multiblock copolymer electrolytes obtained in this investigation, it seems important to remind some features related to original (without hydrophobic segment) polymer and their rheological properties defined at different concentration regimes:

- (1)

Dilute regime C < C*, where C* is the overlap concentration where the zero shear viscosity is to the order of solvent.

- (2)

Semi-dilute unentangled regime C* < C < Ce, in this case Ce represents the concentration where the macromolecules are close one to the other without giving rise to a physical association. At this concentration regime, the polymer generally displays a greater viscosity than its former. It is important to note that Ce/C* ratio is generally is in the order of 5–10 [42].

- (3)

Semi-dilute entangled regime Ce < C < C**. At this concentration regime, the rheological properties of polymers are described by reptation model and depend on the concentration of polymer with an exponential slope near 4.

- (4)

Concentrated regime is defined as the point where the polymer concentration is above the C**. At this concentration regime, the reptation model is preserved but rheological property of polymer is different due to the polymer concentration and interactions in the solution.

Figure 6 shows viscosities at zero shear rate (η0) versus the polymer concentration (C) from associating multiblock copolymers electrolytes obtained in this work. The copolymer electrolyte (RF) obtained in the step 1 presents C* at a concentration 0.4 wt% then a semi-dilute regime untangled regime at a concentration below 4 wt%. In the case of dilute regime, the macromolecules dissolved in the solution are isolated (due to the polymer concentration) and the viscosity basically is in the order of solvent. When the polymer concentration reached the semi-dilute untangled regime, the macromolecules are closer without entanglement between them and the viscosity of solution tends to increase. For the polymer RF, it was not possible to find the semi-dilute entangled regime (Ce) characterized by the physical cross-linking which could be determined by the exponential slope 4. The absence of both semi-dilute entangle and concentrated regime in the polymer RF means that these concentration regimes could be found at a higher polymer concentration than performed in this study (20 wt%).

The copolymer electrolytes (RF2), characterized by the insertion of one hydrophobic block (PLA) obtained in the step 2, display a semi-dilute unentangled regime (Cη) at a polymer concentration ca. to 0.2 wt%. The method of calculating of Cη is similar to C* and represents the point where to start the semi-dilute unentangled regime. It worth mentioning that C* is used for original polymer associating (without hydrophobic segment), whereas Cη refers to associating polymer modified with at least one hydrophobic segment inserted to the backbone. Additional to the semi-dilute unentangled regime, it was possible to obtain the polymer concentration value (CT = 4 wt%) corresponding to the semi-dilute entangled regime using the exponential slope ca. 4. It worth mentioning that calculating CT and Ce values is similar than reported for C* and Cη, and in both cases, their values represent the initiating point of semi-dilute entangled regime. For this polymer (RF2), it was not possible to determine the concentrated regime under the analyses conditions (20 wt%).

Regarding associating copolymer electrolytes RF3 and RF4 obtained from step 3 and 4, the polymer concentration corresponding to the semi-dilute unentangled regimen Cη is detected at 0.1 wt%; it means that the dilute regime is below this concentration. We also found the semi-dilute entangled regime for both polymers at Cη = 0.65 and 0.25, respectively, and this regime is featured by the physical associating between macromolecules and the latter tends to form reversible cross-linking network which increases the viscosity of polymer. In addition to the abovementioned regimes, the polymer RF3 exhibits a concentrated regime at a polymer concentration greater than 2 wt%, whereas the concentrated regime of polymer RF4 is observed at a polymer concentration greater than 1 wt%.

Conclusions

We describe the synthesis of different polymer electrolytes composed of AA, EA and LA under RAFT polymerization using redox condition (TBHP/AsAc) at room temperature (25 °C) in 1,4-dioxane. Yellowish color of resultant polymer was maintained which confirm the chain end fidelity of polymers, and multiblock copolymer electrolytes (from macroagent-RF to heptablock-RF4) were obtained with a high monomer consumption whatever the chain extension polymerization steps. The molecular weight distributions obtained by size exclusion chromatography in THF-SEC were kept < to 1.5, whereas the molecular weights of polymers exhibit a discrepancy between the theoretical and experimental values except the macroagent (RF). This inconsistency could be attributed to different parameters such as: the standard column curve of SEC, the Mark–Houwink–Sakurada constants and the methylation process. Based on the NMR spectra and the composition of polymer, we can affirm the incorporation of hydrophobic or hydrophilic block in each chain extension. Final copolymer electrolytes, mainly the penta- (RF3) and heptablock (RF4) copolymers, demonstrated an excellent rheological property with an important increase in the viscosity of these polymers from the insertion of novel hydrophobic block to the backbone which give rise to the intermolecular interactions. Also, the regime concentrations of polymer at dilute aqueous solution were determined and confirmed the formation of cross-linking network through the hydrophobic association between PLA blocks. Based on the rheological properties of acquired multiblock copolymer electrolytes in the work, we suppose that these copolymers (principally RF3 and RF4) could be employed as rheological modifiers in the enhanced oil recovery process.

References

Llamas S, Guzmán E, Ortega F, Baghdadli N, Cazeneuve C, Rubio RG, Luengo GS (2015) Adsorption of polyelectrolytes and polyelectrolytes-surfactant mixtures at surfaces: a physico-chemical approach to a cosmetic challenge. Adv Colloid Interface Sci 222:461–487

Sabhapondit A, Borthakur A, Haque I (2003) Water soluble acrylamidomethyl propane sulfonate (AMPS) copolymer as an enhanced oil recovery chemical. Energy Fuels 17:683–688

Ghimici L (2016) Cationic polyelectrolyte induced separation of some inorganic contaminants and their mixture (zirconium silicate, kaolin, K-feldspar, zinc oxide) as well as of the paraffin oil from water. J Environ Manag 169:1–7

Saindane P, Jagtap RN (2015) RAFT copolymerization of amphiphilic poly (ethyl acrylate-b-acrylic acid) as wetting and dispersing agents for water borne coating. Prog Org Coat 79:106–114

Rolland J, Poggi E, Vlad A, Gohy J-F (2015) Single-ion diblock copolymers for solid-state polymer electrolytes. Polymer 68:344–352

Phan TNT, Ferrand A, Ho HT, Liénafa L, Rollet M, Maria S, Boucher R, Gigmes D (2016) Vinyl monomers bearing a sulfonyl(trifluoromethane sulfonyl) imide group: synthesis and polymerization using nitroxide-mediated polymerization. Polym Chem 7:6901–6910

Volpert E, Selb J, Candau F (1996) Influence of the hydrophobe structure on composition, microstructure, and rheology in associating polyacrylamides prepared by micellar copolymerization. Macromolecules 29(5):1452–1463

Jiménez-Regalado EJ, Selb J, Cadau F (1999) Viscoelastic behavior of semidilute solutions of multisticker polymer chains. Macromolecules 32:8580–8588

Jiménez-Regalado EJ, Cadenas-Pliego G, Pérez-Álvarez M, Hernández-Valdez Y (2004) Characterization and rheological properties of dilute-solutions of three different families of water-soluble copolymers prepared by solution polymerization. Macromol Res 12(5):451–458

Winnik MA, Yekta A (1997) Associative polymers in aqueous solution. Curr Opin Colloid Interface Sci 2(4):424–436

González-Coronel VJ, Jiménez-Regalado E (2009) Synthesis, characterization and rheological properties of three different microstructures of water-soluble polymers prepared by solution polymerization. J Polym Bull 62(6):727–736

Barrat JL, Joanny JF (1996) Theory of polyelectroyte solutions. Wiley, New York

Schanze KS, Shelton AH (2009) Functional polyelectrolytes. Langmuir 25(24):13698–13702

Alami E, Almgren M, Brown W, François J (1996) Aggregation of Hydrophobically end-capped poly(ethylene oxide) in aqueous solutions. Fluorescence and light-scattering studies. Macromolecules 29:2229–2243

Maechling-Strasser C, Clouet F, François J (1992) Hydrophobically end-capped polyethylene-oxide urethanes: 2. Modelling their association in water. Polymer 33:1021–1025

Lara-Ceniceros AC, Rivera-Vallejo C, Jiménez-Regalado E (2007) Synthesis, characterization and rheological properties of three different associative polymers obtained by micellar polymerization. Polym Bull 58:425–433

Zhu Y, Lowe AB, Roth PJ (2014) Postpolymerization synthesis of (bis)amide (co)polymers: thermoresponsive behavior and self-association. Polymer 55:4425–4431

Díaz-Silvestre SE, St Thomas C, Maldonado-Textle H, Rivera-Vallejo C, Díaz de León-Gómez RE, Jiménez-Regalado EJ (2018) Effect of N-isopropylacrylamide thermoresponsive blocks on the rheological properties of water-soluble thermoassociative copolymers synthesized via RAFT polymerization. Colloid Polym Sci 296:1699–1710

Chen H-X, Tang H-M, Wu X-Y, Liu Y-G, Bai J-H, Zhao F (2016) Synthesis, characterization, and property evaluation of a hydrophobically modified polyacrylamide as enhanced oil recovery chemical. J Disper Sci Technol 37:486–495

Kostansek E (2005) Associative polymer/latex dispersion phase diagrams II: HASE thickeners. J Coat Technol Res 2:417–422

Eisenberg A, Kim J-S (1998) Introduction to ionomers. Wiley, New York

Budd PM (1989) Comprehensive polymer science and supplements, Chap 11. Polyelectrolytes 1:215–230

Alb AM, Paril A, Çatalgil-Giz H, Giz A, Reed WF (2007) Evolution of composition, molar mass, and conductivity during the free radical copolymerization of polyelectrolytes. J Phys Chem B 111:8560–8566

Jenkins AD, Jones RG, Moad G (2010) Terminology for reversible-deactivation radical polymerization previously called “controlled” radical or “living” radical polymerization (IUPAC Recommendations 2010). Pure Appl Chem 82(2):483–491

Matyjaszewski K (2017) Kinetics of atom transfer radical polymerization. Eur Polym J 89:482–523

Perrier S (2017) 50th anniversary perspective: RAFT polymerization—a user guide. Macromolecules 50(19):7433–7447

Moad G, Rizzardo E, Thang SH (2012) Living radical polymerization by the RAFT process—a third update. Aust J Chem 65:985–1076

Chiefari J, Chong YK, Ercole F, Krstina J, Jeffery J, Le TPT, Mayadunne RTA, Meijs GF, Moad CL, Moad G, Rizzardo E, Thang SH (1998) Living free-radical polymerization by reversible addition-fragmentation chain transfer: the RAFT process. Macromolecules 31:5559–5562

Pearson S, St Thomas C, Guerrero Santos R, D’Agosto F (2017) Opportunities for dual RDRP agents in synthesizing novel polymeric materials. Polym Chem 8:4916–4946

Guzmán G, Nava D, Vazquez-Arenas J, Cardoso J, Alvarez-Ramirez J (2018) Polymer electrolytes through functionalization of poly (poly (ethylene glycol) methacrylate) with zwitterionic pendant groups: the role of ion clusters upon conductivity. Solid State Ionic 320:45–54

Chaduc I, Crepet A, Boyron O, Charleux B, D’Agosto F, Lansalot M (2013) Effect of the pH on the RAFT polymerization of acrylic acid in water. Application to the synthesis of poly(acrylic acid)-stabilized polystyrene particles by RAFT emulsion polymerization. Macromolecules 46:6013–6023

Yu Q, Wu X, Li Y, Gao T, Liu S, Hou C, Zheng Z (2018) Synthesis, characterization, and aqueous properties of an amphiphilic terpolymer with a novel nonionic surfmer. Int J Polym Sci. Article ID 9231837

Bray C, Peltier R, Kim H, Mastrangleo A, Perrier S (2017) Anionic multiblock core cross-linked star copolymers via RAFT polymerization. Polym Chem 8:5513–5524

Martin L, Gody G, Perrier S (2015) Preparation of complex multiblock copolymers via aqueous RAFT polymerization at room temperature. Polym Chem 6:4875–4886

Gody G, Maschmeyer T, Zetterlund P-B, Perrier S (2014) Pushing the limit of the RAFT process: multiblock copolymers by one-pot rapid multiple chain extensions at full monomer conversion. Macromolecules 47:3451–3460

Díaz-Silvestre S, Saldívar-Guerra E, Rivera-Vallejo C, St Thomas C, Cabello-Romero J, Guerrero-Santos R, Jiménez-Regaldo E (2018) Synthesis of associative block copolymers electrolytes via RAFT polymerization. Polym Bull 75(3):891–907

Lai JT, Filla D, Shea R (2002) Functional polymers from novel carboxyl-terminated trithiocarbonates as highly efficient RAFT agents. Macromolecules 35:6754–6756

Chaduc I, Lansalot M, D’Agosto F, Charleux B (2012) RAFT polymerization of methacrylic acid in water. Macromolecules 45:1241–1247

Abel AB, McCormick CL (2016) Mechanistic insights into temperature-dependent trithiocarbonate chain-end degradation during the RAFT polymerization of N-arylmethacrylamides. Macromolecules 49:465–474

López-Pérez L, Maldonado-Textle H, Elizalde-Herrera LE, Telles-Padilla JG, Guerrero-Santos R, Collins S, Jiménez-Reglado EJ, St Thomas C (2019) Methylation of poly(acrylic acid), prepared using RAFT polymerization, with trimethylsilyldiazomethane: a metamorphosis of the thiocarbonyl group to a thiol-end group. Polymer 168:116–125

Graessley WW (1980) Polymer chain dimensions and the dependence of viscoelastic properties on concentration, molecular weight and solvent power. Polymer 21:258–262

Acknowledgements

Authors acknowledge the CONACYT for financial support through the project number 255052 and 267962, respectively. Authors also thank M.C. Ricardo Mendoza-Carrizales and M.C. Maria Guadalupe Mendez-Padilla for SEC and DSC characterizations. CST thanks the CONACYT for his nomination as research fellow at CIQA.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Authors declare not competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muñoz-López, C.N., Díaz-Silvestre, S., Telles-Padilla, J.G. et al. Synthesis, characterization and rheological properties of multiblock associative copolymers by RAFT technique. Polym. Bull. 77, 2539–2555 (2020). https://doi.org/10.1007/s00289-019-02867-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02867-z