Abstract

Methylcellulose (MC) and kappa carrageenan (KCG) are widely used in food and pharmaceutical industries as a viscosity modifier, a gelling aid, and a film former due to their reversible thermal gelation properties. Thermoreversible gelation of MC/salt, MC/KCG/water, and MC/KCG/salt mixtures was investigated utilizing dynamic and steady shear rheological measurements. It was found that for the MC/salt mixture, gelation temperatures decreased linearly with increasing salt concentrations independent of valences of cations and molar concentrations of anions. For the MC/KCG blend, double gelation was not observed, and KCG is not influenced or disturbed the gelation properties of MC. Double gelation was observed for the mixture of MC/KCG/KCl for the low concentration of salts of 0.01 M KCl and 0.04 M KCl with the maximum moduli values for the mixture of MC/KCG/0.04 M KCl and then gradually decreased with increasing KCl salt concentration and eventually became similar to the gelation of MC solution. Therefore, KCl concentration played a major role in double gelation properties of MC/KCG/KCl mixture. It was also found that for the MC/KCG/KCl system, gelation transition matrices are linearly depending on salt concentration and independent of KCG and salt type. It was shown that for MC/salt mixture, solution rheology follows the principle of time–temperature superposition (TTS) below the gelation temperature. However, TTS failed above the gelation temperature. TTS also failed for MC/KCG and MC/KCG with low KCl concentration mixtures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Methylcellulose (MC) and kappa carrageenan (KCG) are used extensively in the food and pharmaceutical industries as a film former, a binder, or a thickener due to their ability to form gels at higher temperature and lower temperature, respectively [1,2,3,4,5,6]. MC is hydrophobically modified cellulose ether which is obtained by substituting a certain number of hydroxyl groups of anhydroglucose with methoxyl group. Kappa carrageenan is a linear sulphated naturally occurring polysaccharide extracted from red seaweed [7].

Thermogelation of MC has previously been studied using rheology, nuclear magnetic resonance (NMR), dynamic light scattering, small-angle neutron scattering, and differential scanning calorimetry (DSC) [8,9,10,11,12,13,14,15,16]. It has been shown that the gelation process for MC has two stages [10, 17, 18]. Kobayashi et al. [19] suggested that MC in aqueous solutions associated at low temperatures and then phase separated into (methyl group) clusters of varying hydrophobicity. Consistent to Kobayashi et al., Bodvika et al. showed that gelation occured due to the aggregation and network formation using Cryo-TEM and other spectroscopic techniques [20]. Sekiguchi et al. [21] suggested that hydrogen bonding may be involved in the gelation of MC. Overall, it was widely accepted that the gelation was caused by the hydrophobic association of methocellulose chains at high temperatures. At temperatures below gelation temperature, water molecules form cage-like structures around the methoxyl groups of MC. Upon heating, these cage-like structures break down, and hydrophobic methoxyl groups are exposed. Thus, the hydrophobic methoxyl groups begin to aggregate and form the gel [13, 22]. It was also shown that a fibrillar structure can be formed during gelation process of MC aqueous solution [23].

The effect of salt on thermogelation of an aqueous solution of MC correlated with the Hofmeister series which explains the precipitation behavior of proteins by various salts [24, 25]. More specifically, the thermogelation temperature of aqueous solutions of MC increases with the addition of the same concentration anions following the order of SCN− > ClO _4 > I−, and decreases in the order of NO3− ≈ Br− < Cl− < F− < H2PO4− < S2O32− < SO42−, and increases with the addition of cations following the order of Li+ > Na+> K+ > Mg2+ > Ca2+ > Ba2+. Furthermore, the influence of gelation temperature by anions is more significant than that of cations [26].

It is widely accepted that the gelation mechanism of KCG is described in a conformational change of the KCG molecules from the coil to double helices and then followed by the aggregation of these double helices to form a large gel network structure [27,28,29,30]. Due to negatively charged sulphate groups in the KCG molecules, the counter ions play a significant role in the gelation [29, 31,32,33,34,35]. Interestingly, KCG can form double helices in the presence of K+ ions much easier than in other solutions with or without other counterions [35]. Therefore, the gels formed with K+ are the strongest and most stable [36].

The previous research of MC/KCG/water system has found that the mixture became gel at low and high temperatures and there is no influence or disturb the gelation properties of each other [37]. The aim of the present investigation was to formulate and characterize the MC/salt, MC/KCG/water, and MC/KCG/salt mixtures that would exhibit gel at lower and higher temperatures due to the effect of KCG and MC, respectively.

Materials and methods

Materials

The cellulose ether, METHOCEL™ A15 LV Premium, was generously supplied by The Dow Chemical Company, Midland, Michigan, and is denoted as A15. The A15 sample had a methoxyl content of 30.4 wt% (DS of 1.84), and the viscosity of 17 mPa.s at 2 wt% MC solution and 20 °C. The weight average molecular weight of A15 is 51,000 daltons. Sodium chloride (NaCl), potassium chloride (KCl), and calcium chloride dihydrate (CaCl2.2H2O) were obtained from EMD Chemicals and were used as Kappa carrageenan which was obtained from CPKelco (Genugel carrageenan CP-130).

Purified water obtained from E-pure filter system at 18 MOhm (Barnstead) was used to prepare all solutions in this research. The polymer, 7 wt% A15, and the blend of 7 wt% A15 and KCG (0, 0.1, 0.3 wt%) were first dispersed at 80 °C in distilled water that dissolved with the salt (NaCl, KCl, and CaCl2) from 0.00 to 0.5 M. The resulting dispersion was continuously mixed using magnetic stirrer as it cooled to 22 ± 2 °C and further mixed for more than 3 h at 22 ± 2 °C, and hydrated for more than 12 h at 4 °C before taking rheological measurements.

Methods

Rheology

Oscillatory and steady shear experiments were conducted using AR 2000 rheometer (TA Instrument, New Castle, DE) with a concentric cylinder fixture where the stator inner and rotor outer radius are 15 and 14 mm, respectively, and the height of immersed cylinder is 42 mm. To avoid the dehydration, a small quantity of silicone oil having low viscosity (Fisher Chemical, S159-500) was placed on the top of the polymer solution during experiments.

Small amplitude oscillatory shear (SAOS) [27]

was applied to the sample during oscillatory measurements, the resulting stress output

was obtained to compute the elastic, G′(ω) and viscous modulus, G″(ω). Using these data, the complex viscosity, |η*|, was found from the following equation:

Linear viscoelastic region (LVER) was determined using a strain amplitude sweep. It was found that 2% strain was within the LVER. Thus, 2% strain is used throughout the dynamic oscillatory experiments. Frequency sweep between 0.01 to 100 Hz was carried out isothermally at a temperature range between 10 to 80 °C with 5 °C increment. At each temperature, the sample was equilibrated for 30 min. Using the principle of time–temperature superposition (TTS), master curves were generated by shifting frequency-dependent dynamic spectrum at each temperature to that of the reference temperature (Tref), − 5 °C [38, 39]. The temperature ramps were also performed from 10 to 80 °C at a constant heating/cooling rate of 1 °C/min, the frequency of 1 Hz, and the strain of 2%. The nomenclature of gelation characteristics used in this paper is defined in Table 1. The standard deviation was calculated for the onset of gelation, Theat(G′min), the complex viscosity, Theat(|η*|min), gelation temperature, Theat(G′ = G″), and gel dissolution temperature, Tcool(G′ = G″), which are within ± 0.81.

Results and discussion

Effect of salt on rheological behavior of MC solutions

Figure 1 shows typical heating and cooling curves of elastic and viscous moduli obtained from dynamic rheological measurements of 7% MC solution. At lower temperatures, G″ was greater than G′ showing a highly viscous solution. As temperature increased, the sudden increase of the G′ was identified as the onset of gelation temperature 1 [Theat(G′min)] as defined in Table 1. Further increasing the temperature, G′ became equal to G″ where this cross-over point was identified as gelation temperature 2 [Theat(G′ = G″)] as defined in Table 1. When the temperature was greater than the gelation temperature, G′ was greater than G″ showing an elastic solid. During the cooling process, the gel melted at a lower temperature than that of the gelation temperature showing large hysteresis between the gelation and gel-melting process. This was due to the rate of gel melting is much slower than that of gelation process [40]. Figure 2 shows heating and cooling curves of elastic and viscous moduli for 7% MC solution with various concentrations of KCl. The onset of gelation shifted to a lower temperature with increasing salt concentrations. The key gelation temperatures, Theat(G′min), Theat(|η*|min), and Theat(G′ = G″), that were obtained from Fig. 2 were analyzed as a function of salt concentrations, as shown in Fig. 3. The gelation temperatures, Theat(|η*|min) and Theat(G′ = G″), as a function of salt concentrations can be approximated with linear curve fits with a relatively high coefficient of determination (R2) values (> 0.90), as shown in Fig. 3.

However, the quality of the linear fit of Theat(G′min) was not as good as other matrices shown in Fig. 3 with R2 values of 0.83. All the characteristic gelation temperatures declined linearly with increasing concentrations of salt. Figure 3 shows that gelation temperatures do not depend on the type of the salts. This is consistent with the findings of Xu et al. where the gelation temperatures of an aqueous solution of high-molecular-weight MC decreased as the concentration of NaCl increased from 0 to 0.4 M [25]. In addition, the gel dissolution temperature, Tcool(G′ = G″), also decreased as salt concentration increased, as shown in Fig. 3b.

It has been postulated that the decrease of gelation temperature with the addition of salts is due to the competitive association of salts with water, and, therefore, shifting hydrophobic aggregation of MC chains to a lower temperature [25, 40]. The effect of cations on gelation temperature was minimum which is consistent with what was found by Alexandridis [26]. However, the significant effect of mole concentration of anions was not observed. This may be due to the convoluted effect of both cations and anions which will be further studied in the future.

Effect of KCG and salt on rheological behavior of MC solutions

Figure 4 shows heating and cooling curves of elastic and viscous moduli for the blend of MC and KCG solution. Although the elastic modulus has increased one order of magnitude compared to MC (Fig. 1), G″ is still greater than G′ showed solution state of the mixture before the onset of gelation of MC [Theat(G′min)]. Therefore, KCG gelation was not observed for the mixture. After the onset of gelation, the MC/KCG system rheological properties are very similar to the rheological properties of MC solution. Indeed, in the MC/KCG mixture, double gelation was not observed, and KCG is not influenced or disturb the gelation properties of MC. However, double gelation was observed by Tomšič et al. for the mixture of 2 wt% MC/KCG (1:1) [37]. Moreover, Tomšič et al. used high-molecular-weight MC and high concentration of KCG (1%) in contrast to our low-molecular-weight MC and low concentration of KCG (0.3%) [37]. This may be the reason that we did not observe the double gelation of the MC/KCG mixture. However, with the addition of 0.01 M KCl to the mixture, the elastic modulus increased two orders of magnitude compared to MC solution, as shown in Fig. 5a. Furthermore, G′ is greater than G″ for the entire temperature range studied. Therefore, we observed double gelation at low and higher temperature due to KCG and MC, respectively. With increasing KCl concentration to 0.04 M KCl, G′ increased more than two-order magnitude compared to MC solution, as shown in Fig. 5b. In addition, G′ is greater than G″ for the entire temperature range studied which confirmed the double gelation properties of the mixture. With the addition of 0.1 M KCl, G′ is very close to G″ which indicate the weakening of the KCG gel network, as shown in Fig. 5c. Finally, at a higher salt concentration of KCl (0.43 M), gelation is very similar to the gelation of MC solution, as shown in Fig. 5d. This may be because KCG confirmation is different in the presence of low and high KCl solution. This was also confirmed by Thrimawithana et al. where they observed that the density of the cross links increased and the subsequence arrangement/ordering of KCG structure are similar to honeycomb structure, which increased the mechanical properties of the mixture at 0.12% KCl (w/v) [41]. However, they also observed disruption of the KCG cross-linked structure when KCl concentration was increased to 0.4% (w/v). Also,

Changes of elastic modulus (G′) and viscous modulus (G″) of a 7% MC + 0.3% in 0.01 M KCl solution, b 7% MC + 0.3% KCG in 0.04 M KCl, c 7% MC + 0.3% KCG in 0.1 M KCl, and d 7% MC + 0.3% KCG in 0.43 M KCl solution as a function of temperature. Closed symbols—heating curves; opened symbols—cooling curves

Table 2 showed that the comparison of G′ before and after the onset of gelation of MC. As we discussed in Figs. 2 and 3, the onset of gelation decreased with increasing salt concentration, as shown in Table 2 (column 1). The influence of KCl on MC before the onset of gelation is very minimal base on the G′ data, as shown in Table 2. However, with the addition of KCl, the maximum G′ of 205 Pa was observed for the solution of KCG with 0.04 M KCl and then decreased with increasing KCl concentrations. A gradual decrease of elastic modulus with increasing KCl concentration showed a weakening of the KCG gel network. In other words, when the intermolecular interaction begins to breakdown the network structure which, in turn, the molecules become more and more dispersed and diminishes their organized network structure. The weakening of KCG gel structure at higher KCl concentration has a very minimal effect on the sol–gel transition of MC, as shown in Table 2. For example, during MC sol–gel transition [Table 2 (column 3)], the addition of KCG/0.04 M KCl has the highest elastic modulus of 472 Pa then gradually decreased the elastic modulus with increasing KCl concentration. This further confirmed that in MC/KCG/KCl mixture, above 0.1 M KCl salt concentration did not disturb the gelation properties of these polymers each other. Nevertheless, KCG in the presence of KCl has great influenced in the gel elastic modulus during the MC gelation, as shown in Table 2 (column 3).

The onset of gelation, Theat(G′min), the complex viscosity, Theat(|η*|min), gelation temperature, Theat(G′ = G″), and gel dissolution temperature, Tcool(G′ = G″), are summarized in Fig. 6. Data analysis was performed using Minitab 17 package. In Fig. 6a, b, coefficient of determination (R2) is 0.95, so that more accurate prediction of Theat(G′ = G″) and Theat(|η*|min) can be made from the data. Therefore, Theat(G′ = G″) and Theat(|η*|min) transition matrices linearly depend on salt concentrations and independent of KCG and salt type. Statistically analyzing the standardize residual plots, two points (7% MC + 0.3%KCG in 0.17 M NaCl and 7% MC + 0.3%KCG in 0.01 M NaCl) for Theat(G′min) and three points (7% MC + 0.3%KCG in 0.01 M KCl, 7% MC + 0.1%KCG in 0.01 M KCl, and 7% MC + 0.1%KCG in 0.1 M KCl) for Tcool (G′ = G″) show the outlier for the linear regression. Removing outliers from those plots, R2 increased from 0.83 to 0.85 and 0.81 to 0.89, respectively, as shown in Fig. 6c, d.

The structure and properties of the polymer solution can be studied by accessing a wide-frequency range of a polymer material. Figure 7 illustrates the G′ and G″ of MC/KCl salt solution for various temperatures. As shown in Fig. 7a1, G″ is greater than G′ and depends on angular frequency, i.e., G″ ~ ω0.7, G′ ~ ω1.0 showed a pseudo fluid-like behavior of MC solution, which deviates from typical fluid-like behavior, i.e., G″ ~ ω1 and G′ ~ ω2. This indicated that there were microstructures of polymer, such as associations, at temperatures below gelation temperature. This is consistent with Desbrieres work, where pseudo fluid-like behavior was found, G″ ~ ω0.9 and G′ ~ ω1.5 [42]. As the temperature increased, MC solution became gel, the cross-over frequency shifted to higher frequencies and eventually disappeared out of the detectable range above 55 °C, as shown in Fig. 7a2. Furthermore, G′ and G″ became less dependent on the angular frequency. With the addition of 0.04 M KCl, both moduli show similar pseudo fluid-like behavior at a lower temperature and slightly increase of moduli at a higher temperature, as shown in Fig. 7b1, b2, respectively. However, with the incorporation of 0.43 M KCl, the cross-over frequency, G′, and G″ shifted to a higher value, as shown in Fig. 7c1, c2. As we discussed in the previous section, increasing salt concentration, gelation temperature of MC decrease also confirmed with the dynamic frequency sweep data.

Figure 8a1, a2 shows the examples of the frequency dependence of G′ and G″ of MC/KCG mixture before and after gelation of the MC. At low temperature, G′ is greater than G″ and the cross-over frequency decreasing with increasing temperature shows some elastic behavior of MC/KCG mixture, as depicted in Fig. 8a1. However, as shown in our temperature sweep data, for the same mixture, G′ is smaller than G″ at low temperature which confirms the viscous behavior of the mixture. During MC gelation, the cross-over frequency, G′, and G″ shifted to higher value which shows some influence of KCG, as illustrated in Fig. 8a2. However, with the addition of 0.04 M KCl to the blend of KCG and MC, the cross-over frequency, G′, and G″ further shift to higher values which confirm the highly elastic behavior of the blend, as shown in Fig. 8b1, b2. Therefore, at this concentration, double gelation was observed at lower and elevated temperature due to KCG and MC, respectively, which also confirmed from our dynamic temperature sweep data. Figure 8c1, c2 shows examples of the frequency dependence of G′ and G″ of MC/KCG/0.43 M KCl mixture before and after gelation of the MC. These data confirmed that the gelation properties are very similar to the gelation properties of MC solution with slightly increase moduli value due to KCG.

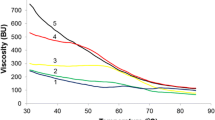

Figure 9 shows steady shear viscosity of 7% A15 solution for various temperatures. At temperatures less than 30 °C, the shear viscosity was independent of shear rates at shear rates less than 10 1/s showing a Newtonian fluid. A shear thinning behavior was observed at higher shear rates which are typical for polymeric solutions. At 35 °C, shear thinning was observed throughout the measured shear rate range which indicated the gelation phase of MC solution. Many authors have used sharp increase of viscosity to identify the gelation temperature [12, 37]. Time–temperature superposition (TTS) was used to shift the viscosity data of 7% MC and 7% MC with 0.1 M KCl, as shown in Fig. 10. A gelation temperature, Tgel, occurred where TTS failed, which can be derived from the data in Fig. 10. TTS failed for the solution of the blend of MC and KCG especially at low shear rate at all temperatures measured, as shown in Fig. 11. In addition, the Newtonian region at low shear rates disappeared, and shear thinning was observed. This indicated that a gel-like structure had formed at low temperatures before the evident sharp increase of viscosity which was dominated by the gelation of MC. This gel-like structure at low temperatures was likely caused by the addition of KCG. The gelation transition of the solutions of MC/KCG was identified as a sharp increase of viscosity, as shown in Fig. 11.

With the addition of low concentration of KCl (0.1 M), the shear thinning slop is significantly higher than that of MC/KCG without salt, as shown in Fig. 12a. The gelation transition dominated by MC was less evident in this mixture which was hypothesized due to the strong gelation nucleated by the optimal mixture of KCG/KCl at low temperatures. At higher KCl concentrations, TTS works for viscosity spectrum at low temperatures and the gelation temperature, Tgel, decreased with increasing KCl concentrations, as shown in Fig. 12b, c. These results confirmed that the gelation temperature of MC/salt solution as a function of salt concentration followed the same linear relationship with the addition of KCG. However, the gel structure of MC/KCG/KCl solutions was dependent on the concentration of KCl which was indicated by the rheological signature of these solutions.

Conclusion

In this study, we present the dynamic and steady shear rheological results on thermoreversible gelation of MC/salt, MC/KCG, and MC/KCG/salt mixtures. It was found that for the MC/salt mixture, gelation temperatures decreased linearly with increasing salt concentrations independent of valences of cations and molar concentrations of anions. For the MC/KCG blend, double gelation was not observed, and KCG is not influenced or disturbed the gelation properties of MC. Double gelation was observed for the mixture of MC/KCG/KCl for the low concentration of salts of 0.01 M KCl and 0.04 M KCl with the maximum moduli values for the mixture of MC/KCG/0.04 M KCl and then gradually decreased with increasing KCl salt concentration and eventually became similar to the gelation of MC solution. Therefore, KCl concentration played a major role in double gelation properties of MC/KCG/KCl mixture. It was also found that for the MC/KCG/KCl system, gelation transition matrices are linearly depending on salt concentration and independent of KCG and salt type. It was shown that for MC/salt mixture, solution rheology follows the principle of time–temperature superposition below the gelation temperature. However, TTS failed above the gelation temperature. TTS also failed for MC/KCG and MC/KCG with low KCl concentrations mixtures.

References

Kumar V, Banker GS (1993) Chemically-modified cellulosic polymers. Drug Dev Ind Pharm 19(1–2):1–30

Lin SY, Wang SL, Wei YS, Li MJ (2007) Temperature effect on water desorption from methylcellulose films studied by thermal FT-IR micro spectroscopy. Surf Sci 601:781–785

Perez OE, Sanchez CC, Pilosof AM, Patino JM (2008) Dynamics of adsorption of hydroxypropyl methylcellulose at the air–water interface. Food Hydrocoll 22:387–402

Hoffman AS (2002) Hydrogels for biomedical applications. Adv Drug Deliv Rev 54:3–12

Chen CH, Tsai CC, Chen W, Mi FL, Liang HF, Chen SC, Sung HW (2006) Novel living cell sheet harvest system composed of thermoreversible methylcellulose hydrogels. Biomacromolecules 7(3):736–743

Guiseley KB, Stanley N, Whitehouse P (1980) chapter 5. In: Davidson R (ed) Industrial gums. McGraw-Hill, New York

Piculell L (2006) Gelling carrageenans. In: Stephen AM, Phillips GO, Williams PA (eds) Food polysaccharides and their applications. CRC Press, Boca raton

Haque A, Morris ER (1993) Thermogelation of methylcellulose. Part I: molecular structures and processes. Polymer 22(3):161–173

Rotbaum Y, Parvari G, Eichen Y, Rittel D (2017) Static and dynamic large strain properties of methyl cellulose hydrogels. Macromolecules 50(12):4817–4826

Kobayashi K, Huang C, Lodge TP (1999) Thermoreversible gelation of aqueous methylcellulose solutions. Macromolecules 32:7070–7077

Li L, Shan H, Yue CY, Lam YC, Tam KC, Hu X (2002) Thermally induced association and dissociation of methylcellulose in aqueous solutions. Langmuir 18:7291–7298

Haque A, Richardson RK, Morris ER, Gidley MJ, Caswell DC (1993) Thermogelation of methylcellulose. Part II: effect of hydroxypropyl substituents. Carbohydr Polym 22(3):175–186

Lam YC, Joshi SC, Tan BK (2007) Thermodynamic characteristics of gelation for methyl-cellulose hydrogels. J Therm Anal Calorim 87(2):475–482

Ford JL (1999) Thermal analysis of hydroxypropylmethylcellulose and methylcellulose: powders, gels and matrix tablets. Int J Pharm 179(2):209–228

Almeida N, Rakesh L, Zhao J (2014) Monovalent and divalent salt effects on thermogelation of aqueous hypromellose solutions. Food Hydrocoll 36:323–331

Almeida N, Rakesh L, Zhao J (2014) Phase behavior of concentrated hydroxypropyl methylcellulose solution in the presence of mono and divalent salt. Carbohydr Polym 99:630–637

Carlssona A, Karlströmb G, Lindman B (1990) Thermal gelation of nonionic cellulose ethers and ionic surfactants in water. Colloids Surf 47:147–165

Ibbett RN, Philp K, Price DM (1992) 13C n.m.r. studies of the thermal behaviour of aqueous solutions of cellulose ethers. Polymer 33(19):4087–4095

Kobayashi K, Huang C, Lodge TP (1993) Thermoreversible gelation of aqueous methylcellulose solutions. Macromolecules 32(21):7070–7077

Bodvika R, Dedinaitea A, Karlsonb L, Bergströma M, Bäverbäckc P, Pedersenc JS, Edwardsd K, Karlssond G, Vargaa I, Claessona PM (2010) Aggregation and network formation of aqueous methylcellulose and hydroxypropylmethylcellulose solutions. Colloids Surf A Physicochem Eng Asp 354:162–171

Sekiguchi Y, Sawatari C, Kondo T (2003) A gelation mechanism depending on hydrogen bond formation in regioselectively substituted O-methylcelluloses. Carbohydr Polym 53(2):145–153

Liu SQ, Joshi SC, Lam YC, Tam KC (2008) Thermoreversible gelation of hydroxypropylmethylcellulose in simulated body fluids. Carbohydr Polym 72:133–143

Lott JR, McAllister JW, Arvidson SA, Bates FS, Lodge TP (2013) Fibrillar structure of methylcellulose hydrogels. Biomacromolecules 14(8):2484–2488

Xu Y, Wang C, Tam K, Li L (2004) Salt-assisted and salt-suppressed sol–gel transitions of methylcellulose in water. Langmuir 20(3):646–652

Xu Y, Wang C, Tam KC, Li L (2004) Salt-assisted and salt-suppressed sol–gel transitions of methylcellulose in water. Langmuir 20(3):646–652

Alexandridis P, Holzwarth JF (1997) Differential scanning calorimetry investigation of the effect of salts on aqueous solution properties of an amphiphilic block copolymer (poloxamer). Langmuir 13:6074–6082

Iijima M, Hatakeyama T, Takahashi M, Hatakeyama H (2007) Effect of thermal history on kappa-carrageenan hydrogelation by differential scanning calorimetry. Thermochim Acta 452(1):53–58

Yuguchi Y, Thuy TTT, Urakawa H, Kajiwara K (2002) Structural characteristics of carrageenan gels: temperature and concentration dependence. Food Hydrocoll 16(6):515–522

Kara S, Arda E, Kavzak B, Pekcan Ö (2006) Phase transitions of κ-carrageenan gels in various types of salts. J Appl Polym Sci 102(3):3008–3016

Kara S, Tamerler C, Bermek H, Pekcan Ö (2003) Cation effects on sol–gel and gel–sol phase transitions of κ-carrageenan-water system. Int J Biol Macromol 31(4):177–185

Arda E, Kara S, Pekcan Ö (2009) Synergistic effect of the locust bean gum on the thermal phase transitions of κ-carrageenan gels. Food Hydrocoll 23(2):451–459

Mangione M, Giacomazza D, Bulone D, Martorana V, San Biagio P (2003) Thermoreversible gelation of κ-Carrageenan: relation between conformational transition and aggregation. Biophys Chem 104(1):95–105

Takemasa M, Chiba A, Date M (2002) Counterion dynamics of κ-and ι-carrageenan aqueous solutions investigated by the dielectric properties. Macromolecules 35(14):5595–5600

Thành TT, Yuguchi Y, Mimura M, Yasunaga H, Takano R, Urakawa H, Kajiwara K (2002) Molecular characteristics and gelling properties of the carrageenan family, 1. Preparation of novel carrageenans and their dilute solution properties. Macromol Chem Phys 203(1):15–23

Ikeda S, Morris VJ, Nishinari K (2001) Microstructure of aggregated and nonaggregated κ-carrageenan helices visualized by atomic force microscopy. Biomacromolecules 2(4):1331–1337

MacArtain P, Jacquier J, Dawson K (2003) Physical characteristics of calcium induced κ-carrageenan networks. Carbohydr Polym 53(4):395–400

Tomšič M, Prossnigg F, Glatter O (2008) A thermoreversible double gel: characterization of a methylcellulose and κ-carrageenan mixed system in water by SAXS, DSC and rheology. J Colloid Interface Sci 322(1):41–50

Ferry JD (1980) Viscoelastic properties of polymers, 3rd edn. Wiley, New Jersey

Macosko CW (1994) Rheology: principles measurements and applications. Wiley-VCH, New Jersey

Liu SQ, Joshi SC, Lam YC (2008) Effects of salts in the hofmeister series and solvent isotopes on the gelation mechanisms for hydroxypropylmethylcellulose hydrogels. J Appl Polym Sci 109:363–372

Thrimawithana TR, Young S, Dunstan DE, Alany RG (2010) Texture and rheological characterization of kappa and iota carrageenan in the presence of counter ions. Carbohydr Polym 82(1):69–77

Desbrieres J, Hirrien M, Ross-Murphy SB (2000) Thermogelation of methylcellulose: rheological considerations. Polymer 41(7):2451–2461

Acknowledgements

Authors are grateful to Dow Pharma and Food Solutions for providing the methylcellulose materials. We also acknowledge the financial support given by The Science of Advanced Materials at Central Michigan University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Almeida, N., Rakesh, L. & Zhao, J. The effect of kappa carrageenan and salt on thermoreversible gelation of methylcellulose. Polym. Bull. 75, 4227–4243 (2018). https://doi.org/10.1007/s00289-017-2256-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2256-z