Abstract

Temperature-responsive flat composite ultrafiltration membranes were prepared by dry–wet phase inversion process from casting solution of polyacrylonitrile and hydrophobically modified polyvinyl alcohol (HMPVA) in dimethylsulfoxide solvent. HMPVA is characterized by multiple reversible temperature-stimulated change of its physicochemical properties with the temperature of transformation (T tr) being dependent on the degree of acetalization. Based on the dynamic viscosity, the limit of the polymer concentration in the solution was established to be from 0.6 to 3.5 wt% for HMPVA at constant concentration of 16 wt% PAN. HMPVA remained homogeneously scattered within the membrane structure which was proved by Fourier transform infrared spectroscopy (FTIR). The studies on membrane morphology by scanning electron microscopy and on permeability (J, l/m2 h) and rejection (R, %) for water and albumin showed an asymmetry of the porous structure with pores having capillary macroporosity—on the surface and inner walls of the pores. The optimal for membrane parameters is a concentration of 1.2 wt% HMPVA. The permeability to water at 0.3 MPa changes from 58 to 80 l/m2 h and permeability to albumin—from 30 to 56 l/m2 h, when changing the temperature relative to T tr = 29.5 °C. Adjusting the temperature, it allows us to control the amount of flow passing through the membrane and widens the possibilities for self-cleaning and regenerations of the membrane.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The widening of the possibilities for application of the polymeric membranes is connected with their modification [1]. For this purpose, a perspective method is the use of the so-called stimuli-responsive or intelligent materials. Exerting influence by external stimuli, temperature, pH, ionic strength, weak electric or magnetic fields, chemical signals, as well as others, an adaptive behavior of the physicochemical parameters of the sensitive materials is induced [2]. Synthetic polymers and copolymers are most often used for this purpose [3].

The stimuli-responsive materials can build membrane structures or can be adapted for use in various membranes. The control of performance of responsive membrane is effected by manipulating the ability of the intelligent material to quickly, rapidly and reversibly adapt to certain external influences. The methods used for their preparation can be classified into two categories: synthesis of membranes from stimuli-responsive materials and modification of membranes with stimuli-responsive materials. Used for modification, they co-participate in the building of the membrane or are introduced into or immobilized onto membrane surface [4,5,6]. Membranes obtained from various materials—polypropylene, polyethylene, polycarbonate, poly(ethylene terephthalate), polyvinylidene fluoride (PVDF), etc., are often used as substrates for modification [7,8,9]. The temperature-responsive polymers are of special interest both for development and implementation in membrane technologies [10,11,12]. Temperature-responsive polymers are the acetals of polyvinyl alcohol (PVAc) where the degree of acetalization determines the critical temperature transformation (Ttr) [13]. This is the temperature at which the polymer chains collapse from unfolded coil conformation to form compact globuli.

PAN is a very well-known polymer used for manufacturing of ultrafiltration membranes. PAN-based membranes allow wide variety of modifications [14,15,16,17]. An often used method of modification with stimuli-responsive polymers, including temperature-responsive ones, is their introduction in the membrane structure by their crosslinking with chemical agents [18].

Phase inversion is a major process used for preparation of PAN membranes [19, 20]. The technology stipulates the opportunity to employ the process also for modification of the membranes obtained from temperature-responsive polymer by its inclusion in the forming polymeric solution [6]. The important considerations in such cases are that it should be soluble in the solvent used and to form homogeneous solutions with the main polymer. It can be supposed that the polymers can form interwoven networks by their co-coagulation in the precipitation medium. The presence of stimuli-responsive polymer, like other additives, would affect the conditions of the phase inversion process which could lead to specific morphologic and, respectively, technological changes in the characteristics of the modified membrane [21,22,23]. The composition of the polymeric solution is one of the main factors determining the formation of an asymmetric membrane structure. Its properties depend to a great extent on the interactions between the components of the polymeric solution. The use of different solvents with the same other components of the solution would be the reason for qualitative changes in its physical state and they can be assessed by solution viscosity [24, 25].

The aim of the present paper is to study the limits of compatibility in a solution of PAN and HMPVA with solvents DMSO or DMF, as well as the morphology, permeability and rejection with respect to T tr of HMPVA in flat asymmetric PAN/HMPVA membranes prepared by dry–wet method of phase inversion. HMPVA is characterized by multiple reversible temperature-stimulated change of its physicochemical properties and possesses the so-called intelligent functionality by the change of its temperature against the critical one (T tr).

The introduction of HMPVA from a solution by phase inversion in PAN membrane might facilitate the formation of intermolecule bonds between the polymer chains of HMPVA and PAN, affect on the forming and remain in the polymer structure [26, 27], keeping the temperature-response with respect to T tr.

The studies on the temperature-responsive membranes widen the possibilities for their potential application as temperature probes, intelligent separation of components, in controlled-release medicines on the basis of their biological compatibility, etc. [28, 29]. Besides the possibility of using them for controlling of the amount of liquid flowing through the membrane, the temperature-responsive membranes are interesting in application for controlling the permeation of nano-particles, as well as improving the efficiency of the processes for self-cleaning and regeneration [30, 31].

Experimental

Materials

Polyacrylonitrile fibers obtained from the ternary copolymer poly(acrylonitrile–methylacrylate–2-acryloamide–2-methylpropanesulphonic acid) produced by LUKOIL Neftochim Burgas Co., Bulgaria, were used.

Hydrophobically modified polyvinyl alcohol was synthesized (Fig. 1) by a solution of acetaldehyde added dropwise to aqueous solution of PVA with vigorous stirring at room temperature for 30 min. The temperature was raised to 40 °C and the reaction was allowed to proceed for 4 h. At the end, the temperature was raised to 60 °C; the obtained HMPVA was precipitated, washed twice with deionized water and finally dried at 60 °C under vacuum. Characteristics of HMPVA used in this work are shown in Table 1.

Preparation of polymeric membranes

The membranes were formed by dry–wet phase inversion technique from polymer solutions in a water coagulation bath. Six polymer solutions of the following compositions: 16 wt% PAN and 16 wt% PAN with added HMPVA in concentrations of 0.6, 1.2, 1.8, 2.4, 3.5 wt% were dissolved in DMSO, product of “Fluka”, Germany. The PAN solution was prepared at room temperature until full dissolution of the polymer. The HMPVA-containing solutions were prepared by dissolution of the necessary quantity of HMPVA at room temperature, then adding PAN until full dissolution and homogenization of the solution obtained by stirring. After filtering and deaeration, the polymer solutions were cast on a calandered polyester matt attached on a glass plate. The polyester matt brand FO-2403, product of “Velidon Filtren”, Germany, had density of 100 ± 5 g/m2 and thickness 2 ± 0.1 nm. About a minute after the deposition, the solution was placed in a bath of distilled water at temperature of 25 ± 1 °C to carry out the process of phase inversion and formation of the membrane structure. The membranes were left for half hour in the coagulation bath, then they were thoroughly washed with water for total removal of the solvent. The membranes obtained were fixed on a metal frame and subjected to heat treatment at 80 °C in water for 10 min.

Characterization of solutions and membranes

The rheological behavior of the polymer solutions were determined on the basis of the change of their dynamic viscosity (η) at gradient of the shear stress (τ) in the range of 27–656 s−1 shear rates at constant temperature of 25 °C using a device with coaxial cylinders RHEOTEST II-2.1, Germany.

Membrane morphology was analyzed from images taken with scanning electron microscope JSM-5510 (“JEOL”, Japan). All samples were sputter-coated with gold before analysis. For cross-section analysis, the membrane samples were freeze fractured in liquid nitrogen.

Infrared spectroscopy of liquid samples of the polymer solutions was carried out on an FTIR spectrophotometer “TENSOR 27” (“Bruker”, Germany). The spectra were registered with samples of the solutions deposited as thin capillary layer on the tablets from KBr under the following conditions: interval studied—3996–399 cm−1, resolution—2.

Fourier transform infrared spectrophotometer (IRAffinity-1 “Shimadzu”) equipped with reflectance measuring appliance (MIRacle Attenuated Total Reflectance Attachment) was used to study solid samples of PAN/HMPVA membranes.

The permeability and rejection of the membranes to water and albumin as calibrant were performed with an ultrafiltration laboratory cell SM 165-26 (“Sartorius”, England). The experiments were carried out at two different temperatures of 18 and 30 °C which are lower and higher than the T tr = 29.5 °C of HMPVA (MM = 15,000 g/mol). The permeability for water was studied as function of the pressure (J = f (P)) under increasing and decreasing pressure between 0.1 and 0.5 MPa. The time for 10 ml of distilled water to pass through the membrane was determined. Based on the results obtained, hysteresis curves were drawn. The time measured at certain pressure was used to calculate membrane permeability by the formula:

where J is the flux permeate through the membrane (l/m2 h), V is the volume of permeated flux (l), S is the effective area of tested samples (m2), and τ is the record time (h).

The rejection of the membranes was determined at pressure of 0.3 MPa by measuring the time for which 10 ml of permeate of calibrant solution passes through the membrane and calculating by the formula:

where R is the rejection of the membrane (%), C 2 is the concentration of calibrant in the field (g/l), C 1 is the concentration of calibrant in the permeate (g/l).

The concentration of porcine serum albumin with molecular weight 76 kDa (“Merck”, Germany) was determined with the method of calibration curve using absorption spectroscopy at the wavelength for albumin λ = 280 nm on a spectrometer UV/VIS “UNICAM” 8625, France. The light absorption is measured against 0.9 wt% solution of NaCl (blank test).

Results and discussion

The importance of HMPVA for the solutions and the membranes prepared from them was studied with polymer solutions of constant PAN concentration and increasing content of HMPVA. It was found that HMPVA with molecular mass of 72,000 g/mol cannot be used as additive to the polymer solution. The higher molecular mass hampers the solubility and disturbs the homogeneity of the forming solution. Furthermore, due to the use of solvent DMF together with the two polymers (PAN and HMPVA), it was not possible to obtain homogeneous solutions suitable for formation of membranes. For this reason, the studies were restricted to the use of HMPVA with molecular mass of 15,000 g/mol and DMSO as solvent. The constant concentration of PAN 16 wt% was chosen on the basis of preliminary experiments carried out in the range 15–18 wt% solution in DMSO.

The flow curves (Fig. 2) corresponding to the solutions are obtained from the logarithmic values for dynamic viscosity as a function of the logarithm of the corresponding shear stress. Within the range of rotation velocities, the increase of HMPVA concentration resulted in increase in solutions’ viscosities but not change in their stability.

The shape of the flow curves corresponded to homogeneous non-Newtonian fluids which preserve their structural stability. This condition is compulsory for formation good membrane structure by the phase inversion of the solutions. The viscosities of the solutions gradually increased with the increase of HMPVA concentration and the flow curve for the solution containing 3.5 wt% HMPVA was the highest. The reason for this is that the total polymers concentration in this case was the highest (19.5 wt% PAN/HMPVA) due to the highest amount of HMPVA used. This concentration turned out to be a boundary one for the possibility to form permeable UF membrane structure.

The spectral data obtained from IR spectroscopy of pure DMSO solvent, solution of PAN/DMSO and PAN/HMPVA/DMSO are compared in Fig. 3. In the presence of HMPVA in the solution, a bond with the C≡N group of PAN was registered indicated by the almost 20% increase of the intensity of the transmission at 2241 cm−1 and slight decrease of the intensity of the C=O group at 1733 cm−1. The acetal groups registered in the interval 1050–1150 cm−1 are probably the reason for the changes observed in the spectral band at 1058 cm−1 corresponding to the S=O group of DMSO. These spectral changes in presence of HMPVA are probably due to intermolecular interactions with functional groups of PAN and DMSO.

All this indicated that HMPVA would affect the structuring of the membrane as early as the phase inversion process through its bonds with the other components of the solution.

The presence of HMPVA in the membrane structure was proved by the IR spectra registered in solid phase (Fig. 4) at total polymers concentration of 18.4 wt%. The red spectral line corresponds to the membrane polymer layer on the substrate side, the red band—to the working surface of the membrane and the blue one—to the inner volume of the membrane. The red and blue spectral bands showed split peaks between 1050 and 1100 cm−1 which correspond to the acetal groups of HMPVA.

The registering of HMPVA presence in these parts of the membrane also proved the homogeneous distribution in the bulk of membrane structure.

The results obtained from the SEM observations of cut-off and surface of the membranes (Fig. 5) showed the asymmetry of their structure. Usually, the wall surface in the capillary has microporous structure while in the bulk of the membrane the structure is macroporous (Fig. 5a). An interesting feature was observed for the membranes containing HMPVA. These membranes had macroporous structure not only on their surface (Fig. 5b1, c1), but also in capillary walls (Fig. 5b, c).

With the increase of the HMPVA concentration the polymer structure are densified, but retained its morphologic characteristic of macroporosity of the wall capillaries [22]. This structure indicated that the phase inversion process in membrane pores probably occurred at very high rate and as a result of the presence of HMPVA [32]. The comparatively low number of pores formed initially visibly expanded by volume and pierced almost all the polymer structure.

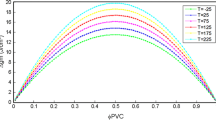

The results obtained from studies on the membrane characteristics, besides the confirmation of the importance of HMPVA for the formation of a modified and optimized membrane, showed and proved also the importance of its concentration for the performance of the membrane in both regimes—at temperatures higher and lower than Ttr of HMPVA. The increase of HMPVA concentration from 0.6 to 2.4 wt% resulted in substantial increase of the permeability values—from 13 to 85 l/m2 h for water and from 6 to 39 l/m2 h for albumin (Table 2), accompanied by a decrease of the rejection values by the same order—from 93 to 60% (Fig. 8). This is a specific feature as it is well known that the increase of the viscosity of the solutions used for preparation of membranes leads to decreased permeability of the membranes [22]. In the present study, the relationship was reversed.

The permeability of the membranes increased with the increase of solution viscosity. It was concluded that this relationship was due to the specific structure and increased macroporosity of capillary walls. This is the reason, increased permeability was observed both at temperatures higher and lower than T tr. The rejection gradually changed with the increase of the HMPVA concentration due to the growth of the macropores on the surface.

The results presented in Table 2 and Figs. 6 and 7 also showed that amounts from 0.6 to 2.4 wt% HMPVA gradually changed membrane characteristics and could be used to form membranes retaining substances of close molecular mass in the UF range.

As a result of the change of HMPVA conformation above the inversion point, the permeability values increased (Figs. 6, 7; Table 2). In this respect, the membranes will have the ability to rapidly and easily release the retained substances with the increase of the temperature above 30 °C. This kind of structure significantly improves the transport conditions for liquids through the membrane without affecting its hysteresis stability. This is achieved by the presence of free liquid within the carcass of the polymer material which takes the membrane pressure as incompressible system, so it does not affect the polymer stability. Because of the increasing density of the selective layer (Fig. 5b, c), the values of rejection above and below the T tr do not undergo considerable changes (Fig. 8).

With the increase of the HMPVA amount, the rejection is slightly changing, in spite of the macropores on the surface. We observe a larger decrease of the rejection (Fig. 8) of the membrane that contains 2.4% HMPVA due its closest proximity to the exact concentration limit of the solution, which forms an asymmetrical permeable membrane structure. At the same time, membranes rejection remains high enough (60–75%) which sustained the assumption that the membranes had well-formed asymmetric structure. The optimal HMPVA concentration for the membrane was found to be 1.2 wt%.

Conclusions

The formation of a UF membrane structure from a solution of PAN/HMPVA/DMSO by dry–wet phase inversion technique is possible in the concentration range of HMPVA from 0.6 to 3.5 wt% at constant PAN concentration of 16 wt%. The rejection on the membranes smoothly changing within 75–60% with the increase of HMPVA content stipulates the possibility of using the membranes to separate substances of close molecular mass.

The analysis of the images taken by SEM and the membrane characteristics determined showed the asymmetry of the porous structure where the pores have macroporosity in the inside and on the surface of the capillary walls. This predetermines their performance stability. HMPVA remains homogeneously distributed in the bulk of the membrane structure which was proved by the IR spectra.

The temperature responsiveness demonstrated by the membrane as a result of the change of HMPVA conformation was proved by the increased values of the permeability with respect to the temperature of transformation (29.5 °C). So far as membrane parameters (J, R) are concerned, the optimum content of HMPVA was found to be 1.2 wt% at which the water permeability determined at 0.3 MPa changed from 58 to 80 l/m2 h, respectively, at T tr. This will accelerate the processes of regeneration and cleaning of the membrane without affecting its separation efficiency.

References

Ulbricht M (2006) Advanced functional polymer membranes. Polymer 47:2217–2262. doi:10.1016/j.polymer.2006.01.084

Debashish R, Cambre JN, Sumerlin BS (2010) Future perspectives and recent advances in stimuli-responsive materials. Prog Polym Sci 35:278–301. doi:10.1016/j.progpolymsci.2009.10.008

Bhattacharyya D, Schafer T, Wickramasinghe SR, Daunert S (2013) Responsive membranes and materials. Wiley, Amsterdam

Mondal S (2014) Stimuli responsive surfaces for fouling-resistant polymeric membranes. J Membr Sci Technol 4:e120. doi:10.4172/2155-9589.1000e120

Gorey CM (2008) Grafting of stimuli-responsive polymer films to ultrafiltration membranes. Dissertation, University of Toledo

Fei ZD, Wan LS, Wang WM, Zhong MQ, Xu ZK (2013) Thermo-responsive polyacrylonitrile membranes prepared with poly(acrylonitrile-g-isopropylacrylamide) as an additive. J Membr Sci 432:42–49. doi:10.1016/j.memsci.2013.01.008

Wandera D, Wickramasinghe RS, Husson SM (2010) Stimuli-responsive membranes. J Membr Sci 357:6–35. doi:10.1016/j.memsci.2010.03.046

Liu F, Hashim NA, Liu YT, Abed MRM, Li K, Liu Y, Moghareh AMR (2011) Progress in the production and modification of PVDF membranes. J Membr Sci 375:1–27. doi:10.1016/j.memsci.2011.03.014

Lee A, Elam J, Darling S (2016) Membrane materials for water purification: design, development and application. Environ Sci Water Res Technol 2:17–42. doi:10.1039/c5ew00159e

Gandhi A, Paul A, Sen SO, Sen KK (2015) Studies on thermoresponsive polymers: phase behaviour, drug delivery and biomedical applications. Asian J Pharm Sci 10:99–107. doi:10.1016/j.ajps.2014.08.010

Liu Z, Wang W, Xie R, Ju XJ, Chu LY (2016) Stimuli-responsive smart gating membranes. Chem Soc Rev 45:460–475. doi:10.1039/C5CS00692A

Santoro S, Moro AJ, Portugal CAM, Crespo JG, Coelhoso IM, Lima JC (2016) Development of oxygen and temperature sensitive membranes using molecular probes as ratiometric sensor. J Membr Sci 514:467–475. doi:10.1016/j.memsci.2016.05.019

Christova D, Ivanova S, Ivanova G (2003) Water-soluble temperature-responsive poly(vinyl alcohol-co-vinyl acetal)s. Polym Bull 50:367–372. doi:10.1007/s00289-003-0178-4

Jung B, Yoon JK, Kim B, Rhee HW (2004) Effect of molecular weight of polymeric additives on formation, permeation properties and hypochlorite treatment of asymmetric polyacrylonitrile membranes. J Membr Sci 43:45–57. doi:10.1016/j.memsci.2004.06.011

Dave YG, Reddy AVR (2011) Preparation, characterization, acid stability and organic fouling of poly(acrylonitrile-co-methacrylic acid) ultrafiltration membranes. Desalination 282:9–18. doi:10.1016/j.desal.2011.08.055

Tang CC, Yun YB, Mao JC, Yu LZ, Wang LH (2010) Performance study on polysulfone-polyacrylonitrile blend ultrafiltration membranes. J Beijing For Univ 32:271–275

Slavova V (2013) Scientific research of the influence of the vacuum metalling over the operational characteristics of the ultrafiltering polymer. GJRA 2:40–41. doi:10.15373/22778160

Petrov St, Ivanova T, Christova D, Ivanova S (2005) Modification of polyacrylonitrile membranes with temperature sensitive. J Membr Sci 261:1–6. doi:10.1016/j.memsci.2004.12.029

Scott K Handbook of Industrial membranes, 2nd edn. Elsevier, Amsterdam

Lali BS, Kochkodan V, Hashaikeh R, Hilal N (2013) A review on membrane fabrication: structure, properties and performance relationship. Desalination 326:77–95. doi:10.1016/j.desal.2013.06.016

Jung B, Yoon JK, Kim B, Rhee HW (2004) Effect of molecular weight of polymeric additives on formation, permeation properties and hypochlorite treatment of asymmetric polyacrylonitrile membranes. J Membr Sci 243:45–57. doi:10.1016/j.memsci.2004.06.011

Aroon MA, Ismail AF, Montazer-Rahmati MM, Matsuura T (2010) Morphology and permeation properties of polysulfone membranes for gas separation: effects of non-solvent additives and co-solvent. Sep Purif Technol 72:194–202. doi:10.1016/j.seppur.2010.02.009

Lohokare H, Bhole Y, Taralkar S, Kharul U (2011) Poly(acrylonitrile) based ultrafiltration membranes: optimization of preparation parameters. Desalination 282:46–53. doi:10.1016/j.desal.2011.04.009

Hołda AK, Aernouts B, Saeys W, Vankelecom IFJ (2013) Study of polymer concentration and evaporation time as phase inversion parameters for polysulfone-based SRNF membranes. J Membr Sci 442:196–205. doi:10.1016/j.memsci.2013.04.017

Sun W, Chen C, Li J, Lin Y (2009) Ultrafiltration membrane formation of PES-C, PES and PPESK polymers with different solvents. Chin J Polym Sci 27:165–172. doi:10.1142/S0256767909003790

Malkin A, Lyin S, Roumyantseva T, Kulichikhin V (2013) Rheological evidence of gel formation in dilute poly(acrylonitrile) solutions. Macromolecules 1:257–266. doi:10.1021/ma301423u

Zhu G, Wang F, Xu K, Gao Q, Liu Y (2013) Study on properties of poly(vinyl alcohol)/polyacrylonitrile blend film. Polímeros 23:146–151. doi:10.4322/polimeros.2013.076

Hilbe W (2016) Stimulus-active polymer actuators for next-generation microfluidic devices. Appl Phys A 122:751. doi:10.1007/s00339-016-0258-6

Tokarev I, Minko S (2010) Stimuli-responsive porous hydrogels at interfaces for molecular filtration, separation, controlled release, and gating in capsules and membranes. Adv Mater 22:3446–3462. doi:10.1002/adma.201000165

Lokuge I, Wang X, Bohn PW (2007) Temperature-controlled flow switching in nanocapillary array membranes mediated by poly(N-isopropylacrylamide) polymer brushes grafted by atom transfer radical polymerization. Langmuir 23:305–311. doi:10.1021/la060813m

Xiao L, Isner A, Waldrop K, Saad A, Takigawa D, Bhattacharyya D (2014) Development of bench and full-scale temperature and pH responsive functionalized PVDF membranes with tunable properties. J Membr Sci 457:39–49. doi:10.1016/j.memsci.2014.01.033

Sadrzadeh M, Bhattacharjee S (2013) Rational design of phase inversion membranes by tailoring thermodynamics and kinetics of casting solution using polymer additives. J Membr Sci 441:31–44. doi:10.1016/j.memsci.2013.04.009

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miteva, M., Christova, D., Ivanova, S. et al. Effect of hydrophobically modified PVA on the temperature-responsive structure and permeation of PAN-based composite ultrafiltration membranes. Polym. Bull. 75, 2805–2817 (2018). https://doi.org/10.1007/s00289-017-2182-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2182-0