Abstract

This study continues the series of experiments that demonstrate the high antibacterial properties of monovalent copper ions (Cu+). While in previous study we examined different metals (copper and silver) and their metal states (mono- and divalent), showing that monovalent copper is best for controlling bacterial growth, the current study focuses on finding conditions which further enhance the antibacterial effect of monovalent copper. This approach may also shed light on mechanisms of Cu+ ions which still remain unknown. To this end, the influence of Cu+ ions on model gram-negative Escherichia coli bacteria at different pH levels with a variety of carbon sources and elevated temperatures was examined. It was found that in both aerobic and anaerobic conditions in a poor growth medium, Cu2+ ions barely suppress any growth of E. coli, whereas Cu+ ions even at very low concentrations dramatically deplete bacterial populations in a time scale of minutes at room temperature, and less than one minute at elevated temperatures. Acidic pH, unfavorable carbon sources, and elevated temperatures boost the antibacterial action of Cu+ ions. On the whole, the study confirms that monovalent copper ions are strongly superior to divalent copper ions in their antibacterial action across a wide range of tested conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The antimicrobial activities of copper are well recognized and have been exploited since ancient times for medicinal purposes [1]. The interest in anti microbial applications of copper has only increased over time. Currently, copper is widely used as a water purifier, fungicide, and bactericide. Plans to introduce copper into cotton fibers, polymeric materials, and clothing to provide them with biocidal properties were suggested more than a decade ago [2], and miscellaneous products are already on the market. Copper applications in healthcare environments might aid in fighting the bacterial contamination on solid surfaces and help limit the spread of multidrug-resistant bacteria in hospitals [3, 4]. All this makes an understanding of the causes of copper’s potency as an anti bacterial agent highly relevant.

In trace concentrations, copper is an essential intracellular element, while in excess it causes toxicity. Due to the ability of copper to exist in metallic and ionic forms, alternating between cuprous (Cu+) and cupric (Cu2+) oxidation states, its action on variety of microorganisms, from fungi to bacteria, is the subject of ongoing research; most of the mechanisms and intracellular targets of this action have not yet been elucidated [5]. For instance, in the case of yeasts, metallic copper surfaces with mediated toxicity target membranes, causing extensive membrane and envelope damage while not affecting DNA; this mechanism is known as a contact-mediated killing [6]. In the case of gram-positive bacteria, such as Staphyllococci, the molecular mechanisms that lead to cell death after contact with both moist and dry copper surfaces are the subject of ongoing debate. It has been reported that exposure of Staphylococcus aureus to copper causes cell death through DNA damage [7]. In addition, cellular respiration is compromised, with little effect on cell membrane integrity [8]. In contrast, other studies exploring the toxic effect of copper surface contact with Staphylococcus haemolyticus point to depolarization of the cytoplasmic membrane as the main mechanism, and suggest that degradation of DNA occurs only after cell death [9]. Regarding gram-negative bacteria, it has also been shown that E. coli O157 is rapidly killed on copper alloy surfaces [10]. The current model of a contact killing on dry surfaces characterizes this process as a cascade of events, such as successive cell membrane rupture and loss of cell content, influx of copper ions into the cells leading to oxidative damage and DNA degradation, although there are disagreements about the sequence of these events [11]. Nevertheless, in our opinion the role of dissolved copper in the killing process should not be underestimated.

In aqueous solution the common oxidation state of copper ion is divalent (Cu2+, cupric). Copper in a monovalent state (Cu+, cuprous) remains in disproportionately low amounts relative to Cu2+ and metallic copper, since it is unstable and rapidly reacts with molecular oxygen which oxidizes Cu+ to Cu2+. Never the less, it is possible to elevate the amount of Cu+ ions: high concentrations of Cu+ ions in a deaerated aqueous environment may be achieved and maintained by adding reagents, which form a more stable complex with Cu+ than with Cu2+. Acetonitrile [12,13,14], benzoic acid [15], and ATP [16] are good examples of Cu+ stabilizing reagents, which shift the existing equilibrium between oxidation states toward the formation of two Cu+ ions from one Cu2+ ion and metallic copper.

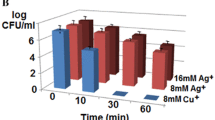

Our previous research [17] succeeded in exploiting this technique of Cu+ ions production, launching a series of studies devoted to investigating the antimicrobial effect of monovalent copper. We have clearly shown the superior efficacy of Cu+ ions over Cu2+ ions in killing E. coli and Staphylococcus aureus. Moreover, our studies have revealed that Cu+ ions had substantially higher efficacy than the Ag+ ions currently in wide use as an anti bacterial agent and effective at low concentration (below the known toxicity level for human) [18]. On the whole, our findings suggest that Cu+ should be considered as a potent antimicrobial agent.

The present study continues our investigation of the antibacterial properties of monovalent copper ions. To better understand the antibacterial action of Cu+, we are testing E. coli, grown in and adapted to different conditions prior to exposure to the copper ions. Most of the experiments are conducted under anaerobic conditions using syringes and penicillin bottle techniques, developed by us. We aim to investigate how Cu+ affects E. coli in different conditions, using M9 and LB broth media as well as saline, and under a variety of pH levels, carbon sources, and temperature regimes.

Materials and Methods

Microorganisms and Culture Media

Escherichia coli (NCIMB, str. K-12 substr. MG1655) was stored in vials with 50% glycerol at − 80 °C until use. The strain was grown either in Luria broth medium (LB broth and agar, Difco) or M9 medium. E. coli was grown in LB broth, typically containing 0.5% yeast extract, 1% bactotryptone, and 1% NaCl, for evaluation of the effect of copper ions on bacteria both in LB broth and saline. For obtaining a medium with controlled pH, the LB broth medium was adjusted to pH 5.0, 7.2, and 8.0, using 6 M HCl for acidic pH and 6 M NaOH for basic pH.

In the set of experiments investigating the effect of various carbon sources on copper ion anti bacterial activity, bacteria were cultured in M9 medium from the very start of these experiments. Typically, 1L of M9 medium contained 100 mL of 10X M9 stock solution, 20 mL of 20% carbon source, 1 mL of 1 M MgSO4 solution, 0.3 mL of 1 M CaCl2 solution, 1 mL of biotin (1 mg/mL), 1 mL of thiamine (1 mg/mL), 10 mL of 100X trace elements solution, and 867 mL DI water.

Preparation of Starter and Growth Methods

Preparation of Starter and Bacterial Growth in LB Broth Medium

LB broth was inoculated by an E. coli colony grown on LB agar. The starter was grown over night in a rotary shaking incubator (37 °C, 170 rpm). The following day, the starter was seeded into fresh LB media at 1:100 dilution and grown to OD600 0.3–0.4 for 2–3 h to bring the bacteria to an exponential growth phase. The resulting bacterial suspension was finally inoculated into fresh LB at 1:100 dilutions. For experiments with defined pH, the starter was grown at pH 7.2 and inoculated into the fresh LB medium with different pH values.

Preparation of Starter and Bacterial Growth in M9 Medium

All starters were grown in an M9 medium with 0.4% glycerol as a sole carbon source for the following reasons: glycerol-grown bacteria have the longest generation time among all the carbon sources used in our experiments, which allows us to lengthen the exponential phase of the starter. Moreover, when the starter is inoculated into a growth medium containing a preferable carbon source such as glucose and lactose, bacteria switch their metabolism to the new source, neglecting glycerol residuals.

Upon inoculation by an E. coli colony grown on LB Agar, the starter was grown for 2 days in a rotary shaking incubator (37 °C, 170 rpm).After this period of time, to guarantee the successful shift of the bacteria’s metabolism to a new carbon source, the starter was supplemented with one of three different 0.4% carbon sources, glycerol, lactose, and glucose, and returned to a rotary shaking incubator (37 °C, 170 rpm) for the next 15 min.

Syringes Technique

Syringes Technique for LB Broth

Bacterial starter was diluted 1:10 in pre-heated LB broth and placed into 50 and 100 mL sterile glass syringes (Ultrafit, Jenaer Glass; Superevaglass) supplemented with magnet bars. To ensure anaerobic conditions, nitrogen gas (UHP) was bubbled through a sterile filter into a glass syringe filled with LB broth. After inoculation, E. coli was grown in LB broth in glass syringes on a stirrer at 37 °C. Bacterial growth was controlled by checking OD600.

Syringes Technique for M9 Medium

Bacterial starter was diluted 1:10 in a pre-heated M9 fresh medium containing the required carbon source, and placed into 50 and 100 mL sterile glass syringes supplemented with magnet bars. Importantly, the starter to medium ratio (1:10) was chosen deliberately to allow the sufficient amount of metabolites, growth factors, and extracellular matrix proteins needed for successful bacterial growth. Deoxidation of syringes was not performed, since E. coli promptly utilized the oxygen remaining in the syringe, bringing the medium to anaerobic/microaerophilic conditions. After inoculation, E. coli was grown in M9 in glass syringes on a stirrer at 37 °C. In the two subgroups in which a switch to lactose or glucose was made, bacterial growth was controlled by checking OD400; the rise of OD values indicated the exit from lag phase. When glycerol was used as carbon source OD checking was not performed, since using the same carbon source in starter media and in syringes did not cause metabolic changes.

Preparation of Copper Ions Containing Solutions, and Exposure of Bacteria to Them

Production of Cu+ Ions in the Experimental Solution

Prior to E. coli exposure to copper containing solutions, Cu+ was produced, by starting with deaerated aqueous solutions containing a mixture of CuSO4 as the source for Cu2+ ions, metallic copper and100 mM acetonitrile as a stabilizing ligand, according to the reaction [12, 14]:

Noticeably, each Cu2+ results with two Cu+ ions in solution.

In certain experimental conditions, 10 mM ascorbic acid also acted as the reducing agent, according to the reaction:

Preparation of the Reference Solution Containing Cu2+ Ions

Since we intended to compare effects of Cu+ and Cu2+ on bacteria, the reference solution contained only Cu2+ ions and was lacking metallic copper and ascorbic acid. Thus, we prevented in situ production of Cu+ ions. Obtained deaerated aqueous solution contained 100 mM acetonitrile and CuSO4 at the concentrations of copper ions equal to the total amount of both copper ions in the solution with Cu+ ions described above.

Injection of Copper Solutions to the Syringes

Solutions containing Cu+ or Cu2+ ions were gently injected through a three-way syringe valve to syringes filled with LB broth or M9 medium containing bacteria, allowing maintenance of anaerobic conditions.

Bacterial Sample Collection and Analysis

Bacterial samples were probed at different time intervals from the syringes in the following manner: the syringe valve was opened, and the plunger was pressed to withdraw and discard the first 3–5 mL of solution. The next 1–2 mL of solution were poured into an empty sterile Petri dish and used for colony-forming units (CFU) counts. Bacteria were counted using a routine CFU technique, i.e., plating bacteria from serial dilutions onto LB agar and incubating overnight at 37 °C.

Penicillin Bottle Technique

In order to obtain a sterile and degassed saline, 8 mL of a sterile 0.9% NaCl solution was added to each penicillin 10 mL glass bottle. The bottles were loosely closed with sterile rubber corks, pre-heated in a boiling water bath for 10 min, and transferred to a hot plate. When the liquid started to boil, the bottles were removed from the hot plate and sealed with aluminum caps.

For the experiments, the bottles were warmed for 15 min in water baths of 20, 30, 40, and 50 °C to equilibrate the temperature, and 100 μL copper ions containing solutions (prepared as described above) with final concentration of 0.4 mM copper ions were injected through the rubber cork using a 1 mL disposable plastic syringe equipped with a 23G needle to avoid penetration of air oxygen. Then 100 μL of fresh E. coli suspension in LB broth was injected in the same way, vortexed and incubated in the water bath at corresponding temperatures. Bacterial samples for CFU counts were also collected using a disposable plastic syringe with a needle at the following time intervals: 1, 5, 10, 20, 30, 40, 50, and 60 min.

Decimal Reduction Time (D-value) Estimation

Decimal reduction time (D-value) is the exposure time required, under a defined set of conditions, to cause one log10 or 90% reduction in the initial bacterial population. In our study the D-values were calculated from log-linear curves of CFU counts over time that traversed at least one log cycle, with coefficients of determination (R2) not less than 0.9. The initial concentration of bacteria exposed to copper ions was equal to 106–108 CFU/mL at zero time. Each experiment was repeated three times before the determination of D-values by the survivor curves.

Results

Finding the Working Range and Critical Cu+ Ions Concentration for M9 Medium

Designing the series of experiments with M9 medium, we suspected that acetonitrile and ascorbic acid, required for Cu+ ions formation, could themselves cause some bacterial depletion. In our previous work conducted using LB broth medium it was shown that 100 mM acetonitrile and 10 mM ascorbic acid do not cause any considerable effect on bacteria [17]. But we cannot neglect the possibility that upon switching to an M9 medium these reducing agents may have a different impact on bacteria. To our understanding, complex nutrients, such as tryptone and yeast extract, present in LB broth, could help E. coli resist the possible antibacterial action of acetonitrile and ascorbic acid. Conversely, a poor M9 medium, lacking these components, cannot protect bacteria from any hazardous agents. Therefore, prior to starting experiments with copper, E. coli growth was checked in an M9 medium containing acetonitrile and ascorbic acid. Concentrations of 100 mM acetonitrile and 10 mM of ascorbic acid were found to be safe; these conditions were used in subsequent experiments and served as a control as well.

For estimating the working range of copper ions, E. coli starter was grown in M9 medium as described in the "Materials and Methods" section, and 0.4% glycerol was added to the starter prior to the experiment. Glycerol-based media was chosen for this evaluation, based on the assumption that glycerol is the most inappropriate carbon source for E. coli. Thus, it was expected that in these harsh conditions the copper ions would provide the maximal antibacterial effect, compared to other substrates.

For simplicity this experiment was done in aerobic conditions; hence syringes and techniques providing anaerobic conditions were not used. Erlenmeyer flasks of 100 mL volume containing 36 mL of M9 glycerol-based media were warmed to 37 °C and then 4 mL of bacterial starter was added into each flask. The flasks were sealed by sterilized cork, and after 5 min incubation at 37 °C different Cu+ or Cu2+ concentrations were added to the flasks. CFU count was checked at 0, 30, 60, and 120 min time intervals.

Basing on the results presented in Fig. 1, we considered a 0.2 mM concentration of copper ions as critical, since in the case of monovalent copper it killed the bacteria promptly, and in the case of divalent copper it started to show initial signs of antibacterial activity. Taking into account that in anaerobic conditions the antibacterial effect should be much stronger [19], an 0.1 mM concentration of copper ions was chosen for further research. At this concentration, Cu+ ions killed bacteria quite effectively, whereas Cu2+ ions did not have any pronounced effect.

Effect of Different Carbon Sources on Anti bacterial Activity of Cu+ Ions in an M9 Medium

To evaluate the antibacterial effect of copper ions on E. coli bacteria grown in a poor medium with a switchable carbon source, the syringe technique was used as described in the Materials and Methods section. The control syringes contained 10 mM ascorbic acid and 100 mM acetonitrile added to M9 medium. Experimental syringes contained 0.1 mM of Cu+ ions, obtained by mixing of 0.05 mM Cu2+ ions, metallic copper, 10 mM ascorbic acid, and 100 mM acetonitrile. For obtaining 0.1 mM Cu2+ ions, 0.1 mM Cu2+ ions were mixed with 100 mM acetonitrile.

Figure 2 presents the results of these experiments. As the figure shows, bacteria in all control syringes continue to grow, though in a low pace as expected due to the poor medium, proving that they are not getting killed by acetonitrile and ascorbic acid in the chosen working concentration. Addition of Cu2+ ions into the M9 medium in all three carbon sources groups slightly inhibits the bacterial growth, but on the whole, the number of viable cells remains like that of the control groups.

Log-linear plots of survivor curves for E. coli grown in M9 medium containing glycerol (left), lactose (middle), glucose (right), as carbon sources and exposed to copper ions versus control; control without copper (squares), Cu2+ (circles), Cu+ (triangles). Each value represents the mean of three replicates. Error bars show standard deviations

Strikingly different effects are seen when Cu+ ions are added to the M9 medium: rapid depletion of bacterial population occurs in all cases, with, notably, glycerol providing the fastest rate of decrease of E. coli, from 108 to 103 CFU/mL within 30 min. In the group utilizing lactose as a carbon source, the death rate is twice as slow. When glucose is used, the slowest death rate is seen; nonetheless, the same depletion level is achieved within 120 min. No viable bacteria were found after 60 min exposure to Cu+ ions in the group using glycerol as the sole carbon source, and after 120 and 180 min in M9 with lactose and glucose, respectively.

The obtained data enabled us to calculate D-values for E. coli grown on different carbon sources and exposed to Cu+ ions. D-value for bacteria grown on glycerol was the lowest (0.2 min), while those for lactose and glucose were substantially higher, 11.9 and 24.6 min, respectively.

Effect of pH on Antibacterial Activity of Cu+ Ions in LB Broth

To test the possible effect of pH on the antibacterial activity of copper ions, an LB broth adjusted to a pH of 7.2, 8, and 5 was used. The experiment was performed using the syringe technique described in the "Materials and Methods" section. As a control, E. coli was inoculated in syringes with LB broth containing acetonitrile only; in experimental syringes E. coli was inoculated to LB broths containing Cu+ or Cu2+ solutions, prepared as described above, both adjusted to an 0.2 mM final concentration. Notably, this concentration is twice higher than that used in experiments with the M9 medium, for reasons explained earlier in this article.

In Fig. 3, viable cell counts are presented. One may observe that in LB broth medium at pH values of 7.2 and 5, Cu2+ ions have very little effect on E. coli, with survivor curves similar to control groups. Regarding pH 8, we have found that Cu2+ was precipitating out of the solution, therefore we omitted this data.

Log-linear plots of survivor curves for E. coli grown in LB medium at pH values of 8.0 (left), 7.2 (middle), 5.0 (right), and exposed to copper ions versus control; control without copper (squares), Cu2+ (circles), Cu+ (triangles). Each value represents the mean of three replicates. Error bars show standard deviations

Conversely, Cu+ ions inhibited E. coli growth at all checked pH values. A moderate effect is seen in slightly basic conditions: at pH 8, after 4 h, the population growth was significantly inhibited, compared to thriving cells of control group. At neutral pH, a gradual death of population is observed; after 5 h's exposure to monovalent copper ions, less than 105 cells/mL remained alive. The most striking effect was obtained in acidic conditions. Cu+ ions were killing bacteria so fast, that even at the shortest time interval no live bacteria were observed. To be able to trace the kinetics of this process, we decided to inoculate 10 times more of the starter to the syringe and collect samples for cell counts more frequently. Results of these specific experiments are presented in Fig. 3: shortly after 30 min from initiating the experiment all bacteria were killed.

D-values for E. coli grown at three pH values and exposed to Cu+ ions were calculated; for acidic pH it was 0.29 min, which is almost 500 times less than D-values estimated for neutral pH (178.6 min) and more than 1000 times less than that for basic pH (500 min).

Effect of Elevated Temperatures on Antibacterial Activity of Cu+ Ions

To evaluate the effect of elevated temperatures on the antibacterial effect of copper ions on E. coli, bacteria were grown in LB at 37 °C; prior to the start of the experiment, the bacteria were inoculated at 1:100 dilution to fresh LB and grown at RT for the next 2 h. After this step, bacteria were injected into the bottled saline kept in a water bath at four different temperatures. Saline was chosen for this experiment as an inactive medium. 0.4 mM final concentration of copper ions was used to trace and compare effects of both divalent and monovalent copper on bacteria versus the control group. The results are summarized in Table 1, which presents D-values for E. coli incubated at various temperatures. Control bacteria, which were not exposed to copper ions, and kept in saline at 20, 30, and 40 °C up to 1 h, showed no decline in quantity; therefore, corresponding D-values could not be estimated in this time interval. The D-value for the control bacteria at 50 °C equaled 40 min. Exposure to divalent copper ions somewhat influenced bacteria survival in a temperature-dependent manner, but the effect of monovalent copper ions was several times as high, with its D-value of 6 min compared to that of 29 min for Cu2+ at 20 °C. At the temperatures of 30, 40, and 50 °C the killing rate was so rapid, that in samples collected at even 1 min of exposure to Cu+ no viable cells were found.

Discussion

To understand in detail the nature of the antibacterial activity of Cu+, we tested E. coli grown in and adapted to different conditions prior to exposure to the copper ions. Most of the experiments were conducted in anaerobic conditions, which are known to increase susceptibility to copper ions [19], using syringes and penicillin bottle techniques. We investigated how Cu+ affects E. coli in diverse conditions that included a variety of pH levels, carbon sources, and temperature regimes.

It is known that E. coli is tolerant to a wide spectrum of pH levels [20], but the initial pH can make bacteria more susceptible to other agents [21]. We found a mild influence of pH on the growth rate of E. coli and its generation time: at pH 7.2 the latter was 22.9 min, at pH 8 it was 24.6 min, while at pH 5 the generation time grew to 32 min. Thus, acidic pH prolongs the generation time by about 50% compared to neutral or slightly basic pH values. Figure 3 depicts the influence of copper ions on the viability of E. coli bacteria, grown at a controlled pH level before exposure to the copper ions.

In acidic conditions, the sensitivity to Cu+ is extraordinarily high and the impact of this antibacterial agent is strong and prompt: even if 10 times more inoculants were added to the medium, bacteria are killed within half an hour. Conversely, in basic conditions the influence of Cu+ ions at the tested concentration is the weakest, with CFU dropping by one order of magnitude after 5 h. At neutral pH the influence of Cu+ is moderate: CFU decreased by three orders of magnitude only after 5 h of exposure to the agent. Here it is worth mentioning that our previous results, published in [17], show that the E. coli population in LB medium (pH 7.2) containing Cu2+ ions was decreasing within 20 h by two orders of magnitude, whereas all bacteria were killed within 1 h in the group treated with Cu+ ions. The prior results fit the new data well, taking into account the fact that previously much higher copper ions concentrations were used, and the current experimental setup has also been slightly modified. [17].

It is very evident that in acidic conditions, at pH 5, Cu+ ions succeed in inhibiting E. coli population growth most effectively. To better understand why pH drastically influences the antibacterial activities of monovalent copper ions, we have to look into the processes taking place with the copper ions under these conditions. Both copper ions, Cu+ and Cu2+, are expected to precipitate in the basic environment, Cu2+ in the form of hydroxide salt (Cu(OH)2, Ksp2*10−19) and Cu+ as an oxide (Cu2O). Yet it is known that in the presence of acetonitrile Cu+ forms a soluble complex at pH 8 [12,13,14]. Presumably, Cu+ ions may partially precipitate at pH 8; despite this, no precipitation was observed in the tested media. It follows that the slightly reduced concentration of Cu+ at moderately basic pH cannot be the cause of the striking difference in its action in acidic and basic conditions, nor be the factor causing thes lower growth rate in less favorable growth conditions for bacteria.

Controlling the carbon source is another way to influence E. coli growth, generation time, and sensitivity to antibacterial agents. It is well known that a poor carbon source such as glycerol prolongs generation time in comparison with lactose and glucose, the latter being a preferred carbon source for bacteria [22]. Figure 2 shows a viable cell count of E. coli grown on glucose, lactose, or glycerol as carbon source after exposure to 0.1 mM Cu+ or Cu2+. We have found that under these conditions, Cu2+ ions have no pronounced effect. Conversely, Cu+ exhibited a potent antibacterial action even at a 0.05 mM concentration; the antibacterial effect of Cu+ is higher in E. coli utilizing glycerol as carbon source compared to lactose and glucose. From our data it is evident that bacteria adapted to glycerol as the sole carbon source are more vulnerable to the impact of antibacterial agents: Cu+ ions killed all bacteria in less than one hour in this group. When E.coli is adapted to grow on lactose, it takes at least twice as much time to eliminate them, and glucose grown E. coli can survive up to 3 h after exposure to Cu+ ions. Calculated D-values support this observation: for bacteria grown on glycerol D-values are 60 and 120 times lower than D-values of bacteria grown on lactose and glucose, respectively.

Elevated temperatures boost the effect of copper ions on bacterial cells. This effect was studied in "pure" conditions, where bacterial cells were exposed to copper ions in saline in attempt to minimize, if not exclude, the impact of biochemicals and nutrients which could mask the studied effects. In these series of experiments we have used a higher concentration of copper ions, in order to clearly distinguish between the vitality of bacteria exposed to each type of copper ion and the control bacteria. We have found that in the control group, bacterial cells were not affected by elevated temperatures of up to 50 °C, where only a slight reduction in live cells was observed. Cu2+ ions affected E. coli, with D-values varying from 29 min at 20 °C to 3.6 min at 50 °C. Expectedly, the effect of Cu+ ions was considerably higher: at temperatures of 30, 40, and 50 °C all bacteria were killed instantly upon addition of copper ions. Here we have to mention that according to the experimental design, bacteria were first grown in LB at 37 °C, then inoculated at 1:100 dilutions to fresh LB and grown at RT for 2 h. It is important to note that if bacterial cells were grown initially at the tested temperatures and had adapted to them, D-values might vary from those obtained in our current experimental conditions [23]. We presume that the anticipated shift in decimal reduction times of E. coli can help elucidate the mechanism of the antibacterial action of copper ions. To this end, the temperature adaptation effect on bacterial survival has become a subject of our ongoing research.

With respect to understanding the mode of action of the copper ions, we have to mention that OD measurements were conducted for bacterial samples collected for CFU counts. We have not noticed that a decrease in viable bacteria counts was followed by changes in optical density. To study this effect in more detail, we have examined dead bacterial cells after exposed to monovalent copper ions by light microscopy. Microscopy of the collected samples did not reveal cell damage or drop in cell quantity. This observation points to the absence of lysed cells and suggests that the antibacterial action of copper ions does not have a bacteriolytic character.

We suggest that the main reason for the effects of pH, carbon source, and elevated temperatures on the activity of Cu+ has to do with specific unknown molecular mechanisms waiting to be explored. We would like to suggest that Cu+ acts by interfering with the enzymatic metabolism, probably with energy production and utilization, since a poor carbon source such as glycerol limited the option of energy production. The fact that temperature enhances the rate of bacterial mortality kinetics implies that Cu+ may active as an uncompetitive inhibition of enzymes, which are crucial for bacterial functioning.

Conclusions

In this study we have confirmed that monovalent copper ion is strongly superior to divalent copper ion in its antibacterial action in a wide range of tested conditions. We have found conditions favoring further enhancement of the antibacterial effect of monovalent copper and have established that acidic pH and poor carbon source boost the action of Cu+ ions, whereas the influence of divalent copper remains moderate and independent of these factors.

We have determined the temperature conditions and copper concentrations that allow one to distinguish and study the antibacterial effect of monovalent and divalent copper ions on E. coli bacteria. In the stated conditions, both divalent and monovalent copper ions cause declines in the bacterial population, but the difference in their action is striking. Monovalent copper ions are able to drastically deplete the bacterial population in a minute’s time at room temperature; at elevated temperatures they kill all the bacteria immediately. Moreover, building on the premise that pre-adaptation to temperature by bacteria influences their survival, as well as on our preliminary results confirming this premise, in our future studies we aim to uncover the mechanism underlying the action of monovalent copper ions on both gram-negative and gram-positive bacteria.

References

Borkow G, Gabbay J (2009) Copper, an ancient remedy returning to fight microbial, fungal and viral infections. Curr Chem Biol 3(3):272–278. https://doi.org/10.2174/187231309789054887

Borkow G, Gabbay J (2004) Putting copper into action: copper-impregnated products with potent biocidal activities. FASEB J. 18:1728–1730. https://doi.org/10.1096/fj.04-2029fje

Casey AL, Adams D, Karpanen TJ, Lambert PA, Cookson BD, Nightingale P, Miruszenko L, Shillam R, Christian P, Elliott TS (2010) Role of copper in reducing hospital environment contamination. J Hosp Infect 74:72–77. https://doi.org/10.1016/j.jhin.2009.08.018

Mikolay A, Huggett S, Tikana L et al (2010) Survival of bacteria on metallic copper surfaces in a hospital trial. Appl Microbiol Biotechnol 87(5):1875–1879. https://doi.org/10.1007/s00253-010-2640-1

Lemire J, Harrison J, Turner R (2013) Antimicrobial activity of metals: mechanisms, molecular targets and applications. Nat Rev Microbiol 11:371–384. https://doi.org/10.1038/nrmicro3028

Quaranta D, Krans T, Santo CE et al (2011) Mechanisms of contact-mediated killing of yeast cells on dry metallic copper surfaces. Appl Environ Microbiol 77(2):416–426. https://doi.org/10.1128/AEM.01704-10

Michels HT, Noyce JO, Keevil CW (2009) Effects of temperature and humidity on the efficacy of methicillin-resistant Staphyllococcus aureus challenged antimicrobial materials containing silver and copper. Lett Appl Microbiol. 49(2):191–195. https://doi.org/10.1111/j.1472-765X.2009.02637.x

Weaver L, Noyce JO, Michels HT, Keevil CW (2010) Potential action of copper surfaces on methicillin-resistant Staphylococcus aureus. J Appl Microbiol. 109(6):2200–2205. https://doi.org/10.1111/j.1365-2672.2010.04852.x

Santo CE, Quaranta D, Grass G (2012) Antimicrobial metallic copper surfaces kill Staphylococcus haemolyticus via membrane damage. Microbiologyopen 1(1):46–52. https://doi.org/10.1002/mbo3.2

Noyce JO, Michels H, Keevil CW (2006) Use of copper cast alloys to control Escherichia coli O157 cross-contamination during food processing. Appl Environ Microbiol 72:4239–4244. https://doi.org/10.1128/AEM.02532-05

Grass G, Rensing C, Solioz M (2011) Metallic copper as an antimicrobial surface. Appl Environ Microbiol. 77(5):1541–1547. https://doi.org/10.1128/AEM.02766-10

Parker AJ (1973) Copper ions in acetonitrile. Search 4:426

Parker AJ, Macleod ID, Singh P (1981) Electrochemistry of copper in aqueous acetonitrile. J Solut Chem 10(11):757–774. https://doi.org/10.1007/BF00649487

Pang J, Ritchie IM, Giles DE (1975) The kinetics of copper dissolution in acetonitrile-water copper(II) solutions. Electrochim Acta. 20(12):923–928

Saphier M, Burg A, Sheps S, Cohen H, Meyerstein D (1999) Complexes of copper(I) with aromatic compounds in aqueous solutions. J Chem Soc Dalton Trans 11:1845–1849

Domenech A et al (2000) Electrochemistry of copper complexes with polyaza[n] paracyclophanes, Influence of ATP as an exogen ligand on the relative stability of the Cu(II) and Cu(I) oxidation states. Inorg Chim Acta 299:238–246. https://doi.org/10.1016/S0020-1693(99)00506-X

Saphier M, Silberstein E, Shotland Y, Popov S, Saphier O (2018) Prevalence of monovalent copper over divalent in killing Esherichia coli and Staphylococcus aureus. Curr Microbiol 75:426–430. https://doi.org/10.1007/s00284-017-1398-4

Abboud EC, Settle JC, Legare TB, Marcet JE, Barillo DJ, Sanchez JE (2014) Silver-based dressings for the reduction of surgical site infection: review of current experience and recommendation for future studies. Burns 40(Suppl 1):S30–S39. https://doi.org/10.1016/j.burns.2014.09.011

Outten FW, Huffman DL, Hale JA, O’Halloran TV (2001) The independent cue and cus systems confer copper tolerance during aerobic and anaerobic growth in Escherichia coli. J Biol Chem. 276(33):30670–30677. https://doi.org/10.1074/jbc.M104122200

Kim C, Wilkins K, Bowers M, Wynn C, Ndegwa E (2018) Influence of pH and temperature on growth characteristics of leading foodborne pathogens in a laboratory medium and select food beverages. Food Sci Nutr. https://doi.org/10.1002/fsn3.1034

Buchanan RL, Klawitter LA (1992) The effect of incubation temperature, initial pH, and sodium chloride on the growth kinetics of Esherichia coli O157: H7. Food Microbiol 9(3):185–196. https://doi.org/10.1016/0740-0020(92)80046-7

Aidelberg G, Towbin BD, Rothschild D, Dekel E, Bren A, Alon U (2014) Hierarchy of non-glucose sugars in Escherichia coli. BMC Syst Biol. 8:133. https://doi.org/10.1186/s12918-014-0133-z

Gabriel AA. (2012) Influences of heating temperature, pH, and soluble solids on the decimal reduction times of acid-adapted and non-adapted Escherichia coli O157:H7 (HCIPH 96055) in a defined liquid heating medium Int J Food Microbiol 160 (1):50–57.https://doi.org/10.1016/j.ijfoodmicro.2012.09.004

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Popov, S., Saphier, O., Popov, M. et al. Factors Enhancing the Antibacterial Effect of Monovalent Copper Ions. Curr Microbiol 77, 361–368 (2020). https://doi.org/10.1007/s00284-019-01794-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-019-01794-6