Abstract

As an important traditional blue dye, indigo has been used in food and textile industry for centuries, which can be produced via the styrene oxygenation pathway in Pseudomonas putida. Hence, the styrene monooxygenase gene styAB and oxide isomerase gene styC are over-expressed in P. putida to investigate their roles in indigo biosynthesis. RT-qPCR analysis indicated that transcriptions of styA and styB were increased by 2500- and 750-folds in the styAB over-expressed strain B4-01, compared with the wild-type strain B4, consequently significantly enhancing the indole monooxygenase activity. Transcription of styC was also increased by 100-folds in the styC over-expressed strain B4-02. Besides, styAB over-expression slightly up-regulated the transcription of styC in B4-01, while styC over-expression hardly exerted an effect on the transcriptional levels of styA and styB and indole monooxygenase activity in B4-02. Furthermore, shaking flask experiments showed that indigo production in B4-01 reached 52.13 mg L−1 after 24 h, which was sevenfold higher than that in B4. But no obvious increase in indigo yield was observed in B4-02. Over-expression of styAB significantly enhanced the indigo production, revealing that the monooxygenase STYAB rather than oxide isomerase STYC probably acted as the key rate-limiting enzyme in the indigo biosynthesis pathway in P. putida. This work provided a new strategy for enhancing indigo production in Pseudomonas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Indigo has been used as an important dye in food and textile industry for a long history [4, 7]. For centuries, the main source of indigo was extracted from plants. Until the end of nineteenth century, chemical synthesis displaced the traditional preparation method because of its advantage in production cost and yield [1]. However, chemical synthesis of indigo may give rise to environmental pollution and health issues due to the toxicity of the substrates, catalysts, and intermediates [13]. Hence, nowadays the natural dyes have been favored by more and more customers.

As is known, microbial fermentation is an effective and environment friendly way to produce various metabolites including the natural dyes. Thus far, the biosynthesis of indigo has been reported in various microorganisms including Pseudomonas sp., Acinetobacter sp., Bacillus megatreium, and so on [2, 3, 6, 9, 11]. Previous studies suggested that some Pseudomonas strains could generate indigo from indole by monooxygenase or dioxygenase, which is closely related to the host’s capacity of degrading aromatic hydrocarbon compounds [9, 14].

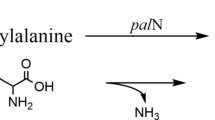

The pathway of indigo conversion from indole in Pseudomonas sp. has been previously proposed as shown in Fig. 1 [11]. The biosynthesis of indigo mainly consists of oxidization and dimerization reactions through two alternative branch pathways. On one hand, indole is first oxidized into indole oxide by monooxygenase; the oxide is then catalyzed into indoxyl by isomerase; two indoxyl molecules generates indigo by dimerization [10]. On the other hand, dioxygenase oxidizes indole into cis-indole-2, 3-dihydrodiol, which is then dehydrated into 3-oxindole and 2-oxindole; 3-oxindole and 2-oxindole turn to indoxyl and 2-hydroxyindole, correspondingly; indoxyl molecules generate indigo by homo-dimerization, and indoxyl plus 2-hydroxyindole could dimerize into indirubin at the same time [5, 15].

In this work, we isolated an indigo-producing Pseudomonas putida strain B4 according to the method described by Douky [3]. The strain B4 expresses high activities of monooxygenase and isomerase, which are encoded by the styrene monooxygenase (SMO) gene styAB and the styrene oxide isomerase (SOI) gene styC located in the styrene degradation gene cluster sty. Previous studies on the sty gene cluster mainly focus on its functionality for the styrene degradation [8, 12, 18]. The role of the sty cluster genes in indigo biosynthesis has rarely been further investigated so far. Our work demonstrated that over-expression of styAB significantly enhanced indigo production in P. putida B4, which probably revealed a new insight into the indigo biosynthesis in P. putida.

Materials and Methods

Strains, Plasmid, and Culture Conditions

Strains and plasmids used in this research are listed in Table 1. Escherichia coli (E. coli) strains were grown at 37 °C in Luria-Bertani (LB) medium with vigorous shaking as the cloning host. P. putida was cultured at 30 °C in LB medium with shaking. The antibiotic kanamycin was added at the concentration of 50 μg mL−1 when needed.

DNA Manipulation and Vector Construction

DNA manipulation procedure was performed as described by Sambrook and Russel [16]. Genomic DNA was isolated using TIANamp Bacteria DNA Kit (TIANGEN Biotech, CN) according to the manufacturer’s instructions. Plasmids was prepared using TIANprep Rapid Mini Plasmid Kit (TIANGEN Biotech, CN) following the manufacturer’s instructions. Restriction endonuclease digestion and DNA ligation were operated according to suppliers’ instructions (TaKaRa, CN). Introducing plasmid DNA to E. coli DH5α followed the procedures of standard heat shock transformation method [16]. Plasmid DNA was transformed into Pseudomonas by electroporation using an ice-cold electroporation cuvette with a 2-mm electrode gap, and the electric pulse was delivered by the Gene Pulser Xcell™ electroporation system (Bio-Rad, Richmond, CA) using the following parameter settings: 1.5 kV, 400 Ω, and 25 μF.

For vector construction, the styAB and styC genes were amplified with primers F-AB, R-AB, F-C, and R-C shown in Table 2 based on the styrene monooxygenase gene and the styrene oxide isomerase gene (GenBank accession no. DQ177365.1). PCR amplification procedures were performed using TaKaRa Ex Taq DNA polymerase following the suppliers’ recommendations (TaKaRa, CN). The PCR product was inserted into the multiple cloning site of the vector pBBR1MCS-2 to construct the recombinant vectors pBBR1MCS-2-styAB and pBBR1MCS-2-styC. The vectors pBBR1MCS-2, pBBR1MCS-2-styAB, and pBBR1MCS-2-styC were then transformed into P. putida B4 by electroporation, respectively.

Shaking Flask Fermentation

Pseudomonas putida strains were grown in LB media at 200 rpm at 30 °C for overnight. The fresh cultures were then inoculated into the fermentation media as described by Qu et al. [14], which was composed of 1.71 g Na2HPO4·12 H2O, 0.3 g KH2PO4, 0.1 g NH4Cl, 0.05 g NaCl, 0.01 g MgSO4, and 0.1 g yeast extract in 100 mL sterile water. The fermentation for indigo production was conducted at 30 °C at 200 rpm. Samples were collected at 4, 8, 12, 24, 36, and 48 h for measurement of indigo concentration.

RT-qPCR Analysis

For real-time quantitative PCR (RT-qPCR) analysis, total RNA was isolated from cells grown in the fermentation media using RNeasy Mini Kit (Qiangen, CN). Reverse transcription was carried out with primers (StyA-F&R, StyB-F&R, styC-F&R, and 16S-F&R) listed in Table 2 using the RevertAid First Strand cDNA Synthesis Kit (Thermo Scientific, CN) according to the manufactures instructions. qPCR was performed using SuperReal PreMix Plus (TIANGEN Biotech, CN) with following conditions: 95 °C for 5 min; 45 cycles of 95 °C for 10 s, 60 °C for 15 s, and 72 °C for 20 s. Relative quantification of gene expression was calculated using the 16s rDNA as the internal control gene.

Enzyme Assays

Indole Monooxygenase activity (IMO) was measured via the indole consumption. Cells were harvested by centrifugation at 10,000 rpm for 10 min, washed twice with 50 mM potassium phosphate buffer (pH 7.0), and resuspended in the same buffer containing 50 mM indole. For enzymatic reaction, 20 mL of suspension was transferred into a 50 mL tube and incubated in shaking water bath at 30 °C at 150 rpm for 30 min, and the indole depletion was monitored every 5 min. Samples were directly analyzed after filtration. 1 μmol of indole depletion in 1 min was defined as 1 unit (U) of IMO activity.

Measurement of Indole and Indigo Concentration

For indigo detection, 50 mL of the fermentation broth was centrifuged for 10 min at 9500 rpm to harvest blue pellets, which were collected and washed with water. Dimethyl formamide (DMF) was added to suspend indigo. The suspension was subjected to sonication for 5 min repeatedly and filtrated for determination.

Indigo and indole were quantified by a high-performance liquid chromatography (HPLC) system (Agilent 1290, USA) equipped with equipped with a Agilent Eclipse Plus C18 RRHD column (1.8 μm, 2.1 × 50 mm) and Diode array detector (DAD) at 610 nm. The mobile phase was water/methanol (10: 90, v/v) and the operating conditions were as follows: detection at 610 nm and flow rate of 0.2 mL min−1. All samples were analyzed in triplicate.

Statistical Analysis

The numerical data were expressed as mean ± standard deviation (SD). A One-Way ANOVA statistical difference was accepted as significant if 0.01 < p < 0.05 and extremely significant if p < 0.01 in this study.

Results and Discussion

Construction of Recombinant Over-Expression Vectors and Strains

The 1815-bp styAB and 510-bp styC genes were cloned from P. putida B4. Sequence analysis indicated that they shared a 100 % identity with the styrene monooxygenase and the styrene oxide isomerase genes (GenBank accession no. DQ177365.1) in P. putida. For over-expression of styAB and styC, the two amplicons were digested by KpnIand Hind III and inserted into pBBR1MCS-2, respectively, generating the 6.9-kb pBBR1MCS-2-styAB and 5.6-kb pBBR1MCS-2-styC. Then pBBR1MCS-2-styAB, pBBR1MCS-2-styC, and the empty vector pBBR1MCS-2 were introduced into the wild-type strain P. putida B4, respectively, generating recombinant strains B4-01, B4-02, and the control strain B4-0.

RT-qPCR Analysis of styAB and styC Genes

To investigate the transcriptional levels of styA, styB, and styC genes at different growth phases during indigo fermentation in P. putida strains, the cell growth was monitored as shown in Fig. 2. The growth curves indicated that the wild-type strain, control strain and recombinant strains shared a highly similar growth tendency during indigo fermentation under the same fermentation conditions. It revealed that introduction of the expression vectors hardly exerted a negative impact on cells growth in the indigo fermentation system.

The transcriptional levels of styA, styB, and styC genes in logarithmic and stationary phase’s cells were evaluated by RT-qPCR analysis. As shown in Figs. 3a, b, over-expression of styAB led to a 2500- and 750-folds higher transcriptional levels of styA and styB in strain B4-01, respectively. Besides, it is found that the transcriptional level of styA was obviously higher than that of styB when the two genes were co-over-expressed at the same time. The possible reason was that styA encoded an oxygenase while styB encoded a NADH-dependent flavin oxidoreductase subunit [17], which was obliged to bind to NADH and flavin sequentially [12]. Hence, the expression of styB was relevant and limited to the levels of NADH and flavin in cells. When styA and styB were co-over-expressed, the transcription level of styB might exhibit lower than that of styA. Additionally, the transcriptional levels of styC encoding styrene oxide isomerase was significantly up-regulated by about 100-folds in strain B4-02 (Fig. 3c), suggesting that styC was successfully over-expressed.

RT-qPCR analysis of mRNA expressions of styA, styB and styC in B4, B4-0, B4-01 and B4-02 strains. a The expression level of styA. b The expression level of styB. c The expression level of styC. B4, wild-type strain; B4-0, recombinant strain harboring the empty vector pBBR1MCS; B4-01, recombinant strain harboring pBBR1MCS-2-styAB; B4-02, recombinant strain harboring pBBR1MCS-2-styC. ** P < 0.01

Besides, it was noteworthy that over-expression of styA and styB led to slight up-regulation of styC expression in B4-01, but over-expression of styC hardly exerted an effect on the transcriptional levels of styA and styB in strain B4-02. The results revealed the transcription of styC was probably regulated by styAB. As styAB was expressed at a high level, the consequent strong IMO activity caused a rapid accumulation of intermediate styrene oxides, further leading to an increase of styC transcription.

Indole Mono Oxygenase Activity Assay

According to the growth curves, cells in the logarithmic and stationary phases of indigo fermentation were selected for indole monooxygenase activity determination, respectively. As shown in Fig. 4, in accord with the expression of styAB genes, a similar changing pattern of monooxygenase activity was observed in all four strains. And the monooxygenase showed highest enzymatic activity when cell growth reached the stationary phase after 12 h of fermentation. Besides, it is notable that strain B4-01 expressed the highest activity of indole monooxygenase at every detected growth phase, more than fivefold higher compared to the wild-type strain B4, the control strain B4-0, and the recombinant strain B4-02. Meanwhile, no obvious difference of enzyme activity was found among the strains B4, B4-0, and B4-02, suggesting that neither introduction of the empty vector pBBR1MCS-2 nor over-expression of styC exerted an effect on indole monooxygenase expression. In all, the results demonstrated that over-expression of styAB via pBBR1MCS-2-styAB led to a significant enhancement of the indole monooxygenase activity in host cells.

Indigo Production in Recombinant Strains

To investigate the effect of the styAB and styC genes on indigo biosynthesis, the wild-type strain B4, the control strain B4-0, and the recombinant strains B4-01 and B4-02 were continuously cultivated in fermentation media for 48 h, respectively. Indigo detection results (Fig. 5) showed that indigo accumulated rapidly as cell proliferated at the beginning in B4-01, reached the peak around 30 h of fermentation and then declined slowly. 52.13 mg L−1 of indigo was obtained in strain B4-01 after 24 h of fermentation, which was approximately sevenfold higher than that in strains B4, B4-0, and B4-02. In sharp contrast, the indigo yield in the recombinant strain B4-02 varied quite moderately and hardly exceeded 10 mg L−1 during the whole fermentation procedure, showing no significant difference compared with the wild-type strain B4 and the control strain B4-0. Obviously, under the same fermentation condition, the strain B4-01 not only produced a remarkable indigo yield but also presented a sharply higher indigo synthesis rate, which definitely resulted from enhanced monooxygenase activity by over-expression of the styAB gene. Besides, the yield of indigo in the recombinant strain B4-01 was significantly increased comparing to previous studies on indigo production in Pseudomonas, which was about 23.60 mg L−1 [11] and 3.54 mg L−1 [2], respectively. Although the styrene oxide isomerase encoded by styC is in charge of catalyzing the intermediate indole oxide into indigo, it is demonstrated that over-expression of styC hardly exerted an influence on the synthesis rate and yield of indigo. Therefore, it concluded that the monooxygenase STYAB rather than the oxide isomerase STYC probably acted as the key rate-limiting enzyme in the indigo biosynthesis pathway in P. putida B4.

Previous work revealed that styAB and styC encoded styrene monooxygenase and oxide isomerase and played a key role in the degradation of styrene through oxidation reaction. The present work demonstrated that the styrene monooxygenase STYAB can also catalyze oxidation of indole efficiently and consequently promoted indigo biosynthesis, revealing STYAB could be the key rate-limiting enzyme in the indigo biosynthesis pathway in P. putida. The reason probably dues to that the substrate indole for indigo synthesis shares a highly similar molecular structure with styrene, which could be recognized correctly and catalyzed by monooxygenase.

Indole can also be oxidized by dioxygenase and converted into indigo and indirubin at the same time [5, 12]. However, the presence of indirubin mixed with indigo in the final metabolic products would certainly give rise to extra difficulty in the separation and purification of indigo. Therefore, the gene styAB encoding monooxygenase was selected for over-expression. The genetic engineering strain has exhibited strong indole monooxygenase activity and high synthesis rate of sole indigo compound, which provided a new strategy for the bio-indigo production enhancement in Pseudomonas.

Conclusions

In this work, the styAB and styC genes located in the styrene degradation gene cluster were cloned and successfully over-expressed in P. putida for indigo production investigation. Over-expression of styAB significantly enhanced indole monooxygenase activity and consequently led to sevenfold higher indigo yield in the recombinant strain. But styC over-expression hardly exerted an effect on indigo biosynthesis. Our study revealed that the styrene monooxygenase encoded by styAB gene probably was the key rate-limiting enzyme for indigo production in P. putida. Taken together, based on the results of present study, styAB was a vital gene in bio-indigo synthesis process, which could be one of the applications to the industrial strains and fermentation systems in the future.

References

Bechtold T, Turcanu A, Geissler S, Ganglberger E (2002) Process balance and product quality in the production of natural indigo from Polygonum tinctorium Ait. applying low-technology methods. Bioresour Technol 81(3):171–177

Bhushan B, Samanta SK, Jain RK (2000) Indigo production by naphthalene-degrading bacteria. Lett Appl Microbiol 31(1):5–9

Doukyu N, Nakano T, Okuyama Y, Aono R (2002) Isolation of an Acinetobacter sp. ST-550 which produces a high level of indigo in a water-organic solvent two-phase system containing high levels of indole. Appl Microbiol Biotechnol 58(4):543–546

Erkan G, Şengül K, Kaya S (2014) Dyeing of white and indigo dyed cotton fabrics with Mimosa tenuiflora extract. J Saudi Chem Soc 18(2):139–148

Furuya T, Takahashi S, Ishii Y, Kino K, Kirimura K (2004) Cloning of a gene encoding flavin reductase coupling with dibenzothiophene monooxygenase through coexpression screening using indigo production as selective indication. Biochem Biophys Res Commun 313(3):570–575

Gillam EM, Aguinaldo AM, Notley LM, Kim D, Mundkowski RG, Volkov AA, Arnold FH, Soucek P, DeVoss JJ, Guengerich FP (1999) Formation of indigo by recombinant mammalian cytochrome P450. Biochem Biophys Res Commun 265(2):469–472

Han GH, Bang SE, Babu BK, Chang M, Shin H-J, Kim SW (2011) Bio-indigo production in two different fermentation systems using recombinant Escherichia coli cells harboring a flavin-containing monooxygenase gene (fmo). Process Biochem 46(3):788–791

Lin H, Qiao J, Liu Y, Wu Z-L (2010) Styrene monooxygenase from Pseudomonas sp. LQ26 catalyzes the asymmetric epoxidation of both conjugated and unconjugated alkenes. J Mol Catal B Enzym 67(3–4):236–241

Mercadal JP, Isaac P, Sineriz F, Ferrero MA (2010) Indigo production by Pseudomonas sp. J26, a marine naphthalene-degrading strain. J Basic Microbiol 50(3):290–293

Mermod N, Harayama S, Timmis KN (1986) New route to bacterial production of indigo. Biotechnology 4(4):321–324

O’Connor KE, Dobson AD, Hartmans S (1997) Indigo formation by microorganisms expressing styrene monooxygenase activity. Appl Environ Microbiol 63(11):4287–4291

Otto K, Hofstetter K, Rothlisberger M, Witholt B, Schmid A (2004) Biochemical characterization of StyAB from Pseudomonas sp. strain VLB120 as a two-component flavin-diffusible monooxygenase. J Bacteriol 186(16):5292–5302

Pathak H, Madamwar D (2010) Biosynthesis of indigo dye by newly isolated naphthalene-degrading strain Pseudomonas sp. HOB1 and its application in dyeing cotton fabric. Appl Biochem Biotechnol 160(6):1616–1626

Qu Y, Ma Q, Zhang X, Zhou H, Li X, Zhou J (2012) Optimization of indigo production by a newly isolated Pseudomonas sp. QM. J Basic Microbiol 52(6):687–694

Qu Y, Shi S, Zhou H, Ma Q, Li X, Zhang X, Zhou J (2012) Characterization of a novel phenol hydroxylase in indoles biotransformation from a strain Arthrobacter sp. W1. PLoS ONE 7(9):e44313

Sambrook J, Russell DW (2001) Molecular cloning—a laboratory manual, 3rd edition. Science 292(5516):446

Tischler D, Eulberg D, Lakner S, Kaschabek SR, van Berkel WJ, Schlomann M (2009) Identification of a novel self-sufficient styrene monooxygenase from Rhodococcus opacus 1CP. J Bacteriol 191(15):4996–5009

Tischler D, Kermer R, Groning JA, Kaschabek SR, van Berkel WJ, Schlomann M (2010) StyA1 and StyA2B from Rhodococcus opacus 1CP: a multifunctional styrene monooxygenase system. J Bacteriol 192(19):5220–5227

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NSFC, Grant Nos. 31571801 and 31401669) and Beijing Municipal Science and Technology Project (Grant No. Z151100001215008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, L., Yin, S., Chen, M. et al. Enhancing Indigo Production by Over-Expression of the Styrene Monooxygenase in Pseudomonas putida . Curr Microbiol 73, 248–254 (2016). https://doi.org/10.1007/s00284-016-1055-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-016-1055-3