Abstract

The chemical widths of grain and phase boundaries in deformed wehrlite (olivine–clinopyroxene; Ol–Cpx) aggregates are characterized by atom probe tomography (APT), a (laser-assisted) field evaporation technique employing time-of-flight mass spectrometry. The wehrlite was deformed to high finite strain in diffusion creep: The effective viscosity measured for the wehrlite is approximately an order of magnitude lower than that of either end-member aggregate; further, phase ordering, in which the spatial density of Ol–Cpx phase boundaries increases with accumulated strain, characterizes the deformation (Zhao et al. in Earth Planet Sci Lett 517:83–94, 2019). The mechanical results imply that the transport properties of the phase boundaries—dictated by their structure and composition—differ from those of grain boundaries. Our APT data show that, indeed, the chemical widths of crystalline Ol–Cpx phase boundaries—3.1–6.6 nm, depending on the element used for their characterization—are up to a factor of two greater than the chemical widths of crystalline Ol–Ol and Cpx–Cpx grain boundaries. Careful statistical analyses of the APT data reveal that the near-boundary compositional profiles of the presented Ol–Cpx phase boundary are consistent with—indeed, evidence for—the rheological model in which diffusion creep is rate-limited by the (mechanism-required) interfacial reactions at the Ol–Cpx phase boundaries. Such an analysis is unavailable by current electron beam/X-ray spectrometry approaches, which have not the requisite spatial precision. APT application to nanometer-scale problems in silicate petrology is challenging, particularly because signal overlap is caused by the evaporation of polyion species. We carefully outline the procedures used to acquire and discriminate the data in order to address the challenges of signal overlap.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction: grain and phase boundaries; diffusion creep; atom probe tomography (APT)

Grain and phase boundaries

In a polymineralic rock, the interfaces between grains of the same mineral (grain boundaries) and interfaces separating two different minerals (phase boundaries) affect the physical properties to first order. Examples are numerous: The mobilities of ions and atoms within boundaries can be several orders of magnitude higher than through the crystal lattices (e.g., Dohmen and Milke 2010), affecting the rates of chemical reactions as well as the electrical conductivity (e.g., Fisher 1951; Frost et al. 1989); relative sliding of grains on either side of a boundary contributes significantly to defining viscosity and effecting attenuation. The magnitude of any effect on rock dynamics is a function of the statistical distribution of structures of the boundaries.

Grain boundaries are recognized (and demonstrated via diffraction) as essentially two-dimensional (2-D) crystals composed of atomic/ionic bonds where the strain energy associated with lattice mismatch is ameliorated by a periodic arrangement of primary and secondary dislocations (e.g., Sutton and Balluffi 1995; Gottstein and Shvindlerman 2009). In chemically complex systems such as silicates, near (but below)-solidus temperatures can promote equilibrium variations of the 2-D boundary structure, known as complexions, which are associated with changes in bulk physical properties (e.g., Cantwell et al. 2014); these can include boundaries becoming amorphous—an equivalent of “premelting.” Our interests here, however, are in the lower-temperature regime associated with crystalline grain and phase boundaries.

The thickness or width of a grain boundary has been described in two ways: the structural width and the chemical width. Atomic and electronic transport across or along boundaries is affected by both the structural and chemical widths: Structure affects species mobility and concentration affects total flux (e.g., Schmalzried 1981; Gottstein and Shvindlerman 2009). The structural width is that described by the elastic distortions into the crystals on either side of the boundary, which are associated with the array of boundary dislocations. The structural width of boundaries and its relationship to the density of boundary dislocations has been carefully studied with X-ray (e.g., Budai et al. 1979; Carter et al. 1980) and electron diffraction (e.g., Carter et al. 1980; Ricoult and Kohlstedt 1983). The chemical width is that described by the spatial extent of chemical segregation to grain and phase boundaries, which is an equilibrium effect characterized by the thermodynamics of point defects, and specifically the balance among thermal, elastic and electrostatic forces among defects (e.g., Yan et al. 1983). To date, the chemical width of grain boundaries has been best characterized by analytical transmission electron microscopy (AEM employing energy-dispersive X-ray spectrometry—EDS), which has spatio-chemical uncertainties greater than the structural width, and, as such, establishes only an upper bound of the chemical width (e.g., Kohlstedt 1990; Hiraga et al. 2004; cf. Marquardt and Faul 2018). This being the case, it is not practicable to employ AEM/EDS to statistically characterize variations in boundary chemical widths associated, say, with local variations in chemical potential wrought by a deviatoric stress. Thus, the question arises: How can grain and phase boundaries in mantle materials be analyzed in order to correlate boundary composition and structure with the bulk physical properties?

Atom probe tomography

We report here on a relatively new approach to directly measure the chemical width of grain and phase boundaries—particularly as applied to nonmetallic geological materials—atom probe tomography (APT). As presented in greater detail within, APT involves the field evaporation of atoms/ions from a specimen initially fabricated into a submicrometer-dimensional needle and accelerating the evaporated, ionized species onto a position-sensitive ion detector, combined with single-ion time-of-flight mass spectrometry (e.g., Kelly et al. 2007). In metals and metallic alloys, one can characterize the exact locations of every atom (subject to detector efficiency) in the specimen and identify its speciation (including isotope); the large dataset can be reconstructed into a three-dimensional (3-D) volume for characterization. APT observations of geologically relevant silicates have heretofore primarily focused on zircons, elucidating the age of zircon crystallization at the ionic scale (Valley et al. 2014; Peterman et al. 2016). In needle specimens of metals that contain one or more grain boundaries, one can identify chemical segregations to the boundaries (e.g., Detor et al. 2007) and, too, to the cores of dislocations (e.g., Miller 2006). APT analysis of semiconductors and insulators—including minerals and rocks—is more difficult for two primary reasons: (1) Effective field evaporation is complicated by the large mechanical (dielectric) stresses accompanying the high electric field, which can cause the specimen to fragment, and (2) the evaporated/accelerated/detected species are not solely single ions but can include polyion species. The first problem has been addressed by the instrument developers by subjecting the needle tip to a picosecond-duration laser pulse while maintaining the electric field. The laser pulse has two effects: increasing the temperature and promoting electrons into the conduction band of the material; both serve to make the specimen more conductive and so less stressed at a given field (Bunton et al. 2010). The second problem is pernicious in that the ratio of mass to charge—the essential data for the detector in APT—may not be unique; that is, there can be signal overlap that makes the exact chemical composition difficult to determine. An illustration of this problem that is particularly applicable to peridotite assemblages is that 40Ca2+ (mass/charge ≡ m/c = 20) presents itself to the detector as identical to the polyion (24Mg–16O)2+ (m/c = 20). This second problem is an ongoing research concern that is being dealt with by many groups in ceramic materials science and petrology/geochemistry (including ours) through experimentation on variations of laser pulse rate, laser power and laser energy and, too, precise, discriminating analysis of data (e.g., Saxey et al. 2018b).

Wehrlite deformed in the regime of grain/phase boundary sliding

A recent deformation study of wehrlite (olivine–clinopyroxene aggregates; Ol–Cpx) deformed in diffusion creep isolated a clear instance of grain and phase boundaries having a primary effect on rheology (Zhao et al. 2019). We outline the mechanical and microstructural aspects of that work here as background for our investigation. The specimens have been deformed to high finite strain under differential stress–temperature–grain size conditions that promote deformation exclusively by grain and phase boundary sliding (GBS; PBS), i.e., there are no contributions to strain by the motion of lattice dislocations, to first order. This is the dynamics regime of mechanical response generally referred to as “diffusion creep” (e.g., Nabarro 1948; Herring 1950; Coble 1963; Raj and Ashby 1971). Under these conditions, wehrlite specimens deform far more rapidly—that is, their effective viscosities are approaching an order of magnitude lower—than pure olivine (dunite) or clinopyroxene (clinopyroxenite) aggregates of the same grain size. Additionally, the deformed wehrlite specimens see their microstructures evolve with continuing strain to optimize the density of olivine–clinopyroxene phase boundaries; that is, with strain, the phases are mixing, even to the point of ordering (cf. Tasaka et al. 2017). Combined, these observations prompt the investigation of the phase and grain boundaries at a fine enough scale to correlate the properties of the phase and grain boundaries with the material dynamics.

Applying APT to solid-state deformation

The use of rheological parameters to ascertain mineral physics at the atomic/ionic scale is a form of “remote sensing”; that is, the kinetic phenomena involved are a convolution of driving force (gradient in chemical/mechanical potential) and transport coefficient, which, itself, is a convolution of the concentration and mobility of active, mobile species. Modern, high-resolution analytical techniques, with their possibility of understanding structure and composition at the atomic level, facilitate the correlation of boundary characteristics at the nm scale with materials dynamics at the mesoscale (cm–m) to macroscale (m–km). This is an outstanding opportunity to apply APT to an important question in mantle dynamics: Phase mixing effects during deformation may well be critical to understanding the plastic instabilities required for creating and sustaining plate tectonics.

We approach the problem from an empirical perspective, seeking to employ APT to address the question(s) of potential structural/chemical differences between grain and phase boundaries in wehrlite that could correlate with the dynamic properties. In what follows, we present the approach to specimen preparation and data analysis, the latter with a perspective on application of APT to problems in mantle petrology. Grain and phase boundaries in wehrlite are demonstrated to be significantly different in terms of chemical width; further, chemical gradients near phase boundaries suggest the operation of reaction(s). We correlate both with the mechanical response.

Experimental/analytical approach

Specimen identification and preparation

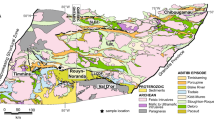

The wehrlite specimens studied (53% olivine, 41% diopside and 5% pigeonite by weight) were synthesized by the pulverization and mixing of natural materials followed by hot isostatic pressing. The source of olivine was San Carlos, AZ, peridot (Fo90). The clinopyroxene source was a lherzolite xenolith from Damaping, China: Optically clear grains of ~ 3 mm diameter were handpicked. Materials were powdered independently, each to particle size ≤ 3 μm; mixing of mineral powders was done under ethanol and the powder subsequently annealed in a controlled-oxygen-activity environment to remove adsorbed water and hydrocarbons. Hot isostatic pressing was done at 1100 °C and 1.5 GPa; subsequent plastic deformation was done at the same pressure and temperature conditions in simple shear at a controlled, constant rate: Specimens experienced a steady-state shear strain rate in the range 1.3 × 10–6 s–1 to 2.7 × 10–5 s–1. Specimens were deformed to shear strains between 2.8 and 5.4. Details of the specimen synthesis and of the rheological data and its reduction can be found in Zhao et al. (2019).

Samples for APT analysis were selected from thin sections cut from the center of the mechanical specimens. The sections were cut (low-speed diamond saw) such that the vectors of maximum shortening and maximum elongation define the planar surface of the thin section. Sections were subsequently epoxied to a petrographic slide, mechanically polished to 1-µm grit with alumina and chemically finished with 0.03-μm colloidal silica. The grain and phase boundaries selected for analysis were chosen for length and straightness. Position within the sample, orientation with regard to the applied stress or crystallographic orientations of the grains adjacent to the phase or grain boundaries were not a primary consideration during sample preparation. Nevertheless, noting the orientation of the boundaries “harvested” relative to the orientation of the stress tensor is important. Here, the Ol–Ol boundary is roughly perpendicular to the direction of primary shear, and the Ol–Cpx phase boundary is subparallel to that direction [Fig. 1: backscattered image (BEI) and secondary image (SEI) in scanning electron microscopy (SEM)].

Orientation of grain and phase boundaries in deformed wehrlite (Ol–Cpx) relative to the direction of shear (specimen W2047; shear stress direction σ12 noted with arrows). a, b BEI. The bright phase is Cpx, and the darker phase is Ol. c SEI taken at a 52° tilt. The traces of the grain and phase boundaries analyzed are depicted as dotted lines (curves); the trace of the FIB liftout is shown as a rectangle. Ol–Ol and Ol–Cpx tips were harvested from a single FIB liftout. The analyzed Ol–Ol interface is approximately perpendicular to the shear plane, and the analyzed Ol–Cpx tip is subparallel to the shear plane. d Schematic of the liftout region highlighted in c, showing the orientation of the APT tips for Ol–Ol and Ol–Cpx grain/phase boundaries relative to σ12

Focused ion beam methods

A critical prerequisite for APT is the shaping of a needle that contains the region of interest within the top several hundred nanometers. This is best performed with a focused ion beam electron microscope (FIB) equipped with ion sources (gallium ion for material ablation and an organic platinum source for welding materials at the nanoscale), an electron beam for imaging, and a nanomanipulator. The combination allows the operator to lift a sample from a specific location, weld the samples to silicon coupons designed for APT usage (CAMECA) and shape/polish the needles (e.g., Miller et al. 2007). Liftout for sample W2047 was performed on an FEI Helios 660 (Harvard University), and liftout of W2087 was performed at on a TESCAN LYRA 3 FIB (University of Alabama). Prior to liftout, the grain/phase boundary was marked with carbon or electron beam-deposited platinum to maintain a positional reference through needle shaping and polishing. Each liftout contains enough material to form into 4–6 needle-shaped specimens suitable for APT analysis. The data presented here were collected from three tips containing at least one grain or phase boundary (seven tips were effectively evaporated). Needle shaping was performed at 30 kV accelerating voltage by Ga-ion milling the liftout with a series of annuli of decreasing sizes while simultaneously decreasing the beam current gradually from 2.9 nA to 16 pA.

Progression of the tips during milling, as imaged in field emission scanning electron microscopy (FE-SEM) employing BEI and SEI, is presented in Fig. 2. Samples were milled with the intent of producing a needle comprised of a conical tip with a small shank angle atop a slightly tapered cylindrical column as shown in Fig. 2d. The goal of shaping the needle this particular way, i.e., with a long, narrow, conical base, is to minimize the increase in tip radius as APT evaporation proceeds. This geometry maximizes the number of evaporated ions while minimizing the increase in electrical potential that can lead to mechanical failure of the APT specimen. Two polishing steps were used: the first at 5 kV, 72 pA and a 50-nm-inner-diameter annulus and the second at 2 kV, 15 pA and no annulus. Efforts to characterize the crystallographic orientations of the minerals within the prepared needles by transmission Kikuchi diffraction were not successful due to the material’s apparent sensitivity to high electron beam currents.

Diagrammatic steps for milling of APT tips. From top left to bottom right are images of the W2047 Tip 3 through the shaping process. a BEI after initial annular milling; b BEI after annular milling with a 350 nm inner diameter. The bright “Pt Cap” on the tip is comprised of two parts: a slightly grayer FE-SEM-deposited platinum that serves to mark the grain boundary and a whiter, brighter FIB-deposited platinum that protects tip shape during continued ion milling. c SEI after initial polishing at 5 kV and 72 pA with 50-nm annulus. The platinum cap has been fully removed at this point, but milling has not proceeded past the grain boundary of interest. (The bright—top—and dark—bottom—vertical bands emanating from the very tip are charging artifacts from the imaging conditions.) d BEI after final polishing with no annulus at 2 kV and 15 pA. The tip shown in d was successfully evaporated, and 98 million ions were detected prior to APT tip failure

APT methods

Obtaining 3-D spatio-chemical data from a properly prepared specimen is contingent on the APT run conditions, the means of reconstructing the data and the assignment of chemical species to detected (poly)ions with a specific m/c. Samples were run in the APT in laser pulse mode. In this mode, a steady voltage is applied to the tip, and field evaporation is induced by imparting energy to the specimen tip with laser pulses. Laser energy was delivered in 12-ps pulses at a 100 kHz pulse rate at a spot size of 1.3 μm. Each pulse delivers 5–50 pJ of energy (laser wavelength of 355 nm). The sample was cooled at the base to 40 K which was empirically found to be the coldest temperature at which evaporation occurred evenly over time. A voltage was applied to the tip, which has a “sweet spot”: If the voltage is too little, field evaporation does not occur; if the voltage is too intense, the specimen fragments in the high-voltage field. Smooth evaporation typically began at 4–5 kV; the applied voltage was increased automatically through the atom probe user interface by fixing the desired yield of evaporated ions per laser pulse (here it was set to 1%) and letting the voltage increase to compensate for the increase in tip radius during evaporation. Tip failure occurred for these specimens typically at 6–8 kV; all tips were run to failure. The instruments employed, including the numbers of ions collected/counted and the detector efficiency, are presented in Table 1 and Supplementary Table A.

Tips were reconstructed in the CAMECA Integrated Visualization and Analysis Software (IVAS) using the tip shape profile from the FE-SEM images on the final shaped tips (i.e., immediately preceding evaporation, e.g., Fig. 2d). Reconstruction takes the raw data file, which contains the x and y detector position and the time at which each (poly)ion hits the detector; the result of the reconstruction is a 3-D dataset wherein each detected (poly)ion has a m/c ratio calculated from time-of-flight and x, y and z positions calculated from the assigned tip shape (reconstruction parameters available in Supplementary Table A). The m/c dataset is converted to chemical composition by assigning a charged (poly)ion to its likely m/c state (e.g., (MgO)1+ assigned to m/c = 40), taking account of the following known constraints: natural isotope ratios (de Laeter et al. 2003), the composition of both phases, and the dominant charge state for the field evaporation of the metallic species as calculated using the “image hump model” of field evaporation (Tsong 1978). The m/c range file (Table 2) isolates the most likely (poly)ion species. For example, m/c = 20 is assigned to the ion Ca2+ as opposed to the polyion (MgO)2+ because Ca2+ is the dominant evaporation state for calcium, and the isotopic signature of isotopologues (25Mg16O)2+ (m/c = 20.5) and (26Mg16O)2+ (m/c = 21) is not present in the data. The approach optimizes the likelihood that the Ca signal is attributed to Ca ions, even if some calcium ions actually evaporate as Ca1+ and are thus misidentified as (MgO)1+ (both m/c = 40). Completely eliminating ambiguities resulting from overlapping m/c ratios will require improvements in instrumentation (Saxey et al. 2018a). Polyion species are “deconstructed” into their component atoms, all of which must, by necessity, be assigned to the same location in the specimen. Application of the assigned polyion chemical composition to the 3-D position file creates a 3-D representation of the evaporated tip from which compositional data (in atomic percent) can be calculated by deconvoluting every polyion into their respective atomic species. The gallium signal was used to identify areas of the specimen that may have been contaminated during sample preparation by the ion beam; areas with an elevated gallium signal were discarded during reconstruction and account for no more than the outermost 10 nm of each tip. Bulk analysis of the tips, post-reconstruction, indicates that the detected ions from each tip comprise less than 33% of the total atoms within the original tip (Table 1).

Boundary chemical composition methods

We employed two approaches to discerning the chemical widths of boundaries, the results from which could be compared: the “1-D” and “proxigram” methods. In the 1-D method, we specify a subvolume of the specimen [i.e., of the (x, y, z) chemical data], either orthorhombic or cylindrical in geometry, that includes the grain/phase boundary of interest; one principal axis of the orthorhombic subvolume or the cylindrical axis is aligned perpendicular to the boundary. Compositions along the boundary normal are calculated as chemical averages in evenly spaced bins perpendicular to the normal. In the proxigram method, multiple irregular surfaces within the dataset are defined, each one as the locus of points (“vertices”) of constant calcium composition; the spatial separation of the proxigram isochemical surfaces can be discriminated in the data.

Calculation of chemical profiles via the proxigram approach is non-trivial: If the vertices comprising a proxigram surface are spaced too far apart, data resolution near to the grain/phase boundary is lost; if the vertices are too close together, processing artifacts due to data oversampling can dominate the result (Isheim et al. 2006). Our efforts in comparing the approaches indicate that (a) while the 1-D method results in higher uncertainties compared to the proxigram method due to counting statistics, the 1-D method is applicable confidently to straight (i.e., essentially planar) boundaries and/or boundaries with small chemical gradients and (b) the proxigram approach is preferred to discern compositional gradients normal to a curved (i.e., ribbonlike) boundary.

Analysis of the compositional profiles of specific grain and phase boundaries for the 1-D and proxigram methods are presented in Supplementary Material, Figs. A through F. For the Ol–Cpx phase boundary, proxigram surfaces employ a uniform vertex spacing of 3 nm; for the Ol–Ol boundary, the vertex spacing is 5 nm. In both cases, the closest spacing that minimizes processing artifacts is selected (Hellman, et al. 2000). The delocalization parameters in the x, y and z dimensions were 3.0 nm, 3.0 nm and 1.5 nm, respectively (IVAS default settings). Proxigram chemical profiles employ a 0.20 nm bin width normal to the isochemical surfaces; additionally, the profiles exclude any data within 1 nm of the exterior surface of the specimen reconstruction. The Cpx–Cpx grain boundary has chemical gradients that are too small for a confident proxigram analysis, necessitating the 1-D method. An oriented subvolume (60 × 40 × 50 nm, with the 50-nm axis perpendicular to the boundary) produces a robust chemical profile across the boundary. Similar to the proxigram approach, chemistries in the 1-D method were calculated with 0.20-nm bin spacing along the boundary normal and data within 1 nm of the exterior surface were excluded.

Results

APT analytical reconstructions

Selected projections of the 3-D APT analytical reconstructions for the Ol–Ol and Ol–Cpx boundaries in specimen W2047 are presented in Fig. 3; data for Al, Ca, Na and Cl are shown. In these images, each dot represents an identified atom and the data presented herein are in atomic percent; each polyion species has been separated into its atomic constituents. The projections presented are oriented nominally parallel to the boundaries, i.e., the trace of the boundary is seen. The grain/phase boundaries are imaged to have slight curvature, consistent with the microstructural images presented earlier (Fig. 1). For the Ol–Ol grain boundary, enrichment in the four elements is clearly evident; indeed, the enrichments (compared to concentrations in the grains on either side of the boundary) are necessary for identifying the boundary in the images. In addition to the elements presented, the boundary also demonstrates enrichment in P, K, Fe and Ni as well as a depletion of Mg. The Ol–Cpx phase boundary reconstruction shows clear enrichment of Cl; K and Ni also are enriched at the boundary. Further, the images reveal that, near the phase boundary, Cpx contains greater concentrations of Al, Ca, Na compared to olivine. A Cpx–Cpx reconstruction containing a grain boundary (Supplementary Fig. J) shows minor boundary enrichment of Al and Ca (Supplementary Figure E).

Selected APT analytical reconstructions from sample W2047 showing incompatible element enrichment at olivine–olivine and olivine–clinopyroxene boundaries. Slices from the 3-D reconstruction are oriented, so the vector normal to the planar surface lies within the plane of the page (i.e., traces of the grain/phase boundaries are perpendicular to the page). Al, Ca, Na and Cl are enriched at the olivine–olivine boundary; Cl is enriched at the Ol–Cpx boundary

Determining the chemical widths of grain and phase boundaries

The chemical widths of grain and phase boundaries reported here are specified in one of the two ways, depending on the shape of the chemical profile of interest. Grain boundary (Ol–Ol and Cpx–Cpx) chemical widths were determined by converting the atomic concentration data to cumulative fraction and calculating the intersection of the three linear segments (e.g., Ca enrichment at Ol–Ol grain boundary shown in Fig. 4a). This approach using cumulative fraction was also used for ions that are enriched in the phase boundary (e.g., Cl). For elements that partition into either olivine or clinopyroxene and are not enriched at the phase boundary, boundary chemical width is determined by “piecewise linearization” of the concentration data: Intersections of the three linear regressions (phase 1, phase boundary, phase 2) define the edges of the boundary (e.g., Ca concentrations at an Ol–Cpx phase boundary, Fig. 4b). Minitab 18 was used to process the linear fits (95% confidence intervals for slopes and intercepts) for each linear segment, which define the error bars of each boundary chemical width described.

a Determination of boundary chemical width for calcium (Ca2+, m/c = 20) at an olivine–olivine grain boundary via the 1-D analysis method. Cumulative concentration is calculated as a function of distance moving from left to right; the slopes of the lines shown represent a normalized (to unity) Ca concentration in atoms nm–1. b Determination of boundary chemical width of calcium at an olivine–clinopyroxene phase boundary via the proxigram analysis method. Dashed gray lines are linear fits for each segment of the cumulative data (a) or raw data (b). Standard error (SE) values represent the discrepancy between the linear fit and the data. The line segments intersect at two points which here define the chemical width of the boundary for ionic Ca. Error bars on individual datum, where visible, represent 1σ statistical error as determined from IVAS; if error bars are not shown, the errors are smaller than the data markers

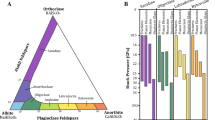

Determining chemical width via cumulative concentration data at grain or phase boundaries is used instead of estimates of the full width at half maximum (FWHM) although the results are similar between the two techniques. The FWHM method has been used previously for estimates of chemical width at Ol–Ol grain boundaries via X-ray spectroscopy in TEM (Hiraga et al. 2004). Cumulative concentration data are preferred because FWHM estimates require a model fit to the raw data or estimates of the total height and shape of the profile (particularly if the compositional profile is asymmetric), while cumulative determinations require no a priori assumptions. Examples showing the appropriate treatment of incompatible and compatible elements at grain boundaries analyzed by APT or FIM (field ion microscopy) can be found in the metallurgical literature (e.g., Krakauer and Seidman 1993; Isheim et al. 2006). Comparison of the boundary chemical widths using these statistical techniques is presented in Fig. 5; the chemical widths range between 2.5 nm and 6.5 nm, depending on what species is analyzed.

Boundary chemical widths discerned from different species, referenced to species’ atomic number. For all olivine-incompatible elements, the chemical widths of Ol–Cpx phase boundaries exceed that of Ol–Ol and Cpx–Cpx grain boundaries. The major component species Mg segregates away from Ol–Ol grain boundaries (boundary chemical composition indicates a deficit—Supplementary Fig. C); this is the sole case of a grain boundary chemical width determination exceeding that of a phase boundary. Error bars are 95% confidence interval predictions from the linear regressions (cf. Fig. 4); where not evident, the error bars are smaller than the symbol

Phase boundary chemical widths of Al, P, Cl, Ca and Ni are uniformly 40% wider (± 5%) than grain boundary widths, and the chemical width based on Na concentration is twice as wide in the phase boundary as compared to the grain boundary. Mg, which demonstrates a depletion at the Ol–Ol grain boundary, reveals a chemical width that is 50% greater than in the phase boundary (Fig. 5, Supplementary Table B).

Discussion

The APT data we collected and analyzed are here employed to identify and characterize the chemical physics involved in the enhanced rate diffusion rheology associated with Ol–Cpx phase boundaries in wehrlite. This application depends critically upon the statistics of APT data analysis as well as upon any physical artifacts associated with field evaporation and data collection by the instrument as they might impact our understanding (e.g., Exertier et al. 2018, for bulk ZrSiO4). As such, we initiate this discussion by addressing those data and instrument considerations; we follow with an examination of the impact of the APT results on our understanding of diffusion creep in wehrlite.

Potential artifacts from APT processing

Several potential sources of systematic errors during acquisition of APT data must be considered. Variations in evaporation field strength of dissimilar materials (including dissimilarities between bulk crystals and grain boundaries) result in a local magnification effect (Gault et al. 2012), which can apparently widen chemical profiles; the effect is exacerbated when the orientation of the vector normal to the grain boundary of interest is perpendicular to the long axis of the needle during evaporation (Blavette et al. 1996). All the interface analyses performed here are oriented such that the vector that is normal to the semi-planar interfaces is at relatively high angles to the long axis of the needle (Ol–Ol interface: 69°, Ol–Cpx interface: 75°–85°, Cpx–Cpx interface: 80°–60°). The relatively high angle of the interface normal is partially due to the necessity of identifying the boundary prior to liftout and partially to ensure the coherence of the tip during field evaporation. The wider chemical profiles characterized for Ol–Cpx phase boundaries compared to those of grain boundaries may partially arise from local magnification effects but is unlikely to be solely an effect of local magnification across all elements given two observations. Firstly, the Mg profile for the Ol–Cpx phase boundary is considerably narrower than its profile for the Ol–Ol grain boundary—i.e., not all elements are wider across the Ol–Cpx boundary. Secondly, the Na profile is approximately twice as wide in the Ol–Cpx phase boundary compared to the Ol–Ol grain boundary, while most other incompatible elements are only 35–45% wider in the phase boundary compared to the grain boundaries. The grain boundary energies of olivine–pyroxene boundaries and olivine–olivine boundaries are within 5% of each other, suggesting that the structure of our phase and grain boundaries are not so different that local magnification effects would dominate one boundary, but not the other (Fujii et al. 1986). The conductivities of olivine and clinopyroxene are believed to be similar enough that we do not expect any major gradients in electrical properties across the mineral interfaces (Xu and Shankland 1999). Explicitly stated, the “real” chemical width is almost certainly narrower than what we measured here; nevertheless, we are primarily concerned with relative chemical widths, given that both grain and phase boundaries are subject to what we argue are similar amounts of local magnification.

Secondly, determination of composition depends on the range file used. Although great care is taken to minimize the convolution of major element data with the chemical profile of elements enriched at grain/phase boundaries, post-processing of data can suggest high or low absolute values (some considered perhaps surprising) for some elements, which is a result of mass interferences. In theory, then, erroneous chemical widths can result from conditions where the ranged ion of interest is dominated by an overlapping polyion species having the same m/c. Although the bulk chemical composition of APT analysis is less accurate than common X-ray or electron emission micro-analytical techniques, the chemical boundary width of incompatible elements observed at grain or phase boundaries does not change with the accuracy of the concentration profile as long as no other enriched species dominate the signal. For example, the width of chemical segregation for Al is not impacted if only half of the Al atoms are ranged as Al3+. As an example, ranging the m/c = 28 signal as the (AlH)1+ polyion, instead of the Si1+ ion, will result in an aluminum profile dominated by the silicon signal. This will result in a compositional profile which is dominated by the silicon signal, improperly ranged as (AlH)1+. Although ranging m/c = 28 as Si1+ may result in erroneously high composition across the analytical profile due to the presence of some (AlH)1+ polyion, the chemical width of the silicon profile would still not be impacted as long as (AlH)1+ does not dominate the signal. Since extremely precise spatial data are required to determine chemical boundary widths but accurate composition is not necessarily required, mass interferences are not believed to negatively impact the analysis here. For ions with several charge states determined within the range file [e.g., (AlH)1+,2+,3+ and (AlOH)1+,2+ overlapping with (Si)1+,2+,3+ and (SiO)1+,2+, respectively], the belief that mass overlaps do not negatively impact the analysis is testable and is affirmed by computing the Al or Si profile using a subset of the total ranged Al or Si ions and confirming that the chemical width of the boundary remains effectively unchanged. Ionic species ranged with singular charge state overlaps [e.g., Ca2+ overlapping with (MgO)2+] are assumed to have the proportion of overlapping ions remain approximately equal across the grain boundaries. Future innovations in hardware are expected to enable deconvolution of overlapping m/c ratios, improving the accuracy of chemical composition while maintaining spatial precision (Saxey et al. 2018a).

Diffusion creep in wehrlite and the anticipated chemical signature at phase boundaries

Diffusion creep occurs because spatial variations of the normal tractions (stresses) on grain boundaries result in grain-scale gradients in chemical potential, which are manifest physically as spatial variations in the concentrations of point defects (Nabarro 1948; Herring 1950; Coble 1963). Chemical diffusion persists as long as a deviatoric stress persists. This diffusion results in both transient and permanent strains; the transient strain is anelastic and is a primary cause of (seismic/subseismic) low-frequency attenuation of elastic waves (e.g., Gribb and Cooper 1998). Diffusion creep acts independently (that is, in kinetic parallel) from dislocation creep, although, in that diffusion creep dynamics are a part of grain boundary sliding, there exists a “window” of thermodynamic/microstructural conditions in which both mechanisms cooperate—the so-called DisGBS dynamic (e.g., Warren and Hirth 2006) that is frequently associated with superplasticity.

As conventionally understood, diffusion creep constitutes three kinetic processes that act dependently (i.e., in series): two interfacial reactions—complementary point defect reactions, one each at the high-traction and low-traction boundaries—and chemical diffusion between these boundaries, the characteristic length scale for the diffusion being the grain size. Deformation kinetics, thus, are very sensitive to atomic/ionic mobility; as such, grain boundary diffusion frequently dominates such kinetics in mineral systems (e.g., Kingery et al. 1976, Ch. 6; Dohmen and Milke 2010). In a monomineralic system, the grain-scale diffusive motion of all constituent atomic/ionic species is required and, in the case of rate limitation by the diffusion process, the slowest moving species dictates the kinetics. In silicates, this is generally understood to be the diffusion of Si4+ along grain boundaries (e.g., Hirth and Kohlstedt 1995). Since the transport coefficient for diffusion is a product of species concentration and mobility (e.g., Schmalzried 1981, Ch. 5), the chemical width of a boundary is of first-order importance to the kinetics of grain boundary diffusion creep. Interestingly, recent work on olivine deforming in diffusion creep indicates that the composition of the grain boundaries influences the rheology of olivine aggregates, with incompatible segregants lowering the viscosity (Marquardt and Faul 2018); the mechanism for such weakening in olivine with the addition of grain boundary impurities is unclear.

Diffusion creep that is rate-limited by grain-scale diffusion along grain boundaries is characterized by a steady-state strain rate that is linearly proportional to stress and inversely proportional to the cube of grain size [i.e., \(\dot{\varepsilon }\propto \sigma^{n} /d^{m}\), where ε is inelastic strain, the superposed dot indicating the first derivative of time, σ is differential stress, d is grain size, n = 1—Newtonian—and m = 3 (Coble 1963; cf. Raj and Ashby 1971)]. Our mechanical experiments on wehrlite, however, demonstrate n = 2 and m = 1 (Zhao et al. 2019). Given the absence of dislocations, and the absence of glass at boundaries and junctions in our specimens, both confirmed by transmission electron microscopy (Zhao et al. 2019), this kinetic signature remains consistent with diffusion creep, but, importantly, it is being rate-limited by one of the interfacial reactions (Arzt et al. 1983; Wheeler 1992; Sundberg and Cooper 2008).

Clearly, the mechanism(s) governing the deformation of the polymineralic Ol–Cpx assemblage differs from that of monomineralic Ol and Cpx aggregates. From the perspective of boundary-dominated chemical kinetics, diffusion creep/grain boundary sliding in wehrlite is actually about three “phases”: Ol–Ol grain boundaries, Cpx–Cpx grain boundaries and Ol–Cpx phase boundaries. Following the general philosophy of non-equilibrium thermodynamics, which emphasizes the tendency of systems that are sustained away from equilibrium to evolve to a texture that (while subject to one or more kinetic constraints) most efficiently dissipates the added energy at steady state (e.g., Kondepudi and Prigogine 1998, Ch. 17), the fact that the wehrlite specimens tend toward phase ordering with continued strain in diffusion creep indicates that phase boundaries are favored kinetically. Given the physics of diffusion creep, the enhanced kinetics can reflect the interfacial reactions, the diffusive transport, or both. One clue to the effect of phase boundaries is revealed in the stress sensitivity of the effective viscosity (to be described within); another clue is perhaps available through studies of boundary width and chemical composition.

The presence of two mineral phases in nominal chemical equilibrium creates a dynamic whereby the slowest-moving ionic species, specifically Si4+ as noted earlier, need not diffuse a long distance to effect diffusion creep. An application of solid-state reaction theory and experiment (e.g., Schmalzried 1981, Ch. 6; cf. Sundberg and Cooper 2008), the dynamic for a mixture of forsterite and diopside is illustrated in Fig. 6. The Ol–Cpx system described in Fig. 6 is similar to the system described in Sundberg and Cooper (2008), the difference being that the Cpx contains olivine-incompatible elements as major compositional components. At phase boundaries of relative compressive traction, the wollastonite (i.e., CaSiO3) component of diopside reacts with forsterite to create diopside and “release” MgO (i.e., Mg2+ and O2–) for grain-scale chemical diffusion:

at phase boundaries of relative tensile (or less compressive) traction, the “arriving” Mg2+ and O2– react with diopside to produce forsterite:

One sees that the overall reaction has ΔrG0 = ΔrG0(1a) + ΔrG0(1b) = 0. The elastic strain energy density associated with the deviatoric stress drives the two half-reactions, which cancel out: Consistent with an understanding of plastic flow, all of the elastic strain energy density is dissipated as heat. (For completeness’ sake, we note that the addition of FeO—i.e., to make olivine–clinopyroxene aggregates of appropriate chemical composition—is consequential, but of secondary importance to the dynamic.)

Schematics of diffusion creep in wehrlite (olivine [Ol]-clinopyroxene [Cpx]). a Application of a far-field shear stress (σ12) sees normal tractions on grain and phase boundaries vary between tensile and compressive, which effects locally the chemical potentials of component oxides. Because of the change in volume of the phases, a potential exists to convert Ol to Cpx at compressive traction interfaces; at the complementary tensile traction interfaces, the potential exists to convert Cpx to Ol. The two reactions (Eq. 1a and b) have Gibbs energies that sum to zero; the elastic strain energy associated with σ12 is dissipated, through creep, as heat. Mass and volume are conserved. b Schematic of reaction-affected diffusion creep during deformation. Phase boundaries migrate opposite the direction of shear; grain boundaries migrate but remain passive to the reactions. Fluxes of material occur along grain boundaries, phase boundaries and within the grains (lattice diffusion) to affect the flow. Critical to the kinetics is the fact that the coupled reactions means that Si4+ need not diffuse, to first order

There are a number of points to comprehend regarding reactions (1a, 1b) and Fig. 6:

-

a.

While the activities of CaMgSi2O6 (diopside) and Mg2SiO4 (forsterite) in the creep experiment are high, approaching unity (these are the crystalline phases present in the aggregate), the activities of CaSiO3 and MgO are quite low: Activities of CaSiO3 and MgO can be considered from the perspective of Ca2+ and Mg2+ point defects, respectively.

-

b.

The transformation of forsterite into diopside [reaction (1a)] and then diopside into forsterite [reaction (1b)] at complementary forsterite–diopside phase boundaries means that Si4+ needs only to diffuse across the boundary, i.e., a distance measured in nanometers.

-

c.

The sense of the reaction, that is, association of reaction (1a) with the more compressive traction, becomes clear by considering the change in volume: ΔrV(1a) = –6.2 × 10–6 J Pa–1 (≡ m3).

-

d.

That the reactions involve the CaSiO3 component as either reactant (1a) or product (1b) means that, at the interface where the reaction occurs, the clinopyroxene solid solution is made inhomogeneous (Fig. 6b). Re-homogenizing the clinopyroxene solution, thus, is a requirement for the reaction to continue; this is the “source” of the reaction limitation in the diffusion creep kinetics. The re-homogenization of the clinopyroxene solution can occur by both lattice diffusion in the clinopyroxene and Ca2+ diffusion along the phase boundaries (both are suggested in the figure); that the kinetic signature of the creep indicates reaction limitation suggests that re-homogenization is dominated by lattice diffusion.

-

e.

Impurities that are relatively incompatible in olivine can affect the reaction kinetics as well in that they would be concentrated in the phase boundary associated with reaction (1b). Their homogenization into the clinopyroxene solution can also affect the rate of the interfacial reaction. [This aspect was critical in understanding diffusion creep and phase ordering in harzburgite (Sundberg and Cooper 2008).].

Consider the re-homogenization of the clinopyroxene, as described in point (d). A potential chemical signature that this reaction is occurring accompanying creep, and which would be strong corroborating evidence for interface reaction control of the deformation dynamic, is complementary gradients in the Mg2+ and Ca2+ contents of the clinopyroxene near the phase boundary. Specifically, at boundaries having a relatively high compressive traction, where olivine is converted into clinopyroxene (Eq. 1a), the Mg2+ content would exceed that of the Ca2+, and moving deeper into the Cpx, one would see the Mg2+ content diminishes as the Ca2+ content increases. Further, at the higher-traction boundary, conversion of olivine into clinopyroxene would produce an excess of Si4+ compared to Al3+, because the olivine contains very little Al3+: Complementary gradients of Si4+ and Al3+ into the Cpx are anticipated. The mirror image for concentrations and gradients would occur at the phase boundaries experiencing a relatively low compressive traction [i.e., where Cpx is transformed into Ol, Eq. (1b)].

Application of the APT results to the deformation problem

An examination of the APT data presented in Fig. 4b reveals a gradient in the Ca signal moving from the phase boundary into the clinopyroxene, i.e., the Ca level is lower near to the phase boundary (but still within the Cpx) than it is deeper in the Cpx. The increase of Ca with depth into the Cpx phase is shown statistically in Fig. 4b as the y3 slope, a measure of the change in atomic percent of Ca with respect to distance in nanometers. The Mg signal is observed as the complement to the Ca signal: Mg is in excess at the boundary compared to at depth in the Cpx (Supplementary Figure A). Further, the signal for Si at the phase boundary is seen as excess to that at depth in the Cpx, while the signal for Al is its complement. Relative to the points made in the previous paragraph, we argue that this chemical signature is evidence of the reaction Eq. (1a): At this phase boundary, deformation is transforming olivine into clinopyroxene. The requirement, relative to the deformation dynamic, is that this phase boundary is one of the relatively high normal compressive tractions. Referring to Fig. 1d, where the geometry of the Ol–Cpx phase boundary relative to the applied shear stress σ12 is presented, one sees that the component of the applied shear stress normal to the boundary is compressive: The analysis is fully consistent.

That the gradients in Ca2+ (Mg2+) and Si4+ (Al3+) in Cpx near the phase boundary are resolvable physically is due to the difference of the diffusion coefficients between the phases. For example, calcium diffusion is one to two orders of magnitude slower in Cpx than in Ol (e.g., Chakraborty 2010; Zhang et al. 2010). That the near-phase boundary chemical gradients in Cpx are resolvable analytically is a profound illustration of the power of APT in doing petrology at the nanometer scale: Electron beam/X-ray emission spectrometry techniques cannot resolve spatially these fine differences in chemical composition, particularly considering that grain and phase boundaries are frequently curved (i.e., ribbonlike).

Other grain boundary phenomena perhaps amenable to study by APT

There are a number of obvious directions to extend the application of APT to grain boundary chemistry and physicochemical processes in mantle materials.

The chemical widths of boundaries in ionic/covalent solids depend on the play-off of mechanical, electrical and thermal potentials, as indicated in “Grain and phase boundaries.” In polycrystalline nonmetals at equilibrium (i.e., not experiencing a deviatoric stress), near-grain boundary regions are characterized by a diffuse buildup or deficit of point defects—true even for the highest purity of materials (e.g., Kliewer and Koehler 1965); these “clouds” of charged defects can affect the rates of internal transport processes like electronic conductivity, dielectric strength and ionic diffusion. APT should be able to resolve the dimensions of this cloud in specimens that are quenched; indeed, the chemical gradients we characterized in our specimens can be directly related to this space charge effect. A deviatoric stress will distort the defect cloud; indeed, the presence of the cloud and its electrostatic properties can act as a spring, perhaps effecting threshold phenomena in creep (e.g., Jamnik and Raj 1996) and, particularly, in attenuation (e.g., Cooper 2002). We expended significant effort to perform APT grain/phase boundary analyses on tips prepared from the non-deformed, hot isostatically pressed wehrlite, so as to discern, by comparison, the effect of deviatoric stress on the near-boundary chemical width and composition. These attempts were all failures: Specimens are fragmented in the high electric field prior to successful evaporation. We believe the cause of mechanical weakness of the tips is remnant nm-scale voids that are present on the boundaries (but which are displaced from the boundaries in the process of high strain deformation in diffusion creep). We are engaged in developing a vacuum hot pressing protocol that we hope will alleviate this problem.

Recent experiments suggest that even modest amounts of incompatible elements, segregated to grain boundaries, reduce the diffusion creep viscosity of polycrystalline olivine (Marquardt and Faul 2018). The result is surprising in that decades of research on creep of oxide ceramics suggest the opposite to be true, i.e., that grain boundary segregants increase the diffusional viscosity and, too, the temperature sensitivity of creep (e.g., Cho et al. 1997). Careful APT study of the chemical widths of boundaries in high-purity synthetic olivine and in appropriately doped material could aid understanding.

There is ample evidence that diffusion creep to high strain can produce crystallographic preferred orientation (fabric) (cf. Wheeler 1992; Bons and den Brok 2000; Sundberg and Cooper 2008), depending on the thermodynamic conditions of deformation. This indicates that grain and/or phase boundary dynamics are anisotropic, as has been beautifully illustrated recently via measurements of electrical conductivity (Pommier et al. 2018). Application of APT to issues of fabric and its development with deformation are clearly suggested.

Conclusion

We applied APT to characterize the chemical widths of grain and phase boundaries in wehrlite that was experimentally deformed in diffusion creep to high strain. Careful, statistically vetted analyses demonstrate (a) that olivine–clinopyroxene (Ol–Cpx) phase boundaries have chemical widths that exceed those of Ol–Ol and Cpx–Cpx grain boundaries up to a factor of two and (b) that distinct chemical gradients, over distances of ~ 20 nm from the phase boundary, are present in the clinopyroxene. Both results are evidence for a deformation dynamic in which diffusion creep is rate-limited by one (or both) of the interfacial reactions that transform olivine into clinopyroxene—or vice versa—at stressed phase boundaries. Only the spatial precision of APT allows this characterization.

Application of APT to problems in mantle petrology involves care in discriminating the (poly)ion species used in the range table. We outline the challenge in the manuscript: Discrimination based on the presence or absence of certain isotopologues in polyion species plays an important role in this work. Thus, while standard independent absolute silicate chemistries at the ≤ 1 at% level remain somewhat problematic, the use of the technique for comparative grain boundary chemical composition is here well demonstrated. Modifications of specimen fabrication (e.g., inclusive needle angle) and of instrumentation protocol (e.g., laser pulse energy and rate) are both approaches to improving discernment of absolute compositions from polycomponent silicates having potential (poly)ion signal overlap.

References

Arzt E, Ashby MF, Verrall RA (1983) Interface controlled diffusional creep. Acta Metall 31(12):1977–1989

Blavette D, Duval P, Letellier L, Guttmann M (1996) Atomic-scale APFIM and TEM investigation of grain boundary microchemistry in Astroloy nickel base superalloys. Acta Mater 44(12):4995–5005

Bons PD, den Brok B (2000) Crystallographic preferred orientation development by dissolution–precipitation creep. J Struct Geol 22(11–12):1713–1722

Budai J, Gauddig W, Sass SL (1979) The measurement of grain boundary thickness using X-ray diffraction techniques. Philos Mag A 40(6):757–767

Bunton JH, Kelly TF, Gribb TT (2010) U.S. patent no. 7,683,318. U.S. Patent and Trademark Office, Washington, DC

Cantwell PR, Tang M, Dillon SJ, Luo J, Rohrer GS, Harmer MP (2014) Grain boundary complexions. Acta Mater 62:1–48

Carter CB, Kohlstedt DL, Sass SL (1980) Electron diffraction and microscopy studies of the structure of grain boundaries in Al2O3. J Am Ceram Soc 63(11–12):623–627

Chakraborty S (2010) Diffusion coefficients in olivine, wadsleyite and ringwoodite. Rev Miner Geochem 72(1):603–639

Cho J, Harmer MP, Chan HM, Rickman JM, Thompson AM (1997) Effect of yttrium and lanthanum on the tensile creep behavior of aluminum oxide. J Am Ceram Soc 80(4):1013–1017

Coble RL (1963) A model for boundary diffusion controlled creep in polycrystalline materials. J Appl Phys 34(6):1679–1682

Cooper RF (2002) Seismic wave attenuation: energy dissipation in viscoelastic crystalline solids. Rev Miner Geochem 51(1):253–290

de Laeter JR, Böhlke JK, De Bièvre P, Hidaka H, Peiser HS, Rosman KJR, Taylor PDP (2003) Atomic weights of the elements. Review 2000 (IUPAC technical report). Pure Appl Chem 75(6):683–800

Detor AJ, Miller MK, Schuh CA (2007) Measuring grain-boundary segregation in nanocrystalline alloys: direct validation of statistical techniques using atom probe tomography. Philos Mag Lett 87(8):581–587

Dohmen R, Milke R (2010) Diffusion in polycrystalline materials: grain boundaries, mathematical models, and experimental data. Rev Miner Geochem 72(1):921–970

Exertier F, La Fontaine A, Corcoran C, Piazolo S, Belousova E, Peng Z, Pedrazzini S (2018) Atom probe tomography analysis of the reference zircon gj-1: an interlaboratory study. Chem Geol 495:27–35

Fisher JC (1951) Calculation of diffusion penetration curves for surface and grain boundary diffusion. J Appl Phys 22(1):74–77

Frost BR, Fyfe WS, Tazaki K, Chan T (1989) Grain-boundary graphite in rocks and implications for high electrical conductivity in the lower crust. Nature 340(6229):134–136

Fujii N, Osamura K, Takahashi E (1986) Effect of water saturation on the distribution of partial melt in the olivine-pyroxene-plagioclase system. J Geophys Res Solid Earth 91(B9):9253–9259

Gault B, Moody MP, Cairney JM, Ringer SP (2012) Atom probe microscopy, vol 160. Springer Science & Business Media, New York

Gottstein G, Shvindlerman LS (2009) Grain boundary migration in metals: thermodynamics, kinetics, applications, 2nd edn. CRC Press, Boca Raton

Gribb TT, Cooper RF (1998) Low-frequency shear attenuation in polycrystalline olivine: Grain boundary diffusion and the physical significance of the Andrade model for viscoelastic rheology. J Geophys Res Solid Earth 103(B11):27267–27279

Hellman OC, Vandenbroucke JA, Rüsing J, Isheim D, Seidman DN (2000) Analysis of three-dimensional atom-probe data by the proximity histogram. Microsc Microanal 6(5):437–444

Herring C (1950) Diffusional viscosity of a polycrystalline solid. J Appl Phys 21(5):437–445

Hiraga T, Anderson IM, Kohlstedt DL (2004) Grain boundaries as reservoirs of incompatible elements in the Earth’s mantle. Nature 427(6976):699–703

Hirth G, Kohlstedt DL (1995) Experimental constraints on the dynamics of the partially molten upper mantle: 2. Deformation in the dislocation creep regime. J Geophys Res Solid Earth 100(B8):15441–15449

Isheim D, Gagliano MS, Fine ME, Seidman DN (2006) Interfacial segregation at Cu-rich precipitates in a high-strength low-carbon steel studied on a sub-nanometer scale. Acta Mater 54(3):841–849

Jamnik J, Raj R (1996) Space-charge-controlled diffusional creep: volume diffusion case. J Am Ceram Soc 79(1):193–198

Kelly TF, Larson DJ, Thompson K, Alvis RL, Bunton JH, Olson JD, Gorman BP (2007) Atom probe tomography of electronic materials. Annu Rev Mater Res 37:681–727

Kingery WD, Bowen HK, Uhlmann DR (1976) Introduction to ceramics, 2nd edn. Wiley, New York

Kliewer KL, Koehler JS (1965) Space charge in ionic crystals. I. General approach with application to NaCl. Phys Rev 140(4A):A1226–A1240

Kohlstedt DL (1990) Chemical analysis of grain boundaries in an olivine-basalt aggregate using high-resolution, analytical electron microscopy. In: Duba AG, Durham WB, Handin JW, Wang HF (eds) The brittle ductile transition in rocks: the heard volume. American Geophysical Union, Washington, pp 211–218

Kondepudi D, Prigogine I (1998) Modern Thermodynamics. In: From heat engines to dissipative structures. Wiley, Hoboken, NJ, p 486

Krakauer BW, Seidman DN (1993) Absolute atomic-scale measurements of the Gibbsian interfacial excess of solute at internal interfaces. Phys Rev B 48(9):6724-6727

Marquardt K, Faul UH (2018) The structure and composition of olivine grain boundaries: 40 years of studies, status and current developments. Phys Chem Miner 45(2):139–172

Miller MK (2006) Atom probe tomography characterization of solute segregation to dislocations. Microsc Res Tech 69(5):359–365

Miller MK, Russell KF, Thompson K, Alvis R, Larson DJ (2007) Review of atom probe FIB-based specimen preparation methods. Microsc Microanal 13(6):428–436

Nabarro FRN (1948) Deformation of crystals by motion of single ions. In: Nooky G (ed) Report on a conference on the strength of solids. Physical Society of London, UK, pp 75–90

Peterman EM, Reddy SM, Saxey DW, Snoeyenbos DR, Rickard WD, Fougerouse D, Kylander-Clark AR (2016) Nanogeochronology of discordant zircon measured by atom probe microscopy of Pb-enriched dislocation loops. Sci Adv 2(9):e1601318

Pommier A, Kohlstedt DL, Hansen LN, Mackwell S, Tasaka M, Heidelbach F, Leinenweber K (2018) Transport properties of olivine grain boundaries from electrical conductivity experiments. Contrib Miner Petrol 173:1–13

Raj R, Ashby MF (1971) On grain boundary sliding and diffusional creep. Metall Trans 2(4):1113–1127

Ricoult DL, Kohlstedt DL (1983) Structural width of low-angle grain boundaries in olivine. Phys Chem Miner 9(3–4):133–138

Saxey DW, Moser DE, Piazolo S, Reddy SM, Valley JW (2018a) Atomic worlds: current state and future of atom probe tomography in geoscience. Scr Mater 148:115–121

Saxey DW, Reddy SM, Fougerouse D, Rickard WD (2018b) The optimization of zircon analyses by laser-assisted atom probe microscopy: insights from the 91500 zircon standard. In: Moser DE, Corfu F, Darling JR, Reddy SM, Tait K (eds) Microstructural geochronology: planetary records down to atom scale. Wiley-Blackwell, UK, pp 293–313

Schmalzried H (1981) Solid state reactions, 2nd edn. Verlag Chemie, Weinheim

Sundberg M, Cooper RF (2008) Crystallographic preferred orientation produced by diffusional creep of harzburgite: effects of chemical interactions among phases during plastic flow. J Geophys Res Solid Earth 113(12):B12208. https://doi.org/10.1029/2008JB005618

Sutton AP, Balluffi RW (1995) Interfaces in crystalline materials. Clarendon Press, Oxford

Tasaka M, Zimmerman ME, Kohlstedt DL, Stünitz H, Heilbronner R (2017) Rheological weakening of olivine + orthopyroxene aggregates due to phase mixing: Part 2. Microstructural development. J Geophys Res Solid Earth 122(10):7597–7612

Tsong TT (1978) Field ion image formation. Surf Sci 70(1):211–233

Valley JW, Cavosie AJ, Ushikubo T, Reinhard DA, Lawrence DF, Larson DJ, Clifton PH, Kelly TF, Wilde SA, Moser DE, Spicuzza MJ (2014) Hadean age for a post-magma-ocean zircon confirmed by atom-probe tomography. Nat Geosci 7(3):219–223

Warren JM, Hirth G (2006) Grain size sensitive deformation mechanisms in naturally deformed peridotites. Earth Planet Sci Lett 248(1–2):438–450

Wheeler J (1992) Importance of pressure solution and Coble creep in the deformation of polymineralic rocks. J Geophys Res Solid Earth 97(B4):4579–4586

Xu Y, Shankland TJ (1999) Electrical conductivity of orthopyroxene and its high pressure phases. Geophys Res Lett 26(17):2645–2648

Yan MF, Cannon RM, Bowen HK (1983) Space charge, elastic field, and dipole contributions to equilibrium solute segregation at interfaces. J Appl Phys 54(2):764–778

Zhang X, Ganguly J, Ito M (2010) Ca–Mg diffusion in diopside: tracer and chemical inter-diffusion coefficients. Contrib Miner Petrol 159(2):175–186

Zhao N, Hirth G, Cooper RF, Kruckenberg SC, Cukjati J (2019) Low viscosity of mantle rocks linked to phase boundary sliding. Earth Planet Sci Lett 517:83–94

Acknowledgements

Prof. Greg Hirth (Brown University) offered lively discussion of aspects of mechanical properties theory. Joseph Bunton (Cameca Instruments, Madison, WI) helped us understand aspects of laser–solid interaction. This work was carried out in part at (a) the Center for Nanoscale Systems, Harvard University (National Science Foundation award number 1541959), and (b) the Central Analytical Facility supported by the University of Alabama. We happily acknowledge very helpful formal reviews by Drs. Steve Reddy and Sandra Piazolo and journal editor Larissa Dobrzhinetskaya. This research was supported financially, in part, through grants from the National Science Foundation Division of Earth Sciences (EAR-1144668, Program in Petrology and Geochemistry; EAR-1620474, Program in Geophysics).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

269_2019_1045_MOESM1_ESM.png

Supplementary Figure A: Proxigram and 1-D analyses of major and minor element chemistry near the olivine–clinopyroxene phase boundary. Proxigram based on a Ca2+ isosurface created with a 3-nm grid-size smoothing. Delocalization parameters are x = 3.0 nm, y = 3.0 nm and z = 1.5 nm. The upper-left graphs represent total detected atomic species (PNG 384 kb)

269_2019_1045_MOESM2_ESM.png

Supplementary Figure B: Proxigram and 1-D analyses of trace element chemistry near the olivine–clinopyroxene phase boundary. Proxigram based on a Ca2+ isosurface created with a 3-nm grid-size smoothing. Delocalization parameters are x = 3.0 nm, y = 3.0 nm and z = 1.5 nm (PNG 426 kb)

269_2019_1045_MOESM3_ESM.png

Supplementary Figure C: Proxigram and 1-D analyses of major and minor element chemistry near the olivine–olivine grain boundary. Proxigram based on a Ca2+ isosurface created with a 5-nm grid-size smoothing. Delocalization parameters are x = 3.0 nm, y = 3.0 nm and z = 1.5 nm. The upper-left graphs represent total detected atomic species (PNG 397 kb)

269_2019_1045_MOESM4_ESM.png

Supplementary Figure D: Proxigram and 1-D analyses of trace element chemistry near the olivine–olivine phase boundary. Proxigram based on a Ca2+ isosurface created with a 5-nm grid-size smoothing. Delocalization parameters are x = 3.0 nm, y = 3.0 nm and z = 1.5 nm (PNG 414 kb)

269_2019_1045_MOESM5_ESM.png

Supplementary Figure E: 1-D analyses of major and minor element chemistry near the clinopyroxene–clinopyroxene grain boundary. Insufficient chemical gradients exist for proxigram calculations at this interface. Delocalization parameters are x = 3.0 nm, y = 3.0 nm and z = 1.5 nm. The upper-left graph represents total detected atomic species (PNG 273 kb)

269_2019_1045_MOESM6_ESM.png

Supplementary Figure F: 1-D analyses of trace element chemistry near the clinopyroxene–clinopyroxene grain boundary. Insufficient chemical gradients exist for proxigram calculations at this interface. Delocalization parameters are x = 3.0 nm, y = 3.0 nm and z = 1.5 nm (PNG 289 kb)

269_2019_1045_MOESM10_ESM.png

Supplementary Figure J: Selected APT analytical reconstructions from the Cpx–Cpx boundary. The 3-D reconstruction is oriented with the vector normal to the grain boundary within the plane of the page. Al and Ca are enriched at the Cpx–Cpx boundary (PNG 729 kb)

Rights and permissions

About this article

Cite this article

Cukjati, J.T., Cooper, R.F., Parman, S.W. et al. Differences in chemical thickness of grain and phase boundaries: an atom probe tomography study of experimentally deformed wehrlite. Phys Chem Minerals 46, 845–859 (2019). https://doi.org/10.1007/s00269-019-01045-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00269-019-01045-x