Abstract

Ligilactobacillus salivarius is a lactic acid bacterium exhibiting several health benefits but remains commercially underexploited due to its inability to survive during long-term storage in the dried state. Our objective was to study the effect of various protective molecules (maltodextrin, trehalose, antioxidants, and fructooligosaccharides), being efficient on other bacteria, on the freeze-dried stability of L. salivarius CECT5713. The culturability was evaluated after freezing, freeze-drying, and subsequent storage at 37 °C, as well as the biochemical composition of cells in an aqueous environment using Fourier transform infrared (FTIR) micro-spectroscopy. The assignment of principal absorption bands to cellular components was performed using data from the literature on bacteria. The membrane fatty acid composition was determined after freeze-drying and storage. Glass transition temperature of the liquid and freeze-dried bacterial suspensions and water activity of the freeze-dried samples were measured. The best storage stability was observed for the formulations involving maltodextrin and antioxidants. The analysis of the FTIR spectra of freeze-thawed cells and rehydrated cells after freeze-drying and storage revealed that freeze-drying induced damage to proteins, peptidoglycans of the cell wall and nucleic acids. Storage stability appeared to be dependent on the ability of the protective molecules to limit damage during freeze-drying. The inactivation rates of bacteria during storage were analyzed as a function of the temperature difference between the product temperature during sublimation or during storage and the glass transition temperature, allowing a better insight into the stabilization mechanisms of freeze-dried bacteria. Maintaining during the process a product temperature well below the glass transition temperature, especially during storage, appeared essential for L. salivarius CECT5713 storage stability.

Key points

• L. salivarius CECT5713 highly resisted freezing but was sensitive to freeze-drying and storage.

• Freeze-drying and storage mainly altered cell proteins, peptidoglycans, and nucleic acids.

• A glassy matrix containing maltodextrin and an antioxidant ensured the highest storage stability.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ligilactobacillus salivarius is a lactic acid bacterium naturally found in humans (breast milk, gastrointestinal tract and oral cavities) that has attracted increasing interest from researchers and the industry in recent years. Several studies in the last decade report probiotic properties of different L. salivarius strains such as antimicrobial activity, immunological effects, and modulation of the intestinal and vaginal microbiota (Guerrero Sanchez et al. 2022). Their incorporation as probiotics in food supplements and medicines requires obtaining a powder, and thus, in turn, a cascade of operations, ranging from fermentation to stabilization (by freeze-drying or spray-drying) and final storage at room temperature (Fenster et al. 2019). However, this multistep manufacturing process, in particular the stabilization step, induces environmental changes that generate stress and potential cell damage (Santivarangkna et al. 2008b; Broeckx et al. 2016; Cunningham et al. 2021). The resulting loss of viability and functionality leads to the industrial underutilization of L. salivarius, since less than 20% of the strains studied at the laboratory level are present in commercialized products (Guerrero Sanchez et al. 2022).

The addition of protective molecules to cell concentrates is an effective strategy currently applied to improve the cell’s functionalities recovery after stabilization and long-term storage. The efficiency of different protective agents to preserve L. salivarius following freeze-drying and spray-drying has been recently reviewed (Guerrero Sanchez et al. 2022; Table S3). Skim milk appears as the most widely tested protective medium, with freeze-drying (Zayed and Roos 2004) leading to higher survival rates than spray-drying (Corcoran et al. 2004). The association of skim milk with sugars (sucrose and/or trehalose) and sodium glutamate seems to give the best results for preserving L. salivarius during freeze-drying (Guerrero Sanchez et al. 2022; Fig. 3). However, the use of skim milk may lead to storage stability problems since lactose may crystallize during storage or participate in non-enzymatic browning (Morgan et al. 2005). The comparison of the efficiency of a protective agent remains however delicate since many factors vary or are not measured among the reported studies (e.g., the concentration of protective agents, the ratio of protective agent to biomass, the residual water content, the water activity of the freeze-dried samples). In addition, studies involving pilot-scale manufacturing processes and including the storage step are scarce (Guerrero Sanchez et al. 2022), thus also preventing the potential generalization of results to other strains.

Understanding L. salivarius cellular damages induced by freeze-drying and storage and the mechanisms underlying cell preservation in the presence of protective molecules is crucial for the development of new products. The bacterial membrane is often reported as the first and the main target of drying injury, which was demonstrated by a loss of membrane integrity, membrane permeabilization, and leakage of intracellular content following rehydration (Schwab et al. 2007; Tymczyszyn et al. 2007; Bensch et al. 2014; Romano et al. 2021). Furthermore, lipid oxidation reactions are influenced by the water activity values of freeze-dried samples. Values lower and higher than 0.2 are consistent with an increase in the reaction rate of lipid oxidation observed in numerous studies on food materials (Nelson and Labuza 1992; Rückold et al. 2001; Cömert and Gökmen 2018), as well as during dried storage of LAB (Castro et al. 1995; Teixeira et al. 1996; Kurtmann et al. 2009; Rodklongtan et al. 2022). Loss of viability after drying (1 log colony forming units per gram, CFU g−1) and dried storage (2 to 6 log (CFU g−1), depending on the water activity) was ascribed to a modification of the membrane fatty acid profile due to oxidation reactions (Castro et al. 1995; Teixeira et al. 1996). Although no study reports an oxidative process on L. salivarius, freeze-drying of lactic acid bacteria often needs the addition of antioxidants to improve the storage stability (Kurtmann et al. 2009; Jalali et al. 2012). Recently, few authors evidenced alteration in the secondary protein structures (Nag et al. 2019), DNA conformation (Romano et al. 2021), and peptidoglycans of the cell walls (Gong et al. 2019) following stabilization processes. The protective effects of protective molecules of sugars and mixtures of sugars and polymers on the stabilization of cell components during drying and subsequent storage have been mainly described by two mechanisms (Crowe et al. 1988; Grasmeijer et al. 2013; Teng et al. 2017): (i) the vitrification theory and (ii) the water replacement theory. The first one is based on the concept of immobilizing the bacterial cells inside a rigid, amorphous glassy sugar matrix, preventing molecular movements and thereby degradation reactions. According to the second theory, disaccharides (such as sucrose and trehalose) protect bacterial cells because they can form hydrogen bonds with membrane polar groups as water is removed during drying allowing the maintenance of a pseudo-hydrate structure even in the dehydrated state and the prevention of drying-induced damage.

To afford protection according to both mechanisms, LAB are currently freeze-dried in the presence of maltodextrin and disaccharides (Passot et al. 2012; Velly et al. 2015; Teng et al. 2017), with structural properties of trehalose giving it some advantage over sucrose for biopreservation purposes (Crowe et al. 2001; Olsson et al. 2020). An antioxidant (e.g., sodium ascorbate) is usually also added to the formulation of dried LAB for limiting oxidative cell deterioration caused by the manufacturing process (Fonseca et al. 2003; Kurtmann et al. 2009; Rodklongtan et al. 2022). Oligosaccharides (fructooligosaccharides (FOS) and galactooligosaccharides (GOSs)) have been proposed as alternative protective compounds (Sosa et al. 2016; Romano et al. 2016; Cejas et al. 2017). These molecules are promising protectants to replace skim milk traditionally reported to protect L. salivarius during freeze-drying and storage.

Fourier transform infrared (FTIR) spectroscopy has emerged in recent years as a powerful tool for studying biochemical changes of lactic acid bacteria following environmental stress (Santivarangkna et al. 2006; Passot et al. 2015; Hlaing et al. 2017). A recently developed FTIR micro-spectroscopic approach enables the exploitation of the entire mid-infrared region of bacterial cells in aqueous conditions (Meneghel et al. 2020) and appears as a promising non-invasive technique to identify markers of resistance to freezing (Girardeau et al. 2022).

This study aimed to investigate the biological (culturability and storage stability), physical (glass transition temperature and water activity of the matrix), and biochemical (fatty acid composition and infrared spectral features) responses of L. salivarius to freeze-drying and storage in the presence of different protective agents. L. salivarius CECT5713, a strain isolated from human breast milk that harbors several health benefits (Sierra et al. 2010; Arroyo et al. 2010; Fernández et al. 2021), was chosen for this study. Eight formulation conditions involving maltodextrin, antioxidants, trehalose, and fructooligosaccharides were considered to better understand the mechanisms involved, and biochemical analysis was implemented to identify the cell components that were altered following freeze-drying and storage. Moreover, manufacturing conditions relevant to the industry (e.g., pilot fermentation and freeze-drying, industrial stability tests) were applied to deliver improved stabilization conditions.

Materials and methods

The experimental approach used in this study as well as the main parameters investigated are shown in Fig. 1.

Production of freeze-dried L. salivarius CECT5713 concentrates and storage conditions

Bacterial strain and culture conditions

The strain used in this study was Ligilactobacillus salivarius CECT5713 (Colección Española de Cultivos Tipo, Spain). Five hundred fifty microliters of cell bank stored at − 80 °C was thawed at room temperature before the inoculation into 550 mL of MRS Broth (Oxoid Ltd.; Basingstoke, Hampshire, England). Pre-culture was incubated at 42 °C up to the early stationary growth phase and then used to inoculate a 5-L bioreactor (Biostat® B Type 8,840,326, B. Braun Biotech International GmbH; Melsungen, Germany) containing 4.95 L of culture medium.

The culture medium, sterilized at 121 °C for 20 min, was composed of 45 g·L-1 glucose (ADM; Chicago, IL, USA), 16 g·L-1 yeast extract (Condalab; Madrid, Spain), 2.5 g·L-1 cysteine hydrochloride (Quimdis; Levallois-Perret, France), 0.2 g·L-1 magnesium sulfate (Panreac Quimica SL; Barcelona, Spain), 0.1 g·L-1 manganese sulfate (Quality Chemicals; Barcelona, Spain), 2 g·L-1 dipotassium phosphate (Omnisal GmbH; Lutherstadt Wittenberg, Germany), and 2 g·L-1 Tween 80 (Quality Chemicals; Barcelona, Spain). The fermentation was performed at 42 °C and pH 5, which was controlled by the automatic addition of a 20% (w/v) NaOH solution. An agitation speed of 120 rpm was applied for culture homogenization.

Harvesting, concentration, and protective conditions

By monitoring the volume of the NaOH solution consumed during the fermentation, it was possible to calculate the acidification rate as the first derivative of the NaOH consumption curve. Cells were harvested 2 h after reaching the maximum acidification rate (corresponding to the peak of the first derivative curve). L. salivarius cells were concentrated by centrifugation (Avanti® JXN-30 centrifuge, Beckman Coulter; CA, USA) at 8763 × g for 10 min at 4 °C. Cell pellets were diluted with the obtained supernatant to reach a final volume of 275 mL corresponding to a concentration factor of 20 (concentrated cell suspension). The concentrated cell suspension was then re-suspended in the protective formulations at a ratio of 3:1 (concentrated cell suspension/protective formulation, v/v). Different molecules were tested as protective agents: maltodextrin (Dextrose equivalent (DE) of 6, Roquette; Lestrem, France), a food polymer; two antioxidants: sodium ascorbate (Royal DSM N.V.; Limburg, Netherland) largely recognized as antioxidant and successfully applied to LAB (Fonseca et al. 2003; Kurtmann et al. 2009; Rodklongtan et al. 2022) and sodium citrate (Quimivita; Barcelona, Spain) reported for its antioxidant properties on food (Sallam 2007; Haghparast et al. 2010); and four sugars: trehalose (Quimidroga SA; Barcelona, Spain), a commercial fructooligosaccharide (Orafti® P95, hereafter called FOSCom) (Beneo Orafti; Tienen, Belgium), and two FOS produced by the Center for Research and Development in Food Cryotechnology (CIDCA, CCT-CONICET; La Plata, Argentina) from sucrose (FOS2 and FOS6). The compositions of the three FOS used in this study are presented in Table S1.

Eight protective formulations were investigated, and their composition (corresponding final concentration in the protected cell concentrate) was the following: (MD) maltodextrin (135 g·L-1), (MDcit) maltodextrin/sodium citrate (125/10 g·L-1), (MDasc) maltodextrin/sodium ascorbate (125/10 g·L-1), (2MD1TRE) maltodextrin/trehalose (90/45 g·L-1), (2MD1FOS6) maltodextrin/FOS6 (90/45 g·L-1), (2MD1FOS2) maltodextrin/FOS2 (90/45 g·L-1), (MDTRE) maltodextrin/trehalose (67.5/67.5 g·L-1), and (MDFOSCom) maltodextrin/FOSCom (67.5/67.5 g·L-1) (Table S2). The dry matter of the protected cell concentrates was kept constant at 23% (w/w); on a dry basis, the composition of samples was 41% (w/w) cells and residual culture medium and 59% (w/w) protective molecules. Five fermentations were carried out in order to consider biological replicates. Since it was not possible to investigate the 8 formulations with the biomass obtained from one fermentation, two groups of formulations were considered: (i) MD, MDasc, 2MD1TRE, and MDTRE and (ii) MD, MDcit, 2MD1FOS2, 2MD1FOS6, and MDFOSCom (Table S2).

Stabilization and storage conditions

Protected cell concentrate was frozen at − 80 °C in sterile petri dishes. The petri dishes were then transferred to pre-cooled shelves at − 45 °C in a pilot-scale freeze-dryer (VirTis Genesis 35 L SQ EL-85, SP Scientific; Warminster, PA, USA). The primary drying was carried out a shelf temperature value between − 10 and 10 °C and at a chamber pressure of 0.2 mbar. The shelf temperature was then increased to 25 °C to perform the secondary drying step. The vacuum was broken, and the samples were milled to a powder, packed in aluminum bags, and stored for 4 weeks at 37 °C. Thermocouples were used to monitor the product temperature during the freeze-drying process. Aliquots of the protected cell concentrates were also stored in cryotubes at − 80 °C for analyzing the freeze-thawed samples.

Biological activity of L. salivarius CECT5713 concentrates through the stabilization process

Biological activity measurements were carried out before and after freezing, after freeze-drying, and every week for 4 weeks of storage at 37 °C. Before analysis, frozen samples were thawed at room temperature for 5 min, and freeze-dried samples were rehydrated in a sterilized solution of 20 g·L-1 peptone water (BioMérieux; Marcy l'Étoile, France) and incubated for 30 min at 37 °C with shaking. The amount of peptone water added to the dried sample was calculated from the difference in weight between before and after freeze-drying, thus recovering the initial water content (77% (w/w)) of the protected bacterial concentrates (before freeze-drying).

Culturability measurements

Bacterial cell concentration was determined using the agar plate count method. Cell suspensions were serially diluted in sterilized solutions of 20 g·L-1 peptone water (BioMérieux; Marcy l’Étoile, France), and the appropriate dilutions were spread into MRS agar plates (VWR International Eurolab; Barcelona, Spain) in triplicate. Colonies were enumerated after incubating the plates for 48 h at 37 °C in anaerobic conditions (AnaeroJar™ 2.5 L, Oxoid Ltd.; Basingstoke, Hampshire, England). Plates containing between 30 and 300 colonies were kept for cell concentration evaluation. Cell plate counts were expressed in log (CFU·mL-1).

The determination of the cell culturability loss (dlog (CFU·mL-1)) after freezing, freeze-drying, and 1 and 4 weeks of storage at 37 °C was calculated using the following equation:

where \(i\) is the step of the process considered and \({\mathrm{log }(\mathrm{CFU}\cdot {\mathrm{mL}}^{-1})}_{\mathrm{BF}}\) the value of the sample’s culturability before freezing.

Accelerated storage stability test

Storage stability was evaluated from the rate of cell culturability loss during 4 weeks of storage at 37 °C. For each protective formulation and biological replicate, the logarithmic value of the cell count (log (CFU·mL-1)) was plotted as a function of the storage time, and the experimental values were fitted using the following equation:

where the inactivation (or cell loss) rate constant K37 (in days−1) refers to the absolute value of the slope of the linear regression. The lower the absolute value of the slope K37, the higher the storage stability was.

Physical properties of L. salivarius CECT5713 concentrates

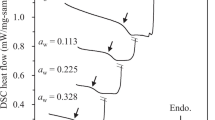

Glass transition temperature measurements

The glass transition temperature of the freeze-thawed protected cell concentrates (Tg′, in °C) and the freeze-dried powder with no storage and after 1 and 4 weeks of storage (Tg, in °C) were determined by differential scanning calorimetry (DSC). Measurements were performed on two different power compensation DSC types of equipment (Perkin Elmer LLC, Norwalk, CT, USA) depending on the type of sample: a Diamond equipped with a liquid nitrogen cooling accessory (CryoFill) for the freeze-thawed samples exhibiting thermal events at negative temperatures and a Pyris 1 equipped with a mechanical cooling system (Intracooler 1P) for the powder samples. Temperature calibration was done using cyclohexane (crystal–crystal transition at − 87.1 °C) and mercury (melting point at − 38.6 °C) for the Diamond and cyclohexane (melting point at 6.5 °C), n-octodecane (melting point at 27.8 °C), and indium (melting point at 156.6 °C) for the Pyris 1. About 15–25 mg of sample was sealed in aluminum pans. An empty pan was used as a reference. Cooling and heating rates of 10 °C·min-1 were used. Freeze-thawed samples were cooled to − 100 °C and then scanned to 20 °C. Powder samples were heated from 10 to 120–150 °C, then cooled to 10 °C and heated again to 120–150 °C. The first heating scan eliminates the thermal history of the sample (enthalpy relaxation) while the second heating enables the determination of the glass transition. The maximum of the first derivative of the heat flow curve (recorded during the second heating step in the case of dried samples) was used to determine the glass transition temperature of the different samples. Results were obtained from at least two replicates.

Water activity measurements

The water activity was measured at 25 °C using an aw meter labMasteraw (Novasina, Precisa, Poissy, France), on freeze-dried samples (no storage) and after 1 and 4 weeks of storage at 37 °C.

Biochemical properties of L. salivarius CECT5713 cells

Fatty acid extraction and analysis by gas chromatography coupled to mass spectrometry

Membrane fatty acid (FA) composition of L. salivarius cells was determined on cell pellets obtained after thorough washing. They were washed three times with Tris–HCl buffer (50 mM, pH 8.8), three times with saline water, and then centrifugated at 13,100 × g for 10 min at 4 °C, according to Folch et al. 1957. Briefly, a chloroform–methanol 2:1 (v/v) mixture was added to the washed pellet (solvent/sample ratio of 20:1), and the mixture was mechanically shaken (vortex) and exposed to ultrasounds (10 min). To wash the crude extract, a NaCl solution (0.05 M) was added (22% of crude extract volume) and gently agitated (30 rpm) in a tube rotator (LabRoller™ rotator, Labnet International; NJ, USA). After centrifugation (12,857 × g for 15 min at room temperature), the organic (lower) phase was collected, and lipids were re-extracted from the remaining aqueous (upper) phase. Both CHCl3 phases were pooled and evaporated by vacuum centrifugation (Jouan RC10.22 vacuum concentrator, Thermo Fisher Scientific; Saint-Herblain, France). The extracted lipids were solubilized in CHCl3, mixed with a C9:0 internal standard (Sigma-Aldrich; St. Louis, MO, USA), and derivatized using trimethylsulfonium hydroxide (TMSH, Sigma-Aldrich; St. Louis, Missouri, USA). FA identification and quantification was carried out using a Hewlett-Packard 6890 gas chromatograph (GMI; Ramsey, MI, USA) coupled to a mass selective detector (5973; Agilent Technologies, Avondale, PA, USA). Results were expressed as FA percentages. The membrane FA composition was determined after freeze-drying and 4 weeks of storage at 37 °C.

Biochemical characterization of L. salivarius cells in an aqueous environment by FTIR micro-spectroscopy

The biochemical characterization of L. salivarius protected concentrates in an aqueous environment was carried out at different steps of the stabilization process (after freezing, after freeze-drying, and after 4 weeks of storage at 37 °C) using FTIR micro-spectroscopy in transmission mode. We assume that measurements of frozen samples are equivalent to the fresh samples as it was not possible to analyze the fresh ones, and no loss of culturability was observed following freezing. The equipment includes a FTIR microscope (Nicolet iN10, Thermo Fisher Scientific; Madison, WI, USA) with a permanently aligned objective (15 × , NA = 0.7), a liquid nitrogen-cooled mercury-cadmium-teluride (MCT) detector, and a specific demountable home-made sample holder for liquid samples designed by Meneghel et al. 2020. The sample holder fits a micro-chamber of CaF2 windows (Hellma Analytics; Paris, France) which can be maintained tightly closed, to limit water evaporation and avoid sample drying for the duration of the measurements. Measurements were performed according to the method detailed in Meneghel et al. 2020.

Briefly, freeze-thawed or rehydrated protected cell concentrates were washed three times in saline solution and then centrifuged at 13,100 × g for 10 min at 4 °C. A very small amount (less than 1 µL) of the resulting cell pellet was deposited over one side of the CaF2 microchamber and separated from the diluent side (saline solution) by a thin (2.5 µm thick) strip of Mylar® (polyethylene terephthalate film from GoodFellow, Lille).

All spectral acquisitions were performed with the Omnic software (version 8.1, Thermo Fisher Scientific; Madison, WI, USA). Each acquired spectrum was obtained from 128 co-added scans in the mid-IR region, between 4000 and 900 cm-1 at a resolution of 4 cm-1 every 45 s and with an aperture set at 50 × 50 μm2. For each bacterial sample, three different sets of spectra were acquired: (i) a background spectrum, recorded in an air bubble in the diluent region; (ii) sample spectra, acquired on multiple points on the liquid sample side (60–90 spectra per biological sample); and (iii) diluent spectra, acquired on the diluent side (15–20 spectra per biological sample were averaged).

Spectral pre-processing was performed according to the procedure described by Meneghel et al. 2020. The Omnic software was used for spectral sorting, and an automatic atmospheric correction was applied to remove the residual contribution from water vapor and carbon dioxide to all spectra. The removal of water contributions from all sample spectra was performed using an in-house Matlab script (version 8.3.0.532, Mathworks, Natick; MA, USA) guided by the method developed by Vaccari et al. 2012. The script involved removing a scaled averaged diluent spectrum from the sample spectra. The scaling factor was determined by an algorithm designed to obtain spectra presenting a similar amide I/II area ratio close to those of dried cells. The calculation of the amide I/II area ratio in dried cells was performed on pre-processed spectra, for each protective condition and type of sample analyzed (frozen or freeze-dried sample). The average amide I/II area ratios obtained ranged between 2.61 and 2.50 for frozen and freeze-dried cell concentrates, respectively (https://doi.org/10.15454/EXGJDH).

Post-processing of water subtracted spectra was performed with the Unscrambler® X software package (Version 10.2, CAMO Software AS; Oslo, Norway) on three distinct spectral regions: (i) the 3016–2800 cm-1 region containing information on fatty acyl chains of the bacterial membrane; (ii) the 1800–1370 cm-1 region containing information on protein, particularly amide I (~ 1700–1600 cm-1) and amide II (~ 1600–1500 cm-1) bands; and (iii) the complex region of 1370–975 cm-1 containing information on protein (amide III band, ~ 1400–1200 cm-1), nucleic acids, and cell wall components (phosphorus-containing molecules such as phospholipid and some polysaccharides). An extended multiplicative scatter correction (EMSC) procedure was used to normalize and correct the baseline of spectra in each of the spectral regions of interest. The resulting spectra were then statistically analyzed by principal component analysis (PCA) to reveal data variance (score plots) and peak positions of interest (loading plots) using the Unscrambler® X software package. The assignment of the principal absorption bands was performed using data from the literature on bacteria.

Additional treatment on the infrared spectra was performed to identify the effect of the protective molecules in the 1800–1370 cm-1 and 1370–975 cm-1 spectral regions. For each formulation condition, each step of the process and biological replicate, the second-order derivative of the average spectrum was calculated using a Savitzky-Golay algorithm (third-degree polynomial and a 9-points smoothing factor) (Fig. S1). For each wavenumber (vi) corresponding to the peaks observed in the second-order derivative spectra, the relative variation (rvFTIR) of the peak’s height (h) compared to the freezing condition was determined as follows:

Statistical analyses

The nonparametric Kruskal–Wallis test and the post hoc Conover Iman test with Bonferroni correction were performed using XLSTAT 19.6 (Addinsoft; Paris, France) to compare data concerning biological activity, water activity, glass transition temperature, and fatty acid composition. A significance level of 95% (p-value < 0.05) was considered.

Results

L. salivarius CECT5713 resistance to freezing, freeze-drying, and storage with different protective agents

Culturability losses during freezing, freeze-drying, and storage

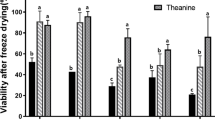

The experimental results pertaining to culturability and culturability losses of L. salivarius concentrates at different steps of the manufacturing process using MD, MDcit, MDasc, 2MD1TRE, 2MD1FOS6, 2MD1FOS2, MDTRE, and MDFOSCom as protective formulations are represented in Fig. 2. The precise values are reported in Table S3 and Table S4.

a Culturability (log (CFU·mL-1)) of Ligilactobacillus salivarius CECT5713 concentrates protected with eight different protective formulations before freezing (BF) and after freezing (F), freeze-drying (FD), 1 week (W1), and 4 weeks (W4) of storage at 37 °C, and b culturability losses (log (CFU·mL-1)) observed after the freezing (F), freeze-drying (FD), and storage (1 week (W1) and 4 weeks (W4)) steps. Formulation compositions are detailed in Tables S1 and S2 and in the “Material and methods” section. MD: maltodextrin; cit: sodium citrate; asc: sodium ascorbate; TRE: trehalose; FOSCom: commercial FOS; FOS: fructooligosaccharide

During freezing, the culturability was unchanged (− 0.035 log units of average), and no statistical differences were observed either among the different protective formulations. After freeze-drying, L. salivarius cells showed a slight loss of culturability (− 0.57 log units of average), and some statistical differences appeared between the protective agents (Table S4). During storage at 37 °C, the culturability decreased significantly in the eight tested formulations. After 1 week of storage, the lowest losses were measured in formulations involving antioxidant molecules (MDasc and MDcit) and the highest losses in two of the formulations containing FOS (MDFOSCom and 2MD1FOS2). After 4 weeks of storage at 37 °C, the protective formulation involving maltodextrin and sodium ascorbate (MDasc), followed by MDcit and MD, presented the highest protection for L. salivarius cells. The formulation involving equal parts maltodextrin and trehalose (MDTRE) presented an intermediate protection followed by 2MD1TRE. The formulations involving FOS (2MD1FOS6, 2MD1FOS2, and MDFOSCom) presented the lowest protection for the selected strain (Table S4).

Inactivation rate during accelerated storage test

Storage stability was evaluated from the inactivation rate constant (K37, in log (CFU·mL-1)·day-1) of L. salivarius CECT5713 cells after 4 weeks of storage at 37 °C. The lower the absolute value of the slope K37, the higher the storage stability was. The inactivation rate constant was calculated for each biological replicate (Table S5). The values of K37 obtained for the samples produced in fermentation no. 4 (biological replicate 4) appeared significantly higher than those of the other biological replicates regardless of the formulation. The protective formulation involving maltodextrin and sodium ascorbate (MDasc) exhibited the best storage stability followed by MD, MDcit, MDTRE, and then 2MD1TRE. The formulations involving FOS (2MD1FOS6, 2MD1FOS2, and MDFOSCom) presented the lowest storage stability at 37 °C (Table S5).

Physical properties of the matrices containing L. salivarius CECT5713 cells

Glass transition temperature (Tg) and water activity (aw) of freeze-dried powders in the presence of the different protective agents were determined after freeze-drying and after 1 week and 4 weeks of storage at 37 °C (Table 1). The liquid formulations were also characterized by the measurement of the glass transition temperature of the maximally freeze-concentrated phase (Tg′).

Except for the formulation MDFOSCom (28.8–33 °C), all the protective formulations exhibited Tg values higher than the storage temperature (37 °C). The initial water activity of the freeze-dried L. salivarius powders in the presence of the different protective agents presented statistical differences. The water activity of the two formulations with the lowest amount of maltodextrin (MDTRE and MDFOSCom) was significantly higher (> 0.1) than that of the other formulations (< 0.055). During storage, the water activity of freeze-dried powders protected with the eight formulations moderately increased to reach values between 0.088 and 0.250, with no significant impact on the Tg value.

Cells protected with only maltodextrin (MD) presented the highest Tg value (~ 100 °C). Addition of sugars (trehalose or FOS), as well as antioxidants (sodium citrate or sodium ascorbate), resulted in decreasing the Tg value. This plastifying effect of sugars and antioxidants was also observed in the glass transition temperatures of the maximally freeze-concentrated phase (Tg′) (Table 1).

Fatty acid composition of L. salivarius CECT5713 protected cell concentrates

The fatty acid (FA) composition of L. salivarius CECT5713 concentrates after freeze-drying and 4 weeks of storage at 37 °C is presented in Table S6.

A total of twelve different FAs were detected, quantified, and identified in the L. salivarius membranes. Regardless of the protection conditions, the bacterial membrane was mainly composed of six fatty acids, accounting for about 90% of the total content: two cyclic fatty acids (CFAs, ΔC19:0 phytomonic (29.2% of average) and ΔC19:0 dihydrosterulic (9%)), one saturated fatty acid (SFA, C16:0 (22.2%)), and three unsaturated fatty acids (UFAs, C18:1 cis 9 (11.1%), C18:2 conjugated (10.1%), and C18:1 cis 11 (9.2%)). The membrane of L. salivarius CECT5713 is thus characterized by a high content of CFA (38.2%), a UFA/SFA ratio of 1.1, and a CFA/UFA ratio of 1.2. A slight decrease in the C18:2 and total UFA contents was observed for some formulations after 4 weeks of storage at 37 °C. However, any minor modification of the membrane fatty acid composition was not statistically significant.

Differences in biochemical compositions after freeze-drying and 4 weeks of storage of L. salivarius CECT5713 cells

PCA was performed on normalized and EMSC-corrected spectra of frozen, freeze dried, and stored L. salivarius cells for 4 weeks at 37 °C in three different regions: the 3016–2800 cm-1, the 1800–1370 cm-1, and the 1370–975 cm-1 region. When the eight protection conditions were considered together, no clustering was observed according to the composition of the protective formulation regardless of the spectral region.

The PC1 versus PC2 score plots in the 1800–1370 cm-1 and 1370–975 cm-1 regions are presented in Fig. 3a and c, respectively. Regardless of the spectral region, we noticed a clear cluster separation along the PC1 axis (83% and 62% of variance, respectively) according to the process steps considered. The cluster of frozen cells is located in the positive area of PC1 whereas the cluster of stored cells is mainly located in the negative area. The cluster of freeze-dried cells is located between the frozen and stored clusters. The principal absorption bands identified in the loading plots were assigned to cellular components using data from the literature (Table S7) and are described below. The positive peaks in the loading plots of PC1 (Fig. 3b and d) reveal that frozen cells are characterized by four spectral features: (i) the 1615–1560 cm-1 range (amide I and amide II bands of proteins); (ii) the 1325–1305 cm-1 range (amide III band of proteins); (iii) the 1140–1105 cm-1 range (sugar rings, phosphodiester groups of phospholipids or some polysaccharides, or the nucleic acid structures); and (iv) the 1085–1075 cm-1 range (symmetric stretching vibrations from PO2- groups). Conversely, the stored cells are characterized by six negative peaks in the PC1 loading plots: (i) the 1760–1710 cm-1 range (nucleic acids); (ii) the 1550–1430 cm-1 range (amide II band of proteins); (iii) the 1300–1280 cm-1 range (amide III band of proteins); (iv) the 1220–1185 cm-1 range (asymmetric stretching vibrations from PO2- groups); (v) and (vi) the 1060–1045 cm-1 and 1035–1005 cm-1 ranges (complex sugar ring modes arising from the peptidoglycan of the cell wall, or the nucleic acid structures). In the 3016–2800 cm-1 region containing information on fatty acyl chains of the bacterial membranes, no separation was observed in the score plots (Fig. S2). The freeze-drying and storage (4 weeks at 37 C) steps resulted thus in damage to the following cellular components: proteins, nucleic acids, and peptidoglycans of the cell wall.

Principal component analysis (PCA) of FTIR normalized and corrected spectra of frozen (blue dots), freeze-dried (red dots), and stored (green dots) Ligilactobacillus salivarius CECT5713 cells in an aqueous environment, in the a, b 1800–1370 cm-1 and c, d 1370–975 cm-1 region. a PC1 versus PC2 score plot explaining 83 and 9% of the variance, respectively. c PC1 versus PC2 score plot explaining 62 and 21% of the variance, respectively. b, d Loading plots of the PC1. Positive peaks characterized frozen cells, whereas negative peaks characterized stored cells of L. salivarius strain

To identify potential effect of the protective molecules, the second-order derivative of the averaged spectra was plotted in the spectral regions of 1800–1370 cm-1 and 1370–975 cm-1 (Fig. S1) for each experimental condition (formulation condition, process step, and biological replicate). The relative variation of the peak’s height compared to the frozen condition (\({r}_{v FTIR}\)) is calculated and displayed in Fig. 4. For the sake of clarity, only the results of the following protective formulations were considered and represented: MD, MDasc, MDTRE, and MDFOSCom. A positive value means that freeze-drying (FD), or the 4 weeks of storage (W4), result in increasing the peak height. The assignment of the main vibrational bands identified in the second-order derivative, as well as the change induced by the process step, is summarized in Table S7.

Changes in the peak height (\({r}_{vFTIR})\) of the infrared vibrational bands in the a 1800–1370 cm-1 and b 1370–975 cm-1 region in the Ligilactobacillus salivarius CECT5713 freeze-dried (FD) and stored for 4 weeks at 37 °C (W4) cells protected with MD, MDasc, MDTRE, and MDFOSCom, compared to their frozen. The peaks were reported from the plotted of the mean second derivatives of the normalized spectrum (Figure S1). Formulation compositions are detailed in Tables S1 and S2 and in the “Material and methods” section. MD: maltodextrin; asc: sodium ascorbate; TRE: trehalose; FOSCom: commercial FOS (fructooligosaccharide)

The main changes in the infrared vibrational bands were observed after the freeze-drying step regardless of the condition used for protecting the L. salivarius cells. The storage for 4 weeks at 37 °C only intensified them. The freeze-drying process increased notably the following infrared vibrational bands: 1714 cm-1 (nucleic acids), 1466 cm-1 (proteins, lipids), 1400 cm-1 (carbohydrates, proteins, lipids), 1058 cm-1 (lipids, carbohydrates, nucleic acids), 1024 cm-1 (carbohydrates), and 995 cm-1 (nucleic acids) and decreased notably these other bands: 1417 cm-1 (carbohydrates, proteins, nucleic acids, lipids), 1317 cm-1 (proteins), 1122 cm-1 (carbohydrates, nucleic acids), and 1041 cm-1 (carbohydrates, nucleic acids). For the formulation including the commercial FOS, the most pronounced changes were observed on the following bands: 1714 cm−1, 1466 cm−1, 1400 cm−1, and 1058 cm−1. The addition of sodium ascorbate resulted in the lowest changes of the bands at 1714 cm−1, 1466 cm−1, and 1317 cm−1, whereas adding trehalose limited the modification of the bands at 1417 cm−1, 1058 cm−1, 1041 cm−1, and 1024 cm−1.

Discussion

The stabilization of L. salivarius during freeze-drying and storage requires an appropriate choice of protective molecules (Guerrero Sanchez et al. 2022). This choice is governed by the need to protect bacteria cells from degradation during freezing and dehydration, as well as to provide a glassy matrix for long-term stability in the dried state. In the present study, we selected a polysaccharide exhibiting a high glass transition temperature, maltodextrin with a dextrose equivalent value (DE) of 6, alone or in combination with non-reducing sugars (trehalose), fructooligosaccharide mixtures (containing low amounts of reducing sugars), or antioxidants (sodium ascorbate or sodium citrate).

To illustrate the importance of the immobilization of bacteria within a glassy matrix for preserving L. salivarius CECT5713, the inactivation rates (K37) observed for the different protective formulations and biological replicates were plotted as a function of the temperature difference (Ts-Tg) between the storage temperature (Ts = 37 °C) and the glass transition temperature of the freeze-dried samples (Tg) (Fig. 5a). Positive values of (Ts-Tg) indicate that the storage of the freeze-dried dried samples occurred at a temperature higher than the Tg value, i.e., that the samples were stored in the viscous state and not in the glassy state (for MDFOSCom). When considering the formulations involving only maltodextrin or a mixture of maltodextrin and fructooligosaccharides (orange points in Fig. 5a), we observe a linear increase in the inactivation rate when increasing (Ts-Tg) from − 75 to 10 °C. The storage stability of freeze-dried L. salivarius CECT5713 samples decreased (i.e., inactivation rate increased) when, even in a glassy state, samples were closer to the viscous state (i.e., Ts-Tg > 0 °C or Ts > Tg). Similar behavior was observed in the mortality of S. thermophilus freeze-dried samples (with different formulations and stored for 12 weeks at 25 °C), which increased progressively for (Ts-Tg) values greater than − 20 °C (Selma et al. 2007). In contrast, no loss of functionality was reported when L. bulgaricus CFL1 freeze-dried samples were stored at 25 °C in a glassy state (Passot et al. 2012). This discrepancy in reported results may be explained by the vacuum storage conditions applied by Passot et al (2012), in addition to other factors that differ such as the formulation composition and strain-specific resistance. Furthermore, a similar trend was observed for the inactivation rate of L. salivarius CECT5713 (K37) and the temperature difference between the sublimation product temperature (Tp = − 25 °C) and the glass transition temperature of the maximally frozen concentrated matrix (Tg′) (Fig. 5b). The higher the temperature difference (Tp-Tg′), the lower the storage stability of L. salivarius was. Following the freezing step (− 80 to − 45 °C), the 8 formulations of L. salivarius were in a glassy state, and the freezing temperature was lower than the Tg′ values (between − 36 °C for MDFOSCom and − 28 °C for MD). During the sublimation step of the freeze-drying process, the product temperature was at approximately − 25 °C, meaning that all the samples left the glassy state and were maintained in the viscous state for a certain time until enough unfrozen water was removed to reach again the glassy state. From these data, we hypothesized that the thermal history of the product during the sublimation step could have an impact on the storage stability behavior of L. salivarius. Consequently, the storage stability could be improved by the following approaches: (i) designing the formulation to increase the glass transition temperature of the protected cell concentrates (Tg′) to values higher than the product temperature during sublimation (Tp); (ii) modifying the freeze-drying process parameters to decrease Tp (Tp < Tg′).

Relationship between the inactivation rate during storage (K37) of Ligilactobacillus salivarius CECT5713 protected with different formulations and the difference between a the storage temperature (Ts = 37 °C) and the glass transition temperature of the freeze-dried samples (Tg) (Ts-Tg, in °C) and b the product temperature (Tp = − 25 °C) at the beginning of the sublimation step and the glass transition of the maximally freeze-concentrated samples (Tg) (Tp-Tg′, in °C). MD: maltodextrin; TRE: trehalose; FOS: fructooligosaccharides; FOSCom: commercial FOS; F4: biological replicate no. 4 (fermentation)

Some deviations from the linear relationship (orange line) can be observed in Fig. 5 according to the composition of the protective formulation. The addition of some molecules such as antioxidants (blue points) and trehalose (grey points), in particular for MDTRE, resulted in decreasing the glass transition temperature of the matrix (and thus an increase of (Ts-Tg) or (Tp-Tg′)) compared to the MD formulation, without compromising the storage stability (similar values of the inactivation rate constants were obtained) (Table S5). In recent years, the use of fructooligosaccharide (FOS), for protecting LAB during the stabilization step, has increased (Corcoran et al. 2004; Golowczyc et al. 2011; Romano et al. 2016) since they present the additional attractiveness of being well-recognized prebiotics (i.e., “non-digestible food ingredients that have a beneficial effect through their selective metabolism in the intestinal tract” (Gibson et al. 2004)). Romano et al. (2016) proposed that the protective role of some FOS mixtures was due to the contribution of larger oligosaccharides to increase the Tg of the vitreous matrix as well as to the capacity of the mono and disaccharides (smallest sugars) to replace water molecules on lipid membranes (Crowe et al. 1988; Golovina et al. 2009). In this work, trehalose appeared as a better protective molecule than fructooligosaccharides (FOS6, FOS2, FOSCom) for stabilizing L. salivarius CECT5713 during subsequent storage (Figs. 2 and 5a). It was proposed that trehalose can penetrate deeply into the lipid membrane, establish hydrogen bonds with the carbonyl and phosphate groups, and replace water molecules from the lipid head group (Villarreal et al. 2004; Santivarangkna et al. 2008a), and thus avoid the deformation of the structure. The trehalose effectiveness in the stabilization process has been also confirmed by several authors in different strains of LAB (Conrad et al. 2000; Zayed and Roos 2004; Giulio et al. 2005; Foerst et al. 2012).

L. salivarius CECT5713 appeared to be resistant to freezing regardless of the formulation tested. However, it displayed slight sensitiveness to freeze-drying, and it was significantly affected by the storage at 37 °C depending on the formulation (Table S4). The loss of culturability observed during storage was not associated with a significant change in the fatty acid profile, even if a very small decrease in the relative percentage of C18:2 conjugated during storage was observed (up to 2.2%) might suggest the occurrence of lipid oxidation reactions. Similarly, important losses of culturability of freeze-dried L. lactis TOMSC161 were reported in a maltodextrin-sucrose matrix after 3 months of storage at 25 °C without any change in the membrane fatty acid composition (Velly et al. 2015). The authors hypothesized that other cellular components of L. lactis cells such as nucleic acids or proteins could be oxidized. In the present study, we applied FTIR micro-spectroscopy to investigate the biochemical changes induced by freeze-drying and storage on L. salivarius cells, after dehydration (i.e., in aqueous solutions). Although the FTIR micro-spectroscopy in aqueous conditions was recently applied to identify potential markers of cryoresistance of freeze-thawed LAB (Meneghel et al 2020; Girardeau et al 2022), to our knowledge, it is the first time that such an approach is applied to study cell biochemical changes induced by freeze-drying and storage. The FTIR results of the present study evidenced that other cellular components than membrane lipids, such as proteins, nucleic acids, and peptidoglycans of L. salivarius CECT5713 cell wall were altered immediately after the freeze-drying process and that the storage only intensified these cellular damages (Fig. 4). Regardless of the formulation composition, the cellular integrity of L. salivarius CECT5713 was thus altered by the freeze-drying process, and this alteration would make the bacterial cells more sensitive to degradation reactions occurring during storage. The negative effect of freeze-drying on storage stability is well known on proteins (Prestrelski et al. 1993; Abdul-Fattah et al. 2008; Carpenter et al. 2016). It appears that the protection condition (MDFOSCom) leading to the most important modification of the infrared spectra (observed in the second derivative, Fig. 4 and Table S7) was associated with the worst storage stability (Table S5). Furthermore, the use of sodium ascorbate which resulted in the best storage stability of L. salivarius provided the best protection to proteins, nucleic acids, and lipids (Table S7), whereas the addition of trehalose seems to limit degradation of cell wall.

In conclusion, this work highlighted the relevance of the glass transition temperature of the matrix or the thermal history of the product during freeze-drying and storage on the stability of L. salivarius CECT5713. The long-term stability of freeze-dried L. salivarius CECT5713 appeared to be associated with the immobilization of cells in a glassy state but not just any glassy state: to maximize survival, the storage has to be performed at a temperature at least 60 °C lower than the glass transition temperature, or at least 40 °C lower if an antioxidant (e.g., sodium ascorbate) is present in the formulation. Similar experiments need to be carried out with other strains to draw common conclusions with L. salivarius, and even with other microorganisms for an eventual generalization of mechanisms. In the future, the potential synergic effect of combining trehalose with maltodextrin and sodium ascorbate and the associated protective mechanisms deserve further study. Furthermore, FTIR micro-spectroscopy appears as an interesting tool for classifying formulations according to their efficiency and optimizing the stabilization processes and emerges as a sensitive method complementary to bacterial culturability.

Data availability

The datasets generated during and/or analyzed during the current study are available in the Data INRAE repository, https://doi.org/10.15454/EXGJDH.

References

Abdul-Fattah A, Lechuga-Ballesteros D, Kalonia D, Pikal M (2008) The impact of drying method and formulation on the physical properties and stability of methionyl human growth hormone in the amorphous solid state. J Pharm Sci 97:163–184. https://doi.org/10.1002/jps.21085

Arroyo R, Martín V, Maldonado A, Jiménez E, Fernández L, Rodríguez JM (2010) Treatment of infectious mastitis during lactation: antibiotics versus oral administration of Lactobacilli isolated from breast milk. Clin Infect Dis 50:1551–1558. https://doi.org/10.1086/652763

Bensch G, Rüger M, Wassermann M, Weinholz S, Reichl U, Cordes C (2014) Flow cytometric viability assessment of lactic acid bacteria starter cultures produced by fluidized bed drying. Appl Microbiol Biotechnol 98:4897–4909. https://doi.org/10.1007/s00253-014-5592-z

Broeckx G, Vandenheuvel D, Claes IJJ, Lebeer S, Kiekens F (2016) Drying techniques of probiotic bacteria as an important step towards the development of novel pharmabiotics. Int J Pharm 505:303–318. https://doi.org/10.1016/j.ijpharm.2016.04.002

Carpenter JF, Izutsu K, Randolph TW (2016) Freezing-and drying-induced perturbations of protein structure and mechanisms of protein protection by stabilizing additives. In: Rey L (ed) Freeze-drying/lyophilization of pharmaceutical and biological products, 3rd edn. CRC Press, Boca Raton, pp 181–211

Castro HP, Teixeira PM, Kirby R (1995) Storage of lyophilized cultures of Lactobacillus bulgaricus under different relative humidities and atmospheres. Appl Microbiol Biotechnol 4:172–176. https://doi.org/10.1007/BF00164498

Cejas L, Romano N, Moretti A, Mobili P, Golowczyc M, Gómez-Zavaglia A (2017) Malt sprout, an underused beer by-product with promising potential for the growth and dehydration of lactobacilli strains. J Food Sci Technol 54:4464–4472. https://doi.org/10.1007/s13197-017-2927-7

Cömert ED, Gökmen V (2018) Evolution of food antioxidants as a core topic of food science for a century. Int Food Res J 105:76–93. https://doi.org/10.1016/j.foodres.2017.10.056

Conrad PB, Miller DP, Cielenski PR, De Pablo JJ (2000) Stabilization and preservation of Lactobacillus acidophilus in saccharide matrices. Cryobiology 41:17–24. https://doi.org/10.1006/cryo.2000.2260

Corcoran BM, Ross RP, Fitzgerald GF, Stanton C (2004) Comparative survival of probiotic lactobacilli spray-dried in the presence of prebiotic substances. J Appl Microbiol 96:1024–1039. https://doi.org/10.1111/j.1365-2672.2004.02219.x

Crowe JH, Crowe LM, Carpenter JF, Rudolph A, Wistrom C, Spargo B, Anchordoguy T (1988) Interactions of sugars with membranes. Biochim Biophys Acta 947:367–384. https://doi.org/10.1016/0304-4157(88)90015-9

Crowe JH, Crowe LM, Oliver AE, Tsvetkova N, Wolkers W, Tablin F (2001) The trehalose myth revisited: introduction to a symposium on stabilization of cells in the dry state. Cryobiology 43:89–105. https://doi.org/10.1006/cryo.2001.2353

Cunningham M, Vinderola G, Charalampopoulos D, Lebeer S, Sanders ME, Grimaldi R (2021) Applying probiotics and prebiotics in new delivery formats – is the clinical evidence transferable? Trends Food Sci Technol 112:495–506. https://doi.org/10.1016/j.tifs.2021.04.009

Fenster K, Freeburg B, Hollard C, Wong C, RønhaveLaursen R, Ouwehand A (2019) The production and delivery of probiotics: a review of a practical approach. Microorganisms 7:83. https://doi.org/10.3390/microorganisms7030083

Fernández L, Castro I, Arroyo R, Alba C, Beltrán D, Rodríguez JM (2021) Application of Ligilactobacillus salivarius CECT5713 to achieve term pregnancies in women with repetitive abortion or infertility of unknown origin by microbiological and immunological modulation of the vaginal ecosystem. Nutrients 13:162. https://doi.org/10.3390/nu13010162

Foerst P, Kulozik U, Schmitt M, Bauer S, Santivarangkna C (2012) Storage stability of vacuum-dried probiotic bacterium Lactobacillus paracasei F19. Food Bioprod Process 90:295–300. https://doi.org/10.1016/j.fbp.2011.06.004

Folch J, Lees M, Stanley GHS (1957) A simple method for the isolation and purification of total lipides from animal tissues. J Biol Chem 226:497–509. https://doi.org/10.1016/S0021-9258(18)64849-5

Fonseca F, Béal C, Mihoub F, Marin M, Corrieu G (2003) Improvement of cryopreservation of Lactobacillus delbrueckii subsp. bulgaricus CFL1 with additives displaying different protective effects. Int Dairy J 13:917–926. https://doi.org/10.1016/S0958-6946(03)00119-5

Gibson GR, Probert HM, Loo JV, Rastall RA, Roberfroid MB (2004) Dietary modulation of the human colonic microbiota: updating the concept of prebiotics. Nutr Res Rev 17:259–275. https://doi.org/10.1079/NRR200479

Girardeau A, Passot S, Meneghel J, Cenard S, Lieben P, Trelea IC, Fonseca F (2022) Insights into lactic acid bacteria cryoresistance using FTIR microspectroscopy. Anal Bioanal Chem 414:1425–1443. https://doi.org/10.1007/s00216-021-03774-x

Giulio BD, Orlando P, Barba G, Coppola R, De Rosa M, Sada A, De Prisco PP, Nazzaro F (2005) Use of alginate and cryo-protective sugars to improve the viability of lactic acid bacteria after freezing and freeze-drying. World J Microbiol Biotechnol 21:739–746. https://doi.org/10.1007/s11274-004-4735-2

Golovina EA, Golovin AV, Hoekstra FA, Faller R (2009) Water replacement hypothesis in atomic detail—factors determining the structure of dehydrated bilayer stacks. Biophys J 97:490–499. https://doi.org/10.1016/j.bpj.2009.05.007

Golowczyc MA, Gerez CL, Silva J, Abraham AG, De Antoni GL, Teixeira P (2011) Survival of spray-dried Lactobacillus kefir is affected by different protectants and storage conditions. Biotechnol Lett 33:681–686. https://doi.org/10.1007/s10529-010-0491-6

Gong P, Sun J, Lin K, Di W, Zhang L, Han X (2019) Changes process in the cellular structures and constituents of Lactobacillus bulgaricus sp1.1 during spray drying. LWT-Food Sci Technol 102:30–36. https://doi.org/10.1016/j.lwt.2018.12.005

Grasmeijer N, Stankovic M, De Waard H, Frijlink HW, Hinrichs WLJ (2013) Unraveling protein stabilization mechanisms: vitrification and water replacement in a glass transition temperature-controlled system. Biochim Biophys Acta 1834:763–769. https://doi.org/10.1016/j.bbapap.2013.01.020

Guerrero Sanchez M, Passot S, Campoy S, Olivares M, Fonseca F (2022) Ligilactobacillus salivarius functionalities, applications, and manufacturing challenges. Appl Microbiol Biotechnol 106:57–80. https://doi.org/10.1007/s00253-021-11694-0

Haghparast S, Kashiri H, Shabanpour B, Pahlavani M (2010) Antioxidant properties of sodium acetate, sodium citrate and sodium lactate on lipid oxidation in rainbow trout (Onchorhynchus mykiss) sticks during refrigerated storage (4˚C). Iran J Fish Sci 9:73–86

Hlaing MM, Wood BR, McNaughton D, Ying D, Dumsday G, Augustin MA (2017) Effect of drying methods on protein and DNA conformation changes in Lactobacillus rhamnosus GG cells by Fourier transform infrared spectroscopy. J Agric Food Chem 65:1724–1731. https://doi.org/10.1021/acs.jafc.6b05508

Jalali M, Abedi D, Varshosaz J, Najjarzadeh M, Mirlohi M, Tavakoli N (2012) Stability evaluation of freeze-dried Lactobacillus paracasei subsp. tolerance and Lactobacillus delbrueckii subsp. bulgaricus in oral capsules. Res Pharm Sci 7:31–36

Kurtmann L, Carlsen CU, Risbo J, Skibsted LH (2009) Storage stability of freeze–dried Lactobacillus acidophilus (La-5) in relation to water activity and presence of oxygen and ascorbate. Cryobiology 58:175–180. https://doi.org/10.1016/j.cryobiol.2008.12.001

Meneghel J, Passot S, Jamme F, Lefrançois S, Lieben P, Dumas P, Fonseca F (2020) FTIR micro-spectroscopy using synchrotron-based and thermal source-based radiation for probing live bacteria. Anal Bioanal Chem 412:7049–7061. https://doi.org/10.1007/s00216-020-02835-x

Morgan F, Nouzille CA, Baechler R, Vuataz G, Raemy A (2005) Lactose crystallisation and early Maillard reaction in skim milk powder and whey protein concentrates. Lait 85:315–323. https://doi.org/10.1051/lait:2005017

Nag A, Waterland M, Janssen P, Anderson R, Singh H (2019) Importance of intact secondary protein structures of cell envelopes and glass transition temperature of the stabilization matrix on the storage stability of probiotics. Int Food Res J 123:198–207. https://doi.org/10.1016/j.foodres.2019.04.058

Nelson KA, Labuza TP (1992) Relationship between water and lipid oxidation rates: Water activity and glass transition theory. In: St Angelo AJ (ed) Lipid Oxidation in Food. ACS Symposium Series, vol 500. American Chemical Society, Washington, DC, pp 93–103

Olsson C, Zangana R, Swenson J (2020) Stabilization of proteins embedded in sugars and water as studied by dielectric spectroscopy. Phys Chem Chem Phys 22:21197–21207. https://doi.org/10.1039/D0CP03281F

Passot S, Cenard S, Douania I, Trelea IC, Fonseca F (2012) Critical water activity and amorphous state for optimal preservation of lyophilised lactic acid bacteria. Food Chem 132:1699–1705. https://doi.org/10.1016/j.foodchem.2011.06.012

Passot S, Gautier J, Jamme F, Cenard S, Dumas P, Fonseca F (2015) Understanding the cryotolerance of lactic acid bacteria using combined synchrotron infrared and fluorescence microscopies. Analyst 140:5920–5928. https://doi.org/10.1039/C5AN00654F

Prestrelski S, Arakawa T, Carpenter J (1993) Separation of freezing-and drying-induced denaturation of lyophilized proteins using stress-specific stabilization: II. Struct Stud Using Infrared Spectrosc 303:465–473. https://doi.org/10.1006/abbi.1993.1310

Rodklongtan A, Nitisinprasert S, Chitprasert P (2022) Antioxidant activity and the survival-enhancing effect of ascorbic acid on Limosilactobacillus reuteri KUB-AC5 microencapsulated with lactose by spray drying. LWT 164:113645. https://doi.org/10.1016/j.lwt.2022.113645

Romano N, Marro M, Marsal M, Loza-Alvarez P, Gomez-Zavaglia A (2021) Fructose derived oligosaccharides prevent lipid membrane destabilization and DNA conformational alterations during vacuum-drying of Lactobacillus delbrueckii subsp. Bulgaricus. Int Food Res J 143:110235. https://doi.org/10.1016/j.foodres.2021.110235

Romano N, Schebor C, Mobili P, Gomez-Zavaglia A (2016) Role of mono- and oligosaccharides from FOS as stabilizing agents during freeze-drying and storage of Lactobacillus delbrueckii subsp. bulgaricus. Int Food Res J 90:251–258. https://doi.org/10.1016/j.foodres.2016.11.003

Rückold S, Grobecker KH, Isengard HD (2001) The effects of drying on biological matrices and the consequences for reference materials. Food Control 12:401–407. https://doi.org/10.1016/S0956-7135(01)00033-0

Sallam KI (2007) Antimicrobial and antioxidant effects of sodium acetate, sodium lactate, and sodium citrate in refrigerated sliced salmon. Food Control 18:566–575. https://doi.org/10.1016/j.foodcont.2006.02.002

Santivarangkna C, Higl B, Foerst P (2008) Protection mechanisms of sugars during different stages of preparation process of dried lactic acid starter cultures. Food Microbiol 25:429–441. https://doi.org/10.1016/j.fm.2007.12.004

Santivarangkna C, Kulozik U, Foerst P (2008) Inactivation mechanisms of lactic acid starter cultures preserved by drying processes. J Appl Microbiol 105:1–13. https://doi.org/10.1111/j.1365-2672.2008.03744.x

Santivarangkna C, Kulozik U, Foerst P (2006) Effect of carbohydrates on the survival of Lactobacillus helveticus during vacuum drying. Lett Appl Microbiol 42:271–276. https://doi.org/10.1111/j.1472-765X.2005.01835.x

Schwab C, Vogel R, Gänzle MG (2007) Influence of oligosaccharides on the viability and membrane properties of Lactobacillus reuteri TMW1.106 during freeze-drying. Cryobiology 55:108–114. https://doi.org/10.1016/j.cryobiol.2007.06.004

Selma MV, MacNaughtan W, Mitchell J, Waites W (2007) Optimisation of production and storage stability of the starter bacteria Streptococcus thermophilus and Lactobacillus plantarum. J Sci Food Agric 87:765–772. https://doi.org/10.1002/jsfa.2745

Sierra S, Lara-Villoslada F, Sempere L, Olivares M, Boza J, Xaus J (2010) Intestinal and immunological effects of daily oral administration of Lactobacillus salivarius CECT5713 to healthy adults. Anaerobe 16:195–200. https://doi.org/10.1016/j.anaerobe.2010.02.001

Sosa N, Gerbino E, Golowczyc M, Schebor C, Gomez Zavaglia A, Tymczyszyn E (2016) Effect of galacto-oligosaccharides: maltodextrin matrices on the recovery of Lactobacillus plantarum after spray-drying. Front Microbio 3:584. https://doi.org/10.3389/fmicb.2016.00584

Teixeira P, Castro H, Kirby R (1996) Evidence of membrane lipid oxidation of spray-dried Lactobacillus bulgaricus during storage. Lett Appl Microbiol 22:34–38. https://doi.org/10.1111/j.1472-765X.1996.tb01103.x

Teng D, Kawai K, Mikajiri S, Hagura Y (2017) Stabilization of freeze-dried Lactobacillus paracasei subsp. paracasei JCM 8130 T with the addition of disaccharides, polymers, and their mixtures. Biosci Biotechnol Biochem 81:768–773. https://doi.org/10.1080/09168451.2017.1279852

Tymczyszyn EE, Del Rosario DM, Gómez-Zavaglia A, Disalvo EA (2007) Volume recovery, surface properties and membrane integrity of Lactobacillus delbrueckii subsp. bulgaricus dehydrated in the presence of trehalose or sucrose. J Appl Microbiol 103:2410–2419. https://doi.org/10.1111/j.1365-2672.2007.03482.x

Vaccari L, Birarda G, Businaro L, Pacor S, Grenci G (2012) Infrared microspectroscopy of live cells in microfluidic devices (MD-IRMS): toward a powerful label-free cell-based assay. Anal Chem 84:4768–4775. https://doi.org/10.1021/ac300313x

Velly H, Bouix M, Passot S, Penicaud C, Beinsteiner H, Ghorbal S, Lieben P, Fonseca F (2015) Cyclopropanation of unsaturated fatty acids and membrane rigidification improve the freeze-drying resistance of Lactococcus lactis subsp. lactis TOMSC161. Appl Microbiol Biotechnol 99:907–918. https://doi.org/10.1007/s00253-014-6152-2

Villarreal MA, Díaz SB, Disalvo EA, Montich GG (2004) Molecular dynamics simulation study of the interaction of trehalose with lipid membranes. Langmuir 20:7844–7851. https://doi.org/10.1021/la049485l

Zayed G, Roos YH (2004) Influence of trehalose and moisture content on survival of Lactobacillus salivarius subjected to freeze-drying and storage. Process Biochem 39:1081–1086. https://doi.org/10.1016/S0032-9592(03)00222-X

Acknowledgements

We thank Pascale Lieben from INRAE and Anne-Claire Peron from AgroParisTech for training MGS to FTIR spectroscopy and fatty acid composition analysis, respectively. We also thank Pablo Mobili and Nelson Romano from CIDCA, CCT-CONICET (La Plata, Argentina) for the production of FOS2 and FOS6. Finally, we thank Cristina Diaz Morillo from Biosearch S.A.U (a Kerry® company) for her implication in the management and coordination of the European project PREMIUM RISE (no. 777657).

Funding

This work has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement N° 777657.

Author information

Authors and Affiliations

Contributions

Conceptualization and methodology MGS, SP, FF; experiments MGS (FF for Tg′ measurement); formal analysis MGS, FF; data curation and statistical treatment MGS, SP, FF: writing original draft of the paper MGS, FF; writing review MGS, SP, FF; final review and editing MGS, SP, FF, SC, MO; supervision and project administration FF, SP, SC, MO; resources and funding acquisition SC, MO.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guerrero Sanchez, M., Passot, S., Campoy, S. et al. Effect of protective agents on the storage stability of freeze-dried Ligilactobacillus salivarius CECT5713. Appl Microbiol Biotechnol 106, 7235–7249 (2022). https://doi.org/10.1007/s00253-022-12201-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-022-12201-9