Abstract

A high production mutated strain Bacillus thuringiensis X023PN (BtX023PN) was screened from the wild strain Bacillus thuringiensis X023 (BtX023) after atmospheric and room temperature plasma (ARTP) and nitrosoguanidine (NTG) mutation. BtX023PN grows faster than the wild strain, and its lysis of mother cell was 6 h ahead BtX023, but the ability of sporulation was significantly reduced. Bioassay indicated that compared with the wild type strain, the virulence of BtX023PN against Plutella xylostella (P. xylostella) and Mythimna seperata (M. seperata) increased to 2.33-fold and 2.13-fold respectively. qRT-PCR and SDS-PAGE demonstrated that the production of Cry1Ac increased by 61%. Resequence indicated that the mutated sites enriched on the key carbohydrate metabolism and amino acid metabolism. This study provides a new strain resource for the development of Bt insecticides and a feasible technical strategy for the breeding of Bt.

Key points

• Atmospheric and room temperature plasma used in breeding of Bacillus thuringiensis.

• Less stationary phase time with more ICP production.

• Semi-lethal concentration against Plutella xylostella reduced by about 57%

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacillus thuringiensis (Bt) is a ubiquitous bacterium that can produce different insecticidal proteins that show toxicity against a wide range of insect orders (Bravo et al. 2007; Santos et al. 2022), including Lepidoptera, Diptera, Coleoptera, Hymenoptera, and Nematodes (Melo et al. 2016; Sayed and Behle 2017), but tend to be much less toxicity to taxa outside the range (van Frankenhuyzen 2009). These insecticidal substances are accumulated during sporulation phase and the vegetative phase, which were classified in insecticidal crystal protein (ICP), vegetative insecticidal protein (Vip), and secreted insecticidal protein (Sip) (Bel et al. 2020; Jouzani et al. 2017), among which the Cry insecticidal proteins were the most widely applied in insecticidal sprayable formulations and transgenic Bt plants (Crickmore et al. 2021; Yang et al. 2021).

Bt has been widely used in biological control of pests for the advantages of high insecticidal activity, environmental friendliness, and harmless to humans and animals (Kumar et al. 2019; Peña-Cardeña et al. 2018; Quan et al. 2020). Commonly, a novel Bt strain was obtained from the nature (soil, water, etc.), and the combination of mutation and natural selection is the key driving force for the evolution of life in the nature (Zhang et al. 2015, 2014). But the natural evolution process is often not efficient enough and time-costly to obtain a novel Bt strain with good performance or function due to the low spontaneous mutation rate (Drake et al. 1998). Since the demand of the public and farmers for the use of safe and more efficient pesticides is increasing in the world (Ricietto et al. 2022), accelerating the mutation process of current resource strains to quickly obtain new high-virulence strains is an efficient strategy.

Therefore, artificial mutation methods are widely used to improve the rates of mutation, such as physical mutagenesis, chemical mutagenesis, and physical–chemical compound mutagenesis (Wang et al. 2016; Zhang et al. 2016).

As for physical mutagenesis, atmospheric temperature plasma (ARTP) mutagenesis technology is a new type of mutagenesis breeding method that could be used in microbial breeding and it has successfully finished the mutagenesis on bacteria, such as Clostridium butyricum, Corynebacterium glutamicum, and Streptomyces albus (Yang et al. 2019; Zhang et al. 2019, 2018). Various microorganisms could be mutated by the charged particles, free radicals, excited neutral substances, high electric fields, and ultraviolet radiation in ARTP; moreover, ARTP is driven by radio frequency power, which can be produced under atmospheric pressure without vacuum system, and its plasma jet could be controlled at room temperature, which facilitated the operations in microbial mutations (Dong et al. 2010; Fang et al. 2013; Jiang et al. 2014).

As for chemical mutagenesis, chemical mutagens such as ethyl methanesulfonate (EMS), nitrosoguanidine (NTG), and n-ethyl-n-nitrosourea (ENU) were used in microorganisms (Yang et al. 2019), which directly act on the microbial genome by substituting purine or pyrimidine bases. Among them, NTG, an alkylating agent in chemical mutagens, known as super mutagen, is one of the most widely used chemical mutagens. Moreover, GC-AT conversion, small-scale DNA excision, frameshift mutation, and GC pair deletion could be induced when the cells were under NTG treatment (Harper and Lee 2012; Harper et al. 2011; Velicer et al. 2006).

Although chemical or physical mutagenesis is promising in strain breeding, the low mutagenesis efficiency caused by single type of mutagenesis often dissatisfies the need of scientific research (Li et al. 2014). Therefore, combinating chemical and physical mutagenesis may be a potence for successful acquiring highly mutant strains (Du et al. 2007; Sivaramakrishnan and Incharoensakdi 2017).

BtX023 (CCTCC No. M2018283) was isolated from the soil of Jinxia Mountain, Xiantan city, Hunan province, China. Its insecticidal protein has been identified, in which the main insecticidal proteins are Cry1, Cry2Aa, and Vip3Aa (Liu et al. 2020b). As a result of the increasing demand for safe and more efficient pesticides is in the world, we were trying to accelerate the mutation process of the current resource strains BtX023 and further expand its applications. Therefore, BtX023 was treated by random mutagenesis combined ARTP and NTG mutagenesis to further improve its insecticidal virulence. So far, this is the first report on the development of Bt with higher toxicity by ARTP and NTG compound mutagenesis.

Material and methods

Strains and culture condition

The wild strain used in this study was previously isolated from the soil in Jinxia Mountain of China and named as BtX023, which could produce three types of ICPs, namely, Cry1, Cry2Aa, and Vip3Aa. The most common ICP was Cry1. Cry1A was the most significant among the Cry1 proteins, particularly Cry1Ac. The amount of other Cry1 proteins, such as Cry1I, Cry1F, and Cry1E, were low, although they also have high specific toxicity to Lepidoptera (Liu et al. 2020b). The obtained highest virulence strain was named as BtX023PN (CCTCC No. M2020264). The Luria–Bertani (LB), 5 g/L yeast extract, 10 g/L tryptone, and 10 g/L NaCl, was used for the seed culture. The fermentation broth is as follows: 18 g/L glucose, 14.5 g/L tryptone, 2.5 g/L K2HPO4, 0.02 g/L FeSO4·7H2O, 0.02 g/L MnSO4·H2O, and 0.25 g/L MgSO4 7H2O.

All the broths were autoclaved at 115 °C for 30 min to confirm the sterility of each batch of broth. The strains used in this study are listed in Table S1.

BtX023 was cultured at 30 °C, 120 rpm in 20 mL LB broth. Subsequently, 300 μL of the overnight bacterial solution was added into 300 mL shake flask containing 30 mL fermentation broth to produce ICPs with 120 rpm at 30 °C.

Preliminary virulence assay of mutational strains

The larvae of P. xylostella were fed with artificial feed at 28 °C with a light/dark cycle of 12 h. Artificial feed comprised flour 60 g/L, yeast extract 20 g/L, bean flour 120 g/L, vitamin B2 2 g/L, vitamin C 2 g/L, ethyl p-hydrobenzoate 2 g/L, sorbic acid 1 g/L, and agar 15 g/L. Transfer 300 μL fermentation products (fermentated for 48 h, concentration: 1 × 109 cfu/mL) of wild strain and mutated strains (blank control: 300 μL sterile water) into 20 mL artificial feed and mix. The mixture was added into three 24-well cell culture plates (Corning, USA). The larvae were cultured in the 24-well cell culture plates (one larva per well), with three replicates. The survival percentage of the larva was recorded after 24 h.

Semi-lethal concentration assay of wild type strain and mutant strain

After the wild type strain and mutated strain fermentated for 48 h (1 × 109 cfu/mL), the fermentation products were collected and diluted to 1.25, 2.5, 3.75, 5, and 10 (μL/mL) mixed well with the artificial feed. The mixture of per concentration was transferred into three 24-well cell culture plates. The larvae were cultured in the 24-well cell culture plates (one larva per well), with three replicates. The survival percentage of the larva was recorded after 48 h.

Mutagenesis by ARTP

ARTP mutagenesis was carried out in the ARTP biological mutagenesis system (Wuxi Yuanqing Tianmu Biological Technology Co., Ltd., Wuxi, China). With 99.99% helium, the working radio-frequency power input, treatment distance, and gas flow were set to 100 W, 2.0, mm and 8.0 SLM, respectively. Ten microliters of the original bacterial solution at its exponential phase (1 × 109 cfu/mL) was dropped onto a sterilized stainless steel plate. In order to get the optimum treatment time, the wild type BtX023 was treated in a range of 0–120 s (the first ARTP mutagenesis) and 10–60 s (the second ARTP mutagenesis); the untreated strain was used as control. After that, the stainless steel plates were transferred to 1.5 mL centrifugal tube with 1 mL LB broth shaken for 2 min to resuspend the cells. One hundred microliters of each resuspended cell was diluted and spread on different LB agar plates, cultivated in 30 °C for 12 h.

Choose the treatment time that caused strain mortality in 60–90% as the optimum treat duration; the resuspended cell broth was diluted and spread in agar plates and cultivated in 30 °C for 12 h. Each clone on these plates was re-cultivated on a slant medium for 48 h, and each sample in 3 random sights was selected to count the number of their crystal protein under microscope observing; the strains containing more crystal protein than the original strain were screened out. The screened strains were cultured in LB broth and preserved in − 80 °C.

Mutagenesis by NTG

The screened strain with the highest virulence against P. xylostella was used as the original strain in NTG mutagenesis. The strain was cultured in LB broth until its exponential phase (1 × 109 cfu/mL), 1 mL strain of which were collected and suspended in 5 mL PBS buffer (13.6 g/L Na2HPO4·12H2O, 25.28 g/L NaH2PO4·2H2O, PH 6.8–7.2) in which NTG was added to make the final concentration is 500 μg/mL. The cells were collected after being incubated at 30 °C, 220 rpm in the dark for 1 h. Wash the cells 4 times with PBS buffer to stop the reaction.

Warning: NTG is a strong carcinogen and highly toxic. The bacterial liquid treated with NTG and the tools used in the experiment should be soaked in 1 M NaOH buffer for 24 h. When operating, it is necessary to wear rubber gloves, overalls, and masks. Avoid contact with eyes or skin. In case of contact, wash immediately with potable water.

Growth curve determination and morphological observation

500 μL bacterial solution (1 × 109 cfu/mL) of BtX023 and the mutated strain was inoculated in the fermentation broth (50 mL per 500 mL shake flask) and cultured at 30 °C, 120 rpm. The growth curve was measured to 60 h with three biological repetitions. The OD600 was measured by spectrophotometer (DR600, HACH, USA), and the samples were taken at each 2 h in time. The cells are observed with phase contrast microscope (AXIO Scope A1, Zeiss, Germany) 12 h intervals.

Preparation of scanning electron microscope sample

1 mL fermentation liquid of BtX023 and BtX023PN fermented for 48 h was collected in 1.5 mL centrifuge tubes respectively. After that, the cells were suspended and washed with sterile ultrapure water 10 times (9,000 × g, 2 min), fixed with 2.5% glutaraldehyde for 6 h at 4 °C. Afterwards, washing three times with sterile ultrapure water again, the samples were dehydrated gradually with 30%, 50%, 70%, 80%, 90%, 95%, and 100% ethanol, which was conducted twice for 10 min each subsequently. The samples were evenly applied on the cover glasses and freeze dried soon to sputtering gold plating, imaged with the scanning electron microscope (Hitachi Su8010, Japan).

Genome sequencing and assembly

The genome of BtX023PN (accession number: SAMN24619035) was sequenced using an Illumina HiSeq 4000 system (Illumina, San Diego, CA, USA) at the Beijing Genomics Institute (Shenzhen, China). Genomic DNA was sheared randomly to construct three read libraries with lengths of 6,334,170 bp by a Bioruptor ultrasonicator (Diagenode, Denville, NJ, USA) and physicochemical methods. The paired-end fragment libraries were sequenced according to the Illumina HiSeq 4000 system’s protocol. Raw reads of low quality from paired-end sequencing (those with consecutive bases covered by fewer than five reads) were discarded. The sequenced reads were assembled using SOAPdenovo v1.05 software.

The variation sites between the query sequence and reference sequence are found out and filtered preliminarily to detect potential SNP sites. The sequences with the length of 100 bp at both sides of SNP in the reference sequence are extracted and aligned with assembly results to verify SNP sites by using BLAT. If the length of aligned sequence is shorter than 101 bp, this SNP is considered incredible and it will be removed; if the extracted sequence can be aligned with the assembly results several times, this SNP is considered locate in repeat region and it will also be removed. Blast (http://blast.ncbi.nlm.nih.gov/Blast.cgi), TRF (http://tandem.bu.edu/trf/trf.html), and Repeatmask (http://www.repeatmasker.org/) software are used to predict SNP in repeat regions. The credible SNP can be obtained through filtering SNP located in repeat regions.

With LASTZ (http://www.bx.psu.edu/miller_lab/dist/README.lastz-1.02.00/) software, the reference sequence and query sequence are aligned to get the alignment results. Through a series of treatment with axt_correction, axtSort, and axtBest, the best alignment results are chosen and the Indel results are preliminarily obtained. 150 bp (3*SD) in the upstream and downstream of Indel site in the reference sequence are extracted and then aligned with the query reads. The alignment results are verified with BWA (http://bio-bwa.sourceforge.net/) and samtools (http://samtools.sourceforge.net/).

Preparation for qRT-PCR samples

BtX023 and BtX023PN were fermented for 28 h; 1 mL fermentation liquid of each strain was collected in 1.5 mL centrifuge tubes (9,000 × g, 2 min). 2 mL TRIzol Reagent (Invitrogen) was added for grinding until the cells becomes clarified liquid. After that, 200 μL trichloromethane were mixed thoroughly and centrifugated (13,000 × g, 4℃, 10 min); take 400 μL of the upper liquid into the new centrifuge tube and add the same volume of isopropyl alcohol, centrifuged at 13,000 × g at 4℃ for 10 min. Water with 75% anhydrous ethanol twice (13,000 × g, 4℃, 10 min). All the materials used in RNA extraction are exclusive. The total RNA was reverse transcripted to cDNA using RevertAidTM First Strand cDNA Synthesis Kit (Fermentas) according to the manuscript. The cDNAs were used as templates to perform relative quantitative real-time PCR with 16S rRNA as endogenous control.

The primers used in this study are listed in Table S1.

Extraction of crystal proteins

The wild strain and BtX023PN were fermented for 48 h. Their Cry1Ac protein was extracted as previously reported (Wang et al. 2013). The dry weight of Cry1Ac was weighed and the concentration of Cry1Ac protein was measured by Bradford method and purity was analyzed by SDS-PAGE. The gray scale analysis of the strips was performed on Gel-Pro analyzer 4.0.

Stability analysis of highly virulent strains

In order to test the genetic stability of the selected high-virulence strains, the strains were successively passaged in 500 mL fermentation broth for five times (the transduction was performed once every 48 h), and each passage was subjected to microscopic examination, semi-lethal (LC50) concentration of virulence bioassay, and crystal proteins extraction.

Statistical method

The mortality of larvae (%) = (A − B)/24 × 100%, where A is the count of dead larvae in each 24-well plate and B is the count of dead larvae in blank control group; the LC50 was calculated by the SPSS software (Inc., version 20, USA). The lethality rate of ARTP mutagenesis (%) = (A − B)/A × 100%, where A is the number of colonies in the each controlled (without mutagenesis) plate and B is the number of colonies in each experimental group (mutagenesis by ARTP) plate.

Results

Improvement of insecticidal virulence by the first ARTP mutagenesis

The lethality of bacteria was in a dose–effect relationship with treatment time (Fig. 1a). The mortality rate of the strain after 20 s of ARTP treatment was nearly 20%, which then followed a significant increase over time and reached about 60% after 40 s of treatment. As the treatment time increased from 40 to 60 s, mortality rate was increased to around 90%. Therefore, the optimal treatment time for the first ARTP mutagenesis in this study is 40 ~ 60 s.

Effects of ARTP treatment time on the mortality rate of original strains and the mortality of P. xylostella caused by the highest virulence ARTP mutant strains. a The mortality rate of BtX023 under 0–120 s ARTP treatment. b The lethality of mutant strain A4 against P. xylostella, ***P < 0.001. c The mortality rate of A4 under 0–60 s ARTP treatment. d The lethality of mutant strain a24 against P. xylostella, nsP > 0.05. ARTP, atmospheric and room temperature plasma; CK, fermentation broth from the original broth. Each point represents the mean and standard deviation of three independent experiments

Three hundred sixty-eight colonies were obtained and 45 of them were screened for bioassay. The screened strain A4 had the highest insecticidal activity among all strains, so it was selected as the starting strain of the second round ARTP mutagenesis (Fig. 1b).

Improvement of insecticidal virulence by the second ARTP mutagenesis

As shown, the mortality rate of A4 increases with time (Fig. 1c). When it was irradiated with ARTP for 30 s, the mortality rate significantly increased to 61.7%, and then reached 91.9% after 10 s more treatment. The optimal treatment time for the second ARTP mutagenesis is 30 ~ 40 s.

Twenty-eight of 249 obtained colonies were selected for bioassay. The mutant strain a24 showed the highest insecticidal activity (Fig. 1d), but the difference was not significant.

NTG mutagenesis further improved the insecticidal virulence

As a result, a24 was subjected to NTG mutagenesis. Four hundred seventy-three colonies were obtained, 48 of which were selected for bioassay experiment. BtX023PN emerged to the highest insecticidal activity mutated strain that increased by about 31% when compared with BtX023 (Fig. 2).

Semi-lethal concentration of wild strain and mutated strain

The LC50 of the wild strain was 7.421 μL/mL and 13.816 μL/mL against P. xylostella and M. seperata respectively, while BtX023PN was 3.189 μL/mL and 6.476 μL/mL, which was determined by probit analysis demonstrating that the toxicity of BtX023PN against P. xylostella and M. seperata increased to 2.33-fold and 2.13-fold respectively (Table 1).

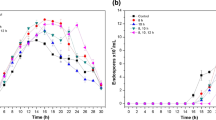

Changes in growth and phenotypes after mutagenesis

The growth curves of the two strains showed that both strains entered the stationary phase at 14 h, but BtX023PN grew slightly faster than the wild strain, and there was no significant difference in biomass. The curve of BtX023PN suddenly dropped at 32 h, demonstrating the entering of decline phase, which was 6 h earlier than wild strain whose curve dropped at 38 h (Fig. 3). At 32 h, many released spores and crystal proteins appeared in BtX023PN but still not visible in wild strain (Fig. 4).

Phase contrast microscope and scanning electron microscope observation of BtX023 and BtX023PN at 32 h. a BtX023 observed by the phase contrast microscope. b BtX023PN observed by the phase contrast microscope. c BtX023 observed by the scanning electron microscope. d BtX023PN observed by the scanning electron microscope. White arrows refer to spores and black arrows refer to crystal proteins

Analysis of resequence and qRT-PCR

The whole genome sequence of BtX023 (accession number: SAMN13118470) was set as the reference sequence of BtX023PN. There were total 66 SNP in BtX023PN, among which 19 were non-synonymous mutations (Table S2). Forty-two Indels were obtained, 15 of which were located on CDS and the other sited on intergenic region (Table S3). These mutated sites are rich in asparagine synthetase B, fatty acid desaturase, serine O-acetyltransferase, succinic dehydrogenase, and etc.

qRT-PCR analysis of related genes was performed on these two strains fermented for 28 h according to phenotypic differences and resequencing analysis results. Differential gene analysis showed that aspB, cysE, and fadD were upregulated while sdhA was downregulated. The sigE and sigF were downregulated and upregulated respectively. The genes cry1Ac and cry2Aa were upregulated to 1.83 and 1.85 times, respectively, and the cell lytic gene cwlC was upregulated to 1.7 times (Fig. 5). The analysis of sporulation-related genes showed spoIIR upregulated, spoIIA, spoIIGA, and spoIVA downregulated, and spoIIID had no significant change. The active spore amount analysis showed that the sporulation ability of BtX023PN was weakened (Fig. S1).

qRT-PCR analysis of selected genes. qRT-PCR was used to substantiate the expression levels of cry1Ac, cry2Aa, spoIIR, spoIIAA, spoIIGA, spoIIID, spoIVA, cwlC, cysE, fadD, sdhA, sigE, and sigK. mRNA levels after 28 h fermentation of BtX023 and BtX023PN were analyzed as values relative to the 16S rRNA gene. The ratio value for BtX023 was set to 1. Error bars are calculated from four independent determinations of mRNA abundance in each sample. Two-tailed T test, nsP > 0.05, **P < 0.005, ***P < 0.001

Effects of mutagenesis on Cry pesticidal protein biosynthesis

The crystal protein of the fermented 48 h optimal strains, obtained after each mutagenesis, was extracted and analyzed by SDS-PAGE. Mutated strains had stronger 130 kDa (Cry1Ac, Table S4) band (the IDOs from lines 2 to 4 were 818.01, 909.12, and 1094.8, respectively) than that of the wild strain (the IDOs of line 1 was 670.42), which indicated that the mutated strains were 1.22-, 1.36-, and 1.63-fold of the wild strain respectively (Fig. 6a). In addition, the bands of the mutagenesis strains at 65 kda (Cry2Aa, supporting information Table S5) were also significantly wider (the IDOs from lines 2 to 4 were 370.26, 379.9, and 493.04 respectively) than those of the wild strain (IDOs = 158.52).

The Cry1Ac protein of wild bacterium and BtX023PN fermented 60 h was extracted and weighed. The dry weights of Cry1Ac protein of BtX023PN and the wild strain were determined to be 0.393 g and 0.244 g, respectively (Fig. 6b), indicating that the Cry1Ac protein yield of BtX023PN increased by 61% times compared with wild strain.

Strain genetic stability analysis

Mutant strains obtained by mutagenesis breeding may undergo back mutation, so it is very important to test the stability of the mutated strains. The morphology, LC50 against P. xylostella, and yield of Cry1Ac of BtX023PN were steady after 5 times of passages (Fig. S2, Table S6).

Discussion

ARTP is a powerful and novel breeding technology, whose high concentration of neutral active particles has effects on microorganisms, such as the excited He, O, N2, and OH particles (Fang et al. 2013; Li et al. 2015). Compared with the molecular genetic modification and traditional mutagenesis technology, ARTP mutagenesis technology has the advantages of simpler operation and higher efficiency.

The optimum ARTP treatment time is distinct in different strains. Liu et al. obtained a mutated artp-aleBC15 with the improvement tolerance to pH 2.5 and 0.3% bile salt with a survival rate of 22.4% after 15 s of ARTP mutation (Liu et al. 2020a). While Li et al. reported that their optimum time to Clostridum acetobutylicum for ARTP was 140 s (Li et al. 2014), and Liang et al. chose 120 s as the best ARTP time for the treatment of Saccharomyces cerevisiae (Liang et al. 2014). It seems like that the fungi are less sensitive to the exposure time of ARTP treatment than bacterium, which maybe caused by their differences in biochemical characters of cell walls that act as a natural barrier against environmental changes.

In this study, BtX023 was set as the start strain treated with ARTP and the best time for ARTP mutagenesis was determined. As is reported, when the lethality of the bacteria is in the range of 60–90%, it is beneficial to produce positive mutant strains (Qiang et al. 2014). Therefore, 50 s and 35 s were selected as the best ARTP treat time of the first and second mutagenesis respectively.

ARTP mutation shows its superiority in some respects. In the process of mutant strains generation, costs are greatly reduced, operations are significantly simplified, and safety is dramatically improved. In addition, more high frequent random mutations induced by the helium-based ARTP could generate desirable stable genetic phenotype in a simple to operate manner (Yu et al. 2022). However, as single ARTP mutagenesis repeatedly performed on strains, the positive mutation rate decreases gradually under every round of mutagenesis. In this study, the number of positive mutated strains greatly decreased after the second ARTP mutagenesis, but it significantly increased after the NTG mutagenesis. Therefore, we speculated that the single repeated mutagenesis may result “fatigue effect” in strains, which caused a decreasing in its positive mutation rate.

In our case, the compound mutation of ARTP and NTG was first applied to screen Bacillus thuringiensis with high insecticidal virulence. Our results illustrated that compound mutation of ARTP and NTG caused in much higher DNA damage levels and positive mutation rates when compared with single mutation method.

Accelerating the mutation process of current resource strains to quickly obtain new high-virulence strains is an efficient strategy to meet the demands of the public and farmers for the use of safe and more efficient pesticides. Obtain a novel Bt strain with desired performance or function by artificial mutagenesis is a quicker and more targeted method. On the basis of our original strain, whose physiological and biochemical features have known clearly, would facilitate the integration of all good characters into the same strain. In addition, the commonness of mutated strains with improved performance in the same batch can be studied through genomics, which provided bases and directions for the directional modification of Bt strains.

Melo et al. reported that the insecticidal crystal proteins were formed during sporulation, which were occurred in the stationary phase, and the spores and crystal proteins were released in the lag phase (Melo et al. 2016). As for the morphological observation, many released spores and crystal proteins appeared in BtX023PN that fermented 32 h but still not visible in the wild strain BtX023, which maybe associated with cwlC. As shown, the production of Cry pesticidal proteins increased while the stationary phase was 6 h reduced. So, we selected many genes related to sporulation, crystal protein, and cell lysis to explain it.

cwlC is a newly discovered cell wall hydrolase, which plays an important role in the lysis of Bt mother cells, the expression of cwlC is dependent on sporulation sigma factor K (σK), and disruption of the cwlC gene completely blocked the mother cell lysis without impacting sporulation, crystal protein production, or insecticidal activity (Chen et al. 2018). The upregulation of cwlC results in early lysis of BtX023PN cells. However, three sporulation-related genes (spoIIAA, spoIIGA, spoIVA) were downregulated in BtX023PN, while the spoIIR gene, which was required for the processing of pro-sigma-E, was upregulated. The downregulation of these sporulation-related genes may be the direct reason leading to the decrease of the sporulation ability.

The expression of most Cry and Cyt proteins is accompanied by the sporulation. There are four main factors associated with Cry pesticidal protein transcription: σA, σH, σE, and σK. Stages II to IV of sporulation (septal-cortical formation) are responsible for σE, and σK becomes active in phase IV. Meanwhile, virulence genes such as Cry1, Cry11A, and Cyt1A also depend on the RNA polymerase of σK (Wanapaisan et al. 2013; Wang et al. 2006; Yang et al. 2012). As the process of sporulation, the sigma factors and the corresponding regulators of sporulation at different stages were activated.

SNP site functional annotation is mainly focused on carbohydrate metabolism and amino acid metabolism in metabolic pathways. The final effects of all the changes promoted the improvement of the yield and activity of Cry pesticidal protein in high-virulence strains. We described a metabolic pathway: the upregulation of gene cysE caused more serine transferred into OAS (O-acetyl-L-serine) and further reduced the yield of pyruvate which is the feed supply of sporulation and the binding of CysK and CysE was inhibited, which means the synthesis of cysteine synthase was affected. The upregulation of gene aspB in amino acid biosynthesis caused the increase of feed supply in ICPs, and downregulation of sdhA in TCA caused the accumulation of succinate and reduction of acetyl-CoA, which further weakened the ability of BtX023PN in sporulation.

Meanwhile, the upregulation of fadA in fatty acid metabolism may provide more energy for the processing of ICPs. The slackness of sporulation ability may be caused by the downregulation of sigE. Moreover, the upregulation of ðk caused the upregulation of cwlC and further regulated the expression of cry1Ac and cry2Aa, causing the increase of Cry pesticidal protein production (Fig. 7). In our previous study, the results of differential proteomic analysis between Btx023 in original fermentation broth and in optimized fermentation broth (the production and activity of Cry pesticidal protein were improved) showed that the asparagine synthase B were upregulated while the cysteine synthase was downregulated (Liu et al. 2020b), which was consist with the results in this study.

In conclusion, a mutated strain BtX023PN was developed in this study by compound mutagenesis (ARTP and NTG), showing 61.1% higher production than that of wild strain. The growth curve showed the stationary phase of BtX023PN reduced by 6 h, but the production of ICPs was increased to 1.6 times, which is a problem worthy of further study and may be also an opportunity to promote the development of Bt insecticide industrial production.

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

References

Bel Y, Ferre J, Hernandez-Martinez P (2020) Bacillus thuringiensis toxins: functional characterization and mechanism of action. Toxins 12(12) https://doi.org/10.3390/toxins12120785

Bravo A, Gill SS, Soberón M (2007) Mode of action of Bacillus thuringiensis Cry and Cyt toxins and their potential for insect control. Toxicon 49(4):423–435. https://doi.org/10.1016/j.toxicon.2006.11.022

Chen X, Gao T, Peng Q, Zhang J, Chai Y, Song F (2018) Novel cell wall hydrolase CwlC from Bacillus thuringiensis is essential for mother cell lysis. Appl Environ Microbiol 84(7):e02640-e2717. https://doi.org/10.1128/aem

Crickmore N, Berry C, Panneerselvam S, Mishra R, Connor TR, Bonning BC (2021) A structure-based nomenclature for Bacillus thuringiensis and other bacteria-derived pesticidal proteins. J Invertebr Pathol 186:107438. https://doi.org/10.1016/J.Jip.2020.107438

Dong XY, Xiu ZL, Li S, Hou YM, Zhang DJ, Ren CS (2010) Dielectric barrier discharge plasma as a novel approach for improving 1,3-propanediol production in Klebsiella pneumoniae. Biotech Lett 32(9):1245–1250. https://doi.org/10.1007/s10529-010-0284-y

Drake JW, Charlesworth B, Charlesworth D, Crow JF (1998) Rates of spontaneous mutation. Genetics 148(4):1667–1686

Du C, Zhang Y, Li Y, Cao Z (2007) Novel redox potential-based screening strategy for rapid isolation of Klebsiella pneumoniae mutants with enhanced 1,3-propanediol-producing capability. Appl Environ Microbiol 73(14):4515–4521. https://doi.org/10.1128/AEM.02857-06

Fang M, Jin L, Zhang C, Tan Y, Jiang P, Ge N, Heping L, Xing X (2013) Rapid mutation of Spirulina platensis by a new mutagenesis system of atmospheric and room temperature plasmas (ARTP) and generation of a mutant library with diverse phenotypes. PLoS ONE 8(10):e77046. https://doi.org/10.1371/journal.pone.0077046

Harper M, Lee CJ (2012) Genome-wide analysis of mutagenesis bias and context sensitivity of N-methyl-N’-nitro-N-nitrosoguanidine (NTG). Mutat Res 731(1–2):64–67. https://doi.org/10.1016/j.mrfmmm.2011.10.011

Harper MA, Chen Z, Toy T, Machado IM, Nelson SF, Liao JC, Lee CJ (2011) Phenotype sequencing: identifying the genes that cause a phenotype directly from pooled sequencing of independent mutants. PLoS ONE 6(2):e16517. https://doi.org/10.1371/journal.pone.0016517

Jiang M, Wan Q, Liu R, Liang L, Chen X, Wu M, Zhang H, Chen K, Ma J, Wei P, Ouyang P (2014) Succinic acid production from corn stalk hydrolysate in an E coli mutant generated by atmospheric and room-temperature plasmas and metabolic evolution strategies. J Industrial Microbiol Biotechnol 41(1):115–23. https://doi.org/10.1007/s10295-013-1346-7

Jouzani GS, Valijanian E, Sharafi R (2017) Bacillus thuringiensis: a successful insecticide with new environmental features and tidings. Appl Microbiol Biotechnol 101(7):2691–2711. https://doi.org/10.1007/s00253-017-8175-y

Kumar LR, Ndao A, Valero J, Tyagi RD (2019) Production of Bacillus thuringiensis based biopesticide formulation using starch industry wastewater (SIW) as substrate: a techno-economic evaluation. Biores Technol 294:122144. https://doi.org/10.1016/j.biortech.2019.122144

Li HG, Luo W, Wang Q, Yu XB (2014) Direct fermentation of gelatinized cassava starch to acetone, butanol, and ethanol using Clostridium acetobutylicum mutant obtained by atmospheric and room temperature plasma. Appl Biochem Biotechnol 172(7):3330–3341. https://doi.org/10.1007/s12010-014-0765-x

Li X, Liu R, Li J, Chang M, Liu Y, Jin Q, Wang X (2015) Enhanced arachidonic acid production from Mortierella alpina combining atmospheric and room temperature plasma (ARTP) and diethyl sulfate treatments. Biores Technol 177:134–140. https://doi.org/10.1016/j.biortech.2014.11.051

Liang MH, Liang YJ, Chai JY, Zhou SS, Jiang JG (2014) Reduction of methanol in brewed wine by the use of atmospheric and room-temperature plasma method and the combination optimization of malt with different adjuncts. J Food Sci 79(11):M2308–M2314. https://doi.org/10.1111/1750-3841.12660

Liu K, Fang H, Cui F, Nyabako BA, Tao T, Zan X, Chen H, Sun W (2020) ARTP mutation and adaptive laboratory evolution improve probiotic performance of Bacillus coagulans. Appl Microbiol Biotechnol 104(14):6363–6373. https://doi.org/10.1007/s00253-020-10703-y

Liu Z, Xie J, Deng Z, Wang M, Dang D, Luo S, Wang Y, Sun Y, Xia L, Ding X (2020) Enhancing the insecticidal activity of new Bacillus thuringiensis X023 by copper ions. Microb Cell Fact 19(1):195. https://doi.org/10.1186/s12934-020-01452-8

Melo AL, Soccol VT, Soccol CR (2016) Bacillus thuringiensis: mechanism of action, resistance, and new applications: a review. Critical Rev Biotechnol 36(2):317–26. https://doi.org/10.3109/07388551.2014.960793

Peña-Cardeña A, Grande R, Sánchez J, Tabashnik BE, Bravo A, Soberón M, Gómez I (2018) The C-terminal protoxin region of Bacillus thuringiensis Cry1Ab toxin has a functional role in binding to GPI-anchored receptors in the insect midgut. J Biol Chem 293(52):20263–20272. https://doi.org/10.1074/jbc.RA118.005101

Qiang W, Ling-ran F, Luo W, Han-guang L, Lin W, Ya Z, Xiao-bin Y (2014) Mutation breeding of lycopene-producing strain Blakeslea trispora by a novel atmospheric and room temperature plasma (ARTP). Appl Biochem Biotechnol 174(1):452–460. https://doi.org/10.1007/s12010-014-0998-8

Quan M, Peng J, Zhu Z, Zhou P, Luo S, Xie J, Xia L, Sun Y, Ding X (2020) Construction of a conditionally asporogenous Bacillus thuringiensis recombinant strain overproducing Cry protein by deletion of the leuB gene. Front Microbiol 11:1769. https://doi.org/10.3389/fmicb.2020.01769

Ricietto APS, Goncalves KCB, Appel RJC, Sosa-Gomez DR, Vilas-Boas GT, Vilas-Boas LA (2022) Complete genome sequence of Bacillus thuringiensis BR145, a strain with insecticidal activity against Lepidoptera pests. Genet Mol Biol 45(2):e20210289. https://doi.org/10.1590/1678-4685-GMB-2021-0289

Santos EN, Menezes LP, Dolabella SS, Santini A, Severino P, Capasso R, Zielinska A, Souto EB, Jain S (2022) Bacillus thuringiensis: from biopesticides to anticancer agents. Biochimie 192:83–90. https://doi.org/10.1016/j.biochi.2021.10.003

Sayed AMM, Behle RW (2017) Evaluating a dual microbial agent biopesticide with Bacillus thuringiensis var. kurstaki and Beauveria bassiana blastospores. Biocontrol Sci Technol 27(4):461–474. https://doi.org/10.1080/09583157.2017.1303662

Sivaramakrishnan R, Incharoensakdi A (2017) Enhancement of lipid production in Scenedesmus sp. by UV mutagenesis and hydrogen peroxide treatment. Biores Technol 235:366–370. https://doi.org/10.1016/j.biortech.2017.03.102

van Frankenhuyzen K (2009) Insecticidal activity of Bacillus thuringiensis crystal proteins. J Invertebr Pathol 101(1):1–16. https://doi.org/10.1016/j.jip.2009.02.009

Velicer GJ, Raddatz G, Keller H, Deiss S, Lanz C, Dinkelacker I, Schuster SC (2006) Comprehensive mutation identification in an evolved bacterial cooperator and its cheating ancestor. Proc Natl Acad Sci USA 103(21):8107–8112. https://doi.org/10.1073/pnas.0510740103

Wanapaisan P, Chumsakul O, Panbangred W (2013) Enhanced Cry1Da production in Bacillus thuringiensis by driving expression from the sigma(E)-dependent BtI promoter. J Appl Microbiol 115(3):859–871. https://doi.org/10.1111/jam.12276

Wang J, Mei H, Qian H, Tang Q, Liu X, Yu Z, He J (2013) Expression profile and regulation of spore and parasporal crystal formation-associated genes in Bacillus thuringiensis. J Proteome Res 12(12):5487–5501. https://doi.org/10.1021/pr4003728

Wang M, Yang Y, Chen Z, Chen Y, Wen Y, Chen B (2016) Removal of nutrients from undiluted anaerobically treated piggery wastewater by improved microalgae. Biores Technol 222:130–138. https://doi.org/10.1016/j.biortech.2016.09.128

Wang ST, Setlow B, Conlon EM, Lyon JL, Imamura D, Sato T, Setlow P, Losick R, Eichenberger P (2006) The forespore line of gene expression in Bacillus subtilis. J Mol Biol 358(1):16–37. https://doi.org/10.1016/j.jmb.2006.01.059

Yang H, Wang P, Peng Q, Rong R, Liu C, Lereclus D, Zhang J, Song F, Huang D (2012) Weak transcription of the cry1Ac gene in nonsporulating Bacillus thuringiensis cells. Appl Environ Microbiol 78(18):6466–6474. https://doi.org/10.1128/AEM.01229-12

Yang M, An Y, Zabed HM, Guo Q, Yun J, Zhang G, Awad FN, Sun W, Qi X (2019) Random mutagenesis of Clostridium butyricum strain and optimization of biosynthesis process for enhanced production of 1,3-propanediol. Biores Technol 284:188–196. https://doi.org/10.1016/j.biortech.2019.03.098

Yang Y, Huang X, Yuan W, Xiang Y, Guo X, Wei W, Soberon M, Bravo A, Liu K (2021) Bacillus thuringiensis Cry toxin triggers autophagy activity that may enhance cell death. Pestic Biochem Physiol 171:104728. https://doi.org/10.1016/j.pestbp.2020.104728

Yu F, Zhang M, Sun J, Wang F, Li X, Liu Y, Wang Z, Zhao X, Li J, Chen J, Du G, Xue Z (2022) Improved neomycin sulfate potency in Streptomyces fradiae using atmospheric and room temperature plasma (ARTP) mutagenesis and fermentation medium optimization. Microorganisms 10(1) https://doi.org/10.3390/microorganisms10010094

Zhang K, Mohsin A, Dai Y, Chen Z, Zhuang Y, Chu J, Guo M (2019) Combinatorial effect of ARTP mutagenesis and ribosome engineering on an industrial strain of Streptomyces albus S12 for enhanced biosynthesis of salinomycin. Front Bioeng Biotechnol 7:212. https://doi.org/10.3389/fbioe.2019.00212

Zhang X, Zhang C, Zhou QQ, Zhang XF, Wang LY, Chang HB, Li HP, Oda Y, Xing XH (2015) Quantitative evaluation of DNA damage and mutation rate by atmospheric and room-temperature plasma (ARTP) and conventional mutagenesis. Appl Microbiol Biotechnol 99(13):5639–5646. https://doi.org/10.1007/s00253-015-6678-y

Zhang X, Zhang X, Xu G, Zhang X, Shi J, Xu Z (2018) Integration of ARTP mutagenesis with biosensor-mediated high-throughput screening to improve L-serine yield in Corynebacterium glutamicum. Appl Microbiol Biotechnol 102(14):5939–5951. https://doi.org/10.1007/s00253-018-9025-2

Zhang X, Zhang XF, Li HP, Wang LY, Zhang C, Xing XH, Bao CY (2014) Atmospheric and room temperature plasma (ARTP) as a new powerful mutagenesis tool. Appl Microbiol Biotechnol 98(12):5387–5396. https://doi.org/10.1007/s00253-014-5755-y

Zhang Y, He M, Zou S, Fei C, Yan Y, Zheng S, Rajper AA, Wang C (2016) Breeding of high biomass and lipid producing Desmodesmus sp. by ethylmethane sulfonate-induced mutation. Biores Technol 207:268–275. https://doi.org/10.1016/j.biortech.2016.01.120

Funding

This study was funded by the National Key Research and Development Program of China (2017YFD0201201) and the National Natural Science Foundation of China (31370116).

Author information

Authors and Affiliations

Contributions

XZD and ZRZ conceived and designed research. ZRZ and WHC conducted experiments. HBZ, HNC, and LQX contributed new reagents or analytical tools. SSL and KXZ analyzed data. XZD and ZRZ wrote the manuscript. XZD and PJZ revised the whole manuscript. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhu, Z., Chen, W., Zhou, H. et al. ARTP and NTG compound mutations improved Cry protein production and virulence of Bacillus thuringiensis X023. Appl Microbiol Biotechnol 106, 4211–4221 (2022). https://doi.org/10.1007/s00253-022-11983-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-022-11983-2