Abstract

Economical production of medium-chain length polyhydroxyalkanoates (mcl-PHA) is dependent on efficient cultivation processes. This work describes growth and mcl-PHA synthesis characteristics of Pseudomonas putida LS46 when grown on medium-chain length fatty acids (octanoic acid) and lower-cost long-chain fatty acids (LCFAs, derived from hydrolyzed canola oil) in microaerophilic environments. Growth on octanoic acid ceased when the oxygen uptake rate was limited by the oxygen transfer rate, and mcl-PHA accumulated to 61.9% of the cell dry mass. From LCFAs, production of non-PHA cell mass continued at a rate of 0.36 g L−1 h−1 under oxygen-limited conditions, while mcl-PHA accumulated simultaneously to 31% of the cell dry mass. The titer of non-PHA cell mass from LCFAs at 14 h post-inoculation was double that obtained from octanoic acid in bioreactors operated with identical feeding and aeration conditions. While the productivity for octanoic acid was higher by 14 h, prolonged cultivation on LCFAs achieved similar productivity but with twice the PHA titer. Simultaneous co-feeding of each substrate demonstrated the continued cell growth under microaerophilic conditions characteristic of LCFAs, and the resulting polymer was dominant in C8 monomers. Furthermore, co-feeding resulted in improved PHA titer and volumetric productivity compared to either substrate individually. These results suggest that LCFAs improve growth of P. putida in oxygen-limited environments and could reduce production costs since more non-PHA cell mass, the cellular factories required to produce mcl-PHA and the most oxygen-intensive cellular process, can be produced for a given oxygen transfer rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Medium-chain length polyhydroxyalkanoates (mcl-PHAs) are bio-polyester polymers synthesized by primarily Pseudomonas species, under nutrient-limited conditions as a means of storing carbon and energy (Anderson and Dawes 1990; López et al. 2015; Anjum et al. 2016). While these polymers may have value as renewable and biodegradable alternatives to traditional petroleum-based polymers, current cost estimates range from 3 to 15-fold higher than polyethylene or polypropylene (Możejko-Ciesielska and Kiewisz 2016; Kourmentza et al. 2017) and must be reduced to facilitate widespread application.

Since the carbon source for PHA production has been reported to account for a significant proportion of the production costs (Choi and Lee 1997; Koller et al. 2017), it is imperative to find inexpensive and readily available feedstocks. Long-chain fatty acids (LCFAs) are a promising candidate for PHA production because the theoretical yield of polymer (3-hydroxydecanoate) from LCFAs (oleic acid) via β-oxidation is relatively high (Chanprateep 2010). There is a significant amount of waste LCFAs available as triacylglycerides (TAGs) or free fatty acids from the food-processing and biodiesel production industries (Chhetri et al. 2008; Du et al. 2012; Nikodinovic-Runic et al. 2013). Both LCFAs and TAGs are carbon-rich waste streams that create significant disposal challenges due to high biochemical oxygen demand and their hydrophobicity and insolubility in aqueous medium (Ravindran and Jaiswal 2016; Wallace et al. 2017). In North America and other temperate regions, waste sources of LCFAs (including biodiesel and hydrolyzed cooking oil wastes) are typically derived from plant oils like canola and soybean (Song et al. 2008; Nikodinovic-Runic et al. 2013). These contain a mixture of fatty acids, predominantly C16:0, C18:0, C18:1, and C18:2 fatty acids (Fu et al. 2014). Fatty acids are degraded to acetyl-CoA and acyl-CoA intermediates using the β-oxidation cycle, producing reduced electron carriers NADH and FADH2. The PHA synthase has low substrate specificity, which allows incorporation of various acyl-CoA monomers into the polymer (Kim et al. 1997). The predominant mcl-PHA monomer units from fatty acids are eight and ten carbons in length, but LCFAs have been reported to produce PHA polymers containing longer as well as unsaturated monomer units (de Waard et al. 1993; Haba et al. 2007).

In addition to using low-cost carbon feedstocks, improving productivity through cultivation techniques or mode of bioreactor operation is crucial to the sustainability of PHAs (Kaur and Roy 2015; Koller et al. 2017). To date, the highest productivities for both short-chain length (scl-) and mcl-PHA production have been achieved through fed-batch strategies, in which cells are grown to high cell densities with high polymer content in short cultivation times (Wang and Lee 1997; Lee et al. 2000; Maclean et al. 2008). However, these high cell density cultures are inevitably limited by the oxygen transfer rate (OTR) from the introduced gas into the liquid phase resulting in environments with low dissolved oxygen (DO). Previously, it was shown that in such microaerophilic environments with excess ammonium, P. putida LS46 accumulates mcl-PHA to 57.3% of the cell dry mass (cdm) in 14 h from 20 mM octanoic acid and that the polymer synthesis rate was improved as the volumetric oxygen mass transfer coefficient (kLa) was reduced (Blunt et al. 2017). While that work showed that oxygen-limited mcl-PHA production could be a viable mcl-PHA production strategy, the results were limited to octanoic acid and productivity was limited by batch cultivation. This work aims to build on previous work by identifying if the previous response observed under oxygen limitation could be extended to other fatty acids, and specifically lower-cost LCFAs, or if it was a unique manifestation of mcl-PHA synthesis from octanoic acid. The objectives of this work are therefore to (1) compare growth and mcl-PHA synthesis characteristics from LCFAs and octanoic in fed-batch cultivations with low DO which are likely to persist in high cell density cultures and large-scale bioreactors, and (2) examine the effect of co-feeding both substrates to improve mcl-PHA productivities and/or yields.

Materials and methods

Microorganism, medium, and substrates

The production strain used in this study was Pseudomonas putida LS46 (International Depository Authority of Canada Accession Number 181110-03) (Sharma et al. 2012). P. putida LS46 was revived from glycerol stock cultures (stored at − 80 °C) and sub-cultured once in LB medium prior to preparation of the experimental inoculum. The inoculum was prepared in a 1000-mL baffled shaker flask with a 300-mL working volume of minimal medium (described below) using the same substrate under investigation in the reactor studies. Experiments were initiated by the addition of 5% (vol vol−1) inoculum that was grown in a shaker flask incubated overnight at 30 °C and 150–200 rpm shaking.

All experiments were conducted using the minimal growth medium defined by Ramsay et al. (1990), but the (NH4)2SO4 concentration was increased to 1.5 g L−1. The carbon source was aseptically added post-autoclave. Required chemicals were of reagent grade and purchased from either Sigma Chemical Co. (St. Louis, MO) or Fisher Scientific (Toronto, ON). Octanoic acid was used as a representative medium-chain length fatty acid, and hydrolyzed food-grade canola oil (No Name®, Superstore, Canada) was used as a representative LCFA. The hydrolysis of canola oil was carried out by saponification using 250 g of NaOH dissolved into 500 mL of H2O per liter of canola oil. Once the reaction was complete, 200 mL of 98% H2SO4 was used to release the free fatty acids of canola oil. In all experiments, the addition of LCFAs, whether adding an initial concentration to a flask or bioreactor, or during fed-batch experiments (described below) was carbon atom molar (C-mol) equivalent to the addition of octanoic acid.

Reactor setup and preparation

All reactor experiments were conducted in a 7-L glass, round-bottom reactor with a 3-L initial working volume. The reactor was equipped with a Rushton impeller, three baffles, an electrochemical DO electrode, and a pH electrode. All reactor equipment was purchased from Applikon Biotechnology (Foster City, CA). The medium (without substrate) was added to the reactor prior to autoclaving for 1 h at 121 °C. The reactor was then cooled to 30 °C and stabilized with air overnight to allow polarization of the DO electrode.

The pH was maintained at 6.5 by addition of 4 M NaOH through automated peristaltic pumps for all single substrate experiments. The DO electrode was allowed to polarize overnight, and calibration was performed at the same temperature (30 °C), aeration rate (6 LPM), and agitation rate (500 rpm) as was maintained during the experiment. A two-point calibration was carried out by gassing the reactor with N2 at 500 mL min−1 until the electrode current was stable at 0 mA; then, aeration was turned on at 6 LPM. After the electrode current had stabilized, this was assigned a value of 100% of air saturation at 30 °C. It was assumed that the solubility of O2 in the medium at 30 °C was 6.77 mg L−1 (Vendruscolo et al. 2012). Since the slope of a one-point calibration was found to be in good agreement with the described two-point calibration, one-point calibrations (at operating conditions) were subsequently performed.

The kLa was determined in the absence of cells in 3-L Ramsay medium (no substrate added) by the dynamic out-gassing method (Garcia-Ochoa et al. 2010). Briefly, the reactor (under operating conditions) was gassed with N2 at 500 mL min−1 until the DO signal was stable. Subsequently, aeration was turned on at 6 LPM and the DO response was measured and recorded in LabBoss software in 5-s intervals. It was assumed that the probe response could be modeled as first order, and the response time was determined to be 24 s, as previously described (Blunt et al. 2017). The corresponding kLa was determined to be 54 ± 3 h−1. Carbon dioxide in the off-gas was measured with either an HPR 40 dissolved species membrane inlet mass spectrometer (MIMS, Hiden Analytical, Warrington, UK) or a BlueInOne Cell O2/CO2 sensor (Bluesens Gas Sensor, GmbH, Germany). The MIMS setup and calibration procedures have been previously described elsewhere (Blunt et al. 2014). Water vapor was condensed from the off-gas stream by circulating water from an ice bath to a condenser mounted on the reactor head-plate with a peristaltic pump.

Feeding rates

During initial attempts at optimizing fed-batch cultivations, several trials on octanoic acid were conducted using a variety of exponential feeding rates and high kLa values resulting from use of a mixing cascade up to 1200 rpm. When those trials were compared to growth on LCFAs using a relatively fast feeding rate (μ = 0.5 h−1), it was observed that under similar oxygen-limited conditions, P. putida LS46 produced significantly higher total biomass and non-PHA cell mass (NPCM). Because of this observation, the feeding of carbon and nitrogen sources was modeled for a specific growth rate (μ) of 0.25 h−1 (Eq. 1). The rate of feeding for carbon and ammonium were calculated according to Eq. 2 and Eq. 3, respectively. In the case of LCFAs, the carbon feed rate was adjusted to be C-mol equivalent to the 0.25 h−1 feeding schedule developed for octanoic acid. Although the feeding schedule was based on maintaining a μ of 0.25 h−1, this will not be achieved in practice upon onset of oxygen limitation. The purpose of this model was to observe how each carbon source is utilized when fed at the same rate (i.e., C-mol h−1) under oxygen-limited conditions.

where X = NPCM (g); Xto = the amount of NPCM present in the bioreactor at the beginning of the time interval (g); and t0, t are the beginning and end of a given time interval (h), respectively. C(t) and N(t) are the required amounts (g) of carbon or ammonia, respectively, fed to the bioreactor in a given time interval; YX/C and YX/N are the yield coefficients of NPCM from the carbon source and ammonium (g g−1), respectively. The yield coefficients were derived from previous experimental values (unpublished data). Square brackets indicate concentration.

After an hour delay following inoculation, carbon (either LCFAs or octanoic acid) and a 200 g L−1 solution of (NH4)2SO4 were continually supplied with two titration syringes adapted to three-way valves. The feeding program described above was automated in LabBoss software (Scion, Rotorua, New Zealand). Calibration and operation of this setup has been previously described in greater detail by Blunt et al. (2014). The initial value of Xto was set as 0.75 g to compare the cell mass production by P. putida LS46 cultured with LCFAs versus octanoic acid. All conditions were run in duplicate.

Co-feeding and prolonged LCFA cultivation experiments

To investigate further potential for production of NPCM and/or mcl-PHA under microaerophilic conditions, experiments were conducted using co-feeding and LCFA feeding with prolonged cultivation under identical aeration conditions (kLa = 54 h−1). To avoid preferential uptake of octanoic acid or LCFAs, the co-feeding experiments were initiated with a 5% (vol vol−1) inoculum from cells grown in LB medium and washed in sterile PBS solution. Due to technical limitations, NH4OH was used in place of (NH4)2SO4 and NaOH for co-feeding experiments to maintain ammonium and pH levels. The co-feeding experiments were started with 10 mM of octanoic acid and C-mol equivalent LCFAs.

The feeding rates for prolonged co-feeding and LCFAs cultivations were identical (C-mol h−1) to the aforementioned experimental rates (0.25 μ) up to 16 h post-inoculation (pi). During co-feeding, each substrate was fed in a 1:1 ratio on a C-mol basis. As the exponential feeding program resulted in highly excess conditions by 16 h pi, feeding rates were decreased for further cultivation. Further cultivation with LCFAs provided substrate and (NH4)2SO4 at linear rates of 1.43 and 0.59 g h−1, respectively, while carbon feeding was ceased at 16 h pi in co-feeding experiments. In all experiments, the feeding after 16 h pi was determined to maintain carbon and ammonium in excess without approaching toxic concentrations.

Sample treatment

After inoculation, 40 mL samples were periodically withdrawn from the reactor, typically in 2-h intervals. Cell mass was separated from the supernatant by centrifugation (16,000×g for 10 min). The pellet was washed with PBS buffer, and the supernatant was decanted and stored at 4 °C for analysis of residual carbon and ammonium. The pellet was then washed in distilled water and transferred to pre-weighed aluminum dishes and dried at 60 °C for 24 h or until no further loss in mass was achieved. NPCM was determined as the difference between total cdm and PHA biomass, which was determined as described below.

Analysis of mcl-PHA, fatty acids, and ammonium

For analysis of the cellular mcl-PHA content, 5 mg of dried biomass was measured and placed in 10-mL reaction vials and the PHA was converted to methyl esters using the acid-catalyzed methanolysis method previously described (Brandl et al. 1988). The extracted 3-hydroxy-methyl esters were quantified using an Agilent 7890 gas chromatograph equipped with a DB-23 capillary column and flame ionization detector. Further details of this setup are given elsewhere (Fu et al. 2014). Response factors for each monomer were derived from 3-hydroxy-methyl esters purchased from Sigma-Aldrich (St. Louis, MO). Since (R)-3-hydroxyacid standards with unsaturation were not found, it was assumed that the response factors for C12:1 and C14:1 were the same as C12 and C14, respectively. Contaminating oleic acid peaks detected in the PHA analysis were quantified and used to correct the total measured biomass. Analysis of residual fatty acids in the supernatant was also performed by gas chromatography following the same procedure, except that the culture supernatant was vortexed and 1 mL added to a reaction vial, oven dried at 60 °C for a minimum of 24 h to remove water, and then methanolysed. Residual ammonium in the culture supernatant was measured using the colorimetric indophenol blue method previously described (Blunt et al. 2017).

Carbon balancing and yield analysis

Carbon balances were performed for both substrates following the approach described by Blunt et al. (2017), in which the carbon moles of detected mcl-PHA monomers, NPCM, and CO2 were compared to the carbon moles of substrate consumed. It was assumed that the chemical composition of P. putida NPCM could be approximated as C4H7O2N and having a molecular weight of 101 g mol−1 (Guedon et al. 1999). It was determined that each mole of PHA monomers derived from the octanoic acid polymer contained 7.9 mol of carbon and had an average molecular mass of 159.4 g mol−1. The corresponding values for carbon content and molecular mass of LCFA PHA were 10.3 C-mol mol−1 and 194.7 g mol−1, respectively. Similarly, the PHA obtained from co-feeding experiments contained 8.2 C-mol mol−1 and had molecular mass of 162.3 g mol−1. These values were obtained as the weighted average of the detected monomers.

The yield of PHA from carbon substrate was calculated as the slope of a plot between PHA titer (g L−1) and substrate uptake (g L−1). The theoretical yield of PHA from octanoic acid and LCFAs were assumed to be 0.98 and 0.72 g g−1, respectively. These values were obtained from the ratio of molecular mass of an average monomer subunit (described in the assumptions above) and dividing it by the molecular mass of the carbon substrate. Due to the mixed composition of LCFAs derived from canola oil, it was assumed to have a molecular mass of 271.5 g mol−1. This value was obtained as the weighted average of the molecular masses of the individual fatty acid components detected by GC.

Due to problems determining the concentration of (insoluble) residual LCFAs in the culture medium, the carbon consumption was back-calculated for LCFA cultures by assuming that all carbon could be accounted for through measurement of mcl-PHA monomers, NPCM, and CO2. The validity of this assumption has been tested through previous HPLC analysis for soluble end-products in the supernatants of both octanoic acid and LCFA-grown cultures (unpublished data). The efficacy of the back-calculation method was verified using the results from octanoic acid, and it was found that octanoic acid uptake could be estimated within an average margin of error of 10%.

Results

On the basis of the results shown in Table 1, a feeding program of μ = 0.25 h−1 was chosen for growth on octanoic acid since higher rates led to rapid accumulation of octanoic acid to inhibitory levels. Stirring was kept constant at 500 rpm to provide consistent OTR throughout both conditions and avoid variations in the response of the DO controller. The following results describe the performance comparison between LCFA and octanoic acid feeds under identical exponential rates (C-mol h−1) with DO as the only growth-limiting variable.

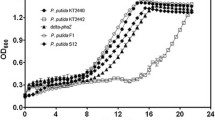

Dissolved oxygen

The measured DO profiles are shown in Fig. 1. The reactor was saturated with air (DO = 100% or 6.77 mg L−1) prior to inoculation, after which the culture consumed DO until the electrode read zero current at 4 h pi, despite constant mixing and aeration. After 4 h pi, the oxygen uptake rate should be equivalent to the OTR, which is in turn limited by kLa. Previous studies have confirmed that such conditions correspond to DO concentrations less than 0.05 mg L−1 (Blunt et al. 2017). The DO remained below detectable limits until the experiment was terminated in the case of growth on LCFAs, or until octanoic acid accumulated to an inhibitory level, which is shown by the rapid rise in DO after 14 h pi.

Total biomass of P. putida LS46 when grown in fed-batch at μ = 0.25 h−1 on LCFAs (filled circles) compared to growth on octanoic acid (empty circles). Dissolved oxygen concentrations of the reactor medium during culturing of P. putida LS46 on LCFAs (filled squares) compared to octanoic acid (empty squares). Error bars represent standard deviations between a minimum of two biological replicates

Total biomass and PHA accumulation in single substrate comparison

Figure 1 shows the total biomass produced throughout the growth curves for each condition. The two conditions produced similar concentrations up to 4 h pi. After 6 h pi, when exponential growth was finished due to onset of oxygen limitation, the difference in total biomass became increasingly higher for the culture grown on LCFAs compared to octanoic acid. Accumulation of PHA is shown in Fig. 2. The mcl-PHA content of octanoic acid-grown cultures was initially 28.0 ± 6.1% cdm due to carry-over from the inoculum, and decreased to 19.2 ± 3.0% cdm at 4 h pi. The onset of oxygen limitation caused PHA to accumulate to 61.5 ± 1.4% cdm by 14 h pi, which is expected when the DO was maintained at 1–5% or less in the presence of excess carbon (Blunt et al. 2017). The maximum mcl-PHA titer of 2.5 ± 0.3 g L−1 (Fig. 2). When the substrate was LCFAs, the initial PHA content detected at 0 h pi was 8.5 ± 5.8% cdm and was similar at 4 h pi when the DO concentration dropped below detectable limits for the electrochemical probe (12.2 ± 6.8% cdm). Following onset of oxygen limitation, the cellular PHA content increased to 34.2 ± 6.1% cdm by 16 h pi. The mcl-PHA titer in P. putida LS46 cultured with LCFAs reached 1.9 ± 0.6 g L−1 cells at 16 h pi.

Intracellular PHA accumulation (% cdm) by P. putida LS46 when grown in fed-batch at μ = 0.25 h−1 on canola oil long chain fatty acids (filled circles) compared to growth on octanoic acid (empty circles). PHA concentrations (g L−1) produced by P. putida LS46 grown in fed-batch at μ = 0.25 h−1 on LCFAs acids (filled squares) compared to growth on octanoic acid (empty squares). The dashed line indicates the onset of oxygen limiting conditions. Error bars represent standard deviations between a minimum of two biological replicates

Analysis of NPCM, residual fatty acid, and residual ammonium concentrations

A contrast in NPCM production was observed for octanoic acid and LCFA cultures following the onset of oxygen-limitation at 4 h pi (Fig. 3). The NPCM became relatively constant from 6 h pi in the octanoic acid-grown cultures, after which the majority of the total biomass increase was due to PHA accumulation. When grown on LCFAs, the NPCM increased at a relatively constant rate (0.36 g L−1 h−1) for 8 h past the onset of oxygen limitation, reaching 3.7 ± 0.1 g L−1. This was more than double the highest value obtained by the culture grown on octanoic acid at 14 h pi (1.6 ± 0.1 g L−1).

Non-PHA cell mass (NPCM) produced by P. putida LS46 when grown in fed-batch at μ = 0.25 h−1 on LCFAs (filled circles) compared to growth on octanoic acid (empty circles). The dashed line indicates the onset of oxygen limiting conditions. Error bars represent standard deviations between a minimum of two biological replicates

Figure 4 displays the residual octanoic acid and LCFA concentrations. Both substrates were slowly depleted for the first 8 h pi, after which the residual substrate levels began to accumulate. After 14 h pi, octanoic acid had accumulated to inhibitory levels (≥ 50 mM), and this toxicity likely led to the observed decrease in the NPCM of octanoic acid fed cultures at 14–16 h pi. When in excess, the LCFAs were observed to form a layer on top of the medium after centrifugation, and the actual concentration of residual LCFAs was difficult to determine. No inhibitory or toxic effects were observed due to excess LCFAs, as was observed with excess octanoic acid. A similar trend was observed with residual ammonium concentrations using both substrates (Fig. 4). The residual concentrations of carbon substrate and free ammonium being measured in excess for the entire cultivation period confirmed that oxygen uptake rate was the only growth-limiting factor.

Concentrations (g L−1) of residual carbon remaining in the culture supernatants titer after growth of P. putida LS46 in fed-batch bioreactors at μ = 0.25 h−1 on LCFAs (filled circles) compared to growth on octanoic acid (empty circles). Concentrations (g L−1) of residual free ammonium left in culture supernatants after growth of P. putida LS46 on LCFAs (filled squares) compared to growth on octanoic acid (empty squares). The dashed line indicates the onset of oxygen limiting conditions. Error bars represent standard deviations between a minimum of two biological replicates

Co-feeding and prolonged cultivation experiments

Due to the higher biomass production and continued growth trends observed over the course of the previous experiments with LCFAs, the cultivations were prolonged with additional feeding to observe further potential capacity of both biomass and PHA production. The NPCM production from these prolonged LCFA experiments is shown in Fig. 5. The total biomass, NPCM, and PHA content continued to increase after 16 h pi, and NPCM finally stabilized near 7.1 ± 0.4 g L−1 (over four times the maximum NPCM obtained from octanoic acid growth), while the final PHA content reached 38.3 ± 2.8% cdm at 30 h pi, resulting in a PHA titer of 4.4 ± 0.8 g L−1 (Table 2).

Non-PHA cell mass of prolonged LCFAs feeding (filled squares) and co-feeding (half-filled squares) produced by P. putida LS46 grown in fed-batch bioreactors at 0.25 μ with prolonged incubation, compared to the aforementioned NPCM production from LCFAs (filled circles) and octanoic acid (empty circles) conditions

The results for the single substrate experiments indicate that for constant bioreactor conditions, the LCFAs have the potential to produce higher total biomass and NPCM under microaerophilic conditions, but the PHA content of the cells was still lower in comparison to octanoic acid cultures. This led to querying the effect of co-feeding both substrates. The total biomass, PHA content, and PHA titer from the co-feed experiments are shown in Fig. 6. By 26 h pi, the total biomass reached 11.7 ± 0.1 g L−1, containing 54.1 ± 2.2% PHA, resulting in a PHA titer of 6.3 ± 0.3 g L−1. The NPCM for the co-feed experiment is shown in Fig. 5 and is overlaid with other results of the single-substrate experiments for comparison. Over the course of the co-feed cultivation, the NPCM was lower compared to when LCFAs were the sole carbon source and reached at final titer of 5.4 ± 0.4 g L−1 at 26 h pi (Table 2) This value is 3.3 times more than the maximum NPCM titer obtained when octanoic acid was the sole substrate.

Growth and production of mcl-PHA through co-feeding of octanoic acid and LCFAs to P. putida LS46. Biomass (half-filled circles), PHA titer (half-filled squares), and PHA content (half-filled triangles). The dashed line indicates the onset of oxygen limiting conditions. Error bars represent standard deviations between a minimum of two biological replicates

Volumetric productivity

Overall volumetric productivities for each process are summarized in Table 2. For the octanoic acid cultivation, volumetric productivity reached a maximum value of 0.18 ± 0.00 g L−1 h−1 by 14 h pi. By comparison, lower volumetric productivity was observed in the LCFA cultivation at 14 h (0.12 ± 0.01 g L−1 h−1). With prolonged feeding, the LCFA cultures reached a maximum volumetric productivity of 0.15 ± 0.02 g L−1 h−1 after 30 h pi. In the co-feed experiments, the maximum volumetric productivity was 0.24 ± 0.01 g L−1 h−1 at 26 h pi.

Carbon balancing and yield analysis

Figure 7 shows the carbon flux under oxygen-excess (0–4 h pi) and oxygen-limiting conditions (6–12 h pi and onward) for octanoic acid (Fig. 7a) and LCFAs (Fig. 7b). When octanoic acid was the substrate, the main tradeoff in carbon flux is between NPCM and PHA. With the onset of oxygen limitation at 4 h pi, the yield of NPCM decreased (0.48 to 0.08 C-mol C-mol−1), while PHA yield increased (0.19 to 0.55 C-mol C-mol−1). Little change was observed in CO2 yield over time regardless of DO content, which is consistent with previous batch results (Blunt et al. 2017). When LCFAs were the substrate, the onset of oxygen limiting conditions increased the carbon flux to PHA (0.12 to 0.25 C-mol C-mol−1), but the reduction in carbon flux to NPCM (0.60 to 0.39 C-mol C-mol−1) was not nearly as significant as in the case of octanoic acid. Further incubation of the LCFA culture beyond 12 h pi resulted in similar carbon flux to PHA and a reduction in carbon flux to NPCM (0.30 C-mol C-mol−1) with increased CO2 production. Since the yield of mcl-PHA from LCFA was well below the calculated theoretical value (0.72 g g−1), it is possible that higher mcl-PHA content was not obtained in the LCFA-grown culture during the first 16 h (Fig. 2) because NPCM also continued to increase and accounted for a significant portion of the carbon consumed during this period. While the presence of some longer chain and unsaturated monomers suggested that a portion of the mcl-PHA was synthesized from octanoic acid, the estimated maximum yield of mcl-PHA from octanoic acid in the co-feed experiments was observed between 8 and 26 h pi was 0.49 ± 0.05 C-mol C-mol−1 and was comparable to the yield obtained when octanoic acid was the sole carbon source.

Monomer composition of PHA

Monomer composition of the PHAs produced from both octanoic acid and LCFAs are shown in Table 3. As indicated, the polymer produced from octanoic acid contained predominantly C8 monomers, which is consistent with the literature (Kellerhals et al. 2000; Elbahloul and Steinbüchel 2009; Fontaine et al. 2017). Previously, it was reported that oxygen-limitation did not significantly affect the monomer composition mcl-PHA polymers when octanoic acid was the substrate (Blunt et al. 2017). The polymer synthesized from LCFAs consists of a distribution of monomers ranging from C6 to C14, with C8 and C10 as the dominant fatty acids. Further, the LCFA-derived polymers also contained monomers with unsaturated carbon-carbon double-bonds (C12:1 and C14:1). Similar monomer compositions have been reported for mcl-PHAs synthesized by other bacteria using LCFAs as substrates (Huijberts et al. 1992; Kellerhals et al. 2000; Fernández et al. 2005; Fontaine et al. 2017). The mcl-PHAs produced by P. putida LS46 from LCFAs remain amorphous, presumably since they contain longer and unsaturated monomers and exhibit a higher degree of disorder. In contrast, mcl-PHA polymers synthesized from octanoic acid crystallize into elastomers. Similar observations have been previously reported (Kellerhals et al. 2000). Co-feeding of octanoic acid and LCFAs produced a polymer dominant in C8 monomers. Comparing the monomer composition of co-feeding against single substrate feeding (Table 3), the C8 monomer content was increased while longer monomer lengths were reduced 90% compared to the PHA from LCFAs.

Discussion

Fed-batch cultures are regarded as the best method for highly productive PHA production (Sun et al. 2007), but producing high cell density cultures can be infeasible at larger scale due to power consumption for aeration, agitation, or use of purified oxygen (Lara et al. 2006). In this study, growth on an equal C-mol basis and under identical, oxygen-limited bioreactor operating conditions resulted in double the NPCM titer from LCFAs compared to cells grown on octanoic acid at 14 h pi. In addition, the yield of NPCM from LCFAs remained relatively high in an oxygen-limited environment at 0.39 C-mol C-mol−1, while the yield of NPCM from octanoic acid was almost negligible at 0.09 C-mol C-mol−1. This suggests that LCFAs may be good substrate to efficiently produce NPCM, or the cell chassis required to accumulate mcl-PHA, particularly when oxygen is limited. However, overall productivity not only a function of high cell titer but also requires obtaining a high intracellular PHA content (Choi and Lee 1999). While lower volumetric productivity was obtained at 14 h pi for LCFA compared to octanoic acid, similar productivity was obtained by extending the LCFA cultivation to 25 h pi. It is important to note that, despite lower intracellular PHA content, the PHA titer from LCFAs at 25 h pi was more than double the maximum titer obtained from octanoic acid. This shows the potential value of sustained growth of NPCM with simultaneous PHA production under low-DO conditions. A recent study of metabolic flux in N-limited fed batch culture of P. putida KT2440 grown on oleic acid has suggested that residual growth may also improve PHA yield by linking production of reduced cofactors of FADH2 and NADH to anabolic demand (Andin et al. 2017). Cell growth simultaneous to PHB synthesis was reported not to affect PHB yield and improved the PHB synthesis rate in P-limited fed batch cultures of C. necator grown on butyric acid (Grousseau et al. 2013).

The sustained growth rate on LCFAs and PHA synthesis from octanoic acid suggest an opportunity to maximize PHA titer and productivity in low-DO environments thereby reducing operating costs. The data obtained through co-feeding of octanoic acid and LCFAs indicates that both substrates were being consumed simultaneously with continued NPCM production after onset of oxygen limitation. The PHA content of 54.1% was improved over LCFA cultivations and the monomer composition was very similar to that obtained from octanoic acid in terms of C8 content (Table 3). Further optimization of the octanoic acid and LCFA feeding proportions and rates could further improve PHA titer, productivity increase polymer uniformity and improve PHA yield from octanoic acid. In a similar way, phase feeding strategies have used glucose or glycerol as an inexpensive carbon source for the growth phase followed by feeding fatty acids to improve polymer content of the cells (Kim et al. 1997; Mozejko and Ciesielski 2014; Davis et al. 2015; Fontaine et al. 2017) or to obtain novel monomer compositions (Dufresne et al. 2001; Kurth et al. 2001; Hartmann et al. 2006). The highest yield of PHA from nonanoic acid was achieved by co-substrate growth with glucose in the presence of acrylic acid to prevent fatty acid degradation (Jiang et al. 2012).

Continued NPCM production from LCFAs (compared to octanoic acid) under oxygen-limited conditions is interesting from a redox perspective. Previously it was shown that in a microaerophilic environment, mcl-PHA is efficiently synthesized from octanoic acid and the polymer consists of predominantly C8 monomers (2 electron oxidation) (Blunt et al. 2017). This was thought to be a possible mechanism to maintain cellular redox through the reduction of a minimal amount of oxygen, while providing some energy conservation through oxidative phosphorylation. When LCFAs are used as the substrate, β-oxidation cycle needs to remain active to shorten oleic acid to C8-C10 (R)-3-hydroxyacyl-CoA monomers (4–5 complete cycles), which appear to be preferentially incorporated by the PHA synthase (Table 3). Because P. putida lacks any fermentative pathways, the resulting reduced electron carriers (NADH, FADH2) must be oxidized via electron transport to O2 (Sohn et al. 2010; Nikel and de Lorenzo 2013). This could create high NADH/NAD+ ratios, a condition previously linked to PHA synthesis (Ren et al. 2009), and result in a major bottleneck for growth in a microaerophilic environment. However, contrary to this expectation, a consistent increase in NPCM was observed in the current study when P. putida LS46 was cultured on LCFAs. Examination of the available literature suggests several possible explanations for this observation: (1) fatty acids are known to exert considerable toxicity on cells by disruption of the membrane potential and electron transport (Desbois and Smith 2010; Jarboe et al. 2013). When the substrate is octanoic acid, less carbon is available per proton translocated (compared to oleic acid), and this could cause greater uncoupling of proton-motive force and result in less ATP conserved, and hence less NPCM produced. (2) Transport of fatty acids could be more limiting for one substrate depending on the hydrophobicity of the molecule (Jarboe et al. 2013). 3) LCFAs have been shown to bind to transcription factors (PsrA, FadR) and cause de-repression of genes associated with fatty acid degradation and electron transport (Dirusso and Black 2004; Fujita et al. 2007; Kang et al. 2008). This would be expected to cause increased growth and less PHA production, which was recently demonstrated in a PsrA deficient mutant of P. putida KT2440 during growth on decanoate (Fonseca et al. 2014). These same observations occurred in this work when LCFAs were present whether as the sole carbon source or when co-fed with octanoic acid. While the mechanism for the observed differences between the two substrates remains unclear, follow-up proteomic or transcriptomic analysis should be done to improve understanding of how the cell may respond at the molecular level to exogenous fatty acids of different chain lengths.

In conclusion, when grown on free fatty acids, carbon flux in P. putida LS46 appears to be greatly influenced by the length of the fatty acid carbon chain, particularly under microaerophilic conditions. In cells cultured with octanoic acid as the sole carbon source, we observed growth arrest and rapid mcl-PHA accumulation when the oxygen uptake rate became limited by the bioreactor OTR. In contrast, we observed continued cell division and lower mcl-PHA accumulation in cells cultured with LCFAs as the sole carbon source under identical conditions. This resulted in over twice the NPCM when grown on LCFAs after 16 h pi of fed-batch cultivation, but with lower intracellular PHA content compared to octanoic acid. With further incubation, the LCFA fed culture produced 4.4 times the maximum NPCM measured in the octanoic acid culture, and achieved similar overall volumetric productivity with much higher mcl-PHA titer, after 30 h pi. Similar behavior was also observed when the two substrates were co-fed, where NPCM production continued after oxygen limitation resulting in 3.3 times the maximum NPCM titer obtained from using octanoic acid as the sole carbon source. Intracellular PHA content also improved from 38.4% cdm to 54.1% compared to using LCFA as the sole carbon source. The PHA titer of 6.4 g L−1, and volumetric productivity 0.24 g L−1 h−1 after 26 h pi of co-feeding were significantly higher than the single substrate conditions. Furthermore, the resulting mcl-PHA was 81% C8, suggesting preferential use of octanoic acid for mcl-PHA synthesis, with growth and maintenance requirements being supplied by LCFA. This data suggests that a greater cell yield for a given aeration input can be obtained when LCFAs are present, a finding which could have important cost-saving implications for design of production processes. Subsequent work will focus on improving productivity of the co-feed cultivation by optimizing feeding rates for improved mcl-PHA content.

References

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472 doi: 0.146–0749/90/040450–23$02.00/0

Andin N, Longieras A, Veronese T, Marcato F, Molina-Jouve C, Uribelarrea JL (2017) Improving carbon and energy distribution by coupling growth and medium chain length polyhydroxyalkanoate production from fatty acids by Pseudomonas putida KT2440. Biotechnol Bioprocess Eng 22:308–318. https://doi.org/10.1007/s12257-016-0449-1

Anjum A, Zuber M, Zia KM, Noreen A, Anjum MN, Tabasum S (2016) Microbial production of polyhydroxyalkanoates (PHAs) and its copolymers: a review of recent advancements. Int J Biol Macromol 89:161–174. https://doi.org/10.1016/j.ijbiomac.2016.04.069

Blunt W, Hossain ME, Gapes D, Sparling R, Levin DB, Cicek N (2014) Real-time monitoring of microbial fermentation end-products in biofuel production with titrimetric off-gas analysis (TOGA). Biol Eng Trans 6:203–219. https://doi.org/10.13031/bet.6.10496

Blunt W, Dartiailh C, Sparling R, Gapes D, Levin DB, Cicek N (2017) Microaerophilic environments improve the productivity of medium chain length polyhydroxyalkanoate biosynthesis from fatty acids in Pseudomonas putida LS46. Process Biochem 59:18–25. https://doi.org/10.1016/j.procbio.2017.04.028

Brandl H, Gross RA, Lenz RW, Fuller RC (1988) Pseudomonas oleovorans as a source for novel poly(beta-hydroxyalkanoates). Appl Environ Microbiol 54:1977–1982

Chanprateep S (2010) Current trends in biodegradable polyhydroxyalkanoates. J Biosci Bioeng 110:621–632. https://doi.org/10.1016/j.jbiosc.2010.07.014

Chhetri AB, Watts KC, Islam MR (2008) Waste cooking oil as an alternate feedstock for biodiesel production. Energies 1:3–18. https://doi.org/10.3390/en1010003

Choi J II, Lee SY (1997) Process analysis and economic evaluation for poly(3-hydroxybutyrate) production by fermentation. Bioprocess Eng 17:335–342. https://doi.org/10.1007/s004490050394

Choi JI, Lee SY (1999) High-level production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by fed-batch culture of recombinant Escherichia coli. Appl Environ Microbiol 65:4363–4368

Davis R, Duane G, Kenny ST, Cerrone F, Guzik MW, Babu RP, Casey E, O’Connor KE (2015) High cell density cultivation of Pseudomonas putida KT2440 using glucose without the need for oxygen enriched air supply. Biotechnol Bioeng 112:725–733. https://doi.org/10.1002/bit.25474

de Waard P, van der Wal H, Huijberts GN, Eggink G (1993) Heteronuclear NMR analysis of unsaturated fatty acids in poly(3-hydroxyalkanoates). Study of beta-oxidation in Pseudomonas putida. J Biol Chem 268:315–319

Desbois AP, Smith VJ (2010) Antibacterial free fatty acids: activities, mechanisms of action and biotechnological potential. Appl Microbiol Biotechnol 85:1629–1642. https://doi.org/10.1007/s00253-009-2355-3

Dirusso CC, Black PN (2004) Bacterial long chain fatty acid transport: gateway to a fatty acid-responsive signaling system. J Biol Chem 279:49563–49566. https://doi.org/10.1074/jbc.R400026200

Du C, Sabirova J, Soetaert W, Ki Carol Lin S (2012) Polyhydroxyalkanoates production from low-cost sustainable raw materials. Curr Chem Biol 6:14–25. https://doi.org/10.2174/187231312799984394

Dufresne A, Reche L, Marchessault RH, Lacroix M (2001) Gamma-ray crosslinking of poly(3-hydroxyoctanoate-co-undecenoate). Int J Biol Macromol 29:73–82. https://doi.org/10.1016/S0141-8130(01)00152-0

Elbahloul Y, Steinbüchel A (2009) Large-scale production of poly(3-hydroxyoctanoic acid) by Pseudomonas putida GPo1 and a simplified downstream process. Appl Environ Microbiol 75:643–651. https://doi.org/10.1128/AEM.01869-08

Fernández D, Rodríguez E, Bassas M, Viñas M, Solanas AM, Llorens J, Marqués AM, Manresa A (2005) Agro-industrial oily wastes as substrates for PHA production by the new strain Pseudomonas aeruginosa NCIB 40045: effect of culture conditions. Biochem Eng J 26:159–167. https://doi.org/10.1016/j.bej.2005.04.022

Fonseca P, de la Peña F, Prieto MA (2014) A role for the regulator PsrA in the polyhydroxyalkanoate metabolism of Pseudomonas putida KT2440. Int J Biol Macromol 71:14–20. https://doi.org/10.1016/j.ijbiomac.2014.04.014

Fontaine P, Mosrati R, Corroler D (2017) Medium chain length polyhydroxyalkanoates biosynthesis in Pseudomonas putida mt-2 is enhanced by co-metabolism of glycerol/octanoate or fatty acids mixtures. Int J Biol Macromol 98:430–435. https://doi.org/10.1016/j.ijbiomac.2017.01.115

Fu J, Sharma U, Sparling R, Cicek N, Levin DB (2014) Evaluation of medium-chain-length polyhydroxyalkanoate production by Pseudomonas putida LS46 using biodiesel by-product streams. Can J Microbiol 60:461–468. https://doi.org/10.1139/cjm-2014-0108

Fujita Y, Matsuoka H, Hirooka K (2007) Regulation of fatty acid metabolism in bacteria. Mol Microbiol 66:829–839. https://doi.org/10.1111/j.1365-2958.2007.05947.x

Garcia-Ochoa F, Gomez E, Santos VE, Merchuk JC (2010) Oxygen uptake rate in microbial processes: an overview. Biochem Eng J 49:289–307. https://doi.org/10.1016/j.bej.2010.01.011

Grousseau E, Blanchet E, Déléris S, Albuquerque MGE, Paul E, Uribelarrea JL (2013) Impact of sustaining a controlled residual growth on polyhydroxybutyrate yield and production kinetics in Cupriavidus necator. Bioresour Technol 148:30–38. https://doi.org/10.1016/j.biortech.2013.08.120

Guedon E, Payot S, Desvaux M, Petitdemange H (1999) Carbon and electron flow in Clostridium cellulolyticum grown in chemostat culture on synthetic medium. J Bacteriol 181:3262–3269

Haba E, Vidal-Mas J, Bassas M, Espuny MJ, Llorens J, Manresa A (2007) Poly 3-(hydroxyalkanoates) produced from oily substrates by Pseudomonas aeruginosa 47T2 (NCBIM 40044): effect of nutrients and incubation temperature on polymer composition. Biochem Eng J 35:99–106. https://doi.org/10.1016/j.bej.2006.11.021

Hartmann R, Hany R, Pletscher E, Ritter A, Witholt B, Zinn M (2006) Tailor-made olefinic medium-chain-length poly[(R)-3-hydroxyalkanoates] by Pseudomonas putida GPo1: batch versus chemostat production. Biotechnol Bioeng 93:737–746. https://doi.org/10.1002/bit.20756

Huijberts GNM, Eggink G, De Waard P, Huisman GW, Witholt B (1992) Pseudomonas putida KT2442 cultivated on glucose accumulates poly(3- hydroxyalkanoates) consisting of saturated and unsaturated monomers. Appl Environ Microbiol 58:536–544

Jarboe LR, Royce LA, Liu P (2013) Understanding biocatalyst inhibition by carboxylic acids. Front Microbiol 4:1–8. https://doi.org/10.3389/fmicb.2013.00272

Jiang X, Sun Z, Marchessault RH, Ramsay JA, Ramsay BA (2012) Biosynthesis and properties of medium-chain-length polyhydroxyalkanoates with enriched content of the dominant monomer. Biomacromolecules 13:2926–2932. https://doi.org/10.1021/bm3009507

Kang Y, Nguyen DT, Son MS, Hoang TT (2008) The Pseudomonas aeruginosa PsrA responds to long-chain fatty acid signals to regulate the fadBA5 β-oxidation operon. Microbiology 154:1584–1598. https://doi.org/10.1099/mic.0.2008/018135-0

Kaur G, Roy I (2015) Strategies for large-scale production of polyhydroxyalkanoates. Chem Biochem Eng Q 29:157–172. https://doi.org/10.15255/CABEQ.2014.2255

Kellerhals MB, Kessler B, Witholt B, Tchouboukov A, Brandl H (2000) Renewable long-chain fatty acids for production of biodegradable medium-chain-length polyhydroxyalkanoates (mcl-PHAs) at laboratory and pilot plant scales. Macromolecules 33:4690–4698. https://doi.org/10.1021/ma000655k

Kim GJ, Lee IY, Yoon SC, Shin YC, Park YH (1997) Enhanced yield and a high production of medium-chain-length poly(3-hydroxyalkanoates) in a two-step fed-batch cultivation of Pseudomonas putida by combined use of glucose and octanoate. Enzym Microb Technol 20:500–505. https://doi.org/10.1016/S0141-0229(96)00179-2

Koller M, Maršálek L, de Sousa Dias MM, Braunegg G (2017) Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol 37:24–38. https://doi.org/10.1016/j.nbt.2016.05.001

Kourmentza C, Plácido J, Venetsaneas N, Burniol-Figols A, Varrone C, Gavala HN, Reis MAM (2017) Recent advances and challenges towards sustainable Polyhydroxyalkanoate (PHA) production. Bioengineering 4:1–43. https://doi.org/10.3390/bioengineering4020055

Kurth N, Brachet F, Robic D, Bourbouze R, Renard E, Guerin P (2001) Poly(3-hydroxyoctanoate) containing pendant carboxylic groups for the preparation of nanoparticles aimed at drug transport and release. Polymer (Guildf) 43:1095–1101. https://doi.org/10.1016/S0032-3861(01)00692-9

Lara AR, Galindo E, Ramírez OT, Palomares LA (2006) Living with heterogeneities in bioreactors: understanding the effects of environmental gradients on cells. Mol Biotechnol 34:355–382. https://doi.org/10.1385/MB:34:3:355

Lee SY, Wong HH, Il CJ, Lee SH, Lee SC, Han CS (2000) Production of medium-chain-length polyhydroxyalkanoates by high-cell- density cultivation Pseudomonas putida under phosphorus limitation. Biotechnol Bioeng 68:466–470. https://doi.org/10.1002/(SICI)1097-0290(20000520)68:4<466::AID-BIT12>3.0.CO;2-T

López NI, Pettinari MJ, Nikel PI, Méndez BS (2015) Polyhydroxyalkanoates: Much More than Biodegradable Plastics. Adv Appl Microbiol 93:73–106. https://doi.org/10.1016/bs.aambs.2015.06.001

Maclean H, Sun Z, Ramsay J, Ramsay B (2008) Decaying exponential feeding of nonanoic acid for the production of medium-chain-length poly (3-hydroxyalkanoates) by Pseudomonas putida. Can J Chem 86:564–569. https://doi.org/10.1139/V08-062

Mozejko J, Ciesielski S (2014) Pulsed feeding strategy is more favorable to medium-chain-length polyhydroxyalkanoates production from waste rapeseed oil. Biotechnol Prog 30:1243–1246. https://doi.org/10.1002/btpr.1914

Możejko-Ciesielska J, Kiewisz R (2016) Bacterial polyhydroxyalkanoates: still fabulous? Microbiol Res 192:271–282. https://doi.org/10.1016/j.micres.2016.07.010

Nikel PI, de Lorenzo V (2013) Engineering an anaerobic metabolic regime in Pseudomonas putida KT2440 for the anoxic biodegradation of 1,3-dichloroprop-1-ene. Metab Eng 15:98–112. https://doi.org/10.1016/j.ymben.2012.09.006

Nikodinovic-Runic J, Guzik M, Kenny ST, Babu R, Werker A, O’Connor KE (2013) Carbon-rich wastes as feedstocks for biodegradable polymer (polyhydroxyalkanoate) production using bacteria. Adv Appl Microbiol 84:139–200. https://doi.org/10.1016/B978-0-12-407673-0.00004-7

Ramsay BA, Lomaliza K, Chavarie C, Dube B, Bataille P, Ramsay JA (1990) Production of poly-(P-hydroxybutyric-Co-3-Hydroxyvaleric ) acids. Appl Environ Microbiol 56:2093–2098

Ravindran R, Jaiswal AK (2016) Exploitation of food industry waste for high-value products. Trends Biotechnol 34:58–69. https://doi.org/10.1016/j.tibtech.2015.10.008

Ren Q, de Roo G, Ruth K, Witholt B, Zinn M, Thöny-Meyer L (2009) Simultaneous accumulation and degradation of polyhydroxyalkanoates: futile cycle or clever regulation? Biomacromolecules 10(4):916–922

Sharma PK, Fu J, Cicek N, Sparling R, Levin DB (2012) Kinetics of medium-chain-length polyhydroxyalkanoate production by a novel isolate of Pseudomonas putida LS46. Can J Microbiol 58:982–989. https://doi.org/10.1139/w2012-074

Sohn SB, Kim TY, Park JM, Lee SY (2010) In silico genome-scale metabolic analysis of Pseudomonas putida KT2440 for polyhydroxyalkanoate synthesis, degradation of aromatics and anaerobic survival. Biotechnol J 5:739–750. https://doi.org/10.1002/biot.201000124

Song JH, Jeon CO, Choi MH, Yoon SC, Park W (2008) Polyhydroxyalkanoate (PHA) production using waste vegetable oil by. J Microbiol Biotechnol 18:1408–1415

Sun Z, Ramsay JA, Guay M, Ramsay BA (2007) Fermentation process development for the production of medium-chain-length poly-3-hyroxyalkanoates. Appl Microbiol Biotechnol 75:475–485. https://doi.org/10.1007/s00253-007-0857-4

Vendruscolo F, Rossi MJ, Schmidell W, Ninow JL (2012) Determination of oxygen solubility in liquid media. ISRN Chem Eng 2012:1–5. https://doi.org/10.5402/2012/601458

Wallace T, Gibbons D, O’Dwyer M, Curran TP (2017) International evolution of fat, oil and grease (FOG) waste management—a review. J Environ Manag 187:424–435. https://doi.org/10.1016/j.jenvman.2016.11.003

Wang F, Lee SY (1997) Poly(3-Hydroxybutyrate ) production with high productivity and high polymer content by a fed-batch culture of Alcaligenes latus under nitrogen limitation. Appl Environ Microbiol 63:3703–3706. https://doi.org/10.1023/a:1012222625201

Funding

This study was funded by the Genome Canada, through the Genome Applications and Partnership Program (GAPP), and the Natural Sciences and Engineering Research Council (NSERC) of Canada through a Collaborative Research and Development (CRD) grant with Minto BioProducts Ltd. as the industrial partner (grant number CRDPJ-490630-15).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Blunt, W., Dartiailh, C., Sparling, R. et al. Carbon flux to growth or polyhydroxyalkanoate synthesis under microaerophilic conditions is affected by fatty acid chain-length in Pseudomonas putida LS46. Appl Microbiol Biotechnol 102, 6437–6449 (2018). https://doi.org/10.1007/s00253-018-9055-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-9055-9