Abstract

Yarrowia lipolytica is an oleaginous yeast species that has attracted attention as a model organism for synthesis of single cell oil. Among over 50 isolates of Y. lipolytica identified, only a few of the strains have been studied extensively. Furthermore, 12 other yeast species were recently assigned to the Yarrowia clade, and most are not well characterized in terms of cell growth and lipid accumulation, especially in industrially relevant conditions. In the present study, we investigated biomass and lipid production by 57 yeast isolates, representing all 13 species in the Yarrowia clade, on a non-detoxified dilute acid-pretreated switchgrass hydrolysate under highly aerobic conditions. The objective was to compare yeast physiology during growth in an abundant, low-cost biomass feedstock and to expand diversity of genetically tractable, oleaginous yeasts available for lipid research. Screening of 45 Y. lipolytica isolates demonstrated considerable variation within the species in terms of lipid accumulation (min = 0.1 g/L; max = 5.1 g/L; mean = 2.3 g/L); three strains (NRRL YB-420, YB-419, and YB-392) were especially promising for cellulosic biomass conversion with average improvements of 43, 57, and 64%, respectively, in final lipid titer as compared to control strain W29. Subsequently, evaluation of strains from 13 distinct species in the Yarrowia clade identified Candida phangngensis PT1-17 as the top lipid producer with a maximum titer of 9.8 g/L lipid, which was over twofold higher than the second-best species in the clade (Candida hollandica NRRL Y-48254). A small set of the most promising strains from the screenings was further characterized to evaluate inhibitor tolerance, lipid production kinetics, and fatty acid distribution. We expect that the results of this study will pave the way for new biotechnological applications involving previously overlooked and under-characterized strains within the Yarrowia clade.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

For almost a century, there has been commercial interest in harvesting yeast lipids as an alternative source of oil especially for food and feed applications (Lindner 1922). More recently, concerns about petroleum prices and greenhouse gas emissions have extended microbial lipid research toward sustainable production of fatty acid derived fuels and chemicals. Triacylglycerols (TAGs), which make up the majority of storage lipids in yeast, can be readily transesterified to biodiesel (i.e., fatty acid methyl esters) or hydrolyzed to release free fatty acids (FFA) for chemical transformation (Jin et al. 2015). Though similar in composition to plant oils, yeast lipids have several important advantages including a shorter process cycle, relative ease of scale-up, and potential for year-round production independent from season or climate (Beopoulos et al. 2011). The identification of suitable host strains and species for optimal lipid production from low-cost feedstocks is a critical aspect of industrial process development and has been the focus of several extensive yeast screening experiments (Pan et al. 2009; Kitcha and Cheirsilp 2011; Sitepu et al. 2012, 2013; Slininger et al. 2016).

Among over 1600 identified yeast species, less than 5% are known to be oleaginous, i.e., accumulate lipids at greater than 20% of dry weight (Sitepu et al. 2013). The best lipid producers among the known oleaginous yeasts come from several genera including Cryptococcus, Lipomyces, Rhodotorula, Rhodosporidium, and Trichosporon; these have been shown to accumulate lipids at levels exceeding 60–70% of biomass under conditions of nutrient limitation (Ratledge and Wynn 2002). Yarrowia lipolytica, the most intensively studied and well characterized of all the oleaginous yeasts, can generate lipids up to approximately 40% of cell mass in similar nutrient-limited culture conditions (Beopoulos et al. 2009). Although mediocre in terms of lipogenesis, Y. lipolytica has emerged as a model lipid-producing microorganism with notable advantages over the aforementioned yeasts for industrial applications. This ascomycete, which attracted commercial attention in the 1970s for its ability to synthesize organic acids (Nicaud 2012), has become an established microorganism in the food industry with generally recognized as safe (GRAS) status for citric acid production and a recent assessment assuring safety of the yeast biomass for human consumption (Groenewald et al. 2014). Y. lipolytica’s ability to assimilate a wide variety of hydrophobic substrates makes feasible the bioconversion of agro-industrial waste residues, such as glycerol or animal fat, to higher value lipids and other useful products (Papanikolaou et al. 2002a, b; Fickers et al. 2005). Furthermore, the availability of an annotated genome sequence (Dujon et al. 2004), efficient transformation methods (Chen et al. 1997), and genetic tools, such as specialized expression vectors and selectable markers (Barth and Gaillardin 1996; Thevenieau et al. 2009), has facilitated advanced genetic engineering techniques. Thus, Y. lipolytica is often preferred as a host organism in metabolic engineering studies for overproduction of single-cell oil (Tai and Stephanopoulos 2013; Blazeck et al. 2014; Qiao et al. 2015) and synthesis of other oleochemicals (Ledesma-Amaro and Nicaud 2016).

Despite numerous advantages of Y. lipolytica for biotechnology, native strains have demonstrated little or no capacity for assimilation of pentoses, such as xylose or arabinose (Kurtzman 2011). These five-carbon sugars constitute a significant portion of polysaccharides in lignocellulosic biomass, an inexpensive and abundant feedstock that does not compete directly with food commodities. Furthermore, the yeast has been reported to have a fairly low tolerance to furfural (Sitepu et al. 2014), a degradation product from xylose and common fermentation inhibitor generated during biomass pretreatment. The inherent challenges to mixed sugar utilization and inhibitor tolerance have limited the number of research studies evaluating performance of the model oleaginous yeast in lignocellulosic hydrolysates. To our knowledge, only five studies have reported lipid accumulation by wild-type Y. lipolytica strains during growth in various hydrolysates—made from wheat straw (Yu et al. 2011), sugarcane bagasse (Tsigie et al. 2011), rice bran (Tsigie et al. 2012), corn stover (Slininger et al. 2016), or woody biomass (Dien et al. 2016b). However, substantial variations in hydrolysate preparation and culture conditions make any comparison of data among the studies difficult or impossible. Also, the previous work has included only a limited number of Y. lipolytica strains (six wild-type strains and one auxotrophic mutant) among the scores of isolates (>50) available in culture collections around the world. The screening study by Slininger et al. (2016) did include five strains of Y. lipolytica producing between 2.5 and 5.8 g/L lipids in ammonia fiber expansion (AFEX)-pretreated corn stover hydrolysate. Still, little or no phenotypic data are available for the majority of isolates to describe growth, lipid production, sugar utilization, or inhibitor tolerance. Prior research on Saccharomyces cerevisiae suggests that yeast strains can vary widely in their tolerance to common inhibitors in cellulosic hydrolysates (Nilsson et al. 2005; Almeida et al. 2007).

Y. lipolytica was the only identified species in its genus for several decades (Nicaud 2012). In 2005, Kurtzman first defined a potential Yarrowia clade and proposed two species from genus Candida as new members based on phylogenetic analysis of 26S rDNA sequences (Kurtzman 2005). Over the past 11 years, the total number of member species in the Yarrowia clade has grown to 13 (Fig. 1) with the new strains isolated from various environments including meat or dairy products, sea water, and insects (Knutsen et al. 2007; Limtong et al. 2008; Chang et al. 2013; Groenewald and Smith 2013; Nagy et al. 2013, 2014). Non-fermentative metabolism and limited growth on non-glucose sugars are traits common to the clade. However, no phenotypic data are available for the Yarrowia clade, with the exception of a few Y. lipolytica isolates, relating to tolerance of common fermentation inhibitors (i.e., furfural, hydroxymethylfurfural (HMF), and acetic acid) or potential for lipid accumulation in lignocellulosic biomass hydrolysates.

Phylogenetic relationships among species of the Yarrowia clade (black) and reference species (red) determined from maximum likelihood analysis of D1/D2 LSU rRNA gene sequences using MEGA 5.2 (Tamura et al. 2011). Bootstrap values >50% are given at nodes and based on 1000 replicates. Strain numbers designated with superscript T are type strains of the species. Species presently placed in Candida need to be transferred to Yarrowia to conform to the International Code of Nomenclature for algae, fungi, and plants (Melbourne Code) (McNeill et al. 2012) (color figure online)

In the present study, we investigated growth and lipid production by 57 yeast isolates, representing 13 species in the Yarrowia clade, in an enzyme saccharified dilute acid-pretreated switchgrass hydrolysate (SGH). The objective was to identify and characterize oleaginous strains in the clade that are most suitable for accumulating lipids using abundant, low-cost biomass feedstocks. “Liberty” switchgrass, the first high-yielding perennial adapted to the US Great Plains and Midwest region (Vogel et al. 2014), was chosen as the feedstock to represent a prototypical lignocellulosic biomass energy crop. The switchgrass was pretreated in dilute sulfuric acid, which is a lower cost option as compared to other alternatives; this method has long been considered to be at the forefront of biomass pretreatment technologies (Slininger et al. 2016). A suitable C/N ratio for the hydrolysate was identified by surveying growth and lipid production by a representative Y. lipolytica strain in synthetic media across a wide range of possible C/N values (data not shown). The initial screenings—comparing 45 Y. lipolytica isolates and type strains from all other species in the Yarrowia clade—were conducted in SGH under aerobic conditions with Y. lipolytica W29 (= CBS 7504) included as the control strain. The W29 strain, which is quite prevalent in the literature, was originally isolated from wastewater in Paris, France (Barth and Gaillardin 1996), and several of its auxotrophic derivatives (e.g., Po1f, Po1g) have been widely used for genetic manipulation of the species (Madzak et al. 2000; Liu and Alper 2014). The results of the initial screening provide meaningful physiological data for a large set of phylogenetically related yeasts and demonstrate surprising phenotypic diversity across the clade (and within the Y. lipolytica species) in terms of lipid titer, cell mass, sugar utilization, and sugar alcohol production. Subsequently, the most promising strains for lipid accumulation were further characterized to evaluate other relevant traits—tolerance to fermentation inhibitors, kinetic data for growth and lipid production, and distribution of fatty acids. We expect that the results of this study will open the way for new biotechnological applications involving previously under-characterized strains in the Yarrowia clade.

Materials and methods

Preparation of SGH

Switchgrass hydrolysates were prepared from pelleted Liberty switchgrass (Vogel et al. 2014) that was passed through a 4-mm knife mill. The SGH preparation at 20% w/w solids was based on a protocol described previously (Slininger et al. 2016) with some modifications as noted below. Dilute acid pretreatment was conducted by loading 20 g dry weight of biomass into a stainless steel vessel with 80 mL of 0.936% v/v H2SO4 solution and 0.3 g Pluronic F-68. The vessels were mounted in a Mathis Labomat IR Dyer Oven and rotated at 50 rpm during heating to 160 °C at 2.6 °C/min, a 15-min hold at 160 °C, and cooling to 40 °C at 6.0 °C/min; the direction of rotation was reversed every minute. Subsequently, the pretreated product was neutralized by adding 3.6 mL of 30% Ca(OH)2 solution and 4.5 mL of 1 M citric acid buffer (pH = 4.5) to each reactor vessel and mixing for 30 min in the Labomat. For enzymatic saccharification, hydrolysates were transferred to 250-mL pyrex bottles with addition of 2.7 mL Ctec2 and 0.5 mL HTec2 (Novozymes, Bagsvaerd, Denmark) to provide cellulases and hemicellulases. Capped bottles were incubated at 50 °C and 175 rpm for approximately 72 h. The resulting product was adjusted to pH 6 with 10 M NaOH and then filter sterilized through a 0.2-μm Nalgene filter unit. An enzyme-based assay kit (Megazyme International, Wicklow, Ireland) was used to measure available nitrogen in the form of primary amino nitrogen (PAN), ammonia, and urea. For all experiments, the SGH was adjusted to C/N = 65 by supplementing with 2.31 g/L (NH4)2SO4 (Fisher Scientific, Waltham, MA, USA) and a vitamin-free casamino acid mix containing 1.81 g/L Difco Vitamin Assay Casamino Acids (Becton, Dickinson and Company, Franklin Lakes, NJ, USA), 0.018 g/L l-tryptophan (Sigma, St. Louis, MO, USA), and 0.072 g/L l-cysteine (Sigma, St. Louis, MO, USA). Amended SGH was diluted with sterile water as specified for each experiment. Table 1 describes the concentration of sugars, inhibitors, and nitrogen compounds in a representative batch of SGH before and after nitrogen amendment.

Yeast strains and culture conditions

Y. lipolytica strain W29 (= CBS 7504) was obtained from the CBS-KNAW Culture Collection in Utrecht, the Netherlands and used as the control in this study. Forty-four other Y. lipolytica isolates, including the type strain NRRL YB-423, were selected from the ARS (NRRL) Culture Collection in Peoria, IL, USA. The strain accession numbers for all 45 Y. lipolytica strains evaluated in this study are included in Table 2. In addition, the type strains of 12 other species in the Yarrowia clade were obtained from the CBS and ARS Culture Collections for comparison with the model oleaginous species Y. lipolytica. The strain number, abbreviated name, and source habitat of all isolates used in the Yarrowia clade screening and subsequent experiments are described in Table 3. A second isolate of Candida phangngensis (strain TM2-16) was generously provided to us by Dr. Savitree Limtong (Kasetsart University, Bangkok, Thailand) and deposited in the ARS Culture Collection (NRRL Y-63792). All strains used in this study are wild-type, prototrophic yeast strains.

After being received from the culture collections, all strains were maintained in 20% glycerol at −80 °C. Yeast strains were revived from cryo-preserved stocks by streaking onto yeast extract-peptone-dextrose (YPD) agar plates, incubating for 48–72 h, and refrigerating for short-term use within 1 week. All Yarrowia strains were cultured at 28 °C on either solid or liquid media. For the rich media preculture, a single colony was inoculated into 10 mL liquid YPD (10 g/L yeast extract, 20 g/L peptone, 20 g/L glucose) in a 50-mL baffled flask and incubated at 250 rpm for approximately 24 h. A 5% (v/v) inoculum of this preculture was transferred into SGH (C/N = 65; pH = 6) diluted to 50% (v/v) strength with sterile water and then 0.5 mL per well was dispensed into deep, 96-well plates (Applikon Biotechnology, Delft, the Netherlands) with at least one empty row between strains. Deep well plates were fitted with standard aeration covers and incubated at 400 rpm for 48 h. Next, hydrolysate precultures were harvested and washed with sterile water before inoculating cells to OD620 nm ≈ 1 in fresh SGH (C/N = 65; pH = 6) diluted to 60, 75, or 90% (v/v) strength as specified for the experiment. Test cultures were dispensed into deep well plates (0.5 mL per well) and incubated as described above for the SGH precultures (400 rpm). For each time point evaluated, yeast samples were harvested in duplicate by pipetting the entire content of two separate wells and analyzing for dry weight, lipids, and HPLC. For the screening of 45 Y. lipolytica strains, there were two minor modifications to the above procedure in order to accommodate a large number of cultures. First, the rich media preculture was conducted by inoculating a single colony into 5 mL YPD and dispensing 0.5 mL per well into deep well plates, which were incubated for ∼24 h at 400 rpm. Second, test cultures were inoculated by a 3.2% (v/v) transfer from the hydrolysate preculture into fresh 60% strength SGH (C/N = 65; pH = 6) in order to achieve initial OD620 nm ≈ 1 for the best-growing strain. Test cultures were grown in deep well plates as described previously.

Time-course profiles of select strains were obtained at larger scale in duplicate flask cultures. For this purpose, precultures were grown up from a single colony in 10 mL YPD in a 50-mL baffled flask as before. After 24 h, a 5% (v/v) inoculum was transferred into 10 mL of 50% strength SGH (C/N = 65; pH = 6) in 50-mL baffled flasks and incubated for 24 h at 250 rpm. Hydrolysate precultures were harvested and washed with sterile water. Then, washed cells were inoculated to OD620 nm ≈ 1 in 25 mL of fresh 50% strength SGH (C/N = 65; pH = 6) in 125-mL baffled flasks. Flask cultures were incubated with 250 rpm shaking and periodically sampled in duplicate for dry weight, lipids, and HPLC.

Lipid quantification

Lipids were quantified using a sulfo-phospho-vanillin (SPV) colorimetric assay modified from Izard and Limberger (2003) and previously described for tracking intracellular lipid accumulation by oleaginous yeast (Wang et al. 2009; Dien et al. 2016a, b; Slininger et al. 2016). Briefly, washed cell pellets (20 μL) were mixed with 0.4 mL concentrated sulfuric acid in glass test tubes and heated for 10 min at 100 °C. The reaction was cooled for 10 min in an ambient water bath. Next, 1 mL of a vanillin-phosphoric acid solution was added to each tube and the reaction was allowed to proceed for 15 min at 37 °C. After cooling for 10 min, the absorbance of each reaction was measured at 530 nm against a reference sample prepared with 20 μL water. For creating a calibration curve, three lipid standards were prepared on the same day by dissolving corn oil in 2:1 (v/v) chloroform/methanol and duplicate samples of each standard (20 μL each) were included in the assay. The vanillin-phosphoric acid solution was prepared fresh for each assay by dissolving 0.12 g vanillin in 20 mL distilled water and 80 mL of 85% o-phosphoric acid. The assay was validated previously for various oleaginous yeast lipids, and common media ingredients were found to provide minimal interference (Dien et al. 2016a). The SPV assay shows a highly linear colorimetric response across a wide range of oil concentrations (Supplementary Fig. S1).

Lipid extraction and fatty acid profiling

Lipids were extracted from yeast by following a procedure based on that described previously by Schneiter and Daum (2006). Briefly, washed cells from 5 mL yeast cultures were lyophilized over two nights in a freeze dryer (Labconco, cat. no. 7960046, Kansas City, MO, USA). Dry cells were lysed in a FastPrep-24 homogenizer (M.P. Biomedicals, Santa Ana, CA, USA) by agitation for 1 min with 0.5 mm zirconia/silica beads. Then, 1 mL of extraction solvent (2:1 v/v, chloroform/methanol) was added to each tube followed by agitation for 1 h in a multi-reaction vortexer (Heidolph, Schwabach, Germany). After centrifugation, 0.6 mL of the extract was transferred to 0.2 mL of 0.3% NaCl for washing to remove water-soluble contaminants. The organic layer was transferred to a separate vial, and the solvent was evaporated overnight at ambient temperature. Transesterification of lipid extracts was performed by adding 2 mL of hexane and 0.2 mL of 2 M KOH in methanol to each sample and mixing for 2 min. For analysis of fatty acid composition, the resulting FAME samples were injected into a GC-FID (Agilent Technologies, Santa Clara, CA, USA) equipped with an Agilent HP-88 capillary column (30 m × 0.25 mm). The following settings were used for the GC analysis: injection volume = 2 μL; inlet = splitless mode; detector temp = 280 °C; H2 flow = 35 mL/min; air flow = 400 mL/min; and oven temp = 135 °C for 5 min, increased at 2 °C/min to 210 °C, increased at 50 °C/min to 220 °C, and held 5 min at 220 °C. To identify peaks, a commercial reference standard containing 31 saturated and unsaturated fatty acid methyl esters (Nu-Chek Prep, Inc., cat. no. GLC-411, Elysian, MN, USA) was also analyzed by GC as above. Total fatty acid content of each sample was based on the sum of all individual FAME peak areas identified in the chromatogram.

Biomass determination

Dry weight was measured from 0.5 mL yeast samples that were washed and resuspended in distilled water. Washed cells were transferred into a preweighed aluminum pan with an equal volume of distilled water for rinsing. Samples were dried in an oven at 80 °C for 24 h before determining gross weight on an analytical balance. Optical density (OD) was measured by absorbance at 620 nm in 1 cm path length cuvettes with an Evolution 60 spectrophotometer. Samples were diluted to obtain absorbance values in the linear range for the instrument.

HPLC analysis

The concentration of extracellular sugars, acetic acid, and aldehyde inhibitors (HMF and furfural) was determined by a Waters high-performance liquid chromatography system equipped with an Aminex HPX-87H column (Biorad Laboratories, Inc., Hercules, CA, USA). Column temperature was kept constant at 60 °C, and the elution was performed with 15 mM HNO3 at a flow rate of 0.6 mL/min. Sugars and acetic acid were detected with a refractive index detector (RID), and inhibitors were detected with an ultraviolet absorbance detector at 245 nm. Sugar alcohols, including xylitol and arabitol, were analyzed by a SpectraSystem liquid chromatography system (Thermo Electron Corporation, Waltham, MA, USA) equipped with an Aminex HPX-87P column (Biorad Laboratories, Inc., Hercules, CA, USA) and RID. Column temperature was maintained at 80 °C, and elution was performed with water at 0.6 mL/min.

Results

Screening of 45 Y. lipolytica strains

The initial screen included Y. lipolytica strains only. All 45 isolates available from the ARS and CBS culture collections were grown in 60% (v/v) strength SGH (Table 1) using deep, 96-well plates for a comparative evaluation of strains within the species. After 72 h, yeast samples were harvested in duplicate and analyzed for growth, lipid accumulation, sugar utilization, and metabolite production (i.e., xylitol and arabitol). Table 2 summarizes the key parameters for all strains evaluated. The reference strain W29 (= CBS 7504) accumulated 3.1 g/L lipid and 15.0 g/L cell mass for a total lipid content of 20.8% dry weight (DW). Among the remaining isolates, 20 out of 44 produced more biomass than the control (W29) and the highest dry weight of 18.6 g/L was observed for NRRL Y-7754. The poorest growing strain (NRRL YB-272) generated 3.3 g/L cell mass and consumed only 12.7% of the initial glucose (35.2 g/L) during the course of the experiment. Also, NRRL YB-272 was the lowest lipid producer with 0.1 g/L total lipids and a lipid content of 2.1% DW. Although 25% of the isolates evaluated (11 out of 44) demonstrated a higher lipid titer than the control, only eight of the 11 (NRRL YB-392, YB-419, YB-420, Y-5384, Y-5386, Y-7207, Y-7212, and Y-7754) were statistically significant improvements (P < 0.05). Among these, the best three strains (NRRL YB-420, YB-419, YB-392) produced 40–65% more lipids than the reference W29. NRRL YB-420 was the top lipid producer among all strains in terms of both titer (5.1 g/L) and cell content (37.9% DW), although its cell mass (13.4 g/L) was below average for the species. In addition, NRRL YB-419 and YB-392 were promising strains for lipid accumulation with final lipid output of 4.9 and 4.5 g/L, respectively, and lipid content of 28.5 and 28.2% DW, respectively. Overall, 12 of the 45 strains tested generated intracellular lipids at greater than 20% of dry cell weight, which is the threshold to be classified as oleaginous (Ratledge 1991).

In terms of sugar utilization, most strains (28 of 45) consumed all glucose in the hydrolysate (35.2 g/L) within 72 h and only nine isolates consumed less than 90% of the initial glucose during this time. As expected, xylose uptake was inhibited in the presence of glucose due to carbon catabolite repression (Gancedo 1998). However, the 28 strains that did exhaust glucose in the hydrolysate showed a surprisingly large variability in xylose consumption, ranging from 2.5 to 25.7 g/L (median = 12.3 g/L). This result not only could be due to a variation in xylose transport or aldose reductase activity within the species but also may be explained by other factors such as glucose consumption rate or inhibitor tolerance. YB-566 and YB-567 were the best xylose-utilizing isolates of Y. lipolytica even though their cell growth and lipid production were below average for the species. For these two strains, almost 75% of consumed pentose was reduced to xylitol and arabitol, and they secreted sugar alcohols at the highest overall titers (20.7 and 19.9 g/L, respectively). The best three lipid producers (YB-420, YB-419, and YB-392) showed surprising variation in terms of xylose consumption (4.0, 17.1, and 6.1 g/L, respectively) and xylitol production (0, 7.1, and 0.7 g/L, respectively) although they were isolated from similar habitats. For comparison, the reference W29 consumed 19.7 g/L xylose and generated 6.6 g/L xylitol during the course of the experiment. Although we originally hypothesized that the xylose assimilation pathway and fatty acid synthesis pathway may be competing for the co-factor NADPH in oleaginous yeast, there was no significant correlation (negative or positive) between xylose consumption and lipid production within the set of 45 isolates evaluated (R 2 = 0.04). However, there was a positive correlation between xylose and arabinose consumption (R 2 = 0.70), which is likely due to overlap in activity toward the two pentoses by some sugar transporters and aldo-keto reductases (Ellis 2002; Träff et al. 2002; Sanchez et al. 2010).

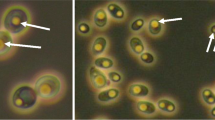

Comparative evaluation of 13 species in the Yarrowia clade

To broaden the search, screening was extended to the entire Yarrowia clade. The reference strain Y. lipolytica W29 and type strains from 12 other species in the clade (Fig. 1) were subsequently evaluated for growth and lipid production in cellulosic hydrolysate. Table 3 lists the abbreviation and source habitat for all strains included in the clade screening. Although Candida alimentaria (CA) was viable on YPD plates and normal-sized colonies appeared within 3 days, there was no growth in liquid YPD flask cultures at 28 °C within 1 week. A previous study reported that this strain showed optimum growth in YPD at 21 °C, but cell growth was inhibited at 25 °C; nevertheless, all other Yarrowia strains evaluated, representing eight different species, grew normally at 28 °C (Michely et al. 2013). Thus, CA was the first to be eliminated in our clade screening due to its temperature sensitivity at ≥25 °C, which is unfavorable for commercial scale-up. The remaining strains were all viable in seed cultures of 50% (v/v) strength SGH, and washed cells were subsequently transferred to fresh 60% (v/v) strength SGH test cultures for periodic monitoring in aerobic conditions. Duplicate wells were harvested at 2, 3, 4, and 6 days, and samples were analyzed for lipids, dry cell weight, and sugars. Two strains (CHi and YY) were unable to tolerate the 60% (v/v) SGH test culture and remained at low cell mass (<1.7 and <0.5 g/L, respectively) with little or no sugar utilization even up to 6 days. We suspect that poor inhibitor tolerance may have been a factor limiting cell growth in the hydrolysate by these two strains. For the remaining ten species, Fig. 2 summarizes the results for growth and lipid accumulation at the four sample times. The control YL29 reached a maximum dry weight of 18.2 g/L at 2 days with lipid production at 3.4 g/L and 18.8% DW. Between 2 and 3 days of incubation, cell mass dropped significantly to 14.6 g/L with one third of the weight loss due to lipid catabolism; thereafter, biomass remained fairly steady for the duration of the experiment. Only two of nine Yarrowia species reached a higher cell mass than the reference strain— Candida hollandica (CHo) and C. phangngensis (CP) achieved a maximum of 22.4 and 19.8 g/L biomass, respectively, at 6 days. CP was by far the top lipid producer in the clade with lipid titer (and cell growth) surpassing the control strain between days 2 and 3 and then steadily increasing to a maximum of 9.8 g/L (49.7% DW) at day 6. Yarrowia keelungensis (YK) and CHo also showed a significant improvement in maximum lipid accumulation as compared to the reference strain (P < 0.05) with maxima occurring at day 2 and day 6, respectively. Similar to the control, YK grew up quickly to 16.9 g/L dry weight and accumulated 3.8 g/L lipids within 2 days, but 30% of total lipid was consumed between days 2 and 3. CHo was the second-best lipid producing strain in the clade under these conditions, but the maximum titer (4.5 g/L) was still less than half that of the CP strain. Overall, 4 out of 13 species that we tested in this experiment achieved a maximum lipid content of greater than 20% of dry weight (CG, CO, CP, and YK); the oleaginicity of these strains has not been demonstrated previously on non-hydrophobic substrates.

Comparative evaluation of species in the Yarrowia clade on SGH. Cells were cultured in 60% (v/v) strength N-amended SGH in deep, 96-well plates and sampled at four time points for analysis of a dry weight and b lipid accumulation. Error bars indicate standard deviation from the mean of duplicate samples. Strains are represented by an abbreviation of their species name, as indicated in Table 3. Three Yarrowia strains were unable to grow in this condition and are not included in the figure (CA, CHi, and YY)

Two strains—YL29 and YK—had the fastest glucose consumption rate in the clade, and both were able to consume all glucose in the hydrolysate within 2 days. After depletion of glucose, these two yeasts consumed 24.0 and 18.0 g/L xylose, respectively, at the 3 day sample time—tops for the clade. The best lipid-producing strain (CP) showed a longer lag time (≈40 h) after inoculation to SGH test cultures and consumed only 0.6 g/L xylose after 3 days; xylose consumption steadily increased to 9.6 g/L after 6 days. All ten Yarrowia species that grew in SGH test cultures showed some capacity for transporting xylose into the cell in the absence of glucose, although to varying degrees. However, cell growth generally slowed or plateaued after glucose depletion, and we found little or no evidence for assimilation of xylose to produce biomass. Supplementary Fig. S2 describes sugar utilization and xylitol production over time for all strains evaluated. After uptake, intracellular xylose was reduced to xylitol and then primarily secreted by the cells rather than being further metabolized to xylulose-5-phosphate for entry into the pentose phosphate pathway. Among the set of 13 Yarrowia strains evaluated, YK produced the most xylitol with a titer of 12.9 g/L at day 3 and yield of 0.72 g/g of xylose consumed. At the same sample time, the control YL29 produced 10.6 g/L xylitol at a yield of 0.44 g/g of xylose consumed. Table 4 summarizes the results for lipid and sugar alcohol production by all strains in the clade.

Physiological characterization of select strains

After screening a total of 57 Yarrowia isolates, we wanted to further characterize the most promising yeasts for current and future applications involving bioconversion of lignocellulosic hydrolysates. Seven strains were selected based on the screening results, including five Y. lipolytica isolates (YL29, YL392, YL419, YL420, and YL567) and two other species from the clade (CHo and CP). First, we evaluated capacity for growth and lipid accumulation at various strengths of hydrolysate in order to test for tolerance to common fermentation inhibitors in SGH (i.e., furfural, HMF, and acetic acid). Yeasts were cultured in either 60, 75, or 90% (v/v) strength SGH in deep 96-well plates, and cells were harvested at 3 days for analysis (Fig. 3). All seven strains grew to >10 g/L cell mass in the 60% SGH, and six of the seven were also able to propagate in the higher strength 75% SGH. Unfortunately, the best lipid producer from the screening experiments, CP, was the only isolate unable to grow in more concentrated hydrolysate; thus, the type strain of C. phangngensis appears to have heightened sensitivity to fermentation inhibitors as compared to other yeasts in the clade. Both YL419 and YL420 accumulated 6.7 g/L lipid in the 75% SGH—the highest lipid titer observed for Y. lipolytica in any condition used in this study—while cell density (22.6 and 17.3 g/L, respectively) and xylitol production (12.1 and 0 g/L, respectively) were quite different between the two isolates. In comparison, control YL29 grew to 18.6 g/L biomass with 4.1 g/L lipid in the same condition. In the 90% SGH, the control strain did not grow and only three of the seven strains were able to achieve cell mass >5 g/L (YL392, YL420, and YL567). Among these three, YL392 reached the highest cell density (17.3 g/L) and lipid output (4.1 g/L) but both parameters were lower than those for the same strain grown in 75% SGH (19.6 g/L DW and 6.2 g/L lipid). In general, the jump from 60% SGH to 75% SGH was beneficial for boosting lipid titers and yields by Y. lipolytica strains, while the subsequent increase to 90% strength was detrimental to productivity—most likely due to increased toxicity from inhibitors. The only exception to this trend was YL567, which grew to similar cell density and lipid content regardless of the hydrolysate concentration. The best pentose-reducing strain from the Y. lipolytica screening, YL567, generated its highest sugar alcohol titer of 29.2 g/L in the 75% SGH, and the titer dropped slightly to 25.7 g/L in the 90% SGH.

Test of strength tolerance for select strains in the Yarrowia clade on SGH. Cells were cultured in either 60, 75, or 90% (v/v) strength N-amended SGH in deep, 96-well plates and sampled for analysis of a dry weight, b lipid accumulation, and c sugar alcohol production. Error bars indicate standard deviation from the mean of duplicate samples. Strains are represented by an abbreviation of their species name and culture collection ID, as indicated in Table 3

To validate microtiter plate results at a larger scale, we cultured select Yarrowia strains using 50% (v/v) strength SGH in highly aerated baffled shake flasks. Duplicate flasks were sampled every 12–16 h throughout the exponential growth phase in order to obtain reliable kinetic data for cell growth and lipid production. A second isolate of C. phangngensis called TM2-16—abbreviated CP2 in this study—was included at this stage to compare its lipogenesis with the type strain of the species (CP). Figure 4 and Supplementary Fig. S3 show time-course profiles for the seven strains included in the flask experiments. Lipid and dry weight numbers were noticeably lower in flask cultures as compared to those in deep well plates likely due to decreased oxygen transfer rate at 250 rpm (versus 400 rpm) and lower total sugars in 50% v/v SGH (versus 60% strength). Still, general trends were very similar among strains at the two different scales. In flasks, CP attained a maximum lipid titer of 6.1 g/L in stationary phase (40.6% DW), which was greater than twofold higher than the control strain at its peak (2.8 g/L). CP2 accumulated lipid to a similar level (5.9 g/L) as the type strain, but lag phase appeared to be approximately 8–12 h shorter for this isolate. Both strains grew to similar cell mass (14.8–15.0 g/L) and consumed xylose slowly after glucose depletion. As compared to the two C. phangngensis isolates, the five Y. lipolytica strains had significantly shorter lag time—likely due to greater tolerance to inhibitors (Fig. 3)—and all showed dry weights in the range of 2.4–5.3 g/L within 13 h. Control YL29 reached a maximum glucose consumption rate of 1.26 g/L/h in exponential phase and quickly grew to 13.3 g/L cell mass at 28 h. However, lipids began to be consumed gradually after this sample time and dry weight had dropped to 10.1 g/L at 96 h. YL419 was the only strain to accumulate greater than 3 g/L lipid within 28 h, and thus, this isolate had the highest lipid productivity in the set (0.12 g/L/h). For YL420, cell growth and glucose consumption rate were lower than other Y. lipolytica strains, but steady lipid accumulation until 96 h eventually led to the maximum lipid titer (4.7 g/L) and cell content (32.1% DW) for the species. The best pentose-reducing strain YL567 was able to consume all glucose and xylose within 72 h and secrete up to 14.7 g/L total sugar alcohols, but maximum lipid titer was still low at 2.1 g/L. Table S1 shows xylitol and arabitol production by all seven strains in the flask cultures at maximum sugar alcohol titer.

Time course profiles of select strains in the Yarrowia clade on SGH. Yeast strains were cultured in 50% (v/v) strength N-amended SGH in baffled shake flasks and sampled periodically for analysis of lipid accumulation. Error bars indicate standard deviation from the mean of duplicate samples. Strains are represented by an abbreviation of their species name and culture collection ID, as indicated in Table 3

Fatty acid composition was determined by GC analysis of transesterified lipid extracts from select strains grown in flask cultures of SGH. Greater than 90% of the total fatty acids were in the form of palmitic acid, palmitoleic acid, stearic acid, oleic acid, and linoleic acid (Fig. 5). Oleic acid was the major component in all lipid extracts constituting 45–57% of total fatty acids. Lipids high in oleic acid content have been recommended for producing biodiesel with desirable fuel properties due to the optimal chain length and degree of unsaturation (Knothe 2005). There were a few notable differences between the fatty acid profiles of the five Y. lipolytica strains evaluated as compared to the two C. phangngensis strains. Mainly, palmitic acid (C16:0) and palmitoleic acid (C16:1) contents were up to twofold higher in the C. phangngensis strains, while oleic acid (C18:1) content was lower by about 5–10% of total fatty acids. Thus, C. phangngensis generated a significantly higher proportion of 16-carbon fatty acids as compared to Y. lipolytica (35 and 18% of total fatty acids, respectively). Composition of fatty acids was very similar for cultures grown in either deep 96-well plates (Supplementary Fig. S4) or baffled shake flasks (Fig. 5).

Fatty acid profile of lipid extracts from select strains after 4-day culture in baffled shake flasks with 50% (v/v) N-amended SGH. Fatty acids are designated as follows: C16:0, palmitic acid; C16:1, palmitoleic acid; C18:0, stearic acid; C18:1, oleic acid; C18:2, linoleic acid. Error bars represent standard deviation of biological duplicates. Strains are represented by an abbreviation of their species name and culture collection ID, as indicated in Table 3

Discussion

Phylogenetic relationships have been used to select relevant strains for evaluation based on the phenotype of a reference strain or species; this strategy has guided screening of yeasts for various applications (Libkind et al. 2005; Kurtzman et al. 2010; Dien et al. 2016a). In the case of the Yarrowia clade, there exist some added benefits to discovery of superior strains with similar phylogeny to Y. lipolytica—most notably a link to safe use, prior commercial-scale applications, and genetic tractability. Thus, several studies have focused on comparative evaluation of multiple species within the Yarrowia clade. For example, Michely et al. (2013) published an interesting study comparing growth parameters and lipid content by nine Yarrowia species in defined media containing either oleic acid or glucose. For all strains, maximum lipid content ranged from 30 to 67% DW on oleic acid but only 4–7% DW on glucose (Michely et al. 2013). Another recent study evaluated 12 species of the Yarrowia clade for sugar alcohol production in a minimal media with glucose, fructose, or glycerol. It was reported that Candida oslonensis was the best producer of erythritol and mannitol with titers up to 69.8 g/L total polyols (Rakicka et al. 2016). The aforementioned work has shown substantial phenotypic diversity within the growing Yarrowia clade and demonstrates unexpected utility by a few previously uncharacterized strains.

Lignocellulosic biomass, which includes agricultural waste, wood and pulp waste, and dedicated energy crops, can yield a sustainable, low carbon footprint harvest of over 1 billion t per year in the USA (Perlack et al. 2011). To date, there has been no thorough screening of the Yarrowia clade for growth and production of lipids using hydrolysates of lignocellulosic biomass. Thus, we have evaluated a total of 57 yeast isolates, including all that were publicly available from the ARS and CBS culture collections, in a non-detoxified dilute acid pretreated switchgrass hydrolysate. Those strains identified as exceptional were further characterized in shake flasks by generating time profiles. The study directly addresses the range of lipogenesis within the Yarrowia clade, the ability to consume pentoses and the sugars’ metabolic fates, and the range of robustness to inhibitors.

In the initial screen, 45 Y. lipolytica isolates were evaluated using the same hydrolysate and culture conditions, and we were able to rank the strains in terms of lipid titer and biomass yield. Lipid accumulation varied widely from 0.1 to 5.1 g/L and lipid content ranged from 2.1 to 37.9% DW (Table 2). NRRL YB-420 emerged from the screen as the top lipid-producing Y. lipolytica isolate in terms of both titer and cell content. However, shake flask studies determined that the second-best from the screening (NRRL YB-419) had faster growth rate and higher lipid production rate than YB-420 through the early stationary phase (Fig. 4). NRRL YB-420 and YB-419 both reached a species high of 6.7 g/L lipid after 3 days in 75% (v/v) SGH, and they grew to cell mass of 17.3 and 22.6 g/L, respectively (Fig. 3a, b). For comparison, other reports have highlighted lipid accumulation by a few of the available Y. lipolytica isolates during growth in cellulosic hydrolysates. For example, Y. lipolytica W29 grew to 7.8 g/L cell mass in flask cultures of wheat straw hydrolysate (initial pH 5.5) supplemented with 1.5 g/L yeast extract; however, lipid titer was low at only 0.4 g/L (Yu et al. 2011). Lipid production was improved to 6.7 g/L (58.5% DW) by culturing auxotrophic strain Y. lipolytica Po1g (derived from W29) in a sugarcane bagasse hydrolysate (initial pH 6.5) amended with 5 g/L each of yeast extract and peptone (Tsigie et al. 2011). It should be noted that initial furfural concentration was much lower in the hydrolysate of sugarcane bagasse (0.9 mM) as compared to that of the wheat straw prepared by Yu et al. (4.5 mM). More recently, an extensive screening of oleaginous yeasts—including five strains of Y. lipolytica from the ARS culture collection—was conducted in AFEX-pretreated corn stover hydrolysate (initial pH 6) with the only nitrogen amendment coming from ammonia added in pretreatment (Slininger et al. 2016). In this condition, all five Y. lipolytica strains grew to high optical density and accumulated 2.5–5.8 g/L lipid. NRRL YB-392 and YB-437 tied for the top spot within the species in terms of maximum lipid titer (5.8 g/L) although the former showed higher lipid productivity (0.096 g/L/h). The enhanced lipogenesis of these two strains in the corn stover hydrolysate screening as compared to our SGH cultures can be attributed to lower initial furfural concentration (0.1 versus 8.8 mM) associated with AFEX pretreatment and higher total sugars without need for diluting inhibitors. Y. lipolytica W29 and NRRL YB-420, among other strains, were not included in the oleaginous yeast evaluation by Slininger et al. (2016).

Besides Y. lipolytica, oleaginicity has not been previously demonstrated for other species in the Yarrowia clade by de novo synthesis from non-hydrophobic substrates. Here, we were able to obtain higher lipid content from mixed sugars in hydrolysate than what was observed in a previous Yarrowia screening in glucose minimal media (Michely et al. 2013) by using highly aerobic conditions and tuning initial C/N ratio. In this way, 10 out of 13 species were able to proliferate in hydrolysate test cultures and maximum lipid content for these strains ranged from 9.1 to 50.4% of dry weight. Furthermore, we identified four species that were able to accumulate lipids at ≥20% of dry weight: Candida galli CBS 9723 (24.3% DW), C. oslonensis Y-48252 (20.3% DW), C. phangngensis PT1-17 (50.4% DW), and Y. keelungensis CBS 11062 (22.2% DW). Since metabolic sensitivity to inhibitors was likely a limiting factor to growth and lipid production, other Yarrowia species may also prove to be oleaginous in a less inhibitory hydrolysate or synthetic media with similar aeration. C. phangngensis was the top lipid-producing species in the clade with lipid titers up to 9.8 g/L in the deep well plate screening (Fig. 2b). In flask cultures, both isolates of C. phangngensis (PT1-17 and TM2-16) had similar time profiles and maximum lipid titers were over twofold higher than that for Y. lipolytica W29 (Fig. 4). A comprehensive genomic and transcriptomic analysis of both C. phangngensis strains is suggested as an avenue of future research to explain the enhanced capacity for lipogenesis in hydrolysate as compared to other strains in the clade.

Y. lipolytica cannot grow on xylose as a sole carbon source (Kurtzman 2011; Sitepu et al. 2014), and thus, a pentose assimilation pathway was long thought to be missing or incomplete. However, several recent studies have reported of xylose consumption after glucose depletion in hydrolysates containing a mixture of cellulosic sugars (Tsigie et al. 2011; Slininger et al. 2016). To rectify the apparent discrepancy, two independent research groups have employed bioinformatics tools to examine xylose metabolism in Y. lipolytica at the molecular level. Their results demonstrate the presence of a complete and functional xylose pathway in this yeast, but the enzymes are poorly expressed and the pathway is limited by the xylitol dehydrogenase step (Rodriguez et al. 2016; Ryu et al. 2016). Based on these findings, we can attribute two general observations in our screening of Yarrowia isolates—little or no growth during the pentose consumption phase and accumulation of sugar alcohols—to weak, unbalanced expression of xylose metabolic genes and a bottleneck at the XDH step. Most strains did produce some sugar alcohols, but xylitol titer and yield varied significantly within the clade and even among Y. lipolytica isolates (Tables 2 and 4). This observation may be related to variable aldose reductase activity and could be better understood by future work involving enzymatic activity assays and transcriptional evaluation. Y. keelungensis CBS 11062 was the top xylitol producer in the clade with titers reaching 19.0 g/L after 4 days in the deep well plate screening at a yield of ∼0.75 g/g of xylose consumed (Supplementary Fig. S2c). Moreover, this strain was also above average in terms of maximum lipid content (22.2% DW) and lipid yield (0.10 g/g of glucose consumed). With some strain engineering and/or process optimization, xylitol could be a promising co-product to offset the costs of biodiesel production from lignocellulosic biomass. Xylitol has a substantial market in the food industry as a sugar substitute since it is low in calories and helps to prevent dental caries (Mäkinen 1992). Also, xylitol is a versatile building block for chemical conversion to xylaric acid, glycols, and other value-added chemicals (Werpy et al. 2004). Current demand for xylitol exceeds 125,000 t per year and is expected to increase steadily in the coming years (de Albuquerque et al. 2014).

Lignocellulosic biomass is recalcitrant and requires extensive pretreatment before enzymatic hydrolysis to release sugars. In the process of pretreatment, various compounds are generated that have been shown to inhibit yeast growth, such as organic acids, phenolics, and furans (Jönsson and Martín 2016). Identification of robust yeast strains that resist common fermentation inhibitors is a longstanding barrier to microbial transformation of crude biomass-derived sugars. In this work, we intended to fill in gaps in the literature regarding the robustness of Yarrowia strains to the complex mixture of inhibitors found in a real biomass hydrolysate. In the initial screening, all 45 Y. lipolytica isolates and type strains from 9 of 12 other species in the clade were able to propagate in 60% (v/v) SGH, which contained 8.8 mM furfural, 2.5 mM HMF, and 2.9 g/L acetic acid (Table 1). Subsequently, we observed that six of seven Yarrowia strains grew to high cell density in 75% (v/v) SGH cultures, and Y. lipolytica NRRL YB-392 was the most tolerant strain among the set with final cell mass of 17.3 g/L in 90% (v/v) SGH (Fig. 3a). The results are noteworthy since the 75 and 90% (v/v) SGH contained furfural at 11.0 and 13.2 mM, respectively, and no previous work has demonstrated growth of Y. lipolytica in a hydrolysate with furfural above 4.5 mM. Furfural is known to be the major inhibitor interfering with cell growth of many oleaginous yeasts (Yu et al. 2011), and thus, we paid particular attention to its concentration as an indicator of toxicity. Even in a minimal media, Y. lipolytica UCDFST 51-30 (not included in our study) was unable to grow with addition of only 5.2 mM furfural, but high optical density was achieved in the same media with 15.9 mM HMF (Sitepu et al. 2014). In our SGH microplate experiments, we used more highly aerobic conditions (400 rpm, square wells) than previous studies, and the results may suggest that increasing oxygen transfer to the cultures can enhance inhibitor tolerance. Higher oxygen supply has been shown to improve cell viability and tolerance of S. cerevisiae (Ryu et al. 1984). Also, C. phangngensis strains PT1-17 and TM2-16, the best lipid producers in the clade (Figs. 2b and 4), appear to have heightened sensitivity to fermentation inhibitors as compared to other Yarrowia strains. Strain PT1-17 was unable to grow in 75% (v/v) SGH (Fig. 3a), and both isolates of C. phangngensis showed significantly longer lag time in flask cultures of 50% (v/v) SGH than Y. lipolytica strains (Fig. 4; Supplementary Fig. S3). Still, the native capacity for conversion of cellulosic sugars to lipid makes this species interesting for future study.

In summary, we have identified and described previously under-characterized Yarrowia strains that outperformed reference Y. lipolytica W29 in actual hydrolysate. Three Y. lipolytica strains (YB-392, YB-419, and YB-420) and C. phangngensis (PT1-17 and TM2-16) were found to be advantageous for lipid production from cellulosic sugars. Fatty acid profiles of select strains were comparable to those of rapeseed (canola) oil or other oleaginous yeast lipids; thus, these yeasts are predicted to be well suited for biodiesel production. Three other Y. lipolytica strains (YB-271, YB-566, YB-567) and Y. keelungensis CBS 11062 may be promising hosts for conversion of pentoses to xylitol and/or arabitol, which are commodity chemicals and potential co-products. Future work will focus on understanding the genetic and regulatory factors underlying these phenotypes and transferring the genetic system developed for the reference strain to newly identified strains in this study.

References

Almeida JR, Modig T, Petersson A, Hahn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82(4):340–349

Barth G, Gaillardin C (1996) Yarrowia lipolytica. In: Wolf W (ed) Nonconventional yeasts in biotechnology. Springer, Berlin, pp. 313–388

Beopoulos A, Cescut J, Haddouche R, Uribelarrea J-L, Molina-Jouve C, Nicaud J-M (2009) Yarrowia lipolytica as a model for bio-oil production. Prog Lipid Res 48(6):375–387

Beopoulos A, Nicaud JM, Gaillardin C (2011) An overview of lipid metabolism in yeasts and its impact on biotechnological processes. Appl Microbiol Biotechnol 90(4):1193–1206

Blazeck J, Hill A, Liu L, Knight R, Miller J, Pan A, Otoupal P, Alper HS (2014) Harnessing Yarrowia lipolytica lipogenesis to create a platform for lipid and biofuel production. Nat Commun 5:3131

Chang CF, Chen CC, Lee CF, Liu SM (2013) Identifying and characterizing Yarrowia keelungensis sp. nov., an oil-degrading yeast isolated from the sea surface microlayer. Antonie Van Leeuwenhoek 104(6):1117–1123

Chen D, Beckerich J, Gaillardin C (1997) One-step transformation of the dimorphic yeast Yarrowia lipolytica. Appl Microbiol Biotechnol 48(2):232–235

de Albuquerque TL, da Silva IJ, de Macedo GR, Rocha MVP (2014) Biotechnological production of xylitol from lignocellulosic wastes: a review. Process Biochem 49(11):1779–1789

Dien BS, Slininger PJ, Kurtzman CP, Moser BR, O’Bryan PJ (2016a) Identification of superior lipid producing Lipomyces and Myxozyma yeasts. AIMS Environ Sci 3(1):1–20

Dien BS, Zhu J, Slininger PJ, Kurtzman CP, Moser BR, O’Bryan PJ, Gleisner R, Cotta MA (2016b) Conversion of SPORL pretreated Douglas fir forest residues into microbial lipids with oleaginous yeasts. RSC Adv 6(25):20695–20705

Dujon B, Sherman D, Fischer G, Durrens P, Casaregola S, Lafontaine I, De Montigny J, Marck C, Neuvéglise C, Talla E (2004) Genome evolution in yeasts. Nature 430(6995):35–44

Ellis EM (2002) Microbial aldo-keto reductases. FEMS Microbiol Lett 216(2):123–131

Fickers P, Benetti P-H, Wache Y, Marty A, Mauersberger S, Smit M, Nicaud J-M (2005) Hydrophobic substrate utilisation by the yeast Yarrowia lipolytica, and its potential applications. FEMS Yeast Res 5(6–7):527–543

Gancedo JM (1998) Yeast carbon catabolite repression. Microbiol Mol Biol Rev 62(2):334–361

Groenewald M, Smith MT (2013) The teleomorph state of Candida deformans Langeron & Guerra and description of Yarrowia yakushimensis comb. nov. Antonie Van Leeuwenhoek 103(5):1023–1028

Groenewald M, Boekhout T, Neuvéglise C, Gaillardin C, Van Dijck PW, Wyss M (2014) Yarrowia lipolytica: safety assessment of an oleaginous yeast with a great industrial potential. Crit Rev Microbiol 40(3):187–206

Izard J, Limberger RJ (2003) Rapid screening method for quantitation of bacterial cell lipids from whole cells. J Microbiol Methods 55(2):411–418

Jin M, Slininger PJ, Dien BS, Waghmode S, Moser BR, Orjuela A, da Costa Sousa L, Balan V (2015) Microbial lipid-based lignocellulosic biorefinery: feasibility and challenges. Trends Biotechnol 33(1):43–54

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112

Kitcha S, Cheirsilp B (2011) Screening of oleaginous yeasts and optimization for lipid production using crude glycerol as a carbon source. Energy Procedia 9:274–282

Knothe G (2005) Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process Technol 86(10):1059–1070

Knutsen AK, Robert V, Poot G, Epping W, Figge M, Holst-Jensen A, Skaar I, Smith MT (2007) Polyphasic re-examination of Yarrowia lipolytica strains and the description of three novel Candida species: Candida oslonensis sp. nov., Candida alimentaria sp. nov. and Candida hollandica sp. nov. Int J Syst Evol Microbiol 57(10):2426–2435

Kurtzman CP (2005) New species and a new combination in the Hyphopichia and Yarrowia yeast clades. Antonie Van Leeuwenhoek 88(2):121–130

Kurtzman C (2011) Yarrowia van der Walt & von Arx (1980). In: Kurtzman C, Fell J, Boekhout T (eds) The yeasts, a taxonomic study. Elsevier, London, pp. 927–929

Kurtzman CP, Price NP, Ray KJ, Kuo T-M (2010) Production of sophorolipid biosurfactants by multiple species of the Starmerella (Candida) bombicola yeast clade. FEMS Microbiol Lett 311(2):140–146

Ledesma-Amaro R, Nicaud J-M (2016) Yarrowia lipolytica as a biotechnological chassis to produce usual and unusual fatty acids. Prog Lipid Res 61:40–50

Libkind D, Sommaruga R, Zagarese H, van Broock M (2005) Mycosporines in carotenogenic yeasts. Syst Appl Microbiol 28(8):749–754

Limtong S, Youngmanitchai W, Kawasaki H, Seki T (2008) Candida phangngensis sp. nov., an anamorphic yeast species in the Yarrowia clade, isolated from water in mangrove forests in Phang-Nga Province, Thailand. Int J Syst Evol Microbiol 58(2):515–519

Lindner P (1922) Das Problem der biologischen Fettbildung und Fettgewinnung. Angew Chem 35(19):110–114

Liu L, Alper HS (2014) Draft genome sequence of the oleaginous yeast Yarrowia lipolytica PO1f, a commonly used metabolic engineering host. Genome Announc 2(4):e00652–e00614

Madzak C, Tréton B, Blanchin-Roland S (2000) Strong hybrid promoters and integrative expression/secretion vectors for quasi-constitutive expression of heterologous proteins in the yeast Yarrowia lipolytica. J Mol Microbiol Biotechnol 2(2):207–216

Mäkinen K (1992) Dietary prevention of dental caries by xylitol-clinical effectiveness and safety. J Appl Nutr 44(1):16–28

McNeill J, Barrie F, Buck W, Demoulin V, Greuter W, Hawksworth D, Herendeen P, Knapp S, Marhold K, Prado J (2012) International code of nomenclature for algae, fungi, and plants (Melbourne Code). Regnum Veg 154(1):208

Michely S, Gaillardin C, Nicaud J-M, Neuvéglise C (2013) Comparative physiology of oleaginous species from the Yarrowia clade. PLoS One 8(5):e63356

Nagy E, Niss M, Dlauchy D, Arneborg N, Nielsen DS, Péter G (2013) Yarrowia divulgata fa, sp. nov., a yeast species from animal-related and marine sources. Int J Syst Evol Microbiol 63(12):4818–4823

Nagy E, Dlauchy D, Medeiros AO, Péter G, Rosa CA (2014) Yarrowia porcina sp. nov. and Yarrowia bubula fa sp. nov., two yeast species from meat and river sediment. Antonie Van Leeuwenhoek 105(4):697–707

Nicaud JM (2012) Yarrowia lipolytica. Yeast 29(10):409–418

Nilsson A, Gorwa-Grauslund MF, Hahn-Hägerdal B, Lidén G (2005) Cofactor dependence in furan reduction by Saccharomyces cerevisiae in fermentation of acid-hydrolyzed lignocellulose. Appl Environ Microbiol 71(12):7866–7871

Pan L-X, Yang D-F, Shao L, Li W, Chen G-G, Liang Z-Q (2009) Isolation of the oleaginous yeasts from the soil and studies of their lipid-producing capacities. Food Technol Biotechnol 47(2):215–220

Papanikolaou S, Chevalot I, Komaitis M, Marc I, Aggelis G (2002a) Single cell oil production by Yarrowia lipolytica growing on an industrial derivative of animal fat in batch cultures. Appl Microbiol Biotechnol 58(3):308–312

Papanikolaou S, Muniglia L, Chevalot I, Aggelis G, Marc I (2002b) Yarrowia lipolytica as a potential producer of citric acid from raw glycerol. J Appl Microbiol 92(4):737–744

Perlack RD, Eaton LM, Turhollow Jr AF, Langholtz MH, Brandt CC, Downing ME, Graham RL, Wright LL, Kavkewitz JM, Shamey AM (2011) US billion-ton update: biomass supply for a bioenergy and bioproducts industry. USDoE. Oak Ridge, TN, Oak Ridge National Laboratory

Qiao K, Abidi SHI, Liu H, Zhang H, Chakraborty S, Watson N, Ajikumar PK, Stephanopoulos G (2015) Engineering lipid overproduction in the oleaginous yeast Yarrowia lipolytica. Metab Eng 29:56–65

Rakicka M, Kieroń A, Hapeta P, Neuvéglise C, Lazar Z (2016) Sweet and sour potential of yeast from the Yarrowia clade. Biomass Bioenergy 92:48–54

Ratledge C (1991) Microorganisms for lipids. Acta Biotechnol 11(5):429–438

Ratledge C, Wynn JP (2002) The biochemistry and molecular biology of lipid accumulation in oleaginous microorganisms. Adv Appl Microbiol 51:1–51

Rodriguez GM, Hussain MS, Gambill L, Gao D, Yaguchi A, Blenner M (2016) Engineering xylose utilization in Yarrowia lipolytica by understanding its cryptic xylose pathway. Biotechnol Biofuels 9(1):149

Ryu DD, Kim Y, Kim J (1984) Effect of air supplement on the performance of continuous ethanol fermentation system. Biotechnol Bioeng 26(1):12–16

Ryu S, Hipp J, Trinh CT (2016) Activating and elucidating metabolism of complex sugars in Yarrowia lipolytica. Appl Environ Microbiol 82(4):1334–1345

Sanchez RG, Karhumaa K, Fonseca C, Nogué VS, Almeida JR, Larsson CU, Bengtsson O, Bettiga M, Hahn-Hägerdal B, Gorwa-Grauslund MF (2010) Improved xylose and arabinose utilization by an industrial recombinant Saccharomyces cerevisiae strain using evolutionary engineering. Biotechnol Biofuels 3(1):1

Schneiter R, Daum G (2006) Extraction of yeast lipids. Yeast Protocol 41–45. doi:10.1385/1-59259-958-3:041

Sitepu I, Ignatia L, Franz A, Wong D, Faulina S, Tsui M, Kanti A, Boundy-Mills K (2012) An improved high-throughput Nile red fluorescence assay for estimating intracellular lipids in a variety of yeast species. J Microbiol Methods 91(2):321–328

Sitepu IR, Sestric R, Ignatia L, Levin D, German JB, Gillies LA, Almada LAG, Boundy-Mills KL (2013) Manipulation of culture conditions alters lipid content and fatty acid profiles of a wide variety of known and new oleaginous yeast species. Bioresour Technol 144(0):360–369

Sitepu I, Selby T, Lin T, Zhu S, Boundy-Mills K (2014) Carbon source utilization and inhibitor tolerance of 45 oleaginous yeast species. J Ind Microbiol Biotechnol 41(7):1061–1070

Slininger PJ, Dien BS, Kurtzman CP, Moser BR, Bakota EL, Thompson SR, O’Bryan PJ, Cotta MA, Balan V, Jin M (2016) Comparative lipid production by oleaginous yeasts in hydrolyzates of lignocellulosic biomass and process strategy for high titers. Biotechnol Bioeng 113(8):1676–1690

Tai M, Stephanopoulos G (2013) Engineering the push and pull of lipid biosynthesis in oleaginous yeast Yarrowia lipolytica for biofuel production. Metab Eng 15:1–9

Tamura K, Peterson D, Peterson N, Stecher G, Nei M, Kumar S (2011) MEGA5: molecular evolutionary genetics analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods. Mol Biol Evol 28(10):2731–2739

Thevenieau F, Nicaud J-M, Gaillardin C (2009) Applications of the non-conventional yeast Yarrowia lipolytica. (ed) Yeast biotechnology: diversity and applications. Springer, pp 589–613

Träff K, Jönsson LJ, Hahn-Hägerdal B (2002) Putative xylose and arabinose reductases in Saccharomyces cerevisiae. Yeast 19(14):1233–1241

Tsigie YA, Wang C-Y, Truong C-T, Y-H J (2011) Lipid production from Yarrowia lipolytica Po1g grown in sugarcane bagasse hydrolysate. Bioresour Technol 102(19):9216–9222

Tsigie YA, Wang C-Y, Kasim NS, Diem Q-D, Huynh L-H, Ho Q-P, Truong C-T, Ju Y-H (2012) Oil production from Yarrowia lipolytica Po1g using rice bran hydrolysate. Biomed Res Int 2012

Vogel K, Mitchell R, Casler M, Sarath G (2014) Registration of ‘Liberty’ switchgrass. J Plant Regist 8(3):242–247

Wang J, Li R, Lu D, Ma S, Yan Y, Li W (2009) A quick isolation method for mutants with high lipid yield in oleaginous yeast. World J Microbiol Biotechnol 25(5):921–925

Werpy T, Petersen G, Aden A, Bozell J, Holladay J, White J, Manheim A, Eliot D, Lasure L, Jones S (2004) Top value added chemicals from biomass, vol. 1: results of screening for potential candidates from sugars and synthesis gas. USDoE. Golden, CO, National Renewable Energy Laboratory

Yu X, Zheng Y, Dorgan KM, Chen S (2011) Oil production by oleaginous yeasts using the hydrolysate from pretreatment of wheat straw with dilute sulfuric acid. Bioresour Technol 102(10):6134–6140

Acknowledgements

We would like to acknowledge Novozymes for the kind donation of enzymes and the ARS Culture Collection and Mr. James Swezey for providing many of the yeast strains used in this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Disclaimer

The mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the US Department of Agriculture. USDA is an equal opportunity provider and employer.

Electronic supplementary material

ESM 1

(PDF 366 kb)

Rights and permissions

About this article

Cite this article

Quarterman, J., Slininger, P.J., Kurtzman, C.P. et al. A survey of yeast from the Yarrowia clade for lipid production in dilute acid pretreated lignocellulosic biomass hydrolysate. Appl Microbiol Biotechnol 101, 3319–3334 (2017). https://doi.org/10.1007/s00253-016-8062-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-016-8062-y