Abstract

pH value and the concentration of dissolved oxygen (DO) are key parameters to monitor and control cell growth in cultivation studies. Reliable, robust and accurate methods to measure these parameters in cultivation systems in real time guarantee high product yield and quality. This mini-review summarises the current state of the art of pH and DO sensors that are applied to bioprocesses from millilitre to benchtop scale by means of a short introduction on measuring principles and selected applications. Special emphasis is placed on single-use bioreactors, which have been increasingly employed in bioprocess development and production in recent years. Working principles, applications and the particular requirements of sensors in these cultivation systems are given. In such processes, optical sensors for pH and DO are often preferred to electrochemical probes, as they allow semi-invasive measurements and can be miniaturised to micrometre scale or lower. In addition, selected measuring principles of novel sensing technologies for pH and DO are discussed. These include solid-state sensors and miniaturised devices that are not yet commercially available, but show promising characteristics for possible use in bioprocesses in the near future.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Modern bioprocesses are currently used to develop and manufacture a large variety of products, including high-value products for diagnosis of and therapies for severe diseases, as well as cosmetics. Among the products are monoclonal antibodies, hormones, vaccines, bioactive cells and tissues, and secondary metabolites. The bioprocesses, which are aseptic and last several days or weeks, typically apply animal cell lines (mammalian and insect cells) (Kaiser et al. 2015) in addition to microorganisms (Sagmeister et al. 2014), plant cell cultures (Georgiev et al. 2013) and, more recently, human stem cells (Heathman et al. 2015) as production organisms, which are often genetically modified. To tap the full potential of production organisms, the cultivation system (that is, the bioreactor) has to ensure optimum conditions for cell growth and product formation, and thus desired product quantity and quality.

This includes measurement and control of key process parameters such as pH value and dissolved oxygen (DO) value in narrow ranges and involves the process development stage, process characterisation and validation and, finally, routine manufacture (Borys et al. 1993; Chotigeat et al. 1994; Kunkel et al. 1998; Muthing et al. 2003). pH and DO sensors are part of process analytical technology (PAT) (FDA 2004). There is a natural pH shift resulting from substrate consumption alongside cell growth and formation of by-products such as lactate, acetate or ethanol. Moreover, in aerobic bioprocesses, the oxygen used for cell respiration during cell growth and the production phase decreases with increasing cell number (biomass). The DO value representing the extracellular amount of dissolved oxygen present in a unit volume of water affects the oxygen uptake rate of cells and is an indicator of cell viability. A non-optimum DO and/or pH value may lead to impaired product quality, cell growth limitations or even cell death, and therefore low product concentrations and possible loss of a batch. By measuring pH and DO, the beginning of apoptosis and presence of a contamination can be detected (Myhre et al. 1985; Simpson et al. 1997; Perani et al. 1998).

As Fig. 1 shows, specific requirements for pH and DO sensors differ depending on the production organism type. Due to the higher metabolic activities, measurement frequency of both sensor types needs to be much higher in microbial cultures compared with animal and human cells or plant cells. In contrast, pH and DO sensors used in cultivations with microorganisms have to provide reliable performance over a shorter span of time, with pH sensors for microbial cells covering the widest measurement range. So far, independent of the production organism type, DO measurement has been found to be more problematic than pH measurement. This particularly concerns processes with adherent cells, high cell density processes and cultivations with non-Newtonian culture broths, in which fouling of the sensor membrane surface can occur. It is also worth mentioning that gas bubbles and restricted flow toward the sensor can affect the DO sensor signal received (Pohlscheidt et al. 2013).

Main specific requirements for pH and DO sensors used in modern aerobic bioprocesses which need to be taken into account in addition to general demands. The general demands comprise (1) adequate sensitivity and specificity, (2) need for calibration, (3) mechanical robustness, (4) stability, (5) ease of use and maintenance, (6) suitability for cleaning in place and sterilisation in place, (7) ease of validation and implementation and (8) appropriate response time

This mini-review describes the development status of pH and DO sensors which are now used in bioprocesses for cultivation systems from millilitre to benchtop scale. It is based on an overview of the sensors currently available on the market, a short discussion of their working principles and identification of their advantages and limitations. Selected sensors for pH and DO as well as their application to bioprocesses are given, and emerging trends briefly summarised. For a detailed and comprehensive summary of recent developments in sensor technology, readers may refer to informative reviews already published in this field (Quaranta et al. 2012; Wang and Wolfbeis 2013; Wencel et al. 2014).

pH and DO measurement in bioprocesses: the state of the art

Electrochemical sensors for pH and DO

To date, conventional bioreactors (that is, re-usable bioreactors with a glass or stainless steel cultivation container) are mostly equipped with electrochemical sensors for pH and DO. To allow in situ monitoring and control, these sensors are directly mounted onto the bioreactor vessel, which implies that these devices need to be treated with cleaning in place (CIP) and sterilisation in place (SIP) procedures.

Online and offline pH measurement in lab and process applications is still dominated by pH glass sensors. The potentiometric electrodes measure an equilibrium potential that is formed between a glass membrane and a reference electrode. With a linear response over almost the entire pH scale and high selectivity, their measurement performance is exceptional. Glass pH sensors are a good choice for aseptic processes as they allow CIP and SIP procedures. In addition, biocompatible materials are generally used as wetted parts.

In conventional bioreactors, DO is frequently measured with amperometric electrodes (Clark sensors), which have been successfully used for decades (Renger and Hanssum 2009; Xiong and Compton 2014). These sensors are based on the reduction of oxygen on the surface of a platinum cathode. The electrochemical reaction takes place upon applying a constant polarisation potential relative to the sensor’s anode, which is mostly composed of silver. The sensor signal, an electrical current in the nanoampere range, is limited by the diffusion of molecular oxygen through a gas-permeable membrane. Clark-type electrodes are robust and long-term stable sensors. However, the maintenance efforts for polarisation and replacement of electrolyte and sensor membranes are comparatively high. Furthermore, oxygen concentrations are affected by the sensing process itself, as oxygen is consumed by the electrochemical reduction reaction. This effect is negligible in large volumes, but it can limit the application of Clark-type electrodes. For these reasons, many conventional electrochemical DO sensors have been replaced by optical counterparts in recent years.

Optical sensing techniques for pH and DO

Working principles and applications of optical pH sensors have recently been compiled in a comprehensive review (Wencel et al. 2014). Optical pH sensors are based on pH indicator dyes that are immobilised on sensing layers (Fig. 2a). Analogous to pH indicators applied to aqueous solutions, the basic and acidic forms of these dyes have distinct spectral properties. Hence, a pH change leads to a change in the protonation degree of these molecules, which in turn can be detected as a shift of absorbance or fluorescence signal. Different techniques have been proposed to immobilise the indicator dyes, such as entrapment in sol-gel-based materials or polymers (Hiruta et al. 2012; Joen et al. 2013; Kassal et al. 2014; Schyrr et al. 2014) or covalent binding to a polymer matrix (Aigner et al. 2012; Aigner et al. 2013; Hutter et al. 2014).

Measurement principle of optical sensors. a Optical pH sensors are often based on the simultaneous excitation of two fluorescent dyes that are embedded in a polymer matrix. While the fluorescence emission of one dye is dependent on the pH value, the second dye acts as a reference indicator. Usually, referenced detection techniques are used, i.e. ratiometric intensity measurements or measuring schemes in the time or frequency domain, such as dual-lifetime referencing. b Most optical oxygen sensors rely on selective luminescence quenching by molecular oxygen. If a modulated light source is used to excite the dye, the intensity and the phase angle of the emission depend on the oxygen concentration

Limitations of optical pH sensors, such as their small measuring range, limited long-term stability and dependence on ionic strength, have prevented their widespread use in bioprocess applications in former years. However, researchers and sensor manufacturers have constantly improved their sensor characteristics over the past few years. As a direct result of the working principle related to the protonation equilibrium of immobilised pH indicators, the measurement range of optical pH sensors is usually limited to 2–3 pH units (Wencel et al. 2014). Since most bioprocesses are operated in a narrow pH range (see Table 1), a small measurement range is not necessarily a major constraint. As the measuring range of an indicator dye is determined by its pKa value, dyes for use in pH sensing can be tailored according to the designated pH range (Zhang et al. 2015b). By applying a pH indicator with an appropriate pKa value to the optical sensor, the pH measurement range can be adapted to the requirements of the process to be monitored. As an example, pH was successfully monitored in anaerobic batch production of acetone, butanol and ethanol by using a sensor optimised for pH values in the range of 4.5 to 5.8 (Janzen et al. 2015). If different pH-sensitive dyes with varying pKa values are co-immobilised, a sensor’s dynamic range can be extended considerably (Chauhan et al. 2011). Optical pH sensors with a dynamic range of more than 5.5 pH units have been reported (Zhang et al. 2015a).

Optical pH sensors are affected by leaching and photobleaching of the indicator dyes, as well as by fluctuations in light source intensity or detector sensitivity. Different measures have been taken to improve the signal stability of optical pH sensors, such as the use of photostable indicator dyes (Jokic et al. 2012) or covalent attachment of the pH-sensitive dye to the polymer matrix (Aigner et al. 2013). As an important step to improve the long-term stability of optical pH sensors, a measurement scheme called dual-lifetime referencing (DLR) was developed in the last few years. This technique is also applied in commercially available optical pH sensors, such as those distributed by PreSens (Table 1). In the frequency-domain scheme, a modulated light source is used that excites both the indicator dye as well as a second fluorescent dye that is pH insensitive and acts as a reference compound (Liebsch et al. 2001; Borisov et al. 2010). The phase shift between excitation and emission signal is related to the protonation degree of the indicator dye (and therefore to the pH value of the measuring solution). However, this signal is not influenced by unspecific effects related to the limited stability of the sensor compounds involved.

Sensor signals of today’s optical pH sensors are sufficiently stable during a cultivation process of several days or weeks. According to the technical specifications of sensor manufacturers, sensor drifts of less than 0.01 pH per day are achievable (see Table 1). Nevertheless, the measurement signal often needs to be corrected during operation. This is usually done by manual process steps (taking a sample, offline measurement, offset correction of measurement value), which are laborious and bear a risk of contamination.

As an alternative to Clark electrodes, optical sensors are well-established tools for reliable measurements of DO in bioprocess applications (Wang and Wolfbeis 2014). As shown in Fig. 2b, they make use of a fluorescent dye that is immobilised in a polymer matrix. In the presence of oxygen molecules, the fluorescence emission of the dye is quenched selectively. Hence, the fluorescence intensity decreases with increasing partial pressure of molecular oxygen. Based on this working principle, different classes of fluorescent dyes have been developed, such as polypyridyl complexes of transition metals or metalloporphyrins. A comprehensive overview of indicator dyes applied to optical oxygen sensors was recently published by Quaranta et al. (2012).

Rather than fluorescence intensities, commercially available optical oxygen sensors detect a shift of phase angle that is observed between excitation of a modulated light source and emission of the fluorescent dye. Using this approach, the sensor signal is barely affected by the stability of the light source or photobleaching of the dye, thereby allowing very reliable and long-term stable measurements. Optical sensor patches for pH and DO are used in both conventional and single-use bioreactors. It is evident that single-use cultivation systems, which have been increasingly implemented in the past 15 years, have strongly influenced pH and DO sensor techniques (Hanson et al. 2007; Naciri et al. 2008; Lam and Kostov 2009; Lindner et al. 2011; Paldus and Selker 2011).

Novel sensors for millilitre and litre scales

Single-use vs. conventional bioreactors: impact on sensor design and specification

Single-use cultivation systems have a transparent or non-transparent cultivation container. The plastic cultivation container is either rigid (multiwell plates, t-flasks, tubes, shake flasks and cylindrical single-use vessels) and made from polycarbonate or polystyrene or is operated with a flexible bag whose contact layer is polyethylene or ethylene vinyl acetate (Eibl et al. 2010). According to Kaiser et al. (2015), there is a clear distinction between static, orbitally shaken, wave-mixed and stirred single-use bioreactors at millilitre and benchtop scales. In contrast to their re-usable counterparts, single-use cultivation containers are provided beta- or gamma-sterilised and are usable without lengthy preparation. After one-time usage, they are discarded.

The installation of sensors in single-use cultivation containers may not entail a hygienic risk or adversely change mass transfer and hydrodynamics (by formation of dead zones, for example). This demand and the fact that sensor dead zones are difficult to avoid at millilitre scale or tend to require miniaturisable sensor solutions also apply to re-usable cultivation containers. But in the face of a reduced contamination risk, single-use cultivation systems should be equipped with single-use sensors instead of re-usable pH and DO sensors with standard geometry (e.g. 12 mm sensor diameter). Although they remain in use, re-usable pH and DO sensors which need to be sterilised outside the containment and connected to a single-use bioreactor via aseptic couplings (e.g. Kleenpak sterile connectors) are regarded only as compromise.

In fact, single-use pH and DO sensors are preferred, which presupposes ready-to-use cultivation containers in which sterilised, calibrated and qualified sensors have been installed. A secretion of leachables, which can be ascribed to single-use sensors, is undesirable. Leachables display chemical substances resulting from the manufacturing process of the cultivation container and its irradiation. Under process conditions, they can migrate from the plastic into the culture broth that contains the cells (Wood et al. 2013). Even small concentrations of leachables can provoke inhibition of cell growth or even cell death (Hammond et al. 2013; Hammond et al. 2014).

Single-use pH and DO sensors need to be as inexpensive as possible as well as environmentally safe. In addition to measurement, they should provide information for identification of physical components and about lifetime cycle and calibration. This is based on the assumption that the data (depending on demand) can be externally read out from the control system, recorded and processed. For current Good Manufacturing Practice (cGMP) applications, both single-use pH as well as DO sensors and control systems also need to be qualifiable. This assists in integration into the superordinated process control system by using standardised communication protocols (plug-and-play) (Eibl 2010).

Single-use pH and DO sensors

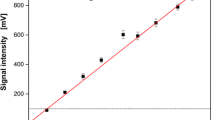

To date, optical sensor spots can be attached inside any transparent vessel, allowing signals to be read out through the wall of the cultivation system. In this setup, the low-cost sensing elements (i.e. the optical sensor spot) are separated from the light source and detector. Readout devices that are directly mounted in incubator shakers facilitate investigations for scale-up and scale-down of microbial or cell cultures. Therefore, optical sensors are ideally suited to monitor pH in shake flasks (Fig. 3) or benchtop bioreactors (Ge et al. 2006; Vallejos et al. 2012; Ragupathy et al. 2015). The small dimensions of the sensor spots also guarantee that fluid dynamics in small-scale bioreactors and shake flasks are not affected by bulky sensors.

As sensor spots can be miniaturised to millilitre scale and lower, they are routinely used to measure pH and DO in microtiter plates (Glauche et al. 2015). To date, measurement of pH and DO in single-use cultivation systems predominantly relies on optical sensing methods. Unfortunately, sensors which have a shelf life of more than 6 months cannot be chosen by applier (they are pretended by the supplier of the single-use cultivation container).

Although pH glass electrodes cannot be easily transferred to single-use cultivation systems (difficult integration into a flexible polymer sheet, need for long-term hydration of the glass membrane), a single-use pH glass sensor which can be operated in two positions was introduced by Metroglas and Sartorius Stedim. In its measurement position, the sensor is introduced into the process medium, while for calibration, maintenance and storage, the sensor can be pulled back and immersed in buffer or storage solution. This setup allows the user to insert a preconditioned and calibrated electrode into the process medium (Bernard et al. 2009). Recently, sensor manufacturers have started to integrate miniature pH glass sensors into standard fittings used in single-use bioreactors (e.g. 1″ Eldon James ports). Gamma irradiation of >25 kGy has been shown to only slightly affect sensor performance, with an average offset of 0.05 pH units. After a dry storage interval of more than 12 months, factory sensor characteristics remained constant within 0.1 pH units in relation to factory calibration data (Arzt et al. 2015).

Solid-state pH sensors

As an alternative to potentiometric pH glass electrodes, different electrochemical solid-state sensors have been proposed. Ion-selective field effect transistors (ISFETs), which are essentially unbreakable solid-state sensors, comprise a semiconductor component that is modified with a pH-sensitive layer consisting of an inorganic gate oxide such as Ta2O5 (Bergveld 2003). ISFET pH sensors have successfully been applied to monitor fermentation processes (Krommenhoek et al. 2008; Bäcker et al. 2011) and used to measure pH in a biogas digestate (Huck et al. 2014). These sensors can be very small in size and are therefore suitable for microbioreactors (Maharbiz et al. 2004). Nevertheless, ISFETs have not been widely accepted in bioprocess applications. An aseptic encapsulation of the semiconductor sensing element is technically feasible, however technically demanding (Oelßner et al. 2005). As a major drawback, ISFETs usually do not qualify for treatment in CIP procedures due to the limited durability of the silicon substrates in hot caustic soda. Capacitive EIS (electrolyte–insulator–semiconductor) field effect sensors based on Ta2O5 as a pH-sensitive material might serve as an alternative. Owing to their simple structure, they showed small changes in pH sensitivity after 30 CIP cycles (Schöning et al. 2005). ISFETs can be stored dry over a long period of time and therefore seem particularly well suited for single-use bioreactors. However, gamma irradiation causes the sensor signal to shift by several pH units (Humenyuk et al. 2008).

A different class of semiconductor material has recently been proposed for pH sensing. Sensors based on AlGaN/GaN heterostructures showed high and constant sensitivities in the pH range between 1 and 12. Whereas the sensitivities of the AlGaN/GaN pH sensors were only minimally influenced by CIP treatment, the sensors showed large shifts of transfer characteristics, resulting in a positive shift of around 0.2 pH units per CIP cycle. Therefore, their use for applications in food industry and biotechnology is questionable (Linkohr et al. 2013).

Furthermore, a different type of electrochemical solid-state sensor has been introduced based on redox active compounds that are immobilised in a working electrode (Lahav et al. 1998; Lawrence and Robinson 2007; Lafitte et al. 2008). Depending on the redox potential of these compounds, applying a potential to the working electrode causes their reduction or oxidation, resulting in a current signal. As a sensor working principle, species with pH-dependent as well as pH-independent redox potentials are immobilised in the sensing layer. Therefore, when the applied potential is scanned in a voltammetric setup, a sensor measures two signal peaks, with the potential difference between the peaks being directly related to the pH value. Voltammetric sensors are usually run in a three-electrode setup, and therefore require a reference electrode in the same way as conventional pH sensors do. However, in contrast to potentiometric sensors, a possibly unstable potential of the reference electrode does not directly influence the measured value. Hence, these sensors provide for long-term stable and ‘calibration-free’ pH measurements, which make them attractive for online pH measurement in bioprocesses. Although there have been attempts to commercialise this technology, voltammetric pH sensors are not yet available in the market (Wilkings 2011).

A novel sensing and signal transduction scheme that was developed for single-use biomanufacturing processes has recently been presented (Potyrailo et al. 2011; Potyrailo et al. 2012). These sensors are based on passive radio-frequency identification (RFID) tags that are attached to single-use cultivation systems. When the RFID sensors are read with an external readout device, an electric field is generated that extends into the process medium and is affected by its dielectric properties. This influences the complex impedance of the RFID resonant antenna, which is measured wirelessly and correlated to several measured parameters, such as conductivity, pH and temperature. A similar wireless sensor based on a resonant circuit consisting of a planar spiral inductor connected to a temperature-dependent resistor and a voltage-dependent capacitor was developed by Bhadra et al. (2013). With a solid-state iridium/iridium oxide pH sensor and a Ag/AgCl reference electrode connected with the circuit, a shift of the circuit’s resonant frequency was observed due to pH variation of the solution. The sensor was used for remote pH monitoring of fermentations in a shake flasks over several days with an accuracy of 0.08 pH units (Bhadra et al. 2014). These sensors are promising in that they allow battery-free, contactless multi-parameter monitoring at low cost. Furthermore, simultaneous digital identification may provide additional information about the single-use component (e.g. production date, calibration date, etc.) over the complete bioprocessing workflow.

Developments of optical sensors

In the past few years, there has been extensive research on fluorescent dyes for use in optical chemical sensors. New types of indicator dyes have been reported with absorption and emission maxima in the red or NIR spectal range (Yu et al. 2015). This is advantageous in biological applications due to the lower spectral interference of biomolecules in the NIR region. Furthermore, standard low-cost light sources can be used to excite the fluorescent dyes were reported. Jokic et al. (2012) and Strobl et al. (2015) reported highly photostable NIR pH sensors based on BF2-chelated tetraarylazadipyrromethenes with emission maxima above 700 nm and distinct pKa values covering a pH range between 1.5 and 13.

Optical oxygen sensors based on platinum and palladium benzoporphyrins have also been recently presented (Hutter et al. 2014; Müller et al. 2015). These sensing materials are excited with red light and show emission maxima in the NIR range of the electromagnetic spectrum. The sensors, based on dyes covalently bound to polymer matrices, have high robustness and photostability. Optical sensors for oxygen based on NIR-emitting dyes are also commercially available, such as the FireSting sensors distributed by Pyro Science.

Sensors for the microlitre scale

As optical sensors can be miniaturised to micro- and nanometre scale, a variety of new approaches to measure pH and DO in microenvironments has emerged. Optical sensors are ideally suited to measuring these parameters in microfluidic systems (miniaturised analysis systems or lab-on-a-chip technologies), which enables cultivations from picolitre to microlitre scale. A complete overview of pH and DO measurements in microfluidic systems is beyond the scope of this paper. For detailed information, the interested reader is referred to the reviews of Young and Beebe (2010), Li et al. (2012), Chen et al. (2014) and Sackmann et al. (2014).

The use of fluorescent dyes that are sensitive to pH and DO embedded in nanoparticles has opened new opportunities to spatially resolve pH and DO in millilitre scale and below. Nanoparticle-based sensors can be used to monitor extracellular oxygen in various applications. Nanobeads with diameters of 350 nm were doped with NIR-emitting platinum(II)-benzoporphyrins. These functionalised beads were used to measure oxygen in bacterial cultivations and for microtoxicological investigations of soil bacteria. Applied to a microfluidic system, the method proved helpful in investigating growth and metabolic activity in microfluid segments (Cao et al. 2015). Fluorescent pH-sensitive nanoparticles with a size of 12 nm were immobilised in a conventional layer of agarose as a sensing layer for fluorescence imaging. In this somewhat simple setup, growth and metabolism of Escherichia coli was monitored by acquiring RGB pictures of Petri dishes illuminated by blue light to excite the fluorescence of the dye (Wang et al. 2013b). Biocompatible oxygen sensing beads which were tens of micrometres in size were used to monitor the local concentration oxygen in cell cultures. The spatial measurement of oxygen enabled the geometry and structural features of the cell culture microwells used to be assessed (Wang et al. 2013a).

A variety of cell-permeable probes for the imaging of oxygen has been described (Dmitriev and Papkovsky 2015). Depending on the experimental conditions, these nanoprobes need to fulfil requirements that are different to those of macroscopic sensors, such as cytotoxicity and compatibility with different cell and tissue models. A hydrogel-based nanosensor with a broad pH range covering the physiological pH range in all living cells was recently reported. It comprises three different pH-sensitive fluorescent dyes and a reference dye. The sensors provided measurements of fluctuations in lysosomal pH in HeLa cells after different treatments (Zhang et al. 2015a).

Conclusion and outlook

For decades, online measurement of pH and DO has been dominated by electrochemical sensors. Due to their robustness, low cost and reliability, potentiometric glass pH electrodes and amperometric DO sensors are still a good choice for bioprocess monitoring today. Optical sensors for pH and DO have been commercially available for many years now and, in recent years, have become established in biotechnological applications.

Two main factors are responsible for the increasing use of optical sensors. Firstly, they allow semi-invasive, contactless measurements through transparent container walls, with the signals read out and processed externally. For this reason, optical sensors are ideally suited for applications in single-use benchtop bioreactors, shake flasks and microtiter plates. Secondly, optical sensors can be miniaturised in a straightforward way to millilitre scale and below. Hence, they are even predestined to be applied to microfluidic systems for measurement of pH and DO with temporal or spatial resolution, as well as for intracellular monitoring of these parameters. Limitations of optical pH sensors, such as a generally restricted long-term stability and small measuring range, have prevented their widespread use in laboratory and process applications to date. In contrast, today’s optical sensors for oxygen are stable, robust and not affected by CIP and SIP procedures. Optical oxygen sensors have been available for some time in standard dimensions for use in stainless steel bioreactors.

From the perspective of users who apply sensors in their daily work, developers and manufacturers of sensors should address the following issues:

-

Operational lifetime and stability of optical pH sensors are not satisfactory for cultivation periods of several days to weeks. If these sensor characteristics were equal to those of optical sensors for DO, higher process reliability and efficiency could be achieved.

-

Electrochemical and optical measuring techniques are very often used interchangeably or simultaneously in the same process. Due to their different working principles, the measurement signals of these sensors may deviate from one another. Comparability between different sensing schemes could be improved if fully traceable procedures and standards were used for calibration of the sensors.

-

In conventional glass or steel bioreactors, sensors are installed using standard process ports and connectors. In single-use bioreactors, however, a variety of process connectors and measurement protocols is available. Standardisation in this field would help users to select a sensor that best fulfils the requirements of a given bioprocess independent of the manufacturer.

References

Aigner D, Borisov SM, Orriach Fernández FJ, Fernández Sánchez JF, Saf R, Klimant I (2012) New fluorescent pH sensors based on covalently linkable PET rhodamines. Talanta 99:194–201

Aigner D, Borisov SM, Petritsch P, Klimant I (2013) Novel near infra-red fluorescent pH sensors based on 1-aminoperylene bisimides covalently grafted onto poly(acryloylmorpholine). Chem Commun 49:2139

Arzt C, Caminada C, Fischbacher R, Arquint P (2015) Hochleistungs-pH-Einwegsensoren. Chemie Plus 3:24–25

Bäcker M, Pouyeshman S, Schnitzler T, Poghossian A, Wagner P, Biselli M, Schöning MJ (2011) A silicon-based multi-sensor chip for monitoring of fermentation processes. Phys Status Solidi A 208:1364–1369

Bergveld P (2003) Thirty years ISFETOLOGY: what happend in the past 30 years and what may happen in the next 30 years. Sensors Actuators B 88:1–20

Bernard F, Chevalier E, Cappia JM, Heule M, Paust T (2009) Disposable pH sensors. Bioprocess Int Suppl 32–36

Bhadra S, Tan DSY, Thomson DJ, Freund MS, Bridges GE (2013) A wireless passive sensor for temperature compensated remote pH monitoring. IEEE Sensors J 13:2428–2436

Bhadra S, Blunt W, Dynowski C, McDonald M, Thomson DJ, Freund MS, Cicek N, Bridges GE (2014) Fluid embeddable coupled coil sensor for wireless pH monitoring in a bioreactor. IEEE T Instrum Meas 63:1337–1346

Borisov SM, Gatterer K, Klimant I (2010) Red light-excitable dual lifetime referenced optical pH sensors with intrinsic temperature compensation. Analyst 135:1711

Borys M, Linzer D, Papoutsakis E (1993) Culture pH affects expression rates and glycosylation of recombinant mouse placental lactogen proteins by Chinese hamster ovary (CHO) cells. Biotechnol 11:720–724

Cao J, Nagl S, Kothe E, Köhler JM (2015) Oxygen sensor nanoparticles for monitoring bacterial growth and characterization of dose–response functions in microfluidic screenings. Microchim Acta 182:385–394

Chauhan VM, Burnett GR, Aylott JW (2011) Dual-fluorophore ratiometric pH nanosensor with tuneable pKa and extended dynamic range. Analyst 136:1799

Chen Y, Li P, Huang P-H, Xie Y, Mai JD, Wang L, Nguyen N-T, Huang TJ (2014) Rare cell isolation and analysis in microfluidics. Lab Chip 14:626

Chotigeat W, Watanapokasin Y, Mahler S, Gray P (1994) Role of enviromental conditions on the expression levels, glycoform pattern and levels of sialyltransferase for hFSH produced by recombinant CHO cells. Cytotechnology 15:217–221

Dittler I, John GT, Eibl R (2014) Online pH measurements in iTube pH bioreactors. PreSens Appl Note 1–2. http://www.presens.de/uploads/tx_presensapplicationnotes/140829_APP_Insect_Cells_in_iTubes_pH_w_02.pdf

Dmitriev RI, Papkovsky DB (2015) Intracellular probes for imaging oxygen concentration: how good are they? Methods Appl Fluoresc 3:034001

Eibl D (2010) Sensortechnik für Einwegzellkulturbioreaktoren: Anforderungen in F&E und der biopharmazeutischen Produktion: Ein Kurzreview aus Anwendersicht. In: Tagungsband zum 15. Heiligenstädter Kolloquium (iba e.V. ed.). pp 9–18

Eibl R, Kaiser S, Lombriser R, Eibl D (2010) Disposable bioreactors: the current state-of-the-art and recommended applications in biotechnology. Appl Microbiol Biotechnol 86:41–49

FDA (2004) Guidance for industry guidance for industry PAT—a framework for innovative pharmaceutical development, manufacturing and quality assurance. U.S. Department of Health and Human Services Food and Drug Administration. http://www.fda.gov/downloads/Drugs/.../Guidances/ucm070305.pdf

Ge X, Hanson M, Shen H, Kostov Y, Brorson KA, Frey DD, Moreira AR, Rao G (2006) Validation of an optical sensor-based high-throughput bioreactor system for mammalian cell culture. J Biotechnol 122:293–306

Georgiev M, Eibl R, Zhong J (2013) Hosting the plant cells in vitro: recent trends in bioreactors. Appl Microbiol Biotechnol 97:3787–3800

Glauche F, John GT, Arain S, Knepper A, Neubauer A, Goelling D, Lang C, Violet N, King R, Neubauer P (2015) Toward microbioreactor arrays: a slow-responding oxygen sensor for monitoring of microbial cultures in standard 96-well plates. J Lab Autom 20:438–446

Hammond M, Marghitoiu L, Lee H, Perez L, Rogers G, Nashed-Samuel Y (2014) A cytotoxic leachable compound from single-use bioprocess equipment that causes poor cell growth performance. Biotechnol Prog 30:332–337

Hammond N, Nunn H, Rogers G, Lee H, Marghitou AL, Nashed-Samuel Y, Anderson C, Vandiver M, Kline S (2013) Identification of a leachable compound detrimental to cell growth in single-use bioprocess containers. PDA J Pharm Sci Technol 67:123–134

Hanson MA, Ge X, Kostov Y, Brorson KA, Moreira AR, Rao G (2007) Comparisons of optical pH and dissolved oxygen sensors with traditional electrochemical probes during mammalian cell culture. Biotechnol Bioeng 97:833–841

Heathman TR, Nienow AW, McCall M, Coopman K, Kara B, Hewitt C (2015) The translation of cell-based therapies: clinical landscape and manufacturing challenges. Regen Med 10:49–64

Hiruta Y, Yoshizawa N, Citterio D, Suzuki K (2012) Highly durable double sol–gel layer ratiometric fluorescent pH optode based on the combination of two types of quantum dots and absorbing pH indicators. Anal Chem 84:10650–10656

Huck C, Poghossian A, Kerroumi I, Schusser S, Bäcker M, Zander W, Schubert J, Buniatyan VV, Martirosyan NW, Wagner P, Schöning MJ (2014) Multiparameter sensor chip with barium strontium titanate as multipurpose material. Electroanal 26:980–987

Humenyuk I, Temple-Boyer P, Sarrabayrouse G (2008) The effect of γ-sterilization on the pH-ChemFET behaviour. Sensors Actuators A Phys 147:165–168

Hutter LH, Müller BJ, Koren K, Borisov SM, Klimant I (2014) Robust optical oxygen sensors based on polymer-bound NIR-emitting platinumbenzoporphyrins. J Mater Chem C 2:7589–7598

Janzen NH, Schmidt M, Krause C, Weuster-Botz D (2015) Evaluation of fluorimetric pH sensors for bioprocess monitoring at low pH. Bioprocess Biosyst Eng 38:1685–1692

Joen D, Yoo WJ, Seo JK, Shin SH, Han KT, Kim SG, Park JY, Lee B (2013) Fiber-optic pH sensor based on sol-gel film immobilized with neutral red. Opt Rev 20:209–213

Jokic T, Borisov SM, Saf R, Nielsen DA, Kühl M, Klimant I (2012) Highly photostable near-infrared fluorescent pH indicators and sensors based on BF 2-chelated tetraarylazadipyrromethene dyes. Anal Chem 84:6723–6730

Jossen V, Schirmaier C, John GT, Eibl D, Eibl R (2015) On-line-pH- und DO-messungen in mikrocarrier-basierter hMSC-kultur. BIOspektrum 4:422–424

Kaiser S, Kraume M, Eibl D, Eibl R (2015) Single-use bioreactors for animal and human cells. In: Al-Rubeai M (ed) animal cell culture, cell engineering 9. Springer International Publishing Switzerland, pp 445–500

Kassal P, Šurina R, Vrsaljko D, Steinberg IM (2014) Hybrid sol–gel thin films doped with a pH indicator: effect of organic modification on optical pH response and film surface hydrophilicity. J Sol-Gel Sci Technol 69:586–595

Krommenhoek EE, van Leeuwen M, Gardeniers H, van Gulik WM, van den Berg A, Li X, Ottens M, van der Wielen LAM, Heijnen JJ (2008) Lab-scale fermentation tests of microchip with integrated electrochemical sensors for pH, temperature, dissolved oxygen and viable biomass concentration. Biotechnol Bioeng 99:884–892

Kunkel J, Dan D, Jamieson J, Butler M (1998) Dissolved oxygen concentration in serum-free continous culture affects N-linked glycosylation of a monoclonal antibody. Biotechnol 62:55–71

Lafitte VGH, Wang W, Yashina AS, Lawrence NS (2008) Anthraquinone–ferrocene film electrodes: utility in pH and oxygen sensing. Electrochem Commun 10:1831–1834

Lahav M, Katz E, Willner I (1998) A covalently linked quinone-ferrocene monolayer-electrode: a pH sensor with an internal reference. Electroanalysis 10:1159–1162

Lam H, Kostov Y (2009) Optical instrumentation for bioprocess monitoring. In: Optical sensor systems in biotechnology. Springer, Berlin Heidelberg, Berlin, Heidelberg, pp. 125–142

Lawrence N, Robinson K (2007) Molecular anchoring of anthracene-based copolymers onto carbon nanotubes: enhanced pH sensing. Talanta 74:365–369

Li XJ, Valadez AV, Zuo P, Nie Z (2012) Microfluidic 3D cell culture: potential application for tissue-based bioassays. Bioanalysis 4:1509–1525

Liebsch G, Klimant I, Krause C, Wolfbeis OS (2001) Fluorescent imaging of pH with optical sensors using time domain dual lifetime referencing. Anal Chem 73:4354–4363

Lindner P, Endres C, Bluma A, Höpfner T, Glindkamp A, Haake C, Landgrebe D, Riechers D, Baumfalke R, Hitzmann B, Scheper T, Reardon KF (2011) Disposable sensor systems. In: Eibl R, Eibl D (eds) Single-use technology in biopharmaceutical manufacture, John Wiley & Sons, Hoboken, pp. 67–81

Linkohr S, Pletschen W, Schwarz SU, Anzt J, Cimalla V, Ambacher O (2013) CIP (cleaning-in-place) stability of AlGaN/GaN pH sensors. J Biotechnol 163:354–361

Maharbiz MM, Holtz WJ, Howe RT, Keasling JD (2004) Microbioreactor arrays with parametric control for high-throughput experimentation. Biotechnol Bioeng 85:376–381

Müller BJ, Burger T, Borisov SM, Klimant I (2015) High performance optical trace oxygen sensors baed on NIR-emitting benzoporphyrins covalently coupled to silicone matrixes. Sensors Actuators B 216:527–534

Muthing J, Kemminer S, Conradt H, Sagi D, Nimtz M, Karst U, Peter K (2003) Effect of buffering conditions and culture pH on production rates and glycosylation of clinical phase I anti-melanoma mouse IgG3 monoclonal antibody R24. Biotechnol 83:321–334

Myhre B, Demianew S, Yoshimori R, Nelson E, Carmen R (1985) pH changes caused by bacterial growth in contaminated platelet concentrates. Ann Clin Lab Sci 15:509–514

Naciri M, Kuystermans D, Al-Rubeai M (2008) Monitoring pH and dissolved oxygen in mammalian cell culture using optical sensors. Cytotechnology 57:245–250

Oelßner W, Zosel J, Guth U, Pechstein T, Babel W, Connery JG, Demuth C, Grote Gansey M, Verburg JB (2005) Encapsulation of ISFET sensor chips. Sensors Actuators B Chem 105:104–117

Paldus BA, Selker MD (2011) Bioinformatics and single use. In: Eibl R, Eibl D (eds) Single-use technology in biopharmaceutical manufacture, Wiley, Hoboken, pp. 83–90

Perani A, Singh R, Chauhan R, Al-Rubeai M (1998) Variable functions of bcl-2 in mediating bioreactor stress-induced apoptosis in hybridoma cells. Cytotechnol 28:177–188

Pohlscheidt M, Charaniya B, Jenzsch M, Noetzel T, Lübbert A (2013) Bioprocess and fermentation monitoring. In: Flickinger M (ed) Upstream industrial biotechnology: equipment, process design, sensing, control and cGMP operations, vol 2, 1st edn. Wiley, Hoboken

Potyrailo R, Surman C, Monk D, Morris WG, Wortley T, Vincent M, Diana R, Pizzi V, Carter J, Gach G, Klensmeden S, Ehring H (2011) RFID sensors as the common sensing platform for single-use biopharmaceutical manufacturing. Meas Sci Technol 22:1–17

Potyrailo RA, Burns A, Surman C, Lee DJ, McGinnis E (2012) Multivariable passive RFID vapor sensors: roll-to-roll fabrication on a flexible substrate. Analyst 137:2777–2781

Quaranta M, Borisov SM, Klimant I (2012) Indicators for optical oxygen sensors. Bioanal Rev 4:115–157

Ragupathy V, Setty MKHG, Kostov Y, Ge X, Uplekar S, Hewlett I, Rao G (2015) Non-invasive optical sensor based approaches for monitoring virus culture to minimize BSL3 laboratory entry. Sensors 15:14864–14870

Renger G, Hanssum B (2009) Oxygen detection in biological systems. Photosynth Res 102:487–498

Sackmann E, Fulton A, Beebe D (2014) The present and future role of microfluidics in biomedical research. Nature 507:181–189

Sagmeister P, Jazini M, Klein J, Herwig C (2014) Bacterial suspension cultures. In: Schmidhalter D (ed) Meyer H-P. Industrial Scale Suspension Culture of Living Cells, WILEY-VCH Verlag GmbH & Co KGaA, pp. 40–93

Schyrr B, Pasche S, Scolan E, Ischer R, Ferrario D, Porchet J-A, Voirin G (2014) Development of a polymer optical fiber pH sensor for on-body monitoring application. Sensors Actuators B Chem 194:238–248

Simpson N, Milner A, Al-Rubeai M (1997) Prevention of hybridoma cell death by bcl-2 during sub-optimal culture conditions. Biotechnol Bioeng 54:1–16

Strobl M, Rappitsch T, Borisov SM, Mayr T, Klimant I (2015) NIR-emitting aza-BODIPY dyes—new building blocks for broad-range optical pH sensors. Analyst 140:715–7153

Vallejos JR, Micheletti M, Brorson KA, Moreira AR, Rao G (2012) Optical sensors enable rocking T-flasks as novel upstream bioprocessing tool. Biotechnol Bioeng 109:2295–2305

Wang L, Acosta MA, Leach JB, Carrier RL (2013a) Spatially monitoring oxygen level in 3D microfabricated cell culture systems using optical oxygen sensing beads. Lab Chip 13:1586–1592

Wang X, Meier RJ, Wolfbeis OS (2013b) Fluorescent pH-sensitive nanoparticles in an agarose matrix for imaging of bacterial growth and metabolism. Angew Chemie Int Ed 52:406–409

Wang X, Wolfbeis OS (2014) Optical methods for sensing and imaging oxygen: materials, spectroscopies and applications. Chem Soc Rev 43:3666–3761

Wang XD, Wolfbeis OS (2013) Fiber-optic chemical sensors and biosensors (2008–2012). Anal Chem 85:487–508

Wencel D, Abel T, McDonagh C (2014) Optical chemical pH sensors. Anal Chem 86:15–29

Wilkings K (2011) Disposable bioreactor sensors play catch-up. Bioprocess Int, Westborough, 56

Wood J, Mahaian E, Shiratori M (2013) Strategy for selecting disposable bags for cell culture media applications based on root-cause investigations. Biotechnol Prog 29:1535–1549

Xiong L, Compton RG (2014) Amperiometric gas detection: a review. Int J Electrochem Sci 9:7152–7181

Young E, Beebe D (2010) Fundamentals of microfluidic cell culture in controlled microenviroments. Chem Soc Rev 39:1036–1048

Yu H, Sun M, Zhang K, Zhu H, Liu Z, Zhang Y, Zhao J, Wu L, Zhang Z, Wang S (2015) A reversible near-infrared pH probes for optical measurements of pH in complete water system and living cells. Sensors Actuators B 219:294–300

Zhang M, Søndergaard RV, Kumar EKP, Henriksen JR, Cui D, Hammershøj P, Clausen MH, Andresen TL (2015a) A hydrogel based nanosensor with an unprecedented broad sensitivity range for pH measurements in cellular compartments. Analyst 140:7246–7253

Zhang X, Jing SY, Huang SY, Zhou XW, Bai JM, Zhao BX (2015b) New fluorescent pH probes for acid conditions. Sensors Actuators B 206:663–670

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Human and animal rights

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Demuth, C., Varonier, J., Jossen, V. et al. Novel probes for pH and dissolved oxygen measurements in cultivations from millilitre to benchtop scale. Appl Microbiol Biotechnol 100, 3853–3863 (2016). https://doi.org/10.1007/s00253-016-7412-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-016-7412-0