Abstract

This work aimed at characterizing the biochemical and biophysical properties of the membrane of Lactococcus lactis TOMSC161 cells during fermentation at different temperatures, in relation to their freeze-drying and storage resistance. Cells were cultivated at two different temperatures (22 and 30 °C) and were harvested at different growth phases (from the middle exponential phase to the late stationary phase). Bacterial membranes were characterized by determining the fatty acid composition, the lipid phase transition, and the membrane fluidity. Cultivability and acidification activity losses of L. lactis were quantified after freezing, drying, and 3 months of storage. The direct measurement of membrane fluidity by fluorescence anisotropy was linked to lipid composition, and it was established that the cyclopropanation of unsaturated fatty acids with concomitant membrane rigidification during growth led to an increase in the freeze-drying and storage resistance of L. lactis. As expected, cultivating cells at a lower fermentation temperature than the optimum growth temperature induced a homeoviscous adaptation that was demonstrated by a lowered lipid phase transition temperature but that was not related to any improvement in freeze-drying resistance. L. lactis TOMSC161 was therefore able to develop a combined biochemical and biophysical response at the membrane level during fermentation. The ratio of cyclic fatty acids to unsaturated fatty acids (CFA/UFA) appeared to be the most relevant parameter associated with membrane rigidification and cell resistance to freeze-drying and storage. This study increased our knowledge about the physiological mechanisms that explain the resistance of lactic acid bacteria (LAB) to freeze-drying and storage stresses and demonstrated the relevance of complementary methods of membrane characterization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lactic acid bacteria (LAB) are of great importance to the food and dairy industries because of both their central role as starters for manufacturing a diversity of fermented products and their potential health benefit (Daly et al. 1998; Leroy and de Vuyst 2004).

Freeze-drying is widely used to provide ready to use highly concentrated starter cultures. This process makes it possible to minimize the degradation reactions and to maintain adequate physical, chemical, and biological stability of the product during long-term storage, even at ambient temperature (Franks 1998; Coulibaly et al. 2011). However, during this low-temperature desiccation process, bacteria are exposed to several environmental stresses (thermal, osmotic, water removal, and oxidative stresses), which could induce major cellular damages, leading to loss of viability and functional activities (acidification, production of aroma compounds and texturizing agents, etc.) (Coulibaly et al. 2010; Velly et al. 2014). Damages to cellular systems resulting from freeze-drying can be attributed to two major causes: changes in the physical state of cytoplasmic membrane lipids, resulting in a loss of bacterial membrane integrity (Crowe et al. 1989a; Linders et al. 1997; Schwab et al. 2007), and changes in the structure of sensitive proteins (Bischof et al. 2002; Oldenhof et al. 2005).

Extensive evidence has been reported on the correlation between active cell responses to environmental stresses and membrane fluidity (Beney and Gervais 2001; Chu-Ky et al. 2005; Wu et al. 2012). When cells are exposed to changes in culture conditions during fermentation (temperature, pH, pressure, oxygen, nutrients, and ethanol), they modulate their membrane composition in order to maintain the lipid bilayer in the liquid crystalline lamellar phase and, more precisely, to maintain an optimal level of fluidity within the lipid bilayer (Johnsson et al. 1995; Drici-Cachon et al. 1996; Guillot et al. 2000; Teixeira et al. 2002; Gautier et al. 2013). This level of fluidity is, in fact, required to preserve cellular functions that take place at the membrane level (solute transport and diffusion, energy transduction, cellular growth, and other metabolic functions). This phenomenon is known as homeoviscous adaptation (Sinensky 1974) and is associated with a modification of the membrane fatty acid composition of bacteria by several processes, including alterations in saturation degree, carbon chain length, branching position, cis/trans isomerization, and cyclopropanation, in order to preserve proper membrane physical properties (Keweloh and Heipieper 1996; Grogan and Cronan 1997; Zhang and Rock 2008).

During the freeze-drying process, bacterial cells are exposed to extreme stresses and are thus unable to modify their membrane properties in order to limit damages. One of the strategies to improve the freeze-drying resistance of bacteria is therefore to limit membrane damages by precisely controlling their physical state before they are stabilized, by modulating their fatty acid composition during the fermentation step. Membrane fatty acid composition of lactic acid bacteria, especially an increase in the cyclopropane fatty acid content, has been previously linked to an improvement of the cell’s freeze-drying survival (Broadbent and Lin 1999; Schoug et al. 2008; Hua et al. 2009; Li et al. 2009; Zhao et al. 2009). In these studies, the authors hypothesize that a change in fatty acid composition results in a modification of membrane fluidity, but, unfortunately, a complete and simultaneous characterization of membrane biophysical properties is still lacking.

In a previous study, we showed that the freeze-drying resistance of L. lactis TOMSC161 was significantly influenced by fermentation temperature and harvesting time (Velly et al. 2014). In this context, the aim of this study was to identify membrane biophysical properties that would make it possible to explain the ability of L. lactis TOMSC161 to better tolerate freeze-drying and storage after applying different fermentation temperatures and harvesting times. Fatty acid composition, membrane fluidity, and lipid phase transition temperature of L. lactis cells were thus characterized at different growth phases and fermentation temperatures. In parallel, the freeze-drying and storage resistance of these starters was quantified after each step of the process by determining cultivability and acidification activity losses. Membrane physical properties were correlated to the freeze-drying and storage resistance of starters, thus allowing a better understanding of the key role of cytoplasmic membrane in freeze-drying and storage resistance of L. lactis TOMSC161.

Materials and methods

Lyophilized starter production

Strain and inoculum preparation

L. lactis subsp. lactis TOMSC161 (Savoîcime, France), a natural cheese isolate, was studied because of its sensitivity to freeze-drying. Frozen cells were stored at −80 °C in M17 medium (Biokar Diagnostics; Beauvais, France) supplemented with 15 % (v/v) glycerol (VWR; Leuven, Belgium). One milliliter of frozen aliquot was precultured in 100 mL of M17 medium at 30 °C for 4.5 h before inoculation in the bioreactor.

Fermentation

The culture medium was composed of 60 g L−1 lactose (VWR; Leuven, Belgium) and 15 g L−1 yeast extract (BD; Sparks, MD, USA). After adjusting the pH to 6.8 with a 30 % KOH solution, the medium was introduced into a 5-L working volume bioreactor (Biostat® A plus, Sartorius-Stedim; Aubagne, France) and sterilized at 120 °C for 20 min. The inoculation was done at a low initial concentration of approximately 100 colony-forming units (CFU) mL−1. The fermentation was performed at 22 or 30 °C, pH 6.2, with an agitation speed of 200 rpm to permit homogenization. The pH was controlled by the automatic addition of 15-N KOH solution (Merck; Darmstadt, Germany) to the bioreactor.

Cell growth was monitored by measuring the optical density every hour at 650 nm (OD650) in a DU_ 640B spectrophotometer (Beckman Coulter).

The fermentation processes were repeated for three times at each temperature.

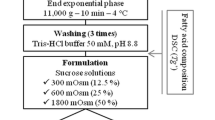

Concentration and lyoprotection

Cells grown at 30 °C were harvested at four different growth phases corresponding to the middle (T1) and late (T2) exponential phases and the early (T3) and late (6 h) (T4) stationary phases, whereas two harvesting times, the early and late stationary phases (T3 and T4), were performed for fermentation at 22 °C (Fig. 1). The cell suspensions were then concentrated for 10 times by centrifugation (Avanti® J-E centrifuge, Beckman Coulter; Fullerton, CA, USA) at 17,000×g for 20 min at 4 °C. Concentrated cells were resuspended in protective medium at a ratio of 1:2 (1 g of concentrated cells for 2 g of sterile protective solution) prior to freeze-drying. The sterile protective solution was composed of 60 g L−1 sucrose (VWR; Leuven, Belgium), 140 g L−1 maltodextrin (dextrose equivalent = 6; M = 3,000 g mol−1) (Glucidex 6D, Roquette; Lestrem, France), and 9 g L−1 NaCl. The lyoprotected cell suspensions were distributed in 5-mL vials (Verretubex; Nogent-Le-Roi, France) with a volume of 1 mL prior to freezing.

Freeze-drying and storage

The samples were frozen at −80 °C in a cold air chamber (freezing rate of 3 °C min−1) and then transferred to a precooled shelf at −50 °C in a prototype pilot freeze-dryer built by Telstar (Terrassa, Spain). After a holding step of 2 h at −50 °C, the chamber pressure was decreased to 20 Pa, and the shelf temperature was increased from −50 to −20 °C at a heating rate of 0.25 °C min−1 to initiate sublimation. After 40 h of sublimation, the shelf temperature was increased to 25 °C at a heating rate of 0.25 °C min−1 to initiate the secondary drying step. After 8 h of desorption, the vacuum was broken by injecting air and the vials were capped. Finally, freeze-dried samples were packed under vacuum in aluminum bags and stored at 25 °C for 3 months to evaluate the stability of starters.

Biological and physical properties of starters

Cultivability measurement

The bacterial cell concentration was determined using the agar plate count method. The frozen cells were thawed for 15 min at room temperature. The freeze-dried cells were rehydrated in 1 mL of saline water (NaCl 9 g L−1) and stirred for 5 min at room temperature. Cell suspension was serially diluted in saline water, plated onto M17 agar (Biokar Diagnostics) and incubated at 30 °C for 48 h in anaerobiosis. The cultivability was measured in triplicate after concentration and lyoprotection, after freezing, after drying, and after 3 months of storage at 25 °C. The cell count was expressed in colony-forming units per milliliter.

The determination of the cultivability loss after each step of the process was calculated using the following equation (Eq. 1):

where i and i + 1 are two successive steps of the process.

Specific acidification activity measurement

The Cinac system (AMS, Frépillon, France) was used to measure the acidification activity of bacterial suspension (Spinnler and Corrieu 1989). Acidification was measured in triplicate at 30 °C using reconstituted skim milk with 100 g L−1 skim milk powder (EPI Ingredients, Ancenis, France), heat-treated at 110 °C for 15 min in 120-mL flasks, and stored at 4 °C for 24 h before use. The flasks were inoculated with 500 μL of bacterial suspension. The inoculated milk pH was continuously measured by the Cinac system and led to the determination of the time necessary to obtain a decrease of 0.7 pH units (tpH0.7, in min). The descriptor tpH0.7 was used to characterize the acidification activity of bacterial suspensions. The higher the tpH0.7 value was, the longer the latency phase was and the lower the acidification activity was. Moreover, the specific acidification activity t spe (in min log (CFU mL−1)−1) was defined as the ratio of tpH0.7 to the corresponding log of the cell concentration (Eq. 2) (Streit et al. 2007). Consequently, the descriptor t spe gives an accurate and meaningful measurement of the biological activity of LAB, including the physiological state and viability.

The specific acidification activity was measured after concentration and lyoprotection, freezing, drying, and 3 months of storage at 25 °C. As a result, the specific acidification activity loss was calculated as follows (Eq. 3):

where and i + 1 are two successive steps of the process. An increase in the dt spe value corresponds to an increased loss of specific acidification activity during the process step considered.

Water activity measurement

The water activity of the samples was measured after freeze-drying using a LabMasteraw aw meter (Novasina, Precisa; Poissy, France). Three freeze-dried samples of the same biological replicate were pooled, and water activity was measured at 25 °C. The instrument was calibrated with saturated pure salt solutions (aw 0.04, 0.06, and 0.11) (SAL-T, Novasina).

Glass transition temperature measurement

Differential scanning calorimetry (DSC) was carried out using a power compensation DSC (Pyris 1, PerkinElmer LLC; Norwalk, CT, USA) equipped with a mechanical cooling system (Intracooler 1P, PerkinElmer). Temperature calibration was done using cyclohexane and indium (melting points at 6.5 and 156.6 °C, respectively). Approximately 15 mg of each freeze-dried sample was placed in 50-μL PerkinElmer DSC sealed aluminum pans, and an empty pan was used as a reference. Linear cooling and heating rates of 10 °C min−1 were applied. The characteristic glass transition temperature (Tg) of the freeze-dried samples was determined as the midpoint temperature of the heat flow step associated with glass transition with respect to the ASTM Standard Method, E 1356-91. Results were obtained from at least three replicates.

Biochemical and biophysical properties of the bacterial membrane

Fatty acid (FA) composition

The membrane fatty acid composition of bacteria cells was determined using the method described by Rozes et al. (1993) with minor modifications. Extraction was performed on concentrated cells and was triplicated. Concentrated cells were washed twice in saline water at 4 °C. Methylation was performed at 4 °C by adding 1.5 mL of sodium methoxide (1 M in methanol) (Sigma-Aldrich; Saint Louis, MO, USA) to 0.15 g of concentrated cells and shaking for 1.5 min. Then, 100 μL of nonanoic acid methyl ester (0.4 mg mL−1 in hexane) (Sigma-Aldrich), the internal standard, was added to each sample. Subsequently, the resulting fatty acid methyl esters (FAMEs) were extracted with 900 μL of hexane. After decanting for 5 min, the upper phase was collected and evaporated to dryness in a vacuum centrifugal evaporator (RC10-22) coupled to a refrigerated trap (RCT 90, Jouan; Saint-Herblain, France) at 1,200 rpm. The FAMEs were then dissolved in 1 mL of hexane, and 100 μL was transferred in vials for GC-MS analysis.

The analysis of FAMEs was performed on a gas chromatograph (HP 6890; Hewlett-Packard; Avondale, PA, USA) coupled to a mass selective detector (Agilent 5973, Hewlett-Packard). The separation was carried out in a capillary column packed with 70 % cyanopropyl polysilphenylene-siloxane BPX70 (60 m × 0.25 mm × 0.25 μm; SGE Analytical Science Pty, Ltd.; Victoria, Australia). The carrier gas was helium (constant flow of 1.2 mL min−1), and the initial column pressure was 1.3 × 105 Pa. Injection of 1 μL of extracts was done splitless at an injector temperature of 250 °C. The oven temperature was held for 1 min at 35 °C and then increased from 35 to 100 °C at 40 °C min−1, held for 1 min at 100 °C and then increased from 100 to 130 °C at 5 °C min−1, followed by an increase from 130 to 180 °C at 1.5 °C min−1, and finally from 180 to 240 °C at 5 °C min−1. A transfer line was set at 280 °C, and the MSD source temperature was 230 °C. The FAMEs were first identified by comparison of their retention times with those of known standards (Sigma-Aldrich), and this identification of FAME was confirmed using the mass selective detector at a scan rate of 3.14 scans/s, with data collected in the range of 33 to 500 amu. The mass spectra of the FAMEs were compared with the Wiley 275.L data bank (Hewlett-Packard; Gaithersburg, MD, USA). The quantification of FA was calculated on target ions using external calibration performed with serial dilutions of commercial standards of methylated fatty acids (Sigma-Aldrich), with nonanoic acid methyl ester as the internal standard. Results were expressed as relative percentages of each fatty acid, 100 % standing for the sum of the absolute concentrations of all the fatty acids in the sample. The membrane fatty acid composition was determined before and after freeze-drying and after 3 months of storage at 25 °C.

Membrane lipid phase transition by Fourier transform infrared (FTIR) spectroscopy

Infrared absorption measurements were carried out using a Nicolet Magna 750 FTIR spectrometer (Thermo Fisher Scientific; Madison, WI, USA) equipped with a narrow-band mercury/cadmium/telluride (MCT) infrared detector and a Specac variable temperature cell holder cooled by liquid nitrogen (Specac, Ltd., Orpington, Kent, UK). The temperature of the sample was recorded separately using an extra thermocouple that was located close to the sample. The optical bench was continuously purged with dry air (Balston; Haverhill, MA, USA). The acquisition parameters were 4-cm−1 resolution, 32 co-added interferograms, and a 4,000 to 900-cm−1 wavenumber range. Fresh bacterial pellet was washed twice in saline water. The washed bacterial pellet was then sandwiched between two CaF2 windows. Samples were mounted onto the Specac cell holder. The temperature dependence of the FTIR spectra was studied by cooling the sample from 50 °C down to −50 °C at a rate of 2 °C min−1 and then by heating the sample from −50 to 80 °C at 2 °C min−1. Experiments were performed in triplicate. Spectral display and analysis were carried out using OMNIC software (Thermo Fisher Scientific; Madison, WI, USA).

According to Crowe et al. (1989b), membrane phase behavior was monitored by observing the position of the symmetric CH2 stretching band at approximately 2,850 cm−1. Spectra analysis (determination of peak location and lipid phase transition temperature (Tm)) was performed with ASpIR software (Infrared Spectra Acquisition and Processing, INRA; Grignon, France) according to the previously described protocol (Gautier et al. 2013).

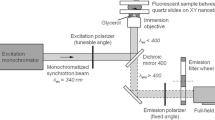

Fluorescence anisotropy by flow cytometry

Membrane fluidity was evaluated on fresh cells by measuring the degree of polarization of the fluorescent probe 1,6-diphenyl-1,3,5-hexatriene (DPH). This fluorescence probe has hydrophobic properties that allow the molecule to be inserted into the lipid membrane of the cells.

Before staining, cell suspension adjusted to 107 cells mL−1 was washed twice with morpholineethanesulfonic acid (MES) buffer at pH 6.2 (Sigma-Aldrich; Saint Louis, MO, USA) and resuspended in 2 mL of MES buffer. Then, 5 μL of DPH solution (6 mM in tetrahydrofuran) (Invitrogen—Molecular Probe; Eragny-sur-Oise, France) was added to 2 mL of the cell suspension to obtain a final DPH concentration of 30 μM. Cell suspension was vigorously stirred for 1 min and centrifuged, and the pellet obtained was resuspended in 2 mL of the MES buffer and used immediately for fluorescence polarization measurements.

Fluorescence polarization was determined by using a flow cytometer (CyFlow Space, Partec; Sainte-Genevieve-des-Bois, France) equipped with a vertically polarized UV laser that emits at 375 nm a half-wave retarder plate (rotating polarizer) to depolarize the excited light, if necessary, and parallel and perpendicular polarizers just prior to entering the two photomultiplier tubes (Fox and Delohery 1987). The measurement was performed at 20 °C with emission wavelengths at 455 nm.

The fluorescence anisotropy (r) was calculated according to the following equation (Eq. 4):

where I // and I ⊥ are the polarized light intensities emitted in the parallel and perpendicular directions with respect to the excitation beam of light, respectively.

For each condition, three samples were analyzed and three measurements per sample were performed.

Statistical analysis

The fermentations were repeated for at least three times, and data are presented as the mean ± standard error of these biological triplicates combined with the measurement replicates, as described above.

To link the bacterial membrane properties to freeze-drying and storage resistance, a Pearson’s correlation coefficient test (XLSTAT software) was performed for all the fermentation conditions studied. This coefficient measures the strength of the linear relationship between two variables, giving a value between −1 and +1. The higher the absolute value of the correlation coefficient between two variables was, the stronger the linear relationship between the two variables was. The following variables were considered for this analysis: the unsaturated fatty acid-to-saturated fatty acid ratio (UFA/SFA), the cyclic fatty acid-to-unsaturated fatty acid ratio (CFA/UFA), the cyclic fatty acid-to-saturated fatty acid ratio (CFA/SFA), the fluorescence anisotropy (r), the lipid phase transition temperature (Tm), and the cultivability and acidification activity losses after freeze-drying and storage (dlog(CFU) and dt spe, respectively). The significance of results was assessed at a 95 % confidence level (p value <0.05).

Results

Influence of fermentation conditions (harvesting time and temperature) on cultivability and specific acidification activity losses following freeze-drying and storage

The loss of cultivability and specific acidification activity was quantified after each step of the preservation process: freezing, drying, and 3 months of storage (Fig. 2).

Cultivability (dlog(CFU)) and acidification activity (dt spe) losses of L. lactis subsp. lactis TOMSC161 grown at different temperatures and harvested at different growth phases (T1, middle exponential phase; T2, late exponential phase; T3, early stationary phase; and T4, late stationary phase) at each step of the process: freezing and drying (a) and total losses including 3 months of storage (b)

Total cultivability and specific acidification activity losses ranged between 2.7 and 5.0 log (CFU mL−1) and between 70 and 163 min (log (CFU mL−1))−1, respectively. Cell resistance was different according to the process step considered. Low degradation was observed after freezing, whereas drying induced considerable losses of cultivability and specific acidification activity (Fig. 2a). Cultivability and specific acidification activity losses caused by the drying step ranged between 0.3 and 0.6 log (CFU mL−1) and between 7 and 19 min (log (CFU mL−1))−1, respectively. No significant differences in cultivability losses after the drying step were observed between the different studied conditions, whereas fermentation temperature and harvesting time highly impacted the specific acidification activity loss after the drying step. Harvesting at the late stationary phase (T4) led to the lowest specific acidification activity loss after drying and consequently after freeze-drying (6.8 min (log (CFU mL−1))-1 at 30 °C). This loss increased almost threefold for cells grown at 30 °C and harvested at the middle exponential phase (T1) (19 min (log (CFU mL−1))−1). Moreover, degradation was approximately 60 % higher for cells grown at 22 °C than at 30 °C and harvested at the early and late stationary phases (T3 and T4).

The cultivability and the specific acidification activity losses for cells grown at 22 °C and harvested at the early and late stationary phases (T3 and T4) were similar to the cultivability and the specific acidification activity losses for cells grown at 30 °C but harvested earlier during the culture (T2 and T3).

Storage at ambient temperature induced the highest losses and was approximately 10 times higher after 3 months than following freeze-drying (Fig. 2b). The growth phase but not the fermentation temperature impacted the stability of L. lactis cells after 3 months of storage at 25 °C. The main decrease in the loss of specific acidification activity was observed between the late exponential phase (T2) and the early stationary phase (T3) for bacteria grown at 30 °C. Loss of specific acidification activity was two times higher at the exponential phase (T1 and T2) than at the stationary phase (T3 and T4).

Physical properties

The water activity of the freeze-dried bacteria was 0.020 ± 0.002 just after lyophilization and 0.026 ± 0.005 after 3 months of storage. Water activity thus remained constant during the storage period, which means that the cultivability and specific acidification activity losses during storage were not caused by modification of the water activity of the samples. Furthermore, the glass transition temperature of the freeze-dried starters was 179 ± 3 °C, indicating that these starters remained in a glassy state during storage at 25 °C.

Influence of fermentation conditions (harvesting time and temperature) on the biochemical and biophysical properties of the cytoplasmic membrane

In this study, the cytoplasmic membrane of L. lactis subsp. lactis TOMSC161 obtained after applying different fermentation conditions was characterized by complementary approaches. The fatty acid composition, lipid phase transition temperature, and membrane fluidity were determined for two fermentation temperatures (22 and 30 °C) and for different growth phases (from the middle exponential phase to the late stationary phase).

FA composition

Fatty acid composition of L. lactis in the studied conditions is summarized in Table 1. Regardless of the culture conditions, the fatty acid composition included four SFAs tetradecanoic acid (C14:0), hexadecanoic acid (C16:0), heptadecanoic acid (C17:0), and octadecanoic acid (C18:0); two UFAs hexadecenoic acid (C16:1cis) and octadecenoic acid (C18:1cis); and one cyclopropane fatty acid (CFA) methylenoctadecenoic acid (cycC19:0). However, only three fatty acids, C16:0, C18:1cis, and cycC19:0, represented more than 90 % of the total amount of all fatty acids. These fatty acid profiles were similar to those reported in previous studies on L. lactis (Schleifer et al. 1985; Johnsson et al. 1995).

Analysis of the membrane composition of L. lactis during growth at 30 °C revealed that the relative content of saturated, unsaturated, and cyclopropane fatty acids and, in particular, the relative contents of C18:1cis, cycC19:0, and C16:0 changed depending on the growth phase. Table 1 shows a decrease in C18:1cis content from 25.4 to 6.2 % and an increase in cycC19:0 content from 18.6 to 35.2 % (from the middle exponential phase (T1) to the early stationary phase (T3)). At the late stationary phase (T4), a decrease in C18:1 content was accompanied by a decrease in cycC19:0 content, as well as an increase in C16:0 content. Consequently, during fermentation, a decrease in UFA content took place in favor of fatty acid cyclopropanation (increase in CFA content) until the early stationary phase (T1-T3), whereas during the stationary phase (T3–T4), CFA and UFA content decreased in favor of SFA content. Accordingly, the CFA/SFA ratio presented a bell-shaped curve with a maximum value (0.61) at the early stationary phase (T3).

Fermentation temperature also affected the fatty acid composition of L. lactis cells. The fatty acid composition measured at 22 °C at the early and late stationary phases (T3 and T4) was similar to FA compositions measured at 30 °C but earlier during the culture (T2 and T3, respectively). This result is clearly demonstrated by the evolution of the cyc19:0 content and the CFA/SFA ratio. Hence, at 22 °C, the modulation of cell membrane lipid composition was slowed down when compared to fermentation at 30 °C. Furthermore, the fatty acid composition was analyzed after freeze-drying and 3 months of storage, but no modification of the fatty acid profile of L. lactis was observed in any condition (data not shown).

Membrane lipid phase transition

FTIR spectroscopy was used to characterize changes in the membrane lipid phase behavior of L. lactis cells during cooling and heating by following the lipid CH2 symmetric stretching band position around 2,850 cm−1 as a function of temperature. An example of this result is shown in Fig. 3. A shift in the position of the CH2 symmetric stretching band from 2,849 to 2,854 cm−1 was observed with increasing temperature. This shift in wavenumbers is known to reflect the trans-gauche isomerization in the hydrocarbon chains of lipids that characterizes the gel-to-liquid crystalline phase transition of the bacterial membrane (Crowe et al. 1989b). In the gel phase (low wavenumbers 2,849 cm−1), all fatty acyl chains are in trans conformation and are able to pack in an ordered manner. In the liquid crystalline phase (high wavenumbers 2,854 cm−1), the chains adopt a predominantly gauche conformation, allowing a more relatively disordered phase with more space between acyl chains.

The first derivative of the CH2 symmetric stretching band position as a function of temperature was plotted to determine the lipid phase transition temperature. Lipid phase transition temperatures (Tm) for all conditions studied are presented in Table 2. For cells cultivated at 30 °C, Tm values exhibited an inverted bell-shaped curve with the highest values of 18 and 17 °C at the middle exponential phase (T1) and the late stationary phase (T4), respectively. As expected, the decrease in growth temperature (from 30 to 22 °C) clearly induced a decrease in Tm values (Tm values of 9 and 10 °C) for maintaining the membrane in a liquid crystalline state during fermentation.

Fluorescence anisotropy

The fluorescence anisotropy (r) measured reflects the rotational motion of the DPH probe and is negatively related to the cytoplasmic membrane fluidity. The measurements were performed at 20 °C, i.e., at a temperature higher than the membrane lipid phase transition temperature for all the experimental conditions studied, meaning that the value of r reported in Table 2 corresponded to cell membranes in a liquid crystalline state. The lower the value is, the more fluid the membrane is. As shown in Table 2, the fluorescence anisotropy of cells grown at 30 °C increased from 0.145 to 0.169 between the middle exponential phase (T1) and the late stationary phase (T4), with a significant increase between the late exponential phase (T2) and the early stationary phase (T3) (from 0.149 to 0.166). Likewise, the fluorescence anisotropy of cells cultivated at 22 °C increased between the early (T3) and the late stationary phase (T4) (from 0.139 to 0.169). These results indicated a rigidification of the cytoplasmic membrane of L. lactis TOMSC161 during its growth.

Relationships between membrane characteristics and freeze-drying and storage resistance

L. lactis TOMSC161 cells cultivated at different fermentation temperatures and harvested at different growth phases showed major changes in membrane characteristics (fatty acid composition, lipid phase transition temperature (Tm), and fluorescence anisotropy (r), i.e., membrane fluidity) and freeze-drying and storage sensitivity. To investigate possible relationships between fatty acid composition, membrane biophysical properties, and cultivability and specific acidification activity losses after freeze-drying and 3 months of storage, a Pearson correlation test was performed. The results (Pearson coefficient R) are represented in Table 3.

The specific acidification activity loss after freeze-drying was significantly (p < 0.05) and positively correlated with the cultivability and acidification activity loss observed after 3 months of storage (R = 0.707 and R = 0.776, respectively). The lower the specific acidification activity loss after freeze-drying was, the higher the storage stability was.

Interesting relationships were also observed between membrane properties and freeze-drying and storage sensitivity (particularly specific acidification activity loss). Significant negative correlations were observed between the CFA/UFA ratio and the specific acidification activity loss after freeze-drying (R = −0.855) and storage (R = 0.767) and also between this ratio and the cultivability loss after storage (R = −0.824). Moreover, the lipid phase transition temperature (Tm) was negatively correlated with the CFA/SFA ratio (R = −0.725), but no relevant relationship could be demonstrated between this membrane physical property and the freeze-drying and storage sensitivity of cells. Fluorescence anisotropy (r) was positively correlated with the CFA/UFA ratio (R = 0.847) and negatively correlated with the UFA/SFA ratio (R = −0.799). Moreover, significant negative correlations were observed between fluorescence anisotropy and specific acidification activity loss following both freeze-drying (R = −0.780) and storage (R = −0.668) and only after storage for cultivability loss (R = −0.706). In other words, the higher the fluorescence anisotropy value was (i.e., higher rigidification of the cytoplasmic membrane), the higher the resistance to freeze-drying and storage was.

Discussion

Due to its location between the external environment and the intracellular medium, the bacterial membrane is the first target of injury during freeze-drying, which was demonstrated by major losses of membrane integrity (Schwab et al. 2007). Cell resistance to this stabilization process is thus strongly dependent on the physical state of its membrane following fermentation. Some studies have already linked the fermentation conditions and the resulting membrane lipid composition to the improvement of freeze-drying resistance of lactic acid bacteria (Broadbent and Lin 1999; Schoug et al. 2008; Hua et al. 2009; Li et al. 2009; Zhao et al. 2009). However, to our knowledge, no study has deeply characterized the membrane biochemical and biophysical properties of lactic acid bacteria during fermentation in relation to their freeze-drying and storage resistance. In agreement with previous pieces of work (Schwab et al. 2007; Hua et al. 2009; Velly et al. 2014), growing L. lactis TOMSC161 at the optimal growth temperature followed by a harvest at the late stationary phase induced the best cell resistance to freeze-drying and storage.

The analysis of membrane fatty acid composition showed that L. lactis TOMSC161 modulated their membrane fatty acid composition with a linear increase over time of the CFA/UFA ratio, from 0.7 at the middle exponential phase (T1) to 9.4 at the late stationary phase (T4) for cells grown at 30 °C (Table 1). In agreement with our results, other authors demonstrated that cells of Leuconostoc oeni and Oenococcus oeni exhibited a higher proportion of cyclopropane fatty acids in the stationary phase than in the exponential phase (Drici-Cachon et al. 1996; Hua et al. 2009). Furthermore, it is recognized that cyclopropane fatty acids are formed “in situ” at the expense of unsaturated fatty acids by conversion of the unsaturated position into a cyclopropane ring due to the transfer of a methyl group from S-adenosylmethionine (SAM) to the double bond catalyzed by the CFA synthase (Grogan and Cronan 1997). This cyclopropanation is thus considered to be a post-synthetic modification of the bacterial membrane lipid bilayer since the fatty acid substrates are already part of the cell membrane structure. In addition, the fatty acid profile of cells cultivated at 22 °C and harvested at the early (T3) and late (T4) stationary phases corresponded to the fatty acid profile of cells cultivated at 30 °C and harvested earlier and, more precisely, at the late exponential phase (T2) and the early stationary phase (T3), respectively. This delay could be explained by the decrease in enzymatic efficacy of CFA synthase at 22 °C.

To illustrate the dynamic behavior of the bacterial membrane during fermentation and the relationships with the freeze-drying and storage resistance of cells, fluorescence anisotropy and specific acidification activity losses after freeze-drying and storage were plotted as a function of the CFA/UFA ratio for all conditions studied (Fig. 4). The specific acidification activity loss after freeze-drying (triangles) decreased linearly with the increase in the CFA/UFA ratio, which is mainly related to the cycC19:0 and C18:1cis content. After storage (circles), specific acidification activity loss decreased with increased CFA/UFA ratios, with the largest decreases in storage loss observed for CFA/UFA ratio values lower than 6. For CFA/UFA ratios higher than 6, the CFA and UFA contents decreased in favor of the SFA content, and only a slight decrease in specific acidification activity loss following storage was observed. In all cases, the higher this ratio was (i.e., the higher the content of cycC19:0), the better the cell resistance to freeze-drying and storage was.

Correlation between CFA/UFA ratio, fluorescence anisotropy (squares), and acidification activity loss after freeze-drying (triangles) and after 3 months of storage (circles) of L. lactis subsp. lactis TOMSC161 grown at different temperatures (22 °C open symbol and 30 °C filled symbol) and for the different growth phases studied

The protective function of cyclopropane fatty acids against freeze-drying stress was demonstrated for Pseudomonas putida by the higher sensitivity of mutants with a knockout in the cfa synthase gene, compared to the wild-type cells (Munoz-Rojas et al. 2006). Moreover, several studies reported the beneficial effect of an increase in CFA (Broadbent and Lin 1999; Schoug et al. 2008; Hua et al. 2009; Li et al. 2009; Zhao et al. 2009) and in UFA (Broadbent and Lin 1999) content on the survival of different strains of lactic acid bacteria after freeze-drying. In these studies, the authors hypothesized that these changes in fatty acid composition result in the modification of membrane fluidity. The contribution of unsaturated fatty acids to membrane fluidification has been demonstrated in many studies (Da Silveira et al. 2003; Tymczyszyn et al. 2005; Beranova et al. 2008). On the contrary, the exact physiological functions of cyclopropane fatty acids are still unclear. Some authors have suggested that cyclopropane fatty acids increase membrane fluidity like unsaturated fatty acids, by preventing close packing of lipids in the cell membrane (Smittle et al. 1974; Wang et al. 2005). On the contrary, other authors have proposed that cyclopropane rings restrict the mobility and disorder of the acyl chains compared to cis double bonds, decreasing membrane fluidity (Hartig et al. 2005; Loffhagen et al. 2007; Thi Mai Huong et al. 2011). Almost no data exist in the literature on the direct measurement of membrane fluidity for various fatty acid profiles and on the correlation between this measurement and freeze-drying resistance of bacteria. Only Li et al. (2009) reported that Lactobacillus bulgaricus cells treated by thermal stress (30 min at 45 °C) presented a higher content of cycC19:0 associated with a more rigid membrane and a higher resistance to freeze-drying when compared to cells cultivated at 37 °C.

To test these hypotheses, two complementary biophysical properties were considered in this study to characterize bacterial membranes. Lipid phase transition temperature describes the gel-to-liquid crystalline transition, i.e., the transition from a rigid to a fluid state that allows cellular functioning. Fluorescence anisotropy directly measures membrane fluidity by quantifying the mobility of a fluorescent probe within the membrane. Growing L. lactis TOMSC161 at a low temperature (22 °C) resulted in a decrease in the membrane lipid phase transition (Tm), associated with a change in the CFA/SFA ratio. This decrease in Tm corresponds to a homeoviscous adaptation (Sinensky 1974) necessary to maintain bacteria membrane in the liquid crystalline phase. However, no correlation was observed between this membrane biophysical property and the freeze-drying resistance of L. lactis TOMSC161. On the contrary, fluorescence anisotropy (squares) significantly increased with the CFA/UFA ratio, thus indicating a decrease in membrane fluidity with fermentation time, while remaining in a liquid crystalline state (Tm <20 °C). The biggest fluorescence anisotropy variation took place for CFA/UFA ratio values ranging from approximately 2 to 5.5 when the cycC19:0 content was sharply increased (Table 1). A plateau was observed for CFA/UFA ratio values higher than 6. This property was also strongly related to the improvement of bacterial acidification activity recovery after freeze-drying and storage. Cells harvested at the stationary phase thus exhibited rigidified membranes with concomitant cyclopropanation of unsaturated fatty acids, an increase of saturated fatty acids, and the highest resistance to freeze-drying and storage. This increased rigidification could be at the origin of higher mechanical resistance of the membrane when bound water is removed during the desorption step.

The strain L. lactis TOMSC161 did not appear to be sensitive to the freezing step but very sensitive to storage in the freeze-dried state. It has been proposed that cocci are not sensitive to freezing due to a high cell surface-to-cell volume ratio (small size and spherical shape), which facilitates water efflux from cells during freezing (Mazur 1977; Fonseca et al. 2000). The main causes of alteration during storage are sugar crystallization, diffusion-controlled degradation reactions (non-enzymatic browning) and oxidation reactions (Jouppila et al. 1997; Kurtmann et al. 2009a, b). However, in this study, starters were in a glassy state, thus limiting molecular mobility and diffusion-controlled degradation reactions such as sugar crystallization. Since the oxidation reaction is strongly accelerated at low water activity (aw <0.2) (Ruckold et al. 2001), it could, in turn, have been the main cause of storage degradation. A decrease in the unsaturated fatty acid content during freeze-drying and spray drying of LAB was previously ascribed to oxidation reactions and associated with the observed losses of viability (Castro et al. 1995; Teixeira et al. 1996). However, no change was observed in the fatty acid profile of L. lactis cells after freeze-drying and 3 months of storage at 25 °C. Consequently, other cellular components of L. lactis cells such as DNA or proteins could be oxidized, and/or other physiological characteristics of cells could be involved in the freeze-drying and storage resistance of this strain.

In conclusion, this work linked membrane biophysical properties, fatty acid composition, and freeze-drying and storage resistance of L. lactis TOMSC161 for the first time. The modulation of membrane lipids for obtaining high ratio of CFA/UFA and the concurrent rigidification made it possible to better resist freeze-drying and storage stress. Furthermore, the direct measurement of membrane fluidity by fluorescence anisotropy appeared to be a rapid and simple tool to determine the optimal fermentation time, making it possible to obtain freeze-drying-resistant cells. In a future study, proteomic and transcriptomic methods will be used to further understand the cellular mechanisms responsible for the degradation of L. lactis TOMSC161 during freeze-drying and storage.

References

Beney L, Gervais P (2001) Influence of the fluidity of the membrane on the response of microorganisms to environmental stresses. Appl Microbiol Biotechnol 57(1–2):34–42

Beranova J, Jemiola-Rzeminska M, Elhottova D, Strzalka K, Konopasek I (2008) Metabolic control of the membrane fluidity in Bacillus subtilis during cold adaptation. BBA-Biomembranes 1778(2):445–453. doi:10.1016/j.bbamem.2007.11.012

Bischof JC, Wolkers WF, Tsvetkova NM, Oliver AE, Crowe JH (2002) Lipid and protein changes due to freezing in dunning AT-1 cells. Cryobiology 45(1):22–32

Broadbent JR, Lin C (1999) Effect of heat shock or cold shock treatment on the resistance of Lactococcus lactis to freezing and lyophilization. Cryobiology 39(1):88–102. doi:10.1006/cryo.1999.2190

Castro HP, Teixeira PM, Kirby R (1995) Storage of lyophilized cultures of Lactobacillus bulgaricus under different relative humidities and atmospheres. Appl Microbiol Biotechnol 44(1–2):172–176

Chu-Ky S, Tourdot-Marechal R, Marechal P-A, Guzzo J (2005) Combined cold, acid, ethanol shocks in Oenococcus oeni: effects on membrane fluidity and cell viability. Biochim Biophys Acta 1717(2):118–24. doi:10.1016/j.bbamem.2005.09.015

Coulibaly I, Dubois-Dauphin R, Destain J, Fauconnier M-L, Lognay G, Thonart P (2010) The resistance to freeze-drying and to storage was determined as the cellular ability to recover its survival rate and acidification activity. Int J Microbiol 2010:625239. doi:10.1155/2010/625239

Coulibaly I, Dubois-Dauphin R, Danthine S, Majad L, Mejoub T, Destain J, Bera F, Wathelet JP, Thonart P (2011) Preservation of industrial’s lactic acid bacteria (probiotics) by freeze-drying. Biotechnol Agron Soc 15(2):287–299

Crowe JH, McKersie BD, Crowe LM (1989a) Effects of free fatty acids and transition temperature on the stability of dry liposomes. Biochim Biophys Acta 979(1):7–10. doi:10.1016/0005-2736(89)90516-6

Crowe JH, Hoekstra FA, Crowe LM, Anchordoguy TJ, Drobnis E (1989b) Lipid phase transitions measured in intact cells with Fourier transform infrared spectroscopy. Cryobiology 26(1):76–84

Da Silveira MG, Golovina EA, Hoekstra FA, Rombouts FM, Abee T (2003) Membrane fluidity adjustments in ethanol-stressed Oenococcus oeni cells. Appl Environ Microbiol 69(10):5826–5832. doi:10.1128/aem. 69.10.5826-5832.2003

Daly C, Fitzgerald GF, O’Connor L, Davis R (1998) Technological and health benefits of dairy starter cultures. Int Dairy J 8(3):195–205. doi:10.1016/s0958-6946(98)00042-9

Drici-Cachon Z, Cavin JF, Divies C (1996) Effect of pH and age of culture on cellular fatty acid composition of Leuconostoc oenos. Lett Appl Microbiol 22(5):331–334. doi:10.1111/j.1472-765X.1996.tb01172.x

Fonseca F, Beal C, Corrieu G (2000) Method of quantifying the loss of acidification activity of lactic acid starters during freezing and frozen storage. J Dairy Res 67(1):83–90

Fox MH, Delohery TM (1987) Membrane fluidity measured by fluorescence polarization using an EPICS V cell sorter. Cytometry 8(1):20–25

Franks F (1998) Freeze-drying of bioproducts: putting principles into practice. Eur J Pharm Biopharm 45:221–229

Gautier J, Passot S, Penicaud C, Guillemin H, Cenard S, Lieben P, Fonseca F (2013) A low membrane lipid phase transition temperature is associated with a high cryotolerance of Lactobacillus delbrueckii subspecies bulgaricus CFL1. J Dairy Sci 96(9):5591–5602

Grogan DW, Cronan JE (1997) Cyclopropane ring formation in membrane lipids of bacteria. Microbiol Mol Biol Rev 61(4):429–441

Guillot A, Obis D, Mistou MY (2000) Fatty acid membrane composition and activation of glycine-betaine transport in Lactococcus lactis subjected to osmotic stress. Int J Food Microbiol 55(1–3):47–51. doi:10.1016/s0168-1605(00)00193-8

Hartig C, Loffhagen N, Harms H (2005) Formation of trans fatty acids is not involved in growth-linked membrane adaptation of Pseudomonas putida. Appl Environ Microbiol 71(4):1915–1922. doi:10.1128/aem. 71.4.1915-1922.2005

Hua L, Zhao WY, Wang H, Li ZC, Wang AL (2009) Influence of culture pH on freeze-drying viability of Oenococcus oeni and its relationship with fatty acid composition. Food Bioprod Process 87(C1):56–61. doi:10.1016/j.fbp.2008.06.001

Johnsson T, Nikkila P, Toivonen L, Rosenqvist H, Laakso S (1995) Cellular fatty acid profiles of Lactobacillus and Lactococcus strains in relation to the oleic acid content of the cultivation medium. Appl Environ Microbiol 61(12):4497–4499

Jouppila K, Kansikas J, Roos YH (1997) Glass transition, water plasticization, and lactose crystallization in skim milk powder. J Dairy Sci 80(12):3152–3160

Keweloh H, Heipieper HJ (1996) Trans unsaturated fatty acids in bacteria. Lipids 31(2):129–137. doi:10.1007/bf02522611

Kurtmann L, Carlsen CU, Risbo J, Skibsted LH (2009a) Storage stability of freeze-dried Lactobacillus acidophilus (La-5) in relation to water activity and presence of oxygen and ascorbate. Cryobiology 58(2):175–180. doi:10.1016/j.cryobiol.2008.12.001

Kurtmann L, Skibsted LH, Carlsen CU (2009b) Browning of freeze-dried probiotic bacteria cultures in relation to loss of viability during storage. J Agric Food Chem 57(15):6736–6741. doi:10.1021/jf901044u

Leroy F, de Vuyst L (2004) Lactic acid bacteria as functional starter cultures for the food fermentation industry. Trends Food Sci Tech 15(2):67–78

Li C, Zhao JL, Wang YT, Han X, Liu N (2009) Synthesis of cyclopropane fatty acid and its effect on freeze-drying survival of Lactobacillus bulgaricus L2 at different growth conditions. World J Microbiol Biotechnol 25(9):1659–1665. doi:10.1007/s11274-009-0060-0

Linders LJM, Wolkers WF, Hoekstra FA, VantRiet K (1997) Effect of added carbohydrates on membrane phase behavior and survival of dried Lactobacillus plantarum. Cryobiology 35(1):31–40. doi:10.1006/cryo.1997.2021

Loffhagen N, Hartig C, Geyer W, Voyevoda M, Harms H (2007) Competition between cis, trans and cyclopropane fatty acid formation and its impact on membrane fluidity. Eng Life Sci 7(1):67–74. doi:10.1002/elsc.200620168

Mazur P (1977) Role of intracellular freezing in death of cells cooled at supraoptimal rates. Cryobiology 14(3):251–272

Munoz-Rojas J, Bernal P, Duque E, Godoy P, Segura A, Ramos JL (2006) Involvement of cyclopropane fatty acids in the response of Pseudomonas putida KT2440 to freeze-drying. Appl Environ Microbiol 72(1):472–477. doi:10.1128/aem. 72.1.472-477.2006

Oldenhof H, Wolkers WF, Fonseca F, Passot SP, Marin M (2005) Effect of sucrose and maltodextrin on the physical properties and survival of air-dried Lactobacillus bulgaricus: an in situ Fourier transform infrared spectroscopy study. Biotechnol Prog 21(3):885–892. doi:10.1021/bp049559j

Rozes N, Garbay S, Denayrolles M, Lonvaudfunel A (1993) A rapid method for the determination of bacterial fatty-acid composition. Lett Appl Microbiol 17(3):126–131

Ruckold S, Grobecker KH, Isengard HD (2001) The effects of drying on biological matrices and the consequences for reference materials. Food Control 12(7):401–407

Schleifer KH, Kraus J, Dvorak C, Kilpperbalz R, Collins MD, Fischer W (1985) Transfer of Streptococcus lactis and related streptococci to the genus Lactococcus gen. nov. Syst Appl Microbiol 6(2):183–195

Schoug A, Fischer J, Heipieper HJ, Schnuerer J, Hakansson S (2008) Impact of fermentation pH and temperature on freeze-drying survival and membrane lipid composition of Lactobacillus coryniformis Si3. J Ind Microbiol Biotechnol 35(3):175–181. doi:10.1007/s10295-007-0281-x

Schwab C, Vogel R, Ganzle MG (2007) Influence of oligosaccharides on the viability and membrane properties of Lactobacillus reuteri TMW1.106 during freeze-drying. Cryobiology 55(2):108–114. doi:10.1016/j.cryobiol.2007.06.004

Sinensky M (1974) Homeoviscous adaptation - a homeostatic process that regulates the viscosity of membrane lipids in Escherichia coli. Proc Natl Acad Sci U S A 71(2):522–5. doi:10.1073/pnas.71.2.522

Smittle RB, Gilliland SE, Speck ML, Walter WM Jr (1974) Relationship of cellular fatty acid composition to survival of Lactobacillus bulgaricus in liquid nitrogen. Appl Microbiol 27(4):738–43

Spinnler HE, Corrieu G (1989) Automatic method to quantify starter activity based on pH measurement. J Dairy Res 56(5):755–764

Streit F, Corrieu G, Beal C (2007) Acidification improves cryotolerance of Lactobacillus delbrueckii subsp. bulgaricus CFL1. J Biotechnol 128(3):659–667. doi:10.1016/j.jbiotec.2006.11.012

Teixeira H, Goncalves MG, Rozes N, Ramos A, San Romao MV (2002) Lactobacillic acid accumulation in the plasma membrane of Oenococcus oeni: a response to ethanol stress? Microb Ecol 43(1):146–153. doi:10.1007/s00248-001-0036-6

Teixeira P, Castro H, Kirby R (1996) Evidence of membrane lipid oxidation of spray-dried Lactobacillus bulgaricus during storage. Lett Appl Microbiol 22(1):34–38

Thi Mai Huong T, Grandvalet C, Tourdot-Marechal R (2011) Cyclopropanation of membrane unsaturated fatty acids is not essential to the acid stress response of Lactococcus lactis subsp. cremoris. Appl Environ Microbiol 77(10):3327–3334. doi:10.1128/aem. 02518-10

Tymczyszyn EE, Gomez-Zavaglia A, Disalvo EA (2005) Influence of the growth at high osmolality on the lipid composition, water permeability and osmotic response of Lactobacillus bulgaricus. Arch Biochem Biophys 443(1–2):66–73

Velly H, Fonseca F, Passot S, Delacroix-Buchet A, Bouix M (2014) Cell growth and resistance of Lactococcus lactis subsp. lactis TOMSC161 following freezing, drying and freeze-dried storage are differentially affected by fermentation conditions. J Appl Microbiol 117(3):729–40

Wang Y, Delettre M, Guillot A, Corrieu G, Beal C (2005) Influence of cooling temperature and duration on cold adaptation of Lactobacillus acidophilus RD758. Cryobiology 50(3):294–307. doi:10.1016/j.cryobiol.2005.03.001

Wu CD, Zhang J, Wang M, Du GC, Chen J (2012) Lactobacillus casei combats acid stress by maintaining cell membrane functionality. J Ind Microbiol Biotechnol 39(7):1031–1039. doi:10.1007/s10295-012-1104-2

Zhang Y-M, Rock CO (2008) Membrane lipid homeostasis in bacteria. Nat Rev Microbiol 6(3):222–233. doi:10.1038/nrmicro1839

Zhao WY, Li H, Wang H, Li ZC, Wang AL (2009) The effect of acid stress treatment on viability and membrane fatty acid composition of Oenococcus oeni SD-2a. Agric Sci China 8(3):311–316. doi:10.1016/s1671-2927(08)60214-x

Acknowledgments

This work was supported by the Centre National Interprofessionnel de l’Economie Laitière (Paris, France). The authors thank Savoîcime for providing the reference strain.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Velly, H., Bouix, M., Passot, S. et al. Cyclopropanation of unsaturated fatty acids and membrane rigidification improve the freeze-drying resistance of Lactococcus lactis subsp. lactis TOMSC161. Appl Microbiol Biotechnol 99, 907–918 (2015). https://doi.org/10.1007/s00253-014-6152-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-6152-2