Abstract

A series of silica-supported macroporous chitosan membranes (CM15, CM20, and CM25) was prepared by varying the ratio of 70–230-μm-sized silica particles. These synthesized membranes were further cross-linked using different cross-linking agents for covalent immobilization of biological macromolecules especially enzymes and in this study, Bovine serum albumin and laccase. Effects of silica particle and cross-linking agents on their flow rates, surface properties, and chemical and biological properties were explored. Pore size of as-synthesized membranes was 0.1192, 0.1268, and 0.1623 μm, respectively, for CM15, CM20, and CM25. The effect of various parameters such as temperature and pH on the relative activity of both free and immobilized enzymes was studied in details. The relative enzyme activity upon immobilization was greatly enhanced several folds of its original activity. The stability of enzymes over a range of temperature and pH was significantly improved by immobilization. The optimum temperature and pH were determined to be 50 °C and pH 3, respectively, for both the free and the immobilized enzymes. The immobilized enzyme possessed good operational stability and reusability properties that support its potentiality for practical applications. Among three membranes, CM25 is confirmed to be efficient candidate due to its improved characteristics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The technical approaches to separate or purify biomolecules/biological macromolecules mainly target on polymer scaffolds which greatly serve to support, reinforce, and organize the biomolecules such as proteins and enzymes. Such scaffolds are expected to provide many application scenarios. These varied functional performances of these scaffolds necessarily demand a porous micro or macrostructure, with the porosity being specific for required applications (Madihally and Matthew 1999). Nano-, meso-, and macroporous composite materials consisting of organic biopolymers are attractive candidates as they may provide new application orientations due to their potential and environmentally benign nature (Sh. Rashidova et al. 2004). Chitosan is one of such promising biopolymers which hold standard chain structure (Sh. Rashidova et al. 2004). In recent years, much of the researches have been devoted to chitosan functional biopolymer as it has numerous significant biological and chemical properties (Kim et al. 2003). Among the various distinct applications of chitosan, chitosan affinity membranes are broadly suggested for the immobilization of proteins and enzymes as they are expected to possess high affinity for these biomolecules. However, the range of potential application of affinity membranes in the field of biotechnology is broad and there is a continuous quest for membrane materials which either possess some specific properties or have wide applicability, and can easily be tailored for desired properties. Thus, we expected that chitosan, an amino polysaccharide, is a suitable candidate for this purpose. As it is known that in acidic solutions, the chitosan molecules are easily soluble due to the protonation of free amino groups, and thus becoming a polycationic polymer (Chen et al. 2007). This pH-dependent solubility of chitosan provides a convenient mechanism for variety of effective synthetic approaches for designing a suitable chitosan membrane candidate for biological and chemical applications (Kim et al. 2003). There have been only a few chitosan membranes reported for clinical purpose (Hu et al. 2001). The main reason behind this limited report is primarily because of the preparation methods. The conventional methods are time consuming, and moreover the prepared membranes possess poor mechanical strength and flexibility (Hu et al. 2001). Thus, the main scope of this investigation is to find an effective method to obtain chitosan membranes with improved physical, chemical, and biological properties. Porous chitosan membranes were significantly reported as affinity membranes and in such cases the selection of porogen is more important (Zeng and Ruckenstein 1996a). In this present study, we tend to suggest a new kind of macroporous chitosan membranes that have suitable mechanical properties using silica particles as porogens. These silica particles in contrast to chitosan are soluble in alkali solutions, whereas chitosan is soluble in acidic solutions. Based on these contrary properties, few macroporous chitosan membranes were reported earlier by us (Yang et al. 2014) and others (Zeng and Ruckenstein 1996a, b). However, so far, detailed studies on how the particle size and ratio of these porogens eventually influence the preparation and properties of porous membranes are not comprehensively explored. It is also believed that the size of the pores of macroporous chitosan membranes and the mechanical properties are effectively controlled by silica porogen which is aimed at this present work. In this work, we tried to explore the effect of particle size and ratio of silica gel porogen on the pore size and properties of macroporous chitosan membranes. After obtaining the macroporous chitosan membranes using different particle sizes and ratios of silica gel porogen, these membranes were cross-linked using different cross-linking agents to prevent the dissolution of porous chitosan membranes. These cross-linking agents also have the potential to play a crucial role on improving the relative properties of chitosan membranes (Chen et al. 2007).

Thus, in this present study, we tested the feasibility of using different particle sizes and ratios of silica gel porogen and successfully obtained macroporous chitosan membranes using casting method with enhanced mechanical properties for enzyme immobilization purpose. These chitosan membranes were further chemically modified using cross-linking agents for the purpose of different enzyme immobilizations. To analyze and compare the properties of as-synthesized as well as modified macroporous chitosan membranes, we have used three different cross-linking agents such as 1,4-butanediol diglycidyl ether, glutaraldehyde, and epichlorohydrin. At the same time, the effect of ratio of cross-linking agents as well as pH and temperature were also explored in this study. For the purpose of immobilization, two enzymes Bovine serum albumin (BSA) and Laccase were chosen, and the extent of immobilization and enzyme activities were studied and discussed. We found that both particle size and ratio of silica gel, cross-linking agents and reaction parameters such as pH and temperature eventually affected the preparation, physico-chemical, and biological properties (immobilization efficacy) of resulted macroporous chitosan membranes.

Materials and Methods

Chemicals

Deionized distilled water was used to prepare all solutions. Chitosan (medium molecular weight, Mw ~ 750,000) was obtained from Sigma. Silica gels (sizes in the range 70–230 μm) were obtained from Silicycle. Cross-linking agent, 1,4-butanediol diglycidyl ether (95 %) was obtained from Aldrich, glutaraldehyde solution (25 wt% in H2O) was obtained from Sigma, and epichlorohydrin (99 %) was obtained from Alfa Aesar. Acetic acid and acetic anhydride were obtained from TEDIA. Sodium hydroxide and glycerol were supplied by J. T. Baker. Enzyme Bovine serum albumin (BSA) and Laccase were purchased from Sigma. All other chemicals and reagents used in this study were of analytical grade and used without any further purification.

Preparation of Macroporous Chitosan Membranes

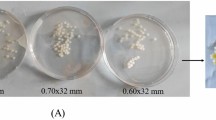

The macroporous chitosan membranes were prepared as follows: a solution of chitosan was first obtained by dissolving 1 g of chitosan in 100 ml of 1 vol % aqueous acetic acid solution. To this solution, silica particles (weight ratio of silica to chitosan of 15:1, 20:1, and 25:1) were added, followed by vigorous stirring for 6 h in order to disperse them uniformly. Then the solution was poured onto a rimmed glass plate and the liquid was allowed to evaporate. The dried membrane was immersed in a 5 wt % aqueous NaOH solution and kept at 80 °C for 2 h in order to dissolve the silica particles and to generate a porous membrane. Finally, the porous membrane was washed with distilled water to remove the remaining NaOH. In order to prevent its shrinkage during drying, the membrane was immersed in a 20 vol % aqueous glycerol solution (softening agent) for 30 min and, after the excess glycerol solution was removed, placed on a glass plate and allowed to dry. Thus, soluble but strong and flexible mechanically stable macroporous chitosan membranes without shrinkage were obtained. The chitosan membranes obtained for different ratios 15:1, 20:1, and 25:1 are referred as CM15, CM20, and CM25, respectively.

The Cross-Linking of Macroporous Chitosan Membranes

The macroporous chitosan membranes were cross-linked by various cross-linking agents such as 1,4-butanediol diglycidyl ether, glutaraldehyde, and epichlorohydrin solutions of various concentrations (1 and 4 %) at room temperature for 13 h. The cross-linking was carried out at mild alkaline condition (NaOH) (Wei et al. 1992). Thereafter, the membranes were washed with distilled water until reaching neutral pH to remove excess of cross-linking agents and subsequently dried in air.

Immobilization of Enzymes Onto Macroporous Chitosan Membranes

The immobilization of enzymes (BSA and Laccase) was carried out separately at room temperature by thoroughly mixing macroporous chitosan membranes (as-synthesized and cross-linked) and enzymes, BSA and Laccase, for 7 h in 0.05 M citrate buffer (pH = 5.6), and the initial immobilization concentration was adjusted. Finally, the immobilized membranes were separated and collected.

Characterization Techniques

The flow rate and the average pore diameter (pore size) were measured by capillary flow analysis using capillary flow meter PSM 165. SEM was carried out on HITACHI-S-800, field emission scanning electron microscope. A Neclit 6700 model, Fourier transform infrared spectrometer (FT-IR) was used to record the FT-IR spectra. UV–visible spectra were obtained using UV–visible spectrophotometer (Hitachi U-2800 A).

Results and Discussions

In this study, preparation, characterization, and application of different macroporous chitosan membranes obtained using various sizes and ratios of silica particle were discussed. Apart from these, various parameters during cross-linking process were also explored. Thus, it is possible to tune and control the physico-chemical and biological properties of chitosan membranes.

Effect of Size and Ratio of Silica Particle

The characteristics of different chitosan membranes CM15, CM20, and CM25 are given in Table 1. The flow rate diagram through different macroporous chitosan membranes is shown in Fig. 1. From Fig. 1, it is clearly understood that the flow rate was greatly affected by drying conditions and the observed flow rate of dried membranes is comparatively higher than that of wet membranes. The results showed that the flow rate is very sensitive to drying conditions and the flow rate is increased if the membranes are dried well. The average pore sizes (pore diameter) of the chitosan membranes CM15, CM20, and CM25 as shown in Table 1 are 0.1192, 0.1268, and 0.1623 μm, respectively. From Table 1, it is clearly understood if the ratio of silica particles is gradually increased, the pore size of the obtained membranes is also gradually increased, and among three membranes CM25 possessed larger pore size. It was already reported that the quantity, particle size, and porosity of the supporting materials play a vital role in determining the flow rate and particle size of the resulted membranes (Oh and Kim 2000). The characteristics of the porogen matrix also are of paramount importance in determining the performance of the immobilized enzyme system. Ideal support properties include physical resistance to compression, hydrophilicity, inertness toward enzymes ease of derivatization, biocompatibility, resistance to microbial attack, and availability at low cost. Larger size and ratio of porogens could enhance the immobilization of enzymes onto the resulted membranes due to the larger pore size of macroporous membranes. In order to understand the effect of particle size and ratio of silica gel used in this study, the physico-chemical characteristics of obtained macrocycles using 70–230 μm particle size silica sel are compared with those obtained using 15–40 μm particle size of silica gel in our previous report (Yang et al. 2014). The information revealed if larger particle size of silica gel is used, the flow rate and pore size of the resulted chitosan membranes are significantly increased. Because on this increased pore size of larger macroporous chitosan membranes, the extent of enzyme immobilization could be expected to be enhanced. With larger macroporous, there are relatively larger pores into which enzymes could be immobilized, and the diffusion of substrate and product will be the rate controlling step. With small ones, enzyme will be immobilized more on the surface, and substrate and product would give less restriction for diffusion (Oh and Kim 2000; de Oliveira et al. 2000). From this point, it is expected that the small-sized support would reduce the loss in activity and diffusion limitation problems in the immobilized enzyme system. Hence, larger particle size and ratio of silica gel support is advised in this study. These larger particle porous supports are generally preferred because the high surface area allows for a higher enzyme loading and the immobilized enzyme receives greater protection from the environment. Thus, in this study, it is suggested that the larger size of silica particle (70–230 μm) is preferred as a support when compared to that of smaller size (15–40 μm) silica particle used in our previous report (Yang et al. 2014). From Table 1, we can assume that the increase in ratio of silica gel gradually increased the thickness of the resultant chitosan membranes. The thickness of the obtained membranes is slightly increased as 0.22, 0.27, and 0.32 mm for CM15, CM20, and CM25, respectively.

A comparative study on flow rate analysis of macroporous chitosan membranes CM15, CM20, and CM 25 obtained using larger silica particle with the one obtained using smaller silica particle clearly revealed that the flow rate capacity of chitosan membranes obtained in this study is observed to be superior even in the low pressure range, i.e., because of the large silica particles used to obtain chitosan membranes, swelling of the membrane is diminished and its compressibility decreased at lower pressure range itself (Ruckenstein and Zeng 1998). Thus, the membranes CM15, CM20, and CM 25 are considered to be effective at low pressure range. Whereas in the case of chitosan membranes obtained using smaller silica particle, the compressibility is not diminished at lower pressure range and such a pressure compression is possibly observed only at higher pressure level due to swelling of membranes. As a result of this, the relationship between flow rate and pressure drop of CM15, CM20, and CM 25 is almost linear below 10–30 psi (Ruckenstein and Zeng 1998). But such a linear relationship is almost continued till higher pressure range in the case of membranes obtained using smaller silica particles. As a consequence of this, the extent of increase in the flow rate capacity of CM15, CM20, and CM25 is more even in the lower pressure range than that of chitosan membranes obtained using smaller silica particles. However, in this study, it is not possible to obtain a correlation between membrane thickness and flow rate. If the membrane thickness was slightly increased for CM20 than that for CM15, the flow rate was decreased for CM20 compared to that for CM15, but for CM25 the flow rate was further increased even the membrane thickness was increased. This can be explained due to the combined effect of thickness and pores size of the obtained membranes. In the case of CM20, the pore size was just slightly increased (0.1268 μm) compared to that of CM15 (0.1192 μm), but in the case of C25, the extent of increase in pore size was slightly more (0.1623 μm). Thus, in the present study, in the case of C25, the effect of pore size of membrane dominated the effect of thickness of the membrane; whereas in the case of C15 and C20, the effect of membrane thickness dominated the effect of pore size. Based on these above results, it is clearly known that the variation of size and ratio of silica particle induced even small changes in the membrane characteristics which are still very significant. Thus, the significance of ratio and size of silica particles used as a porogen in preparing macroporous chitosan membranes is now well established.

Effect of Cross-Linking Agents

In order to increase the mechanical strength and stability of the macroporous chitosan membranes obtained in this study, cross-linking of membranes were carried out using three different cross-linking agents as described in experimental section. Macroporous chitosan membranes CM15, CM20, and CM 25 were characterized by FT-IR and SEM analyses before and after cross-linking. The FT-IT technique is useful to identify the presence of reactive functional groups on macroporous chitosan membrane and also to understand the effect of cross-linking agents. FT-IR spectra of macroporous chitosan membranes showed a peak around 3,480 cm−1 due to ν(O–H) and ν(NH2) (Zakaria et al. 2012), a peak around 2,900 cm−1 is due to alkyl ν(C–H), a peak around 1,600 cm−1 due to ν(N–H), a peak around (1,300–1,500) cm−1 due to deformation from alcoholic and phenolic ν(C–OH) and ν(C–O–C), a peak around (1,050–1,100) cm−1 due to ν(C–O) of chitosan (Anjali Devi et al. 2005; Beppu et al. 2004; Manjubala et al. 2006), and a peak around 800 cm−1 is due to ν(Si–O-Si) and aromatic ν(C–H). If the ratio of cross-linking agents was increased from 1 to 4 %, the peak intensity of respective peaks due to ν(C–H), ν(C–O–C), and ν(C–H) was observed to increase and thus explaining the effective cross-linking. Thus, it was believed that increase in concentration of cross-linking agents in turn would also increase the effectiveness of enzyme immobilization onto cross-linked chitosan membranes.

The SEM images of CM15, CM20, and CM 25 are shown in shown in Fig. 2. As seen in Fig. 2, as-synthesized chitosan membranes are associated with uniformly distributed pores which further indicating the uniform distribution of silica particles also. All the obtained chitosan macrospheres seemed to be spongy hollow fibers. It can also be noted that the structural uniformity regularly increased from CM15 to CM20 which was still further increased for CM25. This also clearly explained the effect of ratio of silica particles used in this study. The SEM images of cross-linked chitosan membranes using different cross-linking agents are shown in Fig. 3. On comparison of chitosan membranes before and after cross-linking, the SEM of membrane alone showed more flat surface than that of cross-linked one. Also the comparison of the SEM pictures of chitosan membrane before and after cross-linking clearly showed the formation of graft branches on the pores of the hollow fibers due to which the swelling of resin phase network structure is also possible (Iwata et al. 1991). Thus, it is expected that the addition of cross-linking agent would also block the pore entrance of the hollow fibrous membranes, and thereby would reduce the pore size. Upon enzyme immobilization, the membranes were still swelled more as shown in Fig. 4. Thus, the difference in the surface morphology as witnessed from Figs. 2, 3, and 4, confirmed the successful cross-linking as well effective immobilization of enzyme. Invariably, the increase in concentration of all three cross-linking agents from 1 to 4 % facilitated the extent of effective cross-linking of as-synthesized chitosan membranes. Thus, in this study, it is confirmed that the different factors of cross-linking agents would obviously affect the structural property of different chitosan membranes, and thereby would also affect the expansion, biodegradable, and mechanical properties of different cross-linked macroporous chitosan membranes.

SEM images of a 0.5 U/ml laccase immobilized cross-linked CM15 using 4 % epichlorohydrin; b 500 ppm BSA immobilized cross-linked CM15 using 4 % epichlorohydrin; c 500 ppm BSA immobilized cross-linked CM20 using 4 % epichlorohydrin; d 500 ppm BSA immobilized cross-linked CM25 using 4 % epichlorohydrin

Enzyme Immobilization Onto Macroporous Chitosan Membranes

Enzyme immobilization technique is currently considered to be the object of interest due to its steadily increased extensive applications. This immobilization enhances the concentration at the proper location and it may also protect the enzyme from being destroyed. The main targeted benefits are easy separation of the enzyme and reuse of the enzyme. The characteristics of immobilized enzyme preparations are governed by the combined properties of both the enzyme and the carrier material. The specific interaction between the enzyme and carrier material would provide an immobilized enzyme with distinct chemical, biochemical, mechanical, and kinetic properties as shown in Fig. 5. Thus, it is very important to keep in mind that the physico-chemical properties of carrier material play an important role in determining the activity of immobilized enzyme. Thus, in order to improve the mechanical stability of macroporous chitosan membranes, cross-linking was carried out before immobilization and after which enzymes were immobilized onto cross-linked membranes. While talking about the stability of the immobilized enzymes, the operational stability is a matter of working conditions and of detrimental effects from the selected reaction conditions, such as pH, temperature, solvents, impurities, and other factors, and such operational stability determines the enzyme’s performance. In order to study the effect of parameters such as temperature and pH on the covalent immobilization of enzymes, the enzymatic activity of enzymes BSA and laccase was studied at different temperatures (30, 40, 50, 60, and 70 °C) as shown in Table 2 and at different pH values (3, 4, 5, 6, and 7) as shown in Table 3. From the experimental results, it is clearly understood that the percentage of enzyme immobilization onto cross-linked membranes is significantly higher if the initial concentration of enzyme was increased. As a consequence of this, the activity of enzyme was accelerated in the case of immobilized enzymes. Both the temperature and pH showed interesting and peculiar characteristics on the relative enzymatic activity as shown in Fig. 6. However, experimental investigations have produced unexpected results such as a significant reduction and also an increase in activity in some conditions especially in the case of temperature effect. For all concentration of enzymes, the activity of free enzymes BSA and laccase gradually increased as the temperature increased from 30 to 60 °C after which, the activity of free enzyme tend to decline at 70 °C. However, for the immobilized enzymes in the case of cross-linked CM15 and CM 25, the activity of immobilized enzyme was sharply increased from 30 to 50 °C after which, the activity suddenly decreased. However, in the case of cross-linked CM20, the activity of immobilized enzyme kept on sharply increasing if the temperature was increased from 30 to 70 °C. In practice, immobilized enzymes are much less temperature dependent when their reaction rate is diffusion controlled. But in the case of pH effect, invariably, the activity of both free and immobilized enzymes was found to be more at lower pH (pH3) and beyond which (pH3 to pH7), it tend to decrease significantly. This is due to the fact that the electrostatic attraction between enzymes and chitosan membranes would tend to decrease at pH values higher than 3. Otherwise another possible explanation may be that there is electrostatic repulsion between enzyme molecules that have bound to chitosan membranes and unbound free enzyme molecules with same charge (Susanto et al. 2013). This decreasing tendency at particular temperature and pH values was also probably due to the steric hinderance of the cross-linked network on the surface of the support (Bautista et al. 1999). This reduced activity rate may also result from external diffusion restrictions on the surface of carrier materials. Thus, for all cases, 50 °C temperature and pH3 were considered to be optimum conditions.

The effects of pH and temperature are critical observations to understand the stability of both free and immobilized enzymes. As observed from the experimental results, as the pH increased, the relative activity gradually decreased, and thus the enzymatic activity is stable at low pH only. In the case of free enzymes, the relative activity was sharply decreased on increasing the pH values, and thus the deactivation of enzymes occurred rapidly; whereas in the case of immobilized enzymes onto cross-linked membranes, such a deactivation was observed slowly compared to that of free enzymes. This higher stability against thermal and pH denaturation compared to that of free enzymes is because of the fact that the cross-linking prevented the unfolding of enzymes under thermal and pH stress conditions (Cabana et al. 2007). Among these, CM25 regularly increased the enzyme activity in all cases without any discrepancy. This observation clearly witnessed the enhanced strength of the cross-linked membranes and also the cross-linking of the membranes definitely increased the enzymatic activity even higher than that of free enzyme upon immobilization. The results obtained from enzyme activity studies clearly indicated that among three membranes reported in this study, under similar conditions, CM25 showed superiority compared to that of other membranes CM15 and CM20 by favorably enhancing the enzyme activity of immobilized enzymes due to its improved characteristics. Thus, the activity of immobilized enzymes was strongly affected by the characteristics of membranes (Malmiri et al. 2012), and in this study increased pore size and thickness of the C25 membrane facilitated the effective immobilization of enzyme as well as the enhanced relative enzyme activity. Thus, the appreciably higher enzymatic activity over wide temperature and pH range due to immobilization is in good agreement with few earlier reports (Liu et al. 2005; Tang et al. 2006; Zhang et al. 2009). Among two enzymes studied in this present work, both BSA and laccase showed similar trend of behavior and hence both are equally capable of enhancing their activity upon immobilization. Thus. both are equally significant in this study.

Conclusions

Three types of silica gel-supported macroporous chitosan membranes (CM15, CM20, and CM25) were prepared successfully using different weight ratios of silica particles in this study. The flow rate, thickness, and porosity, of the membranes were greatly affected by both the particle size and weight ratio of the silica particle. Among these, CM25 possessed larger pore size, thickness, and flow rate. These chitosan membranes were cross-linked using three different cross-linking agents. Enzymes BSA and laccase were immobilized onto these cross-linked membranes. The relative enzyme activity of both free and immobilized enzymes was studied at different temperatures and pH ranges. Invariably, in all cases, the stability and relative enzyme activity increased upon increasing the temperature to some extent beyond which no favorable observation was occurred. However, on increasing the pH values, both the activity and stability of enzymes decreased significantly, and thus lower pH was always preferred, Based on the experimental results, the optimum temperature and pH were found to be 50 °C and pH3, respectively. The extent of immobilization onto cross-linked membranes was further increased upon increasing the enzyme’s concentration. Also the relative enzyme activity of immobilized enzymes was found to be several folds greater than that of free enzyme, and the extent of deactivation in the case of immobilized enzymes onto cross-linked membranes was appreciably lower than that of free enzyme. Both BSA and laccase were equally capable of increasing their enzyme activity upon immobilization and thus both are comparatively significant to each other. Thus, comparatively, CM25 membrane greatly enhanced the activity of immobilized enzymes and it is considered to be effective compared to that of other membranes. In overall, it could be concluded that the present methodology is more advantage due to its simple and feasible approach, the more strong and stable cross-linked immobilized membranes and enhanced relative enzyme activity.

References

Anjali Devi D, Smitha B, Sridhar A, Aminabhavi TM (2005) Pervaporation separation of isopropanol/water mixtures through crosslinked chitosan membranes. J Membr Sci 262:91–99

Bautista FM, Bravo MC, Campelo JM, Garcia A, Luna D, Marinas JM, Romero AA (1999) Covalent immobilization of acid phosphatase on amorphous AlPO4 support. J Mol Catal B 6:473–481

Beppu MM, Arruda EJ, Vieira RS, Santos NN (2004) Adsorption of Cu(II) on porous chitosan membranes functionalized with histidine. J Membr Sci 240:227–235

Cabana H, Jones JP, Agathos SN (2007) Preparation and characterization of cross-linked laccase aggregates and their application to the elimination of endocrine disrupting chemicals. J Biotechnol 132:23–31

Chen P-H, Hwang Y-H, Kuo T-Y, Liu F-H, Lai J-H, Hsieh H-J (2007) Improvement in the properties of chitosan membranes using natural organic acid solutions as solvents for chitisan dissolutions. J Med Biol Eng 27:23–28

de Oliveira PC, Alves GM, de Castro HF (2000) Immobilisation studies and catalytic properties of microbial lipase onto styrene-divinylbenzene copolymer. Biochem Eng J 5:63–71

Hu Q-L, Fang Z-P, Zhao Y, Xu C-W (2001) A new method to prepare chitosan membrane as a biomedical material. Chin J Polym Sci 5:467–470

Iwata H, Saito K, Furusaki S (1991) Adsorption characteristics of an immobilized metal affinity membrane. Biotechnol Prog 7:412–418

Kim JY, Lee JK, Lee TS, Park WH (2003) Synthesis of chitooligosaccharide derivative with quaternary ammonium group and its antimicrobial activity against Streptococcus mutans. Int J Biol Macromol 32:23–27

Liu CG, Chen XG, Park HJ (2005) Self assembled nanoparticles based on linoleic-acid modified chitosan: stability and adsorption of trypsin. Carbohydr Polym 62:293–298

Madihally SV, Matthew HWT (1999) Porous chitosan sca!olds for tissue engineering. Biomaterials 20:1133–1142

Malmiri HJ, Jahanian MAG, Berenjian A (2012) Potential applications of chitosan nanoparticles as novel support in enzyme immobilization. Am J Biochem Biotechnol 8:203–219

Manjubala I, Scheler S, Bössert J, Jandt KD (2006) Mineralisation of chitosan scaffolds with nano-apatite formation by double diffusion technique. Acta Biomater 2:75–84

Oh J-T, Kim J-H (2000) Preparation and properties of immobilized amyloglucosidase on nonporous PS/PNaSS microspheres. Enzyme Microbiol Technol 27:356–361

Sh. Rashidova S, Sh. Shakarova D, Ruzimuradov ON, Satubaldieva DT, Zalyalieva SV, Shpigun OA, Varlamov VP, Kabulov BD (2004) Bionanocompositional chitosan-silica sorbent for liquid chromatography. J Chromatogr B 800:49–53

Ruckenstein E, Zeng XF (1998) Albumin separation with cibacron blue carrying macroporous chitosan and chitin affinity membranes. J Membr Sci 142:13–26

Susanto H, Samsudin AM, Rokhati N, Widiasa IN (2013) Immobilization of glucose oxidase on chitosan-based porous composite membranes and their potential use in biosensors. Enzyme Microbial Technol 52:386–392

Tang ZX, Qian JQ, Shi LE (2006) Characterizations of immobilized neutral proteinase on chitosan nano-particles. Process Biochem 41:1193–1197

Wei YC, Hudson SM, Mayer JM, Kaplan DL (1992) The crosslinking of chitosan fibers. J Polym Sci Part A 30:2187–2193

Yang W-Y, Thirumavalavan M, Malini M, Annadurai G, Lee J-F (2014) Development of silica gel-supported modified macroporous chitosan membranes for enzyme immobilization and their characterization analyses. J Membr Biol 247:549–559

Zakaria Z, Izzah Z, Jawaid M, Hassan A (2012) Effect of degree of deacetylation of chitosan on thermal stability and compatibility of chitosan-polyamide blend. Bioresources 7:5568–5580

Zeng XF, Ruckenstein E (1996a) Supported chitosan-dye affinity membranes and their adsorption of protein. J Membr Sci 117:271–278

Zeng XF, Ruckenstein E (1996b) Control of pore sizes in macroporous chitosan and chitin membranes. Ind Eng Chem Res 35:4169–4175

Zhang L, Zhua X, Zhenga S, Sunb H (2009) Photochemical preparation of magnetic chitosan beads for immobilization of pullulanase. Biochem Eng J 46:83–87

Acknowledgments

We thank the National Central University and National Science Council (NSC, (Grant No.: NSC100-2923-E-008-001-MY3), Taiwan, Republic of China (ROC) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yang, WY., Thirumavalavan, M. & Lee, JF. Effects of Porogen and Cross-Linking Agents on Improved Properties of Silica-Supported Macroporous Chitosan Membranes for Enzyme Immobilization. J Membrane Biol 248, 231–240 (2015). https://doi.org/10.1007/s00232-014-9763-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00232-014-9763-8