Abstract

Simultaneous use of convective hot air and continuous microwave is a new method for drying of agricultural products. This study indicated the effect of different drying methods (Convective Hot Air 45 °C at a speed of 1 m/s (CHA), Microwave 540 W (MIC), simultaneous Convective Hot Air and continuous Microwave (HA-MIC)) on the drying kinetics of potato cubes (moisture ratio, effective moisture diffusion coefficient and energy consumption). In addition, modeling of momentum, heat and mass transfer, along with changes in chemical composition and thermophysical properties of potato (at the same time with temperature change and moisture exit) during HA-MIC drying method was performed. Considering to results, the lowest energy consumption was related to the MIC method. The results of the modeling section showed that, by reducing the mass and volume fraction of water, the ratio of other components (carbohydrates, proteins, fats, ash, and fibre) increases in the total solid. In addition, with decreasing the mass fraction of water along with increasing temperature, total density (kg/m3) and the density of potato constituents increased and decreased, respectively. Total specific heat (J/kg.K) and total heat conductivity (W/m.K) of potato also decreased with decreasing the mass and volume fraction of water; while in specific heat and thermal conductivity of potato constituents, an increasing trend was observed. Finally, a high correlation was obtained between the results of experimental data and numerical modeling for moisture distribution (R2 = 0.9589) and temperature distribution (R2 = 0.9961).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Potato is one of the most important human food sources, which is known as the second simplest and most consumed food source in the world after egg, due to its easy digestion and having good quality protein [1], and it is one of the most important agricultural products after wheat, corn and rice [2, 3]. This product is consumed fresh or frozen and as a main meal or snack after processing (drying, frying, parboiling, baking) [4]. Drying is one of the most important processes in potato processing, which increases its shelf life by reducing the amount of moisture and thus inhibiting microbial and enzymatic activity [5]. One of the most widely used methods for drying is convective hot air [6], which has many problems and disadvantages such as high-energy consumption and long drying time due to the low thermal conductivity of foods [7]. Thus, to reduce these disadvantages, complementary processes such as microwave or infrared drying are used to increase the efficiency and accelerate the quality of various products [8]. As the production of high quality products is the most important issue in the food industry (such as the least amount of shrinkage, color changes, preservation of nutrients and uniform distribution of heat in the products, as well as reducing energy consumption in the process). Therefore, new methods should be used to predict these changes during the process [48, 49]. Unlike conventional heating systems in the microwave drying method, heat spreads throughout the food due to the penetration of microwave waves [9]. The general mechanism of microwave is the volumetric heat generation that causes the transfer of moisture to the surface of the product [10,11,12]. There are two mechanisms for heat generation by microwaves, bipolar rotation and ion polarization [13]. One of the advantages of microwave method is the production of high-quality products in a short time and with appropriate energy consumption [14,15,16]. In spite of the advantages of using microwave in the drying process, this method is less used alone and usually used in combination with other drying methods such as convective hot air [10].

Modeling and simulation are recognized as useful tools in describing operational mechanisms, transfer phenomena and process interactions. Agricultural products drying is a complex process that involves the phenomena of evaporation, heat and mass transfer and shrinkage. Some researchers have proposed mathematical models for alternating hot air-microwave and hot air-infrared drying and the other have done valuable works in the field of wave propagation modelling [50, 51], however, mathematical modeling of simultaneous convective hot air and microwave drying which considers chemical composition and thermophysical properties changes due to heat and mass transfer has been rarely performed [17,18,19]. Finally, due to feel the need to further investigation of the heat and mass transfer in food hybrid drying process, this article was performed with the aim of investigating the chemical composition and thermophysical properties changes of potato cubes due to momentum of air, heat and mass transfer during Convective Hot Air drying (CHA), Microwave (MIC) and simultaneous Microwave-Convective Hot Air (CHA-MIC).

2 Materials and methods

2.1 Drying method

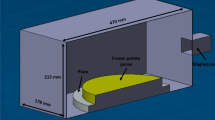

Potatoes (Agria cultivar) were cut into square cubes with sides of 1/2 × 1/2 × 1/2 cm using a hand cutter. After weighing, the samples were blanched in hot water at 100 °C (in bain-marie) for 5 min and immediately cooled in cold water for 5 min to remove excess heat [3]. Finally, the remaining water on the samples was dried using a napkin and the weight was measured again. At last, potato cubes were dried using CHA or Convective Hot Air (45 °C and 1 m/s), MIC or Microwave (540 W) and CHA-MIC or Convective Hot Air-Microwave (simultaneously) methods. The continuous drying process was performed by exposing potato samples to convective hot air and microwave until the final moisture ratio was 0.2 (dimensionless). For this purpose, a combined convective hot air-microwave-infrared dryer was used (Fig. 1).

The dryer consists of a convective hot air system, consisting of a backward centrifugal blower with a 370 W motor, electrical elements with a total power of 5000 W (equivalent to 5 kW) and a PIDFootnote 1 control structure with an accuracy of 1 °C. Inlet, outlet and ambient air temperature was measured by Dallas DS18B20 digital sensors with an accuracy of 0.5 degrees and a response time of 750 µs. The microwave set includes the Samsung’s microwave oven with dimensions of 22 × 36 × 37 cm, with a power of 1100 W (Taiwan). To create different levels of microwave power, a separate control circuit has been designed and replaced the previous circuit. The created circuit operates on the on/off structure for 60 s. When using the microwave source individually, the blower moves the air inside the chamber at a speed of 0.1 m/s to transfer the generated vapours out of the dryer’s chamber. A flexural load cell with a capacity of 1 kg and an accuracy of 0.1 g was used to measure changes in the mass of the sample. The measured parameter values were sent to the computer port via the Arduino board and stored in the Excel program. The temperature of the samples was measured during drying, using the FLIR One Pro IOS Digital Infrared Thermal Camera (USA).

2.2 Evaluation of qualitative characteristics

2.2.1 Chemical composition

The chemical composition (moisture, protein, lipid, carbohydrate, fibre, and ash content) of potato samples was examined according to the standard protocols established by the Association of Official Agricultural Chemists [20].

2.2.2 Moisture ratio

Moisture ratio was calculated using the following equation [21]:

where M is the moisture content (d.b.) at time t (g water/g dry solids), M0 the initial moisture content (d.b.), and Me the equilibrium moisture content, which can be excluded due to its negligible amount compared to M0 and M.

2.2.3 Effective moisture diffusion coefficient

This coefficient is used to describe all the mechanisms of moisture transfer within the food such as liquid diffusion, surface diffusion, capillary flow, and viscous flow [22]. The effective moisture diffusion coefficient was calculated according to the second law of Fick using the following equation [23, 24]:

where MR is moisture ratio, Mt moisture content at time t (g water/g dry solids), M0 and Me initial moisture content and equilibrium moisture content of samples (g water/g dry solids), respectively, \({D}_{eff}\) effective moisture diffusion coefficient (m2/s), n number of series of sentences, L foam half-thickness (m), and t drying time (s). If the equilibrium moisture content can be neglected, for longer drying times, the above equation is as follows:

By taking the natural logarithm from both sides of the Eqs. (3),

Plotting ln(MR) versus time, gives a slope equal to:

2.2.4 Energy consumption

Energy consumption during drying using convective hot air (EHA) is obtained from the following equation [23]:

where EHA is the energy consumption of CHA dryer (kJ/kg water removal), A is the area of sample (m2), Va is the inlet air velocity (m/s), ρa is the air density (kg/m3), ΔH is the air enthalpy (kJ/kg dry air), tHA is the sample drying time using CHA method (s), mHA is the amount of sample moisture reduction during CHA (kg), Cp,a is the air specific heat (kJ/kg˚C), W is the air absolute humidity (kg water vapor/kg dry air), Cp,v is the specific heat of water vapor (kJ/kg˚C), Tin is the temperature inside the dryer (°C), Tamb is the ambient air temperature (°C), and λ is the latent heat of water evaporation (kJ/kg water vapor).

The energy consumption during microwave drying was calculated using the following equation [24]:

where EMW is the energy consumption in MIC method (kJ/kg water removal), PMW is the microwave power (W), tMW is the sample drying time using microwave and mMW is the amount of moisture removal using MIC method (kg).

Finally, the energy consumption of the combined microwave-convective hot air dryer (EHA-MW) was calculated using the following equation [25]:

where EHA is the energy consumption of CHA dryer (kJ/kg water removal), and EMW is the energy consumption of MIC dryer (kJ/kg water removal).

2.3 Mathematical model development

In this study a coupled heat and mass transfer model was developed. To simplify the model, the following hypotheses were considered:

-

1.

Heat and mass transfer took place in three dimensions.

-

2.

Shrinkage or deformation was ignored during the drying process (the material was considered uniform).

-

3.

It was assumed that during the process, moisture is released from inside the product to the ambient air.

-

4.

The properties of the solid were considered dependent on the temperature and humidity.

2.3.1 Governing equations

The air velocity profile during drying was calculated using the continuity equations and Navier-Stokes as follows [26]:

where ρ is the air density (kg/m3), \(\overrightarrow{u}\) is the air velocity vector (m/s), t is time (s), ∇ is the Nabla operator, p is the air pressure (Pa), µ is the dynamic viscosity of air (Pa.s), T is the air temperature (K) and F is Boussinesq approximation which considered as a volume force term (F). It should be noted that in relation (16), because of constant density of drying air, the value of F is considered zero.

The heat and mass transfer equilibrium were solved based on the Fick’s equation and the Fourier’s law according to the following equations [27]:

and

where c is the moisture content (mol/m3), t is time (s), Deff is the effective moisture diffusion coefficient (m2/s), T is temperature (K), ρ is the potato density (kg/m3), Cp is the specific heat of potato (J/kg.K), k is the thermal conductivity of potato (W/m.K), and P is the microwave energy absorption inside the food sample (W/m3). To calculate P, Lambert’s law and Maxwell equations are well-established relations. Maxwell’s equations for thin solids seem precise [28]. Maxwell’s equations are computationally more complicated to use (especially in multi-physical processes such as food drying). In comparison, the application of Lambert’s law is relatively easy and as the sample was quite thick, Lambert’s law was used to calculate the microwave energy absorption inside the food sample [29].

To calculate p, α (microwave attenuation constant, 1/m) must be calculated either. For this purpose, the loss tangent was first calculated using the dielectric properties of the dry solid (dielectric constant ε’ and dielectric loss factor ε’’) as follows [30]:

where P0 is the microwave initial power (W), λ is the wavelength (m), and d is the depth of penetration (m). Finally, the value obtained for P was divided by the volume of the product to be in W/m3.

2.3.2 Initial and boundary conditions

The initial and boundary conditions for the momentum transfer process were defined as follows:

where \(\overrightarrow{u}\) is the air velocity vector (m/s), and p is the air pressure (atm). The boundary condition for the dryer inlet and outlet was velocity and pressure, respectively. Slip boundary condition was also used for dryer’s walls and No-slip boundary (\(\overrightarrow{u}\) = 0) for potato surface [26].

The initial and boundary conditions for the heat transfer process were defined as follows: The temperature at the beginning of the process is uniform. Convection is also considered at the solid surface [27].

where \({h}_{m}\times \phi \times {\rho }_{\infty }\times (X-{X}_{e})\) shows evaporative cooling, h represents convective heat transfer coefficient (W/m2.°C), T∞ drying air temperature (°C), T temperature (°C), \({h}_{m}\)convective mass transfer coefficient (m/s), ϕ latent heat of vaporization (J/kg), ρ∞ air density (kg/m3), X humidity ratio calculated by software (dimensionless), and Xe equilibrium humidity ratio (dimensionless). Similarly, the initial and boundary conditions for mass transfer were defined as follows: at the beginning of the process, the moisture content was uniform, and it was also assumed that the flow at the solid surface was convective.

where \({C}_{0}\) is the amount of moisture at the beginning of the process (mol/m3), and ca is the amount of moisture in the air (mol/m3) which was calculated by multiplying the equilibrium humidity by the density of air divided by the molecular weight of water [27].

2.3.3 Thermophysical properties

Density (kg/m3), specific heat capacity (J/kg.K) and thermal conductivity of potato (W/m.K) was calculated using the following equations based on the chemical composition [31]:

where xj is the mass fraction, and xvj is the volume fraction. It should be noted that in the simulation, these three parameters are dependent on the changes in temperature, moisture and chemical composition of potato. The effect of temperature on thermal conductivity, density and specific heat was calculated using the Fricke and Becker [32] equations [33] (Table 1).

2.3.4 Heat and mass transfer coefficients

h, Convective heat transfer coefficient (W/m2.K), was calculated using following equation:

where Nu is the Nusselt number k∞ is the thermal conductivity of air (W/m.K), and d is the potato samples half-thickness (m). The Nusselt number (Nu) was obtained using the following equation, which is related to Reynolds (Re) and Prandtl number (Pr) [35]:

Re and Pr was calculated based on Incropera and Dewitt equations [35].

where µ∞ is the drying air viscosity (Pa.s), V∞ is the air speed (m/s), and k∞ is the thermal conductivity of air (W/m.K).

Convective mass transfer coefficient (m/s), hm, was calculated based on Bejan equation as follows:

where \({\propto }_{\infty }\) is the air penetration or thermal diffusion coefficient (m2/s), and D∞ is the water diffusion coefficient in air (m2/s). The value of D∞ for different temperatures was calculated using the following equation [34]:

where T is the air temperature (K) and P is the air pressure (Pa).

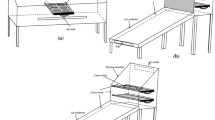

2.3.5 Model implementation

Modeling was performed with COMSOL Multiphysics software (version 5.5, Sweden). Heat transfer in solid, transport of diluted species and laminar flow physics were applied. Normal element size was considered for meshing (Fig. 2). Also, coupling of heat and mass transfer by considering thermophysical properties (density, specific heat, and thermal conductivity) was performed as a function of moisture content, chemical composition, and temperature [21]. To validate the model, mass transfer was performed directly based on measuring the moisture content of the samples and comparing the experimental data with the simulation data and validation of heat transfer modeling was done directly and indirectly, based on the thermal image processing during the process and mass transfer modeling, respectively [31]. The parameters used for modeling are given in Table 2.

2.4 Statistical analysis

This study was performed by statistical analysis of data obtained from experiments in three replications in a completely randomized design using IBM SPSS Statistics software (APSS Inc., version 22, USA). Also, to compare the results of modeling with experimental experiments, Excel software (Microsoft, version 2013, USA) was used. On the other hand, the evaluation of the optimal drying method was performed using Design Expert software (Stat-Ease, Inc., version 11, USA).

3 Results and discussion

3.1 Finding optimum method for potato cubes drying

3.1.1 Moisture ratio

Figure 3a shows the changes in moisture ratio for different drying methods. In all methods, the moisture ratio decreases continuously over the time. The lowest drying speed among the studied methods was related to CHA; because of the lower amount of transferred heat to the product in CHA method in comparison with MIC and CHA-MIC methods, which causes the slower removal of moisture and as a result, the drying time increases. The highest moisture removal rate was observed in CHA-MIC and MIC methods, respectively; in these methods, due to the internal (volumetric) heat generation, which causes faster transfer of moisture from the centre to the surface, the drying speed of the samples is high and as a result, moisture reaches to its lowest point in a very short time. In general, the microwave plays the biggest role in drying in these methods. The result of this research in agreement with the results of Alibas [36], Ozbek and Dadali [37], Contreras et al. [8], Taghinezhad and Rasouli Sharabiani [38] shows the positive effect of microwave on reducing the drying time.

3.1.2 Effective moisture diffusion coefficient

According to the results of Table 3, the effective moisture diffusion coefficient (Deff) of all drying methods has statistically significant differences (P < 0.05(. Figure 3c shows the lowest Deff in CHA method; since there is a direct relationship between Deff and temperature, in addition to the lower power of CHA method for moisture removal in comparison with MIC and CHA-MIC methods. This result was consistent with the result of Pavon-Melendez et al. [39]. In MIC and CHA-MIC methods, a significant increase in the effective moisture diffusion coefficient was observed; because the microwave creates an internal vapor pressure and creates a more porous structure and permeability to steam, and ultimately increases Deff due to the rapid heating of potato samples. These results are in agreement with the results of Horuz et al. [40] related to the drying kinetics of apricot in a microwave‑convective hot air hybrid oven, Khakbaz Heshmati and Seifi Moghadam [41] related to the drying of kiwi slices and Wang et al. [42] Which was related to the drying of apple pomace.

3.1.3 Energy consumption

In Table 4, the differences between final amount of energy consumption in all drying methods of this study were statistically significant) P < 0.05). According to Fig. 3b, the highest energy consumption is related to CHA method. Because in this method, all of the hot air energy is not completely used for drying and a considerable amount of it, is wasted by the output current. Also, the lowest energy consumption is related to the microwave method; because in this method, due to the microwaves absorption of the product moisture and the vibration of water molecules, heat is generated in the entire texture of the product. Thus, the problems related to the product thermal conductivity were reduced in comparison with CHA method and the drying time was reduced. Therefore, the shorter the process time, the lower the energy consumption. On the other hand, in the simultaneous CHA-MIC method, most of the energy consumption is related to the hot air part. In fact, the presence of convective hot air causes a significant amount of energy to be wasted through the outlet valves. In result, the energy consumption of CHA-MIC method is higher than MIC method. These results were consistent with the results of Mierzwa and Pawłowski [19] and Hazervazife et al. [43] which was related to the optimization of energy consumption in the process of drying apple using microwaves.

3.1.4 Optimal method

Based on the maximum (water reabsorption, volume, brightness, and yellowness), the minimum (shrinkage, bulk density, energy consumption and overall color changes) and within the range (moisture and redness ratio) values of potato samples in Design Expert software (Version 11, USA), the CHA-MIC method was chosen as the optimal method for drying of potato cubes (with a desirability of 0.778). In addition, the lowest desirability value was related to CHA method (Fig. 3d).

3.2 Modeling of heat and mass transfer and air velocity

3.2.1 Moisture distribution profile

According to the Fig. 4, the results of numerical modeling of moisture removal using CHA-MIC method were compared with the experimental data and it was found that the theoretical data were highly in agreement with experimental data (correlation coefficient 0.9589); it means the mathematical model has been had a good prediction of drying kinetics of potato samples. Figure 5 shows the moisture distribution ratio of potato cube during drying time using CHA-MIC method. About 10 min (600 s) after beginning of the drying process, the product surface completely loses its moisture and reaches equilibrium moisture, also the moisture of the product centre shows a descending trend due to the microwave volumetric heating. After 50 min (3000 s) of the drying process, removal of moisture was reduced because of the slight moisture difference between the inner and outer layers. Finally, after 70 min (4200 s) of the processing time, the moisture of the inner layers also reached the desired equilibrium moisture. These results were consistent with the results of Zhou et al. [44], Pitchai et al. [45] and Salvi et al. [46].

3.2.2 Temperature distribution profile

According to application of microwaves, the temperature of potato cube is high and the generated heat is distributed from centre to the surface of the product (Fig. 6). In the first 10 min (600 s) of the drying process, the temperature of the inner parts of the potato cube reaches 46 °C due to internal heating, while the temperature of the outer parts of the potato cube is approximately in the range of 44 °C. Finally, after 50 min (3000 s) of the process time, the temperature of the outer layers of the product reaches the range of 54–57 °C and the temperature of the inner layers reaches 58–60 °C, which remains constant at this temperature until the end of the process. Figure 7a shows the experimental and theoretical temperature changes during different drying times and Fig. 7b the comparison of the experimental and theoretical temperature of the potato cube. According to the part “a” of Fig. 7, the temperature is 22 °C at the beginning of the process and it takes 20 min (1200 s) to reach 52 °C (52.462 °C); then the temperature remains approximately close to 59.896 °C until the end of the process at 70 min (4200 s). In other words, temperature stability is established in the potato cube and the surface and centre temperature of the sample are equal to each other. Figure 7 part “b” shows a high correlation between the results of experimental and modeling data (R2 = 0.9961). Figure 8 shows the temperature changes of potato cubes during drying process using CHA-MIC method (taken by a thermal camera). According to different parts of Fig. 8, the samples temperature is about 22 °C at the beginning of the process and after 30 min (1800 s), the temperature increases to 53 °C. Then from 30 min (1800 s) until the end of the process (70 min or 4200 s), the temperature approximately remains in the range of 61–64 °C. Therefore, it can be concluded in this study that the results of temperature simulation and thermal camera are in total agreement. These results were consistent with the research of Zhou et al. [44], Pitchai et al. [45] and Salvi et al. [46]. Figure 9 shows the isothermal regions in the potato cube during the time zero to 70 min (4200 s) of drying process using CHA-MIC method. As can be seen at different parts of Fig. 9, the temperature of the potato cube corners is lower than the other parts of this geometry at all times. In confirmation of the modeling results, in the thermal photographs taken by the infrared camera (Fig. 8), it is also observed that the temperature of the corners is lower than the temperature of the centre of the potato cubes. Pu and Sun [47] compared the moisture uniformity of mango sheets in different shapes (oval, rectangular, square, and triangle) dried with microwave-vacuum, using near-Infrared (NIR) imaging, and concluded that moisture distribution in the oval shape is better than angular shapes such as rectangles and squares. In addition, removal of moisture from the corners of these shapes is slower due to lower temperatures in the corners.

3.2.3 Air velocity distribution profile

According to part “a” and “b” of Fig. 10, the air velocity of the potato inside is zero. While the lowest value of the air velocity is observed near the surface of the potato cube, which is due to the exchange of heat and mass from the surface of the product. By moving from the surface of the potato cube to the upper layers of the dryer container, one can see the highest air speed (1 m/s) in these sections.

3.2.4 Mass fraction changes

Figure 11 shows the changes in mass fraction of potato compounds (water, protein, carbohydrates, fat, ash and fibre) with respect to time change (modeling results). Consider to the results, by decreasing the mass fraction of water (from 0.892 to 0.160), the ratio of other components in the total solid matter increases (carbohydrates from 0.082 to 0.634, protein from 0.017 to 0.135, fat from 0.00007 to 0.0005, ash from 0.006 to 0.048 and fibre from 0.0028 to 0.022). The modeling results shows a good agreement with the experimental results of the mass fractions of the potato constituents (Fig. 11).

3.2.5 Thermophysical properties changes

Figure 12a shows the changes of the total density (kg/m3) and the density of the potato constituents (predicted by the Seri model) with respect to the changes of the water mass fraction, time, and temperature. Considering part “a”, decreasing the mass fraction of water (from 0.892 to 0.160) due to the increasing of temperature (from 22 to 60 °C) during the drying process (0 to 70 min), would decrease all potato constituents density slightly, because the density of the fractions is only influenced by temperature. However, the total density influences by temperature and the mass fraction of the chemical compounds. In conclusion, the total density increases with increasing temperature and consequently increasing the evaporation rate and decreasing the mass fraction of water (due to the product volume reduction after moisture removal) and increasing other components that have a higher density than water (except fat) (from 1036.02 to 1417.11 kg/m3). Figure 12b shows the results of total specific heat (J/kg.K) and specific heat of potato constituents (predicted by the parallel model) relative to the changes of water mass fraction, time, and temperature. As can be seen, by decreasing the mass fraction of water (from 0.892 to 0.160) which occurs simultaneously with increasing the temperature (from 22 to 60 °C) during the drying process (0 to 70 min), the specific heat of all potato constituent compounds grows slightly, because the specific heat of the components is only affected by temperature. However, the total specific heat is affected by both the temperature and the mass fraction of the constituent compounds and decreases with increasing temperature and consequently increasing the evaporation rate and decreasing the mass fraction of water which leads to increase of other components that have less specific heat than water (from 3902.71 to 2098.56 J/kg.K). Figure 12c shows the results of the total thermal conductivity (W/m.K) and the thermal conductivity of potato constituents (predicted by the model presented by Franco et al. [31]) relative to changes in water volume fraction, time, and temperature. By reducing the water volume fraction (from 0.928 to 0.231) which occurs simultaneously with increasing the temperature (from 22 to 60 °C) during the drying process (0 to 70 min), the thermal conductivity of all the constituents of the potato increases slightly, because the thermal conductivity of the components is only affected by temperature. However, the total thermal conductivity is affected by both the temperature and the volume fraction of the constituent compounds and decreases with increasing temperature and consequently increasing the evaporation rate and decreasing the volume fraction of water and increasing other components that have less thermal conductivity than water (from 0.50 to 0.31 W/m.K).

In Fig. 13, the experimental and the predicted values by the model for the parameters of density, specific heat and thermal conductivity during potato drying process are compared. According to the results, there is a high correlation between data from experimental work and modelling.

4 Conclusions

A numerical model for momentum and heat and mass transfer process was continuously developed during the potato drying process using hot air-microwave method. Thus, the kinetic characteristics of the product (moisture ratio, effective diffusion coefficient of moisture and energy consumption) were investigated. Finally, a high correlation was obtained between the results of experimental work and numerical modeling for moisture and temperature distribution.

Notes

Proportional-Integral-Derivative.

References

Zehlender GW, Powerlson ML, Jonsson RK, Roman KV (1994) Advanced in potato pest biology and management. American Phytopathological Society (APS), St Paul, Minnestoa

Pedreschi F (2012) Frying of potatoes: physical, chemical, and microstructural changes. Dry Technol 30(7):707–725

Wang R, Zhang M, Mujumdar AS (2010) Effect of osmotic dehydration on microwave freeze-drying characteristics and quality of potato chips. Dry Technol 28:798–806

Mohd Hanim AB, Chin NL, Yusof YA (2014) Physico-chemical and flowability characteristics of a new variety of Malaysian sweet potato, Vit A to Flour. Food Res Int 21:2099–2107

Sabarez HT (2015) Modeling Food Processing Operations. In: Bakalis S, Knoerzer K, Fryer P (eds) Chap. 4. Woodhead Publishing, Sawston, pp 95–123

Zhao D, An K, Ding S, Liu L, Xu Z, Wang Z (2014) Two-stage intermittent microwave coupled with hot-air drying of carrot slices: drying kinetics and physical quality. Food Bioprocess Technol 7:2308–2318

Orikasa T, Wu L, Shiina T, Tagawa A (2008) Drying characteristics of kiwifruit during hot air drying. J Food Eng 85:303–308

Contreras C, Martın-Esparza ME, Chiralt A, Martınez-Navarrete N (2012) Influence of microwave application on convective drying: Effects on drying kinetics, and optical and mechanical properties of apple and strawberry. J Food Eng 88:55–64

Mertens B, Knorr D (1992) Developments of nonthermal processes for food preservation. J Food Sci Technol 46:124–133

Wray D, Ramaswamy HS (2015) Novel concepts in microwave drying of foods. Dry Technol 33:769–783

Bilbao-Sáinz C, Andrés A, Chiralt A, Fito P (2006) Microwaves phenomena during drying of apple cylinders. J Food Eng 74:160–167

Koné KY, Druon C, Gnimpieba EZ, Delmotte M, Duquenoy A, Laguerre JC (2013) Power density control in microwave assisted air drying to improve quality of food. J Food Eng 119:750–757

Aghilinategh N, Rafiee S, Gholikhani A, Hosseinpur S, Omid M, Mohtasebi SS, Maleki N (2015) A comparative study of dried apple using hot air, intermittent and continuous microwave: evaluation of kinetic parameters and physicochemical quality attributes. Food Sci Nutr 3:519–526

Esturk O (2010) Intermittent and continuous microwave-convective air-drying characteristics of sage (Salvia officinalis) leaves. Food Bioprocess Technol 5:1664–1673

Izli N, Isik E (2015) Color and microstructure properties of tomatoes dried by microwave, convective, and microwave-convective methods. Int J Food Prop 18:241–249

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 44:71–78

Chen Y, Song Ch, Li Zh, Chen H, Jin G (2019) Effects of hot air and combined microwave and hot air drying on the quality attributes of celery stalk slices. J Food Process Preserv 44:14310. https://doi.org/10.1111/jfpp.14310

Talens C, Castro-Giraldez M, Fito P (2018) Effect of microwave power coupled with hot air drying on sorption isotherms and microstructure of orange peel. Food Bioprocess Technol 11:723–734

Mierzwa D, Pawłowski A (2017) Convective drying of potatoes assisted by microwave and infrared radiation–process kinetics and quality aspects. J Food Nutr Res 56:351–361

AOAC (2003) Official method of analysis of Association of Analytical Chemists, 17th edn. Association of Official Analysis Chemists, Virginia

Dehghannya J, Pourahmad M, Ghanbarzadeh B, Ghaffari H (2019) Heat and mass transfer enhancement during foam-mat drying process of limejuice: Impact of convective hot air temperature. Int J Therm Sci 135:30–43

Sharma G, Prasad S (2004) Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J Food Eng 65:609–617

Dehghannya J, Seyed–Tabatabaei SR, Khakbaz Heshmati M, Ghanbarzadeh B (2021) Influence of three stage ultrasound-intermittent microwave-hot air drying of carrot on physical properties and energy consumption. Heat Mass Transf. https://doi.org/10.1007/s00231-021-03074-1

Kassem AS, Shokr AZ, El-Mahdy AR, Aboukarima AM, Hamed EY (2011) Comparison of drying characteristics of Thompson seedless grapes using combined microwave oven and hot air drying. J Saudi Soc Agri Sci 10:33–40

Dehghannya J, Farshad P, Khakbaz Heshmati M (2018) Three-stage hybrid osmotic–intermittent microwave–convective drying of apple at low temperature and short time. Dry Technol 36:1982–2005

Naghavi E, Dehghannya J, Ghanbarzadeh B (2018) 3D computational simulation for the prediction of coupled momentum, heat and mass transfer during deep fat frying of potato strips coated with different concentrations of alginate. J Food Eng 235:64–78

Onwude DI, Hashim N, Abdan Kh, Janius R, Chen G, Kumar Ch (2018) Modelling of coupled heat and mass transfer for combined infrared and hot-air drying of sweet potato. J Food Eng 228:12–24

Liu Ch, Wang Q, Sakai N (2005) Power and temperature distribution during microwave thawing, simulated by using Maxwell’s equations and Lambert’s law. Int J Food Sci Technol 40:9–21

Imran Khan MD, Welsh Z, Gu Y, Karim MA, Bhandari B (2020) Modelling of simultaneous heat and mass transfer considering the spatial distribution of air velocity during intermittent microwave convective drying. In J Heat Mass Transfer 153:119668. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119668

Nelson SO, Trabelsi S (2011) Sensing grain and seed moisture and density from dielectric properties. Int J Agric Biol Eng 4:1–7

Franco TS, Perussello CA, Ellendersen LDSN, Masson ML (2015) Foam mat drying of yacon juice: Experimental analysis and computer simulation. J Food Eng 158:48–57

Fricke BA, Becker BR (2011) Evaluation of thermophysical property models for foods. Hvac&R Res 7:311–330

Valentas K, Rotstein E, Paul Singh R (1997) Handbook of food engineering practice. Chemical Rubber Company (CRC), Boca Raton, Florida

Marrero TR, Mason EA (1972) Gaseous diffusion coefficients. J Phys Chem 1:3–118

Perussello CA, Kumar Ch, Castilhos FD, Karim MA (2014) Heat and mass transfer modeling of the osmo-convective drying of yacon roots (Smallanthus sonchifolius). Appl Therm Eng 64:23–32

Alibas I (2007) Microwave, air and combined microwave–air-drying parameters pumpkin slice. J Food Sci Technol 8:1445–1451

Ozbek B, Dadali G (2007) Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. J Food Eng 4:541–549

Taghinezhad E, Rasouli Sharabiani V (2017) The effect of combination dryer of hot airw–infrared and microwave on some quality properties of parboiled rice. Innov Food Technol 5:25–38

Pavon-Melendez G, Hernandez JA, Salgado MA, Garcıa MA (2005) Dimensionless analysis of the simultaneous heat and mass transfer in food drying. J Food Eng 51:347–353

Horuz E, Bozkurt H, Karataş H, Maskan M (2017) Drying kinetics of apricot halves in a microwave–hot air hybrid oven. Heat Mass Transfer 53:2117–2127

Khakbaz Heshmati M, Seifi Moghadam A (2017) Application of intermittent microwave – convective hot air technique on quality and nutritional characteristics of dried kiwi slices. J Food Res (In Persian) 27:111–126

Wang Z, Sun J, Chen F, Liao X, Hu X (2007) Mathematical modelling on thin layer microwave drying of apple pomace with and without hot air pre-drying. J Food Eng 80:536–544

Hazervazife A, Nikbakht AM, Ahmadi Moghaddam P (2013) Optimizing energy consumption in the apple drying process using microwaves. Mech Sci Agri Machin (In Persian) 1:9–26

Zhou J, Yang X, Zhu H, Yuan J, Huang K (2018) Microwave drying process of corns based on double-porous model. Dry Technol 37:92–104

Pitchai K, Chen J, Birla S, Gonzalez R, Jones D, Subbiah J (2014) A microwave heat transfer model for a rotating multi-component meal in a domestic oven: Development and validation. J Food Eng 128:60–71

Salvi D, Boldor D, Aita GM, Sabliov CM (2011) COMSOL Multiphysics model for continuous flow microwave heating of liquids. J Food Eng 104:422–429

Pu YY, Sun DW (2016) Prediction of moisture content uniformity of microwave-vacuum dried mangoes as affected by different shapes using NIR hyperspectral imaging. Innov Food Sci Emerg Technol 3:348–356

Su T, Zhang W, Zhang ZH, Wang X, Zhang SH (2022) Energy utilization and heating uniformity of multiple specimens heated in a domestic microwave oven. Food Bioprod Process 132:35–51

Sinha A, Bhargav A (2022) A simplified modelling approach for predicting shrinkage and sensitive material properties during low temperature air drying of porous food materials. J Food Eng 317:110732

Abbas IA, Abdalla AEN, Alzahrani FS, Spagnuolo M (2016) Wave propagation in a generalized thermoelastic plate using eigenvalue approach. J Therm Stresses 39(11):1367–1377

Abbas IA (2014) A GN model based upon two-temperature generalized thermoelastic theory in an unbounded medium with a spherical cavity. Appl Math Comput 245:108–115

Acknowledgements

The present study was conducted in the form of a research project at the University of Tabriz. I would like to express my gratitude to the esteemed supervisors and consultants who guided me in this project.

Funding

This work was supported by University of Tabriz.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heshmati, M.K., Khiavi, H.D., Dehghannya, J. et al. 3D simulation of momentum, heat and mass transfer in potato cubes during intermittent microwave-convective hot air drying. Heat Mass Transfer 59, 239–254 (2023). https://doi.org/10.1007/s00231-022-03256-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03256-5