Abstract

The purpose of this study was to experimentally investigate the thermal performance and operating characteristics of various heat pipe working fluids in evacuated tube solar collectors. Heat pipe efficiency was evaluated by calculating the solar collector efficiency value when using four types of working fluids: water, ethanol, flutec-pp9 and methyl acetate under the same operating conditions on an indoor experiment apparatus. The experimental conditions were as follows: The inclination angle of the evacuated tube solar collectors were 20°, 40° and 60° from the normal basis. The mass flow rate into the manifold of the evacuated tubular solar collector was 0.3 kg/min. The heat flux on the collector surface was 870 W/m2. The results showed that, at an angle of incidence of 40°, the values of \({\text{F}}_{\text{R}} \left( {\tau \alpha } \right)\) and \({\text{F}}_{\text{R}} {\text{U}}_{\text{L}}\) with methyl acetate as the working fluid were 0.6572 and −2.0086, respectively, with water they were 0.6636 and −1.8457, respectively, ethanol they were 0.6147 and −0.6353, respectively, and with flutec-pp9 they were 0.525, and −3.2313, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Among solar heat-collection technologies, the evacuated tube solar collector (“ETSC”) uses vacuum technology that drastically reduces convective heat loss from the absorption surface. In addition, through use of a heat pipe, which is a highly efficient exchanger able to rapidly transfer heat and show a thermal response even at relatively low temperature differences, an ETSC works stably within mid-range temperatures and exhibits high heat collection efficiency. The heat pipe applied to the ETSC may be variously classified by the container material [1, 8], the type of working fluid [2, 3], the type of capillary structure [4], the liquid return method [5], the internal geometry, the operating temperature and the charge volume [6]; receding studies, studied have examined the performance impact on the heat pipe through variation of these features (Table 1).

The working fluid selected for the heat pipe should be compatible with the container material. Considering the working fluid’s melting point, boiling point and critical, the operating temperature should be below the working fluid’s and above its melting point. Table 2 lists the boiling point and melting point of typical low-temperature working fluids and the useful temperature range. To achieve more effective performance of the heat pipe, the merit number [7] of the working fluid should be considered. Sometimes, it is referred to as the heat pipe number. Generally, higher density, higher surface tension, higher evaporative latent heat, and lower viscosity of the heat pipe working fluid. The merit number is expressed as shown in Eq. (1). Figure 1 illustrates the merit number of the heat pipe calculated in the temperature function with respect to eleven typical working fluids used within the low temperature range upon considering varying properties.

Currently, commercialized ETSCs generally use water or ethanol for the working fluid of the heat pipe. As illustrated in Fig. 1, water, which is the most applied working fluid in heat pipe, has a higher merit number among various working fluids and its operating temperature range is 20–200 °C, which makes it the typical working fluid of the heat pipe. However, the possibility of water freezing during the winter is a concern. In contrast, while the operating temperature range of ethanol is −30 to 140 °C and it has a relatively low freezing problem, it generates non-condensable gas through a chemical reaction with copper if overheated beyond 200 °C, thereby degrading the performance of the heat pipe [8].

When designing a heat pipe for application in a solar collector, the stagnation temperature of the solar collector should be considered. In general, the stagnation temperature is known that it is approximately 180 °C for the flat plate solar collector and approximately 260 °C for an ETSC.

In this study, several working fluids were selected that can be used in the heat pipe of an ETSC and a study was performed on the dynamic characteristics and thermal performance of the ETSC according to such working fluids. In this study, water, ethanol, flutec-PP9 and methyl acetate were used for working fluids in the heat pipe for ETSC. Applying each working fluid of the heat pipe, four sets of ETSC were produced and the performance of each one was analyzed through experiments according to each working fluid in the heat pipe. The intended was to quantitatively analyze the effect of the heat pipe working fluid of the heat pipe on the ETSC and to collect data useful to solar collector design according to the type of heat pipe working fluid for ETSC.

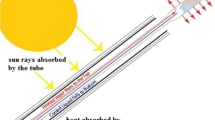

2 Evacuated tube solar collector (ETSC)

An ETSC is composed of a glass tube, an absorber plate and a heat pipe as illustrated in Fig. 2. Its elemental technology and the process of obtaining useful energy from the sun are as follows: The sunlight is irradiated on the absorber plate in the glass tube where the vacuum is maintained and the thermal energy absorbed is delivered to the heat pipe attached to the absorber plate. In the heat pipe, a phase change of the working fluid is induced by the delivered thermal energy. The working fluid steam vaporized from the heat pipe evaporator rises to the heat pipe condenser located at the top of the ETSC. The steam that has risen to the condenser exchanges heat with the solar thermal collector manifold. The heat is then delivered to the heat media that flows through the manifold. For the ETSC used in this experiment, a commercial solar collector was used, and its specifications are given in Table 2. To determine the performance variation of the solar collector according to each type of heat pipe working fluid, the same dimensions were applied to the exterior and heat collection area of the solar thermal collector, the length of the condenser, the diameter of the glass tube, and the same charge volume was applied to the working fluid of the heat pipe; the only variation was the type of working fluid applied. Table 2 is heat pipe working fluid properties used in this study.

2.1 ETSC experimental apparatus

In this study, to analyze the performance and dynamic characteristics of each solar thermal collector under the same experimental conditions, an indoor experimental apparatus was designed so as not to be affected by the external environment. It was tested to measure the performance of the ETSC according to the working fluid type of the heat pipe. The experimental apparatus was composed of an artificial heat flux, a bath circulator, an evacuated tube solar collector, manifolds, a flow meter, a dimmer and a wattmeter. Seven 300 W Philips halogen lamps were used for the heat flux to simulate solar energy. A 3 kW dimmer was used to control the intensity of the heat flux. An Eppley PSP (Precision Spectral Pyranometer) radiometer was used to measure the intensity of the heat flux within an accuracy of ±0.5 W/m2. In addition, since the performance of the ETSC naturally varies depending on its angle, a manual inclinator was mounted to control the angle. To supply heat media at the same temperature to each manifold, a bath circulator with an 800 W cooling capacity accurate to within ±0.05 °C was used. The Macnaught M05 PD(Positive Displacement) flowmeter with an accuracy of ±1% was used to measure the flow rate passing through the manifold. The manifold which exchanged heat from metal to metal with the condenser of the ETSC was made of 99.9% pure copper. The 4 wire-RTD was used to measure the temperature at the inlet and outlet of the manifold. The measured temperature had ±0.01 °C accuracy upon temperature compensation. Figures 3, 4 and 5 respectively illustrate the indoor experimental apparatus, for the ETSC, the manifolds used in this study, and schematic of the experimental apparatus.

Figure 6 illustrates the monitoring screen of the experimental apparatus for the ETSC. Measurements required for performance analysis of the ETSC (temperature, flow rate, intensity of the artificial heat flux, indoor temperature and power consumption) were displayed on the monitoring screen in real time. In addition, the monitoring screen was configured to graphically display the intensity of the artificial heat flux, the power consumption, the inlet and outlet temperatures of the manifold and the temperature of the heat pipe condenser in real time to verify the operating state of the solar thermal collector in real time.

2.2 Experiment method

To analyze the performance of the ETSC according to the type of heat pipe working fluid, four sets of solar collectors were tested under the same experimental conditions. For the conditions of the of the thermal performance experiment, the intensity of the artificial heat flux was maintained at 900 W/m2 (±50 W/m2) and the flow rate was maintained at 0.3LPM. With the manifold temperature kept constant (at 25, 40, 60 and 80 °C), the solar thermal collector performance was analyzed based on variation in the temperature difference between the manifold inlet and outlet. In addition, since the performance of the ETSCs that use a heat pipe naturally varies depending on inclination angle, the solar thermal collectors were tested at various inclination angles by 20°, 40° and 60°.

3 Results and considerations

In this study, several working fluids were selected for application in the heat pipe of the single evacuated tube solar collector and tested, and the dynamic characteristics and thermal performance of the solar thermal collector were analyzed for each working fluid. For performance analysis of the ETSC according to the type of heat pipe working fluid, four sets of ETSC with the same specifications other than the heat pipe working fluid were produced to conduct testing on the solar thermal collector performance. In addition, for performance analysis on each heat collector under identical testing conditions without effects from the external environment, an indoor experimental apparatus was designed and produced to analyze the performance and- dynamic characteristics of the ETSC.

3.1 Dynamic characteristics of ETSC according to type of working fluid

Figure 7 illustrates the dynamic characteristics of four sets of ETSCs used in this study. For measurement of the dynamic characteristics of the ETSC, measured was the time taken to reach the normal state from the moment the artificial heat flux (870 W/m2 ± 30) was applied to the solar thermal collector. The normal state refers to the variation of temperature difference between the manifold inlet and outlet being maintained under 0.05 °C. For the ETSC, the time taken to reach the normal state was closely related to the type of heat pipe working fluid. Less time taken indicates that the ETSC exchanging heat with the heat media in the manifold more stably.

Figure 7a illustrates the dynamic characteristics when water was used as the heat pipe working fluid. As shown in the figure, when water was used, the time taken to reach the normal state of the ETSC was 180 s, temperature difference between the manifold inlet and outlet at the normal state was 3.3 °C.

Figure 7b illustrates the dynamic characteristics of the solar thermal collector when ethanol was used as the heat pipe working under the same experimental conditions. For ethanol, the time taken to reach the normal state was 900 s, and the temperature difference between the manifold inlet and outlet was 3.03 °C.

Figure 7c illustrates the dynamic characteristics of the solar thermal collector when methyl acetate was used for the working fluid. For methyl acetate, the time taken in reaching the normal state of the solar thermal collector was 300 s. The temperature difference between the manifold inlet and outlet at the normal state was 3.19 °C.

Figure 7d illustrates the dynamic characteristics of the solar thermal collector when flutec-pp9 was used for the working fluid. For Flutec-pp9, the time taken to reach the normal state was 370 s, the temperature difference between the manifold inlet and outlet was 2.48 °C. Since the density of Flutec-pp9 is twice that of water and its boiling point is 155 °C, which is far higher than that of water, flutec-pp9 exhibited low performance in the low temperature range.

3.2 Thermal performance of ETSC according to heat pipe working fluid

The solar thermal collector efficiency is the ratio of the actual coefficient of heat transfer to the solar radiation over the entire absorption surface. The solar thermal collector efficiency is calculated from dependent variables composed of the fluid temperature at the entrance of the solar thermal collector, the ambient temperature and the solar radiation. In this study, an indoor experimental apparatus not affected by the external environment was used to analyze the performance of the ETSCs. The actual useful energy gain from the heat flux through the ETSC, \({\text{Q}}_{\text{u}}\), is expressed in Eq. (2) [8, 9].

In Eq. (2), \({\text{A}}_{\text{c}}\) is the collector area, \({\text{U}}_{\text{L}}\) is the overall heat transfer coefficient and S is the value of the incidental heat flux from which the optical loss is deducted [8, 9].

If Eq. (2) is defined as \({\text{F}}_{\text{R}}\), the ratio of the actual coefficient of heat transfer to the maximum possible coefficient of heat transfer, it can be expressed as Eq. (3) [8, 9]

According to Eqs. (2) and (3), the actual coefficient of heat transfer is \({\text{F}}_{\text{R}}\) multiplied by \({\text{Q}}_{\text{U}}\). Therefore, since the solar thermal collector efficiency is the ratio of the actual coefficient of heat transfer to heat flux over the entire absorption surface, it can be expressed as Eq. (4).

In Eq. (4), the multiplication term of \({\text{F}}_{\text{R}}\) and \({\text{U}}_{\text{L}}\) is related to the heat loss of the solar thermal collector and \({\text{F}}_{\text{R}} \left( {\tau \alpha } \right)\) is the term related to the heat gain of the solar thermal collector. The solar thermal collector performance is determined by the momentary efficiency value associated with the heat flux, the external temperature, and the inflow temperature of the working fluid. Therefore, in this study, all of the measurements of the performance of the ETSC were measured from the normal state. Using Eq. (5) with the data acquired here, it is possible to calculate the efficiency of the ETSC.

The value calculated from Eq. (6) becomes that of Y axis value on the efficiency graph of the ETSC, and the X axis is calculated from Eq. (7).

When the two values above are plotted according to varying experimental conditions and linearly fitted, it is possible to make the polynomial expression in the form of \({\text{Y}} = {\text{b}} + {\text{mX}}\) as in Eq. (4), where, the gradient m is the loss term \(\left( {{\text{F}}_{\text{R}} {\text{U}}_{\text{L}} } \right)\) and the intercept b makes the acquisition term \({\text{F}}_{\text{R}} \left( {\tau \alpha } \right)\) [9]

Figure 8 illustrates the efficiency according to the type of heat pipe working fluid and inclination angle for the four ETSC used in this study. Among the four heat pipe working fluids used in this study, water provided the highest efficiency when applied to the ETSC. This is because water has the highest merit number among four working fluids. These findings coincide with those of previous studies on heat pipe working fluids for ETSCs. For the ETSC that used water as its heat pipe working fluid, the maximum efficiency of 67% and minimum efficiency 52.1% at the inclination angle of 60° as shown in Fig. 8. When ethanol was used for the heat pipe working fluid, the solar thermal collector showed maximum efficiency of 65.7% and minimum efficiency of 52.2% at the inclination angle of 60°. When methyl acetate was used for the heat pipe working fluid, the solar thermal collector showed the maximum efficiency of 65.7% and minimum efficiency of 49.2% at the inclination angle of 60°. For the solar thermal collector that used flutec-pp9, the solar thermal collector showed maximum efficiency of 60.4% at the inclination angle of 60°, but unlike the solar thermal collectors using the other three types of working fluid, the collector showed minimum efficiency 24.7% at the inclination angle of 20°. For flutec-pp9, since its density is approximately twice that of water, it appeared that the inclination angle of the solar thermal collector significantly affected its efficiency. In this study, since a thermosiphon type heat pipe which is driven by gravity, was used for the heat pipe of the ETSC, it appeared that the inclination angle of the solar thermal collector significantly affected its efficiency [7].

Figure 8 illustrates the efficiency according to the type of heat pipe working fluid and inclination angle for the four ETSC used in this study. Among the four heat pipe working fluids used in this study, water provided the highest efficiency when applied to the ETSC. This is because water has the highest merit number among four working fluids. These findings coincide with those of previous studies on heat pipe working fluids for ETSCs. For the ETSC that used water as its heat pipe working fluid, the maximum efficiency of 67% and minimum efficiency 52.1% at the inclination angle of 60° as shown in Fig. 8. When ethanol was used for the heat pipe working fluid, the solar thermal collector showed maximum efficiency of 65.7% and minimum efficiency of 52.2% at the inclination angle of 60°. When methyl acetate was used for the heat pipe working fluid, the solar thermal collector showed the maximum efficiency of 65.7% and minimum efficiency of 49.2% at the inclination angle of 60°. For the solar thermal collector that used flutec-pp9, the solar thermal collector showed maximum efficiency of 60.4% at the inclination angle of 60°, but unlike the solar thermal collectors using the other three types of working fluid, the collector showed minimum efficiency 24.7% at the inclination angle of 20°. For flutec-pp9, since its density is approximately twice that of water, it appeared that the inclination angle of the solar thermal collector significantly affected its efficiency. In this study, since a thermosiphon type heat pipe which is driven by gravity, was used for the heat pipe of the ETSC, it appeared that the inclination angle of the solar thermal collector significantly affected its efficiency [7].

Figure 9 illustrates solar thermal collector efficiency curves according to the type of heat pipe working fluid at inclination angles of the solar thermal collector of 20°, 40° and 60°. As the figure shows, water appeared to have the highest solar thermal collector efficiency among the heat pipe working used in this study. This is because water has the highest merit number among the four working fluids. For the ETSC that used water for the heat pipe working fluid, it was found that the \(F_{R} \left( {\tau \alpha } \right)\) value was 0.6636 and the \(F_{R} U_{L}\) value was −1.8475 the inclination angle of 40°.

For the ETSC that used ethanol for the heat pipe working fluid, while relatively low efficiency was shown in the low range, the efficiency reduction was low at a high temperature, and the \(F_{R} U_{L}\) value, the solar thermal collector heat loss term, was −0.6365 (at an inclination angle 40°), which appeared to be the lowest among the heat pipe working fluids. For the ETSC that used ethanol for the heat pipe working fluid, it was analyzed that the \(F_{R} \left( {\tau \alpha } \right)\) value was 0.6147 at inclination angle of 40° lower than that of water, and its boiling point is 57 °C. In addition, it does not generate non-condensible gas by chemical reaction with copper even at 200 °C or higher, and it is known to be a substance that is harmless to the human body. It appeared that the solar thermal collector that used methyl acetate for the heat pipe working fluid had higher efficiency than the solar thermal collector that used ethanol and it was found that it had a tendency to be similar to water. However, it was found that while the solar thermal collector that used methyl acetate had higher efficiency in the low range than the solar thermal collector that used ethanol, it had a slightly lower efficiency in the high range. Therefore, it was found that the inclination value of the solar thermal collector was relatively higher than those of ethanol and water. For the ETSC that used methyl acetate, the \(F_{R} \left( {\tau \alpha } \right)\) value was 0.6572 and the \({\text{F}}_{\text{R}} {\text{U}}_{\text{L}}\) value was −2.0086 at an inclination angle of 40°.

For the ETSC that used flutec-PP9 for the heat pipe working fluid, since the density, boiling point, and viscosity of flutec-pp9 are hig, as mentioned previously, it appeared that the lower the inclination angle, the less fluent the phase change process in which the evaporated gas in the heat pipe is condensed and returns to the evaporator. Therefore, it was found to have exhibited the most intense variation in solar thermal collector efficiency according to the inclination angle. For the ETSC that used flutec-pp9, the \(F_{R} \left( {\tau \alpha } \right)\) value was 0.525 and the \(F_{R} U_{L}\) value was −3.2313 at the inclination angle of 40°. Table 3 summarizes \(F_{R} \left( {\tau \alpha } \right)\) and \(F_{R} U_{L}\) values according to the four types of heat pipe working fluids and inclination angles of the solar thermal collector.

4 Conclusions

In this study, a test of the thermal performance of solar thermal collectors was performed according to the heat pipe working fluid for the ETSC. To do so, ETSCs using four different types (water, ethanol, flutec-pp9 and methyl acetate) of heat pipe working fluids, ETSC were produced. To compare the performance of each ETSC under the identical testing conditions, an indoor experimental apparatus was designed and produced so that the experiment would not be affected by the external environment. The apparatus was used to perform the test of thermal performance of the solar thermal collectors and conclusions were derived as follows:

-

1.

Among four types of heat pipe working fluids used in the ETSCs, water provided the fastest response performance and the highest solar thermal collector performance.

-

2.

At the inclination angle of 40° for the solar thermal collector, for the ETSC using water as its heat pipe working fluid had an \({\text{F}}_{\text{R}} \left( {\tau \alpha } \right)\) value of 0.6636 and \({\text{F}}_{\text{R}} {\text{U}}_{\text{L}}\) value of −1.8457, the ETSC that used ethanol had, an \({\text{F}}_{\text{R}} \left( {\tau \alpha } \right)\) value of 0.6147 and the \({\text{F}}_{\text{R}} {\text{U}}_{\text{L}}\) value of −0.6365, the ETSC that used methyl acetate had an \({\text{F}}_{\text{R}} \left( {\tau \alpha } \right)\) value of 0.6572 and \({\text{F}}_{\text{R}} {\text{U}}_{\text{L}}\) value of −2.0086, and the ETSC that used flutec-pp9 had, an \({\text{F}}_{\text{R}} \left( {\tau \alpha } \right)\) value of 0.525 and \({\text{F}}_{\text{R}} {\text{U}}_{\text{L}}\) value of −3.2313.

-

3.

Since methyl acetate does not generate non-condensible gas by chemical reaction with copper, and it has a wide operating temperature range, it appeared that the ETSC that used it for the heat pipe working worked somewhat stably.

-

4.

For the ETSC that used flutec-pp9 for the heat pipe working, the solar collector efficiency was greatly affected by the inclination angle of the solar thermal collector, because its density, boiling point and viscosity of flutec-pp9 are high.

Abbreviations

- A c :

-

Collector area (m2)

- C p :

-

Specific heat (J/kg °C)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- Q u :

-

Useful energy gain (W)

- \(\tau \alpha\) :

-

Transmittance–absorptance product

- F R :

-

Heat removal factor

- U L :

-

Overall heat transfer coefficient (W/m2 °C)

- G T :

-

Irradiation on a collector surface (W/m2)

- \(\eta\) :

-

Solar collector efficiency (−)

- T :

-

Temperature (°C)

- T ap :

-

Absorber plate temperature (°C)

- T a :

-

Ambient temperature (°C)

- T i :

-

Inlet temperature (°C)

- T o :

-

Outlet temperature (°C)

- M :

-

Merit number (kW/m2)

- \(\rho_{l}\) :

-

Density of the liquid (kg/m3)

- \(\sigma_{l}\) :

-

Surface tension (N/m × 102)

- \(\mu_{l}\) :

-

Viscosity of the liquid (cP)

- \(L\) :

-

Enthalpy of vaporization (kJ/kg)

References

Zhao J, Rao Z, Liu C, Li Y (2016) Experimental investigation on thermal performance of phase change material coupled with closed-loop oscillating heat pipe (PCM/CLOHP) used in thermal management. Appl Therm Eng 93:90–100

Arab M, Abbas A (2014) A model-based approach for analysis of working fluids in heat pipes. Appl Therm Eng 73:751–763

Chun WG, Kang YH, Kwak HY, Lee YS (1999) An experimental study of the utilization of heat pipes for solar water heaters. Appl Therm Eng 19:807–817

Wu SC, Huang CJ, Chen SH, Chen YM (2013) Manufacturing and testing of the double-layer wick structure in a loop heat pipe. Int J Heat Mass Transf 56:709–714

Lu X, Wei JJ (2014) Experimental study on a novel loop heat pipe with both flat evaporator and boiling pool. Int J Heat Mass Transf 79:54–63

Kim HJ, Lee SH, Kong YC, Jang SP, Choi JH, Koo J (2015) Long-term reliability of the thermal performance of a flat-plate heat pipe using a prognostics method. Int J Heat Mass Transf 82:369–372

Dunn PD, Reay DA (1982) Heat pipes, 3rd edn. Pergamon Press, Oxford, pp 23–137

Tiwari GN (2002) Solar energy, fundamentals, design, modelling and applications. Narosa Publishing House, New Delhi, pp 150–168

Duffie JA, Beckman WA (2013) Solar engineering of thermal processes, 4th edn. Wiley, Newark, pp 236–370

Acknowledgements

This research was supported by a Grant (Code 15IFIP-B065893-03) from the Industrial Facilities & Infrastructure Research Program funded by the Ministry of Land, Infrastructure and Transport of the Korean government.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joo, HJ., Kwak, HY. Experimental analysis of thermal performance according to heat pipe working fluids for evacuated tube solar collector. Heat Mass Transfer 53, 3267–3275 (2017). https://doi.org/10.1007/s00231-017-2029-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2029-0