Abstract

Discoloration and browning are caused primarily by various reactions, including Maillard condensation of hexoses and amino components, phenol polymerization and pigment destruction. Convective drying can be combined with various pretreatments to help reduce undesired color changes and improve color parameters of dried products. In this study, effects of ultrasound-assisted osmotic dehydration as a pretreatment before convective drying on color parameters of Mirabelle plum were investigated. Variations of L* (lightness), a* (redness/greenness), b* (yellowness/blueness), total color change (ΔE), chroma, hue angle and browning index values were presented versus drying time during convective drying of control and pretreated Mirabelle plums as influenced by ultrasonication time, osmotic solution concentration and immersion time in osmotic solution. Samples pretreated with ultrasound for 30 min and osmotic solution concentration of 70% had a more desirable color among all other pretreated samples, with the closest L*, a* and b* values to the fresh one, showing that ultrasound and osmotic dehydration are beneficial to the color of final products after drying.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Plums are known to be an excellent source of vitamin A, calcium, magnesium, iron, potassium and fiber. Like other fruits, they have high contents of vitamin C and carbohydrates but a low content of fats and calories. Findings of many studies indicate that due to the existence of their polyphenolic components (coumaric, chlorogenic and neochlorogenic acids, flavonoids and anthocyanins), plums have high antioxidant activity. In addition to contributing towards the color and sensory characteristics, these compounds exhibit a wide variety of physiological properties including antioxidant, anticancer, antimicrobial, antiallergenic, antimutagenic, anti-inflammatory and antithrombotic properties. Furthermore, their use is found to be effective in prevention of both cancer and cardiovascular diseases, a fact which further emphasizes the importance of their study [1].

Drying processes of fruits and vegetables generally provide a lot of advantages such as extended shelf-life; however, some undesirable chemical or physical changes like color loss or browning may also occur simultaneously. Undesirable changes in food color may lead to a decrease in consumers’ acceptance and market value. Discoloration and browning are caused primarily by various reactions, including Maillard condensation of hexoses and amino components, phenol polymerization and pigment destruction [2]. High temperatures or long drying times in conventional air drying may cause serious damage to quality attributes of the dried product such as color. Therefore, there is a close relationship between color changes of fruits and vegetables and pigment nutrients (e.g., carotenoids, flavonoids and phenols) of dried products.

Flavonoids constitute the largest group of plant phenolics, accounting for over half of the eight thousand naturally occurring phenolic compounds. Flavonoids also partly provide plant colors present in fruits such as Mirabelle plums. Besides this antioxidant property, some flavonoids, such as myricetin and quercetin, show the interesting ability to inhibit the ascorbate oxidase, preventing the enzymatic oxidation of ascorbic acid present in plums. Functionality of foodstuffs depends on phenolic compounds’ content, intake and bioavailability. The bioavailability of these compounds can also be affected by differences in cell wall structures, location of glycosides in cells and binding of phenolic compounds within the food matrix, which are directly related to fruit drying conditions [3]. Therefore, it is important to develop or apply processing conditions not to extensively damage color in foods.

Pretreatments of some agricultural foods prior to drying help reduce undesired color changes. Color characteristics of food samples normally differ according to drying and pretreatment methods used. Osmotic dehydration has received considerable attention due to its low energy and temperature requirements compared to other dehydration methods. Other benefits of osmotic dehydration include effective inhibition of polyphenoloxidase (PPO), prevention of loss of volatile compounds, and minimized heat damage to color and flavor during dehydration [4]. Osmotic dehydration with sugar solutions results in minimized color changes. Generally, when an osmotically dehydrated fruit is subjected to a drying process, color as a quality characteristic changes depending on the drying conditions [5]. Regarding low mass transfer rate during osmotic treatment, ultrasound can be used to improve mass transfer rate and dehydration time [6]. Ultrasonic waves can bring about a very rapid series of alternative compressions and expansions, similar to what a sponge does when it is squeezed and released repeatedly. Forces involved in this mechanical mechanism create microscopic channels that may ease moisture removal. In addition, ultrasound produces cavitation, which can be beneficial for removal of the moisture that is strongly attached to the solid [6–9].

Color measurements of food materials can be used as an indirect way to determine changes in quality, since these measurements are simpler and faster than chemical analysis. Hunter color parameters (L*a*b*) have previously proved valuable in describing visual color deterioration and providing useful information for quality control in fruits and vegetables [10]. The L*a*b* model is an international standard for color measurement developed by the Commission Internationale d’Eclairage (CIE) in 1976. The L*a*b* color consists of a luminance or lightness component (L* value, ranging from 0 to 100), along with two chromatic components (ranging from −120 to +120): the a* component (from green to red) and the b* component (from blue to yellow). The L*a*b* color is device independent, providing consistent color regardless of the input or output devices such as digital camera, scanner, monitor or printer. The L*a*b* values are often used in food research studies [11]. There are other parameters derived from the Hunter L, a, and b scale: total color change (ΔE), chroma—which indicates color saturation and is proportional to its intensity—and hue angle—which is frequently used to specify color in food products. An angle of 0° or 360° represents red hue, while angles of 90°, 180°, and 270° indicate yellow, green, and blue hues, respectively. Browning index (BI) represents the purity of brown color and is reported as an important parameter in drying processes where enzymatic and non-enzymatic browning take place [10]. Several researchers have studied the color of food instrumentally by using a colorimeter [5, 10, 12, 13]. Compared with results determined by a colorimeter, image analysis allows quantifying not only color but also morphometric and densitometry characteristics of the images (volume, surface, superficial texture, thickness of the piece). This method is useful when, during a process, the product undergoes a modification of its geometry or appearance such as contraction of the fruit during air drying. As for the measurement of color, the lack of homogeneity in the appearance of the portions of fruit represents an obstacle for the application of the classical method based on the instruments of reflectance. On the contrary, image analysis represents an efficient methodology capable of measuring average chromatic parameters, also in non-homogenous surfaces. Through simple programs, such as Adobe Photoshop, it is possible to measure the color of digitalized images by expressing the results in the usual chromatic coordinates “L,” “a” and “b”. In practice, color heterogeneity has been observed in portions of osmo-dehydrated plums dried by air [14]. This was reflected by the standard deviations among the replicates for values of L*, a* and b* evaluated from colorimeter. But when image analysis was used, deviations were not significant; hence, it was concluded that when appearance is not homogenous, it is advisable to use image analysis to evaluate color. Rodriguez et al. [14] demonstrated that for heterogeneous samples like fruits, analysis through imaging provided a better reproducibility of the color data and was more appropriate when characterizing the samples’ appearance [1].

Although abundant literature exists on the application of osmotic dehydration and convective hot-air drying of plums, no information is available on the influence of ultrasound-assisted osmotic dehydration pretreatment on color change of hot-air-dried Mirabelle plums. Therefore, the aim of this study was to investigate the effect of ultrasound-assisted osmotic dehydration pretreatment (sonication time, concentration of osmotic solution and immersion time in the osmotic solution) on Hunter color parameters (L*, a* and b*), total color change (ΔE); chroma, hue angle and browning index (BI) of Mirabelle plum during convective drying through image analysis.

2 Materials and methods

2.1 Preparation of dried samples

Mirabelle plums (Prunus domestica subsp. syriaca) were purchased from a local garden. The average initial moisture content of the plums was 4.54 g water/g dry matter. Moisture content was gravimetrically measured through drying samples in an oven at 105 °C. Pretreatments were structured in combinations of two ultrasonication times (both at 40 kHz): 10 and 30 min; two osmotic solution concentrations: 50 and 70% sucrose in water (% w/w) and four immersion times in osmotic solution: 60, 120, 180 and 240 min (Table 1). Ultrasonic pretreatments were carried out using an ultrasonic bath (AS ONE Corporation, US-4R, Japan). Water temperature inside the ultrasonic bath was maintained constant at 25 °C. Osmotic pretreatment was also performed at ambient temperature (25 ± 1 °C). The average weight of the samples for each experiment was 0.378 kg (18 plums). Pretreated samples were then placed in Petri dishes in a single-layer arrangement and were dried in a pilot plant convective drier (UOP 8 Tray dryer, Armfield, UK). Air at 25 °C and 40% relative humidity was heated to 80 °C before entering the dryer chamber. Cross-flow air moved from side to side of the dryer at 1.4 m/s, flowing parallel to the drying surface of the samples. Drying process continued until an average moisture content of 0.57 g water/g dry matter was obtained. All the operating conditions in the dryer including air velocity, temperature and relative humidity were monitoring during all the experiments. Unusual non-homogeneity in terms of these operating conditions was not observed during drying. It should also be noted that the primary objective of this study was to find not absolute but relative values of color parameters that allow the comparison among different pretreatments. Results of this study were obtained under the same circumstances in terms of both material and procedure. Stepwise detailed experimental procedures are provided elsewhere [6].

2.2 Determination of color

Yam and Papadakis’ methodology [11] was used for determination of color via image analysis. Based on this method, a high-resolution photographic camera (Proline, PR565S, UK) was used to measure color by capturing the color image of a plum sample under proper lighting. The lighting system consisted of two Commission Internationale d’Eclairage (CIE) source D65 lamps (standard daylight illuminant), mounted on the two sides of a white frame with a trapezoidal cross section, on either side of the plum sample, 30 cm above it and at an angle of 45° to the food sample plane. The camera was held securely on a tripod and the lens faced downwards towards the plum sample. The distance from the bottom of the camera lens to the food sample plane was 30 cm. After zooming the lens (so that the plum covered the whole field of view) and focusing, the picture was taken and saved as TIFF files.

Color attributes of samples in each image (L, a and b) were measured by means of a specific feature (Histogram panel) of the Adobe Photoshop (Adobe Systems Incorporated, San Jose, CA) [1, 11]. This feature allows detailed determination of color distributions of individual samples along the x-axis and y-axis. The Histogram panel displays the statistics (mean, standard deviation, median, percentage, and so on) of the color value, namely, L, a, and b. Hence, the average color of a plum sample was obtained easily using the Histogram panel. The L, a, and b in the Histogram panel are not standard color values. However, they can be converted to L*, a*, b* values using these formulas [11]:

Total color change (ΔE) (Eq. 4), chroma (Eq. 5), hue angle (Eq. 6) and browning index (Eq. 7) were calculated from the L*, a* and b* scales and were used to describe total color change during drying:

where

where \({\text{L}}_{0}^{*} ,{\text{a}}_{0}^{*} \;{\text{and}}\;{\text{b}}_{0}^{*}\) are initial color measurements of raw Mirabelle plums and \({\text{L}}_{\text{t}}^{*} ,{\text{ a}}_{\text{t}}^{*} \;{\text{and}}\;{\text{b}}_{\text{t}}^{*}\) are color measurements at pre-specified time.

2.3 Determination of water loss and solid gain

Water loss, WL (g water/g) and solid gain, SG (g solid/g) were used to evaluate the performance of various pretreatments based on the initial fruit weight basis [15]:

where w is the fruit mass (g), M is the fruit moisture content on a w.b. (g water/g), i is the initial fresh samples before pretreatment, and f is the final treated samples after pretreatment.

2.4 Experimental design

A 2 × 2 × 4 factorial experiment in a randomized complete design with two replicates was executed using SAS 9.4 Software (SAS Institute Inc., Cary, NC, USA). Independent variables were ultrasonication time at two levels: 10 and 30 min; osmotic solution concentration at two levels: 50 and 70% (w/w); and immersion time in osmotic solution at four levels: 60, 120, 180 and 240 min. Duncan’s multiple range test was employed to compare means within pretreatments in terms of color response at 95% confidence level (p < 0.05).

3 Results and discussion

Fresh plums presented the following values of \({\text{L}}_{0}^{*} = 44.52 \pm 1.66\), \({\text{a}}_{0}^{*} = - 5.90 \pm 0.32\) and \({\text{b}}_{0}^{*} = 55.13 \pm 1.10\), \(\Delta {\text{E}} = 0\), \({\text{chroma}} = 55.44 \pm 1.13\), \({\text{hue}}\;{\text{angle}} = 83.90 \pm 0.21\) and \({\text{browning}}\;{\text{index}} = 351.99 \pm 19.55\). Initial values of color parameters suggest a fruit with a relatively light yellow color. Results of changes in L* (lightness), a* (redness/greenness), b* (yellowness/blueness), total color change (ΔE), chroma, hue angle and browning index (BI) values after drying caused by different ultrasound-assisted osmotic dehydration pretreatments in comparison with control sample are displayed in Table 2. Compared to control sample, all color parameters were significantly (p < 0.05) decreased or increased (Table 2). Values of L* ranged between 17.57 and 27.93; parameter a* varied in the range of 0.38–5.01 and parameter b* between 19.98 and 32.53. At first sight, it could be concluded that, compared with fresh fruit, redness of dried plums increased after drying while their yellowness decreased. As expected, luminosity showed a significant decrease during drying since color became darker once the fruit was dehydrated. Decrease in L* value during this period reflects darkening of the plums along with loss of yellowness (decrease in b* value) and greenness (increase in a* value) [12]. In the presence of heat, the change in color initially involves the degradation of thermo-labile pigments; this, in turn, results in formation of dark compounds and a reduction in luminosity. In later stages, thermo-stable pigments become important to color change [5].

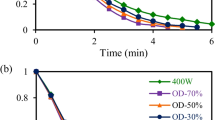

Variations of L* (Fig. 1a), a* (Fig. 1b), b* (Fig. 1c), ΔE (Fig. 1d), chroma (Fig. 1e), hue angle (Fig. 1f) and browning index (Fig. 1g) values are presented versus drying time during convective drying of control and pretreated Mirabelle plum samples as influenced by ultrasonication time, osmotic solution concentration and immersion time in osmotic solution. L*, b*, chroma and hue angle values of all samples decreased continuously with the drying time. The significant reduction in L*, b*, chroma and hue angle values of dried samples can be explained by the Maillard reaction, non-enzymatic browning reactions, caramelization and oxidation of ascorbic acid, all of which normally occur during drying treatments. Decrease in values of these color parameters, as a result of drying treatments, can also be strongly related to degradation and isomerization of carotenoids and other pigments [5, 10, 12, 16].

Variations of L* (a), a* (b), b* (c), total color change (ΔE) (d), chroma (e), hue angle (f) and browning index (BI) (g) values versus drying time in different samples (Table 1) at 60 min immersion time in osmotic solution

By comparing all pretreated and control samples, it was found that the lowest L*, b*, chroma and hue angle values were observed in the control sample (Fig. 1; Table 2). Results showed that L*, b*, chroma and hue angle values of the pretreated samples were generally increased significantly (p < 0.05) by increasing ultrasonication time from 10 to 30 min at different immersion times (60, 120, 180 and 240 min) in osmotic solutions (Table 2). At constant ultrasonication time, L*, b*, chroma and hue angle values of pretreated samples were also increased by increasing osmotic solution concentration from 50 to 70% at different immersion times in osmotic solutions. L* and b* increases were generally found to be statistically insignificant (p > 0.05) at ultrasonication time of 10 min but significant (p < 0.05) at ultrasonication time of 30 min; however, chroma and hue angle increases were generally found to be statistically insignificant (p > 0.05). On the other hand, at constant ultrasonication time and osmotic solution concentration, increasing immersion time from 60 to 240 min generally increased L*, b*, chroma and hue angle values; however, generally, these increases were not statistically significant (p > 0.05) (Data not shown).

Samples pretreated with ultrasound for 30 min and osmotic solution concentration of 70% at different immersion times in osmotic solutions (U30-B70-T60, U30-B70-T120, U30-B70-T180 and U30-B70-T240) had more desirable color among all other pretreated samples, with the closest L*, a* and b* values to the fresh one (Table 2) showing that ultrasound and osmotic dehydration are beneficial to the color of final products after drying. This was because due to short drying time and the solid gain (Table 3) which can drive off the gas in food tissue, osmotically treated samples had less discoloration caused by enzymatic browning [17]. During osmotic dehydration, plasmolysis is accompanied by a loss in the turgor pressure, pectin solublization and solid gain in the cells [18]. Generally, the more the osmotic solution concentration, the more the water loss of the sample (Table 3) and consequently, the less the drying time [19]. Through analyzing different convective drying curves, Dehghannya et al. [6], demonstrated that application of ultrasound-assisted osmotic dehydration pretreatment can lead to a significant increase in effective moisture diffusivity (from 5.84 × 10−9 to 7.36 × 10−9 m2/s) resulting in a 20% decrease in drying time of Mirabelle plums. Higher concentration of osmotic agents creates greater osmotic pressure and increases water loss [20]. The beneficial effect of soaking fruits in sugar solution on retarding enzymatic browning reaction is well known. Water loss and the consequently increased concentration of pigments during osmotic dehydration could also influence the color of dried Mirabelle plums [5]. Moreover, the hue angle of the U30-B70 pretreated samples was very close to the yellowish zone (near 90°) (Table 2), which was similar to the hue angles of fresh (83.90°) samples. This may reflect the reduction in trans–cis isomerisation of b-carotene during drying of osmotically dehydrated Mirabelle plums at higher concentrations of osmotic solution. Similar results were reported by Nimmanpipug et al. [5]. In addition, Dehghannya et al. [6] showed that application of ultrasound pretreatment can lead to a significant increase in effective moisture diffusivity resulting in a significant decrease in drying time, and thus preserving heat labile nutrients such as pigments. Ultrasonic waves created microscopic channels in the fruit; water could use these microscopic channels as an easier pathway to diffuse toward the surface of the fruit [7–9]. Due to faster drying time, L*, b*, chroma and hue angle values of the ultrasound-pretreated samples were significantly (p < 0.05) higher than those of the control sample. Similar results have been reported by Tiwari et al. [21] and Nimmanpipug et al. [5]. Tiwari et al. [21] investigated the effect of ultrasound processing on anthocyanins and color of red grape juice. Authors found a high degree of anthocyanin retention during sonication and concluded that sonication can be employed as a preservation technique for processing of food products where a high retention of pigments is desired.

On the other hand, results indicated that a* and ΔE values of all samples increased continuously with the drying time. Reduction in moisture content and consequent increase in soluble solids concentration lead to color variation [22]. The drastic increase in a* value implies a redder chroma, and this increase can be attributed to the formation of Maillard reaction products. The Maillard reaction products that are brown in color are known to be the result of the formation of various pigments such as melanoidins [12]. The fact that fruits include high levels of fructose and glucose, as reducing sugars, and amino acids implies that a Maillard reaction may occur during drying as a result of the interaction of these compounds [12, 16].

By comparing all pretreated and control samples, it was generally found that a* and ΔE values were significantly higher in the control (Fig. 1; Table 2). Results showed that a* and ΔE values of the pretreated samples were generally decreased significantly (p < 0.05) by increasing ultrasonication time from 10 to 30 min at different immersion times (60, 120, 180 and 240 min) in osmotic solutions (Table 2). At constant ultrasonication time, a* and ΔE values of the pretreated samples were also decreased by increasing osmotic solution concentration from 50 to 70% at different immersion times in osmotic solutions; however, these decreases were generally found to be statistically insignificant (p > 0.05) at ultrasonication time of 10 min but significant (p < 0.05) at ultrasonication time of 30 min. On the other hand, at constant ultrasonication time and osmotic solution concentration, increasing immersion time from 60 to 240 min generally decreased a* and ΔE values; however, generally, these decreases were not statistically significant (p > 0.05) (Data not shown).

Many researches regarded ΔE = 2 as the threshold of visual discrimination [13]. Color changes are invisible when ΔE ranges from 0 to 2, but evident and visible when ΔE > 2. According to Table 2, ΔE of all samples valued higher than 2, indicating great visible color difference in samples before and after drying. However, total color change of the control sample was significantly (p < 0.05) higher than that of pretreated samples. The decrease in total color change (ΔE) in the osmotically pretreated samples, previous to air drying, can be attributed to the solute absorption during the pretreatment because the solute absorption decreases the activity of enzyme phenolase and, hence, enzymatic browning is reduced during air drying [1]. Conversely, Falade et al. [4] reported an increase in ΔE by increasing the osmotic solution concentration for osmo-oven dried watermelons. Falade and Adelakun [23] also noted that ΔE of apple during drying generally increased with increasing sucrose solution concentration from 44 to 60%. However, this parameter was reduced through increasing concentration of glucose solution from 44 to 60%. These changes in ΔE were explained by the state of the bound water and solute mobility in the dried product [23]. In addition, changes in quality parameters are dependent on the nature of the fruits and on process conditions [22].

It is known that drying commonly causes non-enzymatic browning reactions, resulting in a reduction in lightness and consequently an increase in browning index during drying [5]. Bal et al. [10] also noted a significant increase in browning index, which was attributed to Maillard reaction. However, in this study, browning index did not show a defined behavior after drying. The same result was obtained by Rodriguez et al. [1] in the evaluation of the parameter b* after drying of plums. This behavior might be ascribed to destruction and/or formation of new pigments at different drying periods which can increase or decrease the browning index [12].

4 Conclusions

Results indicated that, generally, L*, b*, chroma and hue angle values of the pretreated Mirabelle plum samples were significantly (p < 0.05) increased by increasing ultrasonication time from 10 to 30 min and osmotic solution concentration from 50 to 70% at different immersion times (60, 120, 180 and 240 min) in osmotic solutions. However, a* and ΔE values of the pretreated samples were generally decreased significantly (p < 0.05) by increasing ultrasonication time and osmotic solution concentration at different immersion times. Samples pretreated with ultrasound for 30 min and osmotic solution concentration of 70% had more desirable color among all other pretreated samples, with the closest L*, a* and b* values to the fresh one. For practical commercial drying applications, therefore, ultrasound-assisted osmotic dehydration may be suggested. These results may also be of use to scientific knowledge concerning the effect of ultrasound-assisted osmotic dehydration before convective drying on color of Mirabelle plum because these findings suggest the efficiency of this method in improving the quality of prune production in terms of color parameters. Despite the fact that the application of ultrasound-assisted osmotic dehydration pretreatment can lead to a significant decrease in drying time, and thus results in a higher energy saving, further investigations regarding the total cost of the process are required.

References

Rodriguez MM, Rodriguez A, Mascheroni RH (2015) Color, texture, rehydration ability and phenolic compounds of plums partially osmodehydrated and finish-dried by hot air. J Food Process Preserv 39:2647–2662

Curcio S, Aversa M, Calabro V, Iorio G (2015) Modeling of microbial spoilage and color degradation occurring in convective drying of vegetables: a route to process optimization. J Food Process Eng 38:76–92

Rodriguez K, Ah-Hen K, Vega-Galvez A, Lopez J, Quispe-Fuentes I, Lemus-Mondaca R, Galvez-Ranilla L (2014) Changes in bioactive compounds and antioxidant activity during convective drying of murta (Ugni molinae T.) berries. Int J Food Sci Technol 49:990–1000

Falade KO, Igbeka JC, Ayanwuyi FA (2007) Kinetics of mass transfer, and colour changes during osmotic dehydration of watermelon. J Food Eng 80:979–985

Nimmanpipug N, Therdthai N, Dhamvithee P (2013) Characterisation of osmotically dehydrated papaya with further hot air drying and microwave vacuum drying. Int J Food Sci Technol 48:1193–1200

Dehghannya J, Gorbani R, Ghanbarzadeh B (2015) Effect of ultrasound-assisted osmotic dehydration pretreatment on drying kinetics and effective moisture diffusivity of Mirabelle plum. J Food Process Preserv 39:2710–2717

Dehghannya J, Gorbani R, Ghanbarzadeh B (2016) Shrinkage of Mirabelle plum during hot air drying as influenced by ultrasound-assisted osmotic dehydration. Int J Food Prop 19:1093–1103

Dehghannya J, Gorbani R, Ghanbarzadeh B (2016) Determination of bulk density of Mirabelle plum during hot air drying as influenced by ultrasound-osmotic pretreatment. J Food Meas Charact 10:738–745

Dehghannya J, Naghavi E-A, Ghanbarzadeh B (2016) Frying of potato strips pretreated by ultrasound-assisted air-drying. J Food Process Preserv 40:583–592

Bal LM, Kar A, Satya S, Naik SN (2011) Kinetics of colour change of bamboo shoot slices during microwave drying. Int J Food Sci Technol 46:827–833

Yam KL, Papadakis SE (2004) A simple digital imaging method for measuring and analyzing color of food surfaces. J Food Eng 61:137–142

Yemis O, Bakkalbas E, Artik N (2012) Changes in pigment profile and surface colour of fig (Ficus carica L.) during drying. Int J Food Sci Technol 47:1710–1719

Zheng J, Zhang F, Song J, Lin M, Kan J (2013) Effect of blanching and drying treatments on quality of bamboo shoot slices. Int J Food Sci Technol 49:531–540

Rodriguez MM, Arballo JR, Campanone LA, Cocconi MB, Pagano AM, Mascheroni RH (2013) Osmotic dehydration of nectarines: influence of the operating conditions and determination of the effective diffusion coefficients. Food Bioprocess Technol 6:2708–2720

Kek SP, Chin NL, Yusof YA (2013) Direct and indirect power ultrasound assisted pre-osmotic treatments in convective drying of guava slices. Food Bioprod Process 91:495–506

Corzo O, Alvarez C (2014) Color change kinetics of mango at different maturity stages during air drying. J Food Process Preserv 38:508–517

Akbarian M, Ghanbarzadeh B, Sowti M, Dehghannya J (2015) Effects of pectin-CMC-based coating and osmotic dehydration pretreatments on microstructure and texture of the hot-air dried quince slices. J Food Process Preserv 39:260–269

Zhao D, Zhao C, Tao H, An K, Ding S, Wang Z (2013) The effect of osmosis pretreatment on hot-air drying and microwave drying characteristics of chili (Capsicum annuum L.) flesh. Int J Food Sci Technol 48:1589–1595

Dehghannya J, Emam-Djomeh Z, Sotudeh-Gharebagh R, Ngadi M (2006) Osmotic dehydration of apple slices with carboxy-methyl cellulose coating. Dry Technol 24:45–50

Emam-Djomeh Z, Dehghannya J, Gharabagh RS (2006) Assessment of osmotic process in combination with coating on effective diffusivities during drying of apple slices. Dry Technol 24:1159–1164

Tiwari BK, Patras A, Brunton N, Cullen PJ, ODonnell CP (2010) Effect of ultrasound processing on anthocyanins and color of red grape juice. Ultrason Sonochem 17:598–604

Fante C, Correa J, Natividade M, Lima J, Lima L (2011) Drying of plums (Prunus sp, c.v Gulfblaze) treated with KCl in the field and subjected to pulsed vacuum osmotic dehydration. Int J Food Sci Technol 46:1080–1085

Falade KO, Adelakun TA (2007) Effect of pre-freezing and solutes on mass transfer during osmotic dehydration and colour of oven-dried African star apple during storage. Int J Food Sci Technol 42:394–402

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Dehghannya, J., Gorbani, R. & Ghanbarzadeh, B. Influence of combined pretreatments on color parameters during convective drying of Mirabelle plum (Prunus domestica subsp. syriaca). Heat Mass Transfer 53, 2425–2433 (2017). https://doi.org/10.1007/s00231-017-1995-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-1995-6