Abstract

This study proposes a new procedure for optimal design of shell and tube heat exchangers. The electromagnetism-like algorithm is applied to save on heat exchanger capital cost and designing a compact, high performance heat exchanger with effective use of the allowable pressure drop (cost of the pump). An optimization algorithm is then utilized to determine the optimal values of both geometric design parameters and maximum allowable pressure drop by pursuing the minimization of a total cost function. A computer code is developed for the optimal shell and tube heat exchangers. Different test cases are solved to demonstrate the effectiveness and ability of the proposed algorithm. Results are also compared with those obtained by other approaches available in the literature. The comparisons indicate that a proposed design procedure can be successfully applied in the optimal design of shell and tube heat exchangers. In particular, in the examined cases a reduction of total costs up to 30, 29, and 56.15 % compared with the original design and up to 18, 5.5 and 7.4 % compared with other approaches for case study 1, 2 and 3 respectively, are observed. In this work, economic optimization resulting from the proposed design procedure are relevant especially when the size/volume is critical for high performance and compact unit, moderate volume and cost are needed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

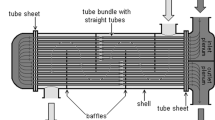

Heat exchangers are used for the effective heat transfer between two fluids (gas or liquid). Shell and tube heat exchangers are widely used in various industries, including HVAC, plants, power and process industries, and many others. This widespread use can be justified by their efficient, compact, and environment-friendly features. The traditional design of shell and tube heat exchangers involves rating a large number of exchanger geometries to identify those that satisfy a given heat duty and a set of geometric and operational constraints. This approach is time consuming and does not guarantee an optimal solution [1]. Given the widespread use of shell and tube heat exchangers, a considerable number of papers that employ various techniques have been devoted to the design optimization problem. For example, the exergetic analysis by [2] focuses on a device based on exergy transfer effectiveness, which is specifically defined for an isolated heat exchanger as a component. Gupta and Das [3] evaluated the exergetic behaviour of a cross-flow heat exchanger. San [4] used the second law analysis in recovering waste heat in heat exchangers. Eryener [5, 6] described in detail the thermoeconomic analysis and optimization of thermal systems. Caputo et al. [7, 8] proposed a genetic algorithm to minimize the total cost of the shell and tube heat exchanger. It was observed a reduction of total costs up to more than 50 % compared with original design. Patel and Rao [9] used a non-traditional optimization technique called particle swarm optimization (PSO) for the design optimization of shell and tube heat exchangers from an economic perspective. They considered the sum of the capital investment related to the heat transfer area and the energy-related costs related to overcoming friction losses in the fluid flow (pumping losses). An approach based on the genetic algorithm (GA), such as the artificial bee colony(ABC) [10] and biogeography-based optimization(BBO) [11, 12] algorithms, for the optimal design of shell and tube heat exchangers was studied by [7, 8, 13–19]. Azad and Amidpour [20] used the GA based on constructal theory to optimize the objective function, mathematical model for the cost of the shell, and tube heat exchanger. Sharma et al. [21] developed an excel-based multi-objective optimization (MOO) program on elitist non-dominated sorting GA and tested it against benchmark problems. The MOO program was applied in designing a falling film evaporator system that consists of a pre-heater, evaporator, vapor condenser, and steam jet ejector for milk concentration. Their results showed a reduction of up to 50 % or more of the total costs. In recent years, methods of optimization technique have been increasingly emphasized to reduce cost and shorten the length of time required for computation in data mining.

Caputo et al. [22] Carried out in a comparison between the actual installed heat exchangers, designed resorting to a leading commercial software tool, and the corresponding equipment configurations obtained by a genetic algorithm-based software tool, developed by the authors for optimal heat exchangers design. Results show that a lower weight was reached due to the reduction of shell diameter and length, as well as tube diameter. Weight reductions between 8 and 58 % were obtained over a wide range of equipment sizes. Hultmann et al. [23] proposed population-based metaheuristic algorithm, inspired from the animals’ behaviour. Results illustrate that multiobjective free search (FS) approach combined with differential evolution (MOFSDE) efficiently achieves two goals of multiobjective optimization problems: to find the solutions that converge to an approximated Pareto-front which is well spread, having the advantage of no parameter tuning apart from the population size and the number of generations.

Birbil and Fang [24] and Birbil et al. [25] proposed an electromagnetism (EM)-like algorithm to solve optimization problems in continuous space. The EM-like algorithm uses the attraction–repulsion mechanism of electromagnetism theory to ascertain the optimal solution. One of the most important and appealing characteristics of the EM-like algorithm is that it requires only a few parameters to be adjusted [26]. The solution obtained through this algorithm is not easily trapped in a local optimum. Jolai et al. [27]. demonstrated that implementing the EM-like algorithm in this problem significantly improves the results relative to those obtained using GA. The performance of the EM-like algorithm is compared with that of the proposed heuristic and GA. Some statistical tests are also conducted to determine the best performance of the GA and EM-like algorithm in terms of various parameters. Abed et al. [28] compared the EM-like algorithm and GA in solving inverse kinematics. They showed that the former needs a smaller population size and number of generations than the latter to obtain the true solution. The EM-like algorithm differs from GA and SA in terms of the exchange of materials between their population members. By contrast, the EM-like algorithm is similar to PSO and ACO in terms of the influence of all other particles in the population [29]. EM algorithm has been used for optimization problems in many practical applications for example; Golmohammdi and Ghodsi [30] developed an integrated EM-like algorithm for the CM scheduling problem. Lin and Sun [31] introduced an EM-like mechanism algorithm to improve the performance of the PSO algorithm. The EM-like algorithm is also used to identify the typical transfer function of thermal processes and the transfer function between primary air and bed temperature in a CFB boiler. Guan et al. [32] proposed a revised EM-like mechanism in manufacturing a system design that solves the layout design problem. Khalili and Tavakkoli-Moghaddam [33] developed a new multi-objective electromagnetism algorithm (MOEM) for a bi-objective flowshop scheduling problem. The motivation behind this algorithm has risen from the attraction–repulsion mechanism of electromagnetic theories. The EM-like algorithm has been applied in optimization in continuous space and in a small number of studies on discrete problems, but it is yet to be applied in the optimization of shell and tube heat exchangers.

The main objectives of this study are: (1) to optimize the effect of the geometrical parameters of SHEs and estimation of the minimum heat transfer area required for a given design configuration and (2) to demonstrate the effectiveness of the EM-like algorithm as a wrapper approach in the design optimization of shell and tube heat exchangers from an economic point of view. The ability of the EM-like technique is demonstrated using different case studies.

2 EM-like algorithm

The EM-like algorithm is a heuristic method proposed by Birbil and Fang [24] in 2003 for global optimization. This algorithm employs the attraction–repulsion mechanism of electromagnetism theory to determine the optimal solution. The EM-like algorithm can approximate the solution more quickly and accurately [34].

Abed et al. [35–37] and Birbil and Fang [24] presented the main phases of the EM-like algorithm as follows. First, the algorithm is initialized and the m points are randomly chosen from a feasible region, which is an n-dimensional space. Each dimension of a point is assumed to be uniformly distributed in the corresponding upper and lower bounds. A search for the local optimum is conducted after the initial solutions are determined. Any method of local optimization, such as hill-climbing [38, 39] or gradient-based methods, can be used in this stage. A random selection near the original solution is proposed in the primary algorithm. Finally, the total force exerted on each point is calculated. In this stage, the authors use the superposition principle of electromagnetism theory. The proportion of the charges of the points and the inverse proportion of the distance between the points are used to calculate the force exerted on the particle through other points [40]. For example, Fig. 1 shows that \(\overrightarrow {{F_{31} }}\) is the force exerted by q3 on q1, that is, q1 is repulsed by q3 if the value of the objective function of q1 is better than that of q3. \(\overrightarrow {{F_{21} }}\) is the force exerted by q2 on q1; that is, q1 is attracted by q2 if the objective function value of q1 is worse than that of q2. Consequently, the eventual force exerted on q1 is \(\overrightarrow {{F_{1} }} = \overrightarrow {{F_{21} }} + \overrightarrow {{F_{31} }}\).

Superposition principle [19]

The main procedures for the algorithm which used in this paper are:

-

1.

Initialization: An n-dimensional population with m points is randomly generated. Each dimension has an upper and lower bound [41]. The objective function of each sample is evaluated after the generation of the samples.

-

2.

Total Force Calculations: The first step in the force calculation is the calculation of the charge for each sample point. The charge calculation for each sample point are performed for each generation and it depends on objective function of the this point and the objective function for the best point as shown in Eq. (1) [42]:

$$q^{i} = \exp \left\{ { - n\frac{{f(q^{i} ) - f(q^{best} )}}{{\sum\nolimits_{k = 1}^{m} {\left[ {f(q^{k} ) - f(q^{best} )} \right]} }}} \right\},\quad \forall i$$(1)where \(f(q^{i} )\) is the objective function value of sample point, \(q^{i}\) and \(f(q^{best} )\) is objective function of current best solution. Observe that, no sign appeared on the charge of a sample point. In its place, the difference between the objectives functions of two points will decide the direction of the force between them, Hence,

$$F^{i} = \mathop \sum \limits_{j \ne i}^{m} \left\{ {\begin{array}{*{20}c} {\left( {q^{j} - q^{i} } \right)\frac{{q^{i} q^{j} }}{{q^{j} - q^{i2} }}\;\;if\;f\left( {q^{j} } \right) < f\left( {q^{i} } \right)\quad \left( {Attraction} \right)} \\ {\left( {q^{i} - q^{j} } \right)\frac{{q^{i} q^{j} }}{{q^{j} - q^{i2} }}\;\; if\;f\left( {q^{j} } \right) \ge f\left( {q^{i} } \right)\quad \left( {Repulsion} \right)} \\ \end{array} } \right\}$$(2)where \(F^{i}\) is the total force exerted on sample point \((q^{i} )\) according to Eq. (2), the point with better objective function attracts the other points. Even so, the point with worse objective function value will repel the others.

-

3.

The Movement along the Total Force: The last step after force calculation is to calculate the movement according to the force. So, the point will move in the direction of the force by random step length. The flow chart of electromagnetism-like algorithm which consists of three main parts is shown in Fig. 2.

3 Heat exchanger design procedure

3.1 Heat transfer

The heat transfer surface area through the mean logarithm temperature difference approach [43]:

and the log mean temperature difference [43],

For sensible heat transfer, the heat transfer rate is given by,

The overall heat transfer coefficient, U, under fouling conditions can be expressed as [43]:

The shell side heat transfer coefficient hs is instead computed resorting to Kern’s formulation referring to segmental baffled shell and tube exchangers [43].

The shell hydraulic diameter computed as [1, 44]:

where, the Prandtl number for shell side follows,

The Reynolds number for shell side, Re, is determined as follows:

Where \(\nu_{s}\) is flow velocity for the shell side and can obtained from [45],

In the above, as is the cross section area normal to flow direction and determined by,

And shell side clearance Cl is:

According to the flow regime, the tube side heat transfer coefficient (hi) is computed from following correlation, For laminar flow [46]

Where ft is the Darcy friction factor [47] given as,

Prt is the tube side Prandtl number, is given by:

\(\text{Re}_{t}\) is the tube side Reynolds number and given by,

Flow velocity for tube side is found by,

N t is the number of tubs which can be found approximately from the following equation [37].

where constants k1 and n1 cofficients that are taking values accroding to flow arrangement and number of passes [43].

3.2 Pressure drop

The effects of the fluid friction on the heat exchanger are equally important because they determine the pressure drop of the fluids flowing in the system and consequently the pumping power or fan work input necessary to maintain the flow. Adding pumps or fans increases the capital cost and becomes a major part of the operating cost of the exchanger. Thus, the final design and selection of a unit are therefore influenced by effectively using the permissible pressure drop and the cost of pump or fan power. The pressure drop along the side of the tube is calculated in [7, 48].

The shell side pressure drop is calculated as [7, 43].

where,

Considering pumping efficiency \((\eta )\), pumping power computed by [10, 43],

3.3 Objective function

The tube sheet patterns (triangle or square), pitch ratio, fouling resistances, and thermophysical properties of the fluids are accepted as the fixed parameters in optimizing the design of heat exchangers. The design specifications identify the heat duty of the heat exchanger and are given by the following parameters: the mass flow rate of the two fluids, inlet and outlet temperatures of the fluids in the shell and the tube, and energy balance. The optimization variables are the inner diameter of the shell (D s ), outer diameter of the tube (do), tube length (L), and baffle (B). Based on the actual values of the design specifications and fixed parameters and the current values of the optimization variables, the exchanger design routine determines the values of the heat transfer coefficients of the shell and tube, heat exchanger area, number of tubes, thickness of the tube, pitch, and flow velocities in the shell and tube. These factors define the constructive details of the exchanger and satisfy the assigned thermal duty specifications. Each time, the process changes the values of the design variables do, Ds, L, and B until the minimum objective function is found or a prescribed convergence criterion is met.

The objective function has been assumed as the total present cost C tot ,

The capital investment C i is computed as a function of the exchanger surface adopting Hall’s correlation [49], for heat exchanger made with stainless steel for both shells and tubes.

where a 1 = 8000, a 2 = 259.2, and a 3 = 0.91.

The total discounted operating cost related to pumping power to overcome friction losses is computed from the following equation,

4 Results and observation

The present study investigates the application of the EM-like algorithm in the design and economic optimization of shell and tube heat exchangers. This method follows the same concepts governing the PSO method [9], wherein the goal is to direct the particles in a population toward the most promising area of the search space. In the EM-like algorithm, the position changes based on the total force that affects the particles in the search space.

4.1 Model validation

The efficiency and validity of the suggested approach was assessed by analyzing some relevant case studies taken from the literature. The reliability of the obtained results was used (Table 1). The original values from Ref [45], and those of the optimization algorithm were used as input values. Three sample case studies were analysed:

-

Case 1: 4.34 (MW) duty, methanol–brackish water exchanger [41]

-

Case 2: 1.44 (MW) duty, kerosene–crude oil exchanger [50]

-

Case 3: 0.46 (MW) duty, distilled water–raw water exchanger [50]

The upper and lower bounds of the optimization variables are followed in the EM-like approach: the inner diameter of the shell (Ds) ranging between 0.1 and 1.5 m, the outer diameter of the tube (do) ranging between 0.015 and 0.051 m, and the baffle spacing (B) ranging from 0.05 m to 0.5 m. The values of the discounted operating costs are computed using the following equation: ny = 10 years, annual discount rate (i) = 10 %, energy cost (Ce) = 0.12 ₤/kW h, and an annual amount of work hours H = 7000 yr/h.

To obtain the optimal solution using the EM-like algorithm, the number of runs used to obtain the average is 50 times, the number of generation 30–100, and the population size 100. However, convergence always occurred within about 50 generations during the tests, as shown in Fig. 3.

4.2 Geometric design parameters analysis

The heat exchanger designs should contain all the necessary detailed information on flow rates of the streams; operating pressures; pressure drop limitations for both streams; temperature; size; length; and other design constraints such as, fluid type and flow arrangements to obtain the reliability, availability and manufacturability of surface that will meet the performance requirement at a minimum cost. Different case studies have been chosen in order to apply the proposed algorithm that will meet design requirements. Moreover, the new approach has been compared with four approaches to check the plausibility of the proposed algorithm.

4.2.1 Case study-1: (methanol–see water exchanger)

Case study- 1, taken from Sinnott [41]. The original design assumed the heat exchanger with two tube side passages and one shell side passage. The same structural design was studied in the other approaches.

Table 2 compares the results of the proposed algorithm for case study-1 with those of the original design solution and other approaches used in literature by the corresponding cited author.

The results show that a significant increase in the diameter of the tube reduces the flow velocity in the tube, which in turn reduces the heat transfer coefficient of the tube. An increase in the tube diameter increases the flow velocity in the shell, which in turn increases the heat transfer coefficient of the shell by 19.84 %. However, a low number of tubes and an increase in the inner diameter of the tube reduce the flow velocity in the tube, which in turn increases the pressure losses. Therefore, the annual pumping cost increases markedly (87.2 %).

It can be also seen from Table 2 the heat transfer surface area in the proposed algorithm reduced by about 78.5, 68.4, 55.8 and 47.3 % compared with the original design, GA, PSO, and BBO respectively. The overall surface area of the heat exchanger can usually be reduced if the heat transfer coefficient of the tube side is reduced. It is also shown that the reduction both the number of tubes and tube length reduce the size of the heat exchanger. Moreover, to meet the design pressure drop constraints may require a reduction in tube length. However, for efficient conditions of heat transfer is to have maximum number of tubes possible in the shell to maximise the turbulence, while long tube lengths with few tubes may give rise to shell side distribution problems. It can be observed that the reduction in tube length from the proposed algorithm about 2.8 times less than that of the original design and 1.25–2.25 times less than that of the other approaches. Therefore, a reduction in the heat exchanger area results in a decrease in the capital investment. Table 2 shows that the results obtained from the EM-like algorithm are better than those obtained in other studies.

4.2.2 Case study-2: (kerosene–crude oil exchanger)

This case study was taken from Kern [50]. The design parameters are assumed to solve this problem using the EM-like approach and are considered appropriate to the literature parameters with a square pitch pattern. Table 3 compares the results obtained by other approaches used in literature with those obtained by the present study for case study 2. It can be seen from Table 3 that the reduction in the heat transfer area about 43 % compared with the original design and 23, 10.5, 43.2, and 40.34 % compared with the GA, PSO, ABS, and BBO respectively. This reduction in the heat transfer area is due to significant decreases in the number of tubes compared with the other approaches. However, the low number of tubes enabled to increase the tube side flow velocity leading to a marked increase of pressure losses. The proposed algorithm has shown low heat exchange surface area with slightly increased in the pressure drop.

4.2.3 Case study-3: (distilled water–raw water exchanger)

The design parameters were taken from [50] to solve the present problem with the EM-like approach and are considered appropriate to the literature parameters with a triangular pitch pattern. Table 4 compares the results obtained by other approaches used in literature with the results obtained from the present study for case study 3. In this case study, the reduction in the heat transfer area about 17, 10.92, 2.52, and 4.414 % compared with the GA, PSO, ABS, and BBO respectively. It can be shown that the reduction in tube length from the proposed algorithm about 2.25 times less than that of the original design while the number of tubes about 1.6 times more than on the original design. Moreover, the other approaches have a shorter length of tubes and high number of tubes compared with the proposed algorithm. The area may be increased by increasing the length of the tube. However, the tube length requirement may be impractical for a given situation. Thus, the number of tubes should be increasing without increased the tube length. As mentioned above, the low number of tubes enabled to increase the tube side flow velocity, resulting in the higher heat transfer coefficient. However, increase the heat transfer coefficient is desirable, but at the expense of high- pressure drop and correspondingly higher pumping costs.

4.3 Cost estimation and optimization

The heat exchange surface area and the pressure drop play key role in the total cost of the heat exchangers. Therefore, savings in heat exchange capital cost should achieve by designing a compact unit with effective use of the acceptable pressure drop (cost of the pump) as they are influenced by the temperature distribution and provision of adequate area for heat transfer. Figure 4 compares the investment, operational, and total cost of all the case studies. A reduction in the investment cost is more important than a reduction in the operating cost. The optimization process of the mathematical model of the heat exchanger design based on the EM-like algorithm leads to a significant decrease in the heat transfer area. It is observed for case study -1 that the optimized shell and tube heat exchanger has a significant reduction of investment cost by about 35, 31.7, and 27.5 % compared with the original design, GA, PSO, and 24.5 % with ABS and BBO respectively, while the increasing in the total discounted operating cost of 47 % compared with the other approaches. This decrease is attributed to the increase in the total heat transfer coefficient and reduction in the number of tubes of the heat exchanger. For case study-2 the reduction in the capital investment of about 9.7, 4.88, 16.42, and 15.5 % compared with GA, PSO, ABS and BBO respectively, Conversely, a very high increase of flow velocities and pressure drops allowed to increase in the total discounted operating cost of 22, 2.7, 127, and 227 % respectively. This was caused by a significantly decreased the number of tubes as well as increases the tube diameter. It is also observed in case study-3, reductions in the capital investment up to 8 % compared with other approaches. However, the increase annual operating expenses and slightly increase the heat transfer area, leading to slightly reduction of the total cost which decreased by about 7.5 % with respect to the other approach.

Figure 5 also compares total cost and results obtained by other approaches used in literature for all the case studies. Overall, it is found that the marked reduction in the total cost of about 30, 29, and 56.15 % compared with the original design and up to 18, 5.5 and 7.4 % compared with other approach for case study 1, 2 and 3 respectively.

The selection criterion is that the size and the performance of heat exchanger must fulfilment the process requirement with minimum capital cost. As a result, the proposed algorithm is found more efficient and flexible for constructing optimal heat exchangers design.

4.4 Sensitivity analysis

For the sake of completeness, trials were also performed by parametrically changing the electricity cost in the total cost function to assess the sensitivity of the EM-like algorithm to variations in the economic parameters. The results shown in Table 5 demonstrate that the EM-like algorithm responds correctly by reducing the pressure losses when the energy price increases at the expense of an increase in the exchanger surface area, and the opposite when Ce decreases. In particular, when Ce increases by 50 %, Ci increases by 1 % and CoD by 27 %, but the total cost increases only by 7 %.

4.5 Economic optimization of heat exchangers

For selection of the most economical unit (high effectiveness, small volume and low cost), it is necessary to consider the effect of the special requirement of the unit on each of the component costs. For example, the same total heat transfer area may be put in a shell that is small diameter and relatively long, or in one that has a larger diameter and shorter length. The cost of a shell-often the largest single cost in the total exchanger cost—increases with the diameter. Figure 6 shows the trade-off between the shell diameter and the tube length with total cost. It can be seen that the total cost of the heat exchanger increases with increase the shell diameter. It is found that with the increases the shell diameter the length of the tubes will be reduced and the number of tubes will be increased.

In some applications the pressure drop is not the most critical aspect. It might be that the gain/benefit of the optimized performance is worthwhile even if a pressure drop penalty is needed. Figure 7 shows the trade-off between the heat transfer area and the pressure drop with energy prices. It can be seen that the heat transfer area of the heat exchanger increases rapidly with increase the energy price, while slightly losses in the pressure drop of the shell and tube with increases the energy price. It can be noticed how the economic scenario influences the resulting optimum design of the heat exchanger.

The important objective, is finding an optimum design that minimizes the yearly cost of the heat exchanger. In addition, in some practical applications, where the size/volume is critical for low cost and compact unit, moderate volume and cost are needed to consider for the specified requirements, and usually the importance between them are not equal for considerations.

Figure 8 illustrates the relationship between the optimal state, capital cost and power cost for optimum heat exchanger with variations of the velocity. In general, a higher flow velocity means a higher heat transfer coefficient, but lead to higher pressure drop and hence a higher pumping power and correspondingly a higher power cost [1, 51]. However, an attempt to limit fouling by acting on the flow velocity can also be pursued. An increase in stream velocity can be benefited from this point of view as the higher the fluid velocity, the lower the tendency to foul, even if an increase of pressure losses occurs [52].

Overall, setting a design value shell diameter, number, diameter and length of the tubes for determining a trade-off between heat exchanger size and capital investment, while setting a flow velocity impacts the trade-off between capital investment, and pumping costs.

5 Conclusions

This study optimized shell and tube heat exchangers using a new method called the EM-like algorithm. The presented technique is simple in concept, has few parameters, and can easily be implemented. These features enhance the applicability of the EM-like technique to finding an optimum design that minimizes the yearly cost of the heat exchanger. The results obtained from this study are compared with those obtained by other approaches used in literature and can be successfully applied in the optimization of shell and tube heat exchangers. Referring to the literature test cases, a significant reduction in the heat transfer area up to 68.4, 23 and 17 % compared with the other approach for case 1, 2 and 3 respectively. The total cost decreased in all sample case studies under similar operating conditions. Overall, thus saving wholly offset the higher capital investment, allowing a marked reduction in the total costs of about 30, 29, and 56.15 % compared with the original design and up to 18, 5.5 and 7.4 % compared with other approaches for case study 1, 2 and 3 respectively.

Abbreviations

- a1 :

-

Numerical constant

- a2 :

-

Numerical constant

- a3 :

-

Numerical constant

- as :

-

Cross section area normal to flow direction (m2)

- AS :

-

Heat transfer surface area (m2)

- B:

-

Baffles spacing (m)

- Cl :

-

Clearance (m)

- Cp :

-

Specific heat (kJ/kg K)

- Ci :

-

Capital investment (€)

- CE :

-

Energy cost (€/kW h)

- Co :

-

Annual operating cost (€/year)

- CoD :

-

Total discounted operating cost (€)

- Ctot :

-

Total annual cost (€)

- d:

-

Tube diameter (m)

- De :

-

Equivalent diameter (m)

- Ds :

-

Shell diameter (m)

- f:

-

Friction factor

- F:

-

Correction factor

- h:

-

Heat transfer coefficient (W/m2 K)

- H:

-

Annual operating time (h/year)

- i:

-

Annual discount rate (%)

- k:

-

Thermal conductivity (W/m K)

- K1 :

-

Numerical constant

- L:

-

Tube length (m)

- m:

-

Mass flow rate (kg/s)

- n:

-

Number of tubes passages

- n1 :

-

Numerical constant

- ny :

-

Equipment life (year)

- Nt :

-

Number of tubes

- P:

-

Pumping power (W)

- p:

-

Numerical constant

- Pr :

-

Prandtl number

- Pt :

-

Tube pitch (m)

- PR:

-

Pitch ratio, PR = 1.25 do (m)

- Q:

-

Heat duty (W)

- Re :

-

Reynolds number

- Rf :

-

Fouling resistance (m2 K/W)

- T:

-

Temperature (K)

- U:

-

Overall heat transfer coefficient (W/m2 K)

- vt :

-

Fluid velocity (m/s)

- \(\Delta P\) :

-

Pressure drop (Pa)

- \(\Delta T_{LM}\) :

-

Logarithmic mean temperature difference (°C)

- π:

-

Numerical constant

- µ:

-

Dynamic viscosity (pa s)

- ν:

-

Kinematic viscosity (m

- ρ:

-

Density (kg/m3)

- H:

-

Overall pumping efficiency

- e :

-

Equivalent

- i :

-

Inlet

- o :

-

Outlet

- s :

-

Belonging to shell

- t :

-

Belonging to tube

- w :

-

Tube wall

- lm :

-

Logarithmic mean

References

Muralikrishna K, Shenoy U (2000) Heat exchanger design targets for minimum area and cost. Chem Eng Res Des 78:161–167

Wu S-Y, Yuan X-F, Li Y-R, Xiao L (2007) Exergy transfer effectiveness on heat exchanger for finite pressure drop. Energy 32:2110–2120

Gupta A, Das SK (2007) Second law analysis of crossflow heat exchanger in the presence of axial dispersion in one fluid. Energy 32:664–672

San J-Y (2010) Second-law performance of heat exchangers for waste heat recovery. Energy 35:1936–1945

Eryener D (2006) Thermoeconomic optimization of baffle spacing for shell and tube heat exchangers. Energy Convers Manag 47:1478–1489

Tsatsaronis G (1993) Thermoeconomic analysis and optimization of energy systems. Prog Energy Combust Sci 19:227–257. doi:10.1016/0360-1285(93)90016-8

Caputo AC, Pelagagge PM, Salini P (2008) Heat exchanger design based on economic optimisation. Appl Therm Eng 28:1151–1159. doi:10.1016/j.applthermaleng.2007.08.010

Ponce-Ortega JM, Serna-González M, Jiménez-Gutiérrez A (2009) Use of genetic algorithms for the optimal design of shell-and-tube heat exchangers. Appl Therm Eng 29:203–209. doi:10.1016/j.applthermaleng.2007.06.040

Patel V, Rao R (2010) Design optimization of shell-and-tube heat exchanger using particle swarm optimization technique. Appl Therm Eng 30:1417–1425

Şencan Şahin A, Kılıç B, Kılıç U (2011) Design and economic optimization of shell and tube heat exchangers using Artificial Bee Colony (ABC) algorithm. Energy Convers Manag 52:3356–3362

Hadidi A, Nazari A (2013) Design and economic optimization of shell-and-tube heat exchangers using biogeography-based (BBO) algorithm. Appl Therm Eng 51:1263–1272. doi:10.1016/j.applthermaleng.2012.12.002

Hadidi A (2015) A robust approach for optimal design of plate fin heat exchangers using biogeography based optimization (BBO) algorithm. Appl Energy 150:196–210. doi:10.1016/j.apenergy.2015.04.024

Selbaş R, Kızılkan Ö, Reppich M (2006) A new design approach for shell-and-tube heat exchangers using genetic algorithms from economic point of view. Chem Eng Process 45:268–275. doi:10.1016/j.cep.2005.07.004

Hadidi A, Hadidi M, Nazari A (2013) A new design approach for shell-and-tube heat exchangers using imperialist competitive algorithm (ICA) from economic point of view. Energy Convers Manag 67:66–74. doi:10.1016/j.enconman.2012.11.017

Saffar-Avval M, Damangir E (1995) A general correlation for determining optimum baffle spacing for all types of shell and tube exchangers. Int J Heat Mass Transf 38:2501–2506

Ozkol I, Komurgoz G (2005) Determination of the optimum geometry of the heat exchanger body via a genetic algorithm. Numer Heat Transf Part A Appl 48:283–296. doi:10.1080/10407780590948891

Valdevit L, Pantano A, Stone H, Evans A (2006) Optimal active cooling performance of metallic sandwich panels with prismatic cores. Int J Heat Mass Transf 49:3819–3830

Allen B, Gosselin L (2008) Optimal geometry and flow arrangement for minimizing the cost of shell-and-tube condensers. Int J Energy Res 32:958–969

Sun S, Lu Y, Yan C (1993) Optimizationin calculation of shell-and-tube heat exchanger. Int Commun Heat Mass Transfer 20:675–685

Azad AV, Amidpour M (2011) Economic optimization of shell and tube heat exchanger based on constructal theory. Energy 36:1087–1096

Sharma S, Rangaiah G, Cheah K (2012) Multi-objective optimization using MS Excel with an application to design of a falling-film evaporator system. Food Bioprod Process 90:123–134

Caputo AC, Pelagagge PM, Salini P (2015) Heat exchanger optimized design compared with installed industrial solutions. Appl Therm Eng 87:371–380. doi:10.1016/j.applthermaleng.2015.05.010

Hultmann Ayala HV, Keller P, Morais MdF, Mariani VC, Coelho LdS, Rao RV (2016) Design of heat exchangers using a novel multiobjective free search differential evolution paradigm. Appl Therm Eng 94:170–177. doi:10.1016/j.applthermaleng.2015.10.066

Birbil Şİ, Fang S-C (2003) An electromagnetism-like mechanism for global optimization. J Global Optim 25:263–282

Birbil Şİ, Fang S-C, Sheu R-L (2004) On the convergence of a population-based global optimization algorithm. J Global Optim 30:301–318

Tsou C-S, Kao C-H (2006) An electromagnetism-like meta-heuristic for multi-objective optimization. In: IEEE Congress on Evolutionary Computation, 2006 CEC, pp 1172–1178

Jolai F, Tavakkoli-Moghaddam R, Golmohammadi A, Javadi B (2012) An electromagnetism-like algorithm for cell formation and layout problem. Expert Syst Appl 39:2172–2182

Abed IA, Koh SP, Sahari KSM, Tiong SK, Yap DF (2012) Comparison between genetic algorithm and electromagnetism-like algorithm for solving inverse kinematics. World Appl Sci J 20:946–954

Yurtkuran A, Emel E (2010) A new hybrid electromagnetism-like algorithm for capacitated vehicle routing problems. Expert Syst Appl 37:3427–3433

Golmohammadi A, Ghodsi R (2009) Applying an integer Electromagnetism-like algorithm to solve the cellular manufacturing scheduling problem with an integrated approach. In: International Conference on IEEE Computers & Industrial Engineering, 2009 CIE, pp 34–39

Liu C, Sun X (2010) Electromagnetism-like mechanism particle swarm optimization and application in thermal process model identification. In: 2010 Chinese IEEE on Control and Decision Conference (CCDC), pp 2966–2970

Guan X, Dai X, Qiu B, Li J (2012) A revised electromagnetism-like mechanism for layout design of reconfigurable manufacturing system. Comput Ind Eng 63:98–108

Khalili M, Tavakkoli-Moghaddam R (2012) A multi-objective electromagnetism algorithm for a bi-objective flowshop scheduling problem. J Manuf Syst 31:232–239

Lee C-H, Chang F-K, Lee Y-C (2010) An improved electromagnetism-like algorithm for recurrent neural fuzzy controller design. Int J Fuzzy Syst 12:280–290

Abed IA, Koh SP, Sahari KSM, Tiong SK, Tan NM (2013) Optimization of task scheduling for single-robot manipulator using pendulum-like with attraction-repulsion mechanism algorithm and genetic algorithm. Aust J Basic Appl Sci 7:426–445

Abed IA, Sahari KSM, Koh SP, Tiong SK, Jagadeesh P (2013) Using Electromagnetism-like algorithm and genetic algorithm to optimize time of task scheduling for dual manipulators. In: 2013 IEEE Region 10 on Humanitarian Technology Conference (R10-HTC), pp 192–197

Abed IA, Koh SP, Sahari KSM, Tiong SK, Tan NM (2014) Solving the inverse kinematics for robot manipulators using modified electromagnetism-like algorithm with record to record travel. Res J Appl Sci Eng Technol 7:3986–3994

Kan AR, Timmer G (1987) Stochastic global optimization methods part I: clustering methods. Math Program 39:27–56

Törn A, Viitanen S (1994) Topographical global optimization using pre-sampled points. J Global Optim 5:267–276

Cowan EW (1968) Basic electromagnetism. Academic Press, New York

Sinnott RK (2005) Chemical engineering, chemical engineering design. Heinemann, Butterworth

Incorpera FP, DeWitt DP, Bergman TL, Lavine AS (1996) Fundamentals of heat and mass transfer. Wiley, Hoboken

Kakac S, Liu H, Pramuanjaroenkij A (2012) Heat exchangers: selection, rating, and thermal design. CRC Press, Boca Raton

Bennett CO, Myers JE (1962) Momentum, heat, and mass transfer. McGraw-Hill, New York

Sinnott R (2005) Heat transfer equipment, Coulson & Richardson’s chemical engineering. Butterworth, Heinemann

Sieder EN, Tate GE (1936) Heat transfer and pressure drop of liquids in tubes. Ind Eng Chem 28:1429–1435

Hewitt GF (1998) Heat exchanger design handbook. Begell House, New York

Lestina T, Serth RW (2010) Process heat transfer: principles, applications and rules of thumb. Academic Press, Kingsville, TX, USA

Taal M, Bulatov I, Klemeš J, Stehlı́k P (2003) Cost estimation and energy price forecasts for economic evaluation of retrofit projects. Appl Therm Eng 23:1819–1835

Kern DQ (1950) Process heat transfer. McGraw-Hill, New York

Xie GN, Sunden B, Wang QW (2008) Optimization of compact heat exchangers by a genetic algorithm. Appl Therm Eng 28:895–906. doi:10.1016/j.applthermaleng.2007.07.008

Antonio C, Caputo PMP, Salini Paolo (2011) Joint economic optimization of heat exchanger design and maintenance policy. Appl Therm Eng 31:1381–1392

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abed, A.M., Abed, I.A., Majdi, H.S. et al. A new optimization approach for shell and tube heat exchangers by using electromagnetism-like algorithm (EM). Heat Mass Transfer 52, 2621–2634 (2016). https://doi.org/10.1007/s00231-016-1769-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1769-6