Abstract

The research examines the possibility of predicting the mechanical [modulus of rupture (MOR) and modulus of elasticity (MOE)] and physical (oven-dry and air-dry densities) properties of thermally modified beech wood (Fagus moesica C.) with red heartwood by using FT-NIR spectroscopy and partial least squares regression. Samples of sapwood and red heartwood were treated for 4 h at temperatures of 170, 190, and 210 °C. FT-NIR spectra (100 scans and 4 cm−1) were collected on the radial surface at eight points before and after the thermal modification. Oven-dry and air-dry densities as well as MOR and MOE determined by three-point bending tests were evaluated. Generally, according to the residual prediction deviation (RPD), the majority of the models obtained can be used for preliminary screening (1.5 < RPD < 2.5). The results of the spectra taken from sapwood were, in most models, better than the spectra of the red heartwood. Statistically, the values of density were mostly better than the values shown in assessment of bending properties. Results show that it is possible to accurately predict the quality of wood after being subjected to high temperatures, based on the spectra collected before the thermal modification. This fact could contribute to a more rational use of wood (especially from red heartwood) in the process of thermal modification.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Preservation of wood using thermal modification is one of the alternatives to the protection of wood using chemicals. This method can reduce wood hygroscopicity and improve its durability, but it may decrease some mechanical properties, mainly bending (Militz and Tjeerdsma 2000; Kubojima et al. 2000; Bekhta and Niemz 2003; Johansson and Morén 2006; Esteves et al. 2007; Shi et al. 2007; Kocaefe et al. 2008). Thermal treatment also gives wood a darker color that has become very interesting on the market, enabling a broader use and increased market value of less valued species (Mitsui et al. 2001; Bekhta and Niemz 2003; Johansson and Morén 2006; Esteves et al. 2008). However, besides the major applications of thermally modified wood (garden furniture, deckings for terraces, spa areas, swimming pools, floorings, etc.), there is still a lack of fast and efficient quality control methods.

Mass loss during treatment is often used as a measure of thermally modified wood quality, but for most of the species, mass loss depends on the extractive content and composition since volatile compounds are the first to leave the wood when wood is submitted to heat. Garcia et al. (2012) evaluated the effect of heat treatment of eucalypt wood (Eucalyptus grandis Hill ex Maiden) on the dynamic modulus of elasticity by using stress wave nondestructive method and also to determine the air-dry density, weight loss and equilibrium moisture content. The results revealed a significant weight loss and significant reduction in air-dry density and equilibrium moisture content. The dynamic modulus of elasticity decreased by about 13 % in the most severe treatment (230 °C for 4 h). Other quality control methods were also reported: high-energy multiple impact (Rapp et al. 2006) and color changes (Bekhta and Niemz 2003; Johansson and Morén 2006; Brischke et al. 2007; González-Peña and Hale 2009b; Todorović et al. 2012). The first method is a destructive analysis, while the results of relationship between color changes and wood properties, especially strength, are contradictory. As alternative, near-infrared spectroscopy has been recognized as one of the most powerful nondestructive techniques for analysis of thermally modified wood. In the last two decades, it has often been used for untreated wood (Hoffmeyer and Pedersen 1995; Thumm and Meder 2001; Gindl et al. 2001; Schimleck et al. 2001; Schimleck and Evans 2004; Tsuchikawa 2007; Yao et al. 2010; Inagaki et al. 2012; Green et al. 2011; Watanabe et al. 2012, 2013).

The characterization of thermally modified wood using NIR spectroscopy was suggested by Hinterstoisser et al. (2003). They reported that NIR spectra of milled wood removed from the surface of heat-treated wood could be used for classification purposes. Schwanninger et al. (2004) reported a close relationship between the chemical changes of thermally modified Fagus sylvatica L. samples and the corresponding NIR spectra, while Mitsui et al. (2008) observed thermally induced alterations of the phenolic and cellulosic hydroxyl groups of Picea sitchensis. Esteves and Pereira (2008) predicted the properties of thermally modified pine (Pinus pinaster Labill.) and eucalypt (Eucalyptus globulus Aiton) by analyzing the radial surface of the samples using a NIR fiber probe. The found calibration models were good for cross-validation results, with coefficients of determination ranging between 96 and 98 % for mass loss, 78 and 95 % for equilibrium moisture content, 53 and 78 % for dimensional stability, 47 and 89 % for MOE, and 75 and 77 % for MOR. Bächle et al. (2010) evaluated the properties of thermally modified beech without red heartwood and spruce wood by FT-NIR spectroscopy. The results of the spectra taken from the spruce samples resulted in better prediction results than the spectra of the beech samples. Same authors suggested that the examination of beech wood should be repeated with a larger number of scans and with more samples. Bächle et al. (2012) investigated NIR spectroscopy in combination with pattern recognition method of soft independent modeling of class analogies (SIMCA). They claim that SIMCA classification based on NIR spectroscopy could be used for quality control of thermally modified beech, spruce and ash wood, but scaling to industrial level needs further investigation.

Common problem in using beech wood is red heartwood out of which products of lower value are made, due to its naturally darker color and a potential presence of fungi. With the optimal thermal modification regime which can lead to no essential difference in the properties of thermally modified beech sapwood and red heartwood (Todorović et al. 2012), the less valuable wood can, in that case, be used for getting highly valuable products. In that aim, NIR spectroscopy can be a reliable technique for nondestructive determination of the physical and mechanical properties of thermally modified beech wood with red heartwood.

In this context, the objective of this study was to explore the feasibility of predicting physical properties (oven-dry density and air-dry density) and mechanical properties [modulus of elasticity (MOE) and modulus of rupture (MOR)] of thermally modified beech wood with red heartwood by NIR spectra and multivariate chemometric methods.

Materials and methods

Materials

Eleven beech (Fagus moesiaca C.) trees that were randomly chosen were obtained from the forest area of Goč Mountain (southwestern Serbia). The average breast height diameter was 45 cm. All the trees had a similar amount of red heartwood (around 50 %) with the absence of visible decay and were cut into 2-m-long logs. The logs were cut from each tree: above breast height, at the middle, and at the height of first green branches. Each log (33 logs in total) was cut into eight radial boards of 30 mm thickness (four from sapwood and four from red heartwood).

From a total of 264 kiln-dried boards, 84 sapwood, and 84 red heartwood boards (with no visible defects and deformations) were selected. Four samples from the central part of selected boards were cut (untreated—marked 1 and 3 for thermal modification—Fig. 1). The samples (marked 1, 2, 3, and 4) had clearly defined anatomic directions and no visible defects. They were cut into specimens that were used to determine the physical and mechanical properties. Specimens that were used for determining the moisture content (MC) and density (oven-dried—Odd, air-dried—Add) had dimensions of 20 × 20 × 20 mm3, and specimens for determining the bending properties (MOR and MOE) were 20 × 20 × 320 mm3 (radial, tangential, and longitudinal).

Thermal modification of wood

Thermal modification was carried out in a laboratory chamber (1 m3, ±1 °C sensitivity, water vapor atmosphere), where samples were exposed to temperatures of 170, 190, or 210 °C. It took approximately 24 h to heat the samples from room temperature to the treating temperature, after which the temperature was kept constant for 4 h. The chosen schedules are often used in industrial thermal modification of beech timber. After the thermal treatment, the samples that did not have visible cracks and defects were used for recording the NIR spectra and property assessment. There were a total of 370 specimens: 190 out of sapwood (84 untreated and 106 thermally modified) and 180 out of red heartwood (84 untreated and 96 thermally modified).

Physical and mechanical testing

The untreated and thermally modified samples were conditioned at 23 °C and relative humidity of 50 % during 8 weeks. The mechanical and physical properties were determined after conditioning. MOR and MOE were determined by a three-point bending test on specimens measuring 20 × 20 × 320 mm3. Distance from supports was 280 mm. MOE was calculated between 100 and 500 N, which was about 5–50 % of the maximum load depending on the species and the treatment intensity. Add, Odd, and MC (20 × 20 × 20 mm3) were determined by oven-drying method subsequent to the bending tests.

Near-infrared spectroscopy

FT-NIR spectra were collected before and after thermal treatment with a Nicolet Nexus 670 FT-IR spectrometer equipped with a Thermo Nicolet Smart Near-IR UpDrift probe in the wavenumber ranging from 11,000 to 4000 cm−1 using the default parameters. The NIR spectra were acquired by an integrating sphere scanning an area of about 7 mm in diameter. For each scanning point, 100 scans (4 cm−1) were collected and averaged into a single spectrum. Eight spectra on the radial longitudinal face of bending test samples were averaged to one average spectrum per face. The measurements were taken on a planed surface.

Multivariate analyses and calibration statistics

Partial least square (PLS) analysis was done by The Unscrambler® (CAMO AS, Norway) software version 9.7. A detailed description of PLS regression is given in Esbensen (2002). PLS calibration was performed with two subsets (calibration set and validation set) with a maximum of ten latent variables (LV). Samples for calibration and validation sets were divided manually. First, the samples were ranked in ascending order of their dependent variables, and every third or fourth sample was taken into the validation set. Secondly, NIR variables were regressed against the tested properties by cross-validation of five randomly chosen groups. Different data treatments were evaluated for the spectral data: first derivative (1stDer), second derivative (2ndDer), standard normal variate (SNV), normalization (norm.), multiplicative scatter correction (msc), and combinations of all. First derivative was obtained by using a nine-point filter and a second-order polynomial as well as the Savitzky–Golay algorithm (Savitzky and Golay 1964). For the second derivative, a 15-point filter and a second-order polynomial were used. Outlier samples were identified by Student residuals and leverage value plot analyses. Model efficiency was then tested by the validation set. Four PLS models were tested (Table 1).

The quality and the final selection of the models were assessed by: determination coefficient of calibration set (R 2c ), standard error of calibration (SEC), standard error of cross-validation (SECV), determination coefficient of validation set (R 2p value calculated to show the ability of the calibration to account for the variation in the validation set), standard error of prediction (SEP—the measure of the calibrations ability to predict wood properties in samples not used in the calibration set), and ratio performance to deviation (RPD—evaluates the predictive ability of the calibration). RPD was used for comparison of the obtained models. The RPD residual prediction deviation or ratio of performance to deviation was introduced by Williams and Norris (2004) several years ago and is calculated as the ratio of two standard deviations: the standard deviation of the reference data for the validation set and the standard error of prediction (from cross-validation or test set validation).

Results and discussion

After conditioning, the average moisture content measured in the untreated sapwood was 9.0 %, while in red heartwood, it was 9.6 %. The high temperature that was applied led to a significant reduction in equilibrium moisture content in both parts of wood. Apart from the hygroscopicity, thermal modification also significantly reduced the density and bending strength, while the modulus of elasticity remained unchanged. The analyzed properties between sapwood and red heartwood mostly did not differ before and after treatment. The detailed results of moisture content (MC), density (Odd and Add), and bending properties (MOR and MOE) in beech sapwood and red heartwood were shown in a paper by Todorović et al. (2012).

Spectroscopic characterization

Based on the raw NIR spectra, untreated red heartwood had higher values of absorption as compared to sapwood (Fig. 2), mostly because of its darker hue.

Unlike the spectra of untreated wood, the average raw spectra of thermally modified sapwood and red heartwood were mostly matched at same temperatures (Fig. 3). The baseline shift to higher wave numbers with increasing temperature intensity can be observed. This is due to the darker colors of the samples (Windeisen et al. 2009; Bächle et al. 2010, 2012). Decreasing lightness and increasing reddish color during heat treatment are often justified by oxidative and hydrolytic reactions of the cell wall constituents and extractives (Sehistedt-Persson 2003; Sundqvist 2004). Formation of the new chromophore system composed of conjugated double bonds, carbonyl groups, and quinone structures varies from one species to another and depends on the presence of oxygen, moisture content, and applied temperature. Lighter color of heat-treated beech could be expected in nitrogen as compared to oxygen atmosphere, as shown for black locust by Chen et al. (2012a). Chen et al. (2012b) reported that the presence of oxygen also resulted in formation of colored quinoid compounds originating from degradation and oxidation of the aromatic hydroxyl groups of lignin and aromatic extractives upon heat treatment. The formation of oxidation products, such as quinones, is referred to as an important reason for color change (Tjeerdsma et al. 1998; Mitsui et al. 2001; Bekhta and Niemz 2003; González-Peña and Hale 2009a).

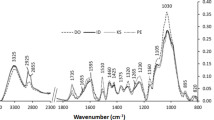

Knowing the fact that raw spectra provide only rough information about spectral alterations (the second overtone of CH stretching vibration around 8300 cm−1 and OH bands at 7100 and 5150 cm−1 show only change in absorption), NIR spectra were observed in the second derivative mode (second derivative). Second derivative spectra of the sapwood show features similar to the spectra of the red heartwood (both before and after thermal treatment). The obtained spectra are in line with the results of Windeisen et al. (2009) for beech and similar to the spectra of the spruce specimens (Bächle et al. 2010). At the CH stretching, first overtone bands at 5800 and 5865 cm−1 alterations (Fig. 4) indicate degradation of carbohydrates and deacetylation reactions of the polyoses. The differences before and after thermal treatment (both for sapwood and red heartwood—Fig. 5) were found at the OH stretching vibration absorption bands of the amorphous (7000 cm−1), semicrystalline (6722 and 6790 cm−1), and crystalline (6460 cm−1) regions of cellulose (Schwanninger et al. 2003; Tsuchikawa and Siesler 2003; Inagaki et al. 2008; Mitsui et al. 2008). These differences could be attributed to the cleavage of OH groups during thermal treatment (Mitsui et al. 2008). Although lignin is supposed to be comparatively stable at higher temperature, the skeletal CH absorption band at 5974 cm−1 (Michell and Schimleck 1996; Schwanninger et al. 2011) shows differences, which indicates modifications in lignin after thermal treatment (Fig. 4). There is also an increase in the absorption band around 6874 cm−1, which can be assigned to the phenolic hydroxyl groups originating from lignin (Fackler and Schwanninger 2010) and to a decrease in the absorption band assigned to the amorphous region in cellulose at 7000 cm−1 (Fig. 5).

Hansmann et al. (2007), using the PCA analysis, found a difference between sapwood and red heartwood after thermal modification, which was a consequence of different levels of lignin deacetylation and degradation. In this paper, PCA analysis of processed NIR spectra after thermal modification was used, and three clusters were observed that indicated that there is a difference between treatments and that there is no difference between samples of sapwood and red heartwood at the same temperatures (Fig. 6). The explained variance (R 2) was 100 %. The first PC (PC1) explained 90 % and the second PC (PC2) 10 % for the beech samples. On the other hand, there are differences in bending strength and density loss between sapwood and red heartwood only at 190 °C (Todorović et al. 2012), but more detailed conclusions could be obtained after chemical analysis of samples.

Prediction of untreated beech wood properties by NIR spectra (UT models)

Better results were obtained in predicting oven-dry density as compared to air-dry density of sapwood, while in red heartwood, the quality of predicting these densities was similar (Table 2).

The coefficient of determination (R 2p ) in prediction of air-dry density of sapwood was 0.74 (RPD = 2.05), while in prediction of oven-dry density of sapwood, it was 0.80, but with significantly higher value of RPD (2.33)—Fig. 7.

Values of standard error of calibration (SEC) and of prediction (SEP) were the same as in the assessment of oven-dry density of sapwood—0.018 g/cm3. These errors also corresponded to one another in air-dry density of sapwood, but their values were significantly higher—0.022 g/cm3. Oven-dry density of red heartwood had lower values of R 2 (0.66) and of RPD (2.00) as compared to sapwood, and therefore the standard errors of calibration were higher. On the other hand, results of assessment of air-dry density of red heartwood were similar to those of sapwood (R 2p = 0.68; RPD = 2.00).

Obtained values of statistical indicators of prediction of density of beech wood by using NIR were mostly in line with already published values of prediction of density of other deciduous species (Via et al. 2003; Defo et al. 2007; Hein et al. 2009; Andrade et al. 2010). Statistical indicators obtained with coniferous species were somewhat better, considering that they have a more homogeneous structure (Thygesen 1994; Gindl et al. 2001; Kelley et al. 2004; Acuna and Murphy 2006). Bächle et al. (2010) reported lower values of R 2p (0.71) and RPD (1.74) when assessing oven-dry density of beech wood, as compared to the values obtained in this research.

According to the obtained values of RPD and R 2p , the application of NIR to the prediction of bending properties is weaker than its application to density of beech wood. According to the same statistical criteria, using NIR to predict MOR is less efficient than prediction of MOE, in both parts of beech wood. As was the case with density, MOR and MOE were also better predicted in sapwood than in red heartwood. Value of R 2p of MOR of sapwood was 0.61 (RPD = 1.65), and in red heartwood, it was 0.43 (RPD = 1.32). Considering MOE, R 2p was 0.73 (RPD = 1.91) for sapwood, and R 2p = 0.66 (RPD = 1.81) for red heartwood.

The published results related to the application of NIR in prediction of MOR and MOE showed variable results. Gindl et al. (2001) tested the possibilities of application of NIR to the prediction of MOR and MOE of larch wood. The authors reported values of coefficient of correlation in calibration samples in MOE to be 0.979 and in MOR to be 0.963, and these values are significantly higher as compared to the data obtained in this research. Yu et al. (2009) found that with Chinese fir, NIR can better predict MOR than MOE, while Andrade et al. (2010) obtained opposite results for eucalyptus wood that are in line with those in this research. In prediction of MOR with the NIR spectra that were also collected on radial surface, Bächle et al. (2010) obtained better results in prediction of MOE as compared to those in MOR, but the values of R 2p and RPD (0.36 and 0.16, respectively) were significantly lower than those obtained in this research.

Prediction of thermally modified beech wood properties by NIR spectra collected from thermally modified samples (TM models)

According to the measured properties and collected NIR spectra on the radial surface of thermally modified beech wood, density and bending properties were predicted by using PLS regression (Table 3). Obtained statistical indicators (R 2p and RPD) in assessment of density of thermally modified beech wood were between 0.66 and 0.82 (R 2p ) and between 1.83 and 2.56 (RPD).

Best results were achieved in predicting the oven-dry density of sapwood (R 2 = 0.82 RPD = 2.56), and statistically poorer results were achieved in predicting the air-dry density of red heartwood (R 2 = 0.66; RPD = 1.83). As is the case with untreated wood, the statistical indicators were better with sapwood than with red heartwood. In both parts of wood, oven-dry density was predicted better than air-dry density. Standard error of prediction (SEP) in prediction of oven-dry density for sapwood was 0.018 g/cm3 and 0.017 g/cm3 for red heartwood. In predicting the air-dry density of sapwood, the corresponding SEP was 0.020 g/cm3, and for red heartwood, SEP was 0.024 g/cm3. Bächle et al. (2010) showed a model of oven-dry density of beech wood whose indicators were R 2 = 0.65 and RPD = 1.74, and for the basic density, they were R 2p = 0.54 and RPD = 1.35. In this research, values of SEP were lower than those results.

In predicting MOE, statistical values in sapwood were weaker than the ones in red heartwood. Compared to the results of untreated samples, thermally modified sapwood showed poorer prediction properties, while thermally modified red heartwood yielded better results as compared to the untreated samples. The corresponding SEP for sapwood was lower (784 N/mm2) than for untreated wood (798 N/mm2). For thermally modified red heartwood, SEP was the same as in untreated wood—723 N/mm2. Esteves and Pereira (2008), who examined the application of NIR to assessment of MOE of thermally treated pine wood, reported that the R 2c in calibration samples was 0.893 and that in eucalyptus, it was significantly lower—0.471 (in this research, R 2c was 0.61 for sapwood and 0.77 for red heartwood). Bächle et al. (2010) predicted MOE of spruce and reported that R 2p = 0.75 while the value for beech wood was significantly lower (R 2p = 0.38) than in this research. Gonzáles-Pena and Hale (2011) reported good results for predicting MOR and MOE by using the mid-infrared spectroscopy (MIR). In thermally modified beech wood, the coefficient Q 2CUM (Q 2CUM = r 2cross-validation ) was found to be 0.985. This value is significantly higher than the R 2c used in this research.

By using the NIR spectra, MOR can be better predicted in thermally modified than in untreated beech wood. Also, assessment of MOR of thermally modified sapwood yielded better results (R 2p = 0.76; RPD = 1.96—Fig. 8) as compared to those of thermally modified red heartwood (R 2p = 0.65; RPD = 1.91). In both parts of wood, values of SEC were between 8.74 and 16.3 N/mm2 and SEP were between 8.95 and 16.5 N/mm2. Statistical indicators of calibration samples were lower than those stated by Esteves and Pereira (2008) for pine wood (R 2c = 0.769) and eucalyptus wood (R 2c = 0.745) and those stated by Gonzáles-Pena and Hale (2011) for beech, pine and spruce. However, the results of prediction of MOR were better than those reported by Bächle et al. (2010) for beech wood (R 2p = 0.57; RPD = 1.52).

Prediction of thermally modified wood properties by NIR spectra collected from untreated samples (UT − TM models)

Data of the quality of thermally modified wood, based on the NIR spectra collected from untreated wood, could significantly improve the utilization of wood (especially in beech wood with red heartwood). Results of application of spectra collected on the surface of untreated beech wood to the prediction of physical and mechanical properties of thermally modified beech wood with red heartwood are shown in Table 4.

In prediction of density of thermally modified wood, the obtained results were much better with sapwood than with red heartwood. The statistical indicators obtained were the same with sapwood in both air-dry and oven-dry densities (R 2p = 0.76; RPD = 2.14). In prediction of air-dry density of red heartwood, significantly higher statistical values were obtained as compared to the oven-dry density. SEP values were the same with both densities of sapwood (SEP = 0.021 g/cm3), while for red heartwood, SEP value of oven-dry density (0.025 g/cm3) was higher than SEP of air-dry density (0.022 g/cm3). Prediction of density of sapwood gave good results in both UT − TM and TM models (RPD > 2). In prediction of oven-dry density of red heartwood, much better results were obtained with TM model. On the other hand, in prediction of air-dry density of thermally modified red heartwood, results indicate that both the NIR spectra collected on the surface of thermally modified wood (TM model) and the spectra collected before treatment (UT − TM model) can be used equally.

NIR is better used in prediction of MOR of sapwood than with the same property of red heartwood, but the results of prediction of MOE were better in red heartwood (Fig. 9) than in sapwood (RPD = 1.70; R 2p = 0.62).

Values of SEP of MOE and MOR of sapwood were lower than those of red heartwood, which indicates a higher stability of the models. In assessment of MOR of thermally modified beech wood, better results were obtained by using the spectra collected from the surface of thermally modified wood (TM models) than by collecting the spectra from the surface of untreated wood. In prediction of MOE of sapwood, higher values of RPD and a better stability of the model were found in the UT − TM model, but the TM model produced much better results with red heartwood than with sapwood. Generally, with density and bending properties, all the UT − TM models had RPD values higher than 1.5 except in prediction of MOR of red heartwood.

Prediction of beech wood properties by NIR spectra collected from untreated + thermally modified samples (UT + TM models)

In assessment of wood density, these models gave results (Table 5) that were mostly poorer than those obtained by UT and TM models. Similar values of RPD and R 2p to the ones in the UT model were only obtained in prediction of air-dry density of sapwood, but they were again lower than those in the TM model. Bächle et al. (2010), using the same set of samples, predicted density of spruce and beech wood, and obtained results that were between those in UT and TM models, but similar to the results for red heartwood in this research.

Prediction of air-dry density of sapwood yielded higher values of RPD and R 2p (Fig. 10) compared to air-dry density of sapwood (R 2p = 0.77; RPD = 2.07). With red heartwood, the statistical parameters were similar for both densities, but according to the values of SEP, a greater stability of the model was achieved in prediction of oven-dry density (SEP = 0.024 g/cm3) compared to air-dry density (SEP = 0.031 g/cm3).

Prediction of MOR gave better statistical results than prediction of MOE in both parts of beech wood. MOR and MOE can be better predicted in sapwood than in red heartwood. For sapwood, the statistical parameters obtained with the UT and TM model were similar to those obtained with the TM model, but were significantly better than those obtained with the UT model. In prediction of MOR of red heartwood, statistical results with UT + TM model were also better than with UT model, but somewhat poorer than with TM model. With MOE of sapwood, statistical parameters were better than with the TM model, but poorer than with the UT model. With red heartwood, a different relation was found, that is, the UT + TM model was, according to RPD and R 2p , poorer than both UT and TM models.

When Bächle et al. (2010) predicted MOR of grouped samples (untreated and thermally modified) of beech wood and spruce wood, they got lower values compared to those obtained in this research. For MOE, same authors got a result that corresponds with statistical values found in red heartwood, but SEP was higher (SEP = 978.77 N/mm2) than in this research (SEP = 923 N/mm2).

Results of statistical parameters obtained with prediction of density and bending properties of grouped samples (sapwood and red heartwood) were mostly between the results of sapwood and red heartwood. This fact indicates the advantage of grouped samples being used to assess the properties when models based on red heartwood samples are poorer. In this sense, with the UT model, the use of these grouped samples is significant in predicting air-dry density (RPD = 2.09) and MOR (RPD = 1.52). With the TM model, good results were obtained with air-dry density, MOR (Fig. 11), and MOE. With this model, the sapwood and red heartwood samples gave better statistical results than those obtained with the UT model.

With UT − TM and UT + TM models, all the examined properties proved the advantage of grouped samples (sapwood and red heartwood) over the samples of red heartwood. With UT − TM model, the highest value of RPD was obtained with MOE (RPD = 2.28) and the lowest with MOR (RPD = 1.53). With UT + TM model, RPD was mostly weaker than with UT − TM model, with the highest value being obtained in prediction of air-dry density (RPD = 1.92) and the lowest with oven-dry density (RPD = 1.64).

Mathematical treatments

The raw spectra (mostly with UT + TM models) and the mathematically processed spectra (mostly with UT models) were used equally. Multiplicative scatter correction (msc) and normalization of spectra were mostly used in individual cases. Compared to raw spectra, first and second processed spectra showed better results in most cases, which corresponds to the results by Bächle et al. (2010). An advantage of application of first over second processed spectra was also found, which corresponds to the results for untreated wood by Kludt (2003), but differs from the results by Schimleck et al. (2001) and Thumm and Meder (2001), who showed advantages of second spectra over first ones.

After analyzing the statistical indicators, this research obtained better results for beech wood as compared to those by Bächle et al. (2010). One of the reasons for this could be that this research used 100 scans per spectrum, while Bächle et al. (2010, 2012) used 32 scans per spectrum. They stated that, in practice, a larger number of scans require more recording time. Esteves and Pereira (2008) used 50 scans, and Mitsui et al. (2008) used 128 scans. The results of this research indicate that the short recording time (low resolution or low number of scans) should only be used in those areas of application of NIR spectroscopy where RPD is expected to be higher than 3.5. So far, studies of prediction of physical and mechanical wood properties with NIR have very rarely produced values of RPD higher than 2.5. Considering this fact, in using the NIR spectroscopes for assessment of wood quality, advantage should be given to a good and high-quality recording resolution, with a large number of samples. This is especially important for deciduous wood species.

Conclusion

Results of research show that it is possible to use the NIR spectroscopy along with PLS regression to predict the properties of thermally modified beech wood of both sapwood and red heartwood. Generally, according to obtained statistical indicators, most of the developed models can be used for preliminary screening (RPD > 1.5). Statistical results of obtained models for wood density prediction were mostly better than of models for bending properties prediction. In addition, with sapwood and with the grouped samples (sapwood and red heartwood), most models yielded better results than with red heartwood. With TM models, results in both sapwood and red heartwood were good enough (1.5 < RPD < 2.56). Considering the preliminary screening, the UT − TM models showed very poor results (i.e., RPD < 1.5) only for oven-dry density and MOR of red heartwood. All other results obtained with UT − TM model are very interesting for practice because they can influence the decrease in waste after the modification process, and a more rational yield of wood (especially from red heartwood). Based on the results of these models and knowing the required properties of heat-treated wood, in practice one can decide which wood to thermally modify. Furthermore, a successful prediction of properties of thermally modified wood can determine its use in advance and also predict the product group in which such wood could be used.

References

Acuna MA, Murphy GE (2006) Use of near infrared spectroscopy and multivariate analysis to predict wood density of Douglas-fir from chain saw chips. For Prod J 56:67–72

Andrade CR, Trugilho PF, Napoli A, Vieira RS, Lima JT, Chagas de Sousa L (2010) Estimation of the mechanical properties of wood from Eucalyptus urophylla using near infrared spectroscopy. Cerne 16(3):291–298

Bächle H, Zimmer B, Windeisen E, Wegener G (2010) Evaluation of thermally modified beech and spruce wood and their properties by FT-NIR spectroscopy. Wood Sci Technol 44:421–433

Bächle H, Zimmer B, Wegener G (2012) Classification of thermally modified wood by FT-NIR spectroscopy and SIMCA. Wood Sci Technol 46:1181–1192

Bekhta P, Niemz P (2003) Effect of high temperature on the change of color, dimensional stability and mechanical properties of spruce wood. Holzforschung 57:539–546

Brischke C, Welbacher CR, Brit K, Rapp AO (2007) Quality control of thermally modified timber: interrelationship between heat treatment intensities and CIE L*a*b* color data on homogenized wood samples. Holzforschung 61(1):19–22

Chen Y, Fan Y, Gao J, Stark MN (2012a) The effect of heat treatment on the chemical and color change of black locust (Robinia pseudoacacia) wood flour. BioResources 7(1):1157–1170

Chen Y, Fan Y, Gao J, Li H (2012b) Coloring characteristics of in situ lignin during heat treatment. Wood Sci Technol 46(1):33–40

Defo M, Taylor AM, Bond B (2007) Determination of moisture and density of fresh sawn red oak lumber by near infrared spectroscopy. For Prod J 57(7):68–72

Esbensen KH (2002) Multivariate data analysis-in practice. An introduction to multivariate data analysis and experimental design, 5th edn. CAMP Process AS, Oslo

Esteves B, Pereira H (2008) Quality assessment of heat-treated wood by NIR spectroscopy. Holz Roh Werkst 66:323–332

Esteves B, Velez Marques A, Domingos I, Pereira H (2007) Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci Technol 41:193–207

Esteves B, Velez Marques A, Domingos I, Pereira H (2008) Heat induced color changes of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci Technol 42(5):369–384

Fackler K, Schwanninger M (2010) Polysaccharide degradation and lignin modification during brown rot of spruce wood: a polarised Fourier transform near infrared study. J Near Infrared Spectrosc 18(6):403–416

Garcia R, Monteiro de Carvalho A, de Figueiredo Vicente, Latorraca J, Monteiro Luis, de Matos J, Santos W, de Medeiros Fonseca, Silva R (2012) Nondestructive evaluation of heat-treated Eucalyptus grandis Hill ex Maiden wood using stress wave method. Wood Sci Technol 46:41–52

Gindl W, Teischinger A, Schwanninger M, Hinterstoisser B (2001) The relationship between near infrared spectra of radial wood surfaces and wood mechanical properties. J Near Infrared Spectrosc 9(4):255–261

González-Peña M, Hale M (2009a) Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 1: colour evolution and colour changes. Holzforschung 63:385–393

González-Peña M, Hale M (2009b) Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 2: property predictions from colour changes. Holzforschung 63:394–401

González-Peña M, Hale M (2011) Rapid assessment of physical properties and chemical composition of thermally modified wood by mid-infrared spectrsocopy. Wood Sci Technol 45:83–102

Green B, Jones PD, Nicholas DD, Schimleck LR, Shmulsky R (2011) Non-destructive assessment of Pinus spp. wafers subjected to Gloeophyllum trabeum in soil block decay tests by diffuse reflectance near infrared spectroscopy. Wood Sci Technol 45:583–595

Hansmann C, Ters T, Stingl R, Leder S, Hinterstoisser B (2007) Thermal modification of beech (Fagus sylvatica L.) containing red heartwood. In: The third European conference on Wood modification: ECWM 2007, Cardiff, Wales, 15–16 Oct 2007, pp 247–250

Hein G, Ricardo P, Campos M, Carolina A, Fernando TP, Tarscisio LJ, Gilles C (2009) Near infrared spectroscopy for estimating wood basic density in Eucalyptus urophylla and Eucalyptus grandis. Cerne 15(2):133–141

Hinterstoisser B, Schwanninger M, Stefke B, Stingl R, Patzelt M (2003) Surface analysis of chemically and thermally modified wood by FT-NIR. In: The first European conference on wood modification ECWM1, Ghent, Belgium, pp 65–70

Hoffmeyer P, Pedersen JG (1995) Evaluation of density and strength of Norway spruce by near infrared spectroscopy. Holz Roh Werkst 53:165–170

Inagaki T, Mitsui K, Tsuchikawa S (2008) Near-infrared spectroscopy investigation of the hydrothermal degradation mechanism of wood as an analogue of archaeological objects. Part I: softwood. Appl Spectrosc 62:1209–1215

Inagaki T, Schwanninger M, Kato R, Kurata Y, Thanapase W, Puthson P, Tsuchikawa S (2012) Eucalyptus camaldulensis density and fiber length estimated by near-infrared spectroscopy. Wood Sci Technol 46:143–155

Johansson D, Morén T (2006) The potential of colour measurement for strength prediction of thermally treated wood. Holz Roh Werkst 64:104–110

Kelley S, Rials T, Snell R, Groom L, Sluiter A (2004) Use of near infrared spectroscopy to measure the chemical and mechanical properties of solid wood. Wood Sci Technol 38:257–276

Kludt KD (2003) Use of near infrared spectroscopy technology for predicting bending properties of clear wood specimens. MSc, Washington State University, USA

Kocaefe D, Poncsak S, Bulok Y (2008) Effect of thermal treatment on the chemical composition and mechanical properties of birch and aspen. BioResources 3(2):517–537

Kubojima Y, Okano T, Ohta M (2000) Bending strength of heat-treated wood. J Wood Sci 46:8–15

Michell AJ, Schimleck LR (1996) NIR spectroscopy of woods from Eucalyptus globulus. Appita J 49:23–26

Militz H, Tjeerdsma B (2000) Heat treatment of wood by the “PLATO-process”. In: Proceedings of the heat treatment conferences, Helsinki, Stockholm, Oslo, Nov 2000

Mitsui K, Takada H, Sugiyama M, Hasegawa R (2001) Changes in the properties of light-irradiated wood with heat treatment. Part 1. Effect of treatment conditions on the change in color. Holzforschung 55:601–605

Mitsui K, Inagaki T, Tsuchikawa S (2008) Monitoring of hydroxyl groups in wood during heat treatment using NIR spectroscopy. Biomacromolecules 9:286–288

Rapp AO, Brischke C, Welzbacher CR (2006) Interrelationship between the severity of heat treatments and sieve fractions after impact ball milling: a mechanical test for quality control of thermally modified wood. Holzforschung 60(1):64–70

Savitzky A, Golay EJ (1964) Smoothing and differentiation of data by simplified least squares procedures. Anal Chem 36:1627–1639

Schimleck R, Evans R (2004) Estimation of Pinus radiata D. Don tracheid morphological characteristics by near infrared spectroscopy. Holzforschung 58:66–73

Schimleck R, Evans R, Ilic J (2001) Estimation of eucalyptus delegatensis wood properties by near infrared spectroscopy. Can J For Res 31(10):1671–1675

Schwanninger M, Gierlinger N, Hanger J, Hansmann C, Hinterstoiser B, Wimmer R (2003) Characterization of thermally treated beech wood by UV-microspectrophotometry, FT-MIR, FTIR spectroscopy. In: Proceedings of 12th ISWPC, vol 3, Madison, WI, 9–12 June 2003, pp 55–58

Schwanninger M, Hinterstoiser B, Gierlinger N, Wimmer R, Hanger J (2004) Application of fourier transform near infrared spectroscopy (FT-NIR) to thermally modified wood. Holz Roh Werkst 62:483–485

Schwanninger M, Rodrigues JC, Fackler K (2011) A review of band assignments in near infrared spectra of wood and wood components. J Near Infrared Spectrosc 19:287–308

Sehistedt-Persson M (2003) Colour responses to heat treatment of extractives and sap from pine and spruce. In: Proceedings of the 8th IUFRO wood drying conference, Brasov, Romania, pp 459–464

Shi J, Kocaefe D, Zhang J (2007) Mechanical behaviour of Quebec wood species heat-treated using ThermoWood process. Holz Roh Werkst 65:255–259

Sundqvist B (2004) Colour changes and acid formation in wood during heating. Doctoral Thesis, Lulea University of Technology

Thumm A, Meder R (2001) Stiffness prediction of radiata pine clearwood test pieces using near infra-red spectroscopy. J Near Infrared Spectrosc 9:117–122

Thygesen LG (1994) Determination of dry matter content and basic density of Norway spruce by near infrared reflectance and transmission spectroscopy. J Near Infrared Spectrosc 2:127–135

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally treated wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56(3):149–153

Todorović N, Popović Z, Milić G, Popadić R (2012) Estimation of heat-treated beechwood properties by color change. BioResources 7(1):799–815

Tsuchikawa S (2007) A review of recent near infrared for wood and paper. Appl Spectrosc Rev 42:43–71

Tsuchikawa S, Siesler HW (2003) Near infrared spectroscopic monitoring of the diffusion process of deuterium-labelled molecules in wood. Part I: softwood. Appl Spectrosc 57:675–681

Via BK, Shupe TF, Groom LH, Stine M, So CH (2003) Multivariate modelling of density, strength and stiffness from near infrared spectra for mature, juvenile and pith wood of longleaf pine (Pinus palustris). J Near Infrared Spectrosc 11:365–378

Watanabe K, Mansfield SD, Avramidis S (2012) Wet-pocket classification in Abies lasiocarpa using visible and near infrared (Vis–NIR) spectroscopy. Eur J Wood Prod 70:61–67

Watanabe K, Kobayashi I, Saito S, Kuroda N, Noshiro S (2013) Nondestructive evaluation of drying stress level on wood surface using near-infrared spectroscopy. Wood Sci Technol 47:299–315

Williams P, Norris K (2004) Near-infrared technology in the agricultural and food industries. American Association of Cereal Chemists, Inc, St. Paul, p 296

Windeisen E, Bächle H, Zimmer B, Wegener G (2009) Relations between chemical changes and mechanical properties of thermally treated wood. Holzforschung 63:773–778

Yao S, Wu G, Xing M, Zhou S, Pu J (2010) Determination of lignin content in Acacia spp. using near-infrared reflectance spectroscopy. BioResources 5(2):556–562

Yu H, Zhao R, Fu F, Fei B, Jiang Z (2009) Prediction of mechanical properties of Chinese fir wood by near infrared spectroscopy. Front For China 4(3):368–373

Acknowledgments

The authors acknowledge the financial support by the Ministry of Education, Science and Technological Development of the Republic of Serbia (TR 37008 and TR 31041).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Todorović, N., Popović, Z. & Milić, G. Estimation of quality of thermally modified beech wood with red heartwood by FT-NIR spectroscopy. Wood Sci Technol 49, 527–549 (2015). https://doi.org/10.1007/s00226-015-0710-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-015-0710-3