Abstract

A highly selective and sensitive “on–off–on” electrochemiluminescence (ECL) aptasensor based on a self-enhanced luminophore was developed for the detection of ochratoxin A (OTA). Specifically, polyethyleneimine functionalized multi-walled carbon nanotubes decorated with gold nanoparticles (AuNPs-PEI-MWCNTs) were used as the electrode matrix to accelerate electron transfer and provide a favorable microenvironment for self-enhanced luminophore loading and ECL signal enhancement. In addition, black phosphorus quantum dots (BPQDs) were used as co-reactants of the ECL reagent tris (2,2′-bipyridyl) ruthenium(II) (Ru(bpy)32+) in ECL experiments, and the reaction mechanism was investigated. The self-enhanced luminophore Ru@SiO2-BPQDs was obtained by encapsulating Ru(bpy)32+ in silica (SiO2) nanoparticles and then combining it with BPQDs through electrostatic interaction. In conventional ECL systems, the emitter and its co-reactants reacted via the inter-nanoparticle pathway, leading to long distance electron transfer. However, the electron transfer distance in the self-enhanced luminophore was significantly shortened due to the intra-nanoparticle electron transfer pathway because BPQDs and oxidized Ru(bpy)32+ were bound within one nanoparticle, thereby improving ECL efficiency to achieve the first “switch-on” state. Then, the luminophore was quenched using ferrocenes (Fc) modified on an aptamer to achieve the “switch-off” state. Finally, OTA was specifically identified by the adapter, causing Fc to be released from the sensor interface, restoring the ECL intensity to achieve the second “switch-on” state. Under optimal conditions, the aptasensor exhibited good sensitivity, stability, and reproducibility, with a linear detection range from 0.1 to 320 ng/mL and a detection limit of 0.03 ng/mL. The novel ECL aptasensor provided a common analytical tool for the detection of mycotoxins and other small molecules.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mycotoxin pollution is a global problem that poses a significant threat to food and feed safety. Among the various types of mycotoxins, ochratoxin A (OTA) is a representative one with abundant reserves, which pollutes food and has been associated with serious health problems such as nephrotoxicity, hepatotoxicity, neurotoxicity, teratogenicity, carcinogenicity, and immunotoxicity in humans [1,2,3,4,5]. The maximum concentration in cereals (5 µg/kg), wine (2 µg/kg), and coffee products (5 µg/kg), respectively, has been determined by the European Union [6, 7]. It is essential to develop fast and sensitive detection technologies for accurate OTA detection.

Several methods have been developed to detect OTA pollution, including enzyme-linked immunosorbent assay (ELISA), chromatography, capillary electrophoresis, colorimetry, fluorescence (FL) analysis, and surface-enhanced Raman spectroscopy (SERS) [8,9,10,11,12]. Although these methods provided quantitative and qualitative results, they are time-consuming, require expensive equipment, involve complex sample preparation steps, and require well-trained personnel [13]. Therefore, a reliable and sensitive method for OTA detection is critical to guarantee food safety. The ECL aptasensor combines ECL and biosensor technology to convert the concentrations of the target object in solution into an ECL signal output, enabling quantitative and qualitative detection of substances according to ECL intensity [14, 15]. This method has several advantages, including high sensitivity, low noise, and fast response, and has been widely used for food safety and environmental monitoring [16, 17].

The choice of luminophore is critical in the construction of an ECL aptasensor. Among the various ECL emitters, the ECL system based on Ru(bpy)32+ provides high luminous efficiency and chemical stability, making it ideal for sensing applications in complex environments [18,19,20,21]. Due to their high luminescence qualities, strong biocompatibility, good stability, and low toxicity, quantum dots (QDs) have been a popular topic in the field of ECL research with the rapid growth of nanotechnology [22,23,24]. Zhang et al. synthesized BPQDs with high luminous quantum yield using a liquid stripping method and investigated their ECL behavior in the annihilation path and co-reaction path, demonstrating the great potential of BPQDs in quantitative detection based on luminescence analysis and luminescent materials [25].

In the conventional ECL system, inter-nanoparticle interaction occurs between the emitter and its co-reactant, resulting in long-range electronic transfer and energy loss [26, 27]. To address this issue and improve ECL efficiency, Li et al. developed a new self-enhanced ECL emitter by combining Ru(bpy)32+ with its co-reactant nitrogen-doped carbon quantum dots (CNQDs) through electrostatic interaction [28]. In addition, Li et al. also developed a highly selective and sensitive “on–off-on” ECL aptasensor based on a self-enhanced luminophore, achieving strong analytical sensitivity and a high signal-to-noise ratio [29]. Furthermore, the introduction of nanomaterials can promote the electron transfer and improve ECL efficiency [30]. Using multi-walled carbon nanotubes (MWCNTs) and gold nanoparticles (AuNPs), Cao et al. developed highly sensitive luminol-hydrogen peroxide ECL immunosensors for protein detection [31]. Polyethyleneimine (PEI) could protect MWCNTs from aggregation and could be used as a co-reactant to increase the luminous of Ru(bpy)32+ [32]. PEI-functionalized MWCNTs decorated with AuNPs (AuNPs-PEI-MWCNTs) exhibited the integrated properties of three components with better biological activity, large specific surface area, and excellent electrical conductivity [33].

The switch-based design also improved the stability and sensitivity of the biosensor, due to its distinct signal differences in different states [34,35,36,37,38]. Qi et al. developed a peptide-based “on–off-on” ECL biosensor strategy by enhancing the ECL signal of Ru(bpy)32+ (the first “switch-on” state) using AuNPs and tripropylamine, quenching the ECL signal (the “switch-off” state) using ferrocene carboxylic acid–labelled peptides, and restoring the ECL signal (the second “switch-on” state) by releasing ferrocene from target peptides [35]. Liu et al. developed a self-enhanced nanocomposite based on nano-CeO2 and AuNPs modified graphitized carbonitride quantum dots, which achieved the “switch-on” state, and used AgNPs-VB2 nanocomposite to quench the ECL signal, resulting in the “switch-off” state, thus demonstrating an “on–off” ECL immunosensing strategy based on ECL resonance energy transfer [36]. In the switching system, getting the high “switch-on” signal and the low “switch-off” signal is crucial to achieving high sensitivity, which are also the two key points in the structural design of the switching system [37].

Building on these concepts, this study presented an “on–off-on” ECL aptasensor based on a novel self-enhanced luminophore. Specifically, polyethyleneimine functionalized multi-walled carbon nanotubes decorated with gold nanoparticles (AuNPs-PEI-MWCNTs) were used as the electrode matrix to accelerate electron transfer and provide a favorable microenvironment for self-enhanced luminophore loading and ECL signal enhancement due to their good catalytic activity, enhanced electrical conductivity, and high specific surface area. In addition, BPQDs were used as co-reactants of Ru(bpy)32+ in ECL experiments, and the reaction principle between the two was investigated. Compared with traditional ECL systems, the electron transfer distance in the self-enhanced luminophore was significantly shortened due to the intra-nanoparticle electron transfer pathway because BPQDs and oxidized Ru(bpy)32+ were bound within one nanoparticle, thereby improved ECL efficiency to achieve the first “switch-on” state. Next, Fc was introduced by combining the OTA aptamer (Apt) with complementary DNA (cDNA), then Fc+ effectively quenched Ru(bpy)32+*, leading to the “switch-off” state. Finally, OTA was specifically identified by the aptamer, causing Fc to be released from the sensor interface, restoring the ECL intensity to achieve the second “switch-on” state. The proposed ECL aptasensor was demonstrated to have good selectivity, stability, and reproducibility for the detection of OTA.

Experimental

Chemicals and reagents

MWCNTs and PEI were purchased from Nanjing XFNANO Materials Tech Co., Ltd. (Nanjing, China). Tris (2,2′-bipyridyl) ruthenium(II) was obtained from Sigma-Aldrich Trading Co., Ltd. (Shanghai, China). OTA standard solution was obtained from Qingdao Pribolab Bioengineering Co., Ltd. (Qingdao, China). N-Methyl-2-pyrrolidone (NMP), potassium chloride, disodium hydrogen phosphate dodecahydrate, methanol, potassium ferricyanide, trisodium citrate dihydrate, and sodium dihydrogen phosphate dihydrate were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). Triton X-100 (TX100), (3-aminopropyl) triethoxysilane (APTES), n-hexanol, cyclohexane, ethanol, and acetone were obtained from Macklin Biochemical Technology Co., Ltd. (Shanghai, China). Aptamers, complementary chains, bovine serum albumin (BSA), and 1 × TE-buff were purchased from Biotech Biotechnology Co., Ltd. (Shanghai, China). The wheat and oats samples were obtained from the local supermarket (Zibo, Shandong, China). The aptamer sequences used in the study [39] are listed as follows:

-

OTA-aptamer:5′-Fc-GATCGGGTGTGGGTGGCGTAAAGGGAGCATCGGACA-3′

-

OTA-complementary:5′-NH2-TGTCCGATGCTCCCTTTACGCCACCCACACCCG-ATC-3′

Apparatus

Xi’an Ruimai Analytical Instruments Co., Ltd. provided the MPI-A electrochemiluminescence workstation, while Shanghai Chenhua Instruments Co., Ltd. provided the CHI-660D electrochemical workstation. A three-electrode system was used for the ECL detection process, with Ag/AgCl as the reference electrode (RE), platinum electrode (PE) as the counter electrode, and glassy carbon electrode (GCE) as the working electrode. Energy-dispersive spectroscopy (EDS) images and transmission electron microscope (TEM) images were collected by the WJGS-032 instrument (USA). Shanghai Anting Scientific Instrument Factory provided the TGL-20 B high-speed centrifuge. Shanghai Lichen Instrument Technology Co., Ltd. provided the FA1004 electronic analytical balance. The ultrapure water utilized in the studies was provided by the LS MK2 PALL raw water purification system.

Preparation of AuNPs-PEI-MWCNTs

For the synthesis of AuNPs, 48.75 mL of ultrapure water was combined with 1.25 mL of 0.4% chloroauric acid, and the mixture was well agitated. After the liquid had simmered for 7–8 min while being constantly stirred, 1.0 mL of sodium citrate solution at 1% was swiftly added. The solution progressively transformed from a light blue to a dark blue, then to a blue-black, and lastly from a fuchsia to a wine red. Subsequently, the heating process was terminated, and the stirring of the solution was sustained for an additional 30 min to ensure the complete synthesis of the AuNPs.

AuNPs-PEI-MWCNTs was synthesized based on the previous method with some modifications [33]. Specifically, 4 mL of PEI solution was added together with 2.0 mg of carboxylated MWCNTs, and the mixture was then ultrasound dispersed. The resulting mixture was then centrifuged and redispersed to obtain PEI-MWCNTs. Subsequently, 1 mL of the synthesized AuNPs was gradually introduced dropwise into 1 mL of the manufactured PEI-MWCNTs, followed by overnight stirring in the dark. After centrifugation, the black solid was redistributed in 2 mL of 0.01 M phosphate-buffered saline (PBS) at pH 7.4, resulting in the successful synthesis of AuNPs-PEI-MWCNTs.

Preparation of Ru@SiO2-BPQDs

The BPQDs used in this study were prepared according to a previously reported method [25]. Specifically, 1 mL of NMP and 5 mg of BP powder were mashed in a mortar for 20 min. The resulting combination and 3 mL of NMP were placed in a glass vial and sonicated for 8 h at 100 W in an ice bath. The resulting dispersion was subjected to centrifugation at a rate of 7000 rpm for a duration of 20 min, followed by a secondary centrifugation at 10,000 rpm for 20 min. The supernatant comprising the top 75% of the solution was collected each time.

The method used to prepare Ru@SiO2-BPQDs is based on a previous report with some improvements [40]. To prepare Ru@SiO2, a water-in-oil reverse microemulsion was first formed by stirring 7.08 mL TX-100 (as surfactant), 30 mL cyclohexane (as oil phase), 7.2 mL n-hexanol (as co-surfactant), and 1.36 mL water for 5 min. Then 320 µL of 0.1 M Ru(bpy)32+ solution was added and stirred for 30 min until the solution became transparent. Then 400 µL of tetraethyl orthosilicate (TEOS) and 240 µL of NH4OH (25 ~ 28 wt%) were rapidly injected to initiate polymerization. Twenty-four hours were spent stirring the mixture in the dark and at room temperature. Forty milliliters of acetone was used to separate the end production during centrifugation at 10,000 rpm for 10 min, and then washed three times with ethanol–water mixture. Finally, Ru@SiO2 was dried in a vacuum freeze dryer and stored at 4℃ for future use.

To obtain Ru@SiO2-NH2, 10 mg of Ru@SiO2 was dispersed in 5 mL of ethanol and 200 µL of APTES was added. After 4 h of stirring, the mixture was washed with ethanol–water mixture. The resulting product was then dried in a vacuum freeze dryer to obtain Ru@SiO2-NH2. To prepare Ru@SiO2-BPQDs, Ru@SiO2-NH2 (170 µL, 10 mg/mL) and BPQDs (850 µL, 3 mg/mL) were added to a beaker and stirred in the dark for 12 h. The BPQDs were electrostatically bonded to the surface of Ru@SiO2-NH2 to create the self-enhanced luminophore Ru@SiO2-BPQDs due to the opposite charges of these two components.

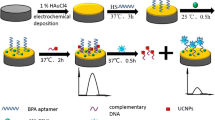

Fabrication of the “on–off-on” ECL aptasensor

Scheme 1 describes the manufacturing principle and mounting steps of the ECL adaptive sensor. The pre-treated GCE was dropped 5 µL of AuNPs-PEI-MWCNTs and Ru@SiO2-BPQDs solutions sequentially and was dried at room temperature naturally. Then, the electrode surface was dropped 5 µL of cDNA solution and incubated at 37 °C to allow fixation by carbonyl amine condensation. Next, to close non-specific binding sites, 0.5% BSA was applied to the electrode surface and allowed to react for 30 min. Afterward, the ferrocene-modified OTA aptamer (Apt-Fc) solution was dropped on the electrode and incubated for 60 min to bind to the complementary chain. Finally, 5 µL of OTA standard solution was applied to the electrode surface and incubated for approximately 60 min at 37 °C to detect OTA in real samples.

Sample pretreatment

To prepare wheat and oats samples for analysis, the method described in a previous report was followed [41]. Briefly, 5 g wheat and oats sample were each mixed with 10 mL of a 50% aqueous methanol solution and subjected to ultrasonic water bath treatment for 20 min. Following a centrifugation at 10,000 rpm for 10 min, the resultant liquid was further diluted 10 times with 0.01 M PBS at pH 7.4 for an ensuing ECL analysis.

Results and discussion

Characterizations of AuNPs-PEI-MWCNTs

Transmission electron microscopy (TEM) was used to characterize the AuNPs-PEI-MWCNTs material. As shown in Fig. 1A, the size of the AuNPs was measured to be approximately 15 nm with a well-defined spherical shape. As shown in Fig. 1B, the TEM image revealed that many AuNPs are homogeneously attached to the surface of PEI-MWCNTs without any aggregation. We could confirm that AuNPs were attached to the outside wall of the PEI-MWCNTs according to the inset image in Fig. 1B, indicating that the AuNPs-PEI-MWCNTs composite was synthesized successfully. The high specific surface area of AuNPs-PEI-MWCNTs provided a platform for effective loading of more luminophore. The PEI in AuNPs-PEI-MWCNTs also could be used as a co-reactant to increase the luminous of Ru(bpy)32+ [32]. Thereby, the AuNPs-PEI-MWCNTs enhanced the first-order amplification of ECL signal.

TEM images of (A) AuNPs, (B) AuNPs-PEI-MWCNTs, (C) Ru@SiO2, and (E) Ru@SiO2-BPQDs. HRTEM images of (D) BPQDs and (F) Ru@SiO2-BPQDs. Insets in B, D, and E are HRTEM images of the respective samples. Insets in F is HRTEM image of BPQDs/Ru@SiO2. (G) STEM image of Ru@SiO2-BPQDs along with elemental distribution mapping analyses of O, Si, P, and Ru

Characterizations of Ru@SiO2-BPQDs

The Ru@SiO2-BPQDs nanomaterial was analyzed by TEM, elemental mapping, FL spectroscopy, and zeta potential measurements. TEM was used to examine the morphology and size distribution of BPQDs (Fig. 1D) and showed that the material had a regular, round morphology with a well-dispersed particle size of approximately 2.6 nm. Furthermore, Ru@SiO2 was created by encasing Ru(bpy)32+ in SiO2 nanoparticles, which displayed an average diameter of 49.5 nm and spherical in shape, monodisperse, with homogeneous particle size distribution (Fig. 1C). Ru(bpy)32+ has a molecular-like structure; it was not immediately apparent from the TEM whether it had been successfully encapsulated in SiO2, but this was confirmed by elemental distribution mapping (Fig. 1G) and FL spectroscopy (Fig. 2A) [42].

Evidence from zeta potential analysis (Fig. 2B) showed that both BPQDs and Ru@SiO2 were characterized by a negative charge. Direct mixing of BPQDs and Ru@SiO2 to form BPQDs/Ru@SiO2 was inefficient as the two materials were unable to bond effectively by electrostatic interaction. As shown in Fig. 1F inset, many BPQDs were not tightly bound on Ru@SiO2 but were scattered around it, which increased the electron transfer distance. For this reason, amino functionalization of Ru@SiO2 was carried out to improve adhesion to BPQDs via electrostatic interaction. As shown in Fig. 1E, it could be clearly observed from the TEM images of Ru@SiO2-BPQDs that a film was formed on the surface of Ru@SiO2 after functionalized with APTES. This film on the surface of Ru@SiO2 improved adhesion to BPQDs. After closer observation of Ru@SiO2-BPQDs by HRTEM, Fig. 1F and E inset revealed that large numbers of BPQDs were attached to the surface of Ru@SiO2-NH2 homogeneously and without any aggregation. Therefore, Ru@SiO2-BPQDs, a self-enhanced luminophore, could react via the intra-nanoparticle electron transfer pathway.

The FL spectra (Fig. 2A) of the Ru@SiO2-BPQDs (curve d) also showed the approximate emission characteristics of both BPQDs (445 nm) and Ru(bpy)32+ (610 nm), indicating that Ru@SiO2-BPQDs retained the original FL characteristics of both BPQDs and Ru(bpy)32+. This finding offered further confirmation of successful attachment between Ru@SiO2-NH2 and BPQDs. Additionally, we carried out zeta potential experiments to verify Ru@SiO2-BPQDs. As depicted in Fig. 2B, after amino functionalization with APTES, the zeta potential of Ru@SiO2 increased from − 19.8 mV (column a) to 3.7 mV (column b), and after negatively charged BPQDs were added (column c, − 14.2 mV), the material clearly changed from positive to negative (column d, − 7.57 mV). The shift in potential also illustrated the self-enhanced luminophore was prepared successfully.

Fabrication and feasibility investigation of the ECL aptasensor

Cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS), and ECL were used to track the construction of the ECL aptasensor. Figure 3A depicts the CV responses obtained from the bare GCE when it was immersed in 10 mM [Fe(CN)6]3−/4− solution containing 0.1 M KCl. A pair of symmetrical redox peaks could be seen on the bare GCE (curve a). A higher current peak was observed when the GCE surface was modified with AuNPs-PEI-MWCNTs (curve b), indicating the composite material possessing superior electrical conductivity. However, the successive modification with Ru@SiO2-BPQDs, cDNA, BSA, and Apt-Fc resulted in a gradual decrease of the redox current signal (curves c–g). This behavior was attributed to the biomolecules’ poor conductivity as well as the antagonistic interactions between [Fe(CN)6]3−/4− and negatively charged cDNA and aptamers. In the presence of OTA, aptamers would be released from the electrode surface, reducing the induced electrostatic repulsion between the negatively charged redox species of [Fe(CN)6]3−/4− and the electrode surface, resulting in an increased in current [43]. In addition, throughout the fabrication process, EIS was employed to monitor and investigate the variations in the electron transfer resistance (Ret) value (Fig. 3B). Compared to the bare electrode (curve a), the Ret of AuNPs-PEI-MWCNTs/GCE was lower due to the superior electron transfer acceleration properties of the material (curve b). The Ret value was raised in comparison to AuNPs-PEI-MWCNTs/GCE by the sequential assembly of Ru@SiO2-BPQDs (curve c), cDNA (curve d), BSA (curve e), and Apt-Fc (curve f) on the GCE surface. In the presence of OTA, the OTA can interact with aptamers, resulting in the Apt-Fc released from the electrode surface. Therefore, the Rct was reduced when OTA was successfully modified (curve g). This result was quite consistent with the CV result, indicating that the ECL aptasensor had been constructed successfully.

(A) CV, (B) EIS, and (C) ECL characterization of aptasensor assembly diagram: (a) bare GCE, (b) AuNPs-PEI-MWCNTs/GCE, (c) Ru@SiO2-BPQDs/AuNPs-PEI-MWCNTs/GCE, (d) cDNA/Ru@SiO2-BPQDs/AuNPs-PEI-MWCNTs/GCE, (e) BSA/cDNA/Ru@SiO2-BPQDs/AuNPs-PEI-MWCNTs/GCE, (f) Apt-Fc/BSA/cDNA/Ru@SiO2-BPQDs/AuNPs-PEI-MWCNTs/GCE, and (g) OTA/Apt-Fc/BSA/cDNA/Ru@SiO2-BPQDs/AuNPs-PEI-MWCNTs/GCE

The performance of the “on–off-on” ECL aptasensor was investigated by recording the ECL responses at each step of the sensor’s operation (Fig. 3C). When Ru@SiO2-BPQDs was modified on AuNPs-PEI-MWCNTs/GCE (curve c), a considerable ECL signal was observed in comparison to the bare GCE (curve a) and AuNPs-PEI-MWCNTs/GCE (curve b). The ECL intensity steadily and significantly decreased after cDNA was modified and blocked by BSA. In addition, modification of Apt-Fc resulted in a notable decrease in ECL intensity due to quenching of electron transfer between Fc+ and Ru(bpy)32+* [44]. The “switch-off” state was achieved (curve f). Finally, OTA bound with its aptamer and released Fc from the sensing interface. This process terminated the quenching process and caused the recovery of ECL intensity (curve g). Thereby, the second “switch-on” state was achieved.

The possible mechanism of the self-enhanced luminophore

To better understand the ECL mechanism of the self-enhanced luminophore, detailed investigations were conducted. The FL and ECL spectra of the Ru@SiO2-BPQDs are presented in Fig. 4A. A remarkable coincidence was observed between the FL spectrum of Ru@SiO2-NH2 and the ECL spectrum of Ru@SiO2-BPQDs, indicating that the emission of ECL in this system was attributed by the Ru(bpy)32+. Figure 4B depicts the ECL responses obtained from the GCE-modified different materials. The ECL intensity (curve a) of Ru@SiO2-NH2/GCE was very low due to the absence of co-reactants. When BPQDs were added to the buffer solution, the ECL intensity was enhanced significantly (curve b), indicating that BPQDs can significantly catalyze the oxidation process of Ru(bpy)32+ and could act as a co-reactant to produce strong luminescence [25]. A similar ECL intensity was attained when the mixture of Ru@SiO2-NH2 and BPQDs was added on GCE (curve c). However, the working electrode modified with Ru@SiO2-BPQDs could produce strong ECL signal (curve d). Luminescence efficiency was enhanced because the electron transfer distance in the self-enhanced luminophore was significantly shortened. This profited from intra-nanoparticle electron transfer pathway between BPQDs and oxidized Ru(bpy)32+.

The possible ECL mechanism of the Ru@SiO2-BPQDs system is described in Fig. 4C. First, the self-enhanced luminophore was electrochemically oxidized and then lost a proton to form Ru(III)@SiO2-BPQDs· (Formula 1 and Formula 2). Second, an intra-nanoparticle process was used to transfer the electron from BPQDs to Ru(III). This procedure led to the complex (Ru(II)*@SiO2-BPQDs) (Formula 3) being in an excited state. Third, when Ru(II)* went back to the ground state, there was a self-enhanced ECL emission (Formula 4). Finally, the oxidation reaction of Fc formed stable Fc+ (Formula 5), which reacted with Ru(II)* to prevent the above reaction (Formula 6), quenched the ECL signal of the system [45].

Optimization of experimental parameters

The detection settings for OTA, including pH value, Apt concentration, hybridization time, and incubation time, have been optimized to produce the highest efficiency and sensitivity in the ECL aptasensor. The base solution’s pH can impact the biological activity of the materials while excessively acidic or alkaline conditions can limit the stability of the aptamers and significantly lower their binding affinity to the mycotoxins. To make the base solution’s pH ideal for the aptasensor, the ECL intensity was measured at different pH values (5.5–9.3) and it was observed (Fig. 5A) that the ECL intensity first increased and then decreased with increasing pH. The maximum value was obtained at pH 7.7, and therefore the base solution’s pH was set at 7.7. The ECL intensity was found to increase with increasing Apt concentration as shown in Fig. 5B. However, the ECL intensity gradually dropped when the Apt concentration rose above 200 nM, indicating that the aptamers on the electrode had become saturated. Therefore, an Apt concentration of 200 nM was chosen considering the efficiency of the hybridization time and the incubation time.

The hybridization time of cDNA and Apt was another factor that can affect the ECL intensity. As depicted in Fig. 5C, the ECL intensity gradually increased with increasing hybridization time up to 60 min and then reached a plateau due to the saturation of the incubation between cDNA and Apt. The ECL intensity was similarly influenced by the OTA and Apt incubation times. According to Fig. 5D, the ECL intensity increased gradually as the OTA and Apt’s incubation time up to 60 min, and then it started to decline. This pattern was brought on by the stable state of the specific binding between Apt and the pesticide. Therefore, 60 min was determined to be the ideal incubation period for OTA and Apt. In conclusion, the optimization of the ECL aptasensor ensured maximum efficiency and sensitivity, enabling rapid and accurate OTA detection in complicated environments.

Analytical performances of the sensor

Under ideal experimental circumstances, investigated was the analytical capability of the suggested “on–off-on” ECL aptasensor for OTA detection. Figure 6A demonstrates that when the concentration of OTA rose from 0.1 to 320 ng/mL, the intensity of the regained ECL steadily increased that was because the increased release of Fc from the GCE surface. The linear relationship between the ECL intensity (IECL) and the logarithm of the OTA concentration (lgcOTA) is shown in Fig. 6B. The corresponding calibration equation was IECL = 6728.17 + 2460.33lgcOTA and the correlation coefficient (R2) was 0.995. The limit of detection (LOD) of 0.03 ng/mL was calculated using a signal-to-noise ratio (ISignal/INoise) of 3 from the previously reported method [49]. Notably, in comparison to other techniques, the current “on–off-on” ECL aptasensor offered a larger linear detection range and a lower LOD (Table 1). The excellent assay performance could be attributed to several factors. Firstly, the self-enhanced luminophore Ru@SiO2-BPQDs significantly shortened the electron transfer distance and improved the ECL efficiency to achieve the high initial ECL signal. Secondly, the quenching of the electron transport between Fc+ and Ru(bpy)32+* resulted in signal differences at different stages. This process improved the sensitivity and stability of the “on–off-on” ECL aptasensor.

The stability of the aptasensor was determined in this study as shown in Fig. 7A. After 7 and 14 days, the ECL signals retained approximately 97.7% and 94.3% of the initial peak intensity, respectively, confirming the superior stability of the aptasensor. Evaluation of the repeatability of the aptasensor by analyzing the ECL reaction of different electrodes independently designed but under the same conditions (Fig. 7B). These electrodes exhibited similar responses with a relative standard deviation (RSD) of 2.2%, demonstrating excellent reproducibility of the fabricated aptasensor. Selectivity is an important parameter to evaluate the ideal aptasensor. To demonstrate the ECL aptasensor’s selectivity in this study, aflatoxin B1 (AFB1), aflatoxin B2 (AFB2), aflatoxin M1 (AFM1), deoxynivalenol (DON), t-2 toxin (T-2), and zearalenone (ZEN) were selected as potential interfering agents. As shown in Fig. 7C, only OTA resulted in a noticeable recovery of the ECL intensity, demonstrating the high affinity between OTA and aptamers. These results confirmed that the aptasensor was highly sensitive for the OTA detection and was not affected by the presence of other fungal toxins.

Real sample analysis

The developed ECL aptasensor was put to the test by being utilized to assess OTA in wheat and oats using the standard addition method. From the experimental results, the recoveries ranged from 95.3 to 103.4%, with RSD values between 2.9 and 6.1%, as shown in Table 2. At the same time, the recoveries of OTA in the same real sample were examined using the conventional LC–MS method and varied from 87.9 to 105.4% (Table 3); the results were consistent with the proposed method. These experimental outcomes made it very evident that the ECL aptasensor could effectively applied for OTA detection in cereal crop samples. It indicated high potential for practical applications.

Conclusions

In this study, the proposed “on–off-on” ECL aptasensor demonstrated exceptional analytical performances for OTA detection, with high sensitivity, low detection limits, and wider detection range. It profited by the self-enhanced luminophore and electron transfer quenching strategy. The first “switch-on” state was provided by Ru@SiO2-BPQDs, resulting in a highest background signal. The “switch-off” state was provided by quenching between Fc and Ru@SiO2-BPQDs, resulting in a lower background signal. The ECL intensity was recovering when OTA was applied, reaching the second “switch-on” state. The “on–off-on” ECL system’s sensitivity was guaranteed by high-intensity “switch-on” signal and low-intensity “switch-off” signal. Furthermore, real wheat and oats samples were successfully used with the developed ECL aptasensor to identify OTA, demonstrating its practicality in practical applications. Overall, high sensitivity, selectivity, stability, sustainability, and repeatability for OTA detection were shown by the developed ECL aptasensor, providing a universal analytical tool for the detection of mycotoxins and other small molecules.

References

Zhou J, Yang Q, Liang C, Chen Y, Zhang X, Liu Z, et al. Detection of ochratoxin A by quantum dots–based fluorescent immunochromatographic assay. Anal Bioanal Chem. 2021;413:183–92.

Zhai S, Zhu Y, Feng P, Li M, Wang W, Yang L, et al. Ochratoxin A: its impact on poultry gut health and microbiota, an overview. Poult Sci. 2021;100(5):101037.

Vlachou M, Pexara A, Solomakos N, Govaris A. Ochratoxin A in slaughtered pigs and pork products. Toxins. 2022;14(2):67.

Chen J, Chen Y, Zhu Q, Wan J. Ochratoxin A contamination and related high-yield toxin strains in Guizhou dried red chilies. Food Control. 2023;145:109438.

Zhang H, Wang Y, Lin Y, Chu W, Luo Z, Zhao M, et al. A catalytic hairpin assembly–based Förster resonance energy transfer sensor for ratiometric detection of ochratoxin A in food samples. Anal Bioanal Chem. 2023;415(5):867–74.

Chen R, Sun Y, Huo B, Yuan S, Sun X, Zhang M, et al. Highly sensitive detection of ochratoxin A based on bio-barcode immunoassay and catalytic hairpin assembly signal amplification. Talanta. 2020;208:120405.

Alhamoud Y, Yang D, Kenston SSF, Liu G, Liu L, Zhou H, et al. Advances in biosensors for the detection of ochratoxin A: bio-receptors, nanomaterials, and their applications. Biosens Bioelectron. 2019;141:111418.

Susca A, Anelli P, Haidukowski M, Probyn CE, Epifani F, Logrieco AF, et al. A PCR method to identify ochratoxin A-producing Aspergillus westerdijkiae strains on dried and aged foods. Int J Food Microbiol. 2021;344:109113.

Okuma TA, Huynh TP, Hellberg RS. Use of enzyme-linked immunosorbent assay to screen for aflatoxins, ochratoxin A, and deoxynivalenol in dry pet foods. Mycotoxin Res. 2018;34:69–75.

Song L, Li J, Li H, Chang Y, Dai S, Xu R, et al. Highly sensitive SERS detection for aflatoxin B1 and ochratoxin A based on aptamer-functionalized photonic crystal microsphere array. Sens Actuators, B Chem. 2022;364:131778.

He K, Sun L, Wang L, Li W, Hu G, Ji X, et al. Engineering DNA G-quadruplex assembly for label-free detection of ochratoxin A in colorimetric and fluorescent dual modes. J Hazard Mater. 2022;423:126962.

Luci G. A rapid HPLC-FLD method for ochratoxin A detection in pig muscle, kidney, liver by using enzymatic digestion with MISPE extraction. MethodsX. 2020;7:100873.

Jia M, Jia B, Liao X, Shi L, Zhang Z, Liu M, et al. A CdSe@CdS quantum dots based electrochemiluminescence aptasensor for sensitive detection of ochratoxin A. Chemosphere. 2022;287:131994.

Chen H, Zhang H, Yuan R, Chen S. Novel double-potential electrochemiluminescence ratiometric strategy in enzyme-based inhibition biosensing for sensitive detection of organophosphorus pesticides. Anal Chem. 2017;89(5):2823–9.

Lu Y, Han S, Xi Y, Yang S, Zhu T, Niu B, et al. TiO2 nanoparticles modified graphitic carbon nitride with potential-resolved multicolor electrochemiluminescence and application for sensitive sensing of rutin. Anal Bioanal Chem. 2023;415(2):221–33.

Tian D, Wang J, Zhuang Q, Wu S, Yu Y, Ding K. An electrochemiluminescence biosensor based on graphitic carbon nitride luminescence quenching for detection of AFB1. Food Chem. 2023;404:134183.

Qin X, Gu C, Wang M, Dong Y, Nie X, Li M, et al. Triethanolamine-modified gold nanoparticles synthesized by a one-pot method and their application in electrochemiluminescent immunoassy. Anal Chem. 2018;90(4):2826–32.

Li L, Chen B, Luo L, Liu X, Bi X, You T. Sensitive and selective detection of Hg2+ in tap and canal water via self-enhanced ECL aptasensor based on NH2–Ru@SiO2-NGQDs. Talanta. 2021;222:121579.

Xiong X, Li Y, Yuan W, Lu Y, Xiong X, Li Y, et al. Screen printed bipolar electrode for sensitive electrochemiluminescence detection of aflatoxin B1 in agricultural products. Biosens Bioelectron. 2020;150:111873.

Luo L, Ma S, Li L, Liu X, Zhang J, Li X, et al. Monitoring zearalenone in corn flour utilizing novel self-enhanced electrochemiluminescence aptasensor based on NGQDs-NH2-Ru@SiO2 luminophore. Food Chem. 2019;292:98–105.

Xiao Y, Wang G, Yi H, Chen S, Wu Q, Zhang S, et al. Electrogenerated chemiluminescence of a Ru(bpy)32+/arginine system: a specific and sensitive detection of acetaminophen. RSC Adv. 2022;12(5):3157–64.

Yang E, Zhang Y, Shen Y. Quantum dots for electrochemiluminescence bioanalysis-a review. Anal Chim Acta. 2022;1209:339140.

Chen J, Wang Q, Liu X, Chen X, Wang L, Yang W. Black phosphorus quantum dots as novel electrogenerated chemiluminescence emitters for the detection of Cu2+. Chem Commun. 2020;56(34):4680–3.

Ou P, Wu J, Lin Y, Tan X, Wu Y, Chen Z et al. Flexible photoelectrochemical sensor for highly sensitive chloramphenicol detection based on M-TiO 2-CdTe QDs/CdS QDs composite. Anal Bioanal Chem. 2022;1–14.

Zhang L, Tian K, Dong Y, Ding H, Wang C. Electrogenerated chemiluminescence of Ru(bpy)32+ at a black phosphorus quantum dot modified electrode and its sensing application. Analyst. 2018;143(1):304–10.

Dong Y-P, Zhou Y, Wang J, Zhu J-J. Electrogenerated chemiluminescence resonance energy transfer between Ru(bpy)32+ electrogenerated chemiluminescence and gold nanoparticles/graphene oxide nanocomposites with graphene oxide as coreactant and its sensing application. Anal Chem. 2016;88(10):5469–75.

Liang R-P, Yu L-D, Tong Y-J, Wen S-H, Cao S-P, Qiu J-D. An ultratrace assay of arsenite based on the synergistic quenching effect of Ru(bpy)32+ and arsenite on the electrochemiluminescence of Au–g-C3N4 nanosheets. Chem Commun. 2018;54(99):14001–4.

Li L, Zhao W, Zhang J, Luo L, Liu X, Li X, et al. Label-free Hg (II) electrochemiluminescence sensor based on silica nanoparticles doped with a self-enhanced Ru(bpy)32+-carbon nitride quantum dot luminophore. J Colloid Interface Sci. 2022;608:1151–61.

Li L, Chen B, Liu X, Jiang P, Luo L, Li X, et al. ‘On-off-on’electrochemiluminescent aptasensor for Hg2+ based on dual signal amplification enabled by a self-enhanced luminophore and resonance energy transfer. J Electroanal Chem. 2022;907:116063.

Fu X, Li X, Han D, Yang W, Liu C, Fan L, et al. Ultrasensitive electrochemical biosensor for des-gamma-carboxy prothrombin analysis based on core-shell Pd@PtCu-alloy loaded on WS2 nanosheet. J Electroanal Chem. 2021;888:115213.

Cao Y, Yuan R, Chai Y, Mao L, Niu H, Liu H, et al. Ultrasensitive luminol electrochemiluminescence for protein detection based on in situ generated hydrogen peroxide as coreactant with glucose oxidase anchored AuNPs@MWCNTs labeling. Biosens Bioelectron. 2012;31(1):305–9.

Hong L-R, Chai Y-Q, Zhao M, Liao N, Yuan R, Zhuo Y. Highly efficient electrogenerated chemiluminescence quenching of PEI enhanced Ru(bpy)32+ nanocomposite by hemin and Au@CeO2 nanoparticles. Biosens Bioelectron. 2015;63:392–8.

Shi X, Liu H, Zhang M, Yang F, Li J, Guo Y, et al. Ultrasensitive electrochemiluminescence aptasensor based on AuNPs@MWCNTs and Au@AgNPs for detection of profenofos residues. Sens Actuators, B Chem. 2021;348:130663.

Ma X, Lin S, Dang Y, Dai Y, Zhang X, Xia F. Carbon dots as an “on-off-on” fluorescent probe for detection of Cu (II) ion, ascorbic acid, and acid phosphatase. Anal Bioanal Chem. 2019;411:6645–53.

Qi H, Li M, Dong M, Ruan S, Gao Q, Zhang C. Electrogenerated chemiluminescence peptide-based biosensor for the determination of prostate-specific antigen based on target-induced cleavage of peptide. Anal Chem. 2014;86(3):1372–9.

Liu Z, Wang J, Cui C, Zheng L, Hu L. Introducing AgNPs-VB2 composites as the dual signal quenching of CeO2–AuNPs-g-CNQDs hybrids for ultrasensitive “on-off” electrochemiluminescence immunosensing of prostate specific antigen. Talanta. 2023;252:123886.

Zhao M, Zhuo Y, Chai Y-Q, Yuan R. Au nanoparticles decorated C60 nanoparticle-based label-free electrochemiluminesence aptasensor via a novel “on-off-on” switch system. Biomaterials. 2015;52:476–83.

Luo X, Zhang W, Han Y, Chen X, Zhu L, Tang W, et al. N, S co-doped carbon dots based fluorescent “on-off-on” sensor for determination of ascorbic acid in common fruits. Food Chem. 2018;258:214–21.

Shao B, Ma X, Zhao S, Lv Y, Hun X, Wang H, et al. Nanogapped Au(core) @ Au-Ag(shell) structures coupled with Fe3O4 magnetic nanoparticles for the detection of ochratoxin A. Anal Chim Acta. 2018;1033:165–72.

Li Y, Liu D, Meng S, Zhang J, Li L, You T. Regulation of Ru(bpy)32+ electrochemiluminescence based on distance-dependent electron transfer of ferrocene for dual-signal readout detection of aflatoxin B1 with high sensitivity. Anal Chem. 2021;94(2):1294–301.

Liu X, Xu Y, Wan D-b, Xiong Y-h, He Z-y, Wang X-x, et al. Development of a nanobody–alkaline phosphatase fusion protein and its application in a highly sensitive direct competitive fluorescence enzyme immunoassay for detection of ochratoxin A in cereal. Anal Chem. 2015;87(2):1387–94.

Luo L, Liu X, Bi X, Li L, You T. Facile fabrication and application of an innovative self-enhanced luminophore with outstanding electrochemiluminescence properties. Sens Actuators, A. 2020;312:112167.

Jiang D, Du X, Chen D, Zhou L, Chen W, Li Y, et al. One-pot hydrothermal route to fabricate nitrogen doped graphene/Ag-TiO2: efficient charge separation, and high-performance “on-off-on” switch system based photoelectrochemical biosensing. Biosens Bioelectron. 2016;83:149–55.

Cao W, Ferrance JP, Demas J, Landers JP. Quenching of the electrochemiluminescence of tris (2,2 ‘-bipyridine) ruthenium(II) by ferrocene and its potential application to quantitative DNA detection. J Am Chem Soc. 2006;128(23):7572–8.

Li L, Zhang J, Zhao W, Liu X, Luo L, Bi X, et al. DNA-modified electrochemiluminescent tris (4, 4’-dicarboxylicacid-2,2’-bipyridyl) ruthenium(II) dichloride and assistant DNA-modified carbon nitride quantum dots for Hg2+ detection. ACS Appl Nano Mater. 2021;4(2):1009–18.

Wang Y, Yu L, Zhang H, Zhu R, Meng Z. Competitive ELISA based on pH-responsive persistent luminescence nanoparticles for autofluorescence-free biosensor determination of ochratoxin A in cereals. Anal Bioanal Chem. 2023;415(10):1877–87.

Hou Y, Long N, Jia B, Liao X, Yang M, Fu L, et al. Development of a label-free electrochemical aptasensor for ultrasensitive detection of ochratoxin A. Food Control. 2022;135:108833.

Hu Y, Xie H, Hu J, Yang D. Disposable electrochemical aptasensor based on graphene oxide-DNA complex as signal amplifier towards ultrasensitive detection of ochratoxin A. Micromachines. 2022;13(6):834.

Sha H, Zhang Y, Wang Y, Ke H, Xiong X, Xue H, et al. Electroluminescent aptasensor based on RuSiO2 nanoparticles for detection cytochrome c using ferrocene as quenching probe. Biosens Bioelectron. 2019;132:203–9.

Acknowledgements

We appreciate the reviewers and the editors for their helpful and constructive comments that greatly improved our work.

Funding

This work was financially supported by the Shandong Provincial Natural Science Foundation (ZR202210210044, ZR2022MC196) and the Central Finance Guidance Local Science and Technology Development Fund Project (YDZX2022163).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sang, M., Meng, X., Zhang, Y. et al. An “on–off–on” electrochemiluminescence aptasensor based on a self-enhanced luminophore for ochratoxin A detection. Anal Bioanal Chem 415, 5833–5844 (2023). https://doi.org/10.1007/s00216-023-04864-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-023-04864-8