Abstract

Polybrominated diphenyl ethers (PBDEs) are considered emerging organic contaminants that attract more attention in the environment. Herein, online coupling of solid-phase microextraction and ultrahigh-resolution mass spectrometry was developed for rapid screening of eight PBDEs in water samples. This procedure was completed in 22 min, about 6 times faster than the routine workflow such as solid-phase extraction coupled with gas chromatography-mass spectrometry. Thermal desorption and solvent-assisted atmospheric pressure chemical ionization were developed for the effective coupling of solid-phase microextraction (SPME) with ultrahigh-resolution mass spectrometry (UHRMS), which contributed to the signal enhancement and made the methodology feasible for environmental screening. The limits of detection and quantification were 0.01–0.50 ng/mL and 0.05–4.00 ng/mL, respectively. The recoveries were 57.2–75.2% for quality control samples at spiking levels of 0.8–10 ng/mL (4–50 ng/mL for BDE209), with relative standard deviation less than 19.0%. Twelve water samples from different river sites near industrial areas were screened using the developed method. The results showed that BDE-209 was the dominant PBDE (1.02–1.28 ng/mL in positive samples), but its amount was lower than the human health ambient water quality criteria. Consequently, the developed method provides a rapid and reliable way of evaluating contamination status and risks of PBDEs in aqueous environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since 1970s, polybrominated diphenyl ethers (PBDEs) had been widely added to consumer merchandise such as electronic products, furniture, and textiles as additive flame retardants [1]. With the dramatic increase in the consumption of flame retardant-containing products, PBDEs inevitably enter the environment through volatilization or exudation. Surface runoff and atmospheric deposition can further transfer PBDEs to the water matrices [2], and the concentration of PBDEs is probably high in water samples near industrial point sources, such as fireproof material factories, wastewater treatment plants, and waste incineration plants. PBDEs are persistent and easy to enter organisms through various exposure pathways [3]. The strong hydrophobicity of PBDEs enhances the bioaccumulation in humans and animals [4], bringing many toxic effects, such as neurodevelopmental toxicity [5], thyroid toxicity [6], and carcinogenicity [7]. All of these threaten the human health and global ecological environment [8]. Hence, PBDEs commercial mixtures had been listed in the Stockholm Convention by 2017 with clear regulations about their production and use [9].

Considering that PBDEs may exhibit persistence, bioaccumulation, and toxicity [3], rapid and accurate detection can provide a reliable monitoring of PBDEs in aqueous environment. Gas chromatography-mass spectrometry (GC–MS) is commonly used for PBDEs analysis [10,11,12], whose procedures were reported in official standards such as the United States Environmental Protection Agency (US EPA) Method 1614A [13], International Organization for Standardization (ISO) 22,032: 2006, and National Environmental Protection Standards of the People’s Republic of China HJ 909–2017 [14], However, analysis efficiency remains challengeable because of the tedious procedure of sample preparation and long chromatographic separation time. Solid-phase extraction (SPE) or liquid–liquid extraction (LLE) has been routinely used to enrich PBDEs from water samples before instrumental analysis [15, 16], but it requires a large amount of sample, making sample storage and transportation difficult. Clean-up and pre-concentration are also necessary after SPE or LLE, which is time-consuming and laborious [17].

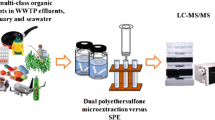

In an attempt to address the above challenges, online detection of PBDEs concentrated on solid-phase microextraction (SPME) fibers using mass spectrometry could be a promising protocol, obviating sophisticated sample pretreatment and chromatographic separation steps. On the one hand, SPME is a solvent-free sample pretreatment technique based on the partition equilibrium of the analytes between the sample matrix and the SPME fiber coatings [18]. It integrates extraction, purification, and concentration in one step [19], greatly shortening the sample pretreatment time compared with SPE or LLE [17, 20]. SPME has been proved as a useful tool for the extraction of compounds in environmental samples [21]. On the other hand, ultrahigh-resolution mass spectrometry (UHRMS) with high mass resolving power of m/Δm50% > 300,000 is powerful for compound identification from complex mixtures without chromatographic separation [22,23,24], which has been successfully employed to contaminant analysis in water [25,26,27], food [28], and other samples [29, 30]. Precise quantification is also important for SPME-UHRMS analysis. Therefore, not only the SPME procedure but also the online desorption and MS ionization processes are of great significance [31,32,33]. A proper desorption and ionization method can provide an efficient transfer for online coupling to obtain stable and strong MS responses. Until now, SPME-UHRMS has not been reported for rapid screening of PBDEs in environmental water bodies.

The aim of this work is to develop an online coupling method of SPME-UHRMS for rapid screening of PBDEs in aqueous samples. Eight PBDE analytes were selected in this work, with 3–10 bromine atoms per molecule, respectively. They were not only the most widely used and concerned PBDEs in production and environmental protection, but also the representative compounds for screening analysis of the different types of BDEs. In this work, the desorption and ionization processes were investigated to achieve effective online coupling of SPME with UHRMS, and also to ensure the reliability and sensitivity of the method. The method was ultimately applied to rapidly screening PBDEs in water samples near industrial point sources, which showed that it fulfilled the requirement of human health risk assessment.

Materials and methods

Standards and reagents

Methanol, n-hexane, toluene, and acetone of HPLC grade were purchased from Fisher Scientific Ltd. (Bartlesville, USA). Ultra-pure water was obtained from HHitech laboratory water purification system (Shanghai, China). Eight PBDE standards (BDE-28, BDE-47, BDE-99, BDE-153, BDE-183, BDE-203, BDE-206, and BDE-209) and six 13C12-labeled internal standards of PBDEs (13C12-BDE-28, 13C12-BDE-47, 13C12-BDE-99, 13C12-BDE-153, 13C12-BDE-183, and 13C12-BDE-209) were purchased from AccuStandard Inc. (New Haven, USA), in which 13C12-BDE-209 was the internal standard of BDE-203, BDE-206, and BDE-209.

Stock solutions of individual PBDEs as well as individual 13C12-labeled PBDEs were stored at the original manufacturer concentrations at − 20 °C. Working solutions at concentration of 10 μg/mL for BDE-209 and 2 μg/mL for other PBDE congeners were prepared in acetone at − 20 °C in amber glass vials before use. For quantitative analysis, 13C12-labeled PBDEs were used as internal standards. Working solutions at concentration of 1 μg/mL for 13C12-BDE-209 and 200 ng/mL for other 13C12-labeled PBDEs were prepared in acetone at − 20 °C in amber glass vials before use.

Sample collection

Twelve water samples were collected from eight rivers in July 2021. The rivers are located at industrial areas in Beijing, China. The sampling locations with detailed information of longitude and latitude are provided in Table S1. All samples were stored in amber glass vials at 4 °C until analysis.

GC–MS analysis

Gas chromatography-triple quadrupole mass spectrometry (GC–MS/MS) was used to optimize SPME conditions. Chromatographic separation was performed by Trace GC Ultra gas chromatograph (Thermo Fisher Scientific, USA), and analytes were detected by TSQ Quantum XLS Ultra mass spectrometer (Thermo Fisher Scientific, USA). Xcalibur was used as the system operating and data processing software.

GC was carried out on a DB-5ht column (15 m length, 0.25 mm i.d., 0.1 μm film thickness; Agilent, USA). The inlet temperature was maintained at 270 °C. Split injection was used, and split ratio was 10:1. Helium gas was used as the carrier gas at a flow rate of 1 mL/min. The temperature profile started at 80 ℃ for 0 min, followed by a 25 ℃/min ramp to 290 ℃, which was held for 0 min, then finally a 35 ℃/min ramp to 325 ℃. The transfer line temperature was 280 °C. In the electron impact ionization (EI) of MS, the ion source temperature was 280 °C, and the electron energy was 70 eV. Ions were monitored in selected reaction monitoring (SRM) mode.

Orbitrap MS analysis

Orbitrap Fusion mass spectrometry (Thermo Fisher Scientific, USA) with a resolution of 500,000 (full width at half maximum; FWHM) at m/z of 195, was used for identification and quantification of PBDEs in the negative ion mode at full-scan mode from m/z 200 to 1000. Orbitrap was chosen as the detector with the resolution of the mass spectrometer setting at 500,000.

When PBDEs were injected by a syringe pump, the following instrument parameters were applied: (1) ion source: APCI, flow rate: 20 μL/min, sheath gas: 20 arbitrary units, auxiliary gas: 5 arbitrary units, sweep gas: 0.1 arbitrary units, vaporizer temperature: 260 ℃, ion transfer tube temperature: 280 ℃, RF lens: 60%, automated gain control (AGC) target: 5 × 105, maximum injection time: 500 ms, and microscans: 1; (2) ion source: APPI, flow rate: 20 μL/min, sheath gas: 20 arbitrary units, auxiliary gas: 5 arbitrary units, sweep gas: 0.1 arbitrary units, vaporizer temperature: 260 ℃, ion transfer tube temperature: 280 ℃, RF lens: 60%, automated gain control (AGC) target: 5 × 105, maximum injection time: 500 ms, and microscans: 1.

SPME-Orbitrap MS analysis

For the SPME procedure, 10 mL of water samples was extracted by direct immersion mode using 85-μm polyacrilate fiber (Supelco, USA). Internal standard compounds were spiked into the investigated sample solution before SPME for analyte quantification. The samples were extracted for 20 min at 60 ℃ with stirring at 1500 rpm. After extraction, the SPME fiber was dried out for analysis.

The SPME fiber was directly placed at the vaporizer tube outlet, and the heated nitrogen stream from vaporizer tube was directed onto the SPME fiber surface. The enriched analytes were desorbed to the gas phase, and then transported to the corona discharge needle, leading to generate charged ions for mass spectrometry analysis with the assistance of methanol.

Parameters for Orbitrap Fusion MS were as follows: sheath gas: 15 arbitrary units, auxiliary gas: 25 arbitrary units, vaporizer temperature: 310 ℃, ion transfer tube temperature: 310 ℃. For other conditions, the same parameters described in the previous section were used. The data acquisition was conducted via the Xcalibur software (Thermo Fisher Scientific, USA).

Results and discussion

Optimization of solid-phase microextraction procedures

Before coupling SPME with Orbitrap MS, conditions of SPME need to be optimized to achieve a maximum yield. Extraction temperature, stirring speed, and extraction time are crucial parameters affecting the efficiency of the SPME process. Optimization of extraction conditions was verified by GC–MS/MS, which is a well-established method [34, 35] and suitable for evaluation of the SPME process separately from the following ionization and UHRMS detection.

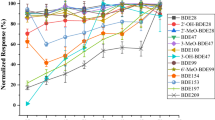

0.1 ng/mL (0.5 ng/mL for BDE-209) PBDEs were spiked to ultra-pure water samples to optimize the extraction process. Figure 1A shows the effects of different extraction temperatures on relative intensity of MS responses, indicating that the signal intensities enhanced with the increase of extraction temperature from 40 to 60 ℃, as higher temperature accelerated analytes transport from aqueous samples to the SPME fiber. However, further increase of temperature led to a decrease of the signal intensities. Analyte adsorption onto the SPME fiber is exothermic [36], so higher temperature is unfavorable to analyte adsorption. Accordingly, 60 ℃ was the optimal extraction temperature. Agitation speed was also investigated (Fig. 1B). Agitation promoted mass transfer in the system; thus, the signal intensities enhanced when agitation speed increased from 1000 to 1500 rpm. If agitation speed continued to increase, the signal intensities no longer enhanced because agitation also increased the mass transfer of the analytes from water to air, which caused analyte loss. Hence, 1500 rpm was selected as the optimal agitation speed for PBDE enrichment. Besides, different extraction times were studied (Fig. 1C). It was found that signal intensities enhanced with the increase of extraction time, and a dynamic equilibrium process between aqueous sample and the SPME fiber was reached at 20 min for most of PBDEs. Therefore, 20 min was the most suitable extraction time.

Thermal desorption and solvent-assisted APCI

Efficient desorption and ionization of analytes from the SPME fibers is the most crucial issue to achieve online coupling of SPME with Orbitrap MS analysis. This section was intended to improve ionization efficiency through regulating ionization modes and ionization environment, and to improve the desorption of enriched analytes.

Atmospheric pressure chemical ionization (APCI) and atmospheric pressure photoionization (APPI) were considered candidates because of the low polarity of PBDEs [37]. Either for APCI or for APPI, [M-Br + O]− was confirmed as the predominant ionization product of PBDEs, which was produced by the reaction between PBDEs and superoxide ion [38]. M−· could also be detected under negative ion mode due to the positive electron affinities of PBDEs, but it was not as abundant as [M-Br + O] −. Therefore, [M-Br + O] − was selected as the characteristic and quantitative ion of PBDEs. Compared with APPI, as shown in Fig. 2A, MS responses of all the analytes under APCI were higher, since it was easier to produce thermal electrons at the tip of corona discharge needle than in the photoionization reaction. Therefore, APCI was chosen for PBDE analysis. Solvent-assisted APCI was investigated, because the concentration of oxygen affected the substitution reaction during the formation of [M-Br + O] −, and the active oxygen could either come from ambient air or be produced during solvent decomposition. Different solvents were tested as shown in Fig. 2B. MS responses were the highest when methanol was used as ionization solvent. As an oxygen-containing solvent, methanol produced an excess of O2−· in the source which resulted in the information of [M-Br + O] − of PBDEs. Hence, methanol was chosen as the assistant ionization solvent for APCI-MS analysis of PBDEs.

The desorption process was carefully investigated to promote the transfer of PBDEs from SPME fibers to gas-phase ionization and following MS detection. High temperature could help to improve the desorption of enriched analytes. PBDEs on the SPME fiber were easily desorbed to the gas phase with the aid of heated nitrogen stream. To make the heated steam focus on the SPME fiber and reduce the loss of analytes, semi-enclosed ion source chamber was adopted. Meanwhile, solvent like methanol that was used in offline SPME for PBDE elution should also assist the online desorption of PBDEs. However, when introducing methanol through solvent-assisted sprayer, it seemed solvent desorption had a negative effect on analyte desorption. As shown in Fig. 3A, MS responses decreased as introduction amounts of methanol spray increased, among which thermal desorption only (0 μL/min methanol injection) resulted in much higher MS response than any other flow rates of methanol introduction. Such a result was unexpected, which was worthy of further investigation because methanol has not only been reported as elution solvent for PBDEs in offline SPME or SPE but also demonstrated effective to significantly improve ionization efficiency of PBDEs as APCI spray. Therefore, the introduction mode of solvent for PBDE desorption was taken into consideration. The original dynamic spray mode was replaced with static dropping mode to avoid dispersing the desorbed PBDEs. The dropping mode was proved effective and could provide about 30% higher MS responses than the other mode (Fig. 3A). Thus, direct dropping of methanol on the SPME fiber was an ideal desorption method. The optimized desorption and ionization process of PBDEs is described in Fig. 3B.

(A) Effect of desorption modes on ionization responses. TD, thermal desorption only; SMD, static methanol desorption; DMD, dynamic methanol desorption. Concentration of each PBDE is 1 μg/mL. Each sample replicates three times. (B) Schematic illustration of desorption and ionization process for analysis of PBDEs by coupling of SPME with APCI-Orbitrap MS

Method validation

Compound identification was based on both accurate molecular formula obtained by Orbitrap MS and specific fragments obtained by collision-induced dissociation (CID). Quantitative ions and qualitative ions of each PBDE are listed in Table 1. Qualitative analysis by UHRMS satisfies the requirement of “in case noise was absent, when extracted ion chromatograms were obtained at HRMS, a signal should be present in at least 5 subsequent scans for identification purposes,” as indicated by European Commission guideline SANTE/11312/2021. Table 2 shows the analytical performance of the developed SPME-Orbitrap MS method for the determination of PBDEs. Satisfactory linearity was obtained with R2 ≥ 0.990 for 8 PBDEs. The limits of detection (LOD) and limits of quantification (LOQ) were obtained with signal-to-noise ratio (S/N) values of 3 and 10, respectively. The LOD and LOQ of PBDEs ranged from 0.01 to 0.50 ng/mL and from 0.05 to 4.00 ng/mL, respectively. As listed in Table 2, the recoveries of all analytes were 57.2–69.7%, 62.6–74.8%, and 64.8–75.2% for low, medium, and high spiked levels, respectively. Relative standard deviation (RSD) was generated from the replicate measurements (n = 6) at each spiked level, with RSD values in the range of 6.4–18.8%. The results indicated that the developed method had satisfactory accuracy and precision.

The sample amount required by the developed method was approximately 1/50 of that by SPE-GC–MS (US EPA Method 1614A). Moreover, the entire analysis process could be completed within 22 min, saving 120 min compared with the SPE-GC–MS workflow. Although the sensitivity of SPME-Orbitrap MS method was lower than that of reported SPE-GC–MS method (LODs and LOQs was 0.02–0.05 ng/L and 0.05–0.1 ng/L [20]), it was higher than the human health ambient water quality criteria (AWQC) of PBDEs [39] that defined the safe level of contaminants in the aqueous environment, below which PBDEs would not pose a risk to human health. Therefore, the SPME-Orbitrap MS method was proposed as a promising way for rapid screening and human health risk evaluation of PBDEs in water. Figure S1 shows the signals obtained for the PBDEs when the SPME-Orbitrap method was applied, by comparing the MS response of blank extraction with the targeted PBDEs at their LOD and LOQ values. The results demonstrated that the developed method was effective to analyze PBDEs.

The matrix effect of the entire method was evaluated by use of the equation [40]:

where ME is the matrix effect (ion suppression/ enhancement), B is the MS response 13C-labeled PBDEs spiked in real sample, and A is the MS response 13C-labeled PBDEs spiked in matrix-free solvent.

The acceptance range of ME is ± 20%. The calculated ME was from − 19.6 to − 3.3%. The ion suppression degree could be successfully compensated by internal standardization with 13C12-labeled PBDEs. Besides, the optimization of extraction and ionization conditions could also reduce the matrix effect. These data prove that the developed method does not suffer the negative matrix effect problems and is applicable to the real water samples.

Rapid screening of PBDEs in water samples

Water samples from twelve sites were analyzed for PBDEs screening. The selected 12 sampling sites were near potential pollution sources, including four sewage treatment plants, one waste incineration plant, one landfill, and one fireproof material factory. The sampling sites covered both the upstream and downstream. The entire analysis procedure was completed within 22 min, improving the analysis efficiency greatly.

As shown in Table S2, only nona-BDE and deca-BDE were detected among all target PBDEs. The concentration levels of ΣPBDEs ranged from 1.02 to 1.51 ng/mL, which were 3 orders of magnitude higher than the reported weighted mean value of ΣPBDEs in China in the past decade [39]. The increase of ΣPBDEs concentrations in the sampling sites indicated a possible contamination release from the industrial point sources. It was observed that deca-BDE (BDE-209) was detected more frequently than other PBDEs, which might be due to that BDE-209 was widely used in commercial mixtures of PBDEs. Although the concentration of detected BDE-209 was as high as 1.28 ng/mL at sampling site S12 in the downstream of the fireproof material factory, it was still much lower than the human health AWQC value (65.2 ng/mL), indicating that BDE-209 might not arouse health risk for human. Additionally, the concentration of BDE-209 found in the downstream was higher than that in the upstream. This was not surprising as the contaminants accumulated gradually in the process of river flowing from upstream to downstream. Thus, it is necessary and urgent to pay more attention to the distribution and risk of pollutants in the downstream.

Conclusion

To summarize, a convenient analytical workflow by online coupling SPME with Orbitrap MS was proposed for rapid screening of PBDEs in water samples. It took only 22 min, about 6 times faster than the standard procedure, significantly improving the analytical efficiency. It was also proved that thermal desorption and solvent-assisted APCI significantly enhanced MS responses when coupling SPME with Orbitrap MS. Moreover, solvent introduction manner was adjusted as static dropping mode to improve chemical ionization efficiency. Given that PBDEs are expected to be ubiquitous and hazardous in aqueous environment, SPME-UHRMS method proposed here shows significant value in providing a rapid and convenient screening method for identifying and determining emerging organic contaminants. Finally, the developed method would also support rapid screening of other contaminants in aqueous samples, which helps to fulfill the analysis of the distribution and potential risks of contaminants in a short time.

References

Blum A, Behl M, Birnbaum L, Diamond ML, Phillips A, Singla V, et al. Organophosphate ester flame retardants: Are they a regrettable substitution for polybrominated diphenyl ethers? Environ Sci Technol Lett. 2019;6(11):638–49.

Ranjbar Jafarabadi A, Dashtbozorg M, Raudonyte-Svirbutaviciene E, Riyahi BA. First report on polybrominated diphenyl ethers in the Iranian Coral Islands: Concentrations, profiles, source apportionment, and ecological risk assessment. Chemosphere. 2020;251: 126397.

Wu Z, He C, Han W, Song J, Li H, Zhang Y, et al. Exposure pathways, levels and toxicity of polybrominated diphenyl ethers in humans: A review. Environ Res. 2020;187: 109531.

Lin C, Zeng Z, Xu R, Liang W, Guo Y, Huo X. Risk assessment of PBDEs and PCBs in dust from an e-waste recycling area of China. Sci Total Environ. 2022;803: 150016.

Gaylord A, Osborne G, Ghassabian A, Malits J, Attina T, Trasande L. Trends in neurodevelopmental disability burden due to early life chemical exposure in the USA from 2001 to 2016: A population-based disease burden and cost analysis. Mol Cell Endocrinol. 2020;502: 110666.

Makey CM, McClean MD, Braverman LE, Pearce EN, He XM, Sjodin A, et al. Polybrominated diphenyl ether exposure and thyroid function tests in North American adults. Environ Health Perspect. 2016;124(4):420–5.

Dunnick JK, Shockley KR, Pandiri AR, Kissling GE, Gerrish KE, Ton TV, et al. PBDE-47 and PBDE mixture (DE-71) toxicities and liver transcriptomic changes at PND 22 after in utero/postnatal exposure in the rat. Arch Toxicol. 2018;92(11):3415–33.

Airaksinen R, Hallikainen A, Rantakokko P, Ruokojarvi P, Vuorinen PJ, Mannio J, et al. Levels and congener profiles of PBDEs in edible Baltic, freshwater, and farmed fish in Finland. Environ Sci Technol. 2015;49(6):3851–9.

Sharkey M, Harrad S, Abou-Elwafa Abdallah M, Drage DS, Berresheim H. Phasing-out of legacy brominated flame retardants: The UNEP Stockholm Convention and other legislative action worldwide. Environ Int. 2020;144: 106041.

Eguchi A, Matsukami H, Takahashi A, Kajiwara N. Simultaneous determination of polybrominated diphenyl ethers and hexabromocyclododecane in plastic waste by short-column gas-chromatography-quadrupole mass spectrometry and electron capture detector. Chemosphere. 2021;277: 130301.

Gustavsson J, Ahrens L, Nguyen MA, Josefsson S, Wiberg K. Development and comparison of gas chromatography–mass spectrometry techniques for analysis of flame retardants. J Chromatogr A. 2017;1481:116–26.

Portoles T, Pitarch E, Lopez FJ, Hernandez F. Development and validation of a rapid and wide-scope qualitative screening method for detection and identification of organic pollutants in natural water and wastewater by gas chromatography time-of-flight mass spectrometry. J Chromatogr A. 2011;1218(2):303–15.

Agency USEP. Brominated diphenyl ethers in water, soil, sediment, and tissue by HRGC/HRMS. Washington, DC: U.S. Environmental Protection Agency; 2010. p. 1–87.

Fengel D. Aging and fossilization of wood and its components. Wood Sci Technol. 1991;25(3):153–77.

Labadie P, Tlili K, Alliot F, Bourges C, Desportes A, Chevreuil M. Development of analytical procedures for trace-level determination of polybrominated diphenyl ethers and tetrabromobisphenol A in river water and sediment. Anal Bioanal Chem. 2010;396(2):865–75.

Wang X, Xi B, Huo S, Sun W, Pan H, Zhang J, et al. Characterization, treatment and releases of PBDEs and PAHs in a typical municipal sewage treatment plant situated beside an urban river, East China. J Environ Sci (Beijing, China). 2013;25(7):1281–90.

Piri-Moghadam H, Ahmadi F, Pawliszyn J. A critical review of solid phase microextraction for analysis of water samples. TrAC, Trends Anal Chem. 2016;85:133–43.

Reyes-Garces N, Gionfriddo E, Gomez-Rios GA, Alam MN, Boyaci E, Bojko B, et al. Advances in Solid Phase Microextraction and Perspective on Future Directions. Anal Chem. 2018;90(1):302–60.

Cheng X, Forsythe J, Peterkin E. Some factors affecting SPME analysis and PAHs in Philadelphia’s urban waterways. Water Res. 2013;47(7):2331–40.

Dominguez I, Arrebola FJ, Gavara R, Martinez Vidal JL, Frenich AG. Automated and simultaneous determination of priority substances and polychlorinated biphenyls in wastewater using headspace solid phase microextraction and high resolution mass spectrometry. Anal Chim Acta. 2018;1002:39–49.

Chen X-F, Cheng C-G, Wang X, Zhao R-S. Sensitive determination of polybrominated diphenyl ethers in environmental water samples with etched stainless steel wire based on solid-phase microextraction prior to gas chromatography-mass spectrometry. Anal Methods. 2012;4(9):2908–13.

Zubarev RA, Makarov A. Orbitrap Mass Spectrometry. Anal Chem. 2013;85(11):5288–96.

Qianhui Z, Shuai M, Jianxun W, Weifeng C, Shengfei Z, Xinge S, et al. Molecular composition of naphthenic acids in a Chinese heavy crude oil and their impacts on oil viscosity. Petroleum Science. 2022.

Chenglong D, Changcheng J, Shuo Z, Hai Z, Dali F, Luyan X, et al. Molecular composition analysis using ultra-high resolution mass spectrometry for lubricating oil process optimization. Petroleum Science Bulletin. 2019;4(04):430–9.

Mirabelli MF, Wolf JC, Zenobi R. Direct coupling of solid-phase microextraction with mass spectrometry: sub-pg/g sensitivity achieved using a dielectric barrier discharge ionization source. Anal Chem. 2016;88(14):7252–8.

Hou YJ, Deng J, He K, Chen C, Yang Y. Covalent organic frameworks-based solid-phase microextraction probe for rapid and ultrasensitive analysis of trace per- and polyfluoroalkyl substances using mass spectrometry. Anal Chem. 2020;92(15):10213–7.

Monaghan J, Jaeger A, Agua AR, Stanton RS, Pirrung M, Gill CG, et al. A direct mass spectrometry method for the rapid analysis of ubiquitous tire-derived toxin N-(1,3-Dimethylbutyl)-N′-phenyl-p-phenylenediamine Quinone (6-PPDQ). Environ Sci Technol Lett. 2021;8(12):1051–6.

Chiesa LM, Nobile M, Malandra R, Pessina D, Panseri S, Labella GF, et al. Food safety traits of mussels and clams: distribution of PCBs, PBDEs, OCPs, PAHs and PFASs in sample from different areas using HRMS-Orbitrap® and modified QuEChERS extraction followed by GC-MS/MS. Food Additives & Contaminants: Part A. 2018;35(5):959–71.

Simonnet-Laprade C, Bayen S, McGoldrick D, McDaniel T, Hutinet S, Marchand P, et al. Evidence of complementarity between targeted and non-targeted analysis based on liquid and gas-phase chromatography coupled to mass spectrometry for screening halogenated persistent organic pollutants in environmental matrices. Chemosphere. 2022;293: 133615.

Zacs D, Bartkevics V. Analytical capabilities of high performance liquid chromatography – Atmospheric pressure photoionization – Orbitrap mass spectrometry (HPLC-APPI-Orbitrap-MS) for the trace determination of novel and emerging flame retardants in fish. Anal Chim Acta. 2015;898:60–72.

Poole JJ, Gomez-Rios GA, Boyaci E, Reyes-Garces N, Pawliszyn J. Rapid and concomitant analysis of pharmaceuticals in treated wastewater by coated blade spray mass spectrometry. Environ Sci Technol. 2017;51(21):12566–72.

Gao W, Tian Y, Liu H, Cai Y, Liu A, Yu YL, et al. Ultrasensitive determination of tetrabromobisphenol A by covalent organic framework based solid phase microextraction coupled with constant flow desorption ionization mass spectrometry. Anal Chem. 2019;91(1):772–5.

Rickert DA, Singh V, Thirukumaran M, Grandy JJ, Belinato JR, Lashgari M, et al. Comprehensive analysis of multiresidue pesticides from process water obtained from wastewater treatment facilities using solid-phase microextraction. Environ Sci Technol. 2020;54(24):15789–99.

Polo M, Gómez-Noya G, Quintana JB, Llompart M, García-Jares C, Cela R. Development of a solid-phase microextraction gas chromatography/tandem mass spectrometry method for polybrominated diphenyl ethers and polybrominated biphenyls in water samples. Anal Chem. 2004;76(4):1054–62.

Dominguez I, Arrebola FJ, Romero-Gonzalez R, Nieto-Garcia A, Martinez Vidal JL, Garrido FA. Solid phase microextraction and gas chromatography coupled to magnetic sector high resolution mass spectrometry for the ultra-trace determination of contaminants in surface water. J Chromatogr A. 2017;1518:15–24.

Diwan A, Singh B, Roychowdhury T, Yan D, Tedone L, Nesterenko PN, et al. Porous, high capacity coatings for solid phase microextraction by sputtering. Anal Chem. 2016;88(3):1593–600.

Zheng X, Dupuis KT, Aly NA, Zhou Y, Smith FB, Tang K, et al. Utilizing ion mobility spectrometry and mass spectrometry for the analysis of polycyclic aromatic hydrocarbons, polychlorinated biphenyls, polybrominated diphenyl ethers and their metabolites. Anal Chim Acta. 2018;1037:265–73.

Kostiainen R, Kauppila TJ. Effect of eluent on the ionization process in liquid chromatography-mass spectrometry. J Chromatogr A. 2009;1216(4):685–99.

Wang J, Yan Z, Zheng X, Wang S, Fan J, Sun Q, et al. Health risk assessment and development of human health ambient water quality criteria for PBDEs in China. Sci Total Environ. 2021;799: 149353.

Peters FT, Remane D. Aspects of matrix effects in applications of liquid chromatography–mass spectrometry to forensic and clinical toxicology—a review. Anal Bioanal Chem. 2012;403(8):2155–72.

Acknowledgements

The authors acknowledge support from State Key Laboratory of Heavy Oil Processing, China University of Petroleum-Beijing.

Funding

This work was financially supported by the National Natural Science Foundation of China (No. 21874153).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, Y., Hu, W., Jia, C. et al. Rapid screening of polybrominated diphenyl ethers in water by solid-phase microextraction coupled with ultrahigh-resolution mass spectrometry. Anal Bioanal Chem 415, 1437–1444 (2023). https://doi.org/10.1007/s00216-023-04531-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-023-04531-y