Abstract

Developing methods that can analyze multiple categories of organic chemical residues such as pesticides, veterinary drugs, mycotoxins, human drugs, and environmental contaminants in food with a single analytical procedure is a growing trend. These methods for mixed organic chemical residues and contaminants focus on the chemical properties of these analytes rather than how they are used and adulterate the food supply. This paper highlights recently published methods for mixed residue and contaminant methods in food including advances in technology (instrumental hardware, data processing programs, and sample cleanup) that allow for a larger number of compounds to be monitored simultaneously. The factors that determine the scope, or number and type of analytes in a given method, including needs for specific food commodities, complexity of the analytical procedure, and the intended purpose (qualitative vs quantitative analysis) will be examined. Although there are clear advantages to expanding the number of unwanted chemicals being monitored in the global food supply, challenges to developing and implementing mixed organic residue and contaminant methods will also be discussed. Going forward, it will be important to implement these methods to more thoroughly protect the food supply for a wide variety of targeted and non-targeted chemical residues and contaminants while also having the regulatory framework in place to effectively manage the results of these comprehensive analyses.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Unwanted chemicals in food can result from naturally occurring toxins, pesticides applied during growing or harvesting, veterinary drugs administered to animals, compounds produced during food processing (e.g., acrylamide), and contaminants from packaging materials such as bisphenol A. These chemicals may be classified as residues (remaining traces of chemicals added intentionally such as pesticides and veterinary drugs) or contaminants (compounds not added intentionally) [1, 2]. Regardless of the source, analytical methods to monitor for residues and contaminants in food are important because these chemicals may have acute or chronic adverse human health effects [3]. For example, toxins in food can cause immediate and potentially severe distress when ingested [4]. Many pesticides have been linked to a large number of reproductive, developmental, and metabolic diseases [5]. Some of these contaminants and residues are known carcinogens. For example, the International Agency for Research on Cancer (IARC) which classifies chemicals on their potential human carcinogenicity based on available evidence lists aflatoxin as “carcinogenic to humans” [6] and certain organophosphate pesticides (glyphosate, malathion, and diazinon) as “probably carcinogenic to human” [7]. The indiscriminate use of antibiotics in food-producing animals can cause drug residues in food and exacerbate the spread of global antimicrobial resistance [8]. The toxicity of polyaromatic hydrocarbons, dioxins, and other environmental contaminants has been extensively documented [9]. Human drugs and other personal care products present in environmental surface waters [10] may also contaminate food. Other potentially harmful chemicals may also occur in food, either due to deliberate adulteration or accidental exposure. For example, the presence of food packaging chemicals [11] or compounds added intentionally to commit food fraud, e.g., melamine added to increase apparent protein content [12]. Because of these concerns, global regulatory agencies have had rigorous programs in place to monitor for chemical residues and contaminants in food products for many years.

Historically, analytical methods were developed to monitor for single or a few related compounds in a common class such as quinolone antibiotic or organophosphate pesticide residues. In recent years, multi-analyte methods have been developed to cover many different compounds in a specific category of chemicals such as pesticides, veterinary drugs, or mycotoxins. These analytical procedures typically utilize mass spectrometry, specifically GC-MS and/or LC-MS instrumentation. Modern methods for pesticide residues in food include hundreds of analytes representing different chemical classes of compounds. Reviews of pesticide methods are available for a variety of foods [13, 14]; both LC-MS/MS and GC-MS platforms are utilized for pesticide residues depending on the specific analytes [15]. For example, organochlorine pesticides are typically analyzed by GC-MS, while carbamates and benzoylureas are more suited for analysis with LC-MS. Many classes of pesticides (organophosphates, pyrethroids) can be monitored by both GC-MS and LC-MS. There are reviews of multi-class veterinary drug residue methods (primarily LC-MS) available which include antibiotics, anthelmintics, as well as other functional drug classes (coccidiostats, NSAIDs, tranquilizers) depending on the food product being tested [13, 16, 17]. Multi-analyte methods for naturally occurring toxins have also been developed for different classes of mycotoxins including aflatoxins, fumonisins, ochratoxin, as well as many potential metabolites [18,19,20]. Analytical procedures to simultaneously monitor different classes of persistent organic pollutants including polyaromatic hydrocarbons and halogenated contaminants in mussels and clams using either GC-MS [21] or a combination of GC-MS and LC-MS [22] have been reported. Several papers also describe methods that have detected a wide variety of human drugs and other emerging chemical contaminants in the environment [10] and some have also evaluated the occurrence of these residues in food, especially fish and other aquatic species [23, 24].

Emergence of mixed organic chemical residue and contaminant (MOCRC) methods

A current trend in monitoring food for chemical residues and contaminants is to combine as many analytes as possible into a single method with an emphasis on developing laboratory methods which simultaneously analyze compounds from multiple categories including pesticides, veterinary drugs, mycotoxins, and other organic chemicals in a variety of food commodities. Methods that combine several categories of residues and contaminants utilize analytical techniques best suited to detect and identify compounds based on their chemical properties regardless of how they were used and adulterated food products. These have been described as “Mega” [25, 26] or “unified approach” [27] methods. Although it is not established terminology, the phrase “mixed organic chemical residues and contaminants” abbreviated for brevity as “MOCRC” succinctly describes the combination of analytes that may be included in these methods and will be used in this paper. Inorganic chemicals (e.g., certain metals and salts) are also of concern in food but would not be included in methods designed for organic chemicals. In addition to reviewing recent examples of analytical methods developed for mixed organic residues and contaminants in foods, the advantages and challenges associated with this approach will be discussed.

One of the first examples of a MOCRC method was published by Mol et al. in 2008 [28]. This method was developed using an iterative approach. Initially, several extraction procedures for pesticides, mycotoxins, and plant toxins were evaluated for animal feeds. It was determined that using acidified acetonitrile (water/acetonitrile/1% formic acid) to extract the samples was best for maximizing the recovery of a wide variety of analytes and minimizing matrix effects. The sample preparation procedure did not involve any cleanup other than the protein precipitation step with acidified acetonitrile. This method was then tested with several other matrices (maize, honey, milk, eggs, and meat) and eventually expanded to include veterinary drugs. Despite the simple extraction and the complexity of the food matrices, very good quantitative results were obtained for majority of compounds including the penicillins and cephalosporins. LC-MS/MS with triple quadrupole detection was utilized for method development and validation, but the use of high-resolution MS (LC-Time-of-Flight) was also explored. This generic extraction procedure was validated for 86 veterinary drugs, 136 pesticides, and 36 natural toxins in feed and honey. Many aspects of this seminal procedure serve as a basis for MOCRC methods being developed and implemented today.

Several other methods combining different categories of compounds have been published since this paper by Mol et al. A 2014 review describes several methods developed for simultaneous analysis of veterinary drugs and pesticide residues [1]. The authors of this paper developed many of the methods described in this review [29,30,31,32,33] for a wide variety of matrices (e.g., honey, meat, milk, feed). The analytical approach used by this group was to develop a generic extraction which also used acidified acetonitrile. Several sample cleanup procedures were also investigated. The use of fluorosil solid phase extraction cartridges was useful as a cleanup for animal feed. For other matrices, such as honey, there was significant recovery loss for some analytes and a simple dilution was used. These early papers utilized the universal detection of full scan high-resolution MS with a single-stage Orbitrap instrument. The methods were applied to many food matrices with real-world sample assignments.

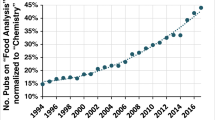

Building on these early successes, many other researchers have continued to develop and implement MOCRC methods. As evidence of the popularity of this trend, many additional publications have become available, and representative MOCRC methods [25,26,27, 34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50] are summarized in Table 1.

Scope of MOCRC methods based on food commodity

One of the defining characteristics of a MOCRC method is the scope of analytes included in the procedure. The number and type of chemicals in the scope will depend on the feasibility of combining different classes of compounds in a single method. The number and diversity of analytes will also determine the analytical techniques used for MOCRC methods. Although most methods focus on pesticides, veterinary drugs, and mycotoxins, other contaminants such as disinfectants, packaging materials, and environmental pollutants continue to be added.

The number and type of analytes selected may depend on the specific food matrix. Table 1 lists the foods tested and the categories of analytes represented in each MOCRC method. Figure 1 further elaborates by giving an estimate of the number of analytes representing each category of compounds. The relative percentage of each type (i.e., the number of pesticides compared with the number of veterinary drugs) varies significantly between the published MOCRC methods and is not necessarily dependent on the food commodity. Often, the number of analytes from each chemical category will depend on how the method was originally developed. Similar to the approach first described by Mol et al. [28], MOCRC methods may first focus on specific chemical categories and then extend the scope of analytes. For example, a method initially developed for a large number of pesticides might be modified to also include veterinary drugs or mycotoxins, while a procedure initially focused on veterinary drugs may later expand to relevant pesticides and other chemical contaminants.

Meat, fish, feed, eggs, and dairy products are food commodities which may be adulterated with a variety of unwanted chemicals. The specific analytes selected may be tailored to the residues and contaminants that can logically be expected to be present in those foods. For example, the MOCRC in a method for aquacultured fish might include veterinary drugs such as antibiotics, antifungals, and pesticides that could be present from nearby agricultural runoff, as well as human drugs and personal care products resulting from environmental contamination of surface waters [46]. Other classes of compounds, such as coccidiostats and mycotoxins, may not need to be monitored in aquacultured fish. On the other hand, for a method intended for poultry tissues and eggs, it would be important to include coccidiostats and insecticides, but not pharmaceutical and personal care products prevalent in environmental surface water. Mycotoxins may be food matrix specific with aflatoxin M1 being of particular importance in milk and patulin more critical to monitor in apples [4]. A wide variety of compounds, such as veterinary drugs, pesticides, mycotoxins, and even plant toxins, are important to monitor in animal feeds. A published method for over 600 analytes representing not only veterinary drugs, pesticides, and mycotoxins but also food packaging components, perfluorinated compounds, and sweeteners was tested in tomatoes, oranges, and baby food [41]. There are also examples of MOCRC methods designed for unique matrices such as edible insects (crickets, mealworms, crickets, etc.) [44].

Advances in technology facilitating development of MOCRC methods

Developments in technology have facilitated the development of analytical methods that are able to detect a wide scope of compounds. Sample preparation techniques which effectively remove matrix components without affecting analyte recovery are used for generic sample extraction procedures. Mixed MOCRC methods often take advantage of the fact that many (but not all) drugs, pesticides, and chemical contaminants have similar basicity, polarity, and volatility. These compounds can generally be effectively extracted from complex food matrices using acidified organic solvents. Many methods listed in Table 1 utilize acidified acetonitrile for the initial extraction as described in early publications [28, 30,31,32]; others used a combination of acidified acetonitrile or acetone and a more nonpolar solvent such as ethyl acetate [36, 44]. MOCRC papers often describe an optimization process to maximize the recoveries and responses for as many analytes as possible by varying the composition of the extracting solvent, the amount of acid added, etc. Some researchers used sophisticated statistical analysis techniques such as response surface modeling design to document the effects of these variables [35, 43, 44].

The sample extraction and cleanup approach known as QuEChERS (“Quick Easy Cheap Effective Rugged and Safe”) developed for pesticides is used for many MOCRC methods in Table 1 [25,26,27, 34, 35, 38, 39, 41, 42, 47, 51]. One recent paper describes a novel adaptation of QuEChERS for MOCRC in eggs using carbon nanotubes [47]. In this method, multi-walled carbon nanotubes were modified with iron oxide and used for dispersive solid phase extraction sample cleanup. The advantage of using these materials was that they effectively removed the egg matrix and could be easily separated from the final extract with an external magnet. However, an overall disadvantage with QuEChERS is that very polar analytes can be lost in the phase separation procedure [28]. For this reason, other MOCRC methods do not use QuEChERS and keep sample cleanup to a minimum to avoid analyte loss. A simple dilute-and-shoot approach can be an effective way to prepare samples to monitor for a wide variety of MOCRC, including metabolites, provided there is adequate instrument sensitivity for detection [20, 28]. Some MOCRC cleanup procedures use techniques to remove excessive lipids which can cause ion suppression with electrospray LC-MS. These may include a hexane wash or use of solid phase extraction cartridges designed to selectively remove lipids [46, 50, 51]. Subjecting food extracts to low temperatures to freeze out lipid components has also gained popularity as a tool for sample cleanup [36, 37]. Another trend in sample preparation is automation to increase sample throughput [42]. Analyzing more samples, along with the expanding the scope of large mixed contaminant methods, has the potential to greatly improve the coverage of harmful chemicals being monitored.

Improvements in instrumentation, for both GC-MS and LC-MS, have also played a critical role in the development of wide-scope MOCRC methods without the need for extensive sample cleanup [52]. Because many analytes of interest are amenable to liquid chromatography separation and electrospray ionization, a majority of methods listed in Table 1 utilize LC-MS/MS for targeted analysis. Increases in sensitivity, scan speed, and data processing for triple quadrupole instruments make it possible to monitor hundreds of targeted analytes at low concentration levels with multiple ion transitions for each compound. Of course, several important classes of chemicals including volatile pesticides, dioxins, and emerging contaminants such as halogenated fire retardants are more applicable to separation by GC. Recent advances in GC technology including the use of faster and/or low-pressure separations, GC × GC, and novel ionization techniques have increased the scope and number of analytes that can be analyzed simultaneously [53]. Developments in data processing software, for both LC-MS and GC-MS, have also facilitated the ability to quickly query MS data for hundreds of analytes in an automated manner. In fact, efficient data processing is a critical aspect of MOCRC methods that monitor hundreds of compounds. Data processing, reporting, and documentation of results for regulatory action is often a limiting step in implementing these methods.

Another strategy for MOCRC methods is to combine LC-MS/MS and GC-MS/MS analyses in a single workflow to greatly expand the scope of analytes; multi-class pesticide methods have often used this approach. Five MOCRC methods listed in Table 1 use GC-MS/MS in combination with LC-MS/MS. For example, Jadhav et al. [27] have published a method that combines LC-MS and GC-MS for the analysis of over 300 pesticides and veterinary drugs using extracts from a QuEChERS procedure. The unified sample preparation protocol used in this method is shown in Fig. 2. A group at the US Department of Agriculture have developed several methods that utilize both LC-MS/MS and robotic mini-SPE plus low-pressure GC-MS/MS for a wide scope of analytes including pesticides and environmental contaminants in meat (cattle, swine, and poultry) and shrimp tissue [34, 42]. Their approach has recently been extended to develop a “mega method” for beef [25] and catfish [26] tissue which also includes veterinary drug residues. This is accomplished by combining workflows from several previously published methods [34, 42, 54].

Unified sample preparation workflow. Reprinted from Food Chemistry, 272: 292–305, Jadhav et al. [27], A unified approach for high-throughput quantitative analysis of the residue of multi-class veterinary drugs and pesticides in bovine milk using LC-MS/MS and GC-MS/MS, (2019), with permission from Elsevier

Using high-resolution (HR) MS is gaining popularity for MOCRC methods because these instruments can acquire full scan data with high mass accuracy. HRMS scanning data acquisition is more adaptable to an expanding number of analytes than multiple reaction monitoring with a triple quadrupole MS because precursor-product ion transitions specific for each analyte do not need to be pre-selected. The most common HRMS instruments used for the analysis of residues and contaminants in food are the Time-of-Flight (ToF) or Orbitrap mass analyzers [52]. With either HRMS instrument, full scan MS1 data for precursor ions (e.g., [M+H]+) are collected and used for analyte detection and quantification. These instruments can also collect MS/MS data for further compound identification when coupled with a quadrupole to filter precursor ions prior to collisional dissociation. Product ion spectra can be generated using either targeted (for specific set of analytes) or non-targeted (for all precursor ions) data acquisition and the advantages and disadvantages of these have been discussed [39, 50, 55, 56].

In one example of using HRMS for MOCRC analysis, the US FDA Center for Veterinary Medicine developed a multi-residue method for 30 veterinary drugs in raw milk using the generic extraction procedure described by Mol et al. in 2008 [28] with very minor modification of extraction solvent composition and extraction times. High-resolution MS (Orbitrap Q Exactive) detection was utilized for method development. This method was validated according to FDA guidelines [57] and all 30 veterinary drugs were quantified at their target levels using positive and negative ionization modes. This method [49] has since been expanded to include many other veterinary drugs, mycotoxins, and pesticides for a total of 76 compounds. After the generic extraction procedure, high-resolution MS (Q-ToF) was utilized for method development and validation. Preliminary results from the generic extraction procedure are very promising producing quantitative results for the majority of analytes. Even though the main emphasis is to develop a screening method, quantitation will be attempted for commonly found compounds in milk.

Although most MOCRC methods using HRMS published thus far have been coupled to LC, GC-HRMS instruments (ToF and Orbitrap) have recently become commercially available. Hayward et al. have demonstrated the successful application of GC-quadrupole-Orbitrap to the analysis of persistent organic pollutants such as polychlorinated dibenzo-p-dioxins and dibenzofurans in human and bovine milk [58]. Other researchers, including Mol [59], have also begun to investigate this platform to develop MOCRC methods for analytes amenable to GC including pesticides, PCBs, PAHs, and flame retardants.

Types of MOCRC methods

MOCRC methods can be qualitative or quantitative in nature. The scope of analytes included and the type of instrumentation used can also depend on whether the primary goal is screening with qualitative identification or if more rigorous quantification is required.

Methods which prioritize quantification typically utilize GC-MS or triple quadrupole LC-MS/MS for a limited set of targeted analytes. LC-MS/MS instruments can have an inherent advantage in terms of sensitivity and selectivity because specific precursor-product ion transitions are selected [52]. Parameters to maximize signal for precursor ions (e.g., solvent declustering potential) and product ions (e.g., collision energies) can be optimized for every analyte. Many of the methods in Table 1 utilize triple quadrupole detection [25,26,27,28, 34, 36, 37, 40, 42, 43, 45, 47] including procedures for over 100 analytes. Quantitative results can also be obtained with HRMS instruments; this is usually done by generating narrow m/z (e.g., 5 ppm window) extracted ion chromatograms for protonated molecules from the MS1 scan data. Several MOCRC papers [30,31,32, 35] describe the quantitative performance for targeted analytes (N up to 300–630) using HRMS. It is also possible to tailor HRMS data acquisition for specific compounds. For example, one MOCRC method used parallel reaction monitoring with an LC-quadrupole Orbitrap [50] to emphasize sensitive quantitation for a limited number of analytes.

Method performance elements that need to be evaluated for quantification include accuracy (recoveries), precision, linearity, and limits of detection and quantitation. Matrix effects, particularly ion suppression and enhancement with LC-MS, must also be addressed. This is especially challenging for methods that include a large number of analytes with different chemical properties because observed matrix effects can depend on the specific compound as well as the matrix. There are several known strategies for mitigating matrix effects for quantitative LC-MS. For certain (more nonpolar) analytes, changing from electrospray to atmospheric pressure chemical ionization (APCI) can help, but that is not generally applicable to the wide range of compounds in a MOCRC method. The use of isotopically labeled internal standards can correct for matrix effects, but this is also difficult to apply to large numbers of analytes. Matrix-matched calibration curve where standards are prepared in corresponding matrix is a practical solution to compensate for variable ion suppression/enhancement. This was used for many of the quantitative methods in Table 1. Dilution of a sample can also be very effective in reducing matrix effects. One study for multi-class pesticide residues showed that diluting samples (avocado, orange, spinach, honey, hazelnut) up to 100 times reduced matrix effects for most analytes [60].

Qualitative screening methods can either be developed for a targeted list of MOCRC or be used to discover unexpected, or non-targeted, compounds. The number of analytes included in a targeted screen method which emphasizes qualitative identification can be significantly higher compared with quantitative methods because performance requirements (recovery, linearity) are less stringent. It is also not necessary to maintain a full suite of current calibration standards for screening methods. With any qualitative GC-MS or LC-MS procedure, including those that use HRMS, there are guidelines describing the criteria (number of product ions, retention time matching) that are required for compound identification [61,62,63,64,65]. If the analytes in a targeted screening MOCRC method have regulatory limits (e.g., maximum residue levels or tolerances), then threshold cutoff limits [57] or screening concentration levels [50, 66] may need to be established to determine if analytes are present at or above levels of concern. Targeted qualitative screening for MOCRC can be performed using either HRMS or more traditional triple quadrupole MS instruments, but the number of analytes that can be monitored using multiple reaction monitoring with a triple quadrupole MS may be limited.

In addition to monitoring for large lists of targeted MOCRCs, a key advantage of HRMS methods is that they can be easily adapted for non-targeted analyses. The ability to detect unexpected potentially harmful chemicals in the food supply is becoming more important; the adulteration of food with melamine is an important example [2, 12]. Methods developed for MOCRC will easily lend themselves to a non-targeted analyte workflow because of the generic sample preparation and use of universal MS detection (full scan GC-MS and/or HRMS). Several MOCRC methods demonstrate this adaptation [33, 55, 67, 68]. They typically utilize a similar generic sample extraction with non-targeted data acquisition along with expanded data analysis techniques such as searching against large compound databases [67], online libraries, or applying chemometrics and metabolomics approaches [68] to find unexpected analytes. For example, retrospective analysis of HRMS data for MOCRC has been used to identify additional metabolites or analyte transformation products such as anhydroerythromycin in honey, 3,5,6-trichloro-2-pyridinal in feed [33], as well as desmethyl leucomalachite green in farmed eel [55].

Another approach used for MOCRC methods, especially with HRMS, is to use a combination of qualitative screening and traditional quantification; several HRMS procedures in Table 1 were developed for wide-scope qualitative screening of hundreds of compounds with a subset of these analytes validated for quantitative or semi-quantitative application. For example, León et al. [38] developed a method for veterinary drugs and toxins in feed using LC-Orbitrap HRMS which was quantitative for 77 analytes, but data were also retrospectively evaluated for the presence of 425 compounds by searching a database with exact mass information. Similarly, Turnipseed et al. developed a LC-HRMS method for MOCRC in aquacultured products [46, 48] which was validated for approximately 130 compounds using a semi-quantitative limit test (i.e., establishing that target analytes were detected, identified, and present at or above a level of concern). An in-house database with exact mass and retention time information was subsequently used to search for additional residues and contaminants (N > 500) in the farmed fish and shellfish.

Advantages and challenges of mixed contaminant methods

The advantages of MOCRC methods are clear. Expanding the scope of chemicals being monitored, especially with a single sample preparation procedure, will allow regulatory agencies to better ensure the safety of the global food supply. For example, it is a challenge to collect and analyze a representative amount of food imported into the USA, so it is critical to perform a thorough investigation of these samples to monitor for any adulteration. A recent report from US FDA recommends developing analytical methods for imported products that produce results more quickly and detect more than one kind of contaminant [69]. Procedures developed for a wide variety of chemical classes also have the flexibility to add additional analytes that may emerge as a concern.

There are also several challenges to developing and implementing MOCRC methods. Some important compounds have chemical properties that are significantly different enough to preclude them from being part of a wide-scope MOCRC procedure. Analytes that are very polar or nonpolar can be difficult to include in these combined methods without requiring more complex, multi-step, sample preparation. For example, polar analytes such as aminoglycoside antibiotics or the herbicide glyphosate and its degradants do not perform well in generic sample extraction procedures and LC separation programs. Efforts to monitor for aminoglycosides in multi-analyte methods have succeeded by adding ion-pair reagent to final reconstitution solution [54] or splitting the extraction procedure into multiple streams [51]. Others have utilized hydrophilic interaction liquid chromatography (HILIC) MS which is well suited for polar analytes [37]. On the other extreme, nonpolar compounds that may not readily form protonated ions including avermectins and pyrethroids may also require additional work to be included in these methods.

Effectively building analytical methods with large numbers of different types of chemicals in food requires the development and dissemination of databases containing important compound information (exact mass of precursor, product ions, relative retention times, etc.). This type of information is beginning to be published [31, 48, 56] or become available in online databases and spectral libraries (e.g., https://www.mzcloud.org/) which should also facilitate the wide spread development and application of MOCRC methods.

Another complicating issue for MOCRC methods is the fact that regulatory levels of concern (allowable concentrations) can vary significantly depending on the category or even specific compound. For example, the target testing levels for veterinary drug residues in aquacultured products can vary from at or below 1 ng/g for triphenyl methane dyes, chloramphenicol, and methyl-testosterone to > 100 ng/g for drugs with approval for use in some fish species such as tetracyclines and florfenicol amine. The persistent organic pollutants (POPs), such as the dioxins and PCB class of environmental contaminants, are a mixture of congeners with varying toxicity and overall very low levels of concern (pg/g) [9, 58]. It is difficult to include POPs in these combined methods due to very lengthy extraction/cleanup procedures specific to these compounds.

Aside from these difficulties, another challenge with implementing MOCRC methods is that food control agencies often have separate organizational structures and programs to regulate pesticides, veterinary drugs, mycotoxin, or chemical contaminants. This reflects the fact that these chemicals adulterate food via different routes whether it be misuse of approved or unapproved veterinary drugs and pesticides, occurrence of naturally occurring toxins, use of poor processing or packaging practices, or even intentional contamination for economic fraud. Although having a single analytical procedure to monitor for these different categories of chemicals may streamline the laboratory portion of the analysis, new approaches for reviewing results and recommending regulatory action may also be required. For example, in both the USA and EU, there are guidance documents that describe criteria for identification of residues that are specific to pesticides [62, 63] or veterinary drugs [61, 65]. Another document written for exact mass data describes criteria applicable to all categories of residues and contaminants in food [64]. Although these guidance documents have common principles to describe criteria for identification (number of ions, signal-noise, ions ratios, exact mass, retention time), the details and approaches to evaluating the results vary depending on the analyte category and their tolerances in different food commodities which may complicate the review of data from MOCRC methods.

The validation of MOCRC methods with hundreds of analytes can also be very challenging. The requirements for method performance will depend on the intended purpose (qualitative screening or quantitative). Regardless, the amount of analytical work and subsequent documentation needed to initially validate and then monitor ongoing performance can be overwhelming. Several guidance documents address validation and quality assurance requirements [57, 62, 66]. The difficulties of evaluating and documenting the performance for a very large number of residues are addressed in the EU procedures for pesticide analysis [62]. This document states that, when practical, the recoveries of all analytes should be measured in each analytical batch. However, alternatives are suggested for a minimum number of representative residues selected for recovery check with a rolling program to monitor the performance of the other pesticides in the method. Many of the current validation guidelines are written for just one category of residue or contaminant making it difficult to ensure that MOCRC methods with several analyte categories adhere to requirements from multiple documents. There has been an effort within the US FDA food and veterinary medicine program to harmonize the validation requirements for chemical residue and contaminant methods. The current guidance document [57] describes quantitative and qualitative method performance criteria for single laboratory and multi-laboratory validations of any category of chemical analytes in food and feed.

Outlook

Because MOCRC methods have the potential to further expand the scope of analytes monitored and better protect the food supply, the expanded development and application of these methods is expected. Indeed, the large number of methods published in the last few years (Table 1) demonstrates this is the case.

As the implementation of this approach in regulatory programs is still evolving, there are not yet extensive case studies documenting the advantages and challenges of MOCRC methods on a large scale. However, several papers listed in Table 1 include a survey of market samples that found food products containing compounds from multiple analyte categories. For example, Xu et al. [47] found an individual egg sample with significant levels of the antibiotic sulfachloropyrazine (72 μg/kg) and the mycotoxin aflatoxin B1 (22 μg/kg); another egg contained sulfachloropyridazine (2.4 μg kg), trimethoprim (6.6 μg kg), and the pesticide fipronil sulfone (313 μg kg). The method for edible insects was applied to real samples and several different compounds were found in the samples including drugs from the environment (salicylic acid, paracetamol, metoprolol), veterinary drugs (nicarbazin), mycotoxins (HT2-toxin, zearalenone), and the pesticide isoproturon [44]. Other papers also report a variety of analytes detected in market survey samples for MOCRCs in baby food [35] and animal feed [38]. These examples demonstrate the added value of using methods that can monitor for a wide variety of chemicals and residues.

More is becoming known about the long-term effect of chemical residues and contaminants on human health. A recent study evaluated contributions to the “dietary exposome” described as the total exposure to chemicals over a person’s lifetime [70]. The study focused on contaminants (rather than residues from allowed use of pesticides and veterinary drugs where risk assessment is established upon approval) and found aflatoxins, persistent organic pollutants, and acrylamide to be among the organic compounds of highest concern. This study also cited how exposure to multiple chemical contaminants over time could result in more adverse health effects than indicated by the risk assessment of individual compounds because many exhibit similar mode of action (i.e., targeting the liver). The synergistic effect of chronic exposure to multiple categories of toxins emphasizes the importance of developing methods to monitor for mixed residues and contaminants in food. Another paper described a non-targeted LC-HRMS study to characterize and validate changes in the metabolic profile of calf urine as a result of exposure to growth promoters such as β-agonists [71]. This forward-looking study raises the possibility of needing to even further expand the scope of analytical methods to secondary metabolites and resulting biomarkers.

Overall, MOCRC methods must strike a balance between protecting the global food supply by monitoring as many foods for as many different residues and contaminants as possible with the need for validated procedures capable of generating supportable information on analyte identity and concentration levels. Going forward, it will be important to take advantage of advances in technology (instrumental hardware, data processing programs, and sample cleanup) to more thoroughly monitor the global food supply for a wide variety of targeted and non-targeted chemical residues and contaminants while also having the regulatory framework in place to effectively manage the results of these comprehensive analyses.

References

Garrido Frenich A, Romero-González R, Aguilera-Luiz MD. Comprehensive analysis of toxics (pesticides, veterinary drugs and mycotoxins) in food by UHPLC-MS. Trends Anal Chem. 2014;63:158–69.

Krska R, Becalski A, Braekevelt E, Koerner T, Cao X, Dabeka R, et al. Challenges and trends in the determination of selected chemical contaminants and allergens in food. Anal Bioanal Chem. 2012;402:139–62.

Rather IA, Koh WY, Paek WK, Lim J. The sources of chemical contaminants in food and their health implications. Front Pharmacol. 2017;8:830.

Alshannaq A, Yu J-H. Occurrence, toxicity, and analysis of major mycotoxins in food. Int J Environ Res Public Health. 2017;14:632.

Mostafalou S, Abdollahi M. Pesticides: an update of human exposure and toxicity. Arch Toxicol. 2017;91:549–99.

Ostry V, Malir F, Toman J, Grosse Y. Mycotoxin as human carcinogens - the IARC Monographs classification. Mycotoxin Res. 2017;3333:65–73.

IARC working group on the evaluation of carcinogenic risk to humans. Some organophosphate insecticides and herbicides. Lyon (FR): International Agency for Research on Cancer 2017. (IARC Monographs on the Evaluation of Carcinogenic Risks to Humans, No. 112.); 2017 Available from: https://www.ncbi.nlm.nih.gov/books/NBK436774/

Verraes C, Van Boxstael S, Van Meervenne E, Van Collie E, Butaye P, Catry B, et al. Antimicrobial resistance in the food chain: a review. Int J Environ Res Public Health. 2013;10:2643–69.

El-Shahawi MS, Hamza A, Bashammakh AS, Al-Saggaf WT. An overview on the accumulation, distribution, transformations, toxicity and analytical methods for the monitoring of persistent organic pollutants. Talanta. 2010;80:1587–97.

Bradley PM, Journey CA, Romanok KM, Barber LB, Buxton HT, Foreman WT, et al. Expanded target-chemical analysis reveals extensive mixed-organic-contaminant exposure in U.S. streams. Environ Sci Technol. 2017;51:4792–802.

Peters RJB, Groeneveld I, Sanchez PL, Gebbink W, Gersen A, de Nijs M, et al. Review of analytical approaches for the identification non-intentionally added substances in paper and board food contact materials. Trends Food Sci Tech. 2019;85:44–54.

Tittlemier SA. Methods for the analysis of melamine and related compounds in foods: a review. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2010;27:129–45.

Masiá A, Saurez-Varela MM, Llopis-Gonzalez A, Picó Y. Determination of pesticides and veterinary drug residues in food by liquid chromatography-mass spectrometry: a review. Anal Chim Acta. 2016;936:40–61.

Lehotay SJ, Son KA, Kwon H, Koesukwiwat U, Fu W, Mastovska K, et al. Comparison of QuEChERS sample preparation methods for the analysis of pesticide residues in fruits and vegetables. J Chromatogr A. 2010;1217:2548–60.

Alder L, Greulich K, Kempe G, Vieth B. Residue analysis of 500 high priority pesticides: better by GC-MS or LC-MS/MS? Mass Spectrom Rev. 2006;25:838–65.

Rocca LM, Gentili A, Pérez-Fernández V, Tomai P. Veterinary drugs residues: a review of the latest analytical research on sample preparation and LC-MS based methods. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2017;34:766–84.

Rossi R, Saluti G, Moretti S, Diamanti I, Giusepponi D, Galarini R. Multiclass methods for the analysis of antibiotic residues in milk by liquid chromatography coupled to mass spectrometry: a review. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2018;35:241–57.

Capriotti AL, Caruso G, Cavaliere C, Foglia P, Samperi R, Laganà A. Multiclass mycotoxin analysis in food, environmental and biological matrices with chromatography/mass spectrometry. Mass Spectrom Rev. 2012;31:466–503.

Zhang K, Schaab MR, Southwood G, Tor ER, Aston LA, Song W, et al. A collaborative study: determination of mycotoxins in corn, peanut butter, and wheat flour using stable isotope dilution assay (SIDA) and liquid chromatography- tandem mass spectrometry (LC-MS/MS). J Agric Food Chem. 2017;65:7138–52.

Malachová A, Sulyok M, Beltrán E, Berthiller F, Krska R. Optimization and validation of a quantititative liquid chromatography-tandem mass spectrometric method covering 295 bacterial and fungal metabolites including all regulated mycotoxins in four model food matrices. J Chromatogr A. 2014;1362:145–56.

Pizzini S, Piazza R, Cozzi G, Barbante C. Simultaneous determination of halogentated contaminants and polycyclic aromatic hydrocarbons: a multi-analyte method applied to filter-feeding edible organisms. Anal Bioanal Chem. 2016;408:7991–9.

Chiesa L, Nobile M, Malandra R, Pessina D, Panseri S, Labella GF, et al. Food safety traits of mussels and clams: distribution of PCBs, PBDEs,OCPs, PAHs and PFASs in sample from different areas using HRMS-Orbitrap and modified QuEChERS extraction followed by GC-MS/MS. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2018;35:959–71.

Burket SR, Sapozhnikova Y, Zheng JS, Chung SS, Brooks BW. At the intersection of urbanization, water, and food security: determination of select contaminants of emerging concern in mussels and oysters from Hong Kong. J Agric Food Chem. 2018;66:5009–17.

Meador JP, Yeh A, Young G, Gallagher EP. Contaminants of emerging concern in a large temperate estuary. Environ Pollut. 2016;213:254–67.

Monteiro SH, Lehotay SJ, Sapozhnikova Y, Ninga E, Lightfield AR. High-throughput mega-method for the analysis of pesticides, veterinary drugs, and environmental contaminants by UHPLC-MS/MS and robotic mini-SPE cleanup + LPGC-MS/MS, part 1: beef. J Agric Food Chem. 2020; Submitted.

Ninga E, Sapozhnikova Y, Lehotay SJ, Lightfield AR, Monteiro SH. High-throughput mega-method for the analysis of pesticides, veterinary drugs, and environmental contaminants by UHPLC-MS/MS and robotic mini-SPE cleanup + LPGC-MS/MS, part 2: catfish. J Agric Food Chem. 2020; Submitted.

Jadhav MR, Pudale A, Raut P, Utture S, Shabeer A, Banerjee K. A unified approach for high-throughput quantitative analysis of the residue of multi-class veterinary drugs and pesticides in bovine milk using LC-MS/MS and GC-MS/MS. Food Chem. 2019;272:292–305.

Mol HGJ, Plaza-Bolaños P, Zomer P, de Rijk TC, Stolker AAM, Mulder PPJ. Toward a generic extraction method for simultaneous determination of pesticides, mycotoxins, plant toxins, and veterinary drugs in feed and food matrixes. Anal Chem. 2008;80:9450–9.

Aguilera-Luiz MD, Plaza-Bolaños P, Romero-González R, Martinez Vidal JL, Garrido FA. Comparison of the efficiency of different extraction methods for the simultaneous determination of mycotoxins and pesticides in milk samples by ultra high-performance liquid chromatography-tandem mass spectrometry. Anal Bioanal Chem. 2011;399:2863–75.

Gómez-Pérez M, Plaza-Bolaños P, Romero-González R, Martínez-Vidal JL, Garrido FA. Comprehensive qualitative and quantitative determination of pesticides and veterinary drugs in honey using liquid-chromatography-Orbitrap high resolution mass spectrometry. J Chromatogr A. 2012;1248:130–8.

Gómez Pérez ML, Romero-González R, Plaza-Bolaños P, Genin E, Vidal JL, Frenich AG. Wide-scope analysis of pesticide and veterinary drug residues in meat matrices by high resolution MS: detection and identification using Exactive-Orbitrap. J Mass Spectrom. 2014;49:27–36.

Gómez Pérez ML, Romero-Gonzáles R, Vidal JL, Frenich AG. Analysis of veterinary drug and pesticide residues in animal feed by high-resolution mass spectrometry: comparison between time-of-flight and Orbitrap. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2015;32:1637–46.

Gómez Pérez ML, Romero-González R, Vidal JL, Frenich AG. Identification of transformation products of pesticides and veterinary drugs in food and related matrices: use of retrospective analysis. J Chromatogr A. 2015;1389:133–8.

Han L, Sapozhnikova Y, Lehotay SJ. Streamlined sample cleanup using combined dispersive solid-phase extraction and in-vial filtration for analysis of pesticides and environmental pollutants in shrimp. Anal Chim Acta. 2014;827:40–6.

Jia W, Chu X, Ling Y, Huang J, Chang J. High-throughput screening of pesticide and veterinary drug residues in baby food by liquid chromatography coupled to quadrupole Orbitrap mass spectrometry. J Chromatogr A. 2014;1347:122–8.

Xie J, Peng T, Zhu A, He J, Chang Q, Hu X, et al. Multi-residue analysis of veterinary drugs, pesticides and mycotoxins in dairy products by liquid chromatography–tandem mass spectrometry using low-temperature cleanup and solid phase extraction. J Chromatogr B. 2015;1002:19–29.

Danezis GP, Anagnostopoulos CJ, Liapis K, Koupparis MA. Multi-residue analysis of pesticides, plant hormones, veterinary drugs and mycotoxins using HILIC chromatography - MS/MS in various food matrices. Anal Chim Acta. 2016;942:121–38.

León N, Pastor A, Yusà V. Target analysis and retrospective screening of veterinary drugs, ergot alkaloids, plant toxins and other undesirable substances in feed using liquid chromatography–high resolution mass spectrometry. Talanta. 2016;149:43–52.

Munaretto JS, May MM, Saibt N, Zanella R. Liquid chromatography with high resolution mass spectrometry for identification of organic contaminants in fish fillet: screening and quantification assessment using two scan modes for data acquisition. J Chromatogr A. 2016;1456:205–16.

Souza R, Pareja L, Cesio MV, Heinzen H. Development of a straightforward and cheap ethyl acetate based method for simultaneous determination of pesticides and veterinary drugs residues in bovine liver and muscle. Chromatographia. 2016;79:1001–112.

Pérez-Ortega P, Lara-Ortega FJ, Gilbert-López B, Moreno-Gonzàles D, García-Reyes JF, Molina-Díaz A. Screening of over 600 pesticides, veterinary drugs, food-packaging contaminants, mycotoxins and other chemicals in food by ultra-high performance liquid chromatography quadrupole time-of-flight mass spectrometry (UHPLC-QTOFMS). Food Anal Methods. 2017;10:1216–44.

Sapozhnikova Y. High-throughput analytical method for 265 pesticides and environmental contaminants in meats and poultry by fast low pressure gas chromatography and ultrahigh-performance liquid chromatography tandem mass spectrometry. J Chromatogr A. 2018;1572:203–11.

Zhou J, Xu J-J, Cong J-M, Cai Z-X, Zhang J-S, Wang J-L, et al. Optimization for quick, easy, cheap, effective, rugged and safe extraction of mycotoxins and veterinary drugs by response surface methodology for application to egg and milk. J Chromatogr A. 2018;1532:20–9.

De Paepe E, Wauters J, Van Der Borght M, Claes J, Huysman S, Croubels S, et al. Ultra-high-performance liquid chromatography coupled to quadrupole orbitrap high-resolution mass spectrometry for multi-residue screening of pesticides, (veterinary) drugs and mycotoxins in edible insects. Food Chem. 2019;293:187–96.

Mijangos L, Ziarrusta H, Zabaleta I, Usobiaga A, Olivares M, Zuloaga O, et al. Multiresidue analytical method for the determination of 41 multiclass organic pollutants in mussel and fish tissues and biofluids by liquid chromatography coupled to tandem mass spectrometry. Anal Bioanal Chem. 2019;411:493–506.

Turnipseed SB, Storey JM, Wu I-L, Andersen WC, Madson MR. Extended liquid chromatography high resolution mass spectrometry screening method for veterinary drug, pesticide and human pharmaceutical residues in aquaculture fish. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2019;36:1501–14.

Xu X, Xu X, Han M, Qiu S, Hou X. Development of a modified QuEChERS method based on magnetic multiwalled carbon nanotubes for the simultaneous determination of veterinary drugs, pesticides and mycotoxins in eggs by UPLC-MS/MS. Food Chem. 2019;276:419–26.

Turnipseed SB, Storey JM, Lohne JJ, Andersen WC, Burger RJ, Johnson AS, et al. Wide-scope screening method for multiclass veterinary drug residues in fish, shrimp, and eel using liquid chromatography-quadrupole high-resolution mass spectrometry. J Agric Food Chem. 2017;65:7252–67.

FDA/Center for Veterinary Medicine. Unpublished results. 2020.

Zhang L-Q, Zhang X-M, Zhang H-W, Wang H, Xu H, Wang F-M, et al. Multiclass and multiresidue screening of veterinary drugs and pesticides in infant formula using Quadrupole-Orbitrap MS with PRM scan mode. J Mass Spectrom. 2020; 55:e4497.

Zhao L, Lucas D, Long D, Richter B, Stevens J. Multi-class multi-residue analysis of veterinary drugs in meat using enhanced matrix removal lipid cleanup and liquid chromatography-tandem mass spectrometry. J Chromatogr A. 2018;1549:14–24.

Hird S, Lau BP-Y, Schuhmacher R, Krska R. Liquid chromatography-mass spectrometry for the determination of chemical contaminants in food. Trends Anal Chem. 2014;59:59–72.

Lorenzo M, Picó Y. Gas chromatography and mass spectroscopy techniques for the detection of chemical contaminants and residues in food. In: Schrenk D, Carlus A, editors. Chemical contaminants and residues in food. Second ed: Elsevier Ltd. Woodhead Publishing, Elsevier; 2017. pp. 15–50

Lehotay SJ, Lightfield AR. Simultaneous analysis of aminoglycosides with many other classes of drug residues in bovine tissues by ultrahigh-performance liquid chromatography-tandem mass spectrometry using an ion-pairing reagent added to final extracts. Anal Bioanal Chem. 2018;410:1095–109.

Wu I-L, Turnipseed SB, Storey JM, Andersen WC, Madson MR. Comparison of various data acquisition modes with Orbitrap high resolution mass spectrometry for targeted and non-targeted residue screening in aquacultured eel. Rapid Commun Mass Spectrom. 2020;34:e8642.

Wong JW, Wang J, Chow W, Carlson R, Jia Z, Zhang K, et al. Perspectives on liquid chromatography-high resolution mass spectrometry for pesticide screening in foods. J Agric Food Chem. 2018;66:9573–81.

FDA. Guidelines for the Validation of Chemical Methods for the FDA Foods and Veterinary Medicine Program, 3rd Edition. 2019.

Hayward D, Archer JC, Andrews S, Fairchild RD, Gentry J, Jenkins R, et al. Application of a high-resolution quadrupole/orbital trapping mass spectrometer to a gas chromatograph for the determination of persistent organic pollutants in cow’s and human milk. J Agric Food Chem. 2018;66:11823–9.

Mol HGJ. Detection of contaminants in feed by gas chromatography with full scan high resolution mass spectrometry (GC-HRMS). Wageningen University Project. 2016. https://www.wur.nl/en/article/Detection-of-contaminants-in-feed-by-gas-chromatography-with-full-scan-high-resolution-mass-spectrometry-GC-HRMS.htm. Accessed April 3, 2020.

Yang P, Chang JS, Wong JW, Zhang K, Krynitsky AJ, Bromirski M, et al. Effect of sample dilution on matrix effects in pesticide analysis of several matrices by liquid chromatography–high-resolution mass spectrometry. J Agric Food Chem. 2015;63(21):5169–77.

European Union Commission Decision 2002/657/EC of 12 August 2002 Implementing Council Directive 96/23/EC Concerning the Performance of Analytical Methods and the Interpretation of Results. Off J Euro Commun. 2002;L221:8.

EU. Guidance document on anlytical quality control and method validation procedures for pesticides residues analysis in food and feed. SANTE/12682/2019. 2019.

FDA. Guidance for the analysis and documentation to support regulatory action on pesticide residues. ORA-LAB010. 2020.

FDA. Acceptance criteria for confirmation of identity of chemical residues using exact mass data for the FDA Foods and Veterinary Medicine Program. 2015.

FDA/CVM. Mass Spectrometry for Confirmation of the Identity of Animal Drug Residues. 2003.

EU. Guidelines for the validation of screening methods for residues of veterinary medicines Community Reference Laboratories Residues (CRLs) 02/1/2010. 2010.

Fu Y, Zhou Z, Kong H, Lu X, Zhao X, Chen Y, et al. Nontargeted screening method for illegal additives based on ultrahigh-performance liquid chromatography−high-resolution mass spectrometry. Anal Chem. 2016;88:8870–7.

Kunzelmann M, Winter M, Åberg M, Hellenäs K-E, Rosén J. Non-targeted analysis of unexpected food contaminants using LC-HRMS. Anal Bioanal Chem. 2018;410:5593–602.

FDA. FDA Strategy for the Safety of Imported Food. 2019. https://www.fda.gov/media/120585/download. Accessed April 3, 2020.

Eskola M, Elliot C, Hajšlová J, Steiner D, Krska R. Towards a dietary-exposome assessment of chemicals in food: an update on the chronic health risks for the European consumer. Crit Rev Food Sci Nutr. 2019.

Dervilly-Pinel G, Royer A-L, Bozzetta E, Pezzolat M, Herpin L, Prevost S, et al. When LC-HRMS metabolomics gets ISO17025 accredited and ready for official controls - application to the screening of forbidden compounds in livestock. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2018;35:1648–958.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no conflict of interest.

Disclaimer

Reference to any commercial materials, equipment, or process does not, in any way, constitute approval, endorsement, or recommendation by the U.S. Food and Drug Administration. In addition, the views expressed in this article are those of the author(s) and may not reflect the official policy of the Department of Health and Human Services, the U.S. Food and Drug Administration, or the U.S. Government.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Published in the topical collection featuring Female Role Models in Analytical Chemistry.

Rights and permissions

About this article

Cite this article

Turnipseed, S.B., Jayasuriya, H. Analytical methods for mixed organic chemical residues and contaminants in food. Anal Bioanal Chem 412, 5969–5980 (2020). https://doi.org/10.1007/s00216-020-02668-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-020-02668-8