Abstract

In this work, the suitability of atmospheric pressure photoionization (APPI) has been assessed for the determination of polychlorinated dibenzo-p-dioxins and furans (PCDD/Fs) and dioxin-like polychlorinated biphenyls (dl-PCBs) by gas chromatography–high-resolution mass spectrometry (GC-HRMS). The APPI of target compounds has been tested in both positive and negative ion modes. Under positive ion mode, the analytes generated the molecular ion, which was favoured using dopants that promote charge exchange gas-phase reactions (i.e., benzene), while in negative ion mode, the ion [M−Cl+O]− for PCDFs and dl-PCBs were mainly formed, providing the best results using benzene and diethyl ether as dopants, respectively. Concerning PCDDs, highly chlorinated congeners were mainly ionized by means of the [M−Cl]− ion, whereas [M−Cl+O2]− was the base peak for tetraCDD and [M−Cl+O]− for penta- and hexaCDDs. Method quality parameters, in accordance with the current EU Regulation guidelines for food and feed analysis, showed the good performance of the two GC-APPI-HRMS (Orbitrap) methods since they provided high detection capability (low fg levels), good linearity, and satisfactory precision (RSD% < 9%). In addition, the GC-APPI-HRMS (Orbitrap) methods were validated by analysing selected environmental and feed samples and the results were compared to those obtained using conventional GC-EI-HRMS, demonstrating the good performance in the analysis of the target compounds. Hence, the GC-APPI-HRMS technique can be proposed as alternative to the conventional methods for the determination of PCDD/Fs and dl-PCBs in environmental and feed matrices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

To protect human health and the environment from hazardous substances, the Stockholm Convention establishes restriction and regulations for eliminating the production and introduction into the environment of several classes of persistent organic pollutants (POPs) [1, 2]. Among them, polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs) as well as dioxin-like polychlorinated biphenyls (dl-PCBs) constitute a class of environmental pollutants of great concern due to their high toxicity, bioaccumulation capacity, and persistence in the environment [1, 3, 4]. PCDD/Fs have never been deliberately produced, but they have been released into the environment as by-products from combustion processes and industrial synthesis of other chlorinated chemicals [5, 6]. In contrast, PCBs have been used in a wide range of industrial and commercial applications, including heat exchange fluids in transformers, capacitors, and other electrical instruments, as well as additives in paints and the production of carbonless copy paper and plastics, due to their high chemical stability and electrical insulating properties [7, 8]. Among the 209 possible chlorinated biphenyls (CBs), some congeners can take a planar conformation (dl-PCBs), which could confer similar harmful effect as PCDD/Fs for living organisms even at very low concentration levels [9]. Although PCDD/F and dl-PCB emissions in most countries have significantly decreased due to regulatory restrictions and control, they are still subjected to large-scale global monitoring programs in the environment and other important fields such as food and feed safety [10,11,12,13].

Traditionally, analyses of PCDD/Fs and dl-PCBs have been closely related and the developed methodologies are based on gas chromatography coupled to high-resolution mass spectrometry (GC-HRMS) using double-focusing magnetic sector as mass analyser and operating in electron ionization (EI) mode. This technique has been accepted as the reference standard method for confirmatory analysis of these compounds [14], since it guarantees the required sensitivity and selectivity for the determination of PCDD/Fs and dl-PCBs in food, feed, and environmental samples down to femtogram level, avoiding the contribution of potentially interfering chlorinated compounds [15]. Nevertheless, EI as an ionization technique produces significant fragmentation, even at low ionization energies (~ 35 eV), reducing the intensity of the molecular ion and, therefore, worsening the detection capabilities of the methods [2]. In addition, when operating double-focusing HRMS instruments in selected ion monitored mode, the sensitivity is inversely related to both the resolution and the number of masses monitored, which effectively limits the number of different compounds that can be monitored at any given time. In 2010, Peterson et al. [16] reported the use of a GC-EI-QLT-Orbitrap hybrid mass spectrometer to achieve high-mass accuracy and resolution in the determination of PCDD/Fs, achieving significant advantages over the traditional magnetic mass instruments, such as high detection capabilities and precision, even operating in full-scan acquisition mode, and an excellent versatility by performing measurements in tandem mass spectrometry. This instrumentation provides useful information on the molecular mass and chemical structure as well as the possibility to perform standard library search. In the last years, the advances achieved on triple quadrupole and ion trap technologies have allowed the development of new analytical methodologies based on gas chromatography coupled to tandem mass spectrometry (GC-MS/MS), which have been accepted as confirmatory methods for the determination of these families of compounds by the EU Regulations [17, 18]. These new methodologies provide enough sensitivity for the determination of PCDD/Fs and dl-PCBs [2, 19, 20] with the advantage of a lower instrumental cost. However, as GC-MS/MS operate at low mass resolution, it is subjected to more potential isobaric interferences, requiring more time-consuming sample fractionation procedures to be applied than those used with GC-HRMS methods to achieve and accurate and selective determination of the analytes [21]. In the last decades, the use of atmospheric pressure ionization (API) sources for GC-MS analysis has significantly increased since they are soft ionization techniques that preserve molecular ion and/or protonated molecule [22, 23]. Moreover, API techniques are able to ionize a wider range of compounds than the high-vacuum ionization sources (e.g., electron and chemical ionization) and they have shown to be useful for the analysis of some families of persistent contaminants [24]. Among the API techniques, the atmospheric pressure chemical ionization (APCI) has been already applied to the GC-MS/MS analysis of both PCDD/Fs and dl-PCBs, obtaining intact molecular ions with low in-source collision-induced dissociation (CID) fragmentation and achieving high detection capability [2, 9, 21, 25,26,27,28,29]. Nevertheless, when APCI is combined with low-resolution tandem mass spectrometry working in multiple-reaction monitoring (MRM) mode, even though the selectivity achieved, the isotopic cluster information is lost, and also tedious sample clean-up procedures are necessary to avoid isobaric interferences. In the last years, a new atmospheric pressure photoionization (APPI) source has been commercialized and successfully applied to the analysis of different families of compounds [30,31,32,33,34]. In addition, this source is available for coupling to GC-MS instruments with Orbitrap mass analysers, which could overcome the limitations observed for MS/MS methods in the analysis of PCDD/Fs and dl-PCBs.

In this work, the performance and capability of the new coupling GC-APPI-HRMS (Orbitrap) for the reliable analysis of PCDD/Fs and dl-PCBs in selected feed and environmental samples have been evaluated as alternative to GC-EI-HRMS. For this purpose, several APPI parameters that affect the ionization of the target compounds were investigated. In addition, the GC-APPI-HRMS method was validated following the EU Regulations and the results were compared with those obtained using GC-EI-HRMS method. The real applicability of the proposed GC-APPI-HRMS method to the analysis of PCDD/Fs and dl-PCBs was assessed by analysing certified reference materials and reference samples used in several interlaboratory exercises.

Materials and methods

Standards and reagents

Calibration solutions of the seventeen regulated 2,3,7,8-chloro-substituted PCDD/Fs (CSL-CS4), EPA-1613, and twelve dl-PCBs (four non-ortho PCBs: CB 77, 81, 126, and 169, and eight mono-ortho PCBs: CB 105, 114, 118, 123, 156, 157, 167, and 189) (CS1-CS6), WP-CVS, containing the corresponding 13C12-labelled compounds in nonane, were obtained from Wellington Laboratories Inc. (Guelph, Ontario, Canada) for quantification purposes. The calibration solutions of PCDD/Fs and dl-PCBs covered a concentration range from 0.1 to 400 ng mL−1 and between 0.1 and 200 ng mL−1, respectively. The 13C12-labelled surrogate standard solutions, EPA-1613 LCS and WP-LCS, and injection standard solutions, EPA-1613 ISS and WP-ISS, for PCDD/Fs and dl-PCBs were also supplied by Wellington Laboratories Inc. Standards and calibration solutions were stored at 4 °C until their analyses.

Dichloromethane, toluene, cyclohexane, isooctane, and n-hexane for organic trace analysis were purchased from JT Baker (Deventer, The Netherlands). Ethyl acetate and nonane were supplied by Fluka (Fluka chemie GmbH., Switzerland). Silica gel was obtained from JT Baker (The Netherlands), basic Alumina ICN was purchased to MP Biomedicals (Germany), while Carbopack C 80/100 was achieved from Fluka (Switzerland). For the optimization of APPI of the target compounds, toluene and chlorobenzene (Chromasolv™ Plus, for HPLC analysis, purity ≥ 99%) from Sigma-Aldrich (St. Louis, MO, USA), acetone (LiChrosolv®, purity ≥ 99.8%), benzene (grade reagent for analysis, purity ≥ 99.7%), and diethyl ether (EMSURE® for analysis, purity ≥ 99.7%) from Merck, and tetrahydrofuran (Photrex™ reagent, purity at 99%) supplied by JT Baker (Deventer, The Netherland), were used as potential dopants. Helium Alphagaz™ 1 (purity ≥ 99.999%), supplied by Air Liquide (Madrid, Spain), was used as the GC carrier gas, whereas nitrogen (purity > 99.995%), from Linde (Barcelona, Spain), was employed as the make-up gas for the GC-APPI source. All glassware was cleaned using chromosulphuric acid and rinsed consecutively with Milli-Q water, methanol, and acetone, and dried at 180 °C overnight.

Samples and sample treatment

Certified reference materials BCR-677 (sewage sludge) and BCR-615 (fly ash) were obtained from the Institute for Reference Materials and Measurements (IRMM) of the European Commission-Joint Research (Geel, Belgium) and were used for validation of the GC-APPI-HRMS method. In addition, a chicken feed sample spiked with PCDD/Fs (0.12–2.27 pg g−1) and dl-PCBs (12.8–30.7 pg g−1), which is used as quality control material (QCM) for routine internal laboratory control, and some selected matrices (soybean meal, feed oil, and sediment) from several international interlaboratory studies were tested for evaluating the performance of the GC-APPI-HRMS method and comparing the results obtained with the two GC-HRMS systems.

Sample treatment was carried out following accredited analytical methods previously described elsewhere [35,36,37]. Owing to the variety of matrices, different extraction procedures were applied depending on the sample nature. All samples were spiked just before extraction step with known amounts of 13C-labelled PCDD/Fs (EPA-1613 LCS) and 13C-labelled dl-PCBs (WP-LCS). Appropriate amounts of soybean meal (40 g) and spiked chicken feed (9 g) samples were Soxhlet extracted for 24 h with 300 mL of toluene/cyclohexane (1:1, v/v), while for the fly ash (1 g), sludge (7 g), and sediment (1 g) samples, 300 mL of toluene was used. All the extracts were rotary evaporated to near dryness and the fatty residue was dissolved in 5 mL of n-hexane. For the feed oil sample, the matrix was directly diluted in n-hexane, after a previous homogenization by manual shaking for 5 min and spiked with known amounts of the 13C-labelled PCDD/F and dl-PCB standard mixtures. Fat and other interfering substances were removed from all the extracts and the diluted feed oil by using an acidified silica gel column (H2SO4, 44%, w/w). Purification and fractionation of all the extracts were carried out by sequential use of a multilayer silica, basic alumina, and carbon columns. The procedure provided two main fractions: fraction 1, containing the dl-PCB congeners, and fraction 2, where the PCDD/Fs were eluted. Both fractions were rotary concentrated and transferred into 1-mL conical vials. The remaining solvent was reduced to near dryness using a gentle stream of nitrogen and the final volume of the extract was adjusted to ca. 20 μL after addition in nonane of a known amount of the corresponding 13C12-isotopically labelled injection standards (EPA-1613 ISS and WP-ISS). The extracts were then analysed by both GC-APPI-HRMS and GC-EI-HRMS.

Instrumentation

The determination of both PCDD/Fs and dl-PCBs by GC-APPI-HRMS was performed in a Trace 1300 gas chromatograph coupled to a Q-Exactive Orbitrap mass spectrometer (Thermo Fisher Scientific, San Jose, CA, USA), using an atmospheric pressure photoionization (GC-APPI) source supplied by MasCom Technologies GmbH (Bremen, Germany). The chromatographic separation of PCCD/Fs and dl-PCBs was carried out using the same GC column, a DB-5ms UI (60 m × 0.25 mm I.D., 0.25-μm film thickness) fused-silica capillary column (Agilent Technologies, Santa Clara, CA, USA). In both cases, the injector was operated at 280 °C in splitless mode (1 min), using helium as carrier gas at a constant flow mode (1.0 mL min−1), and the injection volume was 1.5 μL for PCDD/Fs and 1 μL for dl-PCBs. The oven temperature program for PCDD/Fs was 140 °C (held for 1 min) to 200 °C at 20 °C min−1 (held for 1 min) and then to 300 °C at 2.5 °C min−1 (held for 20 min), and for dl-PCBs, 140 °C (held for 2 min) to 180 °C at 20 °C min−1 (held for 1 min) and to 300 °C at 2.5 °C min−1 (held for 5 min). The transfer line and capillary temperatures were set at 280 °C and 225 °C, whereas the source temperature was set at 250 °C and 225 °C for PCDD/F and dl-PCB analyses, respectively. The GC-APPI source was equipped with a 10.6-eV krypton lamp (Syagen, Santa Ana, CA, USA) and it was operated in negative ion mode for PCDD/Fs and dl-PCBs. Nitrogen was employed as make-up gas (gas pressure of 5 a.u.) and vapours of benzene and diethyl ether at a flow rate of 90 μL min−1 were used as dopants for the APPI of PCDD/Fs and dl-PCBs, respectively. In addition, S-Lens radio frequency was set at 50% to enhance the ion transmission to the mass analyser. Data acquisition was performed in full-scan mode from 100 to 600 m/z at a mass resolution of 70,000 FWHM (full width at half maximum, at 200 m/z). To achieve the highest sensitivity with well-defined peaks (12 points per peak), the automatic gain control (AGC) and maximum injection time were set at 1 × 106 and 50 ms, respectively. The quantitation of the target compounds was performed using the isotope dilution method. The extracted ion chromatograms were obtained using mass extraction windows with a tolerance of ±5 ppm to guarantee a high selectivity and quality of the results. Xcalibur v 3.1 software was used to control the instrument setup and process the data acquisition.

The analysis of the target compounds by GC-EI-HRMS was performed using an Agilent 7890A gas chromatograph (Agilent Technologies, Santa Clara, CA, USA) coupled to a Micromass Premier (Waters, Manchester, UK) high-resolution mass spectrometer (EBE geometry) equipped with an electron ionization source. The separation of PCDD/Fs and dl-PCBs was carried out using the same GC column than that described above for GC-APPI-HRMS system. Injection (1 μL) was performed in splitless mode (1 min) at 280 °C using helium as carrier gas at a constant flow mode (1.0 mL min−1). The oven temperature program was set as follows: 140 °C (held for 1 min) to 200 °C at 20 °C min−1 (held for 1 min) and then 310 °C at 5 °C min−1 (held for 6 min). The HRMS system was operated in EI+ mode at electron energy of 32 eV and at resolution of 10,000 (10% valley definition). The ion source and transfer line temperatures were set at 250 °C and 280 °C, respectively. The acquisition was carried out in selected ion monitoring (SIM) mode, where the two most abundant ions of the molecular cluster of each homologue group for PCDD/Fs and dl-PCBs were monitored at a 50-ms dwell time and a delay time of 20 ms. Trap current and acceleration voltage were set at 500 μA and 8000 V, respectively. Moreover, the quantitation was also performed using the isotope dilution method and a Masslynx data system (Waters) was used for data acquisition and instrument control.

Quality control criteria

Quality control procedures were applied for ensuring the quality of the results. Analyses including tests on isomer-specific GC separation, sensitivity, validity of the instrumental calibration and isotopic mass ratio, and recovery of the target compounds were carried out. In addition, procedural blanks, covering extraction, purification, and instrumental determination, were periodically analysed to evaluate the potential contribution of interfering compounds or potential sample carryover. Recoveries of the target compounds were always in the range of 60 to 120% as indicated in the corresponding EU Regulation [18]. To ensure accurate mass measurements, the Orbitrap mass analyser was calibrated every 72 h using an electrospray source and a calibration solution containing caffeine, MRFA peptide, Ultramark 1621, and butylamine in acetonitrile/methanol/water (2:1:1, v/v) with 1% (v/v) formic acid. PCDD/F and dl-PCB results were expressed as individual congener concentration and in WHO-TEQ (World Health Organization Toxic Equivalent) using the toxic equivalent factors (TEFs) revised in 2005 [6]. TEQ values were calculated in upperbound assuming the method limits of detection for those congeners when they are below these limits.

Results and discussion

Ionization of PCDD/Fs and dl-PCBs by GC-APPI

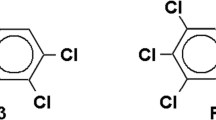

To study the ionization of both native and 13C-labelled compounds in the GC-APPI source, a calibration solution of PCDD/Fs (EN1613-CS4; 40–400 ng mL−1) and dl-PCBs (WP-CS6; 200 ng mL−1) were injected in the GC-APPI-HRMS system using vapours of different solvents (acetone, benzene, chlorobenzene, diethyl ether, tetrahydrofuran, and toluene) as dopants. As an example, Fig. 1 shows the mass spectra obtained for 1,2,3,7,8-PeCDD/Fs and CB-126 in both positive and negative ion modes, using as dopants benzene and diethyl ether, respectively. Generally, PCDD/Fs and dl-PCBs showed a similar ionization behaviour in positive ion mode using the tested dopants. Thus, all the target compounds led to the generation of the molecular ion [M]+● without any in-source collision-induced dissociation (CID) fragment ions and the ionization efficiency of these analytes mainly depended on the nature of the dopant. For instance, Fig. 2 (a–c) shows the effect of different dopants on the response of the molecular ion [M]+●. As can be seen, all compounds showed higher responses with benzene, toluene, and chlorobenzene than those achieved with acetone and tetrahydrofuran. This could be attributed to the different ions generated by each dopant during the photoionization process (see Electronic Supplementary Material (ESM) Table S1). Dopants such as benzene, chlorobenzene, and toluene yielded their molecular ion [D]+● (Table 1, reaction a), which was responsible of the ionization of the target compounds by charge exchange reactions (Table 1, reaction b). In contrast, acetone and tetrahydrofuran underwent a rapid self-protonation due to their high proton affinity that prevented the presence of radical dopant ions in the APPI source (Table 1, reaction c). Since benzene was the dopant that provided the highest responses for most of PCDD/Fs and dl-PCBs in positive ion mode, it was selected as the most appropriate dopant to achieve a high ionization efficiency of the target compounds.

Concerning the negative ion mode, the APPI was generally mediated by the superoxide ion (Table 1, reaction d), which is formed when an oxygen molecule captures the electrons released during the photoionization process of the dopant. Thus, PCDD/Fs and dl-PCBs led to the generation of the phenoxide ion ([M−Cl+O]–) without any in-source CID fragmentation (Fig. 1). For the PCDDs, the nature of the most abundant ion (base peak) was closely related with the number of chlorine atoms in the molecule (Fig. 3). Thus, the tetrachlorinated dibenzo-p-dioxins (TCDD) yielded the [M−Cl+O2]− as base peak (Fig. 3a), whereas pentachlorinated (PeCDDs) and hexachlorinated dibenzo-p-dioxins (HxCDDs) mainly led to the phenoxide ion [M−Cl+O]− (Fig. 3b). In contrast, the highly chlorinated dioxins, such as heptachlorinated (HpCDDs) and octachlorinated dibenzo-p-dioxins (OCDDs), yielded the ion [M−Cl]− (Fig. 3c). This could be due to both a steric hindrance and repulsion effect of chlorine atoms in the molecule that hinders the interaction of the superoxide ion with aromatic rings of the PCDDs. This phenomenon was not observed for PCDFs and dl-PCBs, which only yielded the phenoxide ion. This fact may be due to the less sterically hindered structures to generate the [M−Cl+O]− ion, since they only have one or none oxygen atoms, respectively.

Additionally, a relationship was observed between vapour pressure of the dopant and the analyte ionization efficiency in negative ion mode (Fig. 2). Thus, the higher the vapour pressure of the dopant, the greater the ionization efficiency of the compounds. Dopants with high vapour pressure (e.g., diethyl ether and acetone) may provide a higher number of electrons during the photoionization process, which could promote the subsequent reactions with the analytes in gas-phase (Table 1, reactions e–g). Moreover, PCDD/Fs, especially the TCDD, showed a high ionization efficiency in the presence of benzene (Fig. 2), even though the lower vapour pressure of this dopant, which was probably compensated by its lower ionization potential. Therefore, as a compromise, diethyl ether and benzene were selected as dopants for further studies in negative ion mode.

To maximize the ionization efficiency of the target compounds, the effect of the APPI source (from 180 to 250 °C) and capillary temperatures (from 175 to 225 °C) on the response of the analytes were also investigated. As it can be observed in Fig. 4 for the chromatographic separation of HxCDDs, a decrease on the source temperature resulted in an important peak broadening that negatively affected the chromatographic separation of the compounds. This effect was also observed for PCDFs and dl-PCBs, and it could be related with both the relatively low vapour pressure of the analytes and the source design that could lead to some condensation problems. Thus, high source (250 °C) and capillary temperatures (225 °C) were required to preserve the adequate chromatographic separation for all the compounds.

Performance of the GC-APPI-HRMS methods

In order to select the most suitable dopant for the determination of PCDD/Fs and dl-PCBs by GC-APPI-HRMS, instrumental limits of detection (iLODs) were determined using the dopant that provided the best responses in positive ion (benzene) and negative ion (benzene and diethyl ether) modes and monitoring the ions selected for quantification and confirmation of PCDD/Fs and dl-PCBs (Table 2). Since the extracted ion chromatograms present almost no baseline noise due to the narrow mass error threshold (< 5 ppm), the iLODs were defined as the smallest analyte concentration that provides a well-defined chromatographic peak. Table 3 shows the iLODs achieved for those dopants previously selected in both positive and negative ion modes. For most of the PCDD/Fs, the lowest iLOD values were obtained in negative ion mode using diethyl ether as dopant (0.25–3 fg on-column), which were around twofold lower than those found with benzene (0.5–8 fg on-column) in negative mode and 100-fold lower (10–49 fg on-column) than those achieved in positive ion mode. Nevertheless, the iLOD for the 2,3,7,8-TCDD using diethyl ether (150 fg on-column) was 5 times higher than that achieved employing benzene as dopant (25 fg on-column) due to the high fragmentation observed in the APPI source (ESM Fig. S1 a). This could be attributed to the higher ionization potential of diethyl ether (9.53 eV) compared with benzene (9.24 eV) that may lead to more energetic electrons, which could induce a higher in-source CID fragmentation on this analyte, thus increasing the corresponding iLOD. As a compromise, benzene was selected as the most suitable dopant for the PCDD/F determination by negative ion GC-APPI-HRMS. Concerning the dl-PCBs, the use of diethyl ether as dopant in negative ion mode provided iLODs ranging from 2.5 to 100 times lower than those obtained in positive ion mode (Table 3). Therefore, negative ion GC-APPI-HRMS using diethyl ether as dopant was chosen for the determination of dl-PCBs. In addition, the iLODs achieved with the GC-APPI-HRMS methods were compared with those obtained by GC-EI-HRMS. As can be seen in Table 3, iLODs obtained for most of dl-PCBs by negative ion GC-APPI-HRMS were at least 2 times lower than those achieved by GC-EI-HRMS and even up to a maximum of 60-fold lower than those estimated for the confirmatory method in the case of PCDD/Fs. These results demonstrate the high detection capability of the developed GC-APPI-HRMS methods.

The performance of the proposed GC-APPI-HRMS methods for the determination of PCDD/Fs and dl-PCBs was investigated in compliance with the requirements established in the current EU Regulation (EU Regulation 2017/664-771) [17, 18]. As mentioned before, the GC-APPI-HRMS methods allowed the adequate detection of the target compounds at low femtogram levels (Table 2), which successfully satisfies the analytical criteria established in the EU Regulations. In addition, the chromatographic separation achieved for 1,2,3,4,7,8-HxCDD and 1,2,3,6,7,8-HxCDD congeners was enough (co-elution lower than 7%) to fulfil with the EU Regulation (co-elution < 25%) [17], working at a source temperature of 250 °C (Fig. 4). The linearity was evaluated over the 0.1–400 pg μL−1 range for PCDD/Fs and from 0.1 to 40 pg μL−1 for dl-PCBs (Table 4). Calibration curves were established, and good linearity was obtained within the calibration range with determination coefficients (r2) higher than 0.9997 for all the compounds. In addition, reproducible relative response factors (RRFs) were obtained from the analysis of calibration solutions with relative standard deviations lower than 12% for both PCDD/Fs and dl-PCBs (Table 4). Moreover, the differences between the RRF average obtained for all points and the corresponding values for only the lowest calibration point were less than 14% (Table 4). These differences fulfilled with the criterion established by the EU Regulation (< 30%), demonstrating the high stability on the response of the target compounds using GC-APPI-HRMS methods, even working at very low concentration levels. The ion abundance ratio (IR) of the two ions selected for quantification (see Table 2) along the calibration range was quite stable and ranging from 0.3 to 7% RSD% (Table 4), which also met with the maximum permitted tolerance established in the EU Regulation (± 15%). Moreover, run-to-run and day-to-day precisions were assessed by analysing seven replicates (n = 7) of a standard calibration solution at low concentration levels (PCDD/Fs, 0.25–2.5 pg μL−1; dl-PCBs, 0.5 pg μL−1) on 1 day for run-to-run and on three non-consecutive days for day-to-day. The precision achieved on the variation of quantitative results, expressed as RSD% values, was always lower than 9% (Table 4), showing the good performance of the GC-APPI-HRMS methods for the analysis of PCDD/Fs and dl-PCBs, respectively.

Analysis of reference samples

Once the instrumental methods were validated for the determination of PCDD/Fs and dl-PCBs, selected environmental and feed samples were analysed to evaluate the real applicability in the GC-APPI-HRMS technique. The analysed samples consisted on two certified reference materials, a fly ash (BCR-615) and a sewage sludge (BCR-677), three interlaboratory materials (soybean meal, feed oil, and sediment), and one quality control sample (a spiked chicken feed sample), which is used for the internal laboratory control. All these samples were analysed by triplicate using the sample treatment described in the experimental section (“Samples and sample treatment” section) and the extracts were injected in both GC-EI-HRMS and GC-APPI-HRMS systems. Tables 5 and 6 summarize the results obtained using the proposed GC-APPI-HRMS method, the reference GC-EI-HRMS method, and the certified or assigned value. In addition, quantitative results for the internal quality sample are also given in ESM Table S2. As can be seen, a good agreement between both GC-MS methods was achieved for all individual congeners, with differences in the mean value lower than 23%. To compare these results and extract useful conclusions, statistical treatment of the data was performed using a two-way analysis of variances (ANOVA) test. The p values obtained were always higher than the significance level of 0.05 (p values for PCDD/Fs, 0.15–0.52 and for dl-PCBs, 0.37–0.90), which indicated that there were no statistically significant differences between both GC-EI-HRMS and GC-APPI-HRMS methods. In addition, the statistical study also showed that the results were not significantly different from the reference concentration values. Moreover, the results were also compared in terms of toxic equivalents (TEQs) and the upperbound TEQs corresponding to the reference materials and those achieved using both GC-EI-HRMS and GC-APPI-HRMS methods are shown in Fig. 5. As it can be observed, the results were similar with no significant differences between them (p values from 0.26 to 0.77), which indicates that the GC-APPI-HRMS methods allow the estimation of the TEQ values as well as the reference GC-EI-HRMS methods. In fact, the differences between the lower and the upperbound TEQs did not exceed the 15% for all the samples analysed (15% for PCDD/Fs and 0.02% for dl-PCBs), which fulfils the requirements of the current EU Regulation (< 20%) [18]. These results demonstrate the suitability of the developed method for the analysis of PCDD/Fs and dl-PCBs in environmental and feed samples.

Conclusions

The feasibility of the developed GC-APPI-HRMS (Orbitrap) (negative ion mode) methods for the analysis of both PCDD/Fs and dl-PCBs in environmental and feed samples has been demonstrated. The use of dopants with a high vapour pressure in the negative ion mode provided the highest ionization efficiency for the analytes, being benzene and diethyl ether the dopants that provided the best results for the determination of PCDD/Fs and dl-PCBs, respectively. Under the optimal GC-APPI-HRMS conditions, most of the analytes generated the phenoxide ion as the base peak of the mass spectrum. The two GC-APPI-HRMS methods allowed the detection of target compounds down to low femtogram level (PCDD/Fs, 0.5–25 fg injected; dl-PCBs, 0.5–10 fg injected) and showed a good performance in terms of linearity (RSD% of the RFF lower than 12%), run-to-run and day-to-day precision (RSD < 9%), and stability of the ion ratio values (RSD < 7%), which guarantee the analyte quantitation and confirmation even at very low concentration levels. Moreover, the results obtained for the analysis of selected environmental and feed samples showed that there were no statistically significant differences between the GC-APPI-HRMS methods and the GC-EI-HRMS reference method in terms of both analyte concentration and TEQs. As far as we know, this is the first time that the GC-APPI-HRMS (Orbitrap) (negative ion mode) has been proposed for the analysis of PCDD/Fs and dl-PCBs, showing important advantages over the traditional GC-EI-HRMS confirmatory method.

References

Xu W, Wang X, Cai Z. Analytical chemistry of the persistent organic pollutants identified in the Stockholm Convention: a review. Anal Chim Acta. 2013;790:1–13.

Van Bavel B, Geng D, Cherta L, Nácher-Mestre J, Portolés T, Ábalos M, et al. Atmospheric-pressure chemical ionization tandem mass spectrometry (APGC/MS/MS) an alternative to high-resolution mass spectrometry (HRGC/HRMS) for the determination of dioxins. Anal Chem. 2015;87:9047–53.

Safe S, Hutzinger O, Hill TA. Polychlorinated dibenzo-ρ-dioxins and -furans (PCDDs/PCDFs): sources and environmental impact, epidemiology, mechanisms of action, health risks. 1st ed. Berlin: Springer; 1990.

Kanan S, Samara F. Dioxins and furans: a review from chemical and environmental perspectives. Trends Environ Anal Chem. 2018;17:1–13.

Dioxins: a technical guide, 9th ed. Ministry of Health, Wellington; 2016.

Van den Berg M, Birnbaum LS, Denison M, De Vito M, Farland W, Feeley M, et al. The 2005 World Health Organization reevaluation of human and mammalian toxic equivalency factors for dioxins and dioxin-like compounds. Toxicol Sci. 2006;93:223–41.

Toxicological profile for polychlorinated biphenyls (PCBs). Agency for Toxic Substances and Disease Registry; 2000.

Batang ZB, Alikunhi N, Gochfeld M, Burger J, Al-Jahdali R, Al-Jahdali H, et al. Congener-specific levels and patterns of polychlorinated biphenyls in edible fish tissue from the Central Red Sea coast of Saudi Arabia. Sci Total Environ. 2016;572:915–25.

Portolés T, Sales C, Abalos M, Sauló J, Abad E. Evaluation of the capabilities of atmospheric pressure chemical ionization source coupled to tandem mass spectrometry for the determination of dioxin-like polychlorobiphenyls in complex-matrix food samples. Anal Chim Acta. 2016;937:96–105.

Kauppila TJ, Kersten H, Benter T. Ionization of EPA contaminants in direct and dopant- and atmospheric pressure laser ionization. J Am Soc Mass Spectrom. 2015;26:1036–45.

Abalos M, Abad E, Van Leeuwen SPJ, De Boer J, Lindström G, Van Bavel B, et al. Results for PCDD/PCDF and dl-PCBs in the first round of UNEPs biennial global interlaboratory assessment on persistent organic pollutants. TrAC - Trends Anal Chem. 2013;46:98–109.

Van Leeuwen SPJ, Leslie HA, De Boer J, Van Leeuwen SPJ, Van Bavel B, Abad E, et al. POPs analysis reveals issues in bringing laboratories in developing countries to a higher quality level. TrAC - Trends Anal Chem. 2013;46:198–206.

Leslie HA, van Bavel B, Abad E, de Boer J. Towards comparable POPs data worldwide with global monitoring data and analytical capacity building in Africa, Central and Latin America, and the South Pacific. TrAC - Trends Anal Chem. 2013;46:85–97.

Reiner EJ, Clement RE, Okey AB, Marvin CH. Advances in analytical techniques for polychlorinated dibenzo-p-dioxins, polychlorinated dibenzofurans and dioxin-like PCBs. Anal Bioanal Chem. 2006;386:791–806.

Reiner EJ. The analysis of dioxins and related compounds. Eric Mass Spectrom Rev. 2009;29:526–59.

Peterson AC, Mcalister GC, Quarmby ST, Griep-raming J, Coon JJ. Development and characterization of a GC-enabled QLT-Orbitrap for high-resolution and high-mass accuracy GC / MS. 2010;82:8618–28.

Commission Regulation (EU) 2017/771 of 3 of May amending Regulation (EC) No 152/2009 as regards the methods for the determination of the levels of dioxins and polychlorinated biphenyls. Off J Eur Union. 2017;115/22–115/42.

Commission Regulation (EU) 2017/644 of 5 of April 2017 Laying down methods of sampling and analysis for the control of levels of dioxins, dioxin-like PCBs and non-dioxin like PCBs in certain foodstuffs and repealing Regulation (EU) No 589/2014. Off J Eur Union. 2017;92/9–92/34.

Malavia J, Santos FJ, Galceran MT. Comparison of gas chromatography-ion-trap tandem mass spectrometry systems for the determination of polychlorinated dibenzo-p-dioxins, dibenzofurans and dioxin-like polychlorinated biphenyls. J Chromatogr A. 2008;1186:302–11.

L’Homme B, Scholl G, Eppe G, Focant JF. Validation of a gas chromatography-triple quadrupole mass spectrometry method for confirmatory analysis of dioxins and dioxin-like polychlorobiphenyls in feed following new EU Regulation 709/2014. J Chromatogr A. 2015;1376:149–58.

Organtini KL, Haimovici L, Jobst KJ, Reiner EJ, Ladak A, Stevens D, et al. Comparison of atmospheric pressure ionization gas chromatography-triple quadrupole mass spectrometry to traditional high-resolution mass spectrometry for the identification and quantification of halogenated dioxins and furans. Anal Chem. 2015;87:7902–8.

Revelsky IA, Yashin YS, Sobolevsky TG, Revelsky AI, Miller B, Oriedo V. Electron ionization and atmospheric pressure photochemical ionization in gas chromatography- mass spectrometry analysis of amino acids. Eur J Mass Spectrom. 2003;507:497–507.

McEwen CN, McKay RG. A combination atmospheric pressure LC/MS:GC/MS ion source: advantages of dual AP-LC/MS:GC/MS instrumentation. J Am Soc Mass Spectrom. 2005;16:1730–8.

Li DX, Gan L, Bronja A, Schmitz OJ. Gas chromatography coupled to atmospheric pressure ionization mass spectrometry (GC-API-MS): review. Anal Chim Acta. 2015;891:43–61.

ten Dam G, Pussente IC, Scholl G, Eppe G, Schaechtele A, van Leeuwen S. The performance of atmospheric pressure gas chromatography–tandem mass spectrometry compared to gas chromatography–high resolution mass spectrometry for the analysis of polychlorinated dioxins and polychlorinated biphenyls in food and feed samples. J Chromatogr A. 2016;1477:76–90.

Rivera-Austrui J, Martínez K, Ábalos M, Sales C, Portoles T, Beltran J, et al. Analysis of polychlorinated dibenzo-p-dioxins and dibenzofurans in stack gas emissions by gas chromatography-atmospheric pressure chemical ionization-triple-quadrupole mass spectrometry. J Chromatogr A. 2017;1513:245–9.

Luosujärvi L, Karikko M-M, Haapala M, Saarela V, Huhtala S, Franssila S, et al. Gas chromatography/mass spectrometry of polychlorinated biphenyls using atmospheric pressure chemical ionization and atmospheric pressure photoionization microchips. Rapid Commun Mass Spectrom. 2008;20:425–31.

Geng D, Jogsten IE, Dunstan J, Hagberg J, Wang T, Ruzzin J, et al. Gas chromatography/atmospheric pressure chemical ionization/mass spectrometry for the analysis of organochlorine pesticides and polychlorinated biphenyls in human serum. J Chromatogr A. 2016;1453:88–98.

Stubleski J, Kukucka P, Salihovic S, Lind PM, Lind L, Kärrman A. A method for analysis of marker persistent organic pollutants in low-volume plasma and serum samples using 96-well plate solid phase extraction. J Chromatogr A. 2018;1546:18–27.

Hintikka L, Haapala M, Franssila S, Kuuranne T, Leinonen A, Kostiainen R. Feasibility of gas chromatography-microchip atmospheric pressure photoionization-mass spectrometry in analysis of anabolic steroids. J Chromatogr A. 2010;1217:8290–7.

Haapala M, Luosujärvi L, Saarela V, Kotiaho T, Ketola RA, Franssila S, et al. Microchip for combining gas chromatography or capillary liquid chromatography with atmospheric pressure photoionization-mass spectrometry. Anal Chem. 2007;79:4994–9.

Revelsky IA, Yashin YS. Talanta new approach to complex organic compounds mixtures analysis based on gas chromatography – atmospheric pressure photoionization – mass-spectrometry. Talanta. 2012;102:110–3.

Kondyli A, Schrader W. High-resolution GC/MS studies of a light crude oil fraction. J Mass Spectrom. 2019;54:47–54.

Di Lorenzo RA, Lobodin VV, Cochran J, Kolic T, Besevic S, Sled JG, et al. Fast gas chromatography-atmospheric pressure (photo)ionization mass spectrometry of polybrominated diphenylether flame retardants. Anal Chim Acta. 2019;1056:70–8.

Ábalos M, Parera J, Rivera J, Abad E. PCDD/F and DL-PCB levels in meat from broilers and rabbits fed with fish-oil enriched feeds. Chemosphere. 2010;78:175–84.

Martínez K, Rivera-Austrui J, Adrados MA, Abalos M, Llerena JJ, van Bavel B, et al. Uncertainty assessment of polychlorinated dibenzo-p-dioxins and dibenzofuran and dioxin-like polychlorinated biphenyl analysis in stationary source sample emissions in accordance with the impending European standard EN-1948 using fly ashes. J Chromatogr A. 2010;1216:5888–94.

Ábalos M, Barceló D, Parera J, la Farré M, Llorca M, Eljarrat E, et al. Levels of regulated POPs in fish samples from the Sava River Basin. Comparison to legislated quality standard values. Sci Total Environ. 2019;647:20–8.

Funding

The authors thank the financial support received from the Spanish Ministry of Science, Innovation and Universities (project codes: PGC2018-095013-B-I00 and CEX2018-000794-S) and from the Generalitat of Catalonia (project code: 2017–SGR–310). Juan F. Ayala-Cabrera acknowledges the Spanish Ministry of Education, Culture and Sports for the PhD FPU fellowship (code: FPU14/05539).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 157 kb)

Rights and permissions

About this article

Cite this article

Ayala-Cabrera, J.F., Ábalos, M., Abad, E. et al. Feasibility of gas chromatography-atmospheric pressure photoionization–high-resolution mass spectrometry for the analysis of polychlorinated dibenzo-p-dioxins, dibenzofurans, and dioxin-like polychlorinated biphenyls in environmental and feed samples. Anal Bioanal Chem 412, 3703–3716 (2020). https://doi.org/10.1007/s00216-020-02615-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-020-02615-7