Abstract

Myrtus communis L. (myrtle) is native to the Mediterranean region and Western Asia. Its leaves have demonstrated its potential effect towards different bioactivities like anti-diabetic, anti-diarrheic, anti-ulcer, anti-cancer, among others. These activities have been associated with its phenolic content. In this sense, the aim of this work has been to develop a new pressurized-liquid extraction procedure (PLE), by using a response surface methodology (RSM), to evaluate the phenolic composition from myrtle leaves by HPLC-DAD-TOF-MS. Previously, different solvents such as methanol, ethanol, and acetone/water mixtures were tested by using ultrasound-assisted extraction (UAE) in order to select the most suitable one. Subsequently, a Box-Behnken design (BBD) was performed according to the effect of ethanol/water ratio (50, 75, and 100% (v/v)), temperature (50, 125, and 200 °C), and extraction time (5, 18, and 30 min). The optimal conditions achieved with the established method were 71% ethanol/water, 137 °C, and 19 min. The analysis of the obtained extracts by HPLC-DAD-TOF-MS allowed the characterization of 15 new compounds in myrtle leaves. Finally, high amounts of gallic and ellagic acid were found in the optimized PLE extracts (3.31 ± 0.03 and 3.88 ± 0.09 mg/g leaf dry weight (d.w.), respectively), and PLE reported greater recovery of total phenolic compounds than UAE (30 ± 1 and 22.4 ± 0.6 mg/g leaf d.w., respectively).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Myrtus communis L. (myrtle), known as mirto in Spain and Italy, is a flowering plant which belongs to the Myrtaceae family [1]. From 1 to 5 m tall, this plant could be grown throughout tropical and subtropical regions, although it is native to the Mediterranean region and Western Asia [1, 2]. The popularity of myrtle is due to its applications in cosmetic and food industries, as well as therapeutic agent [3]. In fact, it is one of the oldest ancient remedies [1]. Traditionally, different parts of this shrub have been used against several disorders due to its anti-bacterial, anti-fungal, antioxidant and hypoglycemic properties, among others [1,2,3]. Moreover, these properties have been related to the phenolic composition of the plant [1,2,3], which is greater in the leaves as occurs in many instances [4].

Extraction is the most important step to obtain the target compounds; hence, there is an increasing interest in selecting the proper extraction technology and optimizing the related process parameters [5]. In spite of its drawbacks [5, 6], conventional extraction techniques have generally been used to recover phenolic compounds from myrtle leaves [7, 8]. To overcome the disadvantages of these last techniques, several non-conventional techniques have been developed in the last years [6]. Among them, ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE), and supercritical-fluid extraction (SFE) have been applied for this purpose in myrtle leaves [9, 10]. However, pressurized-liquid extraction (PLE), which has demonstrated to improve the extraction of phenolic compounds in other plants [11,12,13,14,15], has not previously been used. Compared to these alternatives, PLE offers several advantages (i.e., reduction of solvent) and is based on the use of high temperatures and pressures to enhance solubility and mass transfer in a more efficient way [6].

Concerning the extraction process, solvent, temperature, and extraction time are the most critical parameters for this technique; whereas pressure is not usually considered for optimization designs due to its slight effect [15]. In contrast to the typical one-variable-at-a-time methodology, multivariate statistic methodologies have been applied to enable greater extraction efficiency. Especially, response surface methodology (RSM) has become the most preferable approach for the optimization of analytical methods, when a response is affected by several factors [16]. Based on these premises, the goal of this work was to develop a new PLE procedure, evaluating the effect of solvent, temperature, and extraction time, for the characterization of the phenolic composition in myrtle leaves by using HPLC-DAD-TOF-MS, and to find out the optimal extraction conditions for target compounds by PLE.

Material and methods

Chemicals and plant material

Double-deionized water (18.2 MΩ) was obtained with a Milli-Q system (Millipore, Bedford, MA, USA). LC-MS “optima” grade methanol, acetonitrile, ethanol, acetone and sand (extra Pure, SLR, Ottawa, 20–30 Mesh) were purchased from Fisher Scientific (Leicestershire, UK). Acetic acid and the standards: gallic acid, catechin, p-coumaric acid, and quercetin were all from Sigma-Aldrich (Steinheim, Germany).

Myrtus communis L. leaves were collected in the north coast of Naples (Italy). They were middle age intense green leaves and they were collected in March 2016. Leaves were air-dried at room temperature and stored frozen until analysis. The environmental conditions had mean max/min temperature of 15/6 °C, precipitation of 2.3–86 mm, and saturated light duration ranged from 11.19 to 12.41 h day−1.

Extraction procedures

Ultrasound-assisted extraction (UAE)

The phenolic compounds extraction from myrtle leaves was carried out with an ultrasound bath (Branson B3510). Briefly, to 0.5 g of air-dried and grounded leaves were added 10 mL of solvent (mixtures of ethanol, methanol or acetone with water (80% v/v) and sonicated during 10 min at room temperature (× 3). Then, to remove solids, samples were centrifuged for 10 min at 6000 rpm. The supernatants were evaporated and reconstituted in 6 mL of methanol/water (50% v/v). Finally, the extracts were filtered through 0.20-μm (regenerated cellulose) filters and stored at − 18 °C in amber vials until analysis. The samples were run in triplicate (n = 3).

Pressurized-liquid extraction (PLE)

The extraction of phenolic compounds from myrtle leaves by PLE was carried out using an accelerated solvent extractor equipped with a solvent controller (ASE 350, Dionex, Sunnyvale, CA, USA). Briefly, 1 g of plant material was placed into 22 mL volume extraction cells with 14 g of sea sand as dispersing agent to avoid the reduction of the contact surface and the matter transfer, enhancing the efficiency of the extraction [17]. The extraction conditions were as follows: pressure (7 MPa), flush volume (60%), static time (5 min), N2 purge time (100 s), number of cycles (1) and preheat time (0 min). Solvent ratio (ethanol/water ratio (50, 75, and 100% v/v), temperature (50, 125 and 200 °C) and extraction time (5, 18 and 30 min) were changed in order to optimize the extraction. Finally, the extracts were evaporated, reconstituted, filtered and stored until analysis as in UAE.

Experimental design

Box-Behnken design (BBD) was chosen for the optimization of the phenolic compounds extraction since it is more simple and efficient than other three-level factorial designs [16, 18]. The complete design consisted on 15 experimental runs, with three levels (− 1, 0, 1) for each factor, and three center points. The coded and natural values of the factors are shown in Table 1. Briefly, each factor was tested in the following levels: ethanol/water ratio (50, 75, and 100% v/v) (Χ1), temperature (50, 125, and 200 °C) (Χ2), and extraction time (5, 18, and 30 min) (Χ3).

The response variables were fitted to a second-order polynomial model equation (Eq. (1)) obtained by the response surface methodology (RSM):

where Υ represents the response variable, total phenolic content (TPC) via HPLC-DAD-TOF-MS, Χi and Χj are the independent factors affecting the response, and β0, βi, βii, and βij are the regression coefficients of the model (intercept, linear, quadratic and interaction term).

The model was built and fitted using Statistica 7.0 (2002, StatSoft, Tulsa, OK). Analysis of variance (ANOVA) with 95% confidence level was carried out to find out the adequacy of the regression model, which was decided by the regression coefficient (R2), and the p value of the regression model and of the lack of fit (LOF). The significance of the model was evaluated by a Fisher test, with p value obtained for the intercept, linear, quadratic and interaction terms of the model.

HPLC-DAD-TOF-MS analysis

Chromatographic analyses were conducted on an Agilent 1200 series Rapid Resolution Liquid Chromatograph (Agilent Technologies, CA, USA) equipped with a binary pump, a degasser, an autosampler, a column heater, and a DAD detector. A Poroshell 120 EC-C18 analytical column (4.6 mm × 100 mm, particle size 2.7 μm) from Agilent Technologies was used for the separation of the compounds. Water with acetic acid (1%) to enhance separation, and acetonitrile were used as eluents A and B, respectively, and the gradient elution was applied as follows: 0 min, 2.5% B; 5 min, 10% B; 9 min, 15% B; 10 min, 16% B; 12 min, 18% B; 17 min, 20% B; 21 min, 50% B, 25 min, 75% B; 32 min, 100% B; 34 min, 100% B; 36 min, 2.5% B. The injection volume was 5 μL, the flow rate was set at 0.8 mL/min, and the column temperature at 25 °C.

The HPLC system was coupled to a time-of-flight mass spectrometer (micrOTOF™, Bruker Daltonics GmbH, Bremen, Germany), equipped with a model G1607A ESI interface (Agilent Technologies) operating in negative ion mode. At this stage, the use of a T-type splitter (split = 1:3) was required for coupling with the MS detector to achieve reproducible results and stable spray. The optimum values of source parameters were capillary voltage of + 4 kV; drying-gas temperature, 210 °C; drying-gas flow, 10 L/min; nebulizing-gas pressure, 43.5 psi; and end-plate offset, − 0.5 kV. The values of transfer parameters were capillary exit, − 120 V; skimmer 1, − 40 V; hexapole 1, − 23 V; RF hexapole, 50 Vpp; and skimmer 2, − 22.5 V. The source and transfer parameters were optimized to ensure good sensitivity, to reach reasonable resolution within the mass range of the target compounds (50–1500 m/z), and to improve the ionization performance.

External mass spectrometer calibration was performed passing a solution containing sodium acetate clusters (5 mM sodium hydroxide in water/2-propanol 1/1 (v/v), with 0.2% of acetic acid) in quadratic high-precision calibration (HPC) regression mode. With this method, an exact calibration curve was achieved based on numerous cluster masses, each differing by 82 Da (C2H3NaO2). The calibration solution was injected at the beginning of the run using a Cole Palmer syringe pump (Vernon Hills, Illinois, USA) and all the spectra were calibrated prior to phenolic compounds characterization. The micrOTOF does not only allow for accurate mass measurement but also provides a tool for elemental composition suggestions of a compound of interest. Compound mass spectra are selected in the DataAnalysis 4.0 software (Bruker Daltonics, Bremen, Germany) and exported to a molecular formula generator. The GenerateFormula™ editor uses a CHNO algorithm, which provides standard functionalities such as minimum/maximum elemental range, electron configuration and ring-plus double bonds equivalents, as well as a sophisticated comparison of the theoretical with the measured isotope pattern (SigmaValue™) for increased confidence in the suggested molecular formula [19].

The characterization of the phytochemical compounds was based on the accurate mass measurements of the molecular ion [M-H]−, the UV–Vis data and also on the previous related literature from the Myrtus family members, since no commercial standards were available for all detected compounds.

Finally, Data Analysis 4.0 software (Bruker Daltonics, Bremen, Germany) was used for the quantification. The analyses were run in triplicate (n = 3) and results expressed for each compound quantified as μg/g leaf dry weight (d.w.), and for the total amount as mg of phenolic compounds/g leaf dry weight (d.w.). For this purpose, four phenolic standards (gallic acid, p-coumaric acid, quercetin, and catechin) were used to quantify the phenolic composition in myrtle leaf extracts. The calibration curves were prepared at seven concentration levels from the limit of quantification (LOQ) to 250 mg/L in methanol/water (50% v/v). Besides, good linearity (R2 > 0.9962–0.9998) was found for all the standards. The standard deviation of the background noise was determined, for each standard, as the signal-to-noise ratio of 3:1 for the limit of detection (LOD) and 10:1 for the limit of quantification (LOQ). For all the standards, values ranged from 0.002 to 0.03 mg/L for LOD and from 0.005 to 0.099 mg/L for LOQ. It is noteworthy that compounds with no commercial standard available were quantified with the calibration curve of a specie with similar structure.

Results and discussion

Compounds identification and solvent choice

The selection of the extraction solvent was performed via UAE. In general, solvent mixtures, such as methanol, ethanol or acetone/water, reported greater extraction efficiencies for phenolic compounds compared to pure solvents [20]. For this reason, mixtures of ethanol, methanol or acetone with water (80% v/v) were tested in order to select the most suitable solvent for PLE extraction. The myrtle leaves extracts obtained with different solvents were subsequently analyzed by HPLC-DAD-TOF-MS. First, a tentative compound identification (Table 2) was performed by using the retention time, the UV–Vis and mass spectra. These data were compared and contrasted with the information available in the literature. In fact, information from DAD spectra (200–550 nm) was used to support the identification of each family of compounds because phenolic acids usually present maximum between 200 and 290 nm and others absorption band in the range of 270 to 360 nm if they present additional conjugations [21]. In the case of flavonoids, all of them exhibit their main band between 240 and 290 nm and only some of them present a maximum at longer wavelengths (300–550 nm) [22]. Fig. S1 (see Electronic Supplementary Material (ESM)) shows the extract ion chromatograms (EICs), UV-Vis and MS spectra of compounds 16, 37 and 44 as example of experimental data obtained and used for identification.

The Base Peak Chromatogram (BPC) obtained by using ethanol/water mixture (80% v/v) is shown in Fig. S2 (see ESM).

By using UHPLC-ESI-Q-TOF platform, Taamalli et al. [7] previously reported the characterization of several phenolic compounds in water and methanol myrtle extracts obtained by infusion and stirring, respectively. Comparing with our results, compounds 1, 3–7, 9, 10, 13, 15, 16–18, 20, 22, 23, 25, 26, 28, 29, 31, 32, 35, 36, 39, 40, 43, and 45 from Table 2, had previously been described by Taamalli et al. [7]. These compounds were also verified in ethanolic, methanolic and acetone extracts obtained by UAE in the present work. The verification was achieved by the extract ion chromatogram of the compounds (EIC), the UV-Vis and MS spectra; an example is showed in Fig. S1 (see ESM) for compound 16. However, the extraction methodology allowed the recovery of additional phenolic compounds. As far as we are concerned, 15 new compounds were tentatively identified for first time in myrtle leaves. These compounds were classified as gallic acid derivatives, flavonoids, quinic acid derivatives, and other phenolic compounds.

Firstly, six gallic acid derivatives were characterized. Isomers 12 and 14 (m/z 647.0253) with molecular formula C27H20O19 and fragments at m/z 169.0150, due to the loss of a galloyl unit, and at m/z 303.0140, due to the loss of a hexahydroxydiphenoyl (HHDP) unit, were assigned as HHDP-glucopyranuroyl-gallic acid derivatives [23]. The compound detected at m/z 447.0535, molecular formula C20H16O12 (33) with a fragment at m/z 300.9938, was previously identified in Myrtaceae family as rhamnopyranosylellagic acid [24]. Tetra-galloyl-glucose (compound 34) and methyl-ellagic acid (compound 38) were also determined in Myrtaceae family [25, 26]. Moreover, the molecular ion of 34 (m/z 787.0981) and a fragment at m/z 617.0747 were in concordance with Yang et al. [27]. Compound 41 (m/z 585.2180) with molecular formula C34H28O22 was identified as gallomyrtucommulone E [28]. At last, compound 42, m/z 461.0709, was characterized as methyl-ellagic acid rhamnopyranoside as previously reported in Myrtaceae family [29].

Regarding flavonoids, three compounds were detected. Compound 30, with m/z 451.1248 and molecular formula C21H24O11, was identified as catechin glucopyranoside [29]. Compounds 37 and 44 (m/z 463.1008 and 431.0971, respectively) were assigned as quercetin glucoside and kaempferol rhamnopyranoside, respectively. Their fragmentation patterns were in concordance with data showed by Yang et al. in Acer truncatum leaves [27] and it is also showed in Fig. S1 (see ESM).

Besides, two different quinic acid derivatives were determined. Isomers 21 and 24, at m/z 353.0885 and a fragment at m/z 191.0532, due to the loss of a quinic acid unit, corresponded to caffeoylquinic acid [30]. Compound 27, presented a molecular formula C28H24O18, molecular ion at m/z 647.0885 and fragments at m/z 495.0780 and m/z 343.0666 (due to the loss of one and two galloyl units, respectively). Thus, it was proposed as tri-galloyl-quinic acid [29].

Finally, other phenolic compounds were determined. Compound 2, with a molecular ion at m/z 191.0275 and a fragment ion at m/z 111.0088, was identified as citric acid, according to data previously found in myrtle berries [31]. Fukiic acid (8), at m/z 271.0455 and molecular formula C11H12O8, was identified in whole pods of Vicia faba, in agreement to Abu-Reidah et al. [32]. Compound 11 was detected at m/z 391.0769 with a molecular formula C22H16O7. According to Müller et al. [33], it was identified as anthracenone derivative. Anthraquinones have also been found in phytochemical analyses of Myrtus communis flowers [34]. Osmanthuside H (19) was identified due to the signal at m/z 431.1575 and a fragment ion at m/z 137.0503, in concordance with Hu et al. [35]. This compound has also been isolated in Osmanthus asiaticus bark [36] and persimmon leaves [37].

Subsequently, and in order to select the most suitable solvent for the extraction of phenolic compounds in myrtle leaves, the quantification of the characterized compounds was carried out. Table S1 (see ESM) shows the difference for individual compounds, as well as the total amount recovered for each solvent mixture tested. The data show that the total phenolic content was influenced by the type of solvent used in the extraction. Thus, acetone/water mixture (80% v/v) reported the highest amount of phenolic compounds (24.9 ± 0.7 mg/g leaf d.w.), followed by methanol/water mixture (80% v/v) and ethanol/water mixture (80% v/v), which provided a total of 23.7 ± 0.8 and 22.4 ± 0.6 mg/g leaf d.w., respectively. These observations are in concordance with Amensour et al. [4], who found that methanol reported higher values than water and ethanol. Significant differences were also found between acetone and ethanol extracts, and no significant differences were found between them and methanol extract. To our knowledge, there is no literature available about acetone extraction in myrtle leaves, although the same trend was noticed in Feijoa sellowiana (Myrtaceae) fruits [38]. In contrast, in Moringa oleifera Lam. leaves, acetone extracts reported lower values than methanol extracts [39]. However, from environmentally point of view, ethanol is considered a “GRAS” (Generally-Recognized-As-Safe, according to American Food and Drug Administration) solvent and its use is allowed in extracts that will be added to food [5]. Thus, ethanol/water mixture was chosen as solvent for PLE optimization.

Fitting the model

Once the most appropriate solvent mixture was selected, RSM was applied for the optimization of three process parameters which affect to phenolic compounds extraction by PLE. In fact, a BBD was applied to evaluate the effects of ethanol/water ratio (50, 75, and 100% v/v) (Χ1), temperature (50, 125 and 200 °C) (Χ2), and extraction time (5, 18 and 30 min) (Χ3) on the TPC via HPLC-DAD-TOF-MS from myrtle leaves. As can be seen in Table 1, the lowest concentrations of phenolic compounds were reported by low temperatures (5.4–11.9 mg/g leaf d.w.), whereas the highest values were obtained at the center points (27.1–27.9 mg/g leaf d.w.).

The data of the response variable were used to fit the model to a second order-polynomial equation (Eq. (1)) via least squares method (LSM). This task was done using Statistica 7.0 (2002, StatSoft, Tulsa, OK). Based on Fisher test, the evaluation of the model was done according to the significance (α = 0.05) of the regression coefficients, which are showed in Table 3. For this extraction method, each equation term exhibited high significance (0.0001 < p < 0.031). These coefficients are used to complete the equation of the second polynomial order. Based on their term (effect) and their p value (Table 3), the intercept (Χ0) (14.97, < 0.0001), the quadratic (10.53, 0.0006) and linear (7.31, 0.0020) coefficients of temperature (Χ2) were the most influent terms, followed by the terms for ethanol/water ratio (Χ1) (− 4.29, 0.0057). Then, analysis of variance (ANOVA) was carried out in order to confirm the validity of the predictive model. For this purpose, a predictive regression model should provide a high correlation coefficient (R2), a significant regression model, and a non-significant lack of fit (LOF) [5]. ANOVA data are provided in Table 4, demonstrating that the model for phenolic compound extraction from myrtle leaves by PLE reach all the requirements (R2 = 0.987; p < 0.05; p > 0.05) and it is adequate to explain the variance of the results.

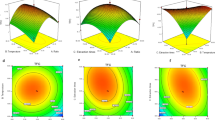

Response surface plots for the predictive model were represented by the software using the coefficients from Table 3, and are displayed in Fig. 1. Firstly, ethanol/water ratio (Χ1) and temperature (Χ2) demonstrate their high effect on the response variable due to the size of the maximum area. It is also observable the negative effect of the linear term of Χ1 because of the shape of the plot (Fig. 1a). Secondly, the low values of the equation terms for time (Χ3) and the high value of the linear term of temperature (Χ2) are the responsible of the form of this plot (Fig. 1b). Lastly, Χ1 and Χ3 provided a good adjust since the value of their coefficients are similar, although is observable the negative effect of the linear term of Χ1 (Fig. 1c).

Optimization of PLE parameters

In order to optimize the extraction conditions to recover phenolic compounds from myrtle leaves by PLE, the proposed response surface plots model was used. Generally, as it has been reported in literature, the most common extraction temperature in this technique is between 75 and 125 °C, and the extraction is usually completed at 20 min [15]. In this case, values for the optimal point were given by the software used, obtaining that the optimal conditions were ethanol/water (71% v/v), 137 °C and 19 min. Similar conditions were also reported by several authors in other plant matrices. In this sense, in sorghum brans the highest total phenols content was found at 70% ethanol content in a temperature range of 120–150 °C [12]. In M. oleifera leaves, temperature, time and ethanol content were also optimized. For this plant, the optimal temperature was 128 °C during 20 min of extraction, which are in concordance with the present results. In contrast, the optimal content of ethanol was 35% [11]. This difference could be probably due to the different type of phenolic compounds present in both leaves. In fact, the flavonoid content is higher in M. oleifera leaves, whereas myrtle leaves had more gallic and ellagic acid derivatives, as happens in sorghum brans.

The validity of the predictive model was confirmed comparing the predicted and the observed values, both at optimal conditions. Actually, no significant differences were found between the value predicted by the model (28 ± 2 mg/g leaf d.w.) and the experimental one (30 ± 1 mg/g leaf d.w.). The quantification of single phenolic compounds is showed in Table 5 at the above mentioned conditions. Regarding the differences between UAE and PLE techniques (Table 5 and Fig. S2 (see ESM)), PLE allowed the extraction of two more isomers of gallomyrtucommulone C (42). Besides, one of these isomers (44), gallic acid (5), and ellagic acid (33) were the major compounds quantified in PLE extract, whereas in UAE extract, major compounds were digalloyl quinic acid 1 (13) and gallomyrtucommulone E (38). This fact might be since high temperatures and pressures in PLE enhance the solubility and diffusion rates of target compounds, and reduce viscosity, improving the extraction of certain analytes [15]. In particular, the content in PLE extracts of gallic and ellagic acid (3.31 ± 0.03 and 3.88 ± 0.09 mg/g leaf d.w., respectively) were similar to those reported for Terminalia chebula (3.68 and 4.08 g/kg d.w., respectively) [40]. From the TPC values, PLE reported higher recoveries (p < 0.05) of the target compounds than UAE.

Finally, comparing the results obtained with other matrices, the quantification of phenolic compounds extracted by PLE, in many instances, has been done by Folin-Ciocalteu method, which is known to display higher contents due to the reaction of sugars and proteins with this reagent. Although in the present work quantification has been done via HPLC-DAD-ESI-TOF-MS platform, myrtle leaves exhibited a phenolic content in the same order of magnitude compared to M. oleifera leaves [11] and sorghum brans [12], and higher than jabuticaba skins [41]. Furthermore, the presence of gallic acid was greater in myrtle leaves than in rosemary, marjoram and oregano [14].

Conclusions

In this work, a new PLE procedure by using a Box-Behnken design (BBD) has been developed to extract phenolic compounds from M. communis leaves, which were subsequently analyzed by HPLC-DAD-TOF-MS. Prior to optimize the PLE extraction, ethanol/water mixture was chosen, among other solvents, as extracting solution since it is considered as green solvent. Results demonstrated the high significance (p < 0.05) of the factors (ethanol/water ratio, temperature, and extraction time) tested, being the linear and quadratic terms of temperature the most influent on the response of TPC (by HPLC-DAD-TOF-MS). It was also confirmed the adequacy of the predictive model and the verification of the model was done at optimal conditions (71%, 137 °C and 19 min). The quantification data obtained by PLE extraction reported high concentration, particularly, of gallic and ellagic acid derivatives (3.31 ± 0.03 and 3.88 ± 0.09 mg/g leaf d.w., respectively). Lastly, based on the TPC, by using HPLC-DAD-TOF-MS data, PLE improved the extraction of phenolic compounds from 22.4 ± 0.6 mg/g leaf d.w. (by UAE) to 30 ± 1 mg/g leaf d.w.

Moreover, it is important to consider that, in this work, 15 new compounds have tentatively been identified for the first time in M. communis leaves.

In view of the results, myrtle leaves have demonstrated to be a good source of phenolic compounds that could be used for nutraceutical formulation.

References

Gençler Özkan AM, Gençler GÇ. A Mediterranean: Myrtus communis L. (Myrtle). In: Morel J-P, Mercuri AM, editors. Plants and culture: seeds of the cultural heritage of Europe. Bari: Edipuglia srl; 2009. p. 159–68.

Alipour G, Dashti S, Hosseinzadeh H. Review of pharmacological effects of Myrtus communis L. and its active constituents, 2014. Phyther Res. 1136:1125–36.

Mekonnen S, Tigist G. Myrtus communis Linn: a review on ethnobotanical, ethnopharmacological and phytochemical studies. J Pharmacogn Phyther. 2017;9(6):77–86.

Amensour M, Sendra E, Abrini J, Bouhdid S, Pérez-Alvarez JA, Fernández-López J. Total phenolic content and antioxidant activity of myrtle (Myrtus communis) extracts. Nat Prod Commun. 2009;4(6):819–24.

Díaz-de-Cerio E, Tylewicz U, Verardo V, Fernández-Gutiérrez A, Segura-Carretero A, Romani S. Design of sonotrode ultrasound-assisted extraction of phenolic compounds from Psidium guajava L. leaves. Food Anal Methods. 2017;10:2781–91.

Heng MY, Tan SN, Yong JWH, Ong ES. Emerging green technologies for the chemical standardization of botanicals and herbal preparations. TrAC Trends Anal Chem. 2013;50:1–10.

Taamalli A, Iswaldi I, Arráez-Román D, Segura-Carretero A, Fernández-Gutiérrez A, Zarrouk M. UPLC-QTOF/MS for a rapid characterisation of phenolic compounds from leaves of Myrtus communis L. Phytochem Anal. 2014;25(1):89–96.

Romani A, Pinelli P, Mulinacci N, Vincieri FF, Tattini M. Identification and quantitation of polyphenols in leaves of Myrtus communis L. Chromatographia. 1999;49(1–2):17–20.

Pereira P, Bernardo-Gil MG, Cebola MJ, Mauricio E, Romano A. Supercritical fluid extracts with antioxidant and antimicrobial activities from myrtle (Myrtus communis L.) leaves. Response surface optimization. J Supercrit Fluids. 2013;83:57–64.

Dahmoune F, Nayak B, Moussi K, Remini H, Madani K. Optimization of microwave-assisted extraction of polyphenols from Myrtus communis L. leaves. Food Chem. 2015;166:585–95.

Rodríguez-Pérez C, Gilbert-López B, Mendiola JA, Quirantes-Piné R, Segura-Carretero A, Ibáñez E. Optimization of microwave-assisted extraction and pressurized liquid extraction of phenolic compounds from Moringa oleifera leaves by multiresponse surface methodology. Electrophoresis. 2016:1938–46.

Barros F, Dykes L, Awika JM, Rooney LW. Accelerated solvent extraction of phenolic compounds from sorghum brans. J Cereal Sci. 2013;58(2):305–12.

Gomes SVF, Portugal LA, dos Anjos JP, de Jesus ON, de Oliveira EJ, David JP, et al. Accelerated solvent extraction of phenolic compounds exploiting a Box-Behnken design and quantification of five flavonoids by HPLC-DAD in Passiflora species. Microchem J. 2017;132:28–35.

Hossain MB, Barry-Ryan C, Martin-Diana AB, Brunton NP. Optimisation of accelerated solvent extraction of antioxidant compounds from rosemary (Rosmarinus officinalis L.), marjoram (Origanum majorana L.) and oregano (Origanum vulgare L.) using response surface methodology. Food Chem. 2011;126(1):339–46.

Sarker SD, Nahar L. Hyphenated techniques and their applications in natural products analysis. In: Natural products isolation Methods and protocols. 2009. p. 75–88.

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta. 2008;76(5):965–77.

Mustafa A, Turner C. Pressurized liquid extraction as a green approach in food and herbal plants extraction: a review. Anal Chim Acta. 2011 Oct 3;703(1):8–18.

Miller JN, Miller JC. Statistics and chemometrics for analytical chemistry. Vol. 6th Ed, Prentice Hall. 2010.

Bruker Daltonics Technical Note #008. Molecular formula determination under automation.

Fatiha B, Khodir M, Farid D, Tiziri R, Karima B, Sonia O, et al. Optimisation of solvent extraction of antioxidants (phenolic compounds) from Algerian mint (Mentha spicata L.). Pharmacogn Commun. 2012;2(4):72–86.

Robbins RJ. Phenolic acids in foods: an overview of analytical methodology. J Agric Food Chem. 2003;51(10):2866–87.

Vihakas M. Flavonoids and other phenolic compounds: characterization and interactions with lepidopteran and sawfly larvae. Turun Yliopiston Julkaisuja – Annales Universitatis Turkuensis, 2014.

Tanaka T, Tong H-H, Xu Y-M, Ishimaru K, Nonaka G, Nishioka I. Tannins and related compounds. CXVII. Isolation and characterization of three new ellagitannins, Lagerstannins A, B and C, having a gluconic acid core, from Lagerstroemia speciosa (L.) Pers. Chem Pharm Bull (Tokyo). 1992;40(11):2975–80.

Gallo MBC, Rocha WC, da Cunha US, Diogo FA, da Silva FC, Vieira PC, et al. Bioactivity of extracts and isolated compounds from Vitex polygama (Verbenaceae) and Siphoneugena densiflora (Myrtaceae) against Spodoptera frugiperda (Lepidoptera: Noctuidae). Pest Manag Sci. 2006;62:1072–81.

Tanaka T, Orii Y, Nonaka G, Nishioka I. Tannins and related compounds. CXXIII. Chromone, acetophenone and phenylpropanoid glycosides and their galloyl and/or hexahydroxydiphenoyl esters from the leaves of Syzygium aromaticum Merr. et Perry. Chem Pharm Bull (Tokyo). 1993;41(7):1232–7.

Amaral ACF, Kuster RM, De Santana BW, Barnes RA, Kaplan MAC, Wessjohann LA. Flavonoids and other phenolics from leaves of two Marlierea species (Myrtaceae). Biochem Syst Ecol. 2001;29(6):653–4.

Yang L, Yin P, Fan H, Xue Q, Li K, Li X, et al. Response surface methodology optimization of ultrasonic-assisted extraction of Acer truncatum leaves for maximal phenolic yield and antioxidant activity. Molecules. 2017;22:232.

Khanh PN, Duc HV, Huong TT, Son NT, Ha VT, Van DT, et al. Alkylphloroglucinol derivatives and triterpenoids with soluble epoxide hydrolase inhibitory activity from Callistemon citrinus. Fitoterapia. 2016;109:39–44.

Djoukeng JD, Abou-Mansour E, Tapondjou LA, Lontsi D, Tabacchi R. Identification of ellagic acid derivatives from stem bark of Syzygium guineense (Myrtaceae). Nat Prod Commun. 2007;2:1–6.

Melguizo-Melguizo D, Diaz-de-Cerio E, Quirantes-Piné R, Švarc-Gajić J, Segura-Carretero A. The potential of Artemisia vulgaris leaves as a source of antioxidant phenolic compounds. J Funct Foods. 2014;10:192–200.

Fadda A, Palma A, D’Aquino S, Mulas M. Effects of myrtle (Myrtus communis L.) fruit cold storage under modified atmosphere on liqueur quality. J Food Process Preserv. 2017;41:e12776.

Abu-Reidah IM, Arráez-Román D, Warad I, Fernández-Gutiérrez A, Segura-Carretero A. UHPLC/MS2-based approach for the comprehensive metabolite profiling of bean (Vicia faba L.) by-products: a promising source of bioactive constituents. Food Res Int. 2017;93:87–96.

Müller K, Gawlik I, Wiegrebe W. Acidity and stability of 10-substituted 1,8-dihydroxy-9(10H)-anthracenones. Arch Pharm. 1995;328(4):359–62.

Jamil DAK. Preliminary phytochemical and screening of biocomponents by GC-MS technique in Myrtus communis L. plant flowers. AL-Qadisiyha J Pure Sci. 2016;1(21):23–33.

Hu YM, Su GH, Sze SC-W, Ye W, Tong Y. Quality assessment of Cortex Phellodendri by high-performance liquid chromatography coupled with electrospray ionization mass spectrometry. Biomed Chromatogr. 2010;24(4):438–53.

Sugiyama M, Kikuchi M. Phenylethanoid glycosides from Osmanthus asiaticus. Phytochemistry. 1993;32(6):1553–5.

Varughese T, Rahaman M, Kim N, Cho S, Moon S. Gamnamoside, a phenylpropanoid glycoside from persimmon leaves (Diospyros kaki) with an inhibitory effect against an alcohol metabolizing enzyme. Bull Kor Chem Soc. 2009;30(5):1–4.

Seo J, Lee S, Elam ML, Johnson SA, Kang J, Arjmandi BH. Study to find the best extraction solvent for use with guava leaves (Psidium guajava L.) for high antioxidant efficacy. Food Sci Nutr. 2014;2(2):174–80.

Rodríguez-Pérez C, Quirantes-Piné R, Fernández-Gutiérrez A, Segura-Carretero A. Optimization of extraction method to obtain a phenolic compounds-rich extract from Moringa oleifera Lam leaves. Ind Crop Prod. 2015;66:246–54.

Pfundstein B, El Desouky SK, Hull WE, Haubner R, Erben G, Owen RW. Polyphenolic compounds in the fruits of Egyptian medicinal plants (Terminalia bellerica, Terminalia chebula and Terminalia horrida): characterization, quantitation and determination of antioxidant capacities. Phytochemistry. 2010;71(10):1132–48.

Santos DT, Veggi PC, Meireles MAA. Optimization and economic evaluation of pressurized liquid extraction of phenolic compounds from jabuticaba skins. J Food Eng. 2012;108(3):444–52.

Acknowledgements

This work was funded by projects AGL2015-67995-C3-2-R (Spanish Ministry of Science and Innovation), as well as by project P11-CTS-7625 (Andalusian Regional Government Council of Innovation and Science)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human or animal subjects.

Informed consent

Informed consent was not applicable.

Additional information

Published in the topical collection Discovery of Bioactive Compounds with guest editors Aldo Laganà, Anna Laura Capriotti and Chiara Cavaliere.

Electronic supplementary material

ESM 1

(PDF 448 kb)

Rights and permissions

About this article

Cite this article

Díaz-de-Cerio, E., Arráez-Román, D., Segura-Carretero, A. et al. Establishment of pressurized-liquid extraction by response surface methodology approach coupled to HPLC-DAD-TOF-MS for the determination of phenolic compounds of myrtle leaves. Anal Bioanal Chem 410, 3547–3557 (2018). https://doi.org/10.1007/s00216-018-0914-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-018-0914-0