Abstract

The aim of the study was to develop a method for quantification of cow’s whey and whole milk powder in goat or sheep milk products including infant formula. A ultra-high performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS) method was established for simultaneous quantification of four caseins and two major whey proteins by detecting their signature peptides, which were able to act as markers for differentiating goat or sheep from cow whey and whole milk powder in infant formulas. The signature peptides were screened based on the computational prediction by Biolynx software, and confirmed by database searching after analysis of liquid chromatography-quadrupole-time-of-flight tandem mass spectrometry (LC-Q-TOF-MS). The isotopic-labeled signature peptide was used as internal standard to compensate the matrix effect. The limits of quantification were 0.01–0.05 g/100 g for target proteins. The observed recovery rates ranged from 82.3 to 116.6 % and the reproducibility was excellent (RSD <12 %) at different spiking levels. The RSDs of intra- and inter-day precision were 2.8–6.2 and 3.3–9.8 %, respectively. The multiple reaction monitoring method was successfully applied to milk powder with different composition, showing high specificity and accuracy in detection of species involved. The calculating formula was designed to assess the composition of adulteration in the actual detection of infant formulas. These results highlight applicability of this method for the detection of infant formulas with complicated matrix.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Raw milk is used to prepare a multitude of dairy products that are characterized by different nutritional values and specific features, depending on the originating dairy animal species and technological processes. Cow milk contains more than 20 allergenic proteins, in which casein and β-lactoglobulin are reported to cause most allergenic effects [1, 2]. Goat and sheep milk products appear to be potentially less allergenic and have consequently become important as a substitute for people (including children) suffering from cow milk intolerance [3]. Furthermore, whey proteins in goat and sheep milk themselves are increasingly being recognized for their bioactivity or health-promoting benefits, such as immunomodulatory, anti-microbial, and transfer of passive immunity activities [4]. Infant formula made by goat milk is considered as an appropriate alternative for infants who cannot be served with breast milk [5].

However, the seasonal availability and the low yield of goat and sheep milk, together with the low price of bovine milk make goat and sheep milk products attractive targets for deliberate adulteration [6]. Apart from economic loss, the adulterations may have serious consequences because consumers may be exposed to invisible allergens such as cow milk proteins containing β-lactoglobulin [7]. Such a circumstance has prompted research in new advanced methods for detecting species origin of dairy products.

For milk and dairy products, the common identifiable techniques can be classified into two kinds of methods based on DNA analysis and milk proteins, respectively. Polymerase chain reaction (PCR) was a useful qualitative tool for the quality control in food industry. PCR-based methods were designed and applied to detect cow milk in goat and sheep cheeses [8, 9]. Recently, different protein-based methods for species identification in milk and dairy products have been developed using electrophoresis, immunological strategies, chromatography, or mass spectrometry. The most commonly employed electrophoretic techniques are polyacrylamide gel electrophoresis [10–13], capillary isoelectric focusing [11], two-dimensional electrophoresis [14], and capillary electrophoresis (CE) [15]. Enzyme-linked immunosorbent assay (ELISA) is a rapid, sensitive, and specific method for the detection of cow milk in adulterated samples. The native cow milk proteins in adulterated goat and sheep milk products have been successfully detected by ELISA [16, 17]. Liquid chromatography methods have also been reported for separating major proteins from bovine, goat, and sheep milk [11]. Furthermore, liquid chromatography-tandem mass spectrometry (LC-MS) [18, 19] and matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI-TOF-MS) [20, 21] have been applied for the qualitative and quantitative analysis of signature proteins and peptides.

Although the above-mentioned approaches are effective in certain instances, their applications were mainly focused on the identification of simple adulteration, for example, the adulteration of goat and sheep cheeses with common cow milk. However, few studies have been focused on the method development and validation for analyzing the adulteration of infant formula, which possesses more complicated matrix and consists of whey and milk powder with certain proportion. In fact, the addition of cow’s whey powder in goat infant formula powder is not illegal on the premise of clear species label in China. Current available methods have difficulty to identify the species of whey powder and whole milk powder, and to quantify their percentage in further. Consequently, the goat milk infant formula becomes a vulnerable product, and it is easily adulterated by cow’s whey or whole milk powder with the false or misleading labeling.

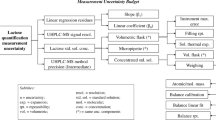

In this work, we aim to develop a UHPLC-MS/MS method for quantification of cow’s whey and whole milk powder percentage in goat or sheep milk products including infant formula by measuring four caseins and two major whey proteins based on their signature peptides as markers. The specific peptides markers of the target proteins were predicted by Biolynx software (Waters, Milford, MA, USA), and confirmed by database searching after liquid chromatography-quadrupole-time-of-flight tandem mass spectrometry (LC-Q-TOF-MS) analysis. The isotope-labeled signature peptides as internal standard were employed for avoiding matrix interference during mass spectrometry analysis. The goat milk infant formula samples were pretreated and subjected to UHPLC-MS/MS analysis using the established method. The acquired data were finally put into the calculation formula for assessing different composition of adulteration in the samples.

Materials and methods

Chemicals and samples

Goat, sheep, and cow milk whey and whole milk powder were obtained from domestic manufacturers. Eleven of goat milk infant formula from different commercial brands were purchased from local supermarkets. Dithiothreitol (DTT), iodoacetamide (IAA), ammonium bicarbonate (NH4HCO3), and hydrochloric acid (HCl, 37 %) were purchased from Sigma-Aldrich (St. Louis, MO, USA). HPLC-grade acetonitrile (ACN) and formic acid (FA) were supplied by Merck (Darmstadt, Germany). Sequencing grade recombinant trypsin was supplied by Shanghai Yaxin Biotechnology Co., Ltd. (Shanghai, China). For all experiments, ultrapure water generated by a Milli-Q Gradient A 10 water purification system (Millipore, Bedford, MA, USA) was used.

Synthetic peptide standards

The selective signature peptides and their stable isotope-labeled signature peptides of α-lactalbumin, β-lactoglobulin, β-casein, αs1-casein, αs2-casein, and κ-casein (Table 1) were synthesized by ChinaPeptides Co., Ltd. (Shanghai, China). All the peptide standards were synthesized with purity of more than 95 %.

Preparation of tryptic hydrolysates

The presented pretreatment procedure was based on our previous study [22]. Before tryptic digestion, 0.1 g of samples were dissolved and diluted to 10 mL with ultrapure water in volumetric flask. Aliquots of 50 μL diluted milk were mixed with 100 μL stable isotope-labeled internal standard and 590 μL ultrapure water. The mixtures were reduced with 10 μL aliquot of 100 mmol/L DTT in 70 °C water bath for 30 min and then alkylated with 10 μL of 300 mmol/L IAA in the dark for 30 min at room temperature. After mixing with 200 μL of 500 mmol/L NH4HCO3 and 30 μL of 1 mg/mL trypsin (freshly prepared), the mixtures were incubated at 37 °C for 3 h. The enzymatic digestion reaction was stopped by adding 10 μL formic acid. After centrifuging the digested mixtures at 13,000 g for 10 min, the supernatants were obtained for analysis by UHPLC-MS/MS.

Liquid chromatography

Separation of tryptic hydrolysates was performed on an UHPLC System equipped with LC-30AD binary solvent manager, SIL-30AC sample manager, and CTO-30A column manager (Shimadzu, Kyoto, Japan). The analytical column was a narrow-bore Acquity UPLC BEH 300 C18 column (1.7 μm, 2.1 mm × 100 mm) equipped with a guard column of the same material (Waters, Milford, MA, USA). The 0.1 % formic acid in water and ACN were used for the mobile phases A and B, respectively. The column temperature was 40 °C and LC flow rate was at 0.3 mL/min. The elution program was shown as follows: linear step to 25 % B from initial 3 % B in 5 min; linear step to 30 % B in 2 min; linear step to 40 % B in 2 min; increasing to 100 % B in 1 min and holding for 2 min before re-equilibration at the initial conditions. The injection volume was 10 μL.

Mass spectrometry

The presented parameters of mass spectrometry were based on our previous study [22]. Search of signature peptide by TOF-MS was performed on a Synapt G2 High Definition Mass Spectrometer equipped with ESI source (Waters, Ltd.). The data were acquired in the electrospray positive ion (ESI+) mode with MSE mode and analyzed by searching sequence databases using ProteinLynx Global Server version 2.5 software. Relevant instrument and software parameters were set as follows: capillary voltage, 3 kV; sampling cone voltage, 25 V; extraction cone voltage, 4 V; source temperature, 100 °C; desolvation temperature, 400 °C; cone gas flow, 30 L/h; desolvation gas flow, 800 L/h; ramp trap collision energy, 15–35 V; lockspray reference compound, leucine-enkephalin; mode, electrospray-MSE; lockmass for charge 1, 556.2771 Da; minimal fragment ion matches per peptide, 2; minimal fragment ion matches per peptide, 5; allowed missed cleavage, 1; fixed modifications, carbamdomethyl C; and variable modifications, oxidation M. The databank was imported from UniProt Knowledgebase (http://www.uniprot.org).

Data acquisition were performed on a Shimadzu LCMS-8050 plus equipped with an electrospray ionization (ESI) source by multiple reaction monitoring (MRM) method. The positive electrospray (ESI+) mode with both quadrupoles tuned for unit resolution was operated with the followed settings: capillary voltage, 3.5 kV; desolvation line (DL) temperature, 250 °C; heat block temperature, 400 °C; nebulizing gas flow, 3.0 L/min; and drying gas flow, 10.0 L/min. Two MRM transitions for each compound were monitored after their parameters were optimized (Table 1).

Results and discussion

Selection of proteins and signature peptide

The principal proteins in sheep and goat milk are about the same as in cow milk [23]. The casein fraction, including β-casein, αs1-casein, αs2-casein, and κ-casein, constitutes about 70–80 % of the total protein in milk. The major whey proteins are β-lactoglobulin and α-lactalbumin that approximately account for 70–80 % of total whey protein [23, 24]. Consequently, the four caseins and two major whey protein were selected for assessing the contents of milk powder and whey powder from different milk species in infant formula.

In order to differentiate the proteins of goat or sheep with cow in infant formula, specific peptides of target proteins were screened by the computational prediction using Biolynx software and online PeptideMass tools provided by UniProt (http://web.expasy.org/peptide_mass), and further confirmed by database searching after liquid chromatography-quadrupole-time-of-flight tandem mass spectrometry (LC-Q-TOF-MS) analysis. The specific peptides were selected usually based on several critical criteria such as specificity of amino acid sequences, intensity of their MS signal, and reproducibility in sample preparation [25]. Methionine is one of the most readily oxidized amino acid in proteins [26], therefore the peptides comprising methionine should be excluded. Furthermore, the peptides with more than 14 amino acids may generally be not used due to their considerable cost for the synthesis and unfavorable LC properties [25]. In the present work, we focused on the assessment of cow milk adulterate because of economic motivation, and the differentiating goat milk with sheep milk was not considered. That is to say, the tryptic-specific peptides shared by goat and sheep milk proteins were selected for their quantification.

Consequently, the candidate peptides were initially screened according to the above criteria (Table 2), and their MRM conditions were optimized, respectively (Table 1). The couple of tryptic-specific peptides of the same protein for differentiating goat/sheep milk with cow milk were selected as the near position of target protein’s sequence as possible. It might largely ensure that the tryptic-specific peptides for differentiating target proteins possess similar physicochemical properties in the pretreatment. The unique suitable peptides were found and synthesized for respective quantification of β-lactoglobulin, α-lactalbumin, β-casein, and κ-casein. Several candidate peptides of αs1-casein and αs2-casein were compared by intensity of their MS signal, and the peptides (FFVAPFPEVFGK, FVVAPFPEVFR, FALPQYLK, and FAWPQYLK) having the largest MS intensity were selected and synthesized as the signature peptides (Fig. 1). It is noteworthy that the peptides GPFPIIV and GPFPILV of β-casein could be completely separated by UHPLC (Fig. 2) though they had the similar parameters of MS.

Synthesis of isotopically labeled signature peptides

Though UHPLC-MS/MS is a highly sensitive and selective tool for peptides quantification, the accuracy of the technology may be influenced by the different ionization efficiency of the analytes in various matrices and susceptibility to collision-induced dissociation of different peptides [27, 28]. In the study of authentic assessment of dairy products, the accurate quantification of various proteins from ambiguous samples is a crucial challenge. The use of isotopically labeled internal standard may minimize the ionization efficiency. Accordingly, the isotope-labeled signature peptides were employed as internal standard in this study (Table 1).

In order to assess the accuracy of established method, two different experiments were designed to respectively simulate the adulteration of goat or sheep whole milk powder and goat milk infant formula: the first mixing sheep or goat whole milk powder with cow whole milk powder (Table 3), and the second mixing goat and cow whole milk powder with goat and cow milk whey powder (Table 4). A quantitative test was run with promising results, as the quantitative values of targeted proteins (Table 5) showed good linear correlation (r > 0.99) between additional percentages of species milk powder. The linear correlation (Table 6) of whole milk powder for different species was showed by average correlation of six signature proteins in the first experiment. And the linear correlation (Table 6) of whey powder were calculated by average correlation of β-lactoglobulin and α-lactalbumin after deducting the blank of whole milk powder in the second experiment.

Method validation

Specificity

The chromatograms of the selected signature peptide from corresponding species’ tryptic milk showed the steep and symmetric peaks without interferences. In fact, when this multianalyte MRM method was applied to tryptic milk samples made with single-specie milk (milk powder for cow, sheep, or goat), the spectra showed unambiguously only specie-specific markers for corresponding species’ protein (Fig. 3). Without tryptic digestion, there was no targeted peak appearing in the chromatogram for milk sample (Fig. 3).

Linearity and sensitivity

The linear regression equation for eight levels of targeted signature peptides had good linearity and coefficient of correlation (r 2 > 0.99) (Table 7). The amounts of the tryptic signature peptides from the digested samples can be obtained from the standard curve by using the synthetic signature peptides as calibration standards. The contents of targeted proteins in samples were calculated based on the molar equivalent relationship between the signature peptides and original proteins.

The LOQ for each analyte was calculated as the lowest concentration providing a signal-to-noise ratio of 10 (Table 7), respectively. The linear range (r > 0.99) and sensitivity (LOQs of 0.01–0.05 g/100 g) could satisfy the quantification requirements for different targeted protein concentrations in various ambiguous adulterate milk samples. In fact, the chromatograms of tryptic sample showed the steep and symmetric peaks without any interference even if the sample consisted of 0.1 % cow whole milk powder and 99.9 % goat whole milk powder (Fig. 4).

Recovery, intra- and inter-day precision

The synthesized signature peptides standards for goat or sheep milk proteins were spiked into the control diluent of cow milk, while the synthesized signature peptides standards for cow milk proteins were spiked into the control diluent of goat milk (Table 7). The spiked samples were pretreated and analyzed with the above-established method. The recovery test was carried out by comparing the measured concentrations of control and spiked samples with the theoretical concentrations. The spiking recoveries were 82.3–116.6 % with 2.9–11.1 % of RSD (Table 7). Aliquots of cow, goat, and sheep milk mixture was pretreated with the above optimal preparation each day for four consecutive days to evaluate the intra-day and inter-day precision of the method. The RSDs of intra- and inter-day precision were observed as 2.8–6.2 and 3.3–9.8 %, respectively. All the results showed that the current method had good accuracy and precision.

Method application

As caseins exists only in whole milk powder other than whey powder, they can serve as the markers for whole milk powder. In this paper, the pure cow’s (goat’s) raw whole milk powder and whey powder were chosen as the standard substance. The addition amount of whole milk powder in samples were assessed by the ratio of sum caseins in samples to that in standard substance of whole milk powder. The whey proteins are simultaneously present in whole milk powder and whey powder, thus the sum of β-lactoglobulin and α-lactalbumin after deducting the part from whole milk powder were divided by the value in standard substance of whey powder to estimate the additive amount of whey powder. The details of calculating formula is given below:

Where M a : addition ratio of whole milk powder; M b : addition ratio of whey powder; C 1 : sum of caseins in sample; C 2 : sum of caseins in standard substance of whole milk powder; W 1 : sum of β-lactoglobulin and α-lactalbumin in sample; W 2 : sum of β-lactoglobulin and α-lactalbumin in standard substance of whole milk powder; W 3 : sum of β-lactoglobulin and α-lactalbumin in standard substance of whey powder; units of all values for caseins, β-lactoglobulin, and α-lactalbumin were g/100 g.

Eleven of goat infant formula milk powder with different commercial brands were pretreated and subjected to UHPLC-MS/MS analysis using current optimized method. The results revealed that there were different percentage of adulteration in the samples (Table 8). The samples with brand 1–3 were consisted of pure goat whey and whole milk powder with certain proportion which conformed to their labels. Although the labels of the samples with brand 3–9 did not give clear indication of species of whey powder, the results of data analysis indicated that their principal components were cow whey powder and goat whole milk powder. Surprisingly, we confirmed that the samples with brand 10 and 11 were adulterated by cow’s whey and whole milk powder with false labeling.

Conclusions

In this study, an analytical method was developed for quantifying the percentage of cow’s whey and whole milk powder in goat or sheep milk products including infant formula. In detail, an UHPLC-MS/MS method for simultaneous quantification of four caseins and two whey proteins was established by detecting their signature peptides, which were able to act as markers for differentiating cow from goat or sheep whey and whole milk powder in infant formula. The relevant tryptic fragment peptides were selected and validated as the specific markers. The isotopic-labeled signature peptide as internal standard was employed for avoiding matrix interference in mass spectrometry. The accuracy, sensitivity, and selectivity of current method were validated via the calibration curves, LOD and LOQ, intra- and inter-day precision, and recovery. The specific calculating formula was established to estimate the addition of whey and whole milk powder from cow and goat. It was successfully applied to routine determination of goat infant formula milk powder with different commercial brands (n = 11), and the results revealed that there were different composition and percentage of adulteration in the samples we analyzed.

References

Claeys WL, Cardoen S, Daube G, De Block J, Dewettinck K, Dierick K, et al. Raw or heated cow milk consumption: review of risks and benefits. Food Control. 2013;31:251–62.

El-Agamy EI. The challenge of cow milk protein allergy. Small Rumin Res. 2007;68:64–72.

Ballabio C, Chessa S, Rignanese D, Gigliotti C, Pagnacco G, Terracciano L, et al. Goat milk allergenicity as a function of alphas(1)-casein genetic polymorphism. J Dairy Sci. 2011;94:998–1004.

Hernandez-Ledesma B, Ramos M, Gomez-Ruiz JA. Bioactive components of ovine and caprine cheese whey. Small Rumin Res. 2011;101:196–204.

Grant C, Rotherham B, Sharpe S, Scragg R, Thompson J, Andrews J, et al. Randomized, double-blind comparison of growth in infants receiving goat milk formula versus cow milk infant formula. J Paediatr Child Health. 2005;41:564–8.

De la Fuente MA, Juarez M. Authenticity assessment of dairy products. Crit Rev Food Sci. 2005;45:563–85.

Monaci L, Tregoat V, van Hengel AJ, Anklam E. Milk allergens, their characteristics and their detection in food: a review. Eur Food Res Technol. 2006;223:149–79.

Maskova E, Paulickova I. PCR-based detection of cow’s milk in goat and sheep cheeses marketed in the Czech Republic. Czech J Food Sci. 2006;24:127–32.

Golinelli LP, Carvalho AC, Casaes RS, Lopes CS, Deliza R, Paschoalin VM, et al. Sensory analysis and species-specific PCR detect bovine milk adulteration of frescal (fresh) goat cheese. J Dairy Sci. 2014;97:6693–9.

Veloso AC, Teixeira N, Ferreira IM. Separation and quantification of the major casein fractions by reverse-phase high-performance liquid chromatography and urea-polyacrylamide gel electrophoresis. Detection of milk adulterations. J Chromatogr A. 2002;967:209–18.

Mayer HK. Milk species identification in cheese varieties using electrophoretic, chromatographic and PCR techniques. Int Dairy J. 2005;15:595–604.

Kaminaridesa SE, Koukiassa P. Detection of bovine milk in ovine yoghurt by electrophoresis of para-kappa-casein. Food Chem. 2002;78:53–5.

Pesic M, Barac M, Vrvic M, Ristic N, Macej O, Stanojevic S. Qualitative and quantitative analysis of bovine milk adulteration in caprine and ovine milks using native-PAGE. Food Chem. 2011;125:1443–9.

Yang Y, Zheng N, Yang J, Bu D, Wang J, Ma L, et al. Animal species milk identification by comparison of two-dimensional gel map profile and mass spectrometry approach. Int Dairy J. 2014;35:15–20.

Rodriguez-Nogales JM, Vazquez F. Application of electrophoretic and chemometric analysis to predict the bovine, ovine and caprine milk percentages in Panela cheese, an unripened cheese. Food Control. 2007;18:580–6.

Song HX, Xue HY, Han Y. Detection of cow’s milk in Shaanxi goat’s milk with an ELISA assay. Food Control. 2011;22:883–7.

Hurley IP, Ireland HE, Coleman RC, Williams JHH. Application of immunological methods for the detection of species adulteration in dairy products. Int J Food Sci Technol. 2004;39:873–8.

Chen RK, Chang LW, Chung YY, Lee MH, Ling YC. Quantification of cow milk adulteration in goat milk using high-performance liquid chromatography with electrospray ionization mass spectrometry. Rapid Commun Mass Spectrom. 2004;18:1167–71.

Bernardi N, Benetti G, Haouet NM, Sergi M, Grotta L, Marchetti S, et al. A rapid high-performance liquid chromatography-tandem mass spectrometry assay for unambiguous detection of different milk species employed in cheese manufacturing. J Dairy Sci. 2015;98:8405–13.

Sassi M, Arena S, Scaloni A. MALDI-TOF-MS platform for integrated proteomic and peptidomic profiling of milk samples allows rapid detection of food adulterations. J Agric Food Chem. 2015;63:6157–71.

Nicolaou N, Xu Y, Goodacre R. MALDI-MS and multivariate analysis for the detection and quantification of different milk species. Anal Bioanal Chem. 2011;399:3491–502.

Chen Q, Zhang J, Ke X, Lai S, Tao B, Yang J, et al. Quantification of bovine beta-casein allergen in baked foodstuffs based on ultra-performance liquid chromatography with tandem mass spectrometry. Food Addit Contam A. 2015;32:25–34.

Park YW, Juarez M, Ramos M, Haenlein GFW. Physico-chemical characteristics of goat and sheep milk. Small Rumin Res. 2007;68:88–113.

Chatterton DEW, Smithers G, Roupas P, Brodkorb A. Bioactivity of beta-lactoglobulin and alpha-lactalbumin—technological implications for processing. Int Dairy J. 2006;16:1229–40.

Bronstrup M. Absolute quantification strategies in proteomics based on mass spectrometry. Expert Rev Proteomic. 2004;1:503–12.

Vogt W. Oxidation of methionyl residues in proteins: tools, targets, and reversal. Free Radic Biol Med. 1995;18:93–105.

Zhang J, Lai S, Cai Z, Chen Q, Huang B, Ren Y. Determination of bovine lactoferrin in dairy products by ultra-high performance liquid chromatography-tandem mass spectrometry based on tryptic signature peptides employing an isotope-labeled winged peptide as internal standard. Anal Chim Acta. 2014;829:33–9.

Zhang J, Lai S, Zhang Y, Huang B, Li D, Ren Y. Multiple reaction monitoring-based determination of bovine alpha-lactalbumin in infant formulas and whey protein concentrates by ultra-high performance liquid chromatography-tandem mass spectrometry using tryptic signature peptides and synthetic peptide standards. Anal Chim Acta. 2012;727:47–53.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ke, X., Zhang, J., Lai, S. et al. Quantitative analysis of cow whole milk and whey powder adulteration percentage in goat and sheep milk products by isotopic dilution-ultra-high performance liquid chromatography-tandem mass spectrometry. Anal Bioanal Chem 409, 213–224 (2017). https://doi.org/10.1007/s00216-016-9987-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-016-9987-9