Abstract

In this research, an electrochemical sensor based on molecularly imprinted polymer (MIP) nanoparticles for selective and sensitive determination of diazinon (DZN) pesticides was developed. The nanoparticles of diazinon imprinted polymer were synthesized by suspension polymerization and then used for modification of carbon paste electrode (CPE) composition in order to prepare the sensor. Cyclic voltammetry (CV) and square wave voltammetry (SWV) methods were applied for electrochemical measurements. The obtained results showed that the carbon paste electrode modified by MIP nanoparticles (nano-MIP-CP) has much higher adsorption ability for diazinon than the CPE based non-imprinted polymer nanoparticles (nano-NIP-CP). Under optimized extraction and analysis conditions, the proposed sensor exhibited excellent sensitivity (95.08 μA L μmol−1) for diazinon with two linear ranges of 2.5 × 10−9 to 1.0 × 10−7 mol L−1 (R 2 = 0.9971) and 1.0 × 10−7 to 2.0 × 10−6 mol L−1 (R 2 = 0.9832) and also a detection limit of 7.9 × 10−10 mol.L−1. The sensor was successfully applied for determination of diaznon in well water and apple fruit samples with recovery values in the range of 92.53–100.86 %.

Procedure for preparation of electrochemical sensor based on MIP nanoparticles for determination of diazinon

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pesticides (herbicides, insecticides…) are widely used in agriculture and industry. In order to limit their toxic effects and their accumulation in living organisms, dosage adjustments and trace level monitoring are necessary. Thus, there is an essential need for the development of new methods for simple pesticide determination at low concentrations [1].

Organophosphorus pesticides (OPPS), as the second-generation of synthetic pesticides, have become popular due to their biodegradability, low durability, and lack of tendency to accumulate in the food chain. Nevertheless, organophosphates are generally more toxic compared to organochlorine or carbamate compounds [2].

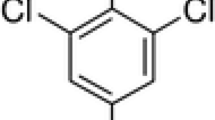

Diazinon (O,O-Diethyl O-[4-methyl-6-(propan-2-yl)pyrimidin-2-yl] phosphorothioate) is a nonsystemic organophosphate pesticide generally used against insects in agriculture and also for controlling cockroaches, silverfish, and ants in commercial and residential buildings. Diazinon (DZN) functions as an acetylcholinesterase (AChE) inhibitor. The inhibition of this enzyme lead to an abnormal accumulation of AChE in the synaptic cleft at muscarinic, nicotinic, and central sites results in numerous toxic effects such as headache, dizziness, convulsions, delirium, and depression. Other toxic effects of DZN on hepatocytes, thymus, spleen, lymph nodes, blood cells, and heart have also been reported in human and animals [3].

Due to the mentioned harmful effects, sensitive and reliable analytical methods for measuring trace amounts of DZN are required. Various analytical methods have been developed for quantitative determination of DZN in different samples, such as FT-Raman spectroscopy [4], spectrophotometric [5], different chromatographic methods (HPLC, HPTLC, LC/MS, GC, GC/MS) [6–15], immunoassays [16–18], biosensor [19–21], and electrochemical methods [22–27].

Electrochemical methods have many advantages over other analytical techniques for environmental research: (1) these techniques are non-destructive, which minimize sample perturbation, (2) the data can be collected rapidly and reproducibly, (3) the detection limits (DL) have suitable sensitivity for most environmental applications, (4) direct information on the chemical speciation can be obtained, (5) ability to achieve very compact instrumentation, which is interesting for field deployment, and (6) capability to miniaturize the electrochemical sensors that provides the non-invasive in-situ sampling [28].

Certainly, in addition to sensitivity, selectivity represents the most desired characteristics in an analytical procedure. Challenging problems associated with enhancement of the selectivity and improving the detection limit, are strong incentives to find new materials for modification of working electrodes for development of electrochemical sensors [29].

Although biological receptors have specific molecular bonding properties and have been widely used in diagnostic bio-assays and chemo-biosensors, they are often produced via complicated, tedious, and costly protocols, and require special handling or processing due to their poor stability. Also, there are no natural receptors for detection of many species. Thus, there has been a strong driving force in synthesizing artificial recognition receptors [30].

Molecular imprinting (MIP) is one of the most efficient strategies to provide the recognition materials with good selectivity continually being used in electrochemical sensors as recognition elements or modifier agents.

Although MIPs as the artificial receptors provide good molecular recognition ability similar to that of the biological receptors, traditional imprinted bulky materials usually showed slow binding kinetics to the target species and suffer from the low rebinding capacity [31].

Preparations of MIP with diameters in a nanometer range provide significantly increased total surface areas per material weight and highly active surfaces. In addition, they provide a better accessibility to the imprinted sites that leads to a faster analyte equilibration to obtain significant performance improvements in sensing and separation events [32].

In recent years, numerous articles on the use of MIP nanoparticles in the preparation of chemical sensors has been published that some of them have been reviewed by Lieberzeit and Wackerlig [33].

Accordingly, electrochemical detection systems based on MIP nanoparticles as sensing elements are widely used by researchers in the current studies. For example:

Ganjali et al. fabricated the voltammetric [32] and potentiometric [34] sensors using MIP nanoparticles for trace level detection of promethazine.

Alizadeh and Akbari developed a capacitive biosensor based on nano-sized MIP for determination of urea [35].

Li et al. fabricated an electrochemical sensor for warfarin sodium determination by coupling nanoporous gold leaf (NPGL) with molecularly imprinted polymer [36].

Merkoci et al. used MIP-decorated magnetite nanoparticles for sulfamethoxazole detection via electrochemical impedance spectroscopy [37].

Madrakian et al. introduced MIP-coated magnetite nanoparticles modified carbon paste electrode for voltammetric determination of venlafaxine antidepressant drug in human urine and blood serum samples [38].

Although some researchers studied MIP using diazinon as template [3, 39–45], there are no reports on the preparation of electrochemical sensor based on MIP for diazinon molecule.

Therefore, in this study, we tried to introduce a new MIP for diazinon with improved properties through the preparation of MIP particles at nano-dimension and its use for preparation of new electrochemical sensors for selective and sensitive determination of diazinon pesticide.

Experimental

Apparatus

The electrochemical analyses were carried out with a 746 VA trace analyzer, Metrohm. A three-electrode system consisted of an Ag/AgCl (reference electrode), a platinum rod (auxiliary electrode), and a nano-MIP modified CPE as the working electrode was used. The pH measurements were made with a Corning-PH meter 140 with a combined glass electrode. The scanning electron microscopy images (SEM) of MIP nanoparticles, were obtained using a Field Emission Scanning Electron Microscope (FE-SEM), Hitachi, model S-4160.

Materials and solutions

Diazinon (Analytical grade) was supplied by Sigma-Aldrich, (Milwaukee, USA). Methacrylic acid (MAA), ethylene glycol dimethacrylate (EDMA), ascorbic acid and graphite powder (spectroscopic grade, particle size < 50 μm) purchased from Merck (Darmstadt, Germany). Also, boric acid, orthophosphoric acid, acetic acid and sodium hydroxide for preparation of Britton–Robinson buffer solution (B.R. buffer) were obtained from Merck. Silicone oil and 2, 2-azobisisobutyronitrile (AIBN) were supplied from Sigma-Aldrich (Munich, Germany). Other chemicals were of analytical grade and obtained from Merck. Standard stock solution (2.5 × 10−3 mol L−1) of diazinon was prepared using deionized triple-distilled water.

Preparation of MIP micro particles

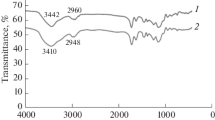

In order to prepare micro-sized MIP, 0.3 mmol of diazinon (template molecule) and 3.0 mmol of MAA (functional monomer) were dissolved in 30 mL chloroform in a 50-ml round bottom flask, and was stirred for 1 h to prepare the preassembly solution. Subsequently, 15 mmol of EGDMA (cross-linker) and 0.04 g of AIBN (initiator) were added into the above solution and stirred for 30 min (molar ratio between DZN-MAA-EGDMA were chosen based on reference 39). After sonication for 5 min, the mixture was purged with N2 for 10 min and the flask was sealed under this atmosphere. Then, the flask was cured at 60 °C for 24 h. The resultant polymeric particles were washed with chloroform to remove unreacted monomers.

Then, the template molecule was removed from polymer by washing the MIP with methanol solvent for several times so that no UV–Vis signal were detected for diazinon in eluent. The obtained MIP was dried in a vacuum oven at 60 °C for 24 h before use. Non-imprinted polymer (NIP) particles were synthesized with a similar manner but in the absence of DZN.

Preparation of MIP nanoparticles by suspension polymerization

MIP nanoparticles were synthesized by suspension polymerization in silicon oil as follows:

The diazinon (0.3 mmol), 3.0 mmol MAA, and 15 mmol of EGDMA were dissolved in 10 mL of chloroform in a 100.0 mL screw-capped glass tube, and were stirred for 30 min to prepare the preassembly solution. Then, 0.04 g of AIBN was added to the above solution. The pre-polymerization mixture was added to 60 ml treated silicon oil (purged with nitrogen gas for 15 min) and was dispersed by stirring at 700 rpm for 10 min. After sonication of mixture for 10 min (in order to create smaller polymerizable droplets), the suspension was purged with nitrogen for 10 min and heated at 65 °C for 24 h to complete polymerization. The synthesized polymer particles were filtered and washed with petroleum ether and toluene several times.

DZN and unpolymerized monomers were removed by washing of polymer particles with methanol for several times so that no UV-Vis signal is observed for diazinon (at 280 nm) in eluent. Finally, the MIP nanoparticles were dried in vacuum at 60 °C overnight. The NIP nanoparticles were prepared in the same manner without DZN.

Preparation of the sensors

For preparation of modified carbon paste (CP) electrodes, 0.06 g of graphite powder was mixed with 0.015 g modifier (nano-MIP, nano-NIP, MIP, and NIP) and homogenized in a mortar. The mixture was added to 0.025 g paraffin oil as a binder and was thoroughly mixed. The final paste was tightly packed into a Teflon tube (2.5 mm, i.d.) equipped with a copper wire through the paste to make an electrical connection. The excess of paste on the electrode surface was removed by polishing it onto a weighting paper and subsequently rinsed with water.

After each measurement, the electrode surface was renewed by cutting a thin layer of paste and polishing the new surface on a weighting paper followed by washing with water.

General procedure for electrochemical measurements

The modified electrode was incubated into the diazinon solution (pH = 7) for 10 min under stirring (400 rpm). Then, the electrode was inserted into the washing solution for 10 s (to remove any weakly adsorbed analyte) and then transferred into an electrochemical cell containing 10 mL B.R. buffer solution with pH = 3.5 and square wave voltammetry signal (SWV) were recorded from −0.90 V to −1.45 V (versus Ag/AgCl) for determination of diazinon.

All measurements were performed at room temperature and the average of reduction peak height (for triplicate analysis) was used to draw a calibration curve.

Determination of diazinon in real samples

The recovery of the DZN in the spiked well water and apple fruit samples were obtained by standard addition method based on triplicate analysis for each concentration.

Well water sample

For this purpose, in four 25-mL volumetric flasks, 2 ml of well water samples and different concentrations of diazinon standard solutions were added. After that, the solutions were diluted to volume with the B.R. buffer (pH = 7). Determination of diazinon was carried out by described method.

Apple fruit sample

For analysis of DZN in apple samples, four apples (purchased from the local market) were washed and dried. Then, apple samples divided into small pieces and mixed in a blender for 5 min to obtain homogeneous mixtures. Next, in 4 centrifuge tubes, 1 g of above sample and then different concentrations of DZN were added and each of solutions, were diluted to volume of 5 ml with B.R. buffer (pH = 7). Next, the solutions were homogenized using a shaker for 10 min and then were centrifuged at 12,000 rpm for 5 min.

Then, 1.0 mL of the supernatant liquid from each tube was transferred into the calibrated flasks, and diluted to volume with Britton–Robinson buffer (pH = 7). The diazinon was determined by the recommended procedure.

Results and discussion

Surface characterization micro and nanoparticles of MIP

Scanning electron microscopy images of the MIP micro and nanoparticles (prepared by precipitation and suspension polymerization techniques respectively) are shown in Fig. 1.

This figure indicates that the agglomerates MIP particles were obtained through the precipitation polymerization method that have micro-sized dimension (Fig. 1, I and II) while, suspension polymerization in silicon oil leading to production of MIP nanoparticles with a particles size less than 100 nm (Fig. 1, III–IV).

Electrochemical behavior of diazinon on the modified carbon paste electrode

Preliminary study to investigate the electrochemical behavior of 1.0 × 10−5 mol L−1 DZN solution at the surface of bare carbon paste electrodes was conducted using cyclic voltammetry method at potential range of 0 to −1500 mV versus Ag/AgCl electrode in B.R. buffer. In previous researches [26], the pH 4.4 was chosen for electrochemical determination of diazinon and initially we also used this pH for electrochemical analysis of DZN, but during the further experiments, the analysis pH will be optimized.

As can be seen in Fig. 2I, a reduction peak at around −1.27 V with no anodic peak on the reverse scan was observed which was in accordance with the earlier reports [22, 26]. This signal was selected as an analytical response for the determination of diazinon.

(I) Cyclic voltammetry (scan rate: 100 mV s−1) behavior of 1.0 × 10−5 mol L−1 DZN and (II) SW voltammetry (∆E = 50 mV, V step = 2 mV, t step = 0.3 s, Frequency = 50 HZ) behavior of 5.0 × 10−6 mol L−1 DZN in B.R. (0.04 M, pH = 4.4) at the surface of bare carbon paste electrode (―) with the corresponding background current (- - -), (III) SW voltammograms obtained at the (a) CP and (b) NIP-CP, (c) nano-NIP-CP, (d) MIP-CP, and (e) nano-MIP-CP electrodes after incubation of them in 1.0 × 10−6 mol L−1 DZN solution for 10 min and recording the voltammograms in B.R. buffer (pH = 4.4)

Square wave voltammetry (SWV), as a fast and sensitive electrochemical technique, was used for quantitative determination of DZN in other studies.

Thus, the SWV response of 5.0 × 10−6 mol L−1 DZN on the CP electrode was investigated (Fig. 2II). As expected, this voltammogram also shows a reduction signal for DZN at −1.24 V.

In order to verify the sensor’s ability to recognize the DZN and also to evaluate the effect of particle size on improving the sensor response, the nano-MIP-CP, nano-NIP-CP, MIP-CP, NIP-CP and CP electrodes were prepared and then incubated in 1.0 × 10−6 mol L−1 DZN solutions with pH 7.0 (because diazinon is hydrolyzed in acidic and alkaline environments, the pH 7.0 was selected for extraction solutions) for 10 min under stirring. Following the incubation step, the electrodes were inserted into the B.R. buffer solution, pH 7.0 to remove any physically and nonspecifically absorbed analyte (washing step) and then transferred into a 0.04 mol L−1 B.R. solution (pH 4.4) and SWV signal was recorded. The results are presented in Fig. 2III.

As can be seen, the SWV reduction signals of DZN at the MIP-based electrodes (Fig. 2III d and e) are higher than those of the NIPs-CP and bare CP electrodes (Fig. 2II a, b and c) indicating non-selective rebinding of DZN in the NIPs which could be removed from the surface of NIP-based sensors in washing step, while incorporating of DZN in the imprinted cavities in MIP based sensors, prevent its rapid desorption during the washing process. Also, it is clear that the signal of nano-MIP-CP is higher than that of MIP-CP electrode.

These observations show that the absorption capability of MIP nanoparticles for diazinon is considerably higher than that of micro-sized MIP. As mentioned previously, in the nano-sized imprinted materials, the majority of the imprinted sites are situated at the surface or almost near the surface of polymer particles. This leads to higher binding capacity for MIP nanoparticles and also enhances the affinity of imprinted sites to the target molecules [45]. Thus, the MIP nanoparticles were used as a selective modifier for preparation of the proposed sensor.

Optimization parameters affecting the sensor response

After securing the response of the proposed sensor to diazinon, factors affecting its response such as the ratio between components in synthesis of nano-MIP and also variables involved in extraction and analysis of DZN were optimized.

Effect of the molar ratio of template molecule to functional monomer

The molar ratio of reaction component has a significant effect on the molecular imprinting processes and thus on the resulting MIP properties. Therefore, the molar ratio of template molecules, functional monomers and cross-linkers in imprinting processes has been modified by changing the amount of template molecules (DZN). The synthesized MIPs were used for modification of carbon paste electrodes and amount of recognition ability of the sensors to DZN were evaluated by SWV method. The results (Table 1) showed that the nano-MIP2 with molar ratio of 1:6:30 (respectively for template, functional monomers, and cross-linkers) has most of the recognition ability to diazinon than the other MIPs and chosen for modification of CPE. Any amount higher than this ratio leads to a decrease in SWV signal (Electronic Supplementary Material (ESM), Fig. S1) apparently due to the high agglomeration between MIP nanoparticles that offer a poor accessibility of template molecules to the imprinting sites [29].

The effect of washing time on the electrode response

In order remove the weakly and nonspecifically absorbed DZN molecules from the surface of modified electrode after extraction step and reproducible response of sensor, the effect of washing time was evaluated. The washing solution was B.R. buffer with pH similar to extraction solution pH.

As can be seen in Fig. 3, by increasing the washing time to 4 s, the sensor response is reduced while longer washing time does not noticeably have an effect on the nano-MIP-CP signal. However, the response of the nano-NIP-CP electrode greatly decreases by increase of washing time until 10 s.

According to Fig. 3, in nano-MIP-CP electrode, after washing step for 10 s, 72.65 % of initial rebinded DZN (DZN adsorbed on the unwashed electrode) has remained while nano-NIP-CP electrode preserved 16.66 % of initial adsorbed DZN after washing step (10 s). This difference could be due to selective recognition sites in imprinted polymer particles compared to NIP particles. Also, due to existence of these imprinted cavities, initial adsorption of DZN in nano-MIP-CP electrode is more than nano-NIP-CP electrode. According to these results, 10 s was chosen for washing time of the sensors.

Optimization of the nano-MIP-CP electrode composition

Due to insulating effect of the binder resulting in a decrease in current response of carbon paste electrode, an appropriate amount of binder is required for preparation of modified CPE.

The effect of variation in the amount of paraffin oil (ESM, Fig. S2-A) shows that when the amount of paraffin is 27 % (0.028 g) of the total CPE composition, the sensor has the best electrochemical response, and more than this amount decreases the electrical current of sensor due to insulating effect of the paraffin oil.

Also, as it is clear, the amount of the recognition sites in nano-MIP based sensor has a significant effect on the extraction amount of analyte and also on the sensor response. Therefore, different nano-MIP-based sensors with various weight ratios of the nano-MIP to graphite powder at fixed amount of paraffin binder (27 %) were fabricated and used for diazinon extraction and its determination by SWV method. The results are illustrated in Fig. S2-B (ESM). As can be seen, an increase in the nano-MIP content in CPE up to weight ratio of 0.258 (15 % nano-MIP and 58 % graphite) leads to an increase in the DZN reduction signal due to an increase in the number of binding sites on the electrode surface as well as DZN extraction.

However, enhancement of the nano-MIP content of electrode of more than 15 % leads to a decrease in the sensor response. This can be related to decreasing in the electrode surface conductivity in the presence of higher amount of nano-MIP in CPE composition. Thus, the best weight ratio for fabrication of sensor is 57:15:28 for graphite:MIP:paraffin.

Effects of extraction and analysis of pH

The dependence of the reduction peak current to the sample solution pH (extraction pH) was evaluated by incubating the nano-MIP-CP electrode with optimized composition into the 1.0 × 10−6 mol L−1 DZN solutions with different pH (2.0 to 10.0) for 10 min. After extraction step, the electrode was washed and immersed into the analysis solution (B.R. buffer with pH 4.4) and SWV signal was recorded. As can be seen in Fig. 4, the amount of DZN extraction in the pH range of 6–8 is higher and has no considerable variation in this pH range. At pH values less than 6 and greater than 8, the extraction amount tends to decrease; this behavior could be due to diazinon hydrolysis in acidic or alkaline environments [46] and so its appropriate form for inclusion in recognition sites was changed. Thus, the pH = 7 was chosen as an optimum pH for DZN extraction solution.

After optimization of extraction pH, the effect of supporting electrolyte pH on the DZN reduction at the surface of nano-MIP-CP electrode in the pH range values from 2.0 to 7.5 was studied.

The results are illustrated in Fig. S3 (ESM). As can be seen in Fig. S3-A, with increasing of pH, up to 3.5, the cathodic peak current is increased and after this pH, an obvious decrease results. Furthermore, Fig. S3B shows a dependence of reduction peak potential to the analysis pH. The potential shifted toward more negative values upon increasing of pH. These results indicated participation of protons in the reduction process of DZN [22, 26], so that the acidic media is better for this reaction, but at a very acidic pH (˂ 3.5), the diazinon is unstable and rapidly hydrolyzed prior to electrochemical analysis [22]. Based on these results, the solution with pH 3.5 was selected as a suitable supporting electrolyte for the DZN analysis.

Optimization of extraction time and stirring rate of sample solution

Because in extraction step the contact surface of sensor with diazinon solution is low, in order to achieve the maximum capacity of sensor, transfer of diazinon molecules to the electrode surface must be accompanied by stirring of DZN solution and sufficient extraction time.

For this purpose, the effects of extraction time and stirring rate of extraction solution on the sensor response was evaluated. The obtained results indicate that increasing of extraction time (ESM, Fig. S4-A) and stirring rate (ESM, Fig. S4-B) up to 12 min and 400 rpm, respectively, leads to considerable increase in the SWV response, and longer extraction times and faster stirring rates did not have a significant effect on the diazinon extraction. Therefore, these values were selected for subsequent experiments.

Electrochemical condition optimization

'Finally, the effect of some of the important electrochemical parameters related to the SWV technique such as pulse amplitude (ΔEs), SW frequency (f), and pulse step (V step) on the response of diazinon reduction was studied. The results given in Table 2 indicate that the best SWV response was obtained for the pulse amplitude of 30 mV, frequency of 70 Hz, and pulse step of 6 mV. The related voltammograms are shown in Fig. 5.

Analytical characteristics

To investigate the analytical performance of the proposed sensor, the nano-MIP-CP electrode used for determination of diazinon solutions with various concentrations to plotting of calibration curve (Fig. 6).

I SW voltammograms of varying concentration of diazinon obtained at the nano-MIP-CP electrode under optimized conditions. II The corresponding calibration curve of diazinon. Extraction solution: DZN solution prepared in B.R. buffer at pH 7.0; the letters a–m correspond to blank, 0.0025, 0.005, 0.008, 0.01, 0.05, 0.08, 0.1, 0.25, 0.5, 0.8, 1.0 and 2.0 μmol L−1 DZN; analysis solution: B.R. buffer at pH 3.5

The SWV results (Fig. 6I) show that the reduction peak current of DZN with peak potential at about −1.22 V increased as a function of DZN concentration. The calibration curve (Fig. 6II) showed two linear regions between the peak current and concentration of DZN. One of these was from 2.5 × 10−9 to 1.0 × 10−7 mol L−1 with a regression equations of I p (μA) = 95.081 C DZN (μmol L−1) + 0.027 (R 2 = 0.9971), and the other from 1.0 × 10−7 to 2.0 × 10−6 mol L−1 with a regression equations of I p (μA) = 17.774 C DZN (μmol L−1) + 10.161 (R 2 = 0.9832). Also, as can be seen, the slope of the first linear range is much higher than that of the second region. This difference in slopes is due to the different activities of the electrode surface with low and high concentrations of the analyte. Due to the high number of active sites (compared to the total number of the analyte molecules) in the electrode surface in the lower DZN concentration, the slope of the first linear region of calibration curve is high. While in the higher concentration of DZN, due to decreasing active binding sites, the slope of the second linear region of the calibration curve decreased [47]. Therefore, the first region was selected for electroanalytical determination of diazinon.

The limit of detection (LOD) and limit of quantification (LOQ) for DZN assay at nano-MIP-CP were calculated using the relation kS b/m (where k = 3 for LOD and 10 for LOQ, S b is the standard deviation of the blank (n = 7) and m is the slope of the first linear region of calibration curve) and 7.90 × 10−10 and 2.63 × 10−9 mol L−1 values were obtained for LOD and LOQ, respectively. The precision (%RSD) for five replicate detections of 2.5 × 10−8 mol L−1 diazinon solution was calculated 2.66 %.

The stability of the proposed sensor was evaluated by determination of 2.5 × 10−8 mol L−1 DZN and the results showed that the current response of the sensor remained up to 91.8 % (RSD = 3.93 %, n = 3) of its initial value after 14 weeks, which suggested that the nano-MIP based sensor possessed good stability.

Also, the response of the nano-NIP-CP electrode under the optimal conditions was compared with the nano-MIP-CP. As can be seen in Fig. 7, the nano-NIP based sensor showed considerably lower response to DZN than the nano-MIP based sensor. This demonstrated the benefit of the selective binding sites in the nano-MIP for recognition and extraction of DZN.

To assess the selectivity of the proposed sensor, the interference potential of some ions and organic compounds in real samples (well water and apple fruit) was tested.

The SW voltammograms were taken for the reduction of DZN (2.5 × 10−8 mol L−1) after addition of different concentrations of each interference species. These results are shown in Table 3 and indicate that the performance of the developed sensor did not significantly get affected by the presence of various interfering molecules and ions studied, and suggest that the proposed method could be applied successfully for the determination of DZN in complex matrices. The high selectivity results from the rigid imprinted cavities formed in the polymer matrixes that are complementary to diazinon molecule both in shape, size, and position of functional groups.

Analysis of real samples

The performance of the proposed sensor for determination of diazinon in complex matrices was evaluated through the determination of diazinon in well water and apple fruit samples according to the procedures described in “Experimental” section. Each experiment was repeated three times and the average of the results is reported in Table 4. Also, the related voltammograms are shown in ESM, Fig. S5.

The resulting range of recovery values (92.53–100.86) showed good performance of the proposed sensor to determine of diazinon in samples with complex matrices.

Comparison of the developed sensor with other electrodes

In Table 5, the performance of the proposed sensor with respect to some characteristics such as detection limit and linear range was compared with other electrodes that have been developed for diazinon determination. As can be seen, except for one case, nano-MIP-CP electrode represents better results in comparison to other reported electrodes.

Conclusions

In this work, the nanoparticles of molecularly imprinted polymer were used as recognition elements for the fabrication of a sensitive and selective voltammetric sensor for the determination of diazinon pesticide.

It was shown that the MIP particle size had considerable effect on the sensor performance so that the electrode modified with MIP nanoparticles showed a much better response than the electrode modified with MIP micro particles. In fact, preparation of MIP particles with nano-dimension in this study compared to past researches leads to an increase in the number of recognition sites and their accessibility for detection of diazinon and demonstrated the potential of nano-MIP-based sensor for sensitive, selective, and cost-effective sample analysis.

The presented sensor has long-term stability and good repeatability with benefits of fairly fast response time, ease of preparation, and regeneration of the electrode surface that provides a rapid and economical electrochemical method for the determination of diazinon in real samples without any considerable matrix interference.

References

Rassaei L, Marken F, Sillanpaa M, Amiri M, Cirtiu CM, Sillanpaa M. Nanoparticles in electrochemical sensors for environmental monitoring. Trends Anal Chem. 2011;30(11):1704–15.

Sohrabi MR, Jamshidi S, Esmaeilifar A. Cloud point extraction for determination of Diazinon: Optimization of the effective parameters using Taguchi method. Chemometr Intell Lab. 2012;110(1):49–54.

Davoodi D, Hassanzadeh-Khayyat M, Rezaei MA, Mohajeri SA. Preparation, evaluation and application of diazinon imprinted polymers as the sorbent in molecularly imprinted solid-phase extraction and liquid chromatography analysis in cucumber and aqueous samples. Food Chem. 2014;158:421–8.

Skoulika SG, Georgiou CA, Polissiou MG. FT-Raman spectroscopy—Analytical tool for routine analysis of diazinon pesticide formulations. Talanta. 2000;51(3):599–604.

Cao H, Nam J, Harmon HJ, Branson DH. Spectrophotometric detection of organophosphate diazinon by porphyrin solution and porphyrin-dyed cotton fabric. Dyes Pigm. 2007;74(1):176–80.

Sanchez M, Mendez R, Gomez X, Martin‐Villacorta J. Determination of diazinon and fenitrothion in environmental water and soil samples by HPLC. J Liq Chromatogr Relat Technol. 2003;26(3):483–97.

Shayeghi M, Khoobdel M, Vatandoost H. Determination of organophosphorus insecticides (malathion and diazinon) residue in the drinking water. Pak J Biol Sci. 2007;10(17):2900–4.

Salm P, Taylor PJ, Roberts D, de Silva J. Liquid chromatography–tandem mass spectrometry method for the simultaneous quantitative determination of the organophosphorus pesticides dimethoate, fenthion, diazinon and chlorpyrifos in human blood. J Chromatogr B. 2009;877(5):568–74.

Inoue S, Saito T, Mase H, Suzuki Y, Takazawa K, Yamamoto I, et al. Rapid simultaneous determination for organophosphorus pesticides in human serum by LC–MS. J Pharm Biomed Anal. 2007;44(1):258–64.

Rastrelli L, Totaro K, De Simone F. Determination of organophosphorus pesticide residues in Cilento (Campania, Italy) virgin olive oil by capillary gas chromatography. Food Chem. 2002;79(3):303–5.

Fytianos K, Raikos N, Theodoridis G, Velinova Z, Tsoukali H. Solid phase microextraction applied to the analysis of organophosphorus insecticides in fruits. Chemosphere. 2006;65(11):2090–5.

Jafari MT, Saraji M, Sherafatmand H. Polypyrrole/montmorillonite nanocomposite as a new solid phase microextraction fiber combined with gas chromatography–corona discharge ion mobility spectrometry for the simultaneous determination of diazinon and fenthion organophosphorus pesticides. Anal Chim Acta. 2014;814:69–78.

Ahmadi F, Assadi Y, Hosseini SM, Rezaee M. Determination of organophosphorus pesticides in water samples by single drop microextraction and gas chromatography-flame photometric detector. J Chromatogr A. 2006;1101(1):307–12.

Menezes Filho A, dos Santos FN, Pereira PAP. Development, validation and application of a method based on DI-SPME and GC–MS for determination of pesticides of different chemical groups in surface and groundwater samples. Microchem J. 2010;96(1):139–45.

Chen P-S, Huang S-D. Determination of ethoprop, diazinon, disulfoton and fenthion using dynamic hollow fiber-protected liquid-phase microextraction coupled with gas chromatography–mass spectrometry. Talanta. 2006;69(3):669–75.

Brun EM, Garces-Garcia M, Escuin E, Morais S, Puchades R, Maquieira A. Assessment of novel diazinon immunoassays for water analysis. Environ Sci Technol. 2004;38(4):1115–23.

Zaruk D, Comba M, Struger J, Young S. Comparison of immunoassay with a conventional method for the determination of Diazinon® in surface waters. Anal Chim Acta. 2001;444(1):163–8.

Garces-Garcia M, Brun EM, Puchades R, Maquieira A. Immunochemical determination of four organophosphorus insecticide residues in olive oil using a rapid extraction process. Anal Chim Acta. 2006;556(2):347–54.

Pogacnik L, Franko M. Determination of organophosphate and carbamate pesticides in spiked samples of tap water and fruit juices by a biosensor with photothermal detection. Biosens Bioelectron. 1999;14(6):569–78.

Mulchandani P, Chen W, Mulchandani A. Flow injection amperometric enzyme biosensor for direct determination of organophosphate nerve agents. Environ Sci Technol. 2001;35(12):2562–5.

Everett WR, Rechnitz GA. Mediated bioelectrocatalytic determination of organophosphorus pesticides with a tyrosinase-based oxygen biosensor. Anal Chem. 1998;70(4):807–10.

Martínez RC, Domínguez FB, Méndez JH, Martín PG. Electroanalytical determination of diazinon: direct current and differential pulse polarography and adsorptive stripping voltammetry. Electroanalysis. 1990;2(7):567–71.

Erdogdu G. A sensitive voltammetric method for the determination of diazinon insecticide. J Anal Chem. 2003;58(6):569–72.

de Albuquerque YDT, Ferreira LF. Amperometric biosensing of carbamate and organophosphate pesticides utilizing screen-printed tyrosinase-modified electrodes. Anal Chim Acta. 2007;596(2):210–21.

Ly SY. Assay of diazinon pesticides in cucumber juice and in the deep brain cells of a live carp. Microchim Acta. 2008;163(3-4):283–8.

Guziejewski D, Skrzypek S, Ciesielski W. Square wave adsorptive stripping voltammetric determination of diazinon in its insecticidal formulations. Environ Monit Assess. 2012;184(11):6575–82.

Arvand M, Vaziri M, Zanjanchi M. Voltammetric characteristics of diazinon on carbon paste electrode modified with tris (ethylenediamine) cobalt (II) iodide. J Anal Chem. 2013;68(5):429–35.

Taillefert M, Rozan TF. Electrochemical Methods for the Environmental Analysis of Trace Elements Biogeochemistry. In: Environmental Electrochemistry. ACS Symposium Series; American Chemical Society: Washington, DC, 2002. pp. 2–14. doi:10.1021/bk-2002-0811.ch001.

Milani Hosseini MR, Motaharian A. Electroanalytical determination of diazepam in tablet and human serum samples using a multiwalled carbon nanotube embedded molecularly imprinted polymer-modified carbon paste electrode. RSC Adv. 2015;5(99):81650–9.

Alizadeh T, Zare M, Ganjali MR, Norouzi P, Tavana B. A new molecularly imprinted polymer (MIP)-based electrochemical sensor for monitoring 2, 4, 6-trinitrotoluene (TNT) in natural waters and soil samples. Biosens Bioelectron. 2010;25(5):1166–72.

Alizadeh T, Ganjali MR, Akhoundian M. Fabrication of an Extra Sensitive Voltammetric Sensor Using Nanoparticles of Molecularly Imprinted Polymer for Determination of Ultra-Trace Promethazine in Plasma Sample. Int J Electrochem Sci. 2012;7:10427–41.

Tokonami S, Shiigi H, Nagaoka T. Review: micro-and nanosized molecularly imprinted polymers for high-throughput analytical applications. Anal Chim Acta. 2009;641(1):7–13.

Wackerlig J, Lieberzeit PA. Molecularly imprinted polymer nanoparticles in chemical sensing–Synthesis, characterisation and application. Sens Actuator B-Chem. 2015;207:144–57.

Alizadeh T, Ganjali MR, Akhoundian M. Synthesis and application of different nano-sized imprinted polymers for the preparation of promethazine membrane electrodes and comparison of their efficiencies. Int J Electrochem Sci. 2012;7:7655.

Alizadeh T, Akbari A. A capacitive biosensor for ultra-trace level urea determination based on nano-sized urea-imprinted polymer receptors coated on graphite electrode surface. Biosens Bioelectron. 2013;43:321–7.

Li Y, Zhang L, Liu J, Zhou S-F, Al-Ghanim KA, Mahboob S, et al. A novel sensitive and selective electrochemical sensor based on molecularly imprinted polymer on a nanoporous gold leaf modified electrode for warfarin sodium determination. RSC Adv. 2016;6(49):43724–31.

Zamora-Gálvez A, Ait-Lahcen A, Mercante LA, Morales-Narváez E, Amine A, Merkoçi A. Molecularly Imprinted Polymer-Decorated Magnetite Nanoparticles for Selective Sulfonamide Detection. Anal Chem. 2016;88(7):3578–84.

Madrakian T, Haryani R, Ahmadi M, Afkhami A. A sensitive electrochemical sensor for rapid and selective determination of venlafaxine in biological fluids using carbon paste electrode modified with molecularly imprinted polymer-coated magnetite nanoparticles. J Iranian Chem Soc. 2016;13(2):243–51.

Bayat M, Hassanzadeh-Khayyat M, Mohajeri SA. Determination of Diazinon Pesticide Residue in Tomato Fruit and Tomato Paste by Molecularly Imprinted Solid-Phase Extraction Coupled with Liquid Chromatography Analysis. Food Anal Methods. 2015;8(4):1034–41.

Rahiminejad M, Shahtaheri S, Ganjali M, Forushani AR, Golbabaei F. Molecularly imprinted solid phase extraction for trace analysis of diazinon in drinking water. J Environ Health Sci. 2009;6(2):97–106.

Rahiminezhad M, Shahtaheri S, Ganjali M, Koohpaei A, Forushani AR, Golbabaei F. An experimental investigation of the molecularly imprinted polymers as tailor-made sorbents of diazinon. J Anal Chem. 2010;65(7):694–8.

Sanagi MM, Salleh S, Ibrahim WAW, Naim AA. Determination of organophosphorus pesticides using molecularly imprinted polymer solid phase extraction. Malaysian J Anal Sci. 2011;15(2):175–83.

Sanagi MM, Salleh S, Ibrahim WAW, Naim AA, Hermawan D, Miskam M, et al. Molecularly imprinted polymer solid-phase extraction for the analysis of organophosphorus pesticides in fruit samples. J Food Compost Anal. 2013;32(2):155–61.

Wang Y-L, Gao Y-L, Wang P-P, Shang H, Pan S-Y, Li X-J. Sol–gel molecularly imprinted polymer for selective solid phase microextraction of organophosphorous pesticides. Talanta. 2013;115:920–7.

Zhao Y, Ma Y, Li H, Wang L. Composite QDs@ MIP nanospheres for specific recognition and direct fluorescent quantification of pesticides in aqueous media. Anal Chem. 2011;84(1):386–95.

Pieda DC. Acid and base catalysed aqueous hydrolysis of the organophosphorus pesticide, diazinon. Ontario: Queen’s University Kingston; 2001. M.Sc. thesis.

Rezaei B, Foroughi-Dehnavi S, Ensafi AA. Fabrication of electrochemical sensor based on molecularly imprinted polymer and nanoparticles for determination trace amounts of morphine. Ionics. 2015;21(10):2969–80.

Acknowledgments

The authors gratefully acknowledge the support of this work by the Electroanalytical Chemistry Research Centre of Iran University of Science and Technology and the Pharmaceutical Research Center of Mashhad University of Medical Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 323 kb)

Rights and permissions

About this article

Cite this article

Motaharian, A., Motaharian, F., Abnous, K. et al. Molecularly imprinted polymer nanoparticles-based electrochemical sensor for determination of diazinon pesticide in well water and apple fruit samples. Anal Bioanal Chem 408, 6769–6779 (2016). https://doi.org/10.1007/s00216-016-9802-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-016-9802-7