Abstract

The present study focuses on investigating 60 strains of yeast isolated from the natural fermentation broth of Vitis labruscana Baily × Vitis vinifera L. These strains underwent screening using lysine culture medium and esculin culture medium, resulting in the identification of 27 local non-Saccharomyces yeast strains exhibiting high β-glucosidase production. Subsequent analysis of their fermentation characteristics led to the selection of four superior strains (Z-6, Z-11, Z-25, and Z-58) with excellent β-glucosidase production and fermentation performance. Notably, these selected strains displayed a dark coloration on esculin medium and exhibited robust gas production during Duchenne tubules’ fermentation test. Furthermore, all four non-Saccharomyces yeast strains demonstrated normal growth under specific conditions including SO2 mass concentration ranging from 0.1 to 0.3 g/L, temperature between 25 and 30 °C, glucose mass concentration ranging from 200 to 400 g/L, and ethanol concentration at approximately 4%. Molecular biology identification confirmed that all selected strains belonged to Pichia kudriavzevii species which holds great potential for wine production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the field of wine-making, non-Saccharomyces refers to a diverse group of yeast species that are distinct from Saccharomyces cerevisiae. These yeasts are commonly found in grape-growing and wine-making environments, such as vineyard soil, fruit skins, and wine-making facilities (Wu 2022). The major genera include Hanseniaspora, Torulaspora, Pichia, Metschnikowid, Candida, Issatchenkia, among others (Xu et al. 2023; Xing et al. 2023; Liu et al. 2023a, b; João et al. 2021). Non-Saccharomyces yeast often exhibit lower fermentation efficiency compared to Saccharomyces cerevisiae, resulting in the conversion of reducing sugars into ethanol and other fermentation by-products. Consequently, non-Saccharomyces yeasts hold great potential for wine production due to their ability to impart complex flavor characteristics while maintaining a lower ethanol content (Wang et al. 2023). For instance, Hansenula uvarum can secrete abundant glycosidase enzymes that hydrolyze glycosidic bonds to release terpenes, while M. pulcherrima secretes α-arabinofuranosidase for their hydrolysis. This enzymatic activity contributes to enhancing floral sweetness and berry aroma characteristics in wines (Hu et al. 2016; Lu et al. 2016). Moreover, Pichia pastoris, a fermenting yeast strain, is capable of producing esters through C4–C8 esterase secretion which further improves the aging aroma profile in wines (Li et al. 2017). Leveraging the advantageous properties of certain non-Saccharomyces strains for participation or assistance during wine fermentation can positively impact the overall flavor profile of wines (Luo et al. 2022), thereby potentially influencing sensory attributes (Liu et al. 2021).

Pichia is a common yeast species in the natural fermentation of wine and is also one of the important ester-producing yeasts, which makes an important contribution to the diversity of wine aroma components (Chen et al. 2021; Ma et al. 2017). Chen et al. (2018) used the sequential inoculation of optimized fermentation Pichia pastoris and Saccharomyces cerevisiae to ferment, and the glycerol content generated was higher than that of pure fermentation of Saccharomyces cerevisiae (7%), indicating that delayed inoculation of Saccharomyces cerevisiae to support the growth of optimized fermentation Pichia pastoris strains could improve the glycerol production in the fermentation process, which had a positive impact on improving the quality of wine. Zhang et al. (2020) found that Pichia kluyveri could increase the content of ethyl esters such as ethyl hexanoate and ethyl butyrate in fermented wine samples, which significantly enhanced the fruit and floral aroma of wine. Anfang et al. (2009) showed that the mixed fermentation of Pichia kluyveri and Saccharomyces cerevisiae could increase the content of fruity thiols in wine.

Research findings have demonstrated that indigenous microbial flora exhibit enhanced adaptability to local climate, soil, and microecological conditions. The utilization of indigenous yeasts for fermentation is conducive to augmenting the flavor diversity and typicality of wine production regions (Wu et al. 2020). Consequently, this study employed traditional isolation methods in conjunction with molecular biology techniques to investigate the yeast strains present in Vitis labruscana Baily × Vitis vinifera L. grapes harvested from Qujing, Yunnan. The analysis focused on assessing temperature tolerance, glucose utilization, ethanol resistance, sulfur dioxide sensitivity, acid endurance, and fermentation performance of these yeasts. Furthermore, other aspects pertaining to yeast fermentation characteristics were examined with the objective of identifying non-Saccharomyces strains exhibiting elevated β-glucosidase production and exceptional tolerance levels. This research aims to provide potential high-quality yeast resources for the production of premium wines.

Materials and methods

Experimental materials

Vitis labruscana Baily × Vitis vinifera L. grapes: harvested in Qilin District, Qujing City, Yunnan Province; Commercial yeast CECA (SY): purchased from Angel Yeast Co., Ltd., 500 g/bag.

Culture medium

Yeast Extract Peptone Dextrose (YPD) (g/L): Yeast Extract Peptone Dextrose 10, Peptone 20, Glucose 20, Agar 15; High-pressure steam sterilization at 121 °C under natural pH conditions for 15 min.

Wallerstein Laboratory Nutrient Agar (WL Nutrient Agar Differentiation Medium) (g/L): Yeast Extract 4, Casein Peptone 5, Glucose 50, Dipotassium hydrogen phosphate 0.55, Potassium chloride 0.425, calcium chloride 0.125, magnesium sulfate 0.125, ferric chloride 0.0025, manganese sulfate 0.0025, bromocresol green 0.022, agar 15; Sterilize with high-pressure steam at 121 °C for 15 min.

Esculin screening medium (g/L): esculin 3, iron citrate 0.5, sodium chloride 2, anhydrous magnesium sulfate 0.5, potassium dihydrogen phosphate 1; Sterilize with high-pressure steam at 121 °C for 20 min.

TTC upper culture medium (g/L): 2,3,5-triphenyltetrazolium chloride (TTC) 0.5, glucose 5, agar 15; boil for 2 min to sterilize.

TTC lower culture medium (g/L): magnesium sulfate 0.4, potassium dihydrogen phosphate 1.0, yeast extract powder 15, peptone 20, glucose 10, agar 15; The sterilization process involves subjecting the sample to high-pressure steam at a temperature of 121 °C for a duration of 15 min, while maintaining a pH value of 5.5.

Qualitative screening medium for YPD ester production (g/L): tributyrin 4 mL, yeast extract 10, peptone 20, glucose 20, agar 15; sterilized by high-pressure steam at 121 °C for 20 min.

Bismuth sulfite glucose glycine yeast agar (BIGGY) (g/L): ammonium citrate 5, sodium sulfite 3, glucose 10, glycine 10, yeast extract 1, agar 15; pH value 6.8 ± 0.2, boil for 1 min to sterilize.

Isolation, purification, and screening of yeast

About 200 g of fresh Vitis labruscana Baily × Vitis vinifera L. were naturally fermented at 28 °C for 3 days, and then diluted with sterile water to obtain 10–1, 10–2 and 10–3 diluents by dilution plate method (Liu et al. 2023a, b). Coated on wort solid medium containing antibiotics (nystatin 100 mg/L, chloramphenicol 100 mg/L) and YPD solid medium, and cultured at 28 °C for 3 days. Single colonies with typical yeast morphology were selected and purified on YPD medium.

The purified yeast was inoculated into liquid medium containing 10 mL YPD at 2% inoculation rate and activated for 24 h, then diluted with sterile water to obtain 10–5 dilute solution, coated and inoculated on WL screening medium, cultured at 28 °C for 5 days, observed and recorded the color and morphology of the colony, and prepared water tablets for observation under microscope (DM750 + ICC50W, Leica Microsystems GmbH, Germany). The colony morphology and microscopic examination results of yeast on WL medium were observed and recorded for analysis and preliminary classification (Jia et al. 2018). Use 80% mass concentration of glycerin stored at −20 °C for backup (Bian et al. 2021).

Rescreening was carried out using the property that lysine could not be used as a nitrogen source for Saccharomyces cerevisiae. The isolated strains were activated and cultured at 28 °C for 24 h to obtain seed liquid. After starvation treatment with 0.1% normal saline, bacterial suspension was obtained after culture for 7 days. The suspensions were inoculated on lysine medium and cultured at 28 °C for 5 days. If good growth is observed, it can be judged that the yeast is non-Saccharomyces, and if there is no colony growth after culture for 15 days, it can be determined that the yeast is Saccharomyces cerevisiae (Gao et al. 2022).

Screen the high-yield β-glucosidase activity

While autoclaving of aesculin medium was performed, 96-well standard enzyme plate was opened and sprayed with sterilized ethanol, and placed in a super-clean table with UV sterilization enabled for about 40 min (Zhao 2020).

Two hundred microliters aesculin medium was absorbed and added into the 96-well standard enzyme label plate. After cooling, 20 µL activated bacteria solution was added to be screened, and cultured at 28 °C for 24 h. The color change was observed. Three groups were performed for each strain, the experiment was repeated three times, and a blank experiment was set. The β-glucosidase production activity of the tested strain was measured according to the color development. Dark black indicated the most high-yielding enzyme activity, black indicated the middle enzyme activity, dark gray indicated the low-producing enzyme activity, and light yellow indicated the non-producing enzyme activity (Zhang et al. 2022a, b).

Fermentation characteristics’ research

Fermentation capacity experiments were conducted by inoculating the activated non-Saccharomyces strain into a 10 mL YPD liquid culture medium in a test tube, with an inoculum volume of 2%. Care was taken to ensure the absence of air bubbles in the Duchenne tube during insertion. The cultivation was carried out in an incubator at 30 °C, with gas production being observed every 12 h and the bubble height recorded in the Duchenne tube (Xu et al. 2021). After 48 h, strains exhibiting excellent fermentation performance, rapid fermentation, and robust growth were selected based on the experimental results.

Determination of hydrogen sulfide production characteristics: Samples of 5 μL activated bacterial solution were absorbed into BIGGY medium. After the bacterial solution was completely absorbed into the medium, it was sealed with a sealing film and cultured invert at 28 °C for 5 days to observe the color depth of the colony. The darker the color, the stronger the hydrogen sulfide production capacity, and commercial yeast CECA (SY) was inoculated as a control (Zheng et al. 2020).

2,3,5-Triphenyltetrazolium chloride (TTC) color test was conducted by pipetting 10 µL of the activated yeast suspension onto the TTC lower culture medium, followed by complete absorption of the yeast suspension into the culture medium. The sealed culture was then incubated at 30 °C for 48 h, ensuring full coverage with the upper culture medium. Sufficient colonies were observed and recorded after a dark incubation period of 36 h to assess color development as an indicator of ethanol-producing ability in yeast strains. Each strain was tested in nine replicates (Tanaka et al. 2021).

Ester production assay was conducted by spotting 10 µL of activated yeast suspension onto YPD ester-producing qualitative screening medium. Following complete absorption of the bacterial culture, the medium was sealed with a film and incubated upside down at 28 °C for 4 days. Subsequently, colony density around transparent circles was observed and measured using nine replicates per strain (Ma et al. 2023).

Tolerance test

The isolated strains were inoculated in YPD liquid medium and incubated at 28 °C for 24 h to obtain yeast suspension. Subsequently, the yeast suspension was used to inoculate SO2 solutions with varying mass concentrations (0.1, 0.15, 0.2, 0.25, and 0.3 g/L) at an inoculation volume of 2% using potassium metabisulfite as an additive). Additionally, different mass concentrations of glucose (200, 250, 300, 350, and 400 g/L), various volume fractions of ethanol (4, 8, 12, 16, and 20%), and diverse temperatures (4, 20, 25, and 30 °C) were employed in YPD liquid culture medium while using YPD liquid medium as a control blank sample. Three parallel groups were cultured statically at 28 °C for 24 h for each strain, and the absorbance value was measured at a wavelength of 600 nm (Liu et al. 2020).

Molecular biology identification of yeast

DNA was extracted and amplified by PCR. After centrifugation, deoxyribonucleic acid (DNA) of yeast genome was extracted by microwave oven (Ren et al. 2022) and used as a template. Primers NL1 (5′-GCATCAATAAGCGGAGGAAAAG-3′) and NL4 (5′-GGTCCGTTTCAAGACGG-3′) were used to perform PCR amplification on the 26S rDNA D1/D2 region gene sequence of the isolated strain. The PCR amplification procedure (Zhang et al. 2022a) was as follows: Preheat at 98 °C for 2 min; Denatured at 98 °C for 10 s, annealed at 53 °C for 10 s, extended at 72 °C for 5 s, 39 cycles; Extend for 5 min at 72 °C. After PCR amplification, the PCR products were sent to Kunming Qiaoke Biotechnology Co., Ltd. for sequencing using the Illumina platform.

Phylogenetic tree construction: The determined 26S rDNA gene sequences of yeast were analyzed by BLAST with GenBank database, and the standard strains that were relatively closely related to the experimental strains were selected for sequence comparison using ClustalW software, and the phylogenetic analysis was performed using MEGA-X software, and the phylogenetic tree was constructed.

Results and discussion

Isolation, screening, and selection of high-yield β-glucosidase activity yeasts

Sixty yeast strains, designated Z-1 ~ Z-60, were isolated from the natural fermentation broth of Vitis labruscana Baily × Vitis vinifera L. They were classified based on their morphological characteristics observed on WL medium. The colonies exhibited predominantly round or oval shapes and varied in color from white to pale yellow or green (Fig. 1).

The growth and reproduction of microorganisms require six essential nutrients, namely, nitrogen sources, energy, water, inorganic salts, and growth factors (Zhao et al. 2022). It is noteworthy that non-Saccharomyces strains can utilize lysine as a nitrogen source; thus, the ability of colonies to grow on lysine medium serves as a decisive factor for distinguishing non-Saccharomyces strains. All 60 yeast strains exhibited robust growth after being cultured on lysine medium for 5 days. Consequently, these strains were classified as non-Saccharomyces. Since all 60 strains displayed consistent growth patterns, only representative strains are depicted in Fig. 2.

The production levels of β-glucosidase in yeast strains were screened using esculin as a substrate, employing a 96-well plate-based color reaction. The ability of the strains to produce β-glucosidase was evaluated by quantifying the color intensity (Ma et al. 2018). As depicted in Fig. 3, three yeast strains did not exhibit any detectable β-glucosidase activity. Fifteen yeast strains displayed low production levels of β-glucosidase (Z-9, Z-15, and Z-18), while additional 26 strains exhibited relatively lower production levels (Z-1, Z-19, Z-21, Z-28, Z-29, Z-31, Z-32, Z-33, Z-36, Z-37, Z-40, Z-41, Z-43, Z-45, Z-47, Z-48, Z-49, Z-51, Z -52, Z-53, Z-54, Z-55, Z-56, Z-57, Z-59, and Z-60). Moreover, 27 yeast strains demonstrated high-production capacity for β-glucosidase (Z-2, Z-4, Z-5, Z-6, Z-7, Z-8, Z-10, Z-11, Z-13, Z-17, Z-20, Z-22, Z-23, Z-24, Z-25, Z-26, Z-27, Z-30, Z-34, Z-35, Z-38, Z-39, Z-42, Z-44, Z-46, Z-50, Z-58).

The gas production experiments were conducted on 27 yeast strains exhibiting high β-glucosidase production, and the results are presented in Table 1. The Dutch tubes of strains Z-2, Z-4, Z-6, Z-7, Z-8, Z-10, Z-11, Z-17, Z-20, Z-22, Z-23, Z-24, Z-25, Z-27, Z-34, Z-35, Z-39, Z-42, Z-44, Z-46, and Z-50 showed significant gas filling capacity indicating their rapid fermentation ability. Strains with codes: Z-6, Z-11, Z-20, Z-24, Z-25, Z-35, and Z-58 exhibited more compact precipitation suggesting stronger gas production and flocculation abilities. Conversely, strains with codes: Z-2, Z-5, Z-7, Z-8, Z-10, Z-13, Z-17, Z-22, Z-23, Z-26, Z-30, Z-38, Z-39, Z-42, Z-44, and Z-46 displayed loose precipitation characteristics. In summary, the 17 yeast strains demonstrating poor fermentation performance were excluded from further experimentation while the remaining 10 strains were selected for subsequent investigations.

H2S is a colorless toxic gas that emits a malodorous scent resembling rotten eggs at high concentrations (Ji 2022). Consequently, the production of H2S by yeast may contribute to undesirable flavors in fruit wine. The capacity of yeast strains to generate H2S was assessed using the BIGGY agar medium, where darker colony pigmentation indicated higher levels of H2S production, while white colonies were non-producers of H2S. As depicted in Fig. 4, Z-11, Z-6, Z-25, Z-58, and Z-27 exhibited a light brown hue signifying lower H2S production, whereas Z-4 displayed the darkest metallic shade indicating the highest level of H2S production.

Non-Saccharomyces, as the primary aroma producer in fruit wine, plays a pivotal role in determining the quality of fruit wine through its ethanol production capacity (Xiang et al. 2021). The color development mechanism of TTC relies on its reduction by yeast dehydrogenase, leading to the formation of red or purple formazan substances and cellular precipitation. Consequently, cells exhibit dark red, pinkish-red, and reddish hues or remain colorless (Mujdeci and Ozbas 2021). Figure 5 illustrates a gradual lightening of color for these 11 strains on TTC medium, indicating a decline in their ethanol-producing capability. In comparison to the commercial yeast SY’s ethanol production capacity, strains Z-6, Z-11, Z-58, and Z-25 show darker colors suggesting stronger ethanol production ability. Conversely, strains Z-27 exhibit lighter colors signifying weaker ethanol production capacity. Strains Z-4, Z-20, and Z-35 display slight pink hues implying limited ethanol production potential.

Based on the results of hydrogen sulfide production and TTC color development, five strains (Z-6, Z-11, Z-25, Z-27, and Z-58) were selected for ester production experiments. Esterase produced by non-Saccharomyces can hydrolyze tributyrin resulting in a transparent halo around the colony. The diameter of this halo is positively correlated with esterase activity (Cao et al. 2023). As depicted in Fig. 6, compared to the commercial yeast SY, strains Z-25, Z-58, Z-11, and Z-6 exhibited distinct and prominent transparent halos with larger diameters that had a ratio greater than one (Z-58 > Z-25 > Z-6 > Z-11), indicating robust corresponding ester-producing capabilities. However, strain Z-27 displayed a blurred transparent halo with a diameter-to-colony diameter ratio of 0.89 suggesting weak ester-producing ability (Table 2).

Tolerance experiment result analysis

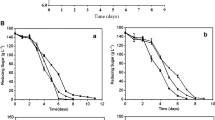

Analysis of the yeast SO2 tolerance experiments revealed that the addition of SO2 during sunshine rose wine production and brewing effectively suppressed detrimental substances in grape juice, thereby ensuring normal fermentation through microbial control, antioxidant properties, and color preservation (Qin et al. 2022). As shown in Fig. 7A, when the mass concentration of SO2 is 0.1–0.25 g/L, strains Z-6, Z-11, and Z-25 can grow normally; when the mass concentration of SO2 is 0.3 g/L, strain Z-25 is significantly inhibited; from the experimental results, strain Z-25 has a poorer tolerance to SO2.

Analysis of the results from the yeast glucose tolerance experiment reveals that in the process of wine production, sugar serves as the energy source for Saccharomyces cerevisiae’s survival. However, high sugar concentrations inhibit yeast growth and hinder glucose metabolism, while elevated osmotic pressure leads to water loss in yeast cells and reduces their activity (Tian et al. 2018). Figure 7B shows that the growth of the strains was inhibited with further increase of glucose concentration, and their growth ability decreased accordingly. The strains grew best when the glucose addition was 200 g/L. It is worth noting that strain Z-58 showed consistent growth ability between 300 and 400 g/L, without a significant decline, indicating its tolerance to high glucose concentrations. In contrast, strains Z-6 and Z-25 were inhibited at 400 g/L glucose concentration, indicating their similarity in intolerance to high glucose concentrations.

Analysis of experimental results on ethanol tolerance in yeast reveals that non-Saccharomyces exhibits a certain level of tolerance to ethanol, thereby enhancing yeast survival probability and facilitating the release of additional enzymes or ester substances (Gao et al. 2022). Figure 7C demonstrates that at an ethanol concentration of 4%, all strains exhibit favorable growth status, with Z-58 displaying the highest growth rate second only to the commercial yeast SY. However, as the ethanol concentration increases, strain growth becomes progressively inhibited, indicating that high levels of ethanol content exert an inhibitory effect on yeast growth and reproduction.

Analysis of experimental results on yeast temperature tolerance reveals that fermentation temperature exerts a significant influence on yeast growth, proliferation, and the aroma profile of fruit wine (Gao et al. 2022). As depicted in Fig. 7D, all five strains exhibit robust growth within the range of 20–30 °C. Notably, strains Z-11, Z-25, and Z-58 demonstrate superior growth capacity at 30 °C compared to commercial yeast SY. Moreover, the yeast can still thrive at a high fermentation temperature of 30 °C, indicating its ability to withstand elevated temperatures. However, it exhibits severe growth inhibition at low temperatures (4 °C), suggesting limited tolerance toward cold conditions.

Molecular identification

The strains Z-6, Z-11, Z-25, and Z-58 were subjected to sequencing analysis. The obtained sequences along with the reference strains were utilized for constructing a phylogenetic tree as depicted in Fig. 8. BLAST algorithm was employed to search for matching reference strains. The sequenced strains and their corresponding reference strains are presented in Table 3. Upon examination of the table, it is evident that strain Z-6 shares a sequence identity of 100% with strain DDNa7, thereby being identified as Pichia kudriavzevii. Similarly, strain Z-11 exhibits a sequence identity of 99.84% with strain S2-6-Y10 and is also classified as Pichia kudriavzevii. Furthermore, strain Z-25 demonstrates a sequence identity of 99.64% with Strain 56 and falls under the category of Pichia kudriavzevii based on this similarity assessment. Finally, there exists a sequence identity of 99.64% between strain Z-58 and clone B22.19514840 which leads to its identification as Pichia kudriavzevii.

The yeast strain Pichia kudriavzevii has been isolated from various food sources, including fruits and traditional fermented beverages (Tolieng et al. 2018). This versatile microorganism exhibits the ability to produce phytases, as demonstrated by Qvirist et al. (2017). Moreover, it has shown promising probiotic potential according to Greppi et al. (2017). Notably, Pichia kudriavzevii is recognized as Generally Recognized As Safe (GRAS) by the FDA and was previously referred to as Issatchenkia orientalis; however, it is now also known as Candida glycerinogenes (Nieto-Sarabia et al. 2022). Furthermore, Pichia kudriavzevii plays a pivotal role in the fermentation process of apricot wine, exhibiting remarkable potential for enhancing the sensory attributes and overall quality of this beverage (Chen et al. 2023). The incorporation of Pichia kudriavzevii during the vinification process enhances the levels of terpenes, high alcohols, and esters, while reducing the concentrations of C6 compounds and fatty acids. Moreover, it significantly improves fruitiness, floral attributes, and overall taste performance (Zhu et al. 2022). Considering the innocuous nature of Pichia kudriavzevii strains and their potential significance in fruit wine fermentation, a subsequent investigation was conducted to assess the impact of four strains (Z-6, Z-11, Z-25, and Z-58) on the brewing process of fruit wine.

Conclusion

The high-yield β-glucosidase strains in the natural fermentation broth of Vitis labruscana Baily × Vitis vinifera L. were screened using WL medium and esculin screening medium. The strains were evaluated for their fermentation characteristics, H2S production capacity, ethanol production capacity, ester production capacity, and tolerance. Four strains (Z-6, Z-11, Z-25, and Z-58) with high-yield β-glucosidase activity and favorable fermentation performance were identified as Pichia kudriavzevii through molecular biology identification. Comprehensive analysis revealed that these strains (Z-6, Z-11, Z-25, and Z-58) exhibited excellent brewing characteristics and had the potential to enhance flavor complexity and regional characteristics of wine. They can be considered as promising strains with potential application value. Subsequently, non-alcoholic yeasts can be screened based on wine aroma composition analysis to further enhance the complexity of wine aroma. Additionally, investigating the interaction mechanism between Pichia kudriavzevii and mixed fermentation of brewing yeast could optimize the fermentation process of Vitis labruscana Baily × Vitis vinifera L., providing valuable insights for producing high-quality wine.

Data availability

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

References

Anfang N, Brajkovich M, Goddard MR (2009) Co-fermentation with Pichia kluyveri increases varietal thiol concentrations in Sauvignon Blanc. Aust J Grape Wine Res 15:1–8

Bian MH, Xu Q, Zhou YZ, Wang LX, Li R, Chen XK (2021) Screening and characterization of non-Saccharomyces for mulberry wine. China Brew 40:70–75

Cao Y, Cao WT, Wang XD, Yang WJ, Liu YM (2023) Screening, identification and characterization of thermotolerant yeast strains with high-yield of alcohol. Sci Technol Food Ind 59:83–89

Chen JH, Ma XC, Li T, Hu ZR, Deng KR, Tao YS (2018) Evaluating application potential of mixed fermentation with Pichia fermentans and Saccharomyces cerevisiae. J Food Sci Technol 36:26–34

Chen Y, Qi JL, Yang HY, Lei XM, Jiang J, Song YY, Qin Y, Liu YL (2023) Fungal dynamic during apricot wine spontaneous fermentation and aromatic characteristics of Pichia kudriavzevii for potential as starter. Food Chem: X 19:100862

Chen YW, Hong MN, Li J (2021) Screening Pichia and Hanseniaspora in ice wine and application in wine. Food Sci Technol 46:8–14

Gao PP, Zhu YT, Liu Y, Zhang XW, Liang LH, Kang WJ, Wang J (2022) Selection, identification and enzymatic property analysis of excellent native yeast strains with high acidic β-glucosidase productivity. Food Ferment Ind 48:30–36

Greppi A, Saubade F, Botta C, Humblot C, Guyot JP, Cocolin L (2017) Potential probiotic Pichia kudriavzevii strains and their ability to enhance folate content of traditional cereal-based African fermented food. Food Microbiol 62:169–177

Hu K, Qin Y, Tao YS, Zhu XL, Peng CT, Ullah N (2016) Potential of glycosidase from non-Saccharomyces isolates for enhancement of wine aroma. J Food Sci 81:M935–M943

Jia RN, Shan WX, Li YX, Zheng FY, Liu CF, Wang JJ, Niu CT, Li Q (2018) The isolation, screening and identification of yeasts for orange wine. Food Ferment Ind 44:122–127

Ji XA (2022) Isolation and identification of vineyard yeast from the east of Helan mountain of Ningxia and analysis their stress resistance. Huazhong Agric Univ, Hongshan

João DN, Ticiana F, Teresa L, Célia P, Ricardo FD (2021) Learning from 80 years of studies: a comprehensive catalogue of non-Saccharomyces yeasts associated with viticulture and winemaking. FEMS Yeast Res 21:foab017

Luo LQ, Lin HM, Jiao YZ, Ding YY, Zhang HD, Zhang F (2022) Effects of mixed-strain fermentation of non-Saccharomyces cerevisiae and Saccharomyces cerevisiae on wine aroma. China Brew 41:89–94

Li T, Chen JH, Ma DC, Wang XC, Tao YS (2017) Growth kinetics and esterase activities of selected Non-Saccharomyces yeast and Saccharomyces cerevisiae in the fermentation of model grape Juice. Food Sci 38:60–66

Liu PT, Xu DD, Xu YH, Duan CQ, Yan GL (2021) Fermentation characteristics of four indigenous non-Saccharomyces wine yeasts. Food Sci 42:86–93

Liu XZ, Huang YM, Yang XX, Kang M, Li YF (2023a) Identification and fermentation performance analysis of non-Saccharomyces yeast strain isolated from Pyrus sinkiangensis. China Brew 42:128–134

Liu XZ, Zhang YL, Zeng S, Li H, Zhang S, Huang MZ (2020) Analysis of the yeasts biodiversity and theirs oenological property from Shine Muscat. Food Res Dev 41:212–218

Liu YR, Wei WL, Su Y, Wu L, Tong LH, Zhang WX (2023b) Mixed culture fermentation optimization and characterization of mulberry wine. Food Res Dev 44:113–119

Lu Y, Huang D, Lee PR, Liu SQ (2016) Assessment of volatile and non-volatile compounds in durian wines fermented with four commercial non-Saccharomyces yeasts. J Sci Food Agric 96:1511–1521

Ma Y, Xie LM, Diao TW, Xiao XJ, Chen XJ, Yu KJ, Wei ZY, Xiong R (2023) Isolation, identification and brewing performance evaluation of local low-yielding hydrogen sulfide yeast. Food Sci Technol 48:10–17

Ma DC, You L, Li AH, Mu HL, Tao YS (2018) Rapid screen of wild yeast with high β-qlucosidase activity and evaluation of its glycosidasein winemaking. J Northwest A & F U 46:129–135

Ma DC, Yan X, Wang QQ, Zhang YA, Tao YS (2017) Performance of selected P. fermentans and its excellular enzyme in co-inoculation with S. cerevisiae for wine aroma enhancement. LWT Food Sci Technol 86:361–370

Mujdeci GN, Ozbas ZY (2021) Technological and enzymatic characterization of the yeasts isolated from natural fermentation media of Gemlik olives. J Appl Microbiol 131:801–818

Nieto-Sarabia VL, Ballinas-Cesatti CB, Melgar-Lalanne G, Cristiani-Urbina E, Morales-Barrera L (2022) Isolation, identification, and kinetic and thermodynamic characterization of a Pichia kudriavzevii yeast strain capable of fermentation. Food Bioprod Process 131:109–124

Qin LQ, Yin H, Cheng LJ, Gong Y, Ding Z, Li XT, Fan GS (2022) A yeast isolate with high yield of ethyl caproate: screening, identification and fermentation optimizatio. Food Ferment Ind 48:55–61

Qvirist L, Vorontsov E, Veide Vilg J, Andlid T (2017) Strain improvement of Pichia kudriavzevii TY13 for raised phytase production and reduced phosphate repression. Microb Biotechno 10:341–353

Ren XM, Yao HH, Yan HR, Zhu X, Yang XS (2022) Screening and identification of non-Saccharomyces yeast strains with high glycosidase production and changes in enzyme activities during their fermentation. Food Sci 43:198–206

Tanaka J, Kiyoshi K, Kadokura T, Suzuki KI, Nakayama S (2021) Elucidation of the enzyme involved in 2, 3, 5-triphenyl tetrazolium chloride (TTC) staining activity and the relationship between TTC staining activity and fermentation profiles in Saccharomyces cerevisiae. J Biosci Bioeng 131:396–404

Tian X, Xu YH, Li HL, Wang YH, Wang J, Wang Y, Wang KL (2018) Effects of Saccharomyces cerevisiae strains producing hydrogen sulfide on the quality of pinot noir dry red wine. Food Ferment Ind 44:115–124

Tolieng V, Kunthiphun S, Savarajara A, Tanasupawat S (2018) Diversity of yeasts and their ethanol production at high temperature. J Appl Pharm Sci 8:136–142

Wang CX, Yu JZ, Zhou WY, Xu YH (2023) Research progress on the application of non-Saccharomyces during wine fermentation. Chin Agric Sci 56:529–548

Wu J, He W, Wang JC, Yang YR, Lan CH, Liu SG, Wu XX, Lin F, Guo A, Yang T (2020) Fermentation characteristics and interaction of Saccharomyces cerevisiae and aroma-producing yeast. Food Ferment Ind 46:78–87

Wu YR (2022) Effect of non-Saccharomyces cerevisiae yeasts on wine aroma. Modern Food 28:39–42

Xiang LP, Fan BQ, Yang ZL, Wu Q, Yu YG (2021) Screening and identification of a strain of Saccharomyces cerevisiae and its characteristics. Food Mach 37:51–55

Xing JA, Yu QQ, Li FD, Suo R, Dang C, Wang J, Liu YQ (2023) Effect of mixed fermentation on aroma quality of syrah wine. Food Res Dev 44:76–82

Xu XY, Wan RQ, Ma YQ, Ma YQ, Ge ZK, Li T, Wang B, Shi XW (2021) Isolation and identification of non-Saccharomyces cerevisiae and key enzyme activity for ester production. China Brew 40:58–64

Xu XY, Wu HM, Wang XW, Li CY, Zhao RR, Wang B, Shi XW (2023) Isolation, identification and fermentation characteristics of enzymeproducing non-Saccharomyces cerevisiae from the epidermis of flat peach. China Food Addit 34:48–57

Zhang BQ, Tang C, Yang DQ, Liu H, Xue J, Duan C, Yan G (2022a) Effects of three indigenous non-Saccharomyces yeasts and their pairwise combinations in co-fermentation with Saccharomyces cerevisiae on volatile compounds of Petit Manseng wines. Food Chem 368:130807

Zhang EH, He P, Liu PP, Jian Y, Chen R, Xu YT, Lu YZ, Luo Z (2022b) Identification and aroma-producing characteristics of yeast strains isolated from tibet-grown Hippophaer hamnoides. Food Sci 43:207–215

Zhang WJ, Yang SN, Du S, Jiang J, Ye DQ, Liu YL (2020) Potential application of mixed starter cultures of indigenous Pichia kluyveri and Saccharomyces cerevisiae to wine aroma enhancement. Food Sci 41:84–90

Zheng HW, Lei L, Li ZY, Zhao XP, Zhang MZ, Li T, Huang HY, Li XJ, Wang CY (2020) Oenological screening for high-quality Chinese Saccharomyces cerevisiae strains. Food Ferment Ind 46:118–122

Zhao WX (2020) Construction of high-yield β-glucosidase engineered strain and research of the effect on ethanol production by Saccharomyces cerevisiae WXY12. Jilin Agric Univ, Jilin

Zhao XP, Wen YJ, Li ZY, Zheng HW, Huang HY, Li XJ (2022) Screening of Saccharomyces cerevisiae from orchards and fermentation mash in Wuhai inner Mongolia. Food Ferment Ind 46:178–183

Zhu WY, Zhang WX, Qin T, Liao J, Zhang XY (2022) Effects of Purified β-Glucosidases from Issatchenkia terricola, Pichia kudriavzevii, Metschnikowia pulcherrima on the flavor complexity and typicality of wines. J Fungi 8:1057

Funding

This work was supported by Special Basic Cooperative Research Programs of Yunnan Provincial Undergraduate Universities’ Association (Grant No. 202301BA070001-081), Yunnan Fundamental Research Projects (Grant No. 202301AU070012), Special Basic Cooperative Research Innovation Programs of Qujing Science and Technology Bureau & Qujing Normal University (Grant No. KJLH2022YB07, KJLH2023ZD06), and College student innovation and entrepreneurship project (Grant No. S202210684076).

Author information

Authors and Affiliations

Contributions

The experiments were designed and conducted by L.Z. Data analysis was performed by X.M.Z., Y.C.W., X.G., Q.F.X., W.L.L., Q.H.X., D.M.Z., L.Z., and J.C. The project was conceived and supervised by L.Z. The paper was written by J.C. and L.Z. with contributions from all authors, in accordance with the approval of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Ethical approval

No experiments involving human participants or animals were conducted by any of the authors in this study.

Additional information

Communicated by Yusuf Akhter.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, L., Zhang, X., Wang, Y. et al. Recovery and characterization of β-glucosidase-producing non-Saccharomyces yeasts from the fermentation broth of Vitis labruscana Baily × Vitis vinifera L. for investigation of their fermentation characteristics. Arch Microbiol 206, 174 (2024). https://doi.org/10.1007/s00203-024-03878-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00203-024-03878-9