Abstract

The present study approaches the capability of Cephalosporium strain NCIM 1251 to degrade pre-treated polystyrene films. Polystyrene was initially treated with UV for the introduction of oxygen molecules in pure polystyrene samples. UV treatment inserts aliphatic ketones functional group in polystyrene whereas it created C–C stretching after chemical treatment in UV-treated polystyrene as analyzed by Fourier-transform infrared spectroscopy (FTIR). The gravimetric study confirmed a decline in the weight of the pre-treated polystyrene by 20.62 ± 1.47% after 8 weeks of the incubation period. pH, total dissolved solids (TDS), and conductivity of mineral salt media were correlated with the extent of biodegradation. Treatment with UV and acid increased the thermal stability of pure polystyrene, whereas thermal stability decreased in pre-treated polystyrene after incubation with Cephalosporium strain NCIM 1251 as studied by Thermogravimetric analysis (TGA). Scanning Electron Microscopy (SEM) analysis observed revisions in the morphology and surface patterns in pre-treated polystyrene after inoculation with Cephalosporium strain NCIM 1251. The observed findings suggest that the Cephalosporium strain NCIM 1251 could be efficient for the decomposition of pre-treated polystyrene.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Accumulation of non-biodegradable plastics has become a serious problem to the environment over the past few decades. Every year, approximately 9.46 million tones of plastic waste are generated in India (Central Pollution control board 2017). Indiscriminate usage of plastics, rampant littering, and lack of effective waste disposal systems are the prime reasons for this plastic waste accumulation. Among the non-biodegradable plastics, polystyrene (PS) is extremely recalcitrant to biodegradation. Polystyrene is a high molecular weight thermoplastic synthesized through polymerization of styrene monomers (Guillet et al. 1974). Properties such as light weight, good thermal and electric insulation, chemical inertness, resistance to degradation, durability, ease of production, and inexpensive made polystyrene an extremely versatile material (Robertson 2013). Major applications of polystyrene include food packaging, packaging foams, electronic parts, laboratory ware, containers, and utensils for domestic use.

Further, polystyrene samples are used for disposable plates, cups, trays, packaging materials, food wrappers, and containers. The process of recovering and recycling this polystyrene waste is very tedious and also expensive (Ali and Ghaffar 2017). Moreover, recycled plastics are more recalcitrant to biodegradation than virgin plastics, due to the addition of several antioxidants, stabilizers and flame retardants while recycling (Central Pollution control board 2013). Land filling is also a futile method for treating polystyrene waste, because these materials persist under the soil for decades, without undergoing any significant degradation. Also, land filling makes the soil infertile. Incineration of polystyrene waste can be used as a last resort, as it solves the land pollution problem but on the other hand, it leads to more dreadful air pollution. Burning of polystyrene discharges several toxic gasses such as styrene, carbon monoxide, carbon dioxide that can endanger several plants and animal lives. Styrene and its derivatives can damage the liver, central nervous system, and can also cause neurological impairment (Mooney et al. 2006). Remediation of the increasing plastic waste, upholding environmental sustainability has become the greatest priority for researchers. Investigations show that the bioremediation can be a reliable method as it does not lead to any other environmental issues directly or indirectly, unlike the abovementioned methods (Gu 2003; Pathak and Navneet 2017). Apart from the environmental issues, degradation studies of polymers are also important in understanding the stability and integrity of the plastic products (Restrepo-florez et al. 2014).

In the process of bioremediation, microorganisms such as bacteria and fungi break down the plastic waste into simpler molecules and use them as a substrate for their growth and metabolism (Bhardwaj et al. 2013; Zheng et al. 2005). Polystyrene is degradable in the natural environment, but the process is extremely slow and arduous (Tian et al. 2017). Approximately, 0.5% degradation of polystyrene by mixed microbial consortium after a treatment period of 11 weeks was reported by Kaplan et al. (1979). Otake et al. (1995) reported negligible biodegradation in a polystyrene sheet when the sheets were buried under soil for 32 years. Properties such as high molecular weight, hydrophobicity, lack of bio susceptible groups, a complex macromolecular structure-made polystyrene recalcitrant to biodegradation (Schlemmer et al. 2009; Krueger et al. 2017). The process of biodegradation is initiated by the secretion of extracellular and intracellular enzymes, followed by colonization of the plastic surface by the microorganisms. But, in the case of polystyrene, the enzymes are not capable enough to degrade the large hydrophobic polymer chains and also the microbes are incapable of colonizing the surface due to the lack of necessary surface properties. Researchers found that the treatment methods such as UV irradiation and acid treatment are capable of modifying the surface and bulk characteristics of polystyrene. These treatment methods alter the molecular weight distribution, induce cross-linking of the polymer chains, cause bond scissions in the polymer matrix, introduce polar functional groups such as C=O, OH, NO2, etc. and also improve the adhesiveness, wettability, and hydrophilicity of the polymer surface (David et al. 1978; Onyiriuka 1993; Hace et al. 1996; Zhang et al. 2000). But the influence of these characteristic property changes on biodegradation of polystyrene was not investigated to date.

Investigations of Brown et al. (1974) showed that the Cephalosporium species (sp.) were capable of assimilating mixed plastic waste, including polystyrene for their metabolism. More Recently, Chaudhary and Vijayakumar (2020a) extensively analyzed the biodegradation of pure polystyrene by Cephalosporium strain NCIM 1251 and reported a weight loss of 2.17 + 0.16%. Biodegradation of UV-irradiated and acid-treated polystyrene in the presence of Cephalosporium strain NCIM 1251 is not reported elsewhere. In this present study, the synergistic effect of UV and nitric acid treatment on the degradation of polystyrene using Cephalosporium strain NCIM 1251 is studied. After these pre-treatments, the polystyrene films are incubated with Cephalosporium strain NCIM 1251 for 8 weeks and the extent of biodegradation was analyzed.

Materials and methods

Preparation of polystyrene films

In the present study, the polystyrene foam was first transformed into films, through the solvent casting method, to facilitate the experimental analyses at different phases of research. Polystyrene foams were dissolved in the benzene solvent and the mixture was transferred to a petri dish, where the mixture was allowed to dry at room temperature for 24 h. After 24 h of natural drying, the petri dish was kept in a vacuum oven at 70 °C for 8 h to ensure complete evaporation of the benzene solvent. After 8 h, a dry thin film of polystyrene was obtained.

Pre-treatments of polystyrene films

The synthesized polystyrene films were cut into 4 × 4 cm sized strips. These strips were washed with distilled water and disinfected with 99.9% ethanol and these films were left to dry in a vacuum oven. After drying, the polystyrene films were exposed to UV irradiation (15 W and 50 Hz) for 7 days in the laminar air-flow chamber. After UV treatment, these films were subjected to acid treatment, with a 69% nitric acid solution. The UV-treated polystyrene films were immersed in a beaker containing 69% nitric acid solution and left undisturbed for 7 days. After combined treatments, these films were washed with distilled water and ethanol and were kept in a vacuum oven for drying purposes.

Source of biodegrading culture

National Collection of Industrial Microorganism (NCIM), NCL, Pune, India provided the microbial culture of Cephalosporium strain NCIM 1251. The microbial culture was conserved regularly on potato dextrose agar (PDA) at a constant temperature of 28 °C and was kept at 4 °C.

In vitro biodegradation study

The Biodegradation of pre-treated Polystyrene was carried out in a laboratory-made mineral salt medium. The mineral salt medium was prepared by dissolving 0.001 gm FeSO4, 0.002 gm CaCl2.2H2O, 0.02 gm MgSO4.7H2O, 0.04 gm KH2PO4, 0.1 gm NaCl, 0.2 gm (NH4)2SO4, 0.5 gm K2HPO4 in one-liter water. 100 ml of this mineral salt medium is taken in a 250-ml conical flask and a pre-treated polymer film was immersed in it. After that, Cephalosporium strain NCIM 1251 were inoculated into the conical flask (positive control). Negative control was also made, which consists of only pre-treated polystyrene and mineral salt medium, for comparative study. Now the conical flasks were incubated in an incubator shaker at 28 °C at a rotating speed of 120 rpm for 8 weeks.

Analysis of biodegradation

Weight reduction measurement

The initial weights of pre-treated polystyrene samples were 0.1469, 0.1321, and 0.1452 g, respectively in each flask before the degradation study. After the degradation period of 8 weeks, the pre-treated polymer samples were weighed again. The variation in the weights of samples in both positive and negative controls was calculated using the Eq. (1).

where, PSi is the weight of pre-treated polystyrene sample before degradation, PSf is the weight of pre-treated polystyrene sample after the degradation period of 8 weeks.

Analysis of pH, TDS, conductivity

Variations in the properties such as pH, Total dissolved solids (TDS), and conductivity of the mineral salt medium during the incubation period were monitored carefully, to analyze the extent of the biodegradation process. The pH, TDS, and conductivity of the mineral salt medium were measured at a regular interval of degradation period. 10 ml of the mineral salt medium was taken from the conical flask and processed with the WENSER LMMP-30 apparatus to measure the pH, TDS, and conductivity. The results were measured in triplets with a standard deviation value.

Characterization of polystyrene films

Changes in several characteristic properties of the polystyrene samples were analyzed after each pre-treatment method. Structural modifications in the polymer chains, such as the introduction of functional groups, bond scissions, variations in chain length, the formation of new chemical bonds, were examined using Fourier transform infrared spectroscopy (FTIR). The FTIR analysis was performed using a Shimadzu FTIR-8400 apparatus in the frequency range of 400–4000 cm−1. The morphological changes were observed using Scanning Electron Microscopy (SEM, ZEISS, EVO 18). Thermogravimetric analysis (TGA) was used to study the variations in the thermal stability of the polystyrene samples by using Shimadzu, TGA—50 apparatus.

Results and discussion

Weight loss measurement

The most basic method to determine the degradation of polymers is weight loss measurement. Microorganisms begin the process of degradation by adhering to the surface of polymers. Subsequently, they secrete different types of acids, proteins, and enzymes that disturb the molecular arrangement in the polymers, which causes the break down of polymer chains and ultimately gives rise to weight depletion. A weight depletion of 20.62 ± 1.47% was evaluated when pre-treated polystyrene samples were kept under the exposure of Cephalosporium strain NCIM 1251 for 8 weeks. Chaudhary and Vijayakumar (2020a) reported a weight loss of 2.17 ± 0.16% for pure polystyrene films when samples were treated with Cephalosporium strain NCIM 1251. Thus, the synergistic effect of UV and acid helped to increase the degradation of polystyrene samples. The weight loss of pre-treated polymer samples interprets the drop in the carbon content through the consumption of polymer samples by the microorganisms (Chaudhary and Vijayakumar 2020b). There was no weight loss observed in the polymer samples when the degradation study was carried out in the absence of microorganisms. Consumption of polymer samples in the form of carbon by the microorganisms reveals the usage of polymer samples to perform their metabolic exercises. Similar results based on weight loss measurements had been reported by Ali and Ghaffar (2017), and Syranidou et al. (2017).

Measurement of pH, TDS, and conductivity of mineral salt media

The alterations in the values of pH, TDS, and conductivity of mineral salt media due to the presence of microorganisms are shown in Table 1. Change in pH value alters the metabolic activity of microorganisms because the cell numbers increase in favorable pH conditions. Initially, the value of pH is 7.01 ± 0.01, which decreases to 5.13 ± 0.07 and 3.75 ± 0.09 in pre-treated polystyrene sample after an incubation period of 4 and 8 weeks respectively in the presence of Cephalosporium strain NCIM 1251. The microbial degradation of pre-treated polystyrene decreased the pH of mineral salt media toward acidity. The alterations in pH confirmed that the microorganisms secreted acids and enzymes during the degradation period (Gu 2003). Awasthi et al. (2017) reported similar observations where the value of pH decreases in the presence of microorganisms. Cephalosporium species is highly active in the pH range of 3.0–8.5 in the presence of mineral salt media (Kita and Heights 1957; Stasinopoulos and Seviour 1989). The initial value of TDS is 0.575 ± 0.024 ppm and the value increased to 12.33 ± 0.72 ppm and 26.53 ± 0.15 ppm when pre-treated polystyrene was exposed to the microorganisms for a period of 4 and 8 weeks, respectively. This increase in the value of TDS is due to the secretions of acids, bio-surfactant, and enzymes from the microorganisms (Gu 2003; Mukherjee et al. 2016). Similar to TDS, the conductivity of nutrient media also increases, as shown in Table 1 after degradation of pre-treated polystyrene. Cassidy et al. (2001) had observed similar increase in the TDS and conductivity values after inoculation with microorganisms. There were no significant variations in pH, TDS, and conductivity of mineral salt media observed when the degradation study was carried out in the negative control (Table 1). All these variations in pH, TDS, and conductivity of the mineral salt medium confirm the ability of Cephalosporium strain NCIM 1251 to degrade pre-treated polystyrene.

Fourier transform infrared spectroscopy (FTIR)

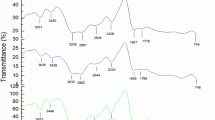

The major characteristic peaks at 3026, 2920, 2850, 1598, 1492, and 752 wavenumbers are seen in the pure polystyrene samples (Fig. 1a). The peaks at 3026 and 1598 cm−1 represent aromatic C–H stretching and C=C vinyl group, respectively. Characteristics peaks at 2920 and 2850 cm−1 are related to CH2 asymmetric stretching and CH2 symmetric stretching respectively. The peak at 1492 cm−1 is due to deformational vibrations of benzene ring whereas the peak at 752 cm−1 suggests deformational vibrations of substituted benzene derivative (Ali and Ghaffar 2017; Pushpadass et al. 2010; Nikolic et al. 2014; Sarmiento et al. 2016; Chaudhary and Vijayakumar 2020c). Formation of an intense sharp peak at 1716 cm−1 appeared after UV treatment which corresponds to aliphatic ketones (Fig. 1b). The formation of this peak suggests the introduction of oxygen molecules into the polystyrene matrix (Bui et al. 2015). A similar peak at 1720 cm−1 was observed by Davidson et al. (2005) after UV-ozone treatment. This functional group was introduced by the reaction of polystyrene samples with continuous UV bombardment that increases the hydrophilicity of the polystyrene (Yusilawati et al. 2011). Further, the intensity of peak at 3741 cm−1 increased after UV treatment. The synergistic effect of UV and acid treatment resulted in the formation of new peaks at 3608 cm−1 and 1647 cm−1 in the pre-treated polystyrene sample (Fig. 1c). Peaks at 3608 cm−1 and 1647 cm−1 mark the presence of O–H stretching and C–C stretching respectively (Umamaheswari and Margandan 2013; Margandan and Umamaheswari 2019). The acid treatment has also resulted in the disappearance of a sharp peak at 1716 cm−1. Peaks at 1346 cm−1 and 3323 cm−1 are identified in pre-treated polystyrene samples after the exposure of Cephalosporium strain NCIM 1251 for 8 weeks (Fig. 1d). Peaks at 1346 cm−1 and 3323 cm−1 correspond to symmetric stretching of aromatic NO of nitro groups and O–H bond stretching of hydroxyls, respectively (Hace et al. 1996; Page et al. 1998; Arifin et al. 2016). Formation of new peaks after treatment with microorganisms suggests the utilization of the pre-treated polystyrene samples by the Cephalosporium strain NCIM 1251.

Thermogravimetric analysis (TGA)—derivative thermogravimetry (DTG)

The reduction in the weight of polystyrene in the temperature range of 215–450 °C is related to the backbone thermal decomposition of polystyrene samples (Ali and Ghaffar 2017). Absolute degradation of the polystyrene samples was observed between 450 and 600 °C (Fig. 2). Similar observations were reported by Zhao et al. (2018) for the degradation of polystyrene samples. TGA analysis revealed a weight reduction of 95% at 419 °C for polystyrene samples. The onset of decomposition temperature increased to 433 °C for UV-treated polystyrene samples. The increase in the decomposition temperature retards the process of depropagation and unzipping in the polymers (Li et al. 2009). Further, the rise in the onset of decomposition temperature up to 435 °C is observed after nitric acid treatment for UV-treated polystyrene samples. TGA analysis interprets the deviation of decomposition temperature of polystyrene to the higher side after treatment with UV and chemical. This result suggests an increase in the stability of polystyrene samples after exposure to UV and chemical. Formation of a highly thermal stable polymer demonstrated as a consequence of several chain scissions and cleavages along with rearrangements in chemical bonds in the polymer. The onset of decomposition temperature reduced to 424 °C for pre-treated polystyrene samples after exposure to microorganisms. This decrease in decomposition temperature suggests a reduction in the thermal stability of pre-treated polystyrene samples. A decrease in thermal stability reveals the modifications in polymer chain length, molecular weight, and crystallinity (Sudhakar et al. 2008). Jeyakumar et al. (2013) showed identical remarks for polypropylenes samples after fungal treatment. Thus, the decrease in thermal stability verified the consumption of pre-treated PS samples by Cephalosporium strain NCIM 1251.

Derivative Thermogravimetry (DTG) graph displays a sharp peak at 376.46 °C for virgin polystyrene samples (Fig. 3). DTG graph for the polystyrene samples shifted to 403.68 °C and 404.64 °C after UV and acid treatment. Further, the temperature reduced to 383.85 °C after 8 weeks of exposure with Cephalosporium strain NCIM 1251. This decrease in temperature interpreted as a decrease in thermal stability due to the combined UV, acid, and microbial treatment. The secretion of enzymes by the microorganisms causes cleavage of bonds which resulted in the drop of thermal stability of the pre-treated polystyrene sample. A similar decrease in the thermal stability in low-density polyethylene (LDPE) samples after exposure to microorganisms was reported by Soni et al. (2009).

Scanning electron microscopy (SEM)

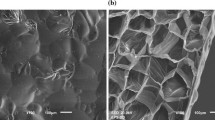

Polystyrene films have a clear, homogeneous, and continuous surface as detected by SEM (Fig. 4a). The clear and smooth surface of the polystyrene films indicates the complete evaporation of the organic solvent used during the solvent casting process (Dhanaraju et al. 2010). Several modifications in the morphology of the polystyrene films were observed after UV and chemical treatment. Exposure to UV irradiation had completely modified the surface texture of the polystyrene films. The smooth and continuous polystyrene film surface was transformed into a rugged and crumbled surface after subjecting to UV irradiation (Fig. 4b). Similar surface modifications were reported by Yusilawati et al. (2011) after UV-ozone treatment of polystyrene. Several micro-cracks, protrusions, and holes also developed on the polymer surface. UV treatment causes bond scissions, generates free radicals, fragments the polymer chains, and introduces polar functional groups which ultimately led to the formation of these surface irregularities (Teare et al. 2001). Further, on subjecting to nitric acid treatment, these micro-cracks developed into large cracks and grooves, suggesting more degradation due to the combined effect of UV and chemical treatment (Fig. 4c). An increase in the surface ruggedness, size, and the number of holes was also observed after the chemical treatment. Treatment of pre-treated polystyrene with Cephalosporium strain NCIM 1251 showed the formation of deeper cavities, holes, cracks, pits, and grooves, suggesting the capability of Cephalosporium strain NCIM 1251 to consume pre-treated polystyrene, in the form of carbon, for their proper functioning of metabolic activities (Fig. 4d, e). The hollow cavities and craters formed at few locations on the surface indicate the penetration of the fungal hyphae and colonization of the polymer surface. The ruptured and eroded polymer surface further depicts the assimilation of polystyrene samples by the microorganisms. Similar kind of changes in the texture of polystyrene samples was analyzed when treated with microbial cultures (Syranidou et al. 2017; Sekhar et al. 2016). Thus, the findings confirmed the ability of Cephalosporium strain NCIM 1251 to consume pre-treated polystyrene samples.

Conclusion

The present study discussed the synergistic effect of UV and chemical treatment on polystyrene and decomposition of pre-treated polystyrene in the microbial environment for 8 weeks, which helped to enhance the decomposition rate of the polystyrene. Based on weight loss analysis, a maximum of 20.62 ± 1.47% loss in weight was obtained. Higher decomposition was achieved after the combined effect of UV and chemical treatment on polystyrene. The decomposition of pre-treated polystyrene films by the Cephalosporium strain NCIM 1251 is also interpreted in terms of pH, TDS, and conductivity of mineral salt media. Appearances of nitro and hydroxyl groups after treatment with Cephalosporium strain NCIM 1251 were analyzed by FTIR. Microbial treatment decreased the thermal stability of the pre-treated polystyrene was studied by TGA. SEM analysis showed alterations in the morphology of pre-treated polystyrene. Thus, the synergistic effects of UV, chemical, and microorganisms may be helpful to eliminate the polystyrene wastes piled up in the environment.

References

Ali HE, Ghaffar AMA (2017) Preparation and effect of gamma radiation on the properties and biodegradability of poly (Styrene/Starch) blends. Radiat Phys Chem 130:411–420

Arifin MA, Mel M, Samsudin N et al (2016) Ultraviolet/ozone treated polystyrene microcarriers for animal cell culture. J Chem Technol Biotechnol 91:2607–2619

Assessment & Quantification of Plastics Waste Generation in Major Cities (2017) A report by Central pollution control board (CPCB), India

Awasthi S, Srivastava N, Singh T et al (2017) Biodegradation of thermally treated low density polyethylene by fungus Rhizopus oryzae NS 5. 3 Biotech 7:73

Bhardwaj H, Gupta R, Tiwari A (2013) Communities of Microbial Enzymes Associated with Biodegradation of Plastics. J Polym Environ 21:575–579

Brown BS, Millls J, Hulse JM (1974) Chemical and biological degradation of waste plastics. Nature 250:161–163

Bui VT, Lee HS, Choi JH, Choi HS (2015) Data from crosslinked PS honeycomb thin film by deep UV irradiation. Data Br 5:990–994

Cassidy DP, Werkema DD, Sauck WA et al (2001) The effects of LNAPL biodegradation products on electrical conductivity measurements. J Environ Eng Geophys 6:47–52

Chaudhary AK, Vijayakumar RP (2020a) Studies on biological degradation of polystyrene by pure fungal cultures. Environ Dev Sustain 22:4495–4508

Chaudhary AK, Vijayakumar RP (2020b) Effect of chemical treatment on biological degradation of high-density polyethylene (HDPE). Environ Dev Sustain 22:1093–1104

Chaudhary AK, Vijayakumar RP (2020c) Synthesis of polystyrene / starch / CNT composite and study on its biodegradability. J Polym Res 27:187

David C, Baeyens-Volant D, Delaunois G et al (1978) Photo-oxidation of polymers-III. Molecular weight changes in the photolysis and photo-oxidation of polystyrene. Eur Polym J 14:501–507

Davidson MR, Mitchell SA, Bradley RH (2005) Surface studies of low molecular weight photolysis products from UV-ozone oxidised polystyrene. Surf Sci 581:169–177

Dhanaraju MD, Sathyamoorthy N, Sundar VD, Suresh C (2010) Preparation of poly (epsilon-caprolactone) microspheres containing etoposide by solvent evaporation method. Asian J Pharm Sci 5:114–122

Gu JD (2003) Microbiological deterioration and degradation of synthetic polymeric materials: recent research advances. Int Biodeterior Biodegrad 52:69–91

Guillet JE, Regulski TW, McAneney TB (1974) Biodegradability of photodegraded polymers. II. Tracer studies of biooxidation of ecolyte PS polystyrene. Environ Sci Technol 8:923–925

Hace D, Kovacevic V, Pajc-Liplin D (1996) Thermally stimulated oxidative degradation of high impact polystyrene with nitric acid. Polym Eng Sci 36:1140–1151

Jeyakumar D, Chirsteen J, Doble M (2013) Synergistic effects of pretreatment and blending on fungi mediated biodegradation of polypropylenes. Bioresour Technol 148:78–85

Kaplan DL, Hartenstein R, Sutter J (1979) Biodegradation of polystyrene, poly(methyl methacrylate), and phenol formaldehyde. Appl Environ Microbiol 38:551–553

Kita DA, Heights J (1957) Production of glutamic actd by Cephalosporium. US Pat no-2789939 2–3

Krueger MC, Seiwert B, Prager A et al (2017) Degradation of polystyrene and selected analogues by biological Fenton chemistry approaches: opportunities and limitations. Chemosphere 173:520–528

Li L, Zhong Y, Li J et al (2009) Thermally stable and solvent resistant honeycomb structured polystyrene films via photochemical cross-linking. J Mater Chem 19:7222–7227

Margandan M, Umamaheswari S (2019) Potential of soil microbes in degrading polystyrene foam. Int J Adv Sci Res Manag 4:109–117

Mooney A, Ward PG, Connor KEO (2006) Microbial degradation of styrene : biochemistry, molecular genetics, and perspectives for biotechnological applications. Appl Microbiol Biotechnol 72:1–10

Mukherjee S, Roy Chowdhuri U, Kundu PP (2016) Bio-degradation of polyethylene waste by simultaneous use of two bacteria: Bacillus licheniformis for production of bio-surfactant and Lysinibacillus fusiformis for bio-degradation. RSC Adv 6:2982–2992

Nikolic V, Velickovic S, Popovic A (2014) Biodegradation of polystyrene-graft-starch copolymers in three different types of soil. Environ Sci Pollut Res 21:9877–9886

Onyiriuka EC (1993) The effects of high-energy radiation on the surface chemistry of polystyrene: a mechanistic study. J Appl Polym Sci 47:2187–2194

Otake Y, Kobayashi T, Asabe H et al (1995) Biodegradation of low-density polyethylene, polystyrene, polyvinyl chloride, and urea formaldehyde resin buried under soil for over 32 years. J Appl Polym Sci 56:1789–1796

Overview of Plastic Waste Management (2013) A report by Central pollution control board (CPCB), India

Page JD, Derango R, Huang AE (1998) Chemical modification of polystyrene’s surface and its effect on immobilized antibodies. Colloids Surfaces A Physicochem Eng Asp 132:193–201

Pathak VM, Navneet (2017) Review on the current status of polymer degradation: a microbial approach. Bioresour Bioprocess 4:1–31

Pushpadass HA, Weber RW, Dumais JJ, Hanna MA (2010) Biodegradation characteristics of starch-polystyrene loose-fill foams in a composting medium. Bioresour Technol 101:7258–7264

Restrepo-florez J, Bassi A, Thompson MR (2014) Microbial degradation and deterioration of polyethylene—a review. Int Biodeterior Biodegradation 88:83–90

Robertson GL (2013) Food Packaging: Principles and Practice. Taylor & Francis Group, Abingdon

Sarmiento AM, Guzmán HL, Morales G et al (2016) Expanded polystyrene (EPS) and waste cooking oil (WCO): from urban wastes to potential material of construction. Waste Biomass Valoriz 7:1245–1254

Schlemmer D, Sales MJA, Resck IS (2009) Degradation of different polystyrene/thermoplastic starch blends buried in soil. Carbohydr Polym 75:58–62

Sekhar VC, Nampoothiri KM, Mohan AJ et al (2016) Microbial degradation of high impact polystyrene (HIPS), an e-plastic with decabromodiphenyl oxide and antimony trioxide. J Hazard Mater 318:347–354

Soni R, Kapri A, Zaidi MGH, Goel R (2009) Comparative biodegradation studies of non-poronized and poronized LDPE using indigenous microbial consortium. J Polym Environ 17:233–239

Stasinopoulos SJ, Seviour RJ (1989) Exopolysaccharide formation by isolates of Cephalosporium and Acremonium. Mycol Res 92:55–60

Sudhakar M, Doble M, Murthy PS, Venkatesan R (2008) Marine microbe-mediated biodegradation of low- and high-density polyethylenes. Int Biodeterior Biodegradation 61(3):203–213

Syranidou E, Karkanorachaki K, Amorotti F et al (2017) Biodegradation of weathered polystyrene films in seawater microcosms. Sci Rep 7:1–12

Teare DOH, Emmison N, Ton-That C, Bradley RH (2001) Effects of serum on the kinetics of CHO attachment to ultraviolet-ozone modified polystyrene surfaces. J Colloid Interface Sci 234:84–89

Tian L, Kolvenbach B, Corvini N et al (2017) Mineralisation of 14C-labelled polystyrene plastics by Penicillium variabile after ozonation pre-treatment. N Biotechnol 38:101–105

Umamaheswari S, Margandan MM (2013) FTIR spectroscopic study of fungal degradation of poly(ethylene terephthalate) and polystyrene foam. Elixir Chem Eng 64:19159–19164

Yusilawati AN, Maizirwan M, Sopyan I et al (2011) Surface modification of polystyrene beads by UV/Ozone treatment. Adv Mater Res 264–265:1532–1537

Zhang D, Dougal SM, Yeganeh MS (2000) Effects of UV irradiation and plasma treatment on a polystyrene surface studied by IR-visible sum frequency generation spectroscopy. Langmuir 16:4528–4532

Zhao H, Nam PK, Richards VL, Lekakh SN (2018) Thermal decomposition studies of eps foam, polyurethane foam, and epoxy resin (SLA) as patterns for investment casting; analysis of hydrogen cyanide (hcn) from thermal degradation of polyurethane foam. Int J Metalcast. https://doi.org/10.1007/s40962-018-0240-5

Zheng Y, Yanful EK, Bassi AS (2005) A review of plastic waste biodegradation. Crit Rev Biotechnol 25:243–250

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Erko Stackebrandt.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaudhary, A.K., Chaitanya, K. & Vijayakumar, R.P. Synergistic effect of UV and chemical treatment on biological degradation of Polystyrene by Cephalosporium strain NCIM 1251. Arch Microbiol 203, 2183–2191 (2021). https://doi.org/10.1007/s00203-021-02228-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00203-021-02228-3