Abstract

In the transition from Industry 4.0 to Industry 5.0, the integration of human-centric considerations into manufacturing processes becomes vital. This study advances beyond conventional Industry 4.0 frameworks by introducing a novel fatigue model that emphasizes ergonomic risk management during the design phase of robotic assembly lines. Utilizing a hybrid model that employs a fuzzy inference system based on ergonomist knowledge, this fuzzy approach manages the imprecise nature of ergonomic optimization more accurately than deterministic models and effectively reflects real-world complexities. By evaluating fatigue at both task and worker levels, this fuzzy inference mechanism addresses technical aspects through feasibility studies and significantly improves ergonomic outcomes. The integration of supportive robots is explored through scenario-based analysis, highlighting productivity enhancements and substantial ergonomic benefits in line with Industry 5.0’s focus on enhancing worker well-being and operational resilience. The proposed heuristic algorithm enables decision-makers to identify the most efficient solutions tailored to individual preferences, showcasing flexibility and real-world applicability. Empirical validation, enriched with synthesized ergonomic-oriented instances, confirms the superiority of this approach in creating more sustainable and ergonomically optimized assembly lines. Implementing this approach is predicted to decrease system costs by up to 47%, particularly advantageous during human resources crises, by reducing ergonomic risk, recovery needs, and additional capacity requirements for fatigue mitigation. This study contributes to the discourse on the practical implications of Industry 5.0 and demonstrates its applicability in designing ergonomically optimized assembly lines that prioritize long-term productivity and worker satisfaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Assembly lines (ALs) are essential components of most production systems, responsible for producing vast quantities of both general and customized products. They play a critical role in manufacturing by enhancing productivity and efficiency. The primary objective of planning ALs is to optimize these factors through assembly line balancing problems (ALBPs), which aim to distribute tasks evenly across workstations to avoid bottlenecks and overloading, thereby maximizing productivity and minimizing operational costs. However, as the final stage in production and the closest link to the market, ALs are particularly vulnerable to market fluctuations and evolving customer demands. These factors introduce uncertainty, necessitating adaptable production systems. While manual tasks within ALs can improve flexibility, they also introduce ergonomic and productivity risks [1].

Traditional ALBPs often neglect the ergonomic risks linked to prolonged and repetitive tasks, which can lead to increased rates of musculoskeletal disorders (MSDs), errors, and absenteeism, ultimately decreasing productivity. To address this, ergonomic assembly line balancing problems (Ergo-ALBPs) have been developed, integrating human factors and ergonomics (HFE) into the optimization process to consider both operational efficiency and ergonomic well-being. Although failure to address ergonomic aspects during the design phase can lead to costly corrective actions in the future [2], only a limited number of studies have considered ergonomic aspects in the design phase of these optimization problems, referred to as ergonomic assembly line design problems (Ergo-ALDPs) [1]. These problems represent strategic planning that can prevent future costs associated with redesigning and implementing corrective measures to resolve ergonomics issues.

Optimization problems in the design phase encompass vague and imprecise aspects, such as future demand rates and diverse worker characteristics, which can affect desired takt times and ergonomic risk levels. Thus, the design optimization model should address these uncertain conditions to find more robust and applicable solutions. Workload calculation in conventional ALBPs relies on station times, assuming workers at stations with equal operation times encounter identical workloads. However, even tasks with equivalent operation times may require different levels of effort, resulting in diverse degrees of fatigue among workers [3]. This can lead to muscle fatigue and MSDs, raising significant concerns. Among the limited studies in Ergo-ALBPs, many used semi-quantitative ergonomics assessment tools (EATs) to evaluate posture risk factors. Therefore, integrating fatigue and recovery models into these optimization problems is crucial to improve operator well-being and efficiency. Selecting and customizing a suitable fatigue/recovery model for use in the design phase under uncertainty is a critical challenge in this research.

This study contributes to the literature on Ergo-ALBPs by introducing several novel contributions. Firstly, it integrates a novel fatigue model into the design optimization process, effectively managing uncertainties related to ergonomic fatigue risks and their associated costs. Unlike existing deterministic models, this approach employs fuzzy logic to interpret and evaluate potential fatigue levels, thereby minimizing ergonomic risks across the assembly line with predetermined cycle times and a fixed number of workstations (feasibility study). Additionally, the proposed model uniquely accounts for muscular fatigue and evaluates fatigue rates under uncertain conditions, leveraging the expertise of ergonomists through a fuzzy inference system (FIS). This facilitates decision-makers in identifying the most desirable solutions at both task and worker levels [4].

Furthermore, this study addresses the challenge of incorporating recovery time into AL planning. To mitigate fatigue levels, it is crucial to integrate sufficient recovery time into the planning process, ensuring the final cycle time (CT) accounts for both operation time and necessary recovery periods while aligning with the defined takt time (the rate at which demand is received). Additional capacity may be introduced by incorporating extra working shifts or adding workstations, but these options require increased human resources. Given the global worker shortage, alternative strategies are essential. One viable approach is the integration of supportive robots, which can alleviate fatigue in specific areas of the body and offer a promising solution to workforce limitations. This study considers the application of supportive robots, specifically supernumerary robotic limbs (SRLs), to assist workers in performing complex and fatigue-prone tasks, thereby improving productivity and efficiency [5]. Despite the benefits of SRLs, such as productivity enhancement, physical strain reduction, and safety improvements, their cost compared to traditional options remains a challenge. Therefore, this study considers different scenarios to compare the investment levels required for each solution, helping decision-makers to find the best option through a managerial dashboard.

Lastly, the optimization procedure in this study presents a hybrid modeling approach that combines the feasibility study of balancing problems with a FIS, developing a heuristic solution method to minimize both the system’s fatigue level and the over-cost of the AL. This hybrid optimization model evaluates several future scenarios, providing decision-makers with sufficient information to make the best choices based on operational and ergonomic aspects during the design phase.

The novelties of this work lie in the integration of fuzzy logic to manage uncertainty and vagueness in modeling complex systems where precise mathematical relationships are unavailable. These contributions collectively advance the field by providing a comprehensive framework for ergonomic risk management in robotic assembly line design. This study is among the first to integrate fuzzy logic theory and supportive robots into Ergo-ALDPs, providing a novel framework for designing ALs that can cope with uncertainty, variability, and human factors. The proposed solution method is validated and verified by applying it to benchmark problem samples from the SALBP dataset [6]. Although these instances are not originally ergonomic-oriented, 60 numerical instances are synthesized based on the original samples to test the efficacy of the solution method.

This manuscript is organized as follows: Section 2 reviews the literature on Ergo-ALBPs, focusing on studies incorporating fatigue and recovery methods. Section 3 introduces the optimization model and the new fuzzy fatigue model. Section 4 details a hybrid heuristic method designed to solve the problem. Section 5 outlines the implementation of the proposed solution algorithm on numerical samples, and Section 6 discusses the research findings. Finally, Section 7 presents the concluding remarks and potential avenues for future research.

2 Literature review

The inception of Ford’s automobile production facilities in the early twentieth century marked a pivotal moment in applying ALs within mass production. Since then, this cornerstone of both mass and lean production systems has undergone significant evolution, transitioning into a more flexible and adaptive system. The optimization of ALs has been a focal point of scholarly research, aiming to balance processes and eliminate inefficiencies hindering their smooth operation. Since ALs represent the terminal phase of most production systems and are proximal to the final market, they are inherently sensitive to market fluctuations, which can critically impact their performance [7]. Consequently, optimizing ALs presents a complex and multifaceted challenge that has been the subject of numerous studies. The subsequent subsections provide a comprehensive review of the literature related to the principal dimensions of these optimization problems.

2.1 Assembly line balancing problems (ALBPs)

The optimization of ALs primarily aims to address imbalances that can lead to bottlenecks, reducing efficiency and negatively impacting key performance metrics. Balancing these lines enhances performance by maximizing productivity and efficiency [4]. The concept of ALBPs traces back to Salveson’s work in 1955 [8]. Although a solution method was proposed in 1961 [9], trial-and-error methodologies dominated the resolution of ALBPs for many subsequent years.

ALBPs are recognized as NP-hard combinatorial optimization problems (COPs), involving identifying the optimal solution from a finite set of possible configurations known as feasible solutions (FSs). There are two primary classifications of ALBPs: simple (SALBP) and general (GALBP) problems.

SALBPs refer to single-sided linear ALs with fixed operation times and usually target the optimization of one or two objectives. They are further categorized into four types: Type 1 focuses on minimizing the number of workstations for a predetermined CT; Type 2 aims to minimize the cycle time with a fixed number of workstations; Type F evaluates the feasibility of a given combination of workstations and CT; and Type E endeavors to minimize both CT and the number of workstations simultaneously.

On the other hand, GALBPs address more complex configurations, including mixed-model product types (MMALBP), parallel ALs (PALBPs), and U-shaped lines (UALBPs), presenting a broader array of challenges [1].

2.2 Ergonomics considerations in assembly lines

Ergonomic considerations are critical in ALBPs due to the high risk of MSDs that workers may develop from repetitive and prolonged assembly activities. Integrating HFE with operational parameters is vital not only for enhancing the efficiency of ALs but also for reducing and preventing potential ergonomic risks. The influential work of Gunther et al. [10] initiated the integration of ergonomic risks into ALBPs. However, significant progress in this area was relatively modest until the pivotal study by Otto and Scholl [11], which incorporated an ergonomic objective into the optimization model of ALBPs, thereby triggering further research into Ergo-ALBPs. Despite extensive studies on various ALBPs, the research on Ergo-ALBPs—especially during the design phase, known as Ergo-ALDPs—remains comparatively limited [4].

Several EATs have been applied to evaluate ergonomic risks associated with ALBPs [1]. Most EATs, such as the Occupational Repetitive Action (OCRA), the Rapid Upper Limb Assessment (RULA), and the Rapid Entire Body Assessment (REBA), produce an index applied as an interval scale to rate ergonomic risks on a scale ranging from low to high. While each tool offers a distinct approach to risk assessment, there is no consensus on a universally preferred tool for all contexts [12].

2.3 Fatigue models in balancing problems

In the manufacturing realm, ergonomic risks include physical, cognitive, and psychosocial factors. Physical tasks involving dynamic or static muscle efforts can lead to fatigue and pain, potentially resulting in MSDs if not managed effectively. Ergonomists try to identify these risks and develop strategies to mitigate them in the workplace [13]. For example, prolonged static muscle exertion may lead to work-related MSDs, and a common mitigation strategy is to introduce recovery breaks to alleviate muscle fatigue. Fatigue is categorized as localized, affecting specific muscle groups, or generalized, affecting the entire body. Generalized fatigue is often measured by energy expenditure (EE) or metabolic rate (MR), particularly in activities engaging a significant portion of muscle mass (approximately 70% or more). Localized muscle fatigue, on the other hand, is evaluated using methods like electromyography (EMG), blood lactate concentration, or the Borg scales, adapted for different body parts such as the shoulder, arm, or back.

Ghorbani et al. [1] found in their review that 35% of studies on Ergo-ALBP from 2011 to 2022 incorporated fatigue considerations into their models. Table 1 presents a summary of these studies, along with recent research in this area, demonstrating that a limited number of fatigue assessment methods have been applied to ALBPs. Typical EATs for fatigue evaluation include:

-

1.

Price [14]: Rohmert [15] pioneered the development of models assessing rest allowance (RA) as the time required for adequate rest following static or dynamic exertion. Building upon Rohmert’s work, Price [14] formulated a model to calculate RA concerning the maximum acceptable energy expenditure (MAEE), presumed to be 4.3 kcal/min.

-

2.

Garg et al. [16]: The Garg model estimates the total average metabolic consumption in a manual handling task by summing EE for activities and posture maintenance, averaged over the job’s duration. This assumes tasks can be broken down into simpler activities, each with a calculable metabolic cost and affected by factors such as gender, body weight, load weight, lifting/lowering heights, lateral arm movements, walking speed with load, postures, and job duration.

-

3.

Borg Scale(s) [17]: The Borg scales offer a psychophysical method to gauge perceived exertion during physical activities, providing a subjective evaluation of how workers feel while performing tasks.

-

4.

Ma et al. [18, 19]: The model introduced by this research group presents a new, straightforward dynamic muscle fatigue model that offers a quantitative analytical method for assessing muscular fatigue and required recovery of assembly workers.

-

5.

PMES: Battini et al. [20] developed a technique known as the predetermined motion energy system (PMES), which builds on the EE formulations by Garg et al. [16]. It includes tables for the rapid estimation of task-related EE, similar to traditional predetermined time motion systems (PTMS).

2.4 Ergonomic assessment in the design of assembly lines

Neglecting ergonomic aspects during the design stages of ALs can lead to a spectrum of long-term issues, ranging from health-related absenteeism to irreversible disabilities. Corrective measures implemented post-design can cost significantly more—up to 9.2 times—than preventive actions taken during the design stage [2]. While research on optimizing ALs by considering HFE is limited, most studies have focused on existing lines, underscoring the need for extensive research into ergonomic integration within the ALDP to address the complexities of real-world design challenges [1].

Baykasoğlu et al. [39] pioneered this field by addressing the design of a simple assembly line using a heuristic approach. Finco et al. [40] optimized the design of a semi-automatic AL by minimizing design costs and ergonomic risks associated with the vibration of automatic hand-held tools. Recently, the application of robots in ALs has evolved design problems in new directions, particularly through the use of collaborative robots (cobots) [7].

2.5 Optimization of assembly lines in the Industry 4.0 era

While most Ergo-ALBPs have concentrated on manual ALs, there is an increasing trend towards incorporating Industry 4.0 technologies. This trend is driven by the need for flexible and adaptive production systems capable of meeting the demands of mass customization in the Industry 4.0 era. Recent studies have begun to focus on robot-assisted ALBPs (RALBPs). The introduction of robots into ALs brings both advantages and challenges related to task allocation, line balancing, and scheduling decisions [41]. These challenges underscore the need to not only optimize technical processes but also to prioritize the ergonomic well-being of the workforce.

Industry 5.0 further evolves these concepts by emphasizing a more human-centric automation approach. It seeks to harmonize the efficiency of robotic precision with human intelligence, thereby enhancing workforce well-being while maintaining high operational efficiency. This paradigm shift is evident in recent Ergo-ALBPs, which now increasingly focus on collaborative human–robot assembly lines (CALBPs) that promote sustainable and resilient manufacturing ecosystems [1].

The interaction between humans and robots in manufacturing systems has been typologically categorized into coexistence, interaction, cooperation, and collaboration [42]. Each category reflects varying degrees of human–robot synergy, from independent operation in the same environment to direct collaborative task completion. The literature shows that ergonomic considerations are increasingly integrated into these interactions, particularly in collaborative settings, where both humans and robots share tasks and spaces. This integration addresses significant ergonomic challenges and enhances both the efficiency and safety of assembly lines. However, among the limited number of Ergo-ALBPs that considered fatigue/recovery models in their studies (as shown in Table 1), around half of them focused on collaborative problems (nine out of 20 articles). Of these, most (seven papers) concentrated on balancing problems in existing ALs while only two papers [29, 38] studied the design of these cobotic lines.

Pioneering research like Weckenborg and Spengler [27] has demonstrated the value of incorporating ergonomic aspects into cost-oriented approaches for CALBP, using models such as Price [14] to balance EE and reduce physical workload. Subsequent studies by Stecke and Mokhtarzadeh [33] and Weckenborg et al. [32] have further explored the EE factor, employing the Garg et al. [16] model and a biomechanical approach, respectively. They solved the mixed integer programming (MIP) models using exact methods. Alternatively, Chutima and Khotsaenlee [31] and Quenehen et al. [34] measured EE in their proposed CALBP applying the PMES approach and solved it with a hybrid metaheuristic approach.

Furthermore, Dalle Mura and Dini [35] applied genetic algorithm (GA) to solve the job rotation problem in collaborative Als, aiming to minimize the cost of allocating workers with varying skill levels and installing different equipment, including cobots. They also tried to minimize the variation of EE among workstations based on the Garg et al. [16] model, considering workers’ movements, physiological characteristics, the degree of collaboration with robots, and job rotations. Keshvarparast et al. [36] proposed a bi-objective optimization model for CALBP to minimize CT and workers’ perceived physical workload, evaluated using the Borg scales approach. They applied a Pareto front to solve the developed model.

Abdous et al. [29] introduced an optimization model in a CALDP context that aimed to minimize both equipment costs and ergonomic risk. This model assessed dynamic muscle fatigue using the formula proposed by Ma et al. [18] for tasks assigned to each workstation. Building on this, Abdous et al. [38] formulated a multi-objective problem to optimize CALDP across various criteria, including equipment and production costs, space utilization, and fatigue risk factors, utilizing the model proposed by Ma et al. [19].

2.6 Addressing uncertainty in optimization problems

As discussed, there is a scarcity of studies integrating ergonomic considerations into ALBPs, especially during the design phase, referred to as Ergo-ALDP. Moreover, much of the existing research has concentrated on deterministic scenarios. However, during the design phase, it is crucial to account for two primary types of uncertainty: environmental and system uncertainty [43]. Environmental uncertainty in the current context includes demand variability due to market fluctuations, while system uncertainty arises from imprecisions within the production process. These system uncertainties encompass human-related aspects such as variability in system reliability, task durations, and the workforce’s physical abilities [7]. Additionally, the imprecision inherent in the inputs of EATs can significantly influence the results [44]. To manage these uncertainties, stochastic programming models are often employed when historical data is available to estimate the probability distributions of uncertain factors. Without such historical data, fuzzy programming is recognized as a beneficial alternative approach [45].

To the best of the authors’ knowledge, Tiacci and Mimmi [46] are the only researchers who have incorporated uncertainty into their optimization problem. They tackled this by factoring in stochastic task durations and imposing penalties for violations of ergonomic constraints or deviations from projected cycle times. For ergonomic factor evaluation, they utilized the OCRA method and applied a GA to optimize cost.

Moreover, ergonomics considerations and operational aspects within assembly line optimization problems often present conflicting objectives. Some research has utilized fuzzy goal programming to tackle the inherent ambiguity in multi-objective models that integrate ergonomics with operational functions [47, 48]. While numerous ALBP-related studies have employed fuzzy set theory (FST) to manage uncertain and imprecise conditions, only Mutlu and Özgörmüş [49] have considered ergonomics risks in the form of fuzzy numbers within the Ergo-ALBP. They employed Bellman and Zadeh’s approach [50] to minimize the number of workstations and the perceived workload.

2.7 Research gaps in the literature

In summary, the literature review has identified several key research gaps within the field of Ergo-ALBP. This study aims to contribute to the existing body of knowledge by addressing these research gaps as shown in Fig. 1.

As Fig. 1 presents, this study makes several key contributions to address the research gaps. The principal contribution is the integration of a fuzzy knowledge-based fatigue model into the ALDP, enhancing the existing framework with a fuzzy extension of Potvin’s fatigue model [51] to effectively manage uncertainties related to fatigue levels. To address ergonomic concerns, the customized fatigue model based on the FIS is integrated into the AL optimization process, assessing the cumulative fatigue levels at each workstation and across the entire line [45].

Moreover, the hybrid heuristic solution approach presented in this paper first identifies FSs meeting operational constraints and calculates fatigue levels through FIS. Then, the best solution is verified using a lexicographic method based on a conventional recovery model. Furthermore, the integration of supportive robots, in the form of SRLs, is examined through scenario-based analysis to find the best combination of robots and workers, aiming to minimize the total cost, including fatigue and robot expenses.

Recognizing that various potential scenarios can yield different FSs during the design stage, this study proposes a comprehensive optimization framework equipped with a visual dashboard. This decision tool aids decision-makers in assessing trade-offs between FSs under different scenarios and selecting the most appropriate solutions based on current conditions. To the best of our knowledge, no previous research has explored these optimization problems from this perspective.

3 Problem definition

This research develops an optimization model for the ergonomic design of an AL by integrating supportive robots in uncertain environments, which is a sort of Ergo-RALDP. This problem extends the SALBP-F with the objective of identifying the optimal (or near optimal) AL configuration that adheres to a predetermined CT and a specified number of workstations. Previous studies, as indicated in Table 1, have often overlooked the inherent vagueness and imprecision in evaluating fatigue levels and recovery times in ALBPs. This study seeks to identify the most ergonomically sound solution without compromising operational efficiency under uncertain conditions. The following subsections elaborate on the proposed fuzzy fatigue model tailored for the optimization problem. Table 2 illustrates all notations used in this study and Fig. 2 presents all components of the model in a schematic framework.

3.1 Initial fatigue model

Muscle fatigue is a significant contributor to MSDs, especially in physical work [19]. Therefore, assessing muscle fatigue is crucial for establishing effective recovery schedules to minimize MSD risks [52]. Among the limited number of fatigue models that assess muscular fatigue, this study selects Potvin’s [51] equation for evaluating localized fatigue in the upper limbs due to its suitability for analysis under uncertainty and fuzzy logic. Potvin’s model delineates the relationship between the maximum acceptable effort (MAE) and the duty cycle (DC), which is the proportion of time spent exerting effort within each CT. This insight is crucial for analyzing repetitive and extended assembly tasks, focusing on the ergonomic risks they pose to the upper body [45]. Equation 1 shows the original formula of this model, which is applied to calculate fatigue level or recovery time, and Fig. 3 illustrates the related curve of this model:

Potvin developed this equation to estimate acceptable forces for repetitive tasks [51]. This model categorizes tasks into two groups: hazardous (points above the curve, indicating positive fatigue or insufficient rest within the cycle) or safe (points below the curve, indicating sufficient rest time within the cycle). Figure 3 depicts the generally inverse correlation between MAE and DC. The fatigue level is influenced by the duration of the task relative to the CT (ti/CT) and the load of the task based on MAE (li).

For instance, in Fig. 3, consider tasks A and B, both with a load representing 20% of the MAE. Task A, with a DC of 20%, falls below the threshold, avoiding excess fatigue. In contrast, task B, with a DC of 70%, results in increased fatigue for the worker. Similarly, tasks A and C share a DC of 20%, but task C induces more fatigue due to its load being 50% of the MAE. To prevent excessive fatigue in C, the DC must be kept below 10%.

Although fatigue level depends on the proportion of task time (ti) in each CT (DC) and task load (li) based on MAE, the uncertainty and vagueness of these influential parameters in the design phase make fatigue calculation complex for the following reasons:

-

Unknown rate of demand: The exact rate of demand is unknown, making takt time (available production time divided by demand) imprecise. Therefore, the desired CT, calculated based on takt time, is also inexact.

-

Variability of task time: Task time can vary based on the worker’s experience, skill, and other characteristic. Moreover, in the design stage, information about the workers who will work on each workstation is unspecific. Thus, task times are not exact parameters, and in most cases, the most possible values are considered as task times.

-

Imprecise task load: Task load, like task time, depends on the characteristics of the operator. Additionally, the estimation of load levels in the design phase contains some degree of error and approximation, making the task load ambiguous.

The vagueness and imprecision in time parameters such as takt time, CT, and task time, along with imprecision in load, result in inaccurate fatigue and recovery assessments. To address uncertainties in the environment and system and to model more realistic optimization problems, these imprecise and vague parameters are managed using stochastic or fuzzy approaches. Stochastic programming requires historical data to develop a proper plan based on the probability of various scenarios. However, in the design phase, sufficient historical data is generally unavailable. Therefore, this paper adopts fuzzy set logic for fatigue/recovery calculation, a promising method to address these challenges.

3.2 Fuzzy fatigue model

In the face of uncertainty, it is necessary to adapt and analyze Potvin’s model to address all vague and imprecise factors. Potvin’s equation is instrumental at the worker level for calculating the necessary recovery time within a work cycle, preventing the accumulation of residual fatigue from repetitive tasks. While Potvin’s fatigue model provides a threshold for evaluating each task based on the MAE, it does not quantify the magnitude of fatigue in terms of categorical ergonomic risk or as the cumulative risk of multiple tasks.

To address these gaps, a fuzzy fatigue model is developed using an expert system based on a fuzzy inference system (FIS) informed by the collective expertise of selected ergonomic specialists. The selection of these experts was based on a set of criteria including their published work, practical experience in ergonomics, and previous involvement in developing ergonomic assessment tools. Expert opinions are crucial in developing FIS models, and selecting the right experts is the first step in creating an effective FIS-based approach [53].

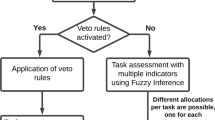

The knowledge extraction process involved structured interviews followed by multiple feedback sessions to iteratively refine the fuzzy rules, ensuring their alignment with both empirical data and theoretical ergonomic principles. The development of the FIS, outlined in Fig. 4, begins with input from the Potvin fatigue equation, which is essential for quantifying necessary recovery times. This input undergoes “Fuzzification” converting precise data into fuzzy values that can better handle uncertainties in ergonomic assessments. Our system includes a comprehensive “Knowledge Base,” consisting of a “Rule Base” with fuzzy logic rules derived from expert insights, which help interpret varying fatigue levels. Defining fuzzy rules is crucial in developing a fuzzy expert system, with the number of rules dependent on the input variables and the membership functions used [53]. These rules are processed in the “Inference Engine,” which applies logical operations to generate fuzzy conclusions. Finally, the “Defuzzification” process converts these fuzzy conclusions back into precise outputs, resulting in the fuzzy fatigue model that provides actionable insights for ergonomic risk management.

Fuzzy inference system to develop a fuzzy fatigue model (generated from [54])

Therefore, this model accounts for variability in task time and load by applying fuzzy logic, allowing for the assessment of fatigue risk levels with a degree of uncertainty during the design stage through possibility sets. The proposed fatigue model relies on a set of fuzzy rules derived from ergonomic specialists’ insights. These rules evaluate potential ergonomic risks of localized fatigue in the upper limbs associated with each task, incorporating Potvin’s equation.

Fuzzy rules are “If…, Then…” statements that evaluate specific conditions to derive conclusions using fuzzy logic. Potvin’s model has an accuracy with a root mean square (RMS) error of 7.2% of MAE. Therefore, to create fuzzy rules, we consider a 7.2% MAE margin and divide the entire potential area around the initial curve into six risk zones, and a fatigue level (fi) is assigned to each risk level that presents the ergonomic risk related to the fatigue magnitude. As illustrated in Fig. 5, fuzzy rules are based on the distance of each point from the initial curve (Di) and can be demonstrated as follows:

-

If \({D}_{i}\le -14.4\% MAE\), then the task imposes no risk, and fi is equal to 0.

-

If \({-14.4\% MAE <D}_{i}\le -7.2\% MAE\), then the task imposes low risk, and fi is equal to 0.25.

-

If \({-7.2\% MAE <D}_{i}\le 0\% MAE\), then the task imposes minor risk, and fi is equal to 0.4.

-

If \(0\% MAE <{D}_{i}\le 7.2\% MAE\), then the task imposes moderate risk, and fi is equal to 0.6.

-

If \(7.2\% MAE <{D}_{i}\le 14.4\% MAE\), then the task imposes medium risk, and fi is equal to 0.75.

-

If \(14.4\% MAE <{D}_{i}\), then the task imposes high risk, and fi is equal to 1.

To explain this method numerically, consider a sample workstation depicted in Fig. 6. Five tasks are assigned to workstation j, and task times and loads (ti and li) are specified based on their most possible values during the design phase. The DCi is then calculated assuming a CT of 60 s.

As shown in Fig. 6, the fatigue level of each task can be evaluated based on its location on the fuzzy Potvin model, considering the distance of the point to the initial curve.

3.3 Cumulative fatigue and ergonomic risk mitigation

The proposed approach evaluates cumulative fatigue in each workstation (Fj) by summing the fatigue levels of all assigned tasks. This is calculated using the following equation:

For instance, in the sample workstation illustrated in Fig. 6, the cumulative fatigue is 1.65. This means that the magnitude of fatigue necessitates assigning an additional 1.65 shifts to a worker. In other words, the current CT does not meet adequate recovery and must be adjusted to achieve an ergonomic, human-centric design.

To mitigate fatigue levels at each workstation and reduce ergonomic risk on the AL, sufficient recovery time must be integrated into the planning process. In manual AL settings, this implies adjusting the CT to include the required recovery time based on the fatigue model. However, during the design phase, the CT is presumed to be predetermined based on takt time to meet potential future demand rates. Thus, an alternative to adjusting the CT is adding extra capacity by employing more workers and covering the associated costs. Given the workforce scarcity in many industries, a viable solution is to utilize supportive robots to assist workers with complex and fatigue-inducing tasks [5].

In manufacturing systems, human–robot interaction during task execution can be categorized into four roles: inactive (resting), active (leading), supportive (following), and adaptive (where the robot dynamically adjusts its role) or intuitive (role determined by human decision) [42]. This study emphasizes the supportive role of robots in the form of SRLs. These robots are additional robotic appendages designed to augment human capabilities in industrial settings like assembly lines and help mitigate fatigue without impacting task execution time. Figure 7 shows an example of an SRL that supports the shoulders to reduce ergonomic risks by lessening the load on them.

Thus, in this paper, we focus on the supportive role of these robots in assisting human workers in handling complex or physically demanding tasks. This support helps decrease fatigue levels while allowing workers to maintain their active roles, with no changes to task execution time.

3.4 Mathematical optimization problem

The proposed mathematical model in this study falls under Type F (feasibility programming) optimization, which is a decision problem aimed at finding the most effective (either maximum or minimum) solution among all FSs that satisfy the constraints of the problem [38]. The initial model, applicable to manual AL, seeks to identify all possible FSs, adhering to the following constraints (Eqs. 3, 4, 5 and 6):

Equation 3 ensures that each task i is assigned to only one workstation. Equation 4 verifies the fixed number of available workstations. Constraint 5 defines the sequence of workstations based on the precedence relations between tasks. Constraint 6 ensures that the total operation time in any open workstation does not exceed the CT. Decision variables xij and yj are binary, as defined in Table 2.

These four constraints form the foundational step in developing the mathematical model. To address ergonomic risk and alleviate fatigue using SRLs, a threshold Fmax is set as the maximum accepted fatigue level in each workstation. Based on Eq. 2, the cumulative fatigue in workstation j (Fj) is the summation of fatigue of all assigned tasks to that workstation. Therefore, Eq. 7 ensures that the cumulative fatigue level in any workstation does not exceed Fmax, and if it does, an SRL must be allocated to that workstation:

The problem model aims to optimize two criteria: the fatigue level and the overall cost of the AL. Among all possible FSs, the model strives to find the best solution based on two objective functions. The first objective (Eq. 8) is to minimize the maximum ergonomic risk (fatigue level) across the entire AL:

The second objective is to minimize the additional costs of the AL, which comprise fatigue costs and robot costs. In this study, fatigue cost represents the need for additional recovery time, reflecting the over cost of providing workers per shift to mitigate the impact of fatigue on productivity. For calculating the fatigue cost (Eq. 9), it is assumed that the magnitude of additional recovery time to eliminate ergonomic risk in each workstation is equal to its fatigue level. It means that if the cumulative fatigue level of a workstation is equal to 1 (high-risk level), a recovery time equal to one working shift should be considered to eliminate the risk. If an SRL is assigned to a workstation, its fatigue level is considered zero. Therefore, the fatigue cost for each FS (the entire AL) is the sum of this cost for all workstations:

Each unit of cost represents a unit of capacity required to meet necessary recovery time, implying that an additional cost of 1 corresponds to one unit of capacity (a workstation with a worker for one shift) needed for addressing required recovery. For simplicity, only one type of SRL (e.g., a supportive robot for shoulders, as shown in Fig. 7) is considered. Thus, the robot cost is calculated as a fixed percentage of the fatigue cost (cost of adding each unit of capacity, worker cost per shift):

Therefore, the second objective is to minimize the total over cost of the AL, which is the sum of fatigue and robot costs, the summation of Eqs. 9 and 10 as follows:

3.5 Problem assumptions

To develop a robust solution approach for the optimization problem, the following assumptions are considered:

-

Work shifts: According to Potvin’s model (2012), work shifts are considered as standard 8 h without any job rotations.

-

Task load and time: Initially, the load and time for each task are assumed to be equal to their most possible values. However, the fatigue level, which is related to both load and time, is evaluated through an FIS to accommodate the uncertainty inherent in the problem.

-

Scenario planning: The problem entails several scenarios for planning ALs based on the maximum allowed fatigue level at each workstation. Although numerical instances in this paper consider only three different fatigue levels, the proposed solution method can be adopted for any predefined levels.

-

Cost considerations: This study considers only the costs associated with fatigue and robot deployment. Other relevant costs, such as equipment maintenance, training, and potential productivity gains from robot utilization, are not included. Fatigue costs encompass factors such as reduced productivity, increased error rates, and absenteeism. These costs are evaluated based on the cumulative fatigue level at each workstation (Fj) and are equated to the overtime cost required to mitigate them. To simplify the model, robot costs are expressed in terms of additional work shifts as well.

-

Supportive robots: Although there are different sorts of SRLs for supporting various parts of the body [5], for simplicity and avoid model complicity, only one type of them is considered in this study.

-

Impact of SRLs: When an SRL is allocated to a workstation, it does not affect the execution time of tasks. It is assumed that assigning a robot to a workstation reduces the fatigue level at that workstation to zero.

4 Proposed solution algorithm

To address the problem outlined in the previous section, an optimization algorithm is proposed, as illustrated in Fig. 8. The initial stage of the algorithm involves finding multiple FSs while considering all constraints, including precedence relationships between tasks, the defined CT, and the limited number of workstations. An appropriate number of iterations (based on the size of problem) are performed to explore a wider range of potential solutions, thereby increasing the chances of finding the optimal or near-optimal solution. In the solution algorithm, tasks are selected randomly from the “assignable tasks” list. This approach was chosen to ensure a broad exploration of possible task assignments, which can help in identifying diverse solutions and avoiding local optima. While priority rules based on fatigue level, task load, or other criteria can be beneficial, random selection allows for a more unbiased exploration of the solution space. Subsequently, for each FS, the fatigue level of each workstation, Fj (Eq. 2), is calculated. Based on different scenarios involving various Fmax, the number of required SRLs (Eq. 7) is determined.

The primary objective is to identify an FS with the minimum fatigue level across workstations (Eq. 8), ensuring that all workers experience the lowest level of pressure, resulting in minimal fatigue and reduced recovery times. To facilitate lexicographical programming, all FSs are sorted in ascending order based on their fatigue levels (the value of the first objective).

The second objective, as expressed in Eq. 11, seeks to minimize the system’s overall cost associated with alleviating the fatigue level of the AL. Considering different scenarios based on various thresholds, as outlined in Eq. 7, can lead to different combinations of fatigue cost (Eq. 9) and robot cost (Eq. 10). Using a lexicographical approach, the best solution with the minimum overall cost from the top of the sorted list is identified as the best (optimal or near optimal) solution. The pseudo-code for the proposed solution approach is presented in Algorithm 1.

4.1 Small-scale numerical example

In this part, an illustrative small-scale numerical example is provided to elucidate the proposed solution approach. For instance, consider an AL comprising 15 tasks. Figure 9 visually represents assembly tasks labelled from A to O, with arrows indicating their precedence relationships. Table 3 details various data for each assembly task. Initial task data, including “Time,” ti, and “Load,” li, is presented in the related columns. The DC is calculated by dividing task time by the CT, with the desired CT set to 60 s in this problem. MAE is determined using Eq. 1 to establish the initial threshold for Potvin’s model. Additionally, the “Distance” column illustrates the gap between MAE and task load, helping in determining the fatigue level according to Fig. 5.

By considering five workstations to assign the tasks, this problem is solved using the coded heuristic algorithm in Python version 3.10. For the second objective of minimizing the over cost, three scenarios are considered in this problem: Fmax = 0.5, 0.75, or 1. Four parts of Fig. 10 display FSs and the optimum solution in each scenario in addition to considering the manual AL option and comparing the optimum solution in each case with the manual option.

The left-side plots in Fig. 10 demonstrate the lexicographic approach, illustrating that the best solution based on the minimum cost is within the group of FSs with the minimum fatigue level. The right-side schematic images present the optimum solution in each scenario while comparing them with the manual option. As Fig. 10 illustrates, applying tighter thresholds results in lower fatigue level, while leading to more need for SRL and consequently increase the robot cost. Thus, for decision making by considering all pros and cons, one useful factor can be saving amount. If the robot cost in the current example is considered equal to 0.5 unit, meaning equal to 50% of worker cost, the optimum cost and saving for optimum solutions in different scenarios can be shown in Fig. 11.

In Fig. 11, cost components are indicated separately, fatigue cost and robot cost, in addition to total cost to make it easier for analyzing. For instance, the cost of the optimum solution in the second scenario (Fmax = 0.75) is equal to 1.75 units, which includes one worker who should do overtime work for 25% of a shift (fatigue cost = 0.25), and the AL applies three SRLs in workstations 2, 3, and 4 (Fig. 10c) with the cost of 1.5 units (robot cost = 3 × 0.5). Based on this diagram, the desirability of the optimum solution in each scenario can be compared to others by considering the area associated to its color. By considering this rule, while the optimum solution of three fatigue-based scenarios has approximately the same desirability, the fatigue level and its cost are decreased as much as the thresholds get tighter. Thus, in scenario 3 (Fmax = 0.5), fatigue level and its related cost are zero which means no ergonomic risk in the design phase.

5 Numerical experiments

This study delves into the implementation of the proposed solution algorithm on a benchmark dataset. In this section, 60 synthesized numerical examples are conducted on a Core i3 3.00 GHz CPU with 20 GB RAM, running Windows 11 OS.

5.1 Characteristics of dataset and data preparation

In this step, several experiments were conducted using the well-known SALBP benchmark dataset proposed by Otto et al. [6]. To prepare the dataset and implement the proposed solution algorithm, some modifications were made. The original benchmark dataset contains four groups of instances, each group contains 525 numerical examples with a constant number of tasks (n) but different number of workstations (m) and precedence relations between tasks. The following adjustments were considered to prepare the dataset for implementing the solution method on it:

-

Sample selection: Four groups of this dataset have been defined based on the number of tasks in each group. Thus, the problem size identifies the groups like “Small” group (n = 20), “Medium” group (n = 50), “Large” group (n = 100), and “Very Large” group (n = 1000). Due to the complex nature of large and very large numerical examples and the extensive computational effort required to solve them, this study focused on small and medium-sized problems. Hence, 30 sample problems were selected from each category to have a sufficient and balanced sample size for the implementation of the solution method. It was ensured the randomness and representativeness of the selection by using a random number generator to pick the sample problems from the original dataset. The distribution and characteristics of the selected sample problems were also checked to make sure that they were similar to the original dataset.

-

Time adjustments: Although CT is constant and predetermined in all groups and it is equal to 1000 s, from an ergonomic perspective, it is not logical to have such a long CT and it is too long and unrealistic for most ALs. Therefore, the CT was changed to 60 s that is a typical CT in most automotive manufacturing industry. A long CT would increase the ergonomic risk and fatigue level of the workers, as they would have to perform the same tasks for a longer duration without sufficient breaks. A shorter CT would reduce the ergonomic impact and improve the productivity and quality of the AL. Consequently, all task times (ti) were adjusted by multiplying them by 0.06.

-

Number of workstations: This dataset is for solving SALBP-Type 1 which tries to find the minimum number of workstations by considering predetermined CT. Then, for each sample problem, the minimum number of workstations was identified in specific number of iterations [6]. In the implementation of the proposed algorithm, it was tried to consider the minimum number of workstations suggested in the reference paper.

-

Ergonomic parameter: To the best of the authors’ knowledge, there is no existing research specifically synthesizing load parameters for fatigue calculation in available benchmark datasets. Therefore, in this study, the load parameter was synthesized through a beta distribution to enable the evaluation of the proposed model on instance problems. The parameters of the beta distribution for the load parameters were determined based on some assumptions and expert opinions. It was assumed that the load parameters are in the range of [2%, 40%] of the MAE. Beta distribution was used to generate the load parameters because it is a flexible and bounded distribution that can model various shapes and behaviors. The parameters of the beta distribution were chosen: α = 1 and β = 2 to generate more numbers near the lower end of the range, as it was expected that most tasks would have a low to moderate load [37]. The assumptions and parameters were also validated by consulting some experts in the field of AL design and ergonomics.

After preparing the dataset, the solution method was implemented to solve all 60 sample problems (2 groups × 30 samples). Moreover, the assumptions for the implementation of the solution algorithm on these samples were the same as what was considered in the small-scale numerical example in Sect. 4.1. As a result, three scenarios were considered including Fmax equal to 1, 0.75, and 0.5; and the cost of allocating each unit of the robot was considered 0.5 unit of capacity.

5.2 Numerical results

Tables 4 and 5 present the output of three scenarios, alongside the initial optimum solution for each case, representing the manual AL. For each scenario, in addition to the values of first and second objectives (fatigue level (Obj1) and total cost (Obj2), respectively), the number of SRL(s) and cost-saving amount are presented to make the analysis process easier.

5.3 Result analysis

The results from the numerical experiments highlight the high quality of solutions achieved. To analyze the final outputs of the optimization method comprehensively, several key indicators have been defined to compare the optimum solution in each scenario with the initial optimum answer for the manual AL. These indicators include:

-

Reduction in fatigue level: \(\frac{{Fatigue}_{manual}- {Fatigue}_{scenario x} }{{Fatigue}_{manual}}\)

-

Reduction in total cost: \(\frac{{Cost}_{manual}- {Cost}_{scenario x} }{{Cost}_{manual}}\)

-

Saving per capacity: \(\frac{{Saving}_{scenario x} }{\#Workstation}\)

The comparison of the average results of measuring these indicators across 30 numerical samples of both small and medium groups is presented in. Table 6 The “Ineffective” parameter in this table indicates the number and percentage of samples that the optimum solutions in them in each scenario did not change the benefit (saving) in comparison to previous scenario. For example:

-

In small-size samples, the first scenario (Fmax = 1) in six samples (20% of all samples) did not show any improvement in comparison to the manual option. Based on these parameters, it is obvious that the second and third scenarios have the same desirability in economic perspective as they both have the same cost reduction factor. However, the third scenario has more fatigue reduction that means it has better performance in ergonomics aspect.

-

In medium-size samples, the third scenario shows less impact as around 37% of samples do not show any improvement in comparison to the second scenario. However, in the other samples the improvements are significant and compensate the ineffective samples.

Therefore, different scenarios, various thresholds, might have diverse impacts on problems based on their characteristics, constraints, and limitations.

Although, the application of each scenario is dependent on the characteristics of the AL, comparing the value of important factors in various scenarios can give some idea about defining the best effective threshold (Fmax) for fatigue reduction and robot assignment. Figure 12 illustrates the comparison between the average of some important factors in different scenarios for small and medium-size samples.

6 Discussion

Subsequent subsections will delve into detailed analysis and discussion of the results of implementing the model on the sample dataset.

6.1 Validation and verification

This study represents a pioneering effort in incorporating fuzzy fatigue models into the realm of RALDPs. While previous studies in Ergo-ALBP have considered fatigue and/or recovery models, none have addressed the uncertain conditions of these problems in the design phase. By employing the fatigue model proposed by Potvin [51], this research has developed a novel fatigue model through a fuzzy expert system and applied it to ALDPs.

Moreover, recognizing the prevailing human resource shortage crisis in many industries and countries, this study incorporated the application of robots, specifically SRLs, to alleviate operators’ fatigue and reduce required recovery times. By considering these factors, several scenarios were developed to optimize RALDPs and minimize the total over costs of the system, encompassing fatigue and robot cost allocations for equipping workstations with SRLs.

Given the novelty of incorporating fuzzy fatigue model in RALDP, direct comparisons with previous research are limited. Additionally, synthesized data in ergonomic and technical aspects may influence optimum results favorably or unfavorably. Nevertheless, to compare the performance of the proposed approach with alternative methods or benchmark datasets, statistical significance testing was conducted using the ANOVA approach. Table 7 reports the statistical significance of the differences in fatigue levels (objective 1) and overall costs (objective 2) between the optimized solutions of different scenarios.

Overall analysis of the results shows the approximately same results for both small and medium instances. One-factor ANOVA analysis reveals significant differences in the first objective function between the four scenarios. The high F-statistic and the very low P-value indicate that the differences between the groups are not due to random chance, and the scenario choice significantly impacts the first objective function. For the second objective, the differences between various scenarios are noticeable, as the P-value is less than 0.05 and the F-statistic is greater than F-critical; however, the impact of scenario choice on the second objective is less pronounced than on the first one.

Two-factor ANOVA analysis also presents consistent results across both instance types. Both the sample effect and the scenario effect are statistically significant, indicating that both the choice of sample and the choice of scenario significantly affect the objective functions. The scenario effect is particularly strong, as indicated by the very high F-statistic and extremely small P-value. However, the interaction effect between sample and scenario is not statistically significant. This means that the effect of the scenario on the objective functions does not depend significantly on the sample chosen.

Therefore, the results of the validation process demonstrate the consistent ability of the proposed solution approach to produce accurate solutions in terms of minimizing fatigue levels and overall costs. This study represents the first attempt to generate customized fuzzy fatigue factors for the conventional ALBP benchmark dataset, paving the way for future sensitivity analyses when incorporating fatigue data into such datasets.

6.2 Academic implementation

The present research introduces a novel approach to fatigue consideration in RALDPs under uncertainty, offering potential applications in academic settings. Firstly, by employing three levels of thresholds as scenarios for decision-making and finding optimum solutions with minimum ergonomic and operational cost, this study lays the groundwork for conducting sensitivity analyses to determine the most suitable scenario for capturing the possibility of future conditions accurately.

Secondly, the thresholds defined in this study based on the expert knowledge can be further explored and analyzed to establish improved fit fuzzy rules. Alternative expert systems can be employed to adjust or modify fuzzy rules based on different methodologies, and various statistical analyses can be applied to different case studies to identify optimal thresholds for fatigue risk evaluation.

Thirdly, the novelty of FIS application in developing the fatigue model presents opportunities for further contributions in future studies. Alternative fatigue and recovery methods can be fuzzified, and the solution approach can be implemented on them for comparative analysis. Furthermore, the model can be applied to other problem types such as assembly line worker assignment and balancing problems (ALWABPs), disassembly cells considering collaborative robots, or rebalancing problems with different scenarios and possibilities. Therefore, this research offers numerous potential contributions to the academic community, stimulating further studies in academic scenarios and fostering advancements and innovative approaches in the field.

6.3 Industrial implementation

The proposed solution method carries significant implications and potential benefits for industrial applications, particularly within the framework of Industry 4.0. This era of manufacturing is characterized by increased automation and a growing emphasis on human–robot collaboration, where the implementation in real-world industrial settings allows for the integration of managerial insights and ergonomic expertise during the optimization process becomes crucial. By applying the fuzzy fatigue evaluation approach during the design phase, the model’s applicability in industrial contexts can be enhanced, influencing by Industry 4.0 innovations. At the task level, the output from this fuzzy fatigue model aids in work cell planning by categorizing possible results into approximate fatigue levels, facilitating a more robust approach to human–robot interaction.

Moreover, the flexibility of the proposed fuzzy rules allows for customization to meet specific industry requirements, such as the integration of supportive robots, cobots, or specialized equipment designed to mitigate potential fatigue levels. This adaptability is particularly relevant in the context of Industry 4.0, where the blend of technical optimization and human-centric considerations is paramount. The proposed hybrid model also addresses the economic aspects of Industry 4.0 by optimizing based on fatigue levels and total system cost. This cost metric can be varied to include different types of SRLs with varying costs or to ensure the smoothness of risk levels across the AL, thus impacting support levels and overall operational performance.

While the focus of this study has primarily been on the feasibility aspect of ALDPs, the optimization model is highly adaptable, able to incorporate additional constraints and limitations to suit specific production system preferences within Industry 4.0 frameworks. By tackling uncertain and imprecise data through fuzzy logic, engineers and ergonomic practitioners can derive more reliable and robust solutions, effectively managing parameter variability. These advancements contribute to planners’ achieving higher productivity and efficiency in automated and human-interactive AL, aligning with the strategic goals of Industry 4.0 and paving the way for the smooth integration of Industry 5.0’s human-centric values. This study not only supports the operational efficiencies desired in Industry 4.0 but also anticipates the ergonomic and collaborative advancements introduced by Industry 5.0, demonstrating a progressive alignment with the evolving needs of modern manufacturing industries.

6.4 Limitations

In this study, several limitations are acknowledged that may affect the validity and reliability of the findings:

-

▪ Data quality and quantity: Despite our efforts to compile comprehensive data and establish logical time parameters and generate ergonomic factors across the benchmark dataset, the quality and quantity of synthesized data could impact the robustness of our findings, potentially limiting their generalizability.

-

▪ Evaluator expertise: While our evaluators possessed adequate expertise, there was some variation, introducing potential subjectivity into the assessments. To mitigate this, we utilized standardized assessment tools to maintain consistency to a certain extent.

-

▪ Solution framework: Our solution framework offers valuable insights into ALDPs; however, it may not guarantee the identification of optimal or Pareto optimal solutions, especially for large-scale instances of the problem. The complexity and size of the problem can affect the efficacy of our framework in uncovering the best solutions. For instances with significant scalability challenges, alternative methods such as metaheuristics might offer greater effectiveness in attaining superior solutions. Future research could explore integrating metaheuristic techniques to enhance solution quality.

-

▪ Ergonomic assessment approach: While we employed the fatigue model developed by Potvin [51] to assess fatigue risk levels, this marks the first instance of using such a distinguished fatigue model for developing fuzzy rules to model uncertainty in the system. Consequently, there might be bugs and weaknesses in our proposed ergonomic evaluation method, potentially hindering a comprehensive view of workplace ergonomics. Future studies should analyze the approach through real-world case studies to gain a thorough understanding and effective mitigation of ergonomic risks.

-

▪ Optimization model: In our optimization model, we aimed to minimize the maximum fatigue level among all workstations and the overall cost of the system. However, other objective functions, such as minimizing cumulative fatigue on various body parts or minimizing the deviation of fatigue levels among workstations, could be considered. Furthermore, our model was constrained with predetermined CT and workstation number limits due to the Type F optimization problems we studied. Future research avenues could explore minimizing the number of workstations (Type 1) or CT (Type 2) or consider new objective functions to address workload balancing, maximizing throughput, or other aspects, potentially leading to the development of alternative multi-objective mathematical models.

These limitations underscore the importance of considering various factors when interpreting our study’s results and implications. They also suggest promising directions for future research in the field of Ergo-RALDPs.

7 Conclusions

In this study, the challenges of optimizing RALDPs were addressed by introducing a novel solution framework that incorporates fuzzy fatigue evaluation and robotic support. Present research aimed to minimize operator fatigue levels and reduce overall system costs in AL environments, directly aligning with the strategic goals of Industry 4.0, which advocates for increased automation and smarter integration of human–robot collaboration.

The modeling part of this paper identified the key challenges faced in RALDPs, including the need to minimize operator fatigue and optimize system costs while considering all constraints. These challenges emphasized the importance of developing a comprehensive solution framework to address the complexities of AL optimization within an Industry 4.0 framework. This approach bridges significant gaps identified in the existing literature, particularly in integrating ergonomic considerations that have often been overlooked in traditional optimization efforts.

The solution approach presented in this research utilized an innovative optimization method, leveraging a heuristic algorithm to generate multiple FSs while addressing task precedence and timing considerations. By incorporating fuzzy fatigue evaluation and robotic support, proposed algorithm aimed to minimize operator fatigue levels and optimize system costs through a heuristic method that incorporates several scenarios in order to facilitate decision-making process. This approach exemplifies the transition from Industry 4.0 to Industry 5.0 by emphasizing a human-centric automation strategy, thereby enhancing worker well-being alongside operational efficiency.

The results of the numerical experiments validated the effectiveness of the solution approach, demonstrating significant reductions in operator fatigue and system costs across various scenarios. Through comparative analysis and rigorous validation efforts, the consistency and reliability of the solution approach in optimizing RALDPs were established, showcasing its practical applicability in real-world industrial settings.

In conclusion, this study contributes significantly to the field of AL optimization by addressing the dual challenges of operator fatigue/recovery management and system cost reduction within the Industry 4.0 paradigm. By integrating fuzzy fatigue evaluation and robotic support into the optimization process, this research offers a practical and effective framework for enhancing productivity, efficiency, and worker well-being in industrial AL environments. This study not only supports the operational efficiencies desired in Industry 4.0 but also anticipates the ergonomic and collaborative advancements introduced by Industry 5.0, demonstrating a progressive alignment with the evolving needs of modern manufacturing industries.

Moving forward, further research can explore additional optimization objectives, incorporate real-world case studies, and refine the solution framework to address evolving challenges and requirements in AL design and operation. By continuing to innovate and refine this approach, it can contribute to the advancement of AL optimization practices and facilitate the transition towards more efficient and ergonomic AL systems.

Data availability

Some or all data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ghorbani E, Keivanpour S, Sekkay F, Imbeau D (2023) Ergonomic assembly line balancing problems evolution and future trends with insights into Industry 5.0 paradigm. Université de Montreal, Bureau de Montreal

Falck AC, Rosenqvist M (2014) A model for calculation of the costs of poor assembly ergonomics (part 1). Int J Ind Ergon 44(1):140–147

Katiraee N, Calzavara M, Finco S, Battaïa O, Battini D (2023) Assembly line balancing and worker assignment considering workers’ expertise and perceived physical effort. Int J Prod Res 61(20):6939–6959

Ghorbani E, Keivanpour S, Sekkay F, Imbeau D (2024) Fuzzy ergonomic expert system for assembly line design problem. Accessibility, Assistive Technology and Digital Environments 121(121)

Tong Y, Liu J (2021) Review of research and development of supernumerary robotic limbs. IEEE/CAA Journal of Automatica Sinica 8(5):929–952

Otto A, Otto C, Scholl A (2013) Systematic data generation and test design for solution algorithms on the example of SALBPGen for assembly line balancing. Eur J Oper Res 228(1):33–45

Ghorbani E, Keivanpour S, Sekkay F, Imbeau D (2023) Optimization framework for assembly line design problem with ergonomics consideration in fuzzy environment. In: IFIP 20th International Conference on Product Lifecycle Management, Montreal (PLM23). Montreal, QC, Canada

Salveson ME (1955) The assembly-line balancing problem. Trans Am Soc Mech Eng 77(6):939–947

Halgeson WB, Birnie DP (1961) Assembly line balancing using the ranked positional weighting technique. J Ind Eng 12(6):394–398

Gunther RE, Johnson GD, Peterson RS (1983) Currently practiced formulations for the assembly line balance problem. J Oper Manag 3(4):209–221

Otto A, Scholl A (2011) Incorporating ergonomic risks into assembly line balancing. Eur J Oper Res 212(2):277–286

Takala EP, Pehkonen I, Forsman M, Hansson GÅ, Mathiassen SE, Neumann WP, Sjøgaard G, Veiersted KB, Westgaard RH, Winkel J (2010). Systematic evaluation of observational methods assessing biomechanical exposures at work. Scand J Work Environ Health 36(1):3–24

Sekkay F, Imbeau D, Chinniah Y, Dubé PA, de Marcellis-Warin N, Beauregard N, Trépanier M (2018) Risk factors associated with self-reported musculoskeletal pain among short and long distance industrial gas delivery truck drivers. Appl Ergon 72:69–87

Price ADF (1990) Calculating relaxation allowances for construction operatives—part 1: metabolic cost. Appl Ergon 21(4):311–317

Rohmert W (1973) Problems of determination of rest allowances. Part 2: Determining rest allowances in different human tasks. Appl Ergon 4(3):158–162

Garg A, Chaffin DB, Herrin GD (1978) Prediction of metabolic rates for manual materials handling jobs. Am Ind Hyg Assoc J 39(8):661–674

Borg G (1990) Psychophysical scaling with applications in physical work and the perception of exertion. Scand J Work Environ Health 16(1):55–58

Ma L, Chablat D, Bennis F, Zhang W (2009) A new simple dynamic muscle fatigue model and its validation. Int J Ind Ergon 39(1):211–220

Ma L, Chablat D, Bennis F, Zhang W, Guillaume F (2010) A new muscle fatigue and recovery model and its ergonomics application in human simulation. Virtual Phys Prototyp 5(3):123–137

Battini D, Delorme X, Dolgui A, Persona A, Sgarbossa F (2016) Ergonomics in assembly line balancing based on energy expenditure: a multi-objective model. Int J Prod Res 54(3):824–845

Battini D, Delorme X, Dolgui A, Sgarbossa F (2015) Assembly line balancing with ergonomics paradigms: two alternative methods. IFAC-PapersOnLine 48(3):586–591

Battini D, Calzavara M, Otto A, Sgarbossa F (2016) The integrated assembly line balancing and parts feeding problem with ergonomics considerations. IFAC-PapersOnLine 49(12):191–196

Battini D, Calzavara M, Otto A, Sgarbossa F (2017) Preventing ergonomic risks with integrated planning on assembly line balancing and parts feeding. Int J Prod Res 55(24):7452–7472

Finco S, Battini D, Delorme X, Persona A, Sgarbossa F (2018) Heuristic methods to consider rest allowance into assembly balancing problem. IFAC-PapersOnLine 51(11):669–674

Abdous MA, Delorme X, Battini D, Sgarbossa F, Berger-Douce S (2018) Multi-objective optimization of assembly lines with workers fatigue consideration. IFAC-PapersOnLine 51(11):698–703

Dalle Mura M, Dini G (2019) Optimizing ergonomics in assembly lines: a multi objective genetic algorithm. CIRP J Manuf Sci Technol 27:31–45

Weckenborg C, Spengler TS (2019) Assembly line balancing with collaborative robots under consideration of ergonomics: a cost-oriented approach. IFAC-PapersOnLine 52(13):1860–1865

Finco S, Battini D, Delorme X, Persona A, Sgarbossa F (2020) Workers’ rest allowance and smoothing of the workload in assembly lines. Int J Prod Res 58(4):1255–1270

Abdous MA, Delorme X, Battini D (2020) Cobotic assembly line design problem with ergonomics. In Boosting Collaborative Networks 4.0: 21st IFIP WG 5.5 Working Conference on Virtual Enterprises, PRO-VE 2020, Valencia, Spain, November 23–25, 2020, Proceedings 21 (pp. 573–582). Springer International Publishing

Finco S, Calzavara M, Sgarbossa F, Zennaro I (2021) Including rest allowance in mixed-model assembly lines. Int J Prod Res 59(24):7468–7490

Chutima P, Khotsaenlee A (2022) Multi-objective parallel adjacent U-shaped assembly line balancing collaborated by robots and normal and disabled workers. Comput Oper Res 143:105775

Weckenborg C, Thies C, Spengler TS (2022) Harmonizing ergonomics and economics of assembly lines using collaborative robots and exoskeletons. J Manuf Syst 62:681–702

Stecke KE, Mokhtarzadeh M (2022) Balancing collaborative human–robot assembly lines to optimise cycle time and ergonomic risk. Int J Prod Res 60(1):25–47

Quenehen A, Klement N, Abdeljaouad AM, Roucoules L, Gibaru O (2023) Economic and ergonomic performance enhancement in assembly process through multiple collaboration modes between human and robot. Int J Prod Res 61(5):1517–1531

Dalle Mura M, Dini G (2022) Job rotation and human–robot collaboration for enhancing ergonomics in assembly lines by a genetic algorithm. The International Journal of Advanced Manufacturing Technology 118(9):2901–2914

Keshvarparast A, Battaia O, Pirayesh A, Battini D (2022) Considering physical workload and workforce diversity in a Collaborative Assembly Line Balancing (C-ALB) optimization model. IFAC-PapersOnLine 55(10):157–162

Abdous MA, Delorme X, Battini D, Sgarbossa F, Berger-Douce S (2023) Assembly line balancing problem with ergonomics: a new fatigue and recovery model. Int J Prod Res 61(3):693–706

Abdous MA, Delorme X, Battini D, Berger-Douce S (2023) Multi-objective collaborative assembly line design problem with the optimisation of ergonomics and economics. Int J Prod Res 61(22):7830–7845

Baykasoglu A, Tasan SO, Tasan AS, Akyol SD (2017) Modeling and solving assembly line design problems by considering human factors with a real-life application. Human Factors and Ergonomics in Manufacturing & Service Industries 27(2):96–115

Finco S, Abdous MA, Battini D, Calzavara M, Delorme X (2019) Assembly line design with tools vibration. IFAC-PapersOnLine 52(13):247–252

Kheirabadi M, Keivanpour S, Chinniah YA, Frayret JM (2023) Human-robot collaboration in assembly line balancing problems: review and research gaps. Comput Ind Eng 186:109737

Wang L, Liu S, Liu H, Wang XV (2020) Overview of human-robot collaboration in manufacturing. Proceedings of 5th International Conference on the Industry 4.0 Model for Advanced Manufacturing: AMP 2020. Springer International Publishing, pp 15–58

Ho CJ (1989) Evaluating the impact of operating environments on MRP system nervousness. Int J Prod Res 27(7):1115–1135

Golabchi A, Han S, Fayek AR (2016) A fuzzy logic approach to posture-based ergonomic analysis for field observation and assessment of construction manual operations. Can J Civ Eng 43(4):294–303

Ghorbani E, Keivanpour S, Sekkay F, Imbeau D (2024) Fuzzy fatigue model for ergonomic design of assembly lines under uncertainty. Intelligent Systems Conference. Cham, Springer Nature Switzerland, pp 392–407

Tiacci L, Mimmi M (2018) Integrating ergonomic risks evaluation through OCRA index and balancing/sequencing decisions for mixed model stochastic asynchronous assembly lines. Omega 78:112–138

Cheshmehgaz HR, Haron H, Kazemipour F, Desa MI (2012) Accumulated risk of body postures in assembly line balancing problem and modeling through a multi-criteria fuzzy-genetic algorithm. Comput Ind Eng 63(2):503–512

Ozdemir R, Sarigol I, AlMutairi S, AlMeea S, Murad A, Naqi A, AlNasser N (2021) Fuzzy multi-objective model for assembly line balancing with ergonomic risks consideration. Int J Prod Econ 239:108188

Mutlu Ö, Özgörmüş E (2012) A fuzzy assembly line balancing problem with physical workload constraints. Int J Prod Res 50(18):5281–5291

Bellman RE, Zadeh LA (1970) Decision-making in a fuzzy environment. Management science 17(4):B-141

Potvin JR (2012) Predicting maximum acceptable efforts for repetitive tasks: an equation based on duty cycle. Hum Factors 54(2):175–188

Imbeau D (2009) Comparison of rest allowance models for static muscular work. Int J Ind Ergon 39(1):73–80

Keivanpour S (2022) Sustainability balanced scorecard approach to Internet of Things enabled logistics systems. Eng Manag J 34(3):450–474

Tavana M, Hajipour V (2020) A practical review and taxonomy of fuzzy expert systems: methods and applications. Benchmarking: An International Journal 27(1):81–136

Funding

This study was conducted with financial support from Dassault Systemes and Mitacs under Mitacs Accelerate program IT28031 and Polytechnique Montreal in the form of PIED grant.

Author information

Authors and Affiliations

Contributions

Elham Ghorbani: conceptualization; methodology; data collection; formal analysis; investigation; writing—original draft; writing—review and editing. Samira Keivanpour: supervision, methodology validation, critical review and editing. Firdaous Sekkay: supervision, validation of ergonomic aspects, critical review and editing. Daniel Imbeau: supervision, validation of ergonomic aspects, critical review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions