Abstract

The process of designing progressive dies can be complex, tedious, time-consuming, and error-prone, which can significantly impact the development period and design quality. This paper presents a systematic methodology that includes the planning design and automated design of die structure. A super process model (SPM) is presented as the output of the planning design of die structure and the input of the automated design of die structure. Subsequently, parametric template methodology based on deformation feature process geometry (DFPG) is proposed to automate the design of punches and dies. Lastly, a layout method based on layout space for standard parts is proposed to perform the automated layout of standard parts for die-sets, punches, and dies; additionally, a robust calculation method of layout space is introduced. This system is then implemented in two home appliance enterprises. Case studies and industrial applications have demonstrated the effectiveness of the developed system, which can improve the design efficiency by a minimum of 85% and reduce design error by an average of 50%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the development of modern industry, mass-produced sheet metal parts have been widely applied in mechanical, electronics, and home appliance industries in recent decades. Because of their high precision, high efficiency, and long service life, progressive dies are commonly used to produce sheet metal parts.

The design of progressive dies can be a complex, tedious, time-consuming, and error-prone process that demands a high level of knowledge on the part of the die designer that can only be achieved through years of practical experience [1, 2]. The design of progressive dies consists of two parts: layout design of the strip and structural design of the progressive die. The design of die-sets, punches, and dies and the layout of standard parts are major activities for the structural design of the progressive die. The traditional methods of conducting these tasks are largely manual and therefore tedious, time-consuming, and error-prone. The quality of die design largely depends on the designer’s skill, experience, and knowledge. Hence, it is of great benefit to automate the structural design of the progressive die.

Because of its importance, many aspects of automated structural design systems for progressive dies have been studied extensively. Kumar and Singh [3, 4] developed an intelligent system for the automatic modeling of a progressive die with a knowledge-based system on AutoCAD; subsequently, they proposed an automated design system for a progressive die on AutoCAD, which was organized into 27 knowledge-based modules and was capable of automating all major activities of the progressive die design process. Potocnik et al. [5] developed an automated design system for compound washer dies based on an intelligent assembly template that consists of washer, strip, and die parts’ generative models with die-design parameters inside. Lin et al. [6] proposed an automated structural design system for progressive dies that successfully reduced the design time from approximately seven working days to within 2 h for the structural design of the main and standard parts of a progressive die for an upper shell of a mobile phone, which dramatically reduces design time and cost while providing excellent design quality. Naranje et al. [7] proposed a knowledge-based system to automate design of deep drawing die for axisymmetric deep drawn parts and finally generated outputs in form of drawings of strip-layout, die components, and die assembly. However, these systems were limited to sheet metal parts with simple geometry or specific parts; the automatic design of punches and dies and the automatic layout of standard parts were not considered.

Punches and dies are operating components for producing sheet metal part features; the design of punches and dies, along with the layout of standard parts, are the key challenges of an automated structural design system. Zhou et al. [8] discussed the application of UDF in blanking punch structure design based on UG software, but the automatic generation of punches and dies were not considered. Jia et al. [9] presented a structural design tool for punches and dies for progressive dies of a motor core based on functional components that can complete the design of five classes of punches and dies automatically. However, the proposed systems are only applicable to punches and dies with a specific shape.

The layout of standard parts refers to assembling a rational amount of particular standard parts in an exact position, and the concrete realization procedure is as below: (1) count calculation for each type of standard part, position, and parameter calculation for each standard part; (2) invoking and assembling; (3) generating holes in corresponding plates. Moreover, most of the researches focus on the standard parts library construction and the reuse of standard parts [10,11,12]. There is less research on the layout of standard parts. Wei et al. [13] proposed a methodology of automated, robust, and rapid layout of standard parts for multi-plate dies based on the distributed assembly modeling strategy (DAMS), but it is only applicable to the layout of standard parts for simple sheet metal parts; additionally, the interference between standard parts and other parts was not checked.

Hence, benefiting from long-term engagement in designing systems for various types of dies, we propose a systematic methodology to automate the structural design of progressive dies, and a methodology to automate the design of various kinds of punches and dies. Meanwhile, a robust methodology for the automated layout of standard parts is introduced. Finally, an automated structural design system for progressive dies is developed based on these methodologies.

2 Integrated design methodology of process and structure

2.1 Traditional design process of progressive die

The traditional design process of a progressive die consists of two parts, as shown in Fig. 1: layout design of the strip (Step 1) and structural design of the progressive die (Step 2). The part model is the input model of the layout design of the strip, as shown in Fig. 1 (a), and the traditional process model (TPM) is the output model, as shown in Fig. 1 (b); the major tasks are listed as below:

-

Determine the layout pattern of parts on the strip;

-

Determine the number of workstations and the position of idle workstations;

-

Model the intermediate geometry of the part for each workstation;

-

Design the shape and position of the blanking line;

-

Design auxiliary features, for example, pilot holes and drawbeads.

TPM consists of the material parameters (name and thickness) and geometry of the strip (sheet body of strip and blanking line). TPM is the input model of the structural design of the progressive die, and the output model is the structure model, as shown in Fig. 1 (c). The designer completes the following design tasks based on TPM:

-

1.

According to the size of the strip layout, the size of the die-sets is determined, and the structure of the die-sets is manually designed;

-

2.

Punches and dies are manually designed, including positioning and generating holes on corresponding plates;

-

3.

Based on the specific circumstances, standard parts are manually inserted, such as pilot pins, ejectors, screws, dowel pins, and springs; additionally, the holes on corresponding plates are manually created.

Based on the analysis of traditional structural design process of the progressive die, there are three significant problems:

-

The design process is largely manual and, therefore, tedious and time-consuming;

-

The design process is complex and, therefore, error-prone; design errors can significantly increase die adjustment and modification times, thereby increasing the development period and cost of production;

-

The quality of die design largely depends on the designer’s skill, experience, and knowledge; thus, many experienced designers are needed, which increases the human resource cost of enterprises.

To solve these problems, an integrated design methodology of process and structure is proposed in this study to realize the automated structural design of progressive dies.

2.2 Integrated design methodology of process and structure

The flow chart of the integrated design methodology of process and structure is shown in Fig. 2, where the layout design of the strip (Step 1) is identical to that of the traditional design process. However, by summarizing methods and experience and standardizing the structural design process, we divide the structural design of the progressive die into two phases: planning design of die structure and automated design of die structure.

In the planning design of die structure phase, those design tasks in the structural design process that rely on the experience of designers or cannot be carried out consistently and automatically are completed. For instance, die-set type selection relies on the experience of designers, and the process geometry design of punches and dies is not stable enough to be automatically conducted. The input model is TPM, and the output model is the super process model (SPM).

In the automated design of die structure phase, with the process information in SPM, those design tasks that are stable enough to carry out automatically are completed. Parametric templates of die-sets, punches, and dies based on their respective types are invoked, and the process geometry in the parametric template is replaced with that of the punches and dies. The count, position, and size of standard parts are calculated, standard parts are automatically assembled, and holes are generated on the corresponding plates. The input model is SPM, and the output model is a structure model. These four libraries: parametric templates of die-sets, parametric templates of punch and die, layout rules of standard parts, and parametric templates of standard parts, are the results of standardization.

Thus, the integrated design methodology of process and structure completes the process information that rely on the experience of designers or cannot be carried out consistently and automatically in the planning design of die structure phase, which ensure that the automated design of die structure is stable enough to conducted. The advantages of this methodology are summarized as follows:

-

Reduce reliance on designer experience: By summarizing methods and experience, we build parametric templates of die-sets and parametric templates of punches and dies that are saved in the libraries of parametric templates, thereby standardizing the design process. These reusable parametric templates can dramatically reduce reliance on designer experience;

-

Improve design efficiency: Designers only have to focus on the planning design of die structure; the die structure with complicated geometry details is generated automatically in the automated design of die structure phase, which can significantly improve design efficiency;

-

Reduce design errors: The parametric templates in the libraries are checked by experienced designers and are applicable to all types of sheet metal parts; additionally, all parts in the die structure are generated automatically, so the design errors can be controlled at a lower level;

-

Strong compatibility: Parametric templates of die-sets, punches, dies, and standard parts can be custom-built to meet the design criteria of an enterprise.

2.3 Super process model

SPM is generated based on TPM, and it integrates design information consisting of two parts: information relying heavily on designer experience, and information that cannot be completed consistently and automatically. Meanwhile, SPM is the key to the automated design of die structure. The design process of SPM is shown in Fig. 3; there are two steps to complete the modeling of SPM from the part model:

-

Step 1, the layout design of the strip, which is identical to that of the traditional design process, where the output model is TPM;

-

Step 2, the planning design of die structure, which consists of the design of the top and bottom die faces, design of deformation feature process geometry (DFPG), and type selection of die-sets. DFPG in SPM consists of various types of feature DFPGs, and each feature DFPG consists of various types of design information. The output model is SPM, as shown in Fig. 3.

The exploded view of SPM of an air conditioning heat conduction plate is shown in Fig. 4, where the component of feature DFPG of rectangle emboss without shear (rectangle EWS) is exhibited.

The components of SPM are described as follows:

-

Type and thickness of material are determined by part properties;

-

Strip geometry consists of all intermediate geometries of each workstation, and the blanking lines are outer contours of blanking bodies;

-

The top die face is extracted from the top surface of the strip geometry by filling holes and extending outer contours, as shown in Fig. 5 (a). Then, the bottom die face is extracted from the bottom surface in the same manner. The top and bottom die faces are used as process geometry for the trim punch and die in the procedure of automated generating of punch and die. Figure 5 (b) shows the procedure of trimming punch with the process geometry of the top die face;

-

Die-sets are closely related to the shape of a part, and the designer chooses the corresponding type of die-sets based on design specification;

-

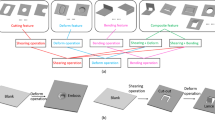

Sheet metal parts contain many deformation features [14, 15], falling into three categories according to forming method: cutting, forming, and bending features. Each main feature has many subtypes; for example, the main type of the cutting feature has nineteen subtypes (TH1–TH12 and IM1–IM7). Those deformation features that can be recognized automatically in this study are shown in Figs. 6 and 7, and all common deformation features in the sheet metal part are listed in Fig. 7.

Each deformation feature has its corresponding feature DFPG, and each feature DFPG consists of feature type, punch type, die type, feature geometry, and feature process geometry. Feature type is the type of deformation feature corresponding to the feature DFPG. Punch type and die type describe the parametric template of punch and die used to form the feature respectively. Feature geometry is the face of the geometry that makes up the feature. The feature process geometry is used to replace the process geometry in the corresponding parametric template, while generating the corresponding punches and dies automatically. There are three categories of feature process geometry: process point, process curve, and process surface.

DFPG is the key component of SPM, which is the set of all feature DFPGs. Each feature DFPG is automatically generated by the DFPG generator, which consists of two parts: deformation feature and feature DFPG generation rules. The design information contained in the feature DFPG differs depending on the subtype of different deformation features. Figure 8 shows the DFPG rules of the partial deformation features and feature DFPGs corresponding to these deformation features. Punch type in a feature DFPG is determined by the subtype of the corresponding deformation feature, and each punch type has a corresponding die type; process geometries (process point, process curve, and process surface) are generated according to the feature DFPG generation rules in the DFPG generator.

3 Automated structural design

3.1 Automated structural design

SPM is the input to the automated structural design. The structural design of the progressive die for sheet metal parts consists of three main parts: (1) design of die-sets, (2) design of punches and dies and generating holes on corresponding main plates, and (3) layout of standard part (calculation of the number, location, and specification), automatic assembly, and generating holes on corresponding parts.

Figure 9 shows the automated structural design process based on the integrated design methodology of process and structure. We use parametric template methodology [16,17,18] to build all parametric templates of die-sets that are saved in the template library. The corresponding parametric template of die-sets is matched with the type of die-sets in SPM. The control parameters in the template are then updated according to the dimensions of the strip geometry to achieve the automated structural design of die-sets.

We propose a parametric template methodology based on feature DFPG that can use the punch type and die type in feature DFPG to match the corresponding parametric template in the punch and die template library, and then replace the process geometry in the template with the process geometry of the feature DFPG to achieve the automated structural design of punches and dies.

After the die-set, punch, and die designs are completed, our proposed automated layout method based on layout space for standard parts can be used to perform the robust calculation of the standard part layout space and complete the layout of standard parts in the layout space automatically according to the layout rules.

The result of each step is shown in Fig. 10. The input is SPM, and the entire structure model of the progressive die will be generated as the output.

3.2 Automated design of punches and dies

3.2.1 Automated design of punches and dies

Punches and dies are the key working parts that determine the geometry, size, and precision of the work piece. Due to the specificity of the different part shapes, punches and dies have a variety of figures and structure types. In the traditional design method, a designer finishes the punch and die designs manually using generic modeling commands in commercial 3D CAD software, but this process is tedious and time-consuming.

To improve the design efficiency of punches and dies, Jia et al. [9] presented a structural design tool for punches and dies for progressive dies of a motor core that can complete the design of five classes of punches and dies automatically. In the study, punches and dies used in the motor core were classified into three categories: standard, half-standard, and non-standard. Standard and half-standard punches and dies were generated by the dimension-driven method, and non-standard punches and dies were generated by the programming method. The dimension-driven method enables the automated generation of all types of standard and half-standard punches and dies. However, the programming method is only applicable to those non-standard punches and dies used in the motor core.

To resolve the problem of insufficient applicability of the programming method, this study proposes a parametric template methodology based on feature DFPG; the flow chart of the methodology is shown in Fig. 11. Each main step is described in the following section.

-

Traverse feature DFPGs in SPM

While generating punches and dies automatically, we traverse all the feature DFPGs in SPM. The components of feature DFPG have been shown in Fig. 3 and Fig. 4 (b).

-

Match the parametric template from the library

The parametric template library already contains all frequently used parametric templates of punches and dies. Punches and dies are still classified into three categories: standard, half-standard, and non-standard. The components of the punch and die parametric template are exhibited in Fig. 12. The punch type contained in feature DFPG is used to match the corresponding punch parametric template in the library of parametric templates.

-

Rename the matched parametric template

The matched parametric template is copied to the temporary directory and renamed. The new name is different from any part in the working directory.

-

Assemble the parametric template onto the die assembly

The parametric template is copied from the temporary directory to the working directory and assembled onto the die assembly.

-

Update the controlling parameters

For the standard and half-standard punches and dies, the design method is the same as that in the dimension-driven method, that is, the control parameters in the template are updated according to the dimensions of feature geometry and system parameters. System parameters contain plate thickness, punch clearance and the material name of the sheet metal part.

-

Replace the process geometry

For the non-standard punches and dies, because the geometry is irregular and cannot be accurately described by control parameters alone, we use process geometry to describe the geometry in the parametric template. In the generation of the punch and die, we update the control parameters and then replace the process geometry in the template with the process geometry in the feature DFPG; this is referred to as the process replacement and will be discussed in the next section.

-

Set machining information for the new punch

The machining information which will be used in engineering drawing is automatically generated according to general machining rules. The surface of the new punch is set to the color corresponding to the machining information.

-

Generate holes on corresponding plates

According to the bool bodies contained in the punch component, holes are generated on plates.

-

Set machining information for the holes

The machining information which will be used in engineering drawing is automatically generated according to general machining rules.

-

The corresponding die is generated

The corresponding die is generated by the same procedure as the punch, except that the die parametric template is matched by the die type contained in feature DFPG.

When a non-standard punch and die that are not supported by the parametric templates in the library needs to be generated automatically. The designer first adds the corresponding parametric template to the library according to the specification, then creates the corresponding feature DFPG in SPM; this allows the user-defined feature DFPG to be matched with the corresponding parametric template. Finally, the control parameters in the template are updated; the process geometry in the template is replaced with the process geometry in the feature DFPG; then, the punch and die are generated automatically. Thus, the parametric template methodology based on feature DFPG can resolve the insufficient applicability problem of the programming method.

An important limitation of the proposed method is that it is difficult for designers to create the corresponding feature DFPG for the complicated non-standard punches which are not supported by the parametric templates in the library. Because the corresponding feature DFPG generally contains several process curves or process surfaces. However, designers are required to have a good understanding of the corresponding parametric template modeling process to properly create these process curves or process surfaces. Thus, how to make it easier for designers to create these feature DFPGs will be studied in the future.

3.2.2 Process replacement

The process replacement consists of replacing the process geometry (process point, process curve, and process surface) in the parametric template with the process geometry in the feature DFPG of the same name, then updating the replaced parametric template. Thus, the process geometry in the parametric template is consistent with that of feature DFPG after the process replacement is completed. The implementation flow of punch and die process replacement is shown in Fig. 13 (a). The process replacement of punch for Feature TH12 is shown in Fig. 13 (b). Then, the process replacement of die is completed in the same manner. The process curve has a directional nature, and the wrong process curve direction will directly lead to the updating failure of the modeling feature in the parametric template, thus leading to failure of punch structure generation. Therefore, we have to perform automatic adjustment of process curve direction in the parametric template to ensure its direction remains unchanged during process replacement.

The process curves are described by feature curves in commercial 3D CAD software, and each feature curve has a start and end point. According to the shape of the process curve and whether it is closed, the process curve is divided into three types, as shown in Fig. 14: linear, non-closed, and closed. Given a point O and a vector V, we define the direction of the process curve to be clockwise if it is clockwise along the curve from the start point to the end point; otherwise, it is counterclockwise. All three types of the process curve in Fig. 14 are clockwise. For the linear type, the O point is the process point in the feature DFPG. For the other two types of process curves, the O point is any point in the closed area enclosed by the process curve with the start and end points connected, and the vector V is the direction of the punch movement.

In the procedure of process replacement, the direction of the new process curve (NPC) in the feature DFPG and the direction of the corresponding old process curve (OPC) in the parametric template are calculated according to the above rules. If the NPC direction is consistent with the OPC direction, the direction of OPC is consistent with NPC when the process replacement is completed. If the NPC direction is inconsistent with the OPC direction, the OPC will be reversed when the process replacement is performing to ensure that its direction remains the same after the process replacement is completed.

3.3 Automated layout of standard parts

There are two categories of standard parts in a progressive die for sheet metal parts: standard parts of die-sets and standard parts of punches and dies. Standard parts of die-sets are clamping plates, springs, sleeves, screws, and pins; standard parts of punches and dies are screws and pins. There can be hundreds of standard parts in a progressive die for sheet metal parts, and the designer needs to calculate the positioning point of each standard part and finish the assembly manually at the positioning point, which is very time-consuming and error-prone; thus, the automated layout of standard parts is very important in the structural design of a progressive die for sheet metal parts.

However, research technically regarding the layout of standard parts has rarely been conducted. Wei et al. [13] proposed a methodology of automated, robust, and rapid layout of standard parts for multi-plate dies, and it consists of two phases: (1) rule-based positioning and (2) interference checking-based positioning.

However, in phase (1), for a rectangular main plate, they assume that the initial standard part layout space (not occupied by other parts and available for standard part layout) must be rectangular; this assumption is only applicable to a simple sheet metal part. For the standard part layout case in Fig. 15 (a), the correct standard part layout space is shown in Fig. 15 (c), while the incorrect standard part layout space (the whole pink rectangular area) assumed in phase (1) is shown in Fig. 15 (b). However, S1 and S2 are occupied by the sheet metal part and punch respectively within the height range of the standard part. It means, the standard parts cannot be arranged in S1 and S2. Thus, the layout space in Fig. 15 (b) is incorrect.

Also, in phase (2), only the interference between the standard parts is checked, not the interference between the standard parts and the other parts, for example, punches, dies, and the sheet metal part, which can result in die installation failure and stamping danger.

To solve the problems mentioned above, we propose an automated layout method based on layout space for standard parts, which performs the automated layout of standard parts of die-sets, punches, and dies. The automated layout of standard parts is done in multiple steps, and the automated layout of one type of standard part is executed in each step, for example, the automated layout of the spring for the die-sets.

In the process of the automated layout of a type of standard part, main plates, punches, or dies that interfere with these standard parts are called the layout target of this type of standard part, as shown in Fig. 15 (a).

From the installation direction of the standard part, the two-dimensional space within the height range of the standard part and the horizontal range of the layout target that is not occupied by other parts and can be used for the layout of the standard part is called layout space, as shown in Fig. 15 (c).

The automated layout of each type of standard part is accomplished in four steps, as shown in Fig. 16: (1) calculation of the Z-position of standard parts; (2) calculation of layout space; (3) rule-based calculation of the size, number, and location of standard parts in the layout space; and (4) automated assembling of standard parts and generation of corresponding holes.

The Z-position of each type of standard part is determined by the design rules of enterprises. The rules in step 3 have been discussed previously by Wei et al. [13]. Calculation of layout space is the core step, and the robust calculation is the basis of the automated layout of standard parts. Therefore, the following sections focus on the robust calculation of the layout space.

According to the relative position relationship between the standard and the layout target, the layout space of the layout target is calculated in the following three cases:

-

The installation direction of the standard part is -Z, and the standard part intersects with the layout target top surface; the layout space is the intersection of the layout target top space (LTTS) and standard part end space (SPES), as shown in Fig. 17 (a). LTTS is the internal space of the top surface of the layout target, and SPES is the intersection space between the plane where the end of the standard part inside layout target (SPEP) is located and the layout target.

-

The installation direction of the standard part is -Z, and the standard part intersects with the layout target top and bottom surfaces; the layout space is the intersection of LTTS and layout target bottom space (LTBS), as shown in Fig. 17 (b). LTBS is the internal space of bottom surface of the layout target.

-

The installation direction of the standard part is + Z, and the standard part intersects with the layout target bottom surface. The layout space is the intersection of SPES and LTBS, as shown in Fig. 17 (c).

LTTS is calculated as the difference between the external contour space and the internal contour space of the top surface, as shown in Fig. 18. The external contour space is the internal space that is inside the external contour of the top surface, and the internal contour space is the internal space that is inside the internal contour of the top surface. LTBS is calculated as the difference between the external contour space and internal contour space of the bottom surface.

The traditional calculation method for SPES is the geometric method. Take the Fig. 17 (c) scenario as an example to describe the calculation process of the geometric method, as shown in Fig. 19:

-

Calculate Z-position (Z0) of the upper end of standard part;

-

Create plane geometry at position Z0 using 3D CAD software general modeling command;

-

Generate intersection curve 1 using the plane geometry to intersect with the external surface of the layout target, and generate intersection curve 2 using the plane geometry to intersect with the non-external surface of the layout target;

-

SPES is the result of the difference between the internal space of intersection curve 1 and the internal space of intersection curve 2.

In the process of this calculation, a large number of geometric intersection operations between the SPEP and the surfaces in layout target are required. If the two intersecting surfaces are in a critical state of partial overlap, as shown in Fig. 20, the intersection of the two surfaces will fail; then, the calculation of SPES fails. Thus, the SPES calculation with the geometric method is not robust.

To achieve a robust calculation of SPES, we propose a mathematical method whose flow chart of calculation is shown in Fig. 21 and take Fig. 17 (c) scenario as an example to describe the calculation of the mathematical method:

-

Calculate Z-position (Z0) of the upper end of standard part;

-

Triangular mesh generation of the layout target surfaces. Triangular mesh of surface is a very mature technology and the triangular mesh of all layout target surfaces is generated by the application program interface (API) provided by the commercial 3D CAD software;

-

Calculation of Qi. There are four cases of the relative position between Ti and SPEP. Case 1—Ti is away from SPEP and on the opposite side of the standard part, and Qi is equal to Ti. Case 2—Ti intersects with SPEP, and Qi is a part of Ti. Case 3—Ti and SPEP are overlapping, and Qi does not exist. Case 4—Ti is away from SPEP and on the same side of the standard part, and Qi does not exist;

-

Calculation of Pi. Each Qi is projected on SPEP along the installation direction of standard part, and the Pi is the inner space of the planar polygon that is the result of Qi projection;

-

SPES is the result of the union of all Pi. The union of planar polygons is calculated by the polygon clipping algorithm [19, 20].

In the mathematical method, the geometric intersection algorithm of two surfaces which is complicated and not robust is replaced with the simple mathematical intersection algorithm of plane and triangle. For the critical state of partial overlap that is mentioned in geometric method, the mathematical intersection algorithm can efficiently and successfully complete the calculation. Thus, the SPES calculation with the mathematical method is robust.

A limitation of the mathematical method is shown in Fig. 22. The SPEP intersects with the hole 2, and the diameters of holes 1 and hole 3 are smaller than that of hole 2. In this case, the SPES obtained by the proposed mathematical method is incorrect, as shown in Fig. 22 (b). The correct SPES is shown in Fig. 22 (c). Although such a case does not exist in a progressive die of sheet metal parts, it may exist in other dies.

4 System implementation and case studies

The proposed automated structural design system for a progressive die of sheet metal parts is implemented as an intelligent CAD system that is seamlessly integrated with NX, which is an interactive CAD/CAE/CAM system with high-performance design functions that provide high performance and flexibility for design and manufacturing [21].

The system architecture has four layers, as shown in Fig. 23: user, application, data, and driver. The user layer includes menus, dialogs, and tips; the interactive dialogs between the designer and the system are used to obtain the user’s intention and parameters.

The application layer is the main program interface and core module of the system, which consists of four submodules: (1) design of strip layout, and the output is TPM; (2) design of die structure, including design of SPM, design of die-sets, design of punches and dies, and layout of standard part and common tools. The common tools contain many simple tools that are useful to designers, for instance, plate splitting; (3) bill of material (BOM) and automatic generation of BOM; (4) interference checking of the entire progressive die with the closed state.

The data layer consists of four types of template parts: parametric templates of die-sets, parametric templates of punch and die, parametric templates of standard part, and layout rules of standard part, which are the basis of automated structural design and can be customized by enterprises.

The driver layer is the NX software, which provides all API functions for the system.

The intelligent CAD system has been applied in the two biggest home appliance enterprises in China and has been tested with 30 sheet metal parts to verify its ability to automate the structural design of the progressive die. A case study of an air conditioner bracket is presented in Fig. 24 to illustrate the major steps of the intelligent CAD system and evaluate its performance, as shown in Fig. 25. The performance of the design process is evaluated in terms of the time spent on the entire design process. The performance data of designing with NX generic modeling commands and designing with this intelligent CAD system are shown in Table 1. As shown in the last column of Table 1, the efficiency obtained by the intelligent CAD system increased by up to 91.7%. The savings in design time is of great help for raising productivity. Meanwhile, the design error is reduced by up to 66.7%, as shown in Table 2.

5 Conclusion

An automated structural design system has been developed on the NX platform based on the integrated design methodology of process and structure to automate the structural design of the progressive die. The SPM is the key model of the integrated design methodology of process and structure, which contains the type and thickness of the material, strip geometry, top and bottom dies, type of die-sets, and DFPG. The initial die-sets are generated according to type and updated with the dimensions of the strip geometry using parametric template methodology. The parametric template methodology based on DFPG is proposed to overcome the problem of insufficient applicability of the existing automated design method of punches and dies. An automated layout method for standard parts based on layout space is proposed for die-sets, punches, and dies to overcome the main limitation of existing methods. The method has the following advantages: (1) the interference between the standard parts and the other parts is checked; (2) the calculation of the layout space is robust. The developed system has been applied in the two biggest home appliance enterprises in China and has been tested with 30 sheet metal parts to verify its ability to automate the structural design of the progressive die and its effectiveness, which improved the design efficiency by a minimum of 85% and reduced the design error by an average of 50%. Thus, it can dramatically save on time and costs for the structural design of progressive dies, while also providing excellent design quality.

The automatic generation of feature DFPGs is only applicable for the deformation features in Fig. 6, and the feature DFPGs for other deformation features must still be generated manually. Meanwhile, the lateral complicated punches cannot be generated automatically. The future work will focus on the automatic generation of feature DFPGs corresponding to other features and lateral complicated punches.

References

Cakir M, Irfan O, Cavdar K (2005) An expert system approach for die and mold making operations. Robot Comput-Integr Manuf 21:175–183

Kumar S, Singh R (2007) A knowledge-based system for selection of progressive die components. J Achiev Mater Manuf Eng 20:475–479

Kumar S, Singh R (2007) An intelligent system for automatic modeling of progressive die. J Mater Process Technol 194:176–183

Kumar S, Singh R (2011) An automated design system for progressive die. Exp Syst Appl 38:4482–4489

Potocnik D, Dolsak B, Ulbin M (2013) An automated design system for compound washer dies. J Braz Soc Mech Sci Eng 35:293–304

Lin B-T, Huang K-M, Su K-Y, Hsu C-Y (2013) Development of an automated structural design system for progressive dies. Int J Adv Manuf Technol 68:1887–1899

Naranje V, Kumar S (2014) A knowledge based system for automated design of deep drawing die for axisymmetric parts. Exp Syst Appl 41:1419–1431

Zhou S, Zhao X, Li J (2008) Application of UDF in blanking punch structure design based on UG. Die Mould Industry 34:22–25

Jia Z, Li H, Zhang X, Li J, Chen B (2011) Computer-aided structural design of punches and dies for progressive die based on functional component. Int J Adv Manuf Technol 54:837–852

Fan Q, Liu G, Wang W (2011) Development of Die Sets standard parts library based on Pro/E. Procedia Eng 15:3802–3807

Sun B, Qin G, Fang Y (2011) Research of standard parts library construction for SolidWorks by Visual Basic. Proc Int Confer Electr Mech Eng Inform Technol 5:2651–2654

Mok H-S, Kim C-H, Kim C-B (2011) Automation of mold designs with the reuse of standard parts. Exp Syst Appl 38:12537–12547

Wei Y, Wang Z, Zhang Z, Liu Y, Yuan X (2018) Methodology of automated and robust and rapid layout of standard part for multi-plate die based on distributed assembly modeling strategy. Int J Adv Manuf Technol 94:1197–1207

Gupta RK, Gurumoorthy B (2013) Classification, representation, and automatic extraction of deformation features in sheet metal parts. Comput Aided Des 45:1469–1484

Yang Y, Hinduja S, Owodunni O, Heinemann R (2021) Recognition of features in sheet metal parts manufactured using progressive dies. Comput Aided Des 134:102991

Lin B-T, Hsu S-H (2008) Automated design system for drawing dies. Expert Syst Appl 34:1586–1598

Hao Y, Wang Y (2017) A knowledge-based parametric design system for trimming dies. DEStech Trans Comput Sci Eng. https://doi.org/10.12783/dtcse/icmsie2016/6315

Wang Y, Hu X (2011) Research on template-based parameterized structure design for drawing dies. In: Proceedings of the 2011 2nd International Conference on Digital Manufacturing and Automation. IEEE, Zhangjiajie, China, pp 1022‒1025

Vatti BR (1992) A generic solution to polygon clipping. Commun Assoc Comput Machinery 35:56–63

Chen X, McMains S (2008) Polygon offsetting by computing winding numbers. In: Proceedings of the ASME 2005 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, vol 2. ASME, Long Beach, CA, pp 565–575

Li B, Zhu W, Eynard B, Bricogne M (2014) Researched on the technology of machining simulation. Adv Mater Res 1039:390–396

Funding

This work was supported by Foshan Institute of Intelligent Equipment Technology (Grant number 2021B0101220001).

Author information

Authors and Affiliations

Contributions

Haijiao Kong was responsible for conceptualization, investigation, methodology, software, and writing of an original draft. Zhibing zhang contributed to the layout of standard parts. Review and editing of the manuscript were provided by Yang Wei and Yuqi Liu.

Corresponding author

Ethics declarations

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kong, H., Zhang, Z., Wei, Y. et al. Development of an automated structural design system for progressive dies based on the integrated design methodology of process and structure. Int J Adv Manuf Technol 126, 4239–4258 (2023). https://doi.org/10.1007/s00170-023-11346-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11346-9