Abstract

Turbine blade plays an extremely important role in the aerodynamic performance of aero-engine. And the repair of damaged turbine blades is of great interest for aerospace industries due to continual increase in raw material and manufacturing costs. This manuscript presents a new repair strategy for damaged turbine blades based on tool path modification. The strategy basically involves three crucial procedures: rigid registration of nominal curve and measured points adjacent to damaged region, B-spline approximation of residual errors based on feasible region, and modification of the tool paths used for repairing machining. Rigid registration of nominal curve to measured points is accomplished using improved ICP algorithm adjacent to damaged region. B-spline approximation of residual errors is used to calculate smooth modification amount corresponding to cutter location points. And finally, modified tool paths are used for repair machining, including grinding and polishing. Tip repairing of a rotor turbine blade has been successfully performed to demonstrate the effectiveness of the proposed methodology. The error of repair machined trace between the repaired area and undamaged area is within 0.01 mm which commendably meets the repair machined requirement. And the repaired results have shown that the repairing strategy proposed in this paper is a reliable solution for repairing tip of turbine blades and can guarantee a surface smooth restoration with higher accuracy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As one of the core components of an aero-engine, blades have a critical influence on its aerodynamic performance. The quality and accuracy of the aero-engine blades determine directly the overall manufacturing level of an aero-engine [1]. Aero-engine turbine blades are responsible for converting thermal energy of high temperature and pressure air expansion into mechanical energy of engine. And they are vulnerable to be damaged due to serving the harsh environment of high temperature, high pressure, and high speed, such as ablation, distortion, wear, and cracks. Normally, turbine blades are made of nickel-based and cobalt-based superalloys with excellent properties which are expensive and rare. Therefore, in order to reduce the cost and extend the service life of aero-engine turbine blades, it is of great significance for repairing damaged turbine blades by remanufacturing [2, 3].

In recent years, repairing blade is a research hotspot with the rapid growth of aviation industries. In a blade repair process, it is crucial to maintain the original blade shape and to achieve maximum efficiency for the restored blade. However, due to the various blade defects such as distortion and worn out, a nominal CAD model from blade design stage is generally different from its corresponding worn blade model and therefore cannot be directly used for tool path generation for the repair process [4, 5]. Presently, there are many references to study turbine blade repairing. Huang [6] developed a robotic grinding and polishing system for auto-repairing of aero-engine blade, but the target model in the process of repairing is still the nominal design model. Gao et al. proposed an integrated repair solution adaptive to worn component geometry based on 3D non-contact measurement for aerospace industries [7,8,9]. Yilmaz et al. [10] presented a repair method that the welded blade tip was reconstructed adaptively considering the geometric characteristics. Zhang et al. [11] presented a geometry reconstruction approach based on cross-section curves blending with wavelet decomposition for adaptive blade repair. Piya et al. [12] considered a semi-automated geometric algorithm for virtually repairing defective blades. The algorithm was constructed by using the sectional gauss map to generate a series of prominent cross-sections along the longitudinal axis of the defective airfoil. Rong et al. [13] studied a surface reconstruction strategy based on the profile’s template. The method repaired the defective blade by the deformation of the template curve, which avoided data preprocessing such as sorting and parameterizations. Ding [14] proposed a reconstruction method of 3D digital model based on GM(1,1) cross-section curve reconstruction algorithm. Hou et al. [15] developed an adaptive solution to reconstruct target surfaces of both welding process and machining process based on measured model, which can meet the design requirements and avoid frequent manual adjustments. Yu et al. [16] proposed a new repairing method of deforming the reference cross-sectional curves adjacent to defective cross-sectional curves recursively. And this method effectively reduces the uncertainty of reconstructing repairing model and has certain applicability in a blade repair process. Document [17,18,19,20] studied that the cladding and metal deposition can be used to repair directly damaged region. And microstructure and thermomechanical properties analysis were carried out to evaluate the repaired part quality. Praniewicz et al. [21] presented an integrated adaptive geometry transformation method for additive/subtractive hybrid manufacturing based on rigid and nonrigid registrations of parent region material and geometric interpolation of the repair region material. The effects of this approach are evaluated and discussed based on effects on repair time and material efficiency. In addition, in the present study, machining code modification strategy has been considered as an applicable and effective solution to compensate deformation error and improve machining accuracy, including tool path modification used in this manuscript. And there are also many literatures about machining with modified tool path. Huang et al. [22] presented an iteration tool path compensation algorithm which is designed to decrease machining errors and avoid unwanted interference by modifying the tool path. And a tool path compensation model considering the machining deviation is proposed. An experiment of impeller blade machining has been performed to demonstrate the effectiveness of proposed strategy. Habibi et al. [23] considered that the effects of the geometric errors for machine tool can be eliminated by modifying the CLSF. And the experimental machining tests show tool deflection and volumetric geometrical errors are compensated and reduced of about 8–10 times by modifying the nominal tool path. Wan et al. [24] proposed a modification strategy of the nominal tool path to compensate the deformation of thin-walled workpiece on the basis of the prediction deviation. Chen et al. [25] divided machining errors into systematic errors and random errors. And the numeric control program is modified to compensate the systematic errors. Sun et al. [26] proposed a cutter orientation adjustment method to obtain an optimized tool path which makes best use of the kinematic characteristics of angular feed for five-axis machining. Hao [27] proposed a tool path transplantation method for adaptive machining of large-sized and thin-walled free form surface parts. The error distribution is mathematically defined based on measured data, and new tool paths adaptive to the actual shape of the workpiece are generated on the basis of the tool paths of nominal model. According to the above researches about machining with modified tool path, we can conclude that many scholars use tool path modification to compensate deformation errors and geometric errors in their research. Therefore, because of the high efficiency and maneuverability of the tool path modification in NC machining, this manuscript innovatively applies tool path modification to the blade repair processing and reversely compensates the deformation of the damaged area by modifying the nominal tool path. So as to achieve the machining purpose of adapting to the shape of undamaged area and ensure smooth transition between the repair machined area and undamaged area.

Simultaneously, according to literatures about blade repairing, these researches have been carried out on performing blade repairing through the approaches of digitizing, laser cladding, and adaptive machining. And many studies focus on reconstructing target surface within the damaged region due to the nominal model inapplicable for repairing. However, there are also many key details to be dealt with in the process of target surface reconstruction. Moreover, for each damaged blade, the target surface should be reconstructed differently. These methods are time-consuming for target surface reconstruction using optical scanning data of damaged parts and have low accuracy of repair machined trace between the repaired area and undamaged area. Therefore, this paper presents a completed strategy for repairing directly turbine blades based on modification of template tool paths instead of surface reconstruction. And the proposed strategy is time saving comparatively because only template tool paths need to be modified according to fewer measurement points. The purpose of the developed strategy is to repair the components to meet tolerance requirements defined by engine manufacturer after being worn or damaged. The strategy basically involves three crucial procedures: registration of nominal curve and measured points adjacent to damaged region, B-spline approximation of residual errors based on feasible region, and modification of the tool paths used for repairing machining. Tip repairing of a turbine rotor blade has been chosen to implement the proposed repair strategy due to its delicate and complex shape.

This paper is organized as follows: Section 1 is the introduction of related study works conducted at an early stage. Section 2 presents an overview of the proposed strategy. Section 3 analyzes a practical example to illustrate the key steps and discusses and analyzes the experimental results. Finally, Section 4 draws the conclusions and future work.

2 Overview of the repair strategy

The proposed repair strategy in this paper consists of a chain of different processes. And this strategy has only concentrated on the parts already metal deposited. The flowchart of the proposed repair strategy is shown in Fig. 1.

In this work, the measured points can be obtained by CMM equipped with a scanning probe. And this repair strategy mainly involves three crucial procedures: registration of nominal curve and measured points adjacent to damaged region, B-spline approximation of residual errors based on feasible region, and modification of the tool paths used for repairing machining. Finally, the blade can be repaired using modified milling and polishing tool path. Moreover, the repaired results will be checked and analytical.

In the following sections, each stage of the proposed repair strategy is introduced by implementing on the tip repair of an aero-engine component: a high-pressure rotor turbine blade.

3 Implementation: a turbine blade tip repairing

Repairing technology is becoming an effective and justified strategy used for aero-engine turbine blades because of their high economic value and manufacturing cost. In this work, a rotor turbine blade with tip geometry to be repaired has been chosen to implement the relevant steps of proposed repair methodology. Figure 2 shows the clamped blade via a special fixture.

3.1 Cross-sectional measurement

For blade repairing, in order to guarantee a surface smooth restoration, the measurement of undamaged area is necessary. Generally, these cross-sectional curves of a blade are basically similar and along the parameter v direction; the similarity is higher if the two cross-sectional curves are close. Therefore, the present authors create a cross-section curve just below the welded portion and measurement data of this cross-sectional curve adjacent to the defective area will represent effectively deformation information of the defective region for blade tip repairing which are shown in Fig. 3a.

As shown in Fig. 3b, the cross-sectional measurement of this blade is conducted with a coordinate-measuring machine PONY866 (AVIC BPEI, Beijing, China; RENISHAW SP25M scanning probe). And the sectional curve of blade was sampled by using chordal deviation criterion [28]. The threshold value of chordal deviation was 0.005 mm.

3.2 Profile rigid registration

Due to distortion or deformation present in the actual component after serving the harsh environment, cross-sectional profile must be registered. The purpose of rigid registration is to find the rotation matrix R and the translation matrix T between the measured points and the nominal CAD model. In this manuscript, the iterative closest point (ICP) method is used to solve the results. The ICP algorithm was proposed by Besl and Mckay in 1992 [29] which mainly consists of two steps: closest point calculation and transformation matrix solving. In the implemented algorithm, transformation matrix can be calculated by solving the following least-squares problem and the mathematical model of ICP algorithms can be expressed as in Eq. (1).

In Eq. (1), where \( {P}_a^i\left(i=1,2,\cdots N\right) \) represents the actual measurement points, and \( {P}_n^i\left(i=1,2,\cdots N\right) \) represents the corresponding points on the nominal CAD. Obviously, E represents the residual sum of squares and N represents the total number of registration points. R and T represent separately rotation matrix and translation matrix, which are to be solved. In this work, rigid registration is mainly used for alignment of nominal cross-sectional curve and measured points adjacent to damaged region. In order to achieve smooth restoration between repaired and non-damaged areas, when the transformation R and T are determined by iterative calculation, the theoretical cross-sectional is moved to closest position to the measurement points according to solved R and T. The result of rigid registration in this work is shown in Fig. 4.

The final 3*3 rotation matrix R and 3*1 translation T solved in rigid registration are shown in Eqs. (2) and (3) which can then be used to modify the cutter location source file.

3.3 B-spline approximation of residual errors

B-spline and NURBS are the most popular choices for curve approximation. A B-spline curve P(u) of degree k is commonly expressed as:

where di(i = 0, 1, ⋯, n) are the control points and Ni, k(u)(i = 0, 1, ⋯, n) are the B-spline basis functions of order k defined over the knot vector U = [u0, u1, ⋯, un + k − 1, un + k].

In order to fit a B-spline curve to a given set of points, some researchers have tried to solve this as a global nonlinear optimization problem [30]. In this paper, the purpose of approximation of residual errors is to obtain modification amount δcls corresponding to ucls of cutter location points. The residual errors shown in Fig. 5 are the distance between an actual measured point and the nominal cross-sectional curve in undamaged region. Each cutter location points are only corresponding to a single parameter (u, v) on the design surface. Therefore, the modification amount of cutter location points can be calculated by unique parameter ucls. However, in order to avoid dramatic changes of machined tool paths, the general smoothness of modified tooltip position must be guaranteed when modifying the original tool paths. Therefore, this strategy obtains the general smooth cutter location points by guaranteeing the smoothness of modification amount δcls along parameter ucls.

Because of the machining tolerance zone, the residual errors δi have a feasible range and there will be a feasible region for B-spline approximation. A fitting B-spline can be found based on ui − δi of measurement points within the feasible region. If the curve is continuous and smooth, the corresponding modification amount δcls of each ucls also is continuous and smooth. And δcls can be used to calculate the modified cutter location point. The B-spline approximation of residual errors flowchart based on feasible region is shown in Fig 6, where Uup and Udown are upper and lower tolerance. ui and δi are the parameter and residual errors of measurement points.

As shown in Fig 7, B-spline approximation of residual errors for the implemented turbine blade was conducted using the algorithm in Fig. 6. And modification amount \( {\delta}_{cls}^n={\left({\delta}_x^n,\kern0.5em {\delta}_y^n,{\delta}_z^n\right)}^T \) can be calculated by parameter ucls of corresponding cutter location points according to fitted B-spline in Fig. 7.

where \( {\delta}_x^n={\delta}_{cls}^n\times {\mathrm{normal}}_x,{\delta}_y^n={\delta}_{cls}^n\times {\mathrm{normal}}_y,{\delta}_z^n={\delta}_{cls}^n\times {\mathrm{normal}}_z \). And (normalx, normaly, normalz) is the normal vector of cutter location point.

3.4 Tool path modification

The machining of a workpiece was implemented by positioning the tooltip and tool axis vector at locations defined in the CLSF (cutter location source file). In computer-aided design/computer-aided manufacture (CAD/CAM) systems, the nominal CLSF is directly generated from the nominal curves and surfaces which to be machined. The tool path information including the machine tool topology, tool radius and type, tooltip position, and tool axis vector are presented in the CLSF. In this paper, the CLSF representing the cutter position and orientation are expressed by \( {\left({P}_x^n,{P}_y^n,{P}_z^n,{V}_x^n,\kern0.5em {V}_y^n,{V}_z^n\right)}^T \), where \( {\left({P}_x^n,{P}_y^n,\kern0.5em {P}_z^n\right)}^T \) stands for the tooltip position and \( {\left({V}_x^n,\kern0.5em {V}_y^n,{V}_z^n\right)}^T \) represents the tool axis vector.

In order to illustrate the relation between the nominal cutter location data and the modified cutter location data, the corresponding nominal and modified cutter location data are defined. \( {P}_i^n={\left({P}_{ix}^n,\kern0.5em {P}_{iy}^n,{P}_{iz}^n\right)}^T \) represents nominal tooltip position and \( {P}_i^m={\left({P}_{ix}^m,\kern0.5em {P}_{iy}^m,{P}_{iz}^m\right)}^T \) represents modified tooltip position.\( {V}_i^n={\left({V}_{ix}^n,\kern0.5em {V}_{iy}^n,{V}_{iz}^n\right)}^T \)stands for nominal tool axis vector and \( {V}_i^m={\left({V}_{ix}^m,\kern0.5em {V}_{iy}^m,{V}_{iz}^m\right)}^T \) stands for modified tool axis vector. Their relation model can be expressed as:

Tool path modification amount of adjusting nominal tool path is adopted based on deviation values according to Eq. (5) where the transformation R and T can be calculated in Section 3.2 and residual errors \( {\delta}_i^n={\left({\delta}_{ix}^n,\kern0.5em {\delta}_{iy}^n,{\delta}_{iz}^n\right)}^T \) can be obtained in Section 3.3. And i = 1, 2⋯n is the number of the cutter location data. This can be illustrated as shown in Fig. 8. Moreover, cutter location points before and after modification displayed in UG 10.0 can be illustrated as shown in Fig. 9.

3.5 Repair machining experiments

3.5.1 Experimental setup

In the experiment, the turbine blade tip to be repaired had been built-up through a laser cladding process. And a special fixture is designed and produced in order to maintain the blade pose in the process of measurement, repairing machining, and subsequent process. The fixture designed has high repositioning precision and can thus be used for clamping different blades adaptive to their geometries to guarantee a high precision repair. It is an appropriate tool for repair of a batch of blades.

The welded blade was first clamped on its tenon via a special fixture to implement blade geometry measurement. This process was performed through a coordinate-measuring machine PONY866 (AVIC BPEI, Beijing, China; RENISHAW SP25M scanning probe) shown in Fig 10. The precision of the contact measurement with CMM is higher than that of digitizing scanning, which can ensure smooth transfer with high precision between the repair machined area and undamaged area. Additionally, the processing equipment used for experiment is a five-axis CNC machine tool with BC axis which can realize effectively repairing processing of blade tip without interference.

3.5.2 Repair machining process

A five-axis machining strategy has been developed to remove the excess weld from the surface effectively. And common machining problems, such as interference, collision, overcut, and undercut, have been considered in the proposed machining process. The deposited material of the blade is known as one of the most difficult to machine superalloys. For instance, high temperatures occur during the machining. Therefore, well-determined repair machining steps including milling, grinding, and polishing have been established for the blade tip machining due to hard machinability of superalloy and characteristics of repair machining. The aim in developing a machining strategy is to remove quickly the excess material from the blade tip surface and to guarantee a surface smooth restoration with higher accuracy and adapt to the undamaged area. Figure 11 presents the blade repair machining process used in the experiment. As shown in the figure, the repair process contains rough milling, semi-finish grinding, and fine polishing.

In this experiment, UG10.0 is chosen as the CAD/CAM environment for tool path generation and modified tool paths are only used in this process. In order to reduce the repair machining time and improve removal efficiency of the deposition on the blade tip, the helical milling and grinding tool path type is used for removing effectively large amounts of material. The number of milling levels is directly related to the maximum depth of cut and the maximum depth of the deposition. In our strategy, the number of cutting levels has been calculated roughly based on the blade material and machine tool properties. In addition, after rough milling, semi-finish grinding with electroplated CBN wheel is chosen to guarantee accurate geometric dimensions of repaired blade. And the type of grinding tool paths is also helical grinding. On top of this, the last procedure of repair machining is automatic polishing using flexible polishing wheel [31]. The zig-zag tool path type of polishing is used for improving repair machined surface quality and achieving smooth transition between the undamaged area and the damaged area.

Figure 12 shows the generated nominal tool paths generated in UG 10.0 for repair machining the blade tip deposited surface. And according to the previous process experiments, the cutting conditions and machining operation parameters are given in Table 1 for the blade tip repair machining.

3.6 Result and discussion

In order to prove the validity of the proposed method, some experiments were carried out. And the results of two repairing turbine blades (blade I and blade II) chosen from these experiments are analyzed and discussed in this section.

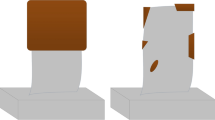

Figure 13 shows the deposited blade before repair machined and repaired blades after repair machined. According to Fig. 13, visually, there is smooth restoration of deposited blade. And after repair machining, the wall thickness of blade tip and the overlap regions between repaired area and undamaged area of these two turbine blades were measured using a 3D coordinate-measuring machine (CMM). Measurement results show that the average wall thickness of these two blades is uniform and meets the design tolerance requirement. Additionally, the repair machined trace errors of blade I and blade II were also analyzed. These measurement data of six iso-u parametric curves respectively extracted from blade I and blade II are used to demonstrate repair machined trace errors for the overlap regions between repaired area and undamaged area. Figure 14 shows the analytical result of blade I and Fig. 15 shows the analytical result of blade II. According to the analytical results, we can know that the error of repair machined trace between the repaired area and undamaged area is within 0.01 mm which meets commendably the repair machined requirement. And there is no obvious sensation if touching with your hand.

The surface characteristics are also examined and analyzed. According to the design requirements, the average surface roughness of the repaired blade airfoil surface should be less than Ra 0.4. And the average roughness of these experiment blades using the proposed strategy is Ra 0.25 which are absolutely better than design requirements. Additionally, the wall thickness of blade tip after repaired is measured and the results are shown in Table 2. From Table 2, evidently, the average wall thickness of these two blades are within required tolerance.

Therefore, according to above experimental results, we will conclude that the proposed strategy can successfully provide an effective solution for an aero-engine turbine blade tip repairing and can guarantee a surface smooth restoration with higher accuracy.

4 Conclusions and future work

Due to continual increase in raw material and manufacturing costs, it is highly crucial for aerospace industries to repair damaged turbine blades with a reliable and fast strategy. Currently, aero-engine blade repairing methods mainly rely on reverse engineering to restructure machining surface of damaged area. But these interactive operations in the process of reconstructing machining surface is time-consuming and inefficient. This study presents a new repair strategy for damaged turbine blades based on tool path modification instead of surface reconstruction. And this strategy mainly involves three crucial procedures: rigid registration of nominal curve and measured points adjacent to damaged region, B-spline approximation of residual errors based on feasible region, and modification of the tool paths used for repairing machining. Tip repairing of a turbine rotor blade has been chosen to implement the proposed repair strategy. And the experimental results have shown that the proposed strategy is a reliable approach for repairing tip of turbine blades and can achieve smooth transition between the repair machined area and undamaged area. The total repair time is about 1 h compared with the current repair solutions to the same type of blade; the repair time is significantly reduced. Therefore, this repair strategy based on tool path modification is valuable and cost-time effective.

Under the current framework, the emphasis of further research activities will be conducted in optimization of measurement data and tool paths which have an important influence on the speed and acceleration of machine tools.

References

Zhang Y, Chen ZT, Ning T (2016) Efficient measurement of aero-engine blade considering uncertainties in adaptive machining. Int J Adv Manuf Technol 86(1–4):387–396

Compressor blades repair and overhaul, Rolls-Royce Plc Internal Report. 2002;10

WANG Hao, WANG Liwen.( 2016).WANG Tao, et al. Method and implementation of remanufacture and repair of aircraft engine damaged blades[J]. Acta Aeronautica Et Astronautica Sinica, 37(03):1036-1048

Tao W, Huapeng D, Jie T, Hao W (2015) Recent repair technology for aero-engine blades. Recent Patents on Engineering 9(2):132–141

Yun Z, Zhi-Tong C, Tao N (2015) Reverse modeling strategy of aero-engine blade based on design intent. Int J Adv Manuf Technol 81(9–12):1781–1796

Huang H, Zhou L, Chen XQ, Gong ZM (2003) SMART robotic system for 3D profile turbine vane airfoil repair. Int J Adv Manuf Technol 21(4):275–283

Gao J, Folkes J, Yilmaz O, Gindy N (2005) Investigation of a 3D non-contact measurement based blade repair integration system. Aircr Eng Aerosp Technol 77(1):34–41

Gao J, Chen X, Zheng D, Yilmaz O, Gindy N (2006) Adaptive restoration of complex geometry parts through reverse engineering application. Adv Eng Softw 37(9):592–600

Gao J, Chen X, Yilmaz O, Gindy N (2008) An integrated adaptive repair solution for complex aerospace components through geometry reconstruction. Int J Adv Manuf Technol 36(11–12):1170–1179

Yilmaz O, Gindy N, Gao J (2010) A repair and overhaul methodology for aeroengine components. Robot Comput Integr Manuf 26(2):190–201

Zhang, Y., Zhang, D., & Wu, B. (2010). A geometry reconstruction approach based on cross-section curve blending for adaptive repair of blades

Piya, C., Wilson, J. M., Murugappan, S., Shin, Y., & Ramani, K. (2011). Virtual repair: geometric reconstruction for remanufacturing gas turbine blades. ASME Paper No. DETC2011-48652

Rong Y, Xu J, Sun Y (2014) A surface reconstruction strategy based on deformable template for repairing damaged turbine blades. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering 228(12):2358–2370

DING H P, Research on Model Reconstruction of Aero-Engine Damaged Blades and Laser Cladding[D]. Tianjin: Civil Aviation University of china,2016–05

Hou F, Wan N, Chang Z, Chen Z, Sun H (2018) An adaptive repair surface modeling approach for worn blades. Int J Adv Manuf Technol 94(1–4):523–532

Yu H, Lyu X (2018) Repair of defective 3D blade model based on deformation of adjacent non-defective cross-sectional curve. Int J Adv Manuf Technol 95(5–8):3045–3055

Rottwinkel B, Nölke C, Kaierle S, Wesling V (2014) Crack repair of single crystal turbine blades using laser cladding technology. Procedia Cirp 22:263–267

Penaranda X, Moralejo S, Lamikiz A, Figueras J (2017) An adaptive laser cladding methodology for blade tip repair. Int J Adv Manuf Technol 92(9–12):4337–4343

Kaierle S, Overmeyer L, Alfred I, Rottwinkel B, Hermsdorf J, Wesling V, Weidlich N (2017) Single-crystal turbine blade tip repair by laser cladding and remelting. CIRP J Manuf Sci Technol 19:196–199

Zhang X, Li W, Liou F (2018) Damage detection and reconstruction algorithm in repairing compressor blade by direct metal deposition. Int J Adv Manuf Technol 95(5–8):2393–2404

Praniewicz M, Kurfess T, Saldana C (2019) An adaptive geometry transformation and repair method for hybrid manufacturing. J Manuf Sci Eng 141(1):011006

Huang N, Bi Q, Wang Y, Sun C (2014) 5-Axis adaptive flank milling of flexible thin-walled parts based on the on-machine measurement. Int J Mach Tools Manuf 84:1–8

Habibi M, Arezoo B, Nojedeh MV (2011) Tool deflection and geometrical error compensation by tool path modification. Int J Mach Tools Manuf 51(6):439–449

Wan XJ, Hua L, Wang XF, Peng QZ, Qin XP (2011) An error control approach to tool path adjustment conforming to the deformation of thin-walled workpiece. Int J Mach Tools Manuf 51(3):221–229

Chen Y, Gao J, Deng H, Zheng D, Chen X, Kelly R (2013) Spatial statistical analysis and compensation of machining errors for complex surfaces. Precis Eng 37(1):203–212

Sun Y, Bao Y, Kang K, Guo D (2013) A cutter orientation modification method for five-axis ball-end machining with kinematic constraints. Int J Adv Manuf Technol 67(9–12):2863–2874

Hao X, Li Y, Deng T, Liu C, Xiang B (2019) Tool path transplantation method for adaptive machining of large-sized and thin-walled free form surface parts based on error distribution. Robot Comput Integr Manuf 56:222–232

Jiang RS, Wang WH, Zhang DH, Wang ZQ (2016) A practical sampling method for profile measurement of complex blades. Measurement 81:57–65

Besl, P. J., & McKay, N. D. (1992, April). Method for registration of 3-D shapes. In Sensor fusion IV: control paradigms and data structures (Vol. 1611, pp. 586-606). International Society for Optics and Photonics

Khameneifar F, Feng HY (2014) Airfoil profile reconstruction under the uncertainty of inspection data points. Int J Adv Manuf Technol 71(1–4):675–683

CHEN Z T. A Complex bus polishing wheel with local reinforcing structure and manufacturing method[P]. 201610168879.X. (in Chinese)

Funding

This work is supported by the National Science and Technology Major Project of the Ministry of Science and Technology of China [grant number 2018ZX04004001].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng-Qing, Z., Yun, Z. & Zhi-Tong, C. A repair strategy based on tool path modification for damaged turbine blade. Int J Adv Manuf Technol 106, 2995–3006 (2020). https://doi.org/10.1007/s00170-019-04801-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04801-z