Abstract

Industries nowadays try their best to remain competitive in a manufacturing world that undergoes a digital transformation driven by smart technology and connected devices. Profit margins quickly shift from products to services, and thus the manufacturing sector industries try to shift from offering products to offering industrial product service systems (IPSS) in order to keep up to date and ensure their market position and economic success. IPSS is a well-rounded solution consisting of the tangible part which is the product and an intangible one being the service. IPSS are efficient and beneficiary not only for the provider but also for the user and even the environment. IPSS is not a simple process of adding services to traditional products but a rather more complex integration process of the mechanical product, sensors, and IoT and software, which are coupled with supportive systems (resources and infrastructures) and the involvement of heterogeneous stakeholders. Due to the high complexity involved in the development and production process of IPSS, tools for IPSS production planning and installation in a dynamic and collaborative environment are extremely essential for manufacturing firms, but they are however absent. In this paper, a methodology for conducting resource planning for the production and installation of IPSS is proposed, and according to this, the architecture of a cloud-based tool is developed. A real-life pilot case from a laser and sheet metal machinery production industry is presented where the developed tool was tested and validated upon its results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays due to the extremely competitive business environment, companies are trying to stay in front of their competition by implementing the latest manufacturing trends. Thus, we are currently witnessing the Fourth Industrial Revolution which is also known as “industry 4.0” [1,2,3]. Industry 4.0 is based on new manufacturing trends like the Internet of Things (IoT), Big Data, Cyber Physical Systems (CPS), advanced sensors and networking, intelligent algorithms, and virtual and augmented reality in order to upgrade the manufacturing process [1, 4, 5], as well as enable the creation of personalized products [6]. In other words, the two basic principles behind industry 4.0 is digitalization [7] and servitization or Internet of Services (IoS) [4]. Digitalization refers to the restructure of the business model in order to take advantage of all the digital and IT-driven technologies like the ones mentioned above by embedding them to their products so as to create new product functions and capabilities as well as boost their value [8,9,10]. The term servitization was first used by [11] back in 1988 and was used to refer to the shift of businesses and manufacturing firms toward offering services which are coupled with their products in order to create extra value and ultimately offer a complete solution to their customers [11,12,13] and also indicates the drive of industries to shift toward manufacturing systems of mass customization [14]. Nowadays, digital technologies and especially web technologies and IoT give companies the opportunity to offer connected products and also keep a closer relationship with their customers and thus share more accurate information which enables providers to customize their desired products and services according to their customers’ needs and generally both sides to create value of this exchange [10, 15, 16]. The recent shift of companies toward servitization [17, 18] gave birth to the concept of “product service systems” (PSS), and in a time span of almost 20 years, the concept of PSS has been examined a lot from numerous researchers, and they all conclude to PSS being a complete solution coupling the tangible product and the intangible service in one offering in order to satisfy the targeted customers’ needs, create value for the provider, and enhance its competitiveness and sustainability [17, 19, 20]. Many researchers also pinpoint the reduction of the environmental footprint as a result of opting for PSS offers [17, 20, 21]. PSS can be classified into three elemental categories [19, 22]: (I) Product-oriented services where the product continues to be the focal point of the business and services are an add-on to the product. (II) Use-oriented services, again here the main offering is the product and services are added in order to enhance its use, extend its life cycle and maximize its value, but in this case, the company retains the ownership rights and only sells the use or the availability of the PSS to one (renting) or multiple (sharing) customers. (III) Result-oriented services, in this case the main offering is the service, and product is of much less significance. In other words, customer pays for a desired result, and company is responsible to accomplish it by any means available. Thus, company again retains full ownership of its PSS. Another way to classify PSS is according to the ownership rights. As the main offers shifts from product to service, ownership rights also transit from customer to provider [17, 21, 23]. IPSS which are also known as technical PSS [18] differ from PSS since there is no virtual distinction between the service and the product during any stage its life cycle, and the product itself has a high net value and involves interactions and transactions between businesses [18, 24]. Despite IPSS exist for more than a decade, their implementation in industry is very challenging due to the planning and design methodologies still being very raw. Apart from the necessary changes in the organizational structure of an industry so as to cope with the new relationships with their customers as well as the differences in ownership rights [19, 25, 26], the implementation of IPSS requires an adaptation to the differences in the life cycle between products and services which ultimately should be considered as one, and at the same time, life cycle itself should be viewed from a more holistic perspective resulting in the conflation of the different phases [27, 28]. Another significant challenge is that IPSS are often approached by industries with methodologies suitable for the development of simple products or services, but such an approach is inadequate since IPSS are far more complex [19, 24]. The higher complexity of IPSS lies in the fact that apart from the physical product, which consist of the simple product, IPSS also entail the implementation of sensors who act as enablers for their servicing aspect. What is more, IPSS display a dynamic behavior within their life cycle [24].

Triggered by this lack in literature regarding IPSS resource planning, this work will examine the alteration needed in resource planning when it comes to IPSS. Firstly, the basic requirements and the structure of IPSS will be researched in order to proceed in building a resource planning tool designed to assist the IPSS provider by finding the optimal way to allocate its resources in order to respond to its customers (planner) as well as by storing all the information needed during the planning phase (procurement).

The rest of the paper is structured as follows: a state-of-the-art review of the designing process for the IPSS, as well as a review of the current resource planning methodologies and supportive tools for IPSS, which are going to indicate the existing gaps. Then, the system architecture for the proposed platform will be presented including the software implementation. On top of that, this framework has been integrated with a support mobile application utilizing augmented reality and cloud infrastructures. The case study of a laser machine industry where the suggested tool was tested will be presented. Finally, conclusions and suggestions for future work will form the last section of the paper.

2 State of the art

As we have already seen in literature, IPSS differ a lot from traditional products. Equivalent differences also apply in designing methods and promotion of an IPSS for the following reasons. First of all, the design process of an IPSS requires a careful combination of all the actors existing in the whole life cycle of an IPSS [29, 30]. Close integration among all factors is required for the organization to make a smoother economic transition into selling services to accompany their products [13, 29]. Moreover, the alterations of IPSS from simple products as far as ownership rights are concerned have created the need for the development of take back or reusing schemes for the IPSS at the end of its life cycle. At the same time, transportation distances are a critical factor which should be minimized. Thus, the designing phase should be done with respect to satisfying customers’ needs and having a lower environmental impact than traditional business models. However, in order to design successfully an IPSS, certain steps should be followed. The whole procedure starts with the customer submitting his order. The submitted order must contain the customer’s exact needs in every detail possible. The next step for an industry is to define the product and the required services to meet customer’s needs; when this is done, the next step is the IPSS planning. If the suggested plan is finally accepted, then the now-specific IPSS is designed, and all necessary adjustments are done in order to deliver the IPSS to the customer. All these steps contain several control loops to ensure the delivered IPSS will meet customer’s demands [29].

However, it is evident that the relationship between the company and a customer plays a key role in the successful designing and the effective use of an IPSS. Thus, companies which focus on offering IPSS instead of simple products tend to work closer to their customers since they greatly depend on getting constant information in order to develop their production. These companies often have early insights into consumer tastes, preferences, and regional buying habits and adjust their designing process accordingly so as to satisfy their needs by offering a personalized IPSS. According to E. Schweitzer and J.C. Aurich [29], there are four different processes that the obtained information should go through in order to become useful for the IPSS design. (I) Identification of information is the process of gathering information and can be initialized both internally on an organizational level and externally by communicating with customers. (II) The next process is gathering information, which describes the admission of field data. For the completion of this process, technicians have to form a formal report either in electronic or written form. Afterward, these reports are pushed forward to the IPSS provider in order to produce the individualized IPSS. (III) The third process is the analysis of information, where the gathered information is thoroughly examined and ultimately assessed upon their relevance and importance. This way information is distinguished in those which can be exploited and those which only present statistical interest. (IV) The last required process is the allocation of information. In this process the selected information is pushed forward once again to a specialized organizational sector of the industry, responsible for the further processing of information. Then a feedback is sent backward to the people responsible for gathering information in the first place. Information that have followed these four processes ensure that information can be successfully used in IPSS designing.

IPSS designing itself can be divided into three dimensions: (I) the result dimension, which includes both the physical (product) part and the nonphysical and intangible service part of an IPSS combined in one entity in order to provide the customer with an expected result or functionality. (II) The process dimension in which the realization of an IPSS includes numerous processes such as product maintenance and training over the entire life cycle of an IPSS. (III) The infrastructure dimension, in this dimension the service network is hold accountable for providing the necessary resources needed for making status changes and for providing the manufacturer with feedback from products, customers, and the market [29]. Apart from the designing phase, the implementation of services has also created the need for the development of new methodologies for the planning phase of the IPSS. According to Baines et al. [21], the designing phase of IPSS has already been thoroughly examined, and plenty of methodologies and designing tools have been proposed, whose main target is the tight integration of all actors within the life cycle of an IPSS [17]. On the other hand, tools for IPSS production and installation planning are missing in a dynamic, collaborative environment. Thus, resource and process planning have to be thoroughly redesigned in order to fit the needs of IPSS. To start with, usually resource planning is initiated when the designing phase of an IPSS for a specific order is complete, and it is therefore ready to be put into production [24]. Resource planning is the procedure of assigning resources to all the necessary processes for the creation of the IPSS. By the term resource encapsulates all the required materials, machines, tools personnel, etc. and all these resources need to be analyzed in order for the optimal plan to be created each and every time [31]. Process planning is the procedure of lining up the required tasks for the production of the IPSS [32]. It has to be stated that resource planning does not only aims to a viable plan, but it aims to find the best possible combination or resource and tasks allocation taking into consideration multiple criteria, such as cost, time, due dates, sequences among tasks, or existing restrictions [24, 33].

However, IPSS have unique characteristics which differentiate them from both the traditional services and traditional products, and at the same time, combining the existing planning methods for the two main elements of an IPSS is considered inadequate. Therefore, new planning methods are needed, and the following unique characteristics of the IPSS should be taken into consideration. An elemental characteristic of the IPSS is the long-lasting relationships that producers maintain with their customers. This close relationship and the constant exchange of information may help the producers minimize troubleshooting processes. Another important characteristic of IPSS is their dynamic behavior over their whole life cycle. This means that an IPSS may change during its use phase according to its customers’ needs and providers’ offerings [34,35,36]. Moreover, many providers offer maintenance and health monitoring as part of the offered services. Therefore, it is possible for the short-term production planning to be interrupted in case of an unexpected malfunction of an already established IPSS, which calls for an urgent resolution. Despite the great customization possibilities of IPSS, the knowledge from already developed IPSS models can be used for the planning and scheduling of new IPSS orders [24]. Customization potential of IPSS is also a great factor to be taken into account in planning, since the planning of two different IPSS, both using the same physical product, might differ significantly due to a different configuration of services. To sum up, the main variances that planning should take into consideration are time, resources, tasks, requirements, costs, and customers’ resources [34]. As far as time is concerned, it includes the due dates for new and existing orders as well as the time needed for each task to be finished and the possibility to reschedule processes in order to fit in new orders or maintenance requests. Resources as a variance refer to the multiple resources, which are able to fulfill the same task, and thus they create numerous alternative plans. The process variance is identified as the set of different choices pleasing the same aim but varying on the customers’ satisfaction. Tasks refer to the different sequences of tasks that they can follow in order for an IPSS to be produced. Requirements refer to the specific customization options of the customer. Lastly, customers’ resources refer to the occasional ability of the provider to use the customers’ resources especially for maintenance issues.

3 Research methodology

The present work was achieved by implementing the following research methodology. At first an extensive literature review was made in order to define what is an IPSS and which are the basic elements that constitutes it. Then the focus turned in the identification of those characteristics which differentiate IPSS from normal products. Consequently, based on these special characteristics, we tried to track down as well the particularities of the resource planning for the production and installation of an IPSS. Apart from the challenges in resource planning, the gaps in resource methodologies, and the absence of supportive solutions and tools for the production of IPSS were also thoroughly explored. Apart from the gained knowledge from the literature review, the development of the tool was also based on the requirements as they were given by the collaborating laser machines industry. The aim of the developed tool was to support the resource planning and installation procedure of the IPSS and also to support the complete life cycle of the IPSS.

The first step of the development of the tool was to determine the essential algorithms which govern its function. As a next step, the type of data required, for the creation of a nearly optimum resource plan, had to be determined. Furthermore, both the methods and the sources for acquiring data were looked into, and the procedures and the resources for the production of an IPSS were defined. Another important aspect which had to be taken into account was the role of the human factor in the production site, since not only many tasks were performed by experienced technicians and not automated machines, but also the final decisions upon the acceptance of the suggested production plan, created by the tool, had to be taken by the corresponding production manager.

When the main algorithms, which consisted the backbone of the tool, were defined, we proceeded with the development of the architecture and UI of the application. The human factor was once again the most critical one that we had to take into consideration during the designing phase. In particular, the scope of the developed tool was to become the missing link which would back up the constant relationship between the IPSS provider and the customer, which is required for the realization of the servicing aspect of the IPSS. This relationship will start with the customers customizing their IPSS upon their individual needs and preferences, and then the developed tool would be responsible to automatically handle any maintenance need of the already established IPSS, based on the data from the IPSS health monitoring.

Lastly, we had to deal with the ethical issues existing in the developed tool. More specifically, the ethics statement constitutes a representation of how the researcher ensures the quality of the research, the way in which informed consent was sought, and how confidentiality, anonymity, and impartiality were maintained. Especially confidentiality was a big concern, since the developed tool aimed to become a multipurpose platform where different parties should have partial access in correspondence to their role, but at the same time, these different parties would upload confidential data on the application’s server which shouldn’t be visible to everyone. Figure 1 presents the research methodology that was followed in this paper.

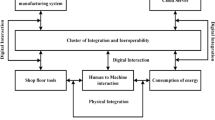

4 System architecture

As we have already stated, resource planning is crucial for the development and production of an IPSS. Therefore, a proposed architecture for a resource planning tool will be described in every detail in this work. The proposed tool was developed in cooperation with a European laser and sheet metal machinery production industry and always according to their needs and requirements. The tool consists of three separate modules, the designer, the planner, and the procurement, but with a high level of interaction among them. Designer is the module which aids the mechanical engineer in designing an IPSS according to customer’s customization options. Customers are able to configure their own IPSS by choosing the parts, services, and subcomponents according to their needs. By the end of this phase, the IPSS design is pushed forward to the planner, which is responsible for creating a nearly optimal resource and production plan, using a weighted multi-criteria algorithm in order to choose from the available resources and line up the execution of tasks. This way the mechanical engineer is given all the information he might need in order to ultimately accept or reject an order. A rejected order can be sent back to the designer module so as to be redesigned with respect to the reasons for which it got rejected. Moreover, apart from managing the new orders, planner is also responsible for conducting rescheduling of the production in order to fit in service and maintenance issues that occur in already established IPSS. The operation of both the designer and planner is greatly supported by the procurement module which stores all the required information regarding the resources needed for the production of the IPSS, including the details of the company and its suppliers’ details. The basic architecture of the developed tool is depicted in Fig. 2

4.1 Procurement

Procurement is the module that constitutes the backbone for the whole tool. The data stored in procurement enable the rest of the modules supported by the developed tool. Thus, procurement aims to serve as the interface, which will support the data entry of products, parts, and sensors in the system. Figure 3 visualizes the concept behind procurement’s operation. The procurement module consists of several subcomponents, and therefore it makes it easier for the user to navigate through the information and for the producer and suppliers to manage their offerings. Entering the procurement module, the user faces the procurement’s dashboard, where he can witness the number of existing products and sensors available in the company. Moreover, the user is able to navigate through the following tabs which are part of the procurement module: company info, products, sensors, parts, product and sensor supply details, parameters of those, and availability in the company. Moreover, user is able to navigate through the following tabs which are part of the procurement module: company info, products, sensors, parts, product supply details, sensor supply details, and parameters. Company info encapsulates all the details regarding the company, including its physical address, a map of the exact position of the company, contact details, and the reference person to get in touch. The products’ tab displays all the existing products together with a brief description of them and their availability. More detailed information and pictures are accessible by clicking on the specific product. Industry’s employees are able to add new products and delete or change the details and parameters of their existing products at any given time. An identical tab with all the details for the available parts allows the customers to choose their desired parts for their personalised IPSS solution. The IPSS provider is able to edit parts likewise products. A similar tab, but this time for sensors, also exists. In this tab one can find detailed specification for every sensor and its use. This time though, sensor suppliers may modify existing sensors’ details or add new ones; however, every change has to be confirmed by the company’s procurement department before being displayed in tool. Products’ and sensors’ supply details include details regarding the cost per unit, the transportation costs, and the delivery time for products and sensors, respectively. The last tab, which is the parameters tab, allows the user through its provided functionalities to customize the existing parameters for products, parts, and sensors and also to add new ones. Parameters are divided into three categories: the quantitative, the qualitative, and the Boolean parameters. Furthermore, parameters are also sorted in groups based on the assignment they are part of.

Apart from the production engineer, customers do also utilize the procurement module in order to configure the IPSS in their own desired way. Since all the information regarding the available parts of the main product, services combined with the required sensors and subcomponents, are stored in the procurement module, customers are able to easily navigate through all the customization options. An order is entirely ready to be forwarded to the planner when the customer has completed his configuration of the IPSS. In other words, he has to surround the main product of interest with his desired, but always compatible with the main product, parts, subcomponents, and services from the lists, available, in the procurement module. When the IPSS configuration is completed, a first design of it is created, with all the possible alternatives for sensors and resources it can utilize, and it is then fed into the planner module.

4.2 Planner

As it has already been made clear, one of the key challenges for the production and delivery of an IPSS is the appropriate resource planning for production, deployment, and installation into customers’ place. Planner comes to fill the lack of proper tools for conducting planning in a dynamic environment that IPSS providers have. Planner is built around a multi-criteria resource planning method for the optimization of the production, delivery, and installation phase. Augmented reality (AR) technologies are greatly utilized to support the production and installation phase. The planner module is also able to handle the machine health monitoring and maintenance schemes for the offered IPSS, taking advantage of cloud in order to draw data from the installed IPSS. Planner is responsible for the semiautomatic configuration of the suppliers’ network and production plan for the realization of the IPSS considering critical sustainability aspects of it. In more details, planner will decide on the optimal set of resources to be used and consequently the equipment suppliers that are going to be used. Moreover, planner organizes the manufacturing processes behind the realization of the IPSS and creates the Bill of Processes by choosing which of the providers’ resources (e.g., machines and technicians) should be used and in what order. Capitalizing on the insight created by the planner module, a production engineer is responsible for accepting or rejecting an IPSS order. If the order is accepted, planner undertakes the task of rescheduling production. The new production plan is forwarded to the manufacturing site where technicians get informed about their new tasks by means of AR technologies. Lastly, a detailed and step-by-step installation guide tailored for the specific customer’s site is created, which is also supported by AR technologies in order to conduct the installation process easier and less time-consuming. All in all, taking advantage of the extremely capable multi-criteria algorithm is able to conclude to a nearly optimal plan and provide estimations regarding IPSS production, delivery time, and transportation costs, whereas in the absence of such a tool, it would require a substantial amount of time to conduct a similar analytical and in-depth search and evaluation of all the possible alternatives. Key objectives among others that planner takes into consideration for creating a process plan are the reduction of lead times in product development and process planning for modular product-services, the improvement of sustainability, and the decrease of time-to-market time and the reduction of set-up and ramp-up times through seamless exchange of process information and knowledge reuse from previous projects. Furthermore, the important part of production planning are the maintenance requests, which usually are of high priority for both the customer and the industry. Through the multiple sensors installed in each machine, planner can gather data regarding machine’s health in real time. These data have a two-way importance for planner and for the producer consequently. Firstly, data from machine monitoring can reveal abnormalities during their operation, which indicates that repair is required. When such an abnormality is identified, planner automatically reschedules the current production schedule in order to fit in the new maintenance request and also notifies the customer and arranges the pickup of the IPSS. Moreover, the gathered data can be analyzed and provide insight for both parties, which can lead to a successful predictive maintenance scheme. In more details, data analysis may provide a trustful number of operating cycles for the machines. This way, producer will be able to schedule way ahead of time and implement in its production planning preemptive maintenance schemes in agreement with its customers. Another advantage, possible to occur from data analyzed, is the development of valid indicators of wear, which are also going to contribute in scheduling maintenance ahead of time. The main architecture behind the planner module can be witnessed in Fig. 4.

Planner consists of several subcomponents presented in Fig. 5. Each subcomponent of the planner provides the interaction with the user and gives to the process engineer the interface in order to have access to the various functionalities of the planner.

Entering the planner module, the user is directed in planners’ dashboard page, where he can have a summary of all the useful data. Dashboard presents all the needed information in order for the engineer to be fully aware of the current status, including the number of process planning and manufacturing estimation requests, the number of the orders, the tasks that the company can execute, and the resources of the company. From the main menu of the planner, the user can navigate through the rest of the applications tabs.

Process Planning Requests tab displays pending, accepted, and rejected process plans, with some basic information regarding the main physical product that the IPSS consists of as well as, the date that it was created. Moreover, the user is able to access further information concerning the services supported by the IPSS according to its process plan and the consequent needs they have for sensors. Through this tab users can create new process plans for any of the pending orders. The engineer is redirected in a new tab where he can see a list with the product, the sensors, and the services that constitute the IPSS pattern of the request, and he can choose from a list and line up the required tasks to form the bill of process which can satisfy the request. Whenever a new task is added, the tool asks the engineer to enter the task properties, and specifically the data needed are the task type, the task name, the task description, and the involved products/sensors/services. The tasks that are added to the process plan appear to the process plan grid along with all their properties. The task interdependencies are also visualized as a tree at the bottom of this screen. After saving the Bill of Processes, the planner takes as input the Bill of Processes along with the available resources of the company and the suitability properties of each resource, and then it plans the tasks, and presents them in a Gantt chart. The user can drag and drop each task through time or even assign it to another resource, except if it belongs in the lock in period since for those days, tasks are being locked. The engineer also has access to further data including a time breakdown among tasks, a correlation of each task with the task type it belongs to, and a cost breakdown. Time breakdown, in particular, visualizes the information regarding the time needed for the production of a specific IPSS giving a graphical comparison of the time needed for the completion of each necessary task, for example, the installation of each sensor (Fig. 6).

In a similar way, cost breakdown graphically depicts the different costs involved in the production of a specific IPSS. These costs include the transportation and production costs as well as detailed costs for each product part and sensor used for the production of the IPSS.

This way the responsible engineer can make a decision on whether to submit a response or reject the order. He is also able to save a draft plan and re-evaluate it later. In the archived solutions tab, the user is able to see successful process plans from previous projects. Details of these process plans and of the specific IPSS pattern they serve are also available for the engineer. When the estimation response tab is launched, the production cost calculator and the production time calculator subcomponents are also launched in order to provide a time and cost estimation for the production of the IPSS request. More specifically, estimations are divided into four separate screens: the overview screen, where the endata needed are the task type, the task name, the task description, and the involved products/sensors/services. The tasks that are added to the process plan appear to the process plan grid along with all their properties. The task interdependencies are also visualized as a tree at the bottom of this screen, where the engineer can see an overview of the subcomponents that consist the IPSS, the estimated time, and cost derived from the Production Cost Calculator and the Production Time Calculator and a map that illustrates the location of the company and the location of the customer. The time breakdown screen, provides visual information depicting the breakdown of the time needed for the production of the specific IPSS order. The The cost breakdown screen is similar to the time breakdown screen but on this case, it depicts the cost breakdown for the specific IPSS. The task manager tab displays a list with all the existing tasks. The engineer can modify or remove the existing tasks or create new ones. The list of tasks that is displayed in the tasks manager tab is the same list of which the engineer forms the Bill of Processes at the process plan response tab. In the resources tab, the user is able to see a list of existing resources and handle them. In the same tab, the engineer is also able to manage or define new suitabilities between the tasks and resources of a specific company. Apart from defining which resource is suitable to execute each task, the engineer is also able to link costs, time, and energy-related properties to each task. The last tab is the orders tab where the engineer can see all the pending orders, and if he wants, he is able to respond to them. When responding to an order, the engineer is presented with the suggested process plan and a Gant chart of the production schedule to help him decide whether to accept the order and allocate the needed resources or reject it.

4.3 Algorithms utilized by the tool

In order for the planner to be able to end up in a nearly optimal resource and process plan, two extremely capable weighted multi-criteria algorithms, one intelligent search algorithm (ISA) [37,38,39] and one exhaustive algorithm, are utilized. The assignment of a set of tasks to a set of resources under multiple and often conflicting optimization criteria conducts the discovery of a nearly optimal solution to an extremely complex and time-consuming problem. The decision-making process can be formalized as a decision matrix, and the ISA is used to obtain a high-quality solution (high utility value) to the resource planning problem in a timely manner. The ISA is based on the methodology proposed by Doukas et al. [38] that uses three adjustable parameters, which are (1) the selected number of alternatives (SNA), which controls the breadth of the search (e.g., the number of alterative trees to be created); (2) the decision horizon (DH), which controls the depth of the search (e.g., the layers searched forward); and (3) the sampling rate (SR), which guides the search through the solution space for the identification of high-quality paths (e.g., number of branches created for each alternative defined by the SNA). It should be mentioned that all the assignments made by the ISA are random. For the implementation of ISA into planner, certain steps should be followed [37]. The first step is the generation of a maximum number of alternatives (MNA). The second step is the calculation of decision-making criteria in order to satisfy a set of manufacturing objectives (CR1… CRn). Step 3 is the weight definition of those criteria. Subsequently, the calculation of the utility value of each one of the alternatives with respect to the selected criteria takes place. It is important to mention here that the utility value (U1… Um) where m ϵ [1, MNA] is the weighted sum of the normalized values of the criteria and takes its values in the range 0 to 1. The final step is the ranking of the alternatives (ALT1… ALTm) and selection of the best alternative with the highest utility value], aka the best resource plan. For improved results, an exhaustive algorithm is also utilized next to ISA. After running the ISA several times, the numerous alternative paths of allocating resources to tasks and executing this tasks have been narrowed down to a handful of different alternatives. Then, an exhaustive algorithm takes charge in order to find the optimal alternative. Again, in order to implement the exhaustive algorithm into planner, the first step (Step A) is to define and set the criteria and goals (e.g., lead times, production cost). The second step (Step B) is to assign weights to the criteria, followed by the calculation and normalization of criteria values (Step C). Afterward, the utility value of each alternative is calculated (Step D), and finally the best alternative is selected (Step E), and the existing production schedule is revised in order to fit in the new order (Step F). The operation of both algorithms is also depicted in Fig. 7.

As already mentioned, IPSS planning in real industrial practice is a complex problem, involving several actors and constraints. To overcome this problem, the planner module follows the presented work structure. The process starts when an IPSS provider receives an order for an IPSS solution from a customer (Step 1). The next step is to make a quick estimation, using both the ISA and the exhaustive algorithm in order to ascertain whether the production of the requested IPSS is feasible (Step2). If the order is determined to be feasible, then the IPSS provider starts designing an IPSS solution that meets the customers’ requirements. During the designing phase, a number of alternative designs are being developed. A design is a solution that integrates a product and a number of services that are implemented through the utilization of hardware (e.g., IoT devices) and software (e.g., data analytics) (Step 3). Every new alternative IPSS design, before it starts being produced, needs to be evaluated with respect to the production feasibility (i.e., there is a feasible process plan that can actually produce the conceived design) and Key Point Indicators (KPIs), such as delivery time and cost (Step 4). A production engineer takes as input the IPSS design and, using some process planning method and tools, develops a feasible process plan (Step 5). The IPSS planning method proposed in this work is used to provide a rough estimation of the time and cost KPIs to implement the process plan. The proposed planning method takes into account the fact that there are a limited number of resources to implement the new IPSS order and that there are already scheduled IPSS orders (Step 6). IPSS designer receives input from the IPSS production engineer and decides if the design solution is acceptable or not. The IPSS designer and production engineer may repeat the whole process several times until a satisfactory result is achieved (Step 7).

In order to deal with the planning problem, some assumptions were made, and some constraints were put. It is assumed that the IPSS provider is also the supplier of the product part of the IPSS. This adds to the simplicity of the planning phase since there is only one supplier option for the product delivery, and moreover for the transportation costs and times of the IPSS solution, it only requires to be transported from the IPSS provider’s site to the customer.

Another constraint is that the IPSS is composed of a product and a number S of services. The planning problem does not include the production of the product which is assumed to be available. The availability of the main product is only taken into account in the preliminary review of the offer together with the required production time and the existing due dates. In many IPSS cases, the product is produced separately, as a first step, and then the tasks that integrate the services into the product take place. The process plan describes a number of N processes and the order in which they are executed. For example, a process such as making a drill to mount a sensor or the process of mounting a sensor in a specific location in the product can be performed on the IPSS provider site. There are a number of R resources that can perform one or more of the N processes. Resources are possessed by IPSS suppliers, product suppliers, and service suppliers on the IPSS manufacturing network. There is a transportation attribute related to a resource since a resource may need to travel to the IPSS provider site or to the customer’s site in order to perform a task. Finally, there is a number of M IPSS orders already scheduled in the IPSS provider’s ecosystem. This practically means that one or more resources within a given time horizon are already scheduled to support the implementation and delivery of other IPSS. The objective of the planning method described below is to find an optimal solution that decides what IPPS equipment (e.g., sensors) suppliers to select, which resources (e.g., IPSS service installation technicians), and when they should perform which processes/tasks at IPSS provider or customer site.

Moreover, the planner module uses to two algorithms to calculate the production time and production cost of an order. The production time calculator computes the time needed for the production and transportation of the IPSS. For the computation, it takes into account the lead time, the setup time, the processing time, and the transportation time. The defined suitabilities provide the information needed for the production time, while the delivery time depends also on the distance between the manufacturer and the customer as well as the parameters for the products and sensors. All the required data for executing the computations are supplied to the planner by the procurement module. In equation (1), t represents tasks ID, T represents the total number of tasks, and the equation provides the total production time.

where

TotalProductionTime is the total time required for the IPSS to be produced and delivered to the customer

ProductionTimet is the required time for the completion of task t

DeliveryTime is the set time needed for the company to prepare the IPSS for transportation

DeliveryTimePerKm is the time required for each Km of travel.

DistanceInKm is the distance in Km between the IPSS provider and the customer’s site

The production time calculator computes the cost needed for the production and transportation of the final product. For the computation, it takes into account properties such as the production cost and the transportation cost. The properties for calculating the production cost are included in each task-resource suitability, while the properties for the calculation of the transportation cost take into account the distance between the location of the customer and the location of the manufacturer as well as the product and sensor parameters, as they are defined in the procurement module. Once again, the procurement module feds all the needed data to the planner. In equation (2), t represents tasks ID and , T represents the total number of tasks, p represents product id, s represents sensor ID, and S represents the total number of sensors and ultimately provides the total production cost.

where

TotalProductionCost is the total cost for the production and delivery of the IPSS to the customer

ProductionCostt is the cost for all the tasks that have to be performed for the IPSS to be produced

UnitCostp is the cost of the physical product

UnitCosts is the cost of the required sensors

TransportationCost is the set cost for preparing the IPSS for transportation

TranspotationCostPerKm is cost per Km traveled until reaching the customer

DistanceInKm is the distance in Km between the IPSS provider and the customer’s site

5 Resource planning tool implementation

The IPSS resource planning tool was developed as a Software-as-a-Service (SaaS) oriented web application. The IPSS tool consists of a user interface and the REST service-oriented module. The user interface is developed as a Java Portlet, following the JSR 168 specification that allows the user interface to be deployed in compatible Java portals, such as Liferay. The Vaadin Java framework was used to develop the Portlet, which exposes the functionality of the IPSS planning tool to the users. The IPSS Planning Tool Portlet can access a knowledge repository where all the required information is stored in an Apache Jena semantic repository. In particular, the repository contains information such as manufacturing resources, already scheduled tasks, preexisting IPSS solution designs, sensors, and product descriptions. The module receives as input all information needed by the IPSS Planning algorithm and produces as an output the result of the planning which includes calculations on the requested KPIs (such as cost and time) and a plan for the production of the IPSS. The input of the service is provided in a specific XML format, and in a similar fashion, the output is provided in an XML format. IPSS Planning Tool Architecture is presented in Fig. 8

6 Case study

In the last part of this paper, a pilot case of a laser and sheet metal machinery production industry, where the suggested methodology was implemented, is going to be presented in order to validate both the functionality and the impact of the designed tool. Moreover, the exploitation of the tool is going to be displayed through the user perspective of the expert engineers of the real-world industrial cases. The laser industry’s need to add services into their preexisting products created the need for a radical revision of the production planning phase, and the implementation of the proposed methodology is going to support this cause.

The laser industry case utilizes the procurement and planner modules of the tool. The laser industry aims to implement services into their products in order to offer longtime services to its customers. These services include a 24/7 machine health monitoring, which is mainly achieved through vibration sensing, process monitoring, and assistance via constant reporting and analytic services. Through the reports and data analytics, the laser industry aims at the performance optimization of their offered solutions. The optimization of the process performance is accomplished through machine natural frequency tests. This service periodically detects the natural frequency of a moving part of the machine and feeds this as a parameter to the motor controllers. Moreover, through the installed optical sensors, industry is able to conduct quality control of the laser cutting procedure, using, for example, an optical system in order to verify the beam centering referred to the nozzle hole and the wear state of the nozzle in terms of process quality. Maintenance is also a crucial new offer that the laser industry aims to implement. Machine data analysis is once again going to be utilized in order to judge and even foresee IPSS needs for urgent and non-urgent maintenance and automatically trigger the requisite sequence for it to happen. Another IPSS offering that the laser industry wanted to implement was to enable customers to customize their products and configure them by choosing which parts, subcomponents, and services meet their needs. Figure 9 depicts an example of the customization options offered to the customer and a possible configuration path.

The implementation of services into their products requires the installation of sensors to their currently offered products. Thus, every new IPSS solution offered by the industry consists of three basic elements (Fig. 10): the machine, which is the main offer of the industry; the sensors, which adds the service aspects; and the extra subcomponents, which boost the customization factor. In order for the IPSS to be ready for installation in customer’s place, all these three elements have to be available and combined through certain tasks implemented by specialized technicians and machines.

Adding customization potential and services to the already existing physical products of the industry resulted in a highly complex process planning procedure and consequently a need for tool which able to assist the engineers in this procedure. This need was covered by the newly developed tool. The laser machine industry implemented the designer, planner, customizer, and procurement module of the tool. The procurement module enables industry to store, edit, and have easy access in all the required information for their production. The industrial engineer can store and update regularly all the details of their offered products and the different configuration options available. Figure 11 presents how product details are depicted within the application tool.

Moreover, industry’s affiliated sensor suppliers are also able to constantly update their product list, and at the same time, industrial engineers can work on the process plan having all these information available (Fig. 12).

Starting from the customer, all the information and configuration options are passed from the procurement to the customizer module, so as the customer can configure his own IPSS solution by simply choosing his desired product (laser machine) and adding to it some or all the available services. The custom IPSS is then pushed forward to the designer module. Using this module an expert engineer may select a preexisting design if it covers the customized requests of the customer, or in any other case a new IPSS design is created, where all the parameters are defined and the required products and parts, as well as the service enabling sensors, are selected. The IPSS design is forwarded to the planner module which is responsible for providing a nearly optimal process plan taking into consideration multiple criteria. Moreover, utilizing the information stored in the procurement, planner is able to create estimations regarding the total cost and the delivery time and depict them via Gant charts (Fig. 13) and pie charts. Industry’s expert engineers are able to make a decision on whether to accept or reject the order, based on these data. If an order is rejected, the IPSS design is fed back to the designer in order for a new design to be created.

However, if the order is accepted, planner takes up the task to reschedule production plan in order to include the production of the specific IPSS. When the new production plan has been created, a step-by-step guide is sent to the technicians, including all the procedures they have to go through for the production of a specific IPSS. AR technologies are also utilized since technicians have tablets with detailed manuals for every procedure. Planners’ last job is to create an installation guide for the IPSS based on the customer’s production site. The installation guide may also facilitate AR technology to ease the installation process. It has to be stated that the laser’s industry engineer isn’t sidelined, but he maintains an active role in the whole procedure. When a new order arrives, the engineer is notified that a new IPSS request exists in dashboard and seeks to be produced. Furthermore, the engineer is also able to intervene in the creation of the bill of process, which is carried out by the planner, and change any parameter (e.g., any resource, supplier, or tasks order) through the process plan response window of the developed tool, which is presented in Fig. 14a–c.

The production engineer is also able to send the complete manufacturing schedule for execution using the planner. All in all, planner is used as a supportive tool for the production engineer in the process planning procedure. Capitalizing on an extremely capable intelligent search algorithm, planner is able to do an initial clarification of the numerous alternatives. Afterward, a weighted multi-criteria algorithm is utilized to decide which requests should be addressed first and how resources should be allocated to every required task for the production of the IPSS which results in a nearly optimal process plan. Figure 15 illustrates how the developed tool was implemented into the Laser industry’s working cycle. In fact, it exhibits a quick overview of the functions and the working structure, which were analyzed in depth previously, and simultaneously it depicts how the developed tool was utilized to assist in every single step.

7 Conclusion and future work

To sum up, due to the rapid changes and the intense digitalization that the manufacturing world goes through, industries try to shift from offering traditional products to offering industrial product service systems in order to keep up to date, remain competitive within the market, and ensure their economic success. Although concept of IPSS has been studied extensively during the past two decades, the field of IPSS planning is still relatively immature and most importantly is missing tools, which could assist in automating the planning phase. Thus, the proposed methodology aims to bridge this gap and provide a tool which is going to support the IPSS planning in all the stages of an IPSS life cycle. IPSS are also linked with a change in the relations between the producer and its customers, which becomes long term with the implementation of services into products. The developed tool aims to become the platform which is going to support this relationship and enable the realization of the servicing aspect offered by the IPSS. The proposed methodology was developed to meet the requirements of a laser machine production industry for a real industrial case. The developed tool was then implemented by the industry in order to be validated and refined according to the recommendations of the industry’s expert engineers. However, despite the fact that the tool was developed in cooperation with the laser machine industry, extra care was taken during its development stage so as to preserve the universal applicability of the created tool.

The developed methodology takes extensive advantage of state-of-the-art technologies and manufacturing trends like big data analytics, cloud technology, and augmented reality. However, an intriguing aspect for future work is to extend the use of AR technologies further than the production stage. An area where there is room for the implementation of AR technologies is maintenance. An algorithm could be developed, which through some specific KPIs, would determine whether an IPSS should be brought back to the producer site to go through the maintenance procedure or maintenance could be completed in customer’s site by means of AR. Moreover, another important aspect which calls for further research is data security. Since many different stakeholders are bound to have access to the developed application and, in most cases, they will upload sensitive data of their company, it should be ensured that only the stakeholders with the right credentials will have access and most importantly, that no third party will have access to these data. This can be ensured via intensive cryptography.

References

Hofmann E, Rüsch M (2017) Industry 4.0 and the current status as well as future prospects on logistics. Comput Ind 89:23–34. https://doi.org/10.1016/j.compind.2017.04.002

Bortolini M, Ferrari E, Gamberi M et al (2017) Assembly system design in the industry 4.0 era: a general framework. IFAC PapersOnLine 50:5700–5705. https://doi.org/10.1016/j.ifacol.2017.08.1121

Kagermann H, Wahlster W, Helbig J, et al (2013) Recommendations for implementing the strategic initiative INDUSTRIE 4.0. Final report of the Industry 4.0 working group

Lee J, Kao HA, Yang S (2014) Service innovation and smart analytics for industry 4.0 and big data environment. Procedia CIRP 16:3–8. https://doi.org/10.1016/j.procir.2014.02.001

Davies R (2015) Industry 4.0 digitalisation for productivity and growth, briefing for the European Parliament (PE 568.337) September 2015. European parliamentary research service

“INDUSTRY 4.0”—TOWARDS OPPORTUNITIES AND CHALLENGES OF IMPLEMENTATION. Available from: https://www.researchgate.net/publication/322449256_INDUSTRY_40-TOWARDS_OPPORTUNITIES_AND_CHALLENGES_OF_IMPLEMENTATION. Accessed Oct 25 2019

Yao X, Lin Y (2016) Emerging manufacturing paradigm shifts for the incoming industrial revolution. Int J Adv Manuf Technol 85:1665–1676. https://doi.org/10.1007/s00170-015-8076-0

Lasi H, Fettke P, Kemper HG et al (2014) Industry 4.0. Bus Inf Syst Eng 6:239–242. https://doi.org/10.1007/s12599-014-0334-4

Bloomberg J (2018) Digitization, Digitalization, And Digital Transformation: Confuse Them At Your Peril. Forbes

Porter ME, Heppelmann JE (2015) How Smart, connected products are transforming companies www.hbr.org 2 how smart, connected products are transforming companies. Harvard bussiness rev 1–9. https://doi.org/10.1017/CBO9781107415324.004

Lenka S, Vinit P, Wincent J (2017) Digitalization capabilities as enablers of value co-creation in servitizing firms. Psychol Mark 34:92–100. https://doi.org/10.1002/mar.20975

Vandermerwe S, Rada J (1988) Servitization of business: adding value by adding services. Eur Manag J 6:315–324

Lightfoot H, Baines T, Smart P et al (2013) Trends the servitization of manufacturing a systematic literature review of interdependent trends. Int J Oper Prod Manag 33:1408–1434. https://doi.org/10.1108/IJOPM-07-2010-0196

Sousa-zomer TT, Miguel PAC (2016) A QFD-based approach to support sustainable product-service systems conceptual design. Int J Adv Manuf Technol 88:701–717. https://doi.org/10.1007/s00170-016-8809-8

Mourtzis D, Fotia S, Boli N, Pittaro P (2018) Product-service system (PSS) complexity metrics within mass customization and industry 4. 0 environment. Int J Adv Manuf Technol 97:91–103

Baines T, Lightfoot H, Benedetinni O, Kay JM (2009) The servitization of manufacturing: a review of literature and reflection of future challenges. J Manuf Technol Manag 20:547–567. https://doi.org/10.1108/17410380910960984

Economics IJP, Rymaszewska A, Helo P, Gunasekaran A (2017) IoT powered servitization of manufacturing – an exploratory case study. Int J Prod Econ 192:92–105. https://doi.org/10.1016/j.ijpe.2017.02.016

Mont OK (2002) Clarifying the concept of product – service system. J Clean Prod 10:237–245

Erkoyuncu JA, Roy R, Shehab E, Cheruvu K (2011) Understanding service uncertainties in industrial product-service system cost estimation. Int J Adv Manuf Technol 52:1223–1238. https://doi.org/10.1007/s00170-010-2767-3

Beuren FH, Gitirana M, Ferreira G, Miguel PAC (2013) Product-service systems: a literature review on integrated products and services. J Clean Prod 47:222–231. https://doi.org/10.1016/j.jclepro.2012.12.028

Goedkoop MJ, van Halen CJG, te Riele HRM, Rommens PJM (1999) Product service systems, Ecological and Economic Basics

Baines TS, Lightfoot H, Steve E et al (2007) State-of-the-art in product service-systems. J Eng Manuf 221:1543–1552. https://doi.org/10.1243/09544054JEM858

Kuo TC, Ma H, Huang SH (2010) Barrier analysis for product service system using interpretive structural model. Int J Adv Manuf Technol 49:407–417. https://doi.org/10.1007/s00170-009-2399-7

Gaiardelli P, Resta B, Martinez V et al (2014) A classification model for product-service offerings. J Clean Prod 66:507–519. https://doi.org/10.1016/j.jclepro.2013.11.032

Meier H, Roy R, Seliger G (2010) CIRP annals - manufacturing technology industrial product-service systems — IPS 2. CIRP Ann Manuf Technol 59:607–627. https://doi.org/10.1016/j.cirp.2010.05.004

Park H, Yoon J (2015) A chance discovery-based approach for new product–service system (PSS) concepts. Serv Bus 9:115–135. https://doi.org/10.1007/s11628-013-0222-x

Huang GQ, Qu T, Zhong RY, Li Z, Yang HD, Zhang YF, Chen QX, Jiang PY, Chen X (2011) Establishing production service system and information collaboration platform for mold and die products. Int J Adv Manuf Technol 52:1149–1160. https://doi.org/10.1007/s00170-010-2762-8

Wuest T, Wellsandt S (2016) Design and development of product service systems (PSS) - impact on product life cycle perspective. Procedia Technol 26:152–161. https://doi.org/10.1016/j.protcy.2016.08.021

Wiesner S, Freitag M, Westphal I, Thoben K (2015) Interactions between service and product life cycle management. Procedia CIRP 30:36–41. https://doi.org/10.1016/j.procir.2015.02.018

Schweitzer E, Aurich JC (2010) Continuous improvement of industrial product-service systems. CIRP J Manuf Sci Technol 3:158–164. https://doi.org/10.1016/j.cirpj.2010.04.002

Durugbo C, Tiwari A, Alcock JR (2011) A review of information flow diagrammatic models for product – service systems. Int J Adv Manuf Technol 52:1193–1208. https://doi.org/10.1007/s00170-010-2765-5

Meier H, Völker O, Funke B (2011) Industrial product-service systems (IPS2): paradigm shift by mutually determined products and services. Int J Adv Manuf Technol 52:1175–1191. https://doi.org/10.1007/s00170-010-2764-6

Schuh G, Prote JP, Luckert M, Hünnekes P (2017) Knowledge discovery approach for automated process planning. Procedia CIRP 63:539–544. https://doi.org/10.1016/j.procir.2017.03.092

Hees A, Reinhart G (2015) Approach for production planning in reconfigurable manufacturing systems. Procedia CIRP 33:70–75. https://doi.org/10.1016/j.procir.2015.06.014

Meier H, Völker O, Funke B (2011) Industrial Product-Service Systems (IPS2). Int J Adv Manuf Technol 52:1175 -1191. https://doi.org/10.1007/s00170-010-2764-6

Sakao T, Paulsson S, Müller P (2011) Integrated Evaluation of a PSS Business Case and a PSS Design Method - Application of the PSS Layer Method to an industrial Drilling Solution. Functional Thinking for Value Creation 153–158. Springer Berlin Heidelberg. https://doi.org/10.1007/978-3-642-19689-8

Alexopoulos K, Koukas S, Boli N, Mourtzis D (2017) Resource Planning for the Installation of Industrial Product Service Systems. In: Lodding H, Riedel R, Thoben KD et al (eds) Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing. APMS 2017. IFIP advances in information and communication technology. Springer, Cham, 514:205–213. Springer, Cham. https://doi.org/10.1007/978-3-319-66926-7_24

Doukas M, Psarommatis F, Mourtzis D (2014) Planning of manufacturing networks using an intelligent probabilistic approach for mass customised products. Int J Adv Manuf Technol 74:1747–1758. https://doi.org/10.1007/s00170-014-6121-z

Michalos G, Makris S, Mourtzis D (2012) An intelligent search algorithm-based method to derive assembly line design alternatives. Int J Comput Integr Manuf 25:211–229. https://doi.org/10.1080/0951192X.2011.627949

Funding

This work has been partially supported by the H2020 EC-funded project ICP4LIFE: “An Integrated Collaborative Platform for Managing the Product-Service Engineering Lifecycle” (GA No. 636862).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mourtzis, D., Zervas, E., Boli, N. et al. A cloud-based resource planning tool for the production and installation of industrial product service systems (IPSS). Int J Adv Manuf Technol 106, 4945–4963 (2020). https://doi.org/10.1007/s00170-019-04746-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04746-3