Abstract

With a wide applicability in several types of engineering problems, topology optimization is one of the most interesting fields of structural optimization. Many meshless methods have been developed, however, they were less explored in topology optimization compared to other methods, as the Finite Element Method (FEM). The Direct Meshless Local Petrov–Galerkin (DMLPG) is characterized as a truly meshless method since it does not use a mesh at any stage of its development. It has been applied to solve many boundary value problems, achieving results with good precision and computational efficiency. Instead of performing the numerical integral of complicated shape functions, the DMLPG considers low-degree polynomials. The new topology optimization approach proposed in this work couples the DMLPG method with a Bi-Directional Evolutionary Structural Optimization (BESO) method. DMLPG is used to obtain smooth nodal displacements, strains, and stresses, and BESO updates the structural geometry based on design sensitivity values. Numerical examples performed were compared with the results obtained with FEM and with other works in the literature, showing the applicability and validity of the technique.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the last 30 years, the topology optimization of structures has attracted the attention of several researchers, and it was successfully applied in many fields of engineering (Sigmund and Maute 2013; Zhu et al. 2020; Stoiber and Kromoser 2021). Topology optimization aims to find the optimal distribution of material within a fixed design domain, minimizing or maximizing an objective function subject to appropriate constraints. Several approaches have already been proposed: the homogenization method (Bendsøe and Kikuchi 1988) and its variant, the Solid Isotropic Microstructure with Penalization (SIMP) method (Bendsøe 1989; Zhou and Rozvany 1991; Sigmund 2001; Bruns and Tortorelli 2001); the Evolutionary Structural Optimization (ESO) method (Xie and Steven 1992, 1993; Chu et al. 1996) and its variant, the Bi-Directional Evolutionary Structural Optimization (BESO) method (Querin et al. 1998); the Level-Set method (Sethian and Wiegmann 2000; Wang et al. 2004, 2007; Ullah and Trevelyan 2016); Topological Derivative (Eschenauer et al. 1994; Norato et al. 2007); among others (Wang and Zhou 2004; Sigmund and Maute 2013).

Traditionally, most approaches proposed in topology optimization are based on the Finite Element Method (FEM) (Bendsøe and Kikuchi 1988; Bendsøe 1989; Eschenauer et al. 1994; Querin et al. 1998; Sethian and Wiegmann 2000), owing to its efficiency and accuracy (Li et al. 2020). However, they are accompanied by the difficulties inherent in ensuring good quality meshes, particularly when remeshing becomes necessary. (Zheng et al. 2012; Juan et al. 2010; Li et al. 2020; Sohouli et al. 2020). Thus, in an endeavor to address some challenges linked with mesh-based approaches, several meshless methods have been proposed (Gingold and Monaghan 1977; Belytschko et al. 1994; Liu et al. 1995; Oñate et al. 1996; Babuska and Melenk 1997; Sukumar et al. 1998; Mirzaei 2013). Some of those meshless methods also have been applied to topology optimization of structures: Element-Free Galerkin (EFG) (Juan et al. 2010; Zhao 2014; He et al. 2014; Cui et al. 2017; Khan et al. 2019; Li et al. 2022; Zhang et al. 2022b; Ullah et al. 2022a); Meshless Local Petrov–Galerkin (MLPG) Mixed Collocation (Li and Atluri 2008a, b); Smoothed Particle Hydrodynamics (SPH) (Lin et al. 2017; Li et al. 2020); Finite Volume Meshless Local Petrov–Galerkin (FVMLPG) (Zheng et al. 2009); Meshless Galerkin (Luo et al. 2012a, b); Radial Point Interpolation Method (RPIM) (Zheng et al. 2010; Ai and Gao 2019); Natural Neighbour Radial Point Interpolation Method (NNRPIM) (Gonçalves et al. 2022c); Reproducing Kernel (RK) (Cho and Kwak 2006).

In meshless methods, the domain is discretized into a set of nodes, without any explicit connectivity between them. The high-order continuity of the trial functions leads to good precision and better adaptability, making meshless approaches very attractive (Li and Atluri 2008b; Zhang et al. 2022a; Nguyen and Bui 2022). However, most meshless approaches used in topology optimization cited previously, make use of a background grid during the integration process.

Mirzaei (2011) proposed the Direct Meshless Local Petrov–Galerkin (DMLPG) method, which is considered a truly meshless approach since it does not use mesh in any stage of the development. Based on a generalized form of Moving Least Squares (MLS), it completely ignores complicated shape functions and numerical integration is performed on low-degree polynomials, as in FEM (Mirzaei 2013), thus achieving results with accuracy equivalent to the original MLPG method, but with greater computational efficiency (Mirzaei 2011, 2013, 2014; Mirzaei and Schaback 2014; Ilati and Dehghan 2016). The DMLPG method can achieve an equivalent precision to finite element-based methods (Abbaszadeh et al. 2022), and it can also consume less computational time since it does not require the mesh generation step (Dehghan et al. 2022). Despite being a relatively recent method, DMLPG has already been used in several applications (Mazzia et al. 2012; Mirzaei 2014; Taleei and Dehghan 2014; Mirzaei and Schaback 2014; Mirzaei and Hasanpour 2015; Darani 2017; Hasanpour and Mirzaei 2018; Abbaszadeh and Dehghan 2020; Shokri and Bahmani 2021), but, to our knowledge, it has not yet been used in the field of topology optimization of structures.

Evolutionary approaches, in particular, have become quite popular among topology optimization methods due to their conceptual simplicity and ease of implementation (Ansola et al. 2007; Huang and Xie 2009; Koke et al. 2015; Teimouri and Asgari 2019; Jiang et al. 2023). In the ESO method, the structure evolves towards an optimum by slowly removing material from regions considered inefficient. A criterion associated with the level of stress or strain energy is used to assess inefficiency. Material is removed from regions with low stress or strain energy. The BESO method is an extension of the ESO method since, in addition to allowing the removal of material, it also allows the addition of material in regions considered efficient. Material is added in locations close to regions with high stress or strain energy. Although these methods have been coupled with meshless approaches, this field is still relatively less explored. For instance, Lee et al. (2009) combined ESO with RPIM to evolve two-dimensional truss structures, while Juan et al. (2010) integrated ESO with EFG to optimize continuum structures, aiming to minimize the weight as the objective function. Another study by Zhao (2014) coupled a modified BESO with EFG, employing the Shepard function to create a dual-level density approximation. Similarly, Shobeiri (2015) applied EFG with BESO to minimize mean compliance while constraining material weight. Recently, Gonçalves et al. (2022a) proposed a new approach using a BESO algorithm with RPIM, reinforcing important parts of the structure to prevent the material domain from becoming too thin, based on a methodology utilizing the cubic average of the Von Mises stress. Additionally, in subsequent works by Gonçalves et al. (2022b, 2022c), the RPIM was replaced with the NNRPIM.

Mesh-based methods have a rich history and are extensively utilized across various scientific and engineering disciplines. In contrast, meshless methods are relatively recent but are emerging as a significant alternative, offering complementary advantages to mesh-based approaches. Researchers in the meshless methods domain are thus tasked with following the trajectory of mesh-based methods to identify potential advantages and applications. In this paper, we explore the utilization of a true meshless method—the DMLPG method—in conjunction with the BESO optimization method to demonstrate their viability in topology optimization. As a result, adjustments have been made to the FEM-based BESO algorithm to facilitate its integration with a meshless framework. Tests performed on problems involving the minimization of the compliance of elastic structures demonstrate good convergence and feasibility of the method.

The article is organized as follows. In Sect. 2, we explain the DMLPG formulation based on the Generalized Moving Least Squares (GMLS) approximations, showing the elasticity problem to be addressed. In Sect. 3, we define the structural optimization problem and describe the process steps of the BESO method. In Sect. 4, we present the tests performed and discuss the obtained results. Finally, in Sect. 5, we present our conclusions.

2 Direct Meshless Local Petrov–Galerkin Method

In this section, the DMLPG formulation is presented, using an elastostatic problem. The section is organized in seven subsections: in Sect. 2.1, the elastostatic boundary value problem is defined; in Sect. 2.2, the local weak form is established and described in matrix form; in Sects. 2.3 and 2.4, the trial and test functions are given; in Sect. 2.5, the linear system to be solved is formalized; in Sect. 2.6, the enforcement of the essential boundary conditions is considered; and, in Sect. 2.7, an algorithm is presented.

2.1 Boundary value problem

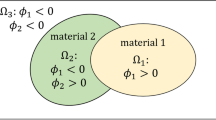

Consider the following linear elastic problem on a body with domain \(\Omega \subset {\mathbb {R}}^d\) and boundary \(\Gamma\), where d is the dimension of the problem. The solid is assumed to undergo infinitesimal deformations (Fig. 1), and the equation of equilibrium is given by (Mirzaei 2014)

where \(\sigma _{ij}\) are the components of the Cauchy stress tensor, \(b_i\) are the components of the body force, \(1 \le i,j \le d\) and \((\cdot )_{,j}\) denotes \(\partial (\cdot )/\partial x_j\).

The global domain \(\Omega\) and the global boundary \(\Gamma\) of an arbitrary two-dimensional body. The boundaries \(\Gamma _u\) and \(\Gamma _t\) are, in that order, the parts of \(\Gamma\) in which the essential and natural boundary conditions are specified. \(\bar{{\textbf{u}}}\) and \(\bar{{\textbf{t}}}\) are the prescribed displacement and traction, respectively, and \({\textbf{n}}\) is the unit outward normal vector at \(\Gamma\)

Two types of boundary conditions are established on \(\Gamma\): the essential boundary condition at \(\Gamma _u \subset \Gamma\) and the natural boundary condition at \(\Gamma _t \subset \Gamma\) (Fig. 1), i.e.,

where \(\bar{u}_i\) denotes the prescribed displacement components at \(\Gamma _u\), \(\bar{t}_i\) denotes the prescribed traction components at \(\Gamma _t\) and \(n_j\) denotes the component of the unit outward normal vector at \(\Gamma\) (Mirzaei 2014). The displacement field \({\textbf{u}}({\textbf{x}})\) in the domain and on the domain’s boundary must be the solution of Eq. (1), and must satisfy Eqs. (2a) and (2b).

2.2 Local weak form

Consider that the domain of the body and its boundary are covered by arbitrarily scattered nodes, and that each node I has a local subdomain \(\Omega _I\) with a local boundary \(\Gamma _I\). The subdomains can have arbitrary shapes, such as squares, circles etc., as illustrated in Fig. 2 (Atluri and Shen 2002). Mirzaei (2014) observed that both circular and rectangular shapes yield satisfactory results in meshless methods. Hence, the selection between these shapes primarily depends on convenience (Liu 2009). In this work, we use only circular subdomains.

Nodes distributions for the DMLPG approach. A local subdomain, with its local boundary, is assigned to each node, which can have an arbitrary shape as illustrated by the nodes \(I=K\) (inner circle), \(I = L\) (circle cutting the boundary) and \(I = J\) (inner rectangle). \(\Omega _J\), \(\Omega _K\) and \(\Omega _L\), represent, in this order, the local subdomains of the nodes J, K and L and their respective borders are \(\Gamma _J\), \(\Gamma _K\) and \(\Gamma _L\). The boundary \(\Gamma _L = \Gamma _{L0} \cup \Gamma _{Lu} \cup \Gamma _{Lt}\), where \(\Gamma _{L0}\) is a part of \(\Gamma _L\) in which no boundary condition is established and \(\Gamma _{Lu}\) and \(\Gamma _{Lt}\), respectively, are parts of \(\Gamma _L\) in which the essential boundary condition and the natural boundary condition are specified. If a node is completely inside the domain, as nodes J and K, then \(\Gamma _J=\Gamma _{J0}\) and \(\Gamma _K=\Gamma _{K0}\)

The boundary \(\Gamma _I\) of node I’s subdomain \(\Omega _I\) can be decomposed as (Liu 2009)

where \(\Gamma _{Iu}\) and \(\Gamma _{It}\) are, respectively, the parts of \(\Gamma _I\) where the essential boundary condition and the natural boundary condition are specified and \(\Gamma _{I0}\) is the part of \(\Gamma _I\) where no boundary condition is established, as illustrated in Fig. 2.

The local Petrov–Galerkin approach is based on a local weak form developed over the local subdomains. The differential equation can be rewritten as a generalized local weak form over the local subdomain \(\Omega _{I}\) as (Liu 2009)

where \(v_{Ii}({\textbf{x}})\) is the component of the test function associated with node I.

Applying the divergence theorem, decomposing boundary \(\Gamma _{I}\) into its constituent parts [Eq. (3)] and imposing the natural boundary condition [Eq. (2b)] (Mirzaei 2014), Eq. (4) can be written in matrix form as

where \(\varvec{\sigma }\) is the vector representation of the stress tensor, \({\textbf{V}}_{I}\) is the test function matrix, \({\textbf{N}}\) is the matrix of the components of the unit outward normal at the boundary \(\Gamma\), \(\mathbf {\bar{t}}\) is the prescribed traction vector at \(\Gamma _{It}\), \({\textbf{b}}\) is the body force vector and \({\textbf{L}}_d\) is the matrix of differential operators used in \(\varvec{\Psi }_{I} = {\textbf{L}}_d{\textbf{V}}_{I}\).

The stress is related to the displacement through (Liu 2009)

where \(\varvec{\varepsilon }\) is the vector representation of the strain tensor, \({\textbf{u}}\) is the displacement vector and \({\textbf{D}}\), in this work, is the elastic stiffness matrix of an isotropic material.

Substituting Eqs. (6a) and (6b) into Eq. (5), the local weak form is written as

2.3 Trial functions

The DMLPG method uses the Generalized Moving Least Squares (GMLS) to approximate the displacement in the problem. In this section, we introduce GMLS and its weight function, based on Mirzaei (2013), Abbaszadeh and Dehghan (2020).

2.3.1 Generalized moving least squares

Consider the linear equation

where \(\lambda\) and \(\beta\) are linear functionals and the components of the unknown function \({\textbf{u}}\), e.g. displacement, \(u_i \in C^m (\Omega )\) (the space of m times differentiable continuous functions).

Let \({\textbf{X}} = \{ {\textbf{x}}_1, \ldots , {\textbf{x}}_N \}\) be a set of nodes scattered in the domain \(\Omega\). The GMLS approximation \({\hat{\lambda }}({\textbf{u}})\) of \(\lambda ({\textbf{u}})\) is the linear combination

of the functionals \(\mu _{J} ({\textbf{u}})\) with coefficients \(a_{J}\). The functionals \(\lambda\) and \(\mu _{J}\) can represent, for example: point evaluations of \({\textbf{u}}\) or any of its derivatives up to order m; a local integral that contains \({\textbf{u}}\) or any of its derivatives in the integrand etc. (Mirzaei 2013).

Consider \({\mathcal {P}} = \text {span} \{ {\textbf{p}}_1, \ldots , {\textbf{p}}_G \}\) a finite dimensional subspace, where the components, \(p_{ki},~i = 1,\dots , d\), of a basis vector \({\textbf{p}}_k\), for \(k=1,\dots ,G\), have continuity \(C^m(\Omega )\), with \(G = \frac{(m+d)!}{m! d!}\). For all functions \({\textbf{p}} \in {\mathcal {P}}\), the equality

holds. Thus, we seek an approximation \({\textbf{p}}^*\) of \({\textbf{u}}\) that minimizes

where \(w_{J}\) is value of a weight function that measures the importance of node J on the minimization process.

Rewriting \({\textbf{p}}\) as a linear combination of the basis vectors of \({\mathcal {P}}\) and taking into account the linearity of the functionals \(\mu _{J}\), then

where \({\textbf{p}}^\mathrm{{T}}_{\mu _{J}} = [ \mu _{J}({\textbf{p}}_1({\textbf{x}})) \; \cdots \; \mu _{J}({\textbf{p}}_G({\textbf{x}}))]\) and \({\textbf{b}}^\mathrm{{T}} = [ b_{1} \; \cdots \; b_{G}].\)

Substituting Eq. (12) into Eq. (11) yields

The coefficients \({\textbf{b}}^*\) from the optimal polynomial, \({\textbf{p}}^*~\in ~{\mathcal {P}}\) are obtained by minimizing \(J({\textbf{b}})\), whose solution can be written as

where \({\textbf{A}}={\textbf{P}}^\mathrm{{T}}{\textbf{W}}{\textbf{P}}\) and \({\textbf{B}} = {\textbf{P}}^\mathrm{{T}}{\textbf{W}}\), with

and \({\varvec{\mu }}{({\textbf{u}})} =[ {\mu }_1{({\textbf{u}})} \; \cdots \; {\mu }_N{({\textbf{u}})} ]^{\mathrm{{T}}}.\)

In the GMLS approximation, the optimal solution is \({\hat{\lambda }}({\textbf{u}}) = \lambda ({\textbf{p}}^*)\) (Mirzaei 2013). Considering Eqs. (12) and (14), we have

2.3.2 Weight function

Several weight functions can be used with the GMLS approximation, for instance: Gaussian function and spline function, both with circular compact support domain. In this work, we use the Gaussian function (Mirzaei 2014)

for \(0 \le r_J \le 1\), where \(r_J = \Vert {\textbf{x}} - {\textbf{x}}_J\Vert / r_w\), with \(r_w\) as the radius of the compact support of the weight function centered in \({\textbf{x}}\), and \(\epsilon\) is a shape parameter of the function’s surface. As illustrated in Fig. 3, the nodes closer to \({\textbf{x}}\) give more contribution and the nodes outside the support region, i.e., \(r_J\ge r_w\), do not give any contribution (\(w(r_J)=0\)). To ensure the invertibility of matrix \({\textbf{A}}\) [Eq. (14)], the number of nodes adjacent to \({\textbf{x}}\) with non-null contribution, N, must be greater or equal to the number of basis vectors, G, i.e. \(N \ge G\) (Atluri and Zhu 1998; Liu 2009).

A model illustrating radius \(r_w\) that defines the compact support of the weight function centered at point \({\textbf{x}}\). Since node J is close to \({\textbf{x}}\), its associated weight is strong. On the other hand, since node K is located at the border of the support region, its associated weight is equal to zero

2.4 Test functions

The test functions are centered at the nodes, and their support regions are defined by the radius \(r_e\). In this work, we use the DMLPG5 approach (Mirzaei 2014), which defines the test function as a Heaviside step function (Fig. 4). For a node I, the test function used in Eqs. (4)–(5) and (7) is defined as (Li et al. 2003)

for \(i = 1, \dots , d\).

2.5 Discretization

Since the Heaviside step function is used as test function, the first integral from Eq. (7) vanishes. Based on Eq. (8), we can define the discretized problem as

where

for \(I = 1,\ldots M\). Considering \({\tilde{N}}\) as the total number of nodes that discretize the domain \(\Omega\), then \(M \ge {\tilde{N}}\) (Mirzaei 2013). In this work, for simplicity, \(M={\tilde{N}}\). Note that the functionals \(\lambda ({\textbf{u}})\) and \(\beta\) [Eq. (8)] are also defined for each dimension \(i = 1,\dots ,d\).

Considering Eqs. (9) and (15), in which the components of \({\varvec{\mu }}\) were taken as the evaluation of the displacement in direction i at the sample point \({\textbf{x}}_J\), we can approximate \(\varvec{\lambda }_I({\textbf{u}})\) as

where N is the number of nodes, adjacent to node I, at which the weight function centered at \({\textbf{x}}_I\) does not vanish, i.e. \(w_J > 0\); and \({\textbf{p}}_{\varvec{\lambda }_I}^\mathrm{{T}} \in {\mathbb {R}}^{d\times dG}\) is defined as

with

for \(k = 1, \ldots , G\) and \({\textbf{P}}_k = {\textbf{L}}_d \begin{bmatrix} \text {diag}\{{\textbf{p}}_k\} \end{bmatrix}\). The notation \(\text {diag}\{{\textbf{p}}_k\}\) represents a diagonal matrix whose diagonal elements are the basis vectors \({\textbf{p}}_k\) applied to \({\textbf{x}}\). \(\varvec{\Phi } \in {\mathbb {R}}^{dG\times dN}\) is the block matrix

with each \(d\times d\) block

In Eq. (24), \(\varvec{\phi }_{kJ}\) is the element \([{\textbf{A}}^{-1}{\textbf{B}}]_{kJ}\) [Eq. (14)].

The linear system

is assembled from each block \({\textbf{K}}_{IJ} \in {\mathbb {R}}^{d\times d}\) and \({\textbf{f}}_{I} \in {\mathbb {R}}^{d\times 1}\) where

and

Here, \(\varvec{\Phi }_{:,J}\) represents the J-th column of \(\varvec{\Phi }\).

2.6 Enforcement of the essential boundary conditions

In this work, since the Kronecker Delta property cannot be guaranteed at the nodes, the essential boundary conditions are imposed using the MLS collocation method (Liu 2009; Mirzaei 2014). For a node I on the \(\Gamma _u\) boundary, the corresponding row of the global linear system [Eq. (25)], where the condition is established for direction i, is zeroed. Then, based on Eq. (9), the following equation is applied,

where \(\bar{u}_{i}({\textbf{x}}_I)\) is the prescribed essential boundary condition at node I with \(i = 1, \dots , d\), the functional \(\delta _{{\textbf{x}}_{I}}\) is the point evaluation at \({\textbf{x}}_I\), \(\varvec{\phi }=~{\textbf{A}}^{-1}{\textbf{B}}\), \({\textbf{p}}_{\delta _{{\textbf{x}}_{I}}}^\mathrm{{T}} =[ p_{1i}({\textbf{x}}_{I}) \; \cdots \; p_{Gi}({\textbf{x}}_{I}) ]\) and \({\textbf{u}}_i^\mathrm{{T}} =[ u_{1i} \; \cdots \; u_{Ni} ]\).

After solving the linear system, a good approximation of the displacements are obtained (Mirzaei et al. 2012). However, to find the actual displacement at any point \({\textbf{x}}\), we can modify Eq. (20) as

where the components of \(\varvec{\delta }_{\textbf{x}}\) are taken as the functionals \(\delta _{{\textbf{x}}_i}\), then \({\textbf{p}}_{\varvec{\delta }_{{\textbf{x}}}}^\mathrm{{T}} =[ {\textbf{p}}_{1}({\textbf{x}}) \; \cdots \; {\textbf{p}}_{G}({\textbf{x}}) ].\)

2.7 Algorithm

The steps of DMLPG method are presented in Algorithm 1. The input model is discretized (Line 2). Then, the adjacent nodes from a node I are found (Line 4) and the \({\textbf{A}}^{-1}{\textbf{B}}\) matrix is computed (Line 5). If \({\textbf{x}}_I \notin \Gamma _u\), the integration points are created, the local stiffness matrix and the local force vector are determinate and assembled in the global system (Lines 6 to 13). Otherwise, the essential boundary condition is enforced in the global system (Lines 14 to 19). The linear system is solved and the nodal displacements are obtained.

3 Topology optimization

The Topology Optimization is performed with a modified BESO method, which is based in the method presented by Huang and Xie (2010). Figure 5 illustrates the flowchart of the proposed technique. The structural optimization problem is defined as

where C is the approximation of the mean compliance (Lin et al. 2017), \({\mathcal {X}}_I\) is the binary design variable at node I, with \({\mathcal {X}}_I=1\) representing solid material and \({\mathcal {X}}_I= {\mathcal {X}}_{\mathrm{{min}}}\) denoting the void, \(V^*\) is the prescribed volume and \(V_I\) is the overestimated nodal volume. A small value, \({\mathcal {X}}_{\mathrm{{min}}}\), is used to represent the void material and to avoid the singularity of the stiffness matrix (Huang and Xie 2009).

The initial model is entered with its boundary conditions. Then, the nodes and the associated integration points are created. To reduce the computational costs, the matrix \({\textbf{A}}^{-1}{\textbf{B}}\) (14) is precomputed for each node.

The iterative procedure begins with the DMLPG analysis where a linear system is constructed and solved to find the displacements, strains and stress at each node. The nodal design sensitivity is calculated (Sect. 3.2) and some post processing is applied (Sect. 3.3). Next, the design variables are updated (Sect. 3.4) by the algorithm, which decides whether material will be added or removed at a node. If the optimization process converges (Sect. 3.5), the optimal design is achieved, otherwise the elastic stiffness matrix is updated at each integration point (Sect. 3.1) and the iterative process continues.

3.1 Elastic stiffness matrix

At each step of the iterative process, the elastic stiffness matrix must be updated at each integration point. For this purpose, an estimated design variable, \({\mathcal {X}}_q\), is defined for each integration point, at position \({\textbf{x}}_q\), as a weighted mean value based on the design variables at the adjacent nodes,

where w is the weight function centered in \({\textbf{x}}_q\) [Eq. (16)] and N is the number of nodes inside the influence radius \(r_w\).

The elastic stiffness matrix is calculated at each integration point in the numerical analysis, and also at each node in the sensitivity analysis. The matrix is modified as (Huang and Xie 2010)

where \({\mathcal {X}}\) is the design variable at an integration point (\({\mathcal {X}} = {\mathcal {X}}_q\)) or at a node (\({\mathcal {X}} = {\mathcal {X}}_I\)), p is the penalty exponent and \({\textbf{D}}_0\) is the initial elastic stiffness matrix [Eq. (6a)].

3.2 Sensitivity analysis

The sensitivity analysis is calculated as the design derivative of the compliance at a node. First, we substitute Eq. (32) into the definition of the stress tensor in Eq. (6a) to yield

Next, considering Eq. (33), the compliance [Eq. (30a)] is rewritten as

Finally, the design derivative is calculated as

Based on Eq. (35), the design sensitivity value at node I is defined as

3.3 Filter and stabilization processes

The use of filtering techniques is a common practice to avoid the numerical instabilities that usually occurs in topology optimization, e.g. checkerboard pattern. The filter used is based on a radius, \(r_{\min }\), that helps to find the adjacent nodes that influence the sensitivity of a node I (Xia et al. 2018)

with

where \({\bar{N}}\) is the number of nodes that are inside the influence radius \(r_{\mathrm{{\min }}}\) and \(r = r_{IJ}\) is the Euclidean distance between nodes I and J.

To guarantee a better convergence of the BESO method, the average of design sensitivity values at the current and previous steps is used as a stabilization procedure (Huang and Xie 2010)

where k is the current iteration of the method.

3.4 Design update

The update of the design variables begins with the computation of the volume fraction at the current iteration (Huang and Xie 2009)

where ER is the evolutionary ratio, which represents a gradual decrease in the target volume until it archives the prescribed volume fraction, \(V^*\).

The BESO method tries to balance the Strain Energy Density (SED) between all the nodes. The design variable of a node, \({\mathcal {X}}_I\), should be increased when the SED is high, and decreased when it is low (Huang and Xie 2010). The optimality criteria is defined as: strain energy densities of solid materials are always higher than those of soft materials (Zhao 2014). Therefore, if the design sensitivity at a node is high, the design variable \({\mathcal {X}}_I\) is updated to value 1, otherwise it is updated to \({\mathcal {X}}_{\mathrm{{min}}}\). The threshold used to rank the sensitivity value starts with the mean value of the maximum and minimum sensitivity values, and it is updated based on how much the structure must change to reach the target volume \(V_k\).

3.5 Convergence criteria

The algorithm converges when the objective function stabilizes and the volume fraction is achieved. The first convergence criterion, based on the variation of the objective function, is defined as (Huang and Xie 2009)

where k is the current iteration number, \(\tau\) is the defined threshold, \(\eta\) is the number of iterations in which the compliance is analyzed. The convergence is achieved when the compliance stabilizes for at least \(2\eta\) iterations.

4 Results

The tests presented in this section demonstrate the effectiveness of the DMLPG method combined with the BESO method applied to Topology Optimization problems of elastic structures. The implementation used C++ and the Eigen Library (Guennebaud et al. 2019). Eigen was used to handle matrix operations and to solve the linear system of algebraic equations. The tests were performed with an 11th Gen Intel®Core\(^{\hbox {TM}}\) i7-11800 H @ 2.30 GHz \(\times\) 16, 16.0 GB RAM running on Ubuntu 21.10.

The examples presented in this section are two-dimensional (\(d=2\)). Thus, the matrices in Eqs. (5) to (7) can be written as:

and

with

where E is the Young’s modulus and \(\nu\) is the Poisson’s ratio of the material.

The integrations in Eq. (19) use Gauss–Legendre quadrature. Since the body force is not used, only the integrals over the boundary of the domain and subdomains are considered. Then the integration points are defined in the one-dimensional parametric space, \(\xi\), of the curve (Fig. 6). For integration purposes, the circular domain is divided into four circular sectors of \(90^{\circ }\) with four integration points each.

The intersection line between the subdomain (\(\Omega _I\)) and the body’s boundary (\(\Gamma\)) can be used to create the integration points (\({\textbf{x}}_q\)) at the border. Each subdomain is divided into circular sector of angle \(90^{\circ }\), where the integration points can be created on the boundary of the subdomain. Each circular arc is parametrized as a line domain with \(-1\le \xi \le 1\)

In all tests, the following parameters are used for the numerical analysis with the DMLPG method: Polynomial order, \(m = 2\), leading to \(G = 6\); Shape parameter of the Gaussian function, \(\epsilon = 4\); Radii, \(r_w = 4 d_{\mathrm{{min}}}\) and \(r_e = 0.7 d_{\mathrm{{min}}}\), where \(d_{\mathrm{{min}}}\) is the minimum Euclidean distance between two nodes. The radius \(r_w\) is increased by \(10\%\) if the matrix \({\textbf{A}}\) [Eq. (14)] is singular (Taleei and Dehghan 2014). The Elasticity modulus and Poisson’s coefficient of the material under plane stress are \(E = 200\) GPa and \(\nu = 0.3\), respectively.

For the structural topology optimization method the following parameters are defined: \({\mathcal {X}}_{\mathrm{{min}}} = 10^{-3}\), \(r_{\mathrm{{min}}} = 3 d_{\mathrm{{min}}}\), \(p = 3\), \(ER=2\%\), \(\eta = 5\) and \(\tau = 10^{-3}\).

Since there is no analytical solution for topology optimization problems, the results are considered plausible when they are similar to the results in the literature (Eschenauer and Olhoff 2001; Li and Atluri 2008b). In order to validate our results, some tests were compared with a FEM-based BESO.

4.1 Cantilever beam

The cantilever beam problem uses the model illustrated in Fig. 7, where \(L=0.08\) m, \(D=0.05\) m, \(P = 4500\) N is distributed over a region of \(h = 0.004\) m times the thickness of \({0.001} {\text{m}}\) and \(V^* = 40\%\). First, a test with a discretization of \(81\times 51\) nodes was used to compare with a FEM solution of similar discretization. Since, in the FEM test, the mesh has \(80\times 50\) elements, the number of nodes in both tests are the same. Despite small differences in the obtained designs, it can be seen that both methods yield similar results (Fig. 8).

Cantilever beam results. a Optimal design with \(81 \times 51\) nodes. b Optimal design of a FEM based on Huang and Xie (2010) with \(80 \times 50\) elements

To analyze the behavior of the technique with different discretizations, two tests with grid sizes of \(65\times 41\) and \(97\times 61\) nodes were conducted (Fig. 9). All optimal structures obtained have equivalent designs with the same number of holes, but the design with fewer nodes exhibits a different boundary shape. While some parameters and methods used may vary, our results align with others found in the literature (Huang and Xie 2007; Li and Atluri 2008b; Gonçalves et al. 2022c; Ullah et al. 2022a).

The evolution history of the objective function for all discretizations is shown in Fig. 10. While the mean compliances increased, the volume fractions decreased. The abrupt jumps in the objective function are due to sudden design changes. In approximately 45 iterations, the volume fractions reached the volume target of \(40\%\). The mean compliances stabilized until they satisfied the convergence criterion. It can be noted that the finer discretization yields a topology design with lower compliance, indicating higher structural stiffness. However, it required more iteration steps. Since there are more nodes, it also has an increased computational cost. Therefore, there is a trade-off between computational cost and achieving better compliance.

4.2 Simply supported beam

A simply supported beam, as shown in Fig. 11a, is considered. To save computational effort, only the symmetrical part of the beam is analyzed (Fig. 11b), where \(L=1.2\) m, \(D=0.6\) m, \(P = 200000\) N is distributed over a region of \(l = 0.004\) m times the thickness of \({0.01} {\text{m}}\), and \(V^* = 60\%\). The problem was initially analyzed with a discretization of \(61 \times 61\) nodes to allow a fair comparison with the BESO based on FEM using \(60\times 60\) elements (Fig. 12). Additionally, two more discretizations were tested with \(56\times 56\) and \(66\times 66\) nodes and are shown in Fig. 13. All results are plausible, as similar results have been archived in other works in the literature (Lee et al. 2009; Challis 2010; Zuo 2010). It is noteworthy that the final design with fewer nodes has a simpler design compared to the others. This indicates that a finer discretization can lead to designs with different topologies. A finer set of nodes is more capable of describing local substructures during the design, which is equivalent to the mesh dependency phenomenon in finite element-based topology optimization of structures (Luo et al. 2013).

Simply supported beam results. a Optimal design with \(61 \times 61\) nodes. b Optimal design of a FEM based on Huang and Xie (2010) with \(60 \times 60\) elements

Figure 14 presents the designs obtained with a discretization of \(61\times 61\) nodes, both with and without the sensitivity filter process. It is evident that the DMLPG method, when combined with the BESO method, fails to eliminate the numerical instability of the checkerboard pattern unless additional schemes are included.

4.3 Beam with fixed supports

A beam with fixed supports, as depicted in Fig. 15a, is considered. To reduce computational effort, only half of the design domain is analyzed, as illustrated in Fig. 15b, due to symmetry. The parameters were set as \(L=1.0\) m, \(D=0.5\) m, \(P = 200000\) N distributed over a region of \(l = 0.004\) m times the thickness of \({0.01} {\text{m}}\), with a target volume fraction of \(V^* = 40\%\). A discretization of \(51\times 51\) nodes was utilized for comparison with a test using \(50\times 50\) elements of the FEM based on (Huang and Xie 2010). Similar results were obtained (Fig. 16), reinforcing the plausibility of the proposed technique.

Beam with fixed supports. a Optimal design with \(51 \times 51\) nodes. b Optimal design of a FEM based on Huang and Xie (2010) with \(50 \times 50\) elements

Figure 17 illustrates the iterative process of the previous result, showing the gradual addition/removal of material as the design evolves towards optimality. The evolution history of the objective function is presented in Fig. 18. The mean compliance begins to stabilize when the volume fraction reaches its target value around iteration 45. Around iteration 20, holes start to appear, leading to oscillations in the objective function, as depicted in Fig. 18. At iteration 40, an abrupt change in compliance occurs due to a structural connection break. Design and objective function stabilization is observed from around iteration 50, with the optimal design achieved at iteration 56.

4.4 L-shaped beam

The L-shaped beam problem utilizes the model depicted in Fig. 19, where \(L=0.1\) m, \(P = 35000\) N distributed over a region of \(l = 0.002\) m times the thickness of \({0.01} {\text{m}}\), and \(V^* = 40\%\). The problem was analyzed with two different numbers of nodes: 2821 and 4033 (Fig. 20). This analysis aimed to investigate the influence of the number of nodes on the final design. As observed in Sect. 4.2, different discretizations can yield distinct designs. However, the obtained results are consistent with those found in the literature (Gonçalves et al. 2022c; Zhao 2014; Ullah et al. 2022b; Picelli et al. 2018). With an increase in the number of nodes, more holes appeared in the topology. Across all tests shown in previous sections, distinct material interfaces were observed in the designs, which would facilitate the manufacturing stage.

The effectiveness of the filtering process is also examined, as depicted in Fig. 21. It is evident that without the filter, the checkerboard pattern instability becomes prominent, emphasizing the necessity of its application. However, the primary structural features are discernible in both cases.

5 Conclusions

We have presented a novel approach to Topology Optimization, which combines the truly meshless method, DMLPG, with the well-known BESO method. The DMLPG approach has been applied to various engineering problems, demonstrating its efficiency and yielding accurate results.

Our examples focused on minimizing the compliance of two-dimensional elasticity problems. The optimal designs obtained were consistent with FEM results and findings from existing literature, thereby highlighting the feasibility of our proposed method. Notably, our technique distinguishes itself from other meshless methods in its integration procedure, as it operates without the need for a background mesh.

By incorporating a sensitivity filter, we ensured that our method remained robust against the occurrence of the checkerboard pattern, a common challenge in topology optimization. However, the phenomenon of discretization dependency persists. As part of future work, we aim to extend our method to handle multiple material problems and three-dimensional structures.

References

Abbaszadeh M, Dehghan M (2020) The fourth-order time-discrete scheme and split-step direct meshless finite volume method for solving cubic-quintic complex Ginzburg-Landau equations on complicated geometries. Eng Comput 38:1543–1557

Abbaszadeh M, Bayat M, Dehghan M (2022) Numerical investigation of the magnetic properties and behavior of electrically conducting fluids via the local weak form method. Appl Math Comput 433:127–293

Ai L, Gao XL (2019) Topology optimization of 2-D mechanical metamaterials using a parametric level set method combined with a meshfree algorithm. Compos Struct 229:111318

Ansola R, Veguería E, Canales J, Tárrago JA (2007) A simple evolutionary topology optimization procedure for compliant mechanism design. Finite Elem Anal Des 44(1–2):53–62

Atluri SN, Shen S (2002) The meshless local Petrov-Galerkin (MLPG) method: a simple & less-costly alternative to the finite element and boundary element methods. Comput Model Eng Sci 3:11–51

Atluri SN, Zhu T (1998) A new meshless local Petrov–Galerkin (MLPG) approach in computational mechanics. Comput Mech 22(2):117–127

Babuska I, Melenk JM (1997) The partition of unity method. Int J Numer Methods Eng 40(4):727–758

Belytschko T, Lu YY, Gu L (1994) Element-free Galerkin methods. Int J Numer Methods Eng 37(2):229–256

Bendsøe MP (1989) Optimal shape design as a material distribution problem. Struct Optim 1:193–202

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197–224

Bruns TE, Tortorelli DA (2001) Topology optimization of non-linear elastic structures and compliant mechanisms. Comput Methods Appl Mech Eng 190(26):3443–3459

Challis VJ (2010) A discrete level-set topology optimization code written in Matlab. Struct Multidisc Optim 41:453–464

Cho S, Kwak J (2006) Topology design optimization of geometrically non-linear structures using meshfree method. Comput Methods Appl Mech Eng 195(44):5909–5925

Chu D, Xie YM, Hira A, Steven GP (1996) Evolutionary structural optimization for problems with stiffness constraints. Finite Elem Anal Des 21(4):239–251

Cui M, Chen H, Zhou J, Wang F (2017) A meshless method for multi-material topology optimization based on the alternating active-phase algorithm. Eng Comput 33:1–14

Darani MA (2017) Direct meshless local Petrov-Galerkin method for the two-dimensional Klein-Gordon equation. Eng Anal Bound Elem 74:1–13

Dehghan M, Hooshyarfarzin B, Abbaszadeh M (2022) Numerical simulation based on a combination of finite-element method and proper orthogonal decomposition to prevent the groundwater contamination. Eng Comput 38:3445–3461

Eschenauer HA, Olhoff N (2001) Topology optimization of continuum structures: a review. Appl Mech Rev 54:331–390

Eschenauer HA, Kobelev VV, Schumacher A (1994) Burble method for topology and shape optimization of structures. Struct Optim 8:42–51

Gingold RA, Monaghan JJ (1977) Smoothed particle hydrodynamics: theory and application to non-spherical stars. Mon Not R Astron Soc 181:375

Gonçalves D, Lopes J, Campilho R, Belinha J (2022a) The radial point interpolation method combined with a bi-directional structural topology optimization algorithm. Eng Comput 38:1–15

Gonçalves D, Lopes J, Campilho R, Belinha J (2022b) Topology optimization of light structures using the natural neighbour radial point interpolation method. Meccanica 57:659–676

Gonçalves D, Lopes J, Campilho R, Belinha J (2022c) Topology optimization using a natural neighbour meshless method combined with a bi-directional evolutionary algorithm. Math Comput Simul 194:308–328

Guennebaud G, Jacob B et al (2019) Eigen v3.3.7. http://eigen.tuxfamily.org

Hasanpour K, Mirzaei D (2018) A fast meshfree technique for the coupled thermoelasticity problem. Acta Mech 229:2657–2673

He Q, Kang Z, Wang Y (2014) A topology optimization method for geometrically nonlinear structures with meshless analysis and independent density field interpolation. Comput Mech 54:629–644

Huang X, Xie YM (2007) Convergent and mesh-independent solutions for the bi-directional evolutionary structural optimization method. Finite Elem Anal Des 43:1039–1049

Huang X, Xie YM (2009) Bi-directional evolutionary topology optimization of continuum structures with one or multiple materials. Comput Mech 43:393–401

Huang X, Xie YM (2010) A further review of ESO type methods for topology optimization. Struct Multidisc Optim 41:671–683

Ilati M, Dehghan M (2016) Remediation of contaminated groundwater by meshless local weak forms. Comput Math Appl 72:2408–2416

Jiang X, Ma J, Teng X (2023) A modified bi-directional evolutionary structural optimization procedure with variable evolutionary volume ratio applied to multi-objective topology optimization problem. Comput Model Eng Sci 135:511–526

Juan Z, Shuyao L, Guangyao L (2010) The topology optimization design for continuum structures based on the element free Galerkin method. Eng Anal Bound Elem 34(7):666–672

Khan W, Siraj-ul-Islam, Ullah B (2019) Structural optimization based on meshless element free Galerkin and level set methods. Comput Methods Appl Mech Eng 344:144–163

Koke H, Weiss L, Hühne C (2015) BESO with strain controlled material assignment. In: 2015 IEEE congress on evolutionary computation (CEC). pp 626–631

Lee SJ, Lee CK, Bae JE (2009) Evolution of 2D truss structures using topology optimization technique with meshless method. In: Symposium of the international association for shell and spatial structures (50th. 2009. Valencia). Evolution and trends in design, analysis and construction of shell and spatial structures: proceedings. Editorial Universitat Politècnica de València, pp 1059–4065

Li S, Atluri SN (2008a) The MLPG mixed collocation method for material orientation and topology optimization of anisotropic solids and structures. Comput Model Eng Sci 30(1):37–56

Li S, Atluri SN (2008b) Topology-optimization of structures based on the MLPG mixed collocation method. Comput Model Eng Sci 26:61–74

Li Q, Shen S, Han ZD, Atluri SN (2003) Application of meshless local Petrov-Galerkin (MLPG) to problems with singularities, and material discontinuities, in 3-D elasticity. Comput Model Eng Sci 4:571–586

Li J, Guan Y, Wang G, Wang G, Zhang H, Lin J (2020) A meshless method for topology optimization of structures under multiple load cases. Structures 25:173–179

Li L, Liu C, Du Z, Zhang W, Guo X (2022) A meshless moving morphable component-based method for structural topology optimization without weak material. Acta Mech Sin 38(5):361–365

Lin J, Guan Y, Zhao G, Naceur H, Lu P (2017) Topology optimization of plane structures using smoothed particle hydrodynamics method. Int J Numer Methods Eng 110(8):726–744

Liu GR (2009) Meshfree methods: moving beyond the finite element method. CRC Press, Boca Raton

Liu WK, Jun S, Zhang YF (1995) Reproducing kernel particle methods. Int J Numer Methods Fluids 20(8–9):1081–1106

Luo Z, Zhang N, Gao W, Ma H (2012a) Structural shape and topology optimization using a meshless Galerkin level set method. Int J Numer Methods Eng 90(3):369–389

Luo Z, Zhang N, Ji J, Wu T (2012b) A meshfree level-set method for topological shape optimization of compliant multiphysics actuators. Comput Methods Appl Mech Eng 223–224:133–152

Luo Z, Zhang N, Wang Y, Gao W (2013) Topology optimization of structures using meshless density variable approximants. Int J Numer Methods Eng 93:443–464

Mazzia A, Pini G, Sartoretto F (2012) Numerical investigation on direct MLPG for 2D and 3D potential problems. Comput Model Eng Sci 88:183–209

Mirzaei D (2011) Development of moving least squares based meshless methods. PhD Thesis, Amirkabir University of Technology

Mirzaei D (2013) Direct meshless local Petrov-Galerkin (DMLPG) method: a generalized MLS approximation. Appl Numer Math 68:73–82

Mirzaei D (2014) A new low-cost meshfree method for two and three dimensional problems in elasticity. Appl Math Model 39:7181–7196

Mirzaei D, Hasanpour K (2015) Direct meshless local Petrov-Galerkin method for elastodynamic analysis. Acta Mech 227:619–632

Mirzaei D, Schaback R (2014) Solving heat conduction problems by the direct meshless local Petrov–Galerkin (DMLPG) method. Numer Algorithms 65:275–291

Mirzaei D, Schaback R, Dehghan M (2012) On generalized moving least squares and diffuse derivatives. IMA J Numer Anal 32:983–1000

Nguyen MN, Bui TQ (2022) A meshfree-based topology optimization approach without calculation of sensitivity. Vietnam J Mech 44:45–58

Norato JA, Bendsøe MP, Haber RB, Tortorelli DA (2007) A topological derivative method for topology optimization. Struct Multidisc Optim 33:375–386

Oñate E, Idelsohn S, Zienkiewicz OC, Taylor RL (1996) A finite point method in computational mechanics. Applications to convective transport and fluid flow. Int J Numer Methods Eng 39(22):3839–3866

Picelli R, Townsend S, Brampton C, Norato J, Kim HA (2018) Stress-based shape and topology optimization with the level set method. Comput Methods Appl Mech Eng 329:1–23

Querin O, Steven G, Xie Y (1998) Evolutionary structural optimisation (ESO) using a bidirectional algorithm. Eng Comput 15:1031–1048

Sethian J, Wiegmann A (2000) Structural boundary design via level set and immersed interface methods. J Comput Phys 163(2):489–528

Shobeiri V (2015) Topology optimization using bi-directional evolutionary structural optimization based on the element-free Galerkin method. Eng Optim 48(3):380–396

Shokri A, Bahmani E (2021) A study of nonlinear systems arising in the physics of liquid crystals, using MLPG and DMLPG methods. Math Comput Simul 187:261–281

Sigmund O (2001) A 99 line topology optimization codewritten in Matlab. Struct Multidisc Optim 21:120–127

Sigmund O, Maute K (2013) Topology optimization approaches. Struct Multidisc Optim 48:1031–1055

Sohouli A, Kefal A, Abdelhamid A, Yildiz M, Suleman A (2020) Continuous density-based topology optimization of cracked structures using peridynamics. Struct Multidisc Optim 62:2375–2389

Stoiber N, Kromoser B (2021) Topology optimization in concrete construction: a systematic review on numerical and experimental investigations. Struct Multidisc Optim 64:1725–1749

Sukumar N, Moran B, Belytschko T (1998) The natural element method in solid mechanics. Int J Numer Methods Eng 43(5):839–887

Taleei A, Dehghan M (2014) Direct meshless local Petrov-Galerkin method for elliptic interface problems with applications in electrostatic and elastostatic. Comput Methods Appl Mech Eng 278:479–498

Teimouri M, Asgari M (2019) Multi-objective BESO topology optimization algorithm of continuum structures for stiffness and fundamental natural frequency. Struct Eng Mech 72:181–190

Ullah B, Trevelyan J (2016) A boundary element and level set based topology optimisation using sensitivity analysis. Eng Anal Bound Elem 70:80–98

Ullah B, Khan W, Siraj-ul-Islam, Ullah Z (2022a) A coupled meshless element-free Galerkin and radial basis functions method for level set-based topology optimization. J Braz Soc Mech Sci Eng 44:89

Ullah Z, Ullah B, Khan W, Siraj-ul-Islam (2022b) Proportional topology optimisation with maximum entropy-based meshless method for minimum compliance and stress constrained problems. Eng Comput 38:5541–5561

Wang MY, Zhou S (2004) Phase field: a variational method for structural topology optimization. Comput Model Eng Sci 6(6):547–566

Wang X, Wang MY, Guo D (2004) Structural shape and topology optimization in a level set based framework of region representation. Struct Multidisc Optim 27:1–19

Wang SY, Lim KM, Khoo BC, Wang MY (2007) An extended level set method for shape and topology optimization. J Comput Phys 221(1):395–421

Xia L, Xia Q, Huang X, Xie YM (2018) Bi-directional evolutionary structural optimization on advanced structures and materials: a comprehensive review. Arch Comput Methods Eng 25:437–478

Xie Y, Steven G (1992) Shape and layout optimization via an evolutionary procedure. In: Proceedings of the international conference computational engineering science, Hong Kong. p 471

Xie Y, Steven G (1993) A simple evolutionary procedure for structural optimization. Comput Struct 49(5):885–896

Zhang J, Peng J, Liu T, Chen J, Luo T, Gong S (2022a) Multi-objective periodic topology optimization of thermo-mechanical coupling structure with anisotropic materials by using the element-free Galerkin method. Int J Mech Mater Des 18:939–960

Zhang J, Zhang H, Chen J, Liu T, Peng J, Zhang D, Yin S (2022b) Topology optimization of periodic mechanical structures with orthotropic materials based on the element-free Galerkin method. Eng Anal Bound Elem 143:383–396

Zhao F (2014) Topology optimization with meshless density variable approximations and BESO method. Comput Aided Des 56:1–10

Zheng J, Long S, Xiong Y, Li G (2008) A topology optimization design for the continuum structure based on the meshless numerical technique. Comput Model Eng Sci 34(2):137–154

Zheng J, Long S, Xiong Y, Li G (2009) A finite volume meshless local Petrov–Galerkin method for topology optimization design of the continuum structures. Comput Model Eng Sci 42(1):19–34

Zheng J, Long S, Li G (2012) Topology optimization of free vibrating continuum structures based on the element free Galerkin method. Struct Multidisc Optim 45:119–127

Zhou M, Rozvany G (1991) The COC algorithm, part II: topological, geometrical and generalized shape optimization. Comput Methods Appl Mech Eng 89(1):309–336 (Second World Congress on Computational Mechanics)

Zhu B, Zhang X, Zhang H, Liang J, Zang H, Li H, Wang R (2020) Design of compliant mechanisms using continuum topology optimization: a review. Mech Mach Theory 143:103622

Zuo ZH (2010) BESO2D manual—getting started with BESO2D. https://www.cism.org.au/tools. Accessed 15 June 2023

Acknowledgements

The present research benefited from BESO MATLAB code made available by the researchers at the Centre for Innovative Structures and Materials. We would like to thank our colleagues from the Federal University of Ceará and from the State University of Piauí who provided insight and expertise.

Funding

The authors did not receive funds, grants or other support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

L.S, S.O. and C.V developed the theory. All authors conceived and planned the experiments. L.S and S.O. carried out the experiments. L.S and S.O. wrote the manuscript with support from C.V. C.V. and J.CN. supervised the project. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no Conflict of interest.

Replication of results

We provided all the information needed to reproduce the results. Interested readers can contact the corresponding author for any additional information.

Additional information

Responsible editor: Xu Guo

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sousa, L., Oliveira, S., Vidal, C. et al. A truly meshless approach to structural topology optimization based on the Direct Meshless Local Petrov–Galerkin (DMLPG) method. Struct Multidisc Optim 67, 110 (2024). https://doi.org/10.1007/s00158-024-03813-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-024-03813-y