Abstract

A topology optimization method is presented to design straight channel cooling structures for efficient heat transfer and load carrying capabilities. The optimization is performed on the structural cross section that consists of solid, void, and fluid coolant. A simplified convective heat transfer model is used to simulate the flow characteristic in the channels with a low computational cost. Besides, a continuous design-dependent surface-based penalty approach is proposed to ensure a meaningful inlet fluid temperature during the continuous process of the fluid topology alteration. Coupled thermomechanical problems are solved to account for the engineering requirements on the uniformity of temperature and structural deformation tolerance. Furthermore, a phase-interface constraint is implemented to prevent unrealistic boundaries that adjoin the liquid to the void or to the outer boundaries of a design domain. Numerical examples of designing a lightweight cooling support frame and a hot stamping tool structure subject to uniform or non-uniform thermomechanical loads are given to demonstrate its applicability. Verification results of 3D structures by a full-blown turbulent fluid simulation show that the proposed approach is effective in yielding channel cooling structures with optimized heat transfer capabilities and well-controlled structural deformation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The focus of this paper is to present a topology optimization approach for designing channel cooling structures with efficient heat transfer and load-carrying capabilities. The considered structure contains straight fluid channels for heat dissipation, void channels for weight reduction, and solid material for load carrying and heat conduction. Such a structural pattern can be found in many industrial apparatuses, such as heat sinks (Shabgard et al. 2015), injection molds (Qiao 2006), stamping tools (Hu et al. 2016), battery supporting frames (Jarrett and Kim 2014; Mao and Yan 2018), etc. However, to simultaneously design the layout of three materials under the lightweight and thermomechanical requirements, such as for a uniform heat transfer and a prescribed deformation level subject to complex thermomechanical and thermal-induced loads, is a challenging task.

In engineering practice, a widely used technique for the cooling-channel design is the simulation-based parametric method, which is by altering the parameters (e.g., position, size and shape) of a predefined set of channels based on computational fluid dynamic (CFD) simulation results to achieve an optimized performance such as maximized heat transfer or minimized pressure drop (Wang et al. 2011; Ferreira et al. 2010; Jarrett and Kim 2014). However, finding a good initial channel set to optimize is non-trivial in practice, as it usually requires trial-and-errors of different numbers of channels or different combinations of parameterizations before reaching a desirable structural performance. Besides, since a CFD model for turbulent flow simulation is computationally expensive, a time-consuming parameterization study and repetitive simulations are always needed, even with surrogate models (Hu et al. 2016; Wang et al. 2011). Hence, the parametric design method is more pertinent to be applied after a proper topology of cooling channels is conceived.

Topology optimization (Bendsøe and Kikuchi 1988; Xie and Steven 1993; Wang et al. 2003) is a powerful structural design tool to form the topology of cooling channels from the scratch, where the fluid, void, and solid materials can be distributed freely in a design domain without bounding to any particular size- or shape-based parameterizations. Previously, much effort has been made on applying this technology to fluid-based design problems.

The fluid topology optimization aims at pursuing a continuum fluid-solid domain with optimized flow performances such as reduced flow power dissipation or minimized pressure drop. In the pioneered study by Borrvall and Petersson (2003), a Stokes flow-based model is used for the flow simulation and a permeability-based interpolation scheme is developed to model the transition between the solid and fluid phases to allow for a continuous design optimization. Similar interpolation schemes have been applied with different fluid models, such as the Navier-Stokes model (Gersborg-Hansen et al. 2005), the Darcy-Stokes model (Guest and Prevost 2006), and the turbulent flow model (Dilgen et al. 2018). These approaches are also developed and applied to 3D problems (Dilgen et al. 2018; Niels et al. 2008; Alexandersen et al. 2016). Although the studies above can provide optimized fluid topologies, the approaches for fluid design problems are sometimes too time-consuming for practical applications, especially when a full-blown CFD model is used to get the velocity and pressure fields as well as for sensitivity analysis. Besides, these studies usually start with predefined configuration of inlets or outlets, while to simultaneously determine the optimal location of fluid inlets and outlets is also worthwhile.

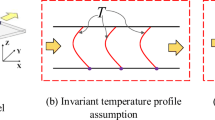

For thermofluidic topology optimization, an efficient heat transfer capability becomes the major concern besides the fluid flow requirements. A variety of different flow problems have been addressed such as the forced convective flow (Yoon 2010), natural convective flow (Alexandersen et al. 2015), the Stokes flow (Koga et al. 2013; Yaji et al. 2016), Navier-Stokes flow (Yaji et al. 2015; Dede 2012; Haertel and Nellis 2017; Li et al. 2018), and Darcy flow (Zhao et al. 2018). Among these works, some recent design approaches are based on the idea of applying a simplified and computationally cheap model with acceptable accuracy for topology optimization. The work by Zhou et al. (2016) used a design-dependent Robin-type boundary condition to model the convective boundary on the interface between fluid and solid domain. Although there are simulation errors, especially on the heat convection at some local regions with complex structural details, between the simplified and a CFD model, the proposed approach is found effective and computationally efficient in industrial applications of topology optimization for combined conductive and convective heat transfer problems. Haertel and Nellis (2017) propose a 2D topology optimization approach to design the cross section of channel cooling structure by considering a fully developed flow that is perpendicular to the design domain. The thermofluidic analysis is performed in 2D by assuming a predefined pressure and temperature variation in the out-of-plane direction. Although the approach is computationally efficient in generating fluid channel layout, the assumption on temperature variation depends on the external load and it must be carefully validated to cope with practical industrial cases with complex thermal loads. Zhao et al. (2018) use a simplified Darcy-based flow model for channel topology optimization to reduce the computational cost in calculating the fluid velocity field. The approach can yield 2D channel topology with efficient heat transfer, which is verified by a full-blown turbulent flow model.

For thermomechanical problems in which the thermal-induced load is introduced as a coupling factor, many thermal-related responses can be optimized by topology alteration, such as thermal expansion (Sigmund and Torquato 1997), design-dependent thermal load (Iga et al. 2009; Gao et al. 2016), thermal fatigue (Madsen et al. 2016), thermal behavior under material with defects (Takalloozadeh and Yoon 2017), etc. Although some monolithic or multi-scale (Wu et al. 2017) structures with well-performing heat transfer or mechanical properties are obtained, to the authors’ best knowledge, few works have been published before to consider the convective heat transfer coupled with the mechanical behavior by designing the topology of fluid, void channels, and solid at the same time. Recently, Munk et al. (2017) carried out a study on the fluid-thermal structural behavior in an aircraft design, in which the air flow convection is considered as an aerodynamics load. However, because the impact force of the liquid flow in channel is much smaller than that in subsonic flow, the approach is not directly applicable to the considered application in this paper. Li et al. (2017) present a topology optimization approach to design an internally cooled turning tool by considering thermomechanical behaviors. However, their optimization model considers linear static and conductive heat-transfer problem without coupling though the design is verified using CFD models.

To overcome the limitation of the high-computational cost in the fluid-related design optimization and to allow for a continuous optimization of fluid inlet and outlet positions together with the structural topology, a multi-phase topology optimization approach consisting of solid, liquid, and void is presented in this paper for lightweight straight-channel cooling structural design considering thermomechanical behavior. The idea is based on leveraging a simplified fluid analysis model by assuming a uniform velocity field in the straight channels. Besides, a design-dependent surface-based penalty approach is proposed to impose a correct inlet temperature boundary condition as well as to allow for a continuous optimization.

The thermomechanical topology optimization is extended to incorporate the fluid effect, whose property is expressed by a multi-phase solid isotropic material with penalization (SIMP)-based interpolation (Bendsøe and Sigmund 2003). In this method, the density filtering (Bourdin 2001; Sigmund 2007) and the projection-based scheme (Guest et al. 2004; Guest 2009; Wang et al. 2011) are leveraged to yield a clear topology without any parameter continuation during the optimization process. In addition, unrealistic boundaries which adjoin the liquid phase to the void or to the outer boundary of design domain are overcome by a phase-interface constraint. A uniformity of displacement constraint is also developed in the optimization process to meet the industrial requirement on a uniform structural deformation tolerance. A 3D FEM model is used for simulation to address the commonly applied non-uniform thermomechanical loads in practice, by which the temperature difference along the extrusion direction can be well captured.

The remainder of this paper is organized as follows. In Section 2, the considered straight-channel cooling structure and the simplified simulation model are first introduced. Then, the parameterization of the multi-phase topology optimization method and the optimization problem with various design responses are given in Section 3. Numerical examples are demonstrated in Section 4, including a cooling support frame design and a hot stamping tool design. All the optimization results are verified using a fully blown turbulent model on the corresponding 3D structural designs. Conclusions are given in Section 5.

2 Channel cooling structure and physical model

2.1 Channel cooling structure

The considered channel cooling structure in this work is an extrusion surface by the same geometry along the straight fluid and void channels, as illustrated in Fig. 1. The cross section Ω consists of solid Ωs (white color), liquid Ωl (blue color), and an unfilled void space Ωv (orange color), respectively. A heat flux and an external pressure loads are applied simultaneously on the top surface Γ1 (red color) of an arbitrary shape (e.g., the working zone of a stamping die). The fluid temperature at the inlet Γ2 is T = TA and a fixed boundary are applied at the bottom (purple color) Γ3. In this structure, the heat is assumed to be dissipated only through the fluid channels and there is no air flow or heat exchange in the voids. By properly arranging the layout of the solid, fluid, and void, a lightweight structure with desirable heat transfer and load-carrying capabilities is expected.

2.2 Convective and diffusive heat transfer

2.2.1 Simplified model

For the simulation of the cooling channel flow with high Reynolds numbers, a turbulent model is usually needed to capture the boundary effect and detailed flow characteristics (Erhard et al. 2010). However, topology optimization with such a model is not only computationally expensive, but it sometimes also requires a cumbersome parameter tuning process on the material interpolation model or on the optimization strategy before obtaining a physically meaningful result.

For cooling channel topology optimization, one practical way to gain computationally efficiency is by using a simplified flow model as long as the errors in the temperature field distribution comparing to that of using a turbulent model does not jeopardize the effectiveness on finding an optimized design solution (Zhao et al. 2018). Inspired by this idea, a uniform flow with a constant velocity field is assumed here in the straight cooling channels instead of the turbulent flow to simplify the simulation and make the computational cost of the multi-phase topology optimization tractable. By assuming the convective heat transfer in the direction of extrusion, the following simplified thermofluidic model is used to predict the temperature distribution:

The notations of each variable above are given as follows: ρ the density, cp the specific heat capacity, uz the average velocity in the fluid channel, T the temperature, k the conductivity, Q the volumetric heat source, n the normal vector, and q the heat flux at boundary Γ1 and TA the ambient temperature.

To impose the Dirichlet temperature condition at the channel inlets, a surface-based penalty approach is used here by adding a penalty term γ into the weak form of the above equations as:

where w is a test function. As will be discussed in the next sections, by setting a large value to the penalty parameter γ, the temperature at the fluid inlets Γ2 will approach the ambient such that a prescribed temperature boundary condition can be recovered. Moreover, since the locations of fluid channels are unknown in priori during topology optimization, formulating γ as design-dependent will facilitate a continuous layout optimization of the channels. As a result, emerging fluid channels during topology optimization can be accompanied with a correct inlet fluid temperature, while the boundaries of the other regions remain insulated. Hence, a pertinent convective heat transfer simulation is guaranteed during the topology optimization process. Note that, although the topology optimization is performed on the 2D cross section, the simulation is carried out on the 3D extruded model to cope with general thermomechanical loads in practice.

The discretized equation by the finite element method (Zienkiewicz et al. 2013) can be written as follows:

where k, ku, and kγ are the diffusion, the convection, and the penalization matrix, respectively. fQ, fq, and fγ denote the volume heat, the heat flux, and the penalization load vectors, respectively. The corresponding elemental matrices and vectors are defined as:

where Nt is the shape function and the subscript t denotes the temperature field.

2.2.2 Model verification

To verify the performance of the simplified model for simulating the straight channel cooling, several case studies are carried out and the results are compared with a Reynolds Average Navier-Stokes (k − 𝜖) model (Erhard et al. 2010). The considered models are shown in Fig. 2 with different channel geometries and topologies. The Case I shown in Fig. 2a has one circular cooling channel in the center, while an extended structure Case II shown in Fig. 2b possesses nine channels of the same size near the top surface. The Case III shown in Fig. 2c has nine elliptical channels of the same size but with different orientations. By applying a heat flux on the top surface of each model and assuming different flow velocities in the channels, the impacts of choosing different γ value, Reynolds numbers, and mesh types, including structural regular mesh (SRM) and boundary layer mesh (BLM), are studied.

For the simulation with the k − 𝜖 model, a velocity boundary condition −n ⋅u = u0 and a temperature boundary condition T = 293.15 K are used at the fluid inlet. Besides, a slip boundary condition is assumed at the walls between the liquid and the solid. For the simplified model, a uniform velocity field uz = u0 and an ambient temperature TA = 293.15 K are assumed. The penalty term γ on the inlet boundary is a parameter to be studied in this section. The detailed geometric parameters and the heat flux values of each model are given in Table 1.

The relative errors between simplified and CFD models are measured based on the average and maximum temperatures at the top surface, the inlet, and the outlet. The indicators are defined as: \(\phantom {\dot {i}\!}E_{a} = \frac {\left | \bar {T}_{C}-\bar {T}_{S} \right |}{\bar {T}_{C}}\) and \(\phantom {\dot {i}\!}E_{m} = \frac {\left | \hat {T}_{C}-\hat {T}_{S} \right |}{\hat {T}_{C}}\), where \(\phantom {\dot {i}\!}\bar {T}_{C}\), \(\phantom {\dot {i}\!}\hat {T}_{C}\), \(\phantom {\dot {i}\!}\bar {T}_{S}\), and \(\phantom {\dot {i}\!}\hat {T}_{S}\) are the average (−) and maximum (∧) temperatures on the top surface in CFD(C) model and simplified(S) model, respectively. Since the variation of temperature at the inlet and outlet is not obvious, the error of maximum temperature is not considered there and the relative errors of average temperature on inlet and outlet are marked as Ei and Eo, respectively.

First, to illustrate how the parameter γ affects the temperature at channel inlets and outlets, three different flow velocities u0 = 0.25 m/s, 0.5 m/s, and 1.0 m/s are simulated for Case II, which correspond to Reynolds numbers Re = 5000, 10,000, and 20,000, respectively. The results of using BLM and SRM meshes are shown in Fig. 3a and b. The relative temperature errors at the inlets and outlets of all cases decline as the γ value increases, while the drop of the the outlet errors becomes nearly stable around E = 0.0001 ∼ 0.01 when γ ≥ 1 × 105W/(m ⋅K), regardless of mesh types. It indicates that with a high γ value (e.g., γ ≥ 1 × 106), the simplified model can have a correct ambient temperature at the channel inlet but it nonetheless has limitation to ensure an accurate temperature at the outlet. Secondly, the relative temperature error at the top surface is given in Fig. 3c and d for different Re and mesh types. Similar to the above, the temperature errors at the top surface decline as γ increases from 10 to 104 and then becomes nearly stable around E = 0.0001 ∼ 0.01 when γ ≥ 1 × 106. Although the final error level is generally not the minimum, which is case dependent and hard to realize, the relative errors of each case become stable when γ ≥ 1 × 107W/(m ⋅K). Thirdly, the impacts of different topologies are further studied and the results are compared in Fig. 3e and f. Although the stable temperature errors at the top surface exhibit different trends when different mesh types are used, the stable errors are nearly in the range of E = 0.0001 ∼ 0.01 when a high γ value is used.

Relative temperature errors by applying different γ values with boundary layer mesh (BLM) and structural regular mesh (SRM): (a–b) temperature errors at channel inlet and outlet of Case II; (c–d) temperature errors at top surface for different Re; (e–f) temperature errors at top surface for different channel topologies and geometries

The temperature distributions of each case are given in Fig. 4, where the first column is obtained by CFD model with BLM, the second column is obtained by simplified model with BLM, and the third column is obtained by simplified model and SRM. Comparing the cases in the first column to that in the second column, the distribution of temperature field in CFD model and in simplified model is almost the same when BLM mesh is used. However, there are differences in the distribution and maximum temperature when a structural regular mesh is used comparing the second, third, and fourth rows of the first and the third columns. Such errors are mainly due to using the structural regular mesh, which is unable to capture the boundary effect precisely unless a denser discretization is used.

Temperature fields of different Reynolds numbers and by various modeling schemes: CFD model with BLM (the first column), simplified model with BLM (the second column), and simplified model with SRM (the third column). Different topologies: single channel (the first row), nine circle channels (the second, third, and fourth rows), and nine elliptic channels (the fifth row). Ave.T. and Max.T. denote the average temperature and maximum temperature on top surface, respectively

The above studies show that the simplified model can yield a similar temperature distribution compared with that obtained by using a fully blown turbulent model. Besides, a high γ value should be applied in order to impose a correct ambient boundary condition at the channel inlet as well as to stabilize relative error level. In this paper, the simplified model is served as an alternative to the turbulent model for topology optimization mainly due to its high computational efficiency despite facts of simulation errors. Such a leverage is important in practical applications when a fast turn-around of topology forming is required. Nonetheless, the design process will be accompanied with a verification step by using more advance CFD models, as shown in later sections.

2.3 Thermomechanical problem

For the coupled thermomechanical problem, the thermal expansion load is defined based on the linear strain that is caused by the temperature difference:

where α is the thermal expansion coefficient, and T and T0 are the current and initial temperatures, respectively. By considering the stress with the thermal effect:

where D is the elasticity matrix, the static government equation is given as:

where f is the structural force and fte is the thermal load induced by temperature. The discretized finite element formulation is written as:

where K is the stiffness matrix and U is the displacement vector. The load vectors f and fte denote the external and the thermal expansion loads, respectively. The element-wise forms of the above matrices and vectors are defined as:

where the Ns and L represent the shape function and Laplace operator, respectively. In the simulation of the channel cooling structure, the heat transfer (3) is first solved and the result is forwarded as an input to the above structural equation.

3 Multi-phase topology optimization

To design a structural layout consisting of solid, fluid, and void in a monolithic way, a multi-phase topology optimization approach is introduced in this section. The distribution of different materials is realized by transforming two continuous design variables into three discrete physical variables, each of which represents a certain domain with unique material properties. In addition, the optimization model including the objective function and engineering constraints is also given. A novel phase-interface constraint is developed to eliminate unrealistic phase-interface in the optimized design.

3.1 Design parametrization and material interpolation

In an earlier study on structural topology optimization of extreme thermal expansion properties (Sigmund and Torquato 1997), a multi-phase interpolation scheme is proposed to define three materials including rigid, soft, and void by two independent design variable fields. Many other multi-phase applications have been presented afterwards (Gibiansky and Sigmund 2000; Stegmann and Lund 2005; Tavakoli and Mohammad 2014) by following a similar interpolation scheme. Recently, an ordered multi-material SIMP method is proposed in Zuo and Saitou (2017), which utilizes only one design variable field to design multiple phases. In this paper, an interpolation scheme similar to that in Sigmund and Torquato (1997) is developed.

As shown in Table 2, it requires two physical variables \(\phantom {\dot {i}\!}\hat {x}\) and \(\phantom {\dot {i}\!}\hat {y}\) to represent three materials. A combination of \(\phantom {\dot {i}\!}\hat {x}\) and \(\phantom {\dot {i}\!}\hat {y}\) with the integer values 0 or 1 corresponds to a certain material with unique properties of Young’s modulus E, heat conductivity k, and penalty term γ as well as the fluid velocity uz.

For a continuous gradient-based optimization, the material properties need to be interpolated properly among each phase when the physical variables \(\phantom {\dot {i}\!}\hat x\) and \(\phantom {\dot {i}\!}\hat y\) take intermediate values between 0 and 1. In this work, the SIMP model is adopted to interpolate them as follows:

where p = 3 is chosen for all physical properties. The above parameterization and material interpolation schemes are illustrated in Fig. 5.

Multi-phase material interpolations: a design-dependent temperature boundary condition parameter and b fluid velocity in z-direction are dominated by both \(\hat x\) and \(\hat y\). c Young’s modulus is dominated by \(\hat y\). d Thermal conductivity is dominated by both \(\hat x\) and \(\hat y\) but the effect of \(\hat x\) is small

In topology optimization of elasticity and heat transfer problems, it is common to apply a density filtering (Bourdin 2001) firstly to regularize the problem by avoiding the mesh-dependent and check-board issues, and then a projection to obtain a crisp layout without “gray elements” of intermediate physical property values. In this work, the above physical variables \(\phantom {\dot {i}\!}\hat x\) and \(\phantom {\dot {i}\!}\hat y\) are obtained from the design variables x, y and the filtered variables \(\phantom {\dot {i}\!}\tilde x\), \(\phantom {\dot {i}\!}\tilde y\) by the same filtering and projection below. For brevity, another variable χ is used to represent x and y. Hence, the density filtering is defined as:

where Ne denotes the neighborhood element set of element e and the weighting function Hei is defined based on the distance between the element e and i and :

where x denotes the coordinate of the corresponding element center and rmin is the radius of density filter.

Applying the density filtering alone may result in design solutions consisting of a large amount of “gray elements,” of which the corresponding material properties are difficult to realize in practice and it is undesirable from a manufacturing point of view. In order to overcome this drawback, a projection scheme based on a smooth Heaviside function is further applied (Sigmund 2007; Guest et al. 2004):

where β determines the steepness of the projection and η is the threshold value. In practice, there are two popular strategies to perform the projection, either by raising the steepness parameter β from 1 to a large number (e.g., β = 64) using a continuous approach or by setting β to a constant large value from the beginning of optimization (Guest et al. 2011). The latter strategy is adopted to obtain the numerical results in Section 4.

3.2 Optimization model

The channel cooling structures typically require efficient heat transfer and uniform structural deformation under external or heat-induced loads as well as lightweight designs. The discretized optimization problem can be formulated as follows:

where ϕ denotes the objective functional, hj represents the design constraints besides two state equations for the coupled thermofluidic and mechanical simulation, and N is the number of designable finite elements. The design objective and practical constraints are introduced as follows.

3.2.1 Regional temperature minimization

The objective of cooling channel design is to find the best cooling efficiency for the overall structure, which can be measured by the temperature of an area near the heat source. In this work, the average temperature at the heat flux region Ω∗ is chosen to assess the cooling efficiency, for which the design objective is defined as follows:

where \(\phantom {\dot {i}\!}A_{{\Omega }^{*}}\) is the area of the heat flux region. L1 is an indexing vector with values 1 in the considered area Ω∗ but values 0 elsewhere. N1 is the number of nodes included in this domain.

3.2.2 Phase volume constraint

For a lightweight structural design, the weight constraint is defined by the volume of the solid material:

where Vs is the predefined volume fraction of the solid phase. Note that, a volume constraint on the liquid phase may also be prescribed if the total flow rate needs to be controlled. However, such a constraint is not typical in practice so that only the weight of the solid phase is considered in the current study.

3.2.3 Structural deformation constraint

Another critical design constraint for a load-bearing structure is on the stiffness and the capability to carry loads in a uniform way. Herein, a regional and uniform displacement constraint is considered, which can be found in many engineering applications such as a cooling support frame or a casting die structure. To characterize the uniformity of the displacement at certain regions, the following measure is proposed:

where I1 and L2 are a diagonal matrix and a vector, respectively, to identify the nodes in the considered area. N2 is the total number of these nodes. U0 is an expected displacement value to control the overall structural deformation level. The uniformity constraint is written in a normalized form as:

where U∗ is a tolerance parameter representing the overall deformation uniformity. Its value is determined by the expected deformation uniformity level in an actual application. Note that, a solution may not exist if a too tight uniformity constraint with a small U∗ value is set, because a perfectly uniform deformed state may not be realized in practice.

3.2.4 Phase-interface control

When designing a multi-phase structure as shown in Fig. 1, a critical issue that must be resolved is the appearance of non-physical neighboring of liquid and void. As shown in Fig. 6, the phase interfaces marked in red color are either adjoining the liquid phase to the void inside the structure or to the outer boundary of the design domain, which leave the liquid hanging in air. These unrealistic interfaces must be prohibited in the optimized design.

The unrealistic boundary that avoids the liquid phase to the void or the outer domain boundary. In the “ghost layer” region, the design variable x = 0 is applied and no liquid phase exists in this layer according to the interpolation frame in Table 2

One solution is by adding an interface constraint in the optimization model to penalize the length of the unrealistic interface. According to the parametrization in Section 3.1, the liquid and the void only appear in the “non-solid” domain where \(\phantom {\dot {i}\!}\hat y = 0\). The interface between the liquid and the void lies in the regions where the gradient of physical design variable \(\phantom {\dot {i}\!}\hat x\) is non-zero. In light of these facts, an indicator function pc based on the non-zero gradient value of \(\phantom {\dot {i}\!}\nabla \hat {x}\) in the void is developed to measure the total length of the unrealistic interface in the design domain:

Thus, a phase-interface constraint can be written as:

where 𝜖p is a tolerance parameter of a small value. Ideally, this number should approach 0 in order to eliminate the unrealistic boundaries completely. However, due to discretization errors and the approximate Heaviside projection scheme, the above indicator pc usually does not have zero value but with a small number even though the field values of x and y are of binary values 0 or 1, if distributed randomly. To the author’s experiences, setting 𝜖p = 0.01 × havg, where havg is the average size of the discretized elements can give converged optimization solutions with unrealistic boundaries properly eliminated. A too small value for 𝜖p may bring difficulties in yielding a solution.

Note that the above indicator pc is only able to capture the interface between the liquid and the non-liquid phases inside the design domain. To prevent the liquid from adjoining the outer boundary of the domain, a “ghost layer” of non-liquid domain (x = 0) can be added outside of the design domain artificially, as shown in Fig. 6. In this way, one phase-interface constraint (19) is adequate in capturing and eliminating all boundaries that adjoin the liquid to the void and to the outer domain boundary, without separating treatments. Besides, the ghost layer imposes no side effect to the optimization since only the design domain is considered in the structural performance evaluation.

3.2.5 Minimal length-scale control

To avoid extremely thin structural members and void or fluid channels in the optimized design, two geometric constraints inspired by Zhou et al. (2015) are developed to impose minimal length scales to all three regions:

where,

In the above equations, Iv and Is denote structural indicator functions for the non-solid and the solid regions, respectively. r = rmin/he is the number of elements covered by the filter radius, where he is the elemental size. ηd and ηe are user-specified thresholds (ηd < η < ηe) and 𝜖g is a small number to compensate the discretization errors.Footnote 1 According to the discussions in Qian and Sigmund (2013), for a desirable minimal length scale b on both materials of a single-phase solid-void structure, ηd can be determined based on the following expression, provided that η = 0.5 and ηe = 1 − ηd used:

e.g., a desired length scale of b = rmin is obtained for ηd = 0.75.

Essentially, each region (solid or void) requires one geometric constraint with a unique indicator function in order to control its minimum length scale (Zhou et al. 2015). However, in this work, due to the implementation of the phase-interphase constraint, the void and liquid regions cannot adjoin each other. Whenever the length-scale constraint (21) is imposed, the fluid and the void as non-solid regions will have the same length-scale control effect. Therefore, two constraints are able to control the minimum length scale of three regions herein.

3.3 Optimization workflow

Upon defining the topology optimization model of multi-phase channel cooling structures as in the previous section, a sensitivity analysis based on the adjoint method is performedFootnote 2, followed by a non-linear programming using the Method of Moving Asymptote (MMA) (Svanberg 1987).

The workflow of the presented optimization is given in Fig. 7 and the solution procedure is summarized as follows:

- Step 1:

-

Initialize the design variables, set up the design domain and ghost layers;

- Step 2:

-

Perform density filtering and projection;

- Step 3:

-

Solve the thermofluidic equation for the temperature field;

- Step 4:

-

Solve the thermomechanical equation for the displacement field;

- Step 5:

-

Perform the adjoint-based sensitivity analysis;

- Step 6:

-

Invoke the MMA solver to update the design variables;

- Step 7:

-

Repeat steps 2 ∼ 7; if the change of objective function value is less than 0.005 and all applied constraints are satisfied (convergence), go to Step 8;

- Step 8:

-

Apply the minimal length-scale constraintsFootnote 3 if required and repeat steps 2 ∼ 8; if minimal length scale is not required or the minimal length-scale constraints have already been implemented, stop iteration.

4 Numerical examples

4.1 Cooling support frame design

The first example is to design a supportive frame structure for holding heat-generating facilities, such as hot-water pipes or silos (Wang et al. 2017). As illustrated in Fig. 8, a core component of a high temperature is located in the middle and supported by four symmetric frame structures with cooling channels. The outside boundaries are fixed by reinforced concrete structures, and other blank regions are reserved empty zones for facility repair or for placing electrical components.

4.1.1 Problem definition

A 3D geometry of the frame structure is illustrated in Fig. 9, where a heat flux generated by the hot core is applied to the top surface. In the meantime, an external pressure boundary condition is exerted at the top surface to represent the pre-stress. The detailed load values and boundary conditions are given in Fig. 9. The structure is assumed to be comprised of steel for solid and water for coolant.

The design goals of this structure are to have a high cooling efficiency by properly distributing the cooling channel and to facilitate a stable supporting capability to the inner core structure. Besides, a lightweight is another important consideration to reduce the fabrication and installation cost. Hence, the objective function and constraints introduced in Section 3.2 are employed to process a topology optimization design.

The cross section is discretized with a SRM of 200 × 200 elements, while the simulation and the sensitivity analysis are performed on the corresponding 3D extruded structure. A passive non-liquid design domain of a thickness 0.04 m is assumed on each boundary of the cross section. Other parameters are set as follows: 𝜖p = 2.5 × 10−5, β = 64, U0 = − 0.2 mm, U∗ = 0.1 mm, and the upper volume bound on the solid Vs = 0.5.

4.1.2 Discussion

With the above problem settings, the impacts of the phase-interface and the minimum length-scale constraints on designing the multi-phase channel cooling structures are first studied. Three optimization cases with or without the two constraints are illustrated in Fig. 10 and their corresponding structural performances are compared in Table 3.

The result shown in Fig. 10a is obtained by solving (14) without neither the phase-interface nor the minimum length-scale constraints. The solid phase, which has almost a discrete distribution of the expected upper volume, carries the external and heat-induced loads such that the upper surface deforms uniformly as constrained. However, the liquid phase, which consists of large amount of “gray elements,” partly lies near the heat source for an efficient cooling but partly hangs in the void which is unrealistic. This is due to an insufficient penalization of intermediate design variables. Having different penalization factors for the different material properties could in theory remedy this issue. Besides, using additional regulations to the optimization model may also help yield a discrete design solution.

By applying the phase-interface constraint from the beginning of optimization, another design is obtained as shown in Fig. 10b. In this case, there is no liquid hanging in the air and seven clear channels appear symmetrically near the top surfaceFootnote 4. The unrealistic boundaries adjoining the liquid to the void are properly avoided. This example clearly shows that the proposed phase-interface constraint is effective and necessary in obtaining meaningful channel cooling structures. It also helps to remove “gray fluid regions” and to ensure a discrete solution under the filtering-projection scheme. However, small structural features may still remain between the fluid channels as seen in Fig. 10b.

The length-scale constraints (21–23) are further applied to give full control on the feature sizes on all phases. In this case, a minimal length scale b = 0.03 m is imposed and correspondingly ηd = 0.64,ηe = 0.36 are set according to (25). A tolerance value 𝜖g = 10−6 is used. Note that the constraints are applied after the optimized design in Fig. 10b was obtained. As shown in Fig. 10c, the minimum feature sizes for all phases in the optimized design are realized and it thus ensures the manufacturability.

In this example, the first design without the phase-interface and geometric constraints has the lowest average temperature 304.53 K at the heat source. The value rises by 3.77 K after the phase-interface constraint is implemented and 1.33 K more with the extra minimal length-scale constraint. The volume constraint is satisfied for all three cases. The convergence curve of the design shown in Fig. 10c is illustrated in Fig. 11. To give a clear display of the history of constraint values, h2 ∼ h5 are given as a logarithmic form. It can be seen that the solid volume constraint h1 and the uniform displacement constraint h2 are satisfied within the first ten iterations, while the phase-interface constraint h3 is satisfied in about 250 iterations. The minimal length-scale constraint is applied after 350 iterations. The constraint becomes satisfied quickly in about 5 iterations before the change of objective becomes less than 0.005 K in iteration 370 and the whole process converges. During the optimization, the objective function value changes smoothly and the whole optimization process is stable.

Convergence history of Fig. 10c

4.1.3 Result verification

The optimized cross-section designs in Fig. 10b and c and the intuitive design in Fig. 9 are rebuilt into smoothed 3D geometries as shown in Fig. 12. Their thermomechanical behaviors are verified using the k − 𝜖 model enabled by the commercial software COMSOL. In the CFD simulation, the flow velocity field is obtained by setting a velocity boundary condition −n ⋅u = u0 at the inlet and a pressure boundary condition p = 0 at the outlet. For the heat transfer, a temperature boundary condition T = TA is applied.

The first row shows that both the mean temperature value of the top surface and its uniformity become better after optimization. As shown in Fig. 12, the average temperatures of the optimized designs (b) and (c) exhibit 13.12 K and 10.93 K lower, respectively, than that in the intuitive design. The second row compares the structural deformation in the direction of the pressure load. The average displacements of the optimized structures are 0.33 mm and 0.32 mm smaller, respectively, and the standard deviations of the displacement variation are also 0.08 mm smaller after optimization.

The verification results show that not only the uniformity of the structures deformation but also the overall stiffness of the lightweight channel cooling structure can be controlled and improved by using the proposed design approach. It is worth mentioning that although the temperature distribution between the simplified and the turbulent models is generally similar, there are errors on the local and maximum temperature values. However, for the optimization objective of a temperature-based global design response, such errors are acceptable and the proposed method is a compromise for efficiency and accuracy.

4.1.4 Designs with different materials

To further illustrate the applicability of the approach, another set of materials considering the aluminum alloy and a special coolant is considered in the following study. The optimization settings are the same as those in the previous example with all constraints applied. The material properties of the solid become E1 = 69GPa,k1 = 210W/ (m ⋅K) and α = 2.38 × 10−5K−1. The liquid property is set as ρ = 900kg/m3 and cp = 2000J/ (kg ⋅K). A relaxed displacement constraint value U0 = − 1 mm, U∗ = 1 mm is applied since the aluminum alloy is softer than the steel in the previous case.

The optimized result is shown in Fig. 13 with a clear phase layout but a different topology compared to that in Fig. 10c. The average temperature of the top surface is 302.027 K and the mean displacement on y direction on top surface is − 0.97 mm with a standard deviation of 0.04 mm. This design exhibits a better cooling performance than the previous one due to the higher conductivity of the solid material. Moreover, the deformation level is properly controlled with a nearly uniform displacement field.

These two designs are further studied by switching the material properties and performing a cross-check. The mean temperature and the mean displacement in Y-direction at the top surface are used as two measures to evaluate the design performance. The results shown in Table 4 reveal that the design optimized for a certain material performs better than the other when the same material is used for verification.

4.2 Hot stamping tool design

The second example is to design a hot stamping die structure for high-strength steel-based impact guardrail boards, which is widely used on highways to prevent vehicles running off the road. Figure 14a shows the geometry of the die structure, where the working zone on the top surface has a complex shape of the guardrail board. For the hot stamping process, it operates on a flat sheet metal of a high temperature and a high cooling rate necessary for the die structure to dissipate the heat away from the working zone as well as to ensure a high strength of the final guardrail boards. Besides, during the stamping process, the working zone must deform as uniformly as possible to minimize the manufacturing defects. With these design requirements, the proposed approach is applied to design the topologies of cooling channels and voids to ensure an efficient thermomechanical behavior on the surface of a lightweight die structure.

4.2.1 Problem definition

The considered die structure is an extended geometry with a depth of 0.5 m in z direction, whose cross section and design domain Ω are shown in Fig. 14a. A pressure of 50 MPa and a heat flux of 20,000 W/m2 are applied on part of the top surface shown in the blue-shaded area in Fig. 14a. Besides, a fixed boundary condition is applied at the bottom plane. For topology optimization, a non-liquid strip of “ghost” layer of a width 0.02 m is assumed near the outer boundary as shown in green color (Fig. 14b). The rectangular domain is discretized by a SRM of 320 × 140 elements. Similar to the previous example, the average temperature at the flux region is chosen as the objective function. Besides, two uniform displacement constraints are applied as U0 = − 0.165 mm in y direction, U0 = 0mm in x direction. The tolerance parameter U∗ = 0.1 mm is set for both directions. Other parameters are defined as follows: minimal length scale b = 0.03m, 𝜖g = 10−6 and the upper volume bound of the solid Vs = 0.5.

4.2.2 Optimization result and verification

Starting with a uniform gray design, an optimized structure with a clear topology is obtained as shown in Fig. 14c. For this optimized result, the mean temperature on the top surface is 308.19 K. Moreover, the average displacement in y direction is − 0.07 mm with a standard deviation of 0.04 mm. With the phase-interface constraint and the minimal length-scale constraint, there is no unrealistic boundaries or small feature details.

The optimized result is compared with a reference design as shown in Fig. 15a, which has circular channels distributed near the top surface and rectangular holes at the bottom. Both the referenced and the optimized cross-sectional designs are rebuilt to 3D models and further verified with a CFD model. For the optimized structure, the average temperature of the top surface is 13.18 K lower than that of the reference design. Besides, the temperature distribution becomes more uniform after optimization. The average deformation on the top surface remains almost the same for the two designs as seen from Fig. 15. However, the uniformity of the displacement is obviously improved in the optimized design, where the standard deviation value of the displacement field drops by 20% from 0.05 to 0.04 mm.

5 Conclusion

This work presents a topology optimization method for fast design straight channel cooling structures with efficient heat transfer and load-carrying capability. Two industrial applications with various geometries and material properties are used to demonstrate the applicability of this approach. By properly modeling the multi-phase configuration using SIMP-based schemes and constraining the phase-interface and the length scale with geometric constraints, manufacturable structural design of clear topologies and optimized thermomechanical behaviors are obtained. Besides, by combining with the proposed interpolation scheme and the phase-interface constraints, the minimal length scales of three different regions are controlled by only two constraints.

Central to this solution is a simplified model with a uniform flow velocity for simulating the convective heat transfer in straight cooling channels. On one hand, this model helps gain a desirable computationally efficiency for topology optimization compared to using a fully blown turbulent model. On the other hand, the general trends of the temperature field distribution are similar, though there are some errors in the temperature simulation. The actual performances of the optimized designs by using the simplified model are verified with a more advanced one, all of which exhibit improved thermomechanical behaviors compared to the reference designs. In practice, the proposed approach can be used as a fast computational tool in the conceptual design phase in forming a straight channel cooling structural topology. Importantly, the optimized cross-section design should always be rebuilt into a refined mesh and verified using a more advanced CFD model. Further investigation will be carried out in a separate work to design conformal cooling structures with combined straight and non-straight channels.

Notes

More technical details and discussions can be found in Zhou et al. (2015).

The derivation of the adjoint-based sensitivity analysis is given in Appendix.

The minimal length-scale constraint is a strong geometric constraint, which can easily lead to a non-physical result (local minima) if applied at the beginning of an optimization process (Zhou et al. 2015). Therefore, it is suggested to be applied once a proper topology is formed.

In this work, no symmetric constraint is used.

References

Alexandersen J, Aage N, Andreasen C, Sigmund O (2015) Topology optimisation for natural convection problems. Int J Numer Methods Fluids 76(10):699

Alexandersen J, Sigmund O, Aage N (2016) Large scale three-dimensional topology optimisation of heat sinks cooled by natural convection. Int J Heat Mass Transfer 100:876

Bendsøe M, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71(2):197

Bendsøe M, Sigmund O (2003) In: Topology optimization: theory, methods and applications. Springer, Berlin

Borrvall T, Petersson J (2003) Topology optimization of fluids in stokes flow. Int J Numer Methods Fluids 41(1):77

Bourdin B (2001) Filter in topology optimization. Int J Numer Methods Eng 50:2143

Dede EM (2012) Optimization and design of a multipass branching microchannel heat sink for electronics cooling. J Electron Packag 134(4):041001

Dilgen C, Dilgen S, Fuhrman D, Sigmund O, Lazarov B (2018) Topology optimization of turbulent flows. Comput Methods Appl Mech Eng 331:363

Erhard P, Etling D, Mller U, Riedel U (2010) Prandtl’s essentials of fluid mechanics, 3rd edn. Springer, New York

Ferreira I, de Weck O, Saraiva P, Cabral J (2010) Multidisciplinary optimization of injection molding systems. Struct Multidiscip Optim 41(4):621

Gao T, Xu P, Zhang W (2016) Topology optimization of thermo-elastic structures with multiple materials under mass constraint. Comput Struct 173:150

Gersborg-Hansen A, Sigmund O, Haber R (2005) Topology optimization of channel flow problems. Struct Multidiscip Optim 30:181

Gibiansky L, Sigmund O (2000) Multiphase composites with extremal bulk modulus. J Mech Phys Solids 48(3):461

Guest J, Prevost J, Belytschko T (2004) Achieving minimum length scale in topology optimization using nodal design variables and projection functions. Intern J Numer Methods Eng 61(2):238

Guest J, Prevost J (2006) Topology optimization of creeping fluid flows using a Darcy-Stokes finite element. Intern J Numer Methods Eng 66:461

Guest J (2009) Topology optimization with multiple phase projection. Comput Methods Appl Mech Eng 199:123

Guest J, Asadpoure A, Ha S (2011) Eliminating beta-continuation from Heaviside projection and density filter algorithms. Struct Multidiscip Optim 44(4):443

Haertel JH, Nellis GF (2017) A fully developed flow thermofluid model for topology optimization of 3d-printed air-cooled heat exchangers. Appl Therm Eng 119:10

Hu P, He B, Ying L (2016) Numerical investigation on cooling performance of hot stamping tool with various channel designs. Appl Therm Eng 96:338

Iga A, Nishiwaki S, Izui K, Yoshimura M (2009) Topology optimization for thermal conductors considering design-dependent effects, including heat conduction and convection. Int J Heat Mass Transfer 52(11-12):2721

Jarrett A, Kim I (2014) Influence of operating conditions on the optimum design of electric vehicle battery cooling plates. J Power Sources 245(1):644

Koga A, Lopes E, Nova H, de Lima C, Silva E (2013) Development of heat sink device by using topology optimization. Int J Heat Mass Transfer 64:759

Li T, Wu T, Ding X, Chen H, Wang L (2017) Design of an internally cooled turning tool based on topology optimization and CFD simulation. Int J Adv Manuf Technol 91(1):1327

Li Z, Wang X, Gu J, Ruan S, Shen C, Lyu Y, Zhao Y (2018) Topology optimization for the design of conformal cooling system in thin-wall injection molding based on bem. Int J Adv Manuf Technol 94(1):1041

Mao Z, Yan S (2018) Design and analysis of the thermal-stress coupled topology optimization of the battery rack in an AUV. Ocean Engineering 148:401

Madsen S, Lange N, Giuliani L, Jomaas G, Lazarov B, Sigmund O (2016) Topology optimization for simplified structural fire safety. Eng Struct 124:333

Michaleris P, Tortorelli DA, Vidal C (1994) Tangent operators and design sensitivity formulations for transient non-linear coupled problems with applications to elastoplasticity. Int J Numer Methods Eng 37:2471

Munk D, Verstraete D, Vio G (2017) Effect of fluid-thermal-structural interactions on the topology optimization of a hypersonic transport aircraft wing. J Fluids Struct 75:45

Niels A, Thomas P, Gersborg-Hansen A, Sigmund O (2008) Topology optimization of large scale stokes flow problems. Struct Multidiscip Optim 35(2):175

Qian X, Sigmund O (2013) Topological design of electromechanical actuators with robustness toward over- and under-etching. Comput Methods Appl Mech Eng 253:237

Qiao H (2006) A systematic computer-aided approach to cooling system optimal design in plastic injection molding. Int J Mech Sci 48:430

Shabgard H, Allen M, Sharifi N, Benn S, Faghri A, Bergman T (2015) Heat pipe heat exchangers and heat sinks: opportunities, challenges, applications, analysis, and state of the art. Int J Heat Mass Transfer 89:138

Sigmund O, Torquato S (1997) Design of materials with extreme thermal expansion using a three-phase topology optimization method. Proceed SPIE - Int Soc Opt Eng 45(6):1037

Sigmund O (2007) Morphology-based black and white filters for topology optimization. Struct Multidiscip Optim 33:401

Stegmann J, Lund E (2005) Discrete material optimization of general composite shell structures. Int J Numer Methods Eng 62(14):2009

Svanberg K (1987) The method of moving asymptotes: a new method for structural optimization. Int J Numer Methods Eng 24:359

Takalloozadeh M, Yoon G (2017) Development of Pareto topology optimization considering thermal loads. Comput Methods Appl Mech Eng 317:554

Tavakoli R, Mohammad MS (2014) Alternating active-phase algorithm for multimaterial topology optimization problems: a 115-line matlab implementation. Struct Multidiscip Optim 49(4):621

Wang M, Wang X, Guo D (2003) A level set method for structural topology optimization. Comput Methods Appl Mech Eng 192:227

Wang F, Lazarov B, Sigmund O (2011) On projection methods convergence and robust formulations in topology optimization. Struct Multidiscip Optim 43:767

Wang G, Zhao G, Li H, Guan Y (2011) Research on optimization design of the heating/cooling channels for rapid heat cycle molding based on response surface methodology and constrained particle swarm optimization. Expert Syst Appl 38:6705

Wang C, Liu L, Liu M, Zhang D, Tian W, Qiu S, Su G (2017) Conceptual design and analysis of heat pipe cooled silo cooling system for the transportable fluoride-salt-cooled high-temperature reactor. Ann Nucl Energy 109:458

Wu T, Liu K, Tovar A (2017) Multiphase topology optimization of lattice injection molds. Comput Struct 192:71

Xie Y, Steven G (1993) A simple evolutionary procedure for structural optimization. Comput Struct 49(5):885

Yaji K, Yamada T, Kubo S, Izui K, Nishiwaki S (2015) A topology optimization method for a coupled thermalCfluid problem using level set boundary expressions. Int J Heat Mass Transfer 81:878

Yaji K, Yamada T, Yoshino M, Matsumoto T, Izui K, Nishiwaki S (2016) Topology optimization in thermal-fluid flow using the lattice boltzmann method. J Comput Phys 307:355

Yoon G (2010) Topological design of heat dissipating structure with forced convective heat transfer. J Mech Sci Technol 24(6):1225

Zhao X, Zhou M, Sigmund O, Andreasen C (2018) A “poor man’s approach” to topology optimization of cooling channels based on a Darcy flow model. Int J Heat Mass Transfer 116:1108

Zhou M, Lazarov B, Wang F, Sigmund O (2015) Minimum length scale in topology optimization by geometric constraints. Comput Methods Appl Mech Eng 293:266

Zhou M, Alexandersen J, Sigmund O, Pedersen C (2016) Industrial application of topology optimization for combined conductive and convective heat transfer problems. Struct Multidiscip Optim 54:1045

Zienkiewicz O, Taylor R, Zhu J (2013) In: The finite element method: its basis and fundamentals, 7th edn. Butterworth-Heinemann, Oxford

Zuo W, Saitou K (2017) Multi-material topology optimization using ordered SIMP interpolation. Struct Multidiscip Optim 55:477

Funding

The authors acknowledge the support from National Natural Science Foundation of China (Grant No. 51705311) and from the State Key Laboratory of Mechanical System and Vibration of Shanghai Jiao Tong University (Grant No. MSVZD201709).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Anton Evgrafov

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Xi Zhao and Mingdong Zhou contributed equally to this paper

Appendix: Sensitivity analysis

Appendix: Sensitivity analysis

By using the adjoint method (Michaleris et al. 1994), the objective function is augmented by a product of an adjoint field and the residual of the state equation:

The derivative of the new objective functional w.r.t \(\phantom {\dot {i}\!}\hat {\chi }\) can be written as:

where \(\phantom {\dot {i}\!}\hat \chi \) denotes the design variable field. By collecting the temperature gradient terms and setting up the following adjoint equation, λ thus can be obtained by:

where

Similarly, with another augmented functional for the displacement uniformity constraint:

its derivative is expressed as:

where

and

The adjoint terms \(\phantom {\dot {i}\!}{\boldsymbol {\lambda }}_{c}^{\text {T}}\) and \(\phantom {\dot {i}\!}{\boldsymbol {\lambda } }_{ct}^{\text {T}}\) are calculated using the following equations:

where

and

where

As a result, the derivative of the uniformity constraint is written as:

The derivatives of the terms K,ft,k,ku,kγ, and fγ w.r.t. \(\phantom {\dot {i}\!}\hat {\chi }\) are obtained according to the corresponding material interpolation schemes.

Rights and permissions

About this article

Cite this article

Zhao, X., Zhou, M., Liu, Y. et al. Topology optimization of channel cooling structures considering thermomechanical behavior. Struct Multidisc Optim 59, 613–632 (2019). https://doi.org/10.1007/s00158-018-2087-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-018-2087-z