Abstract

In this paper, a model validation framework is proposed and applied to a large vibro-acoustic finite element (FE) model of a passenger car. The framework introduces a p-box approach with an efficient quantification scheme of uncertainty sources and a new area metric which is relevant to the responses in the frequency domain. To prioritize the input uncertainties out of the enormous FE model, the experts’ knowledge is utilized to select candidate input parameters which have large potential influences on the response of interests (ROI) among several thousands of input parameters. Next, a variance-based sensitivity analysis with an orthogonal array is introduced in effort to quantify the influence of the selected input parameters on the ROIs. The employment of the eigenvector dimension reduction method and orthogonal combinations of interval-valued input parameters provides the p-box of the ROI even if the size of the FE model is very large. A color map and the u-pooling of the p-boxes over the frequency band as well as the p-box at different frequencies are introduced to assess the model error and quantitative contributions of the aleatory and the epistemic input uncertainties to the overall variability of the ROIs in the frequency domain. After assessing the model error, the FE model is updated. It was found that the sensitivity results and the experts’ knowledge about the associated components effectively determine the modifications of the component models and the input parameter values during the updating process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Numerical models are widely used in many industrial areas for designing products and/or for solving problems in products. The automotive industry also intensively utilizes various numerical models in the design or trouble-shooting stages. Vibro-acoustic responses such as the levels of interior noise and vibration are among the key performances which indicate the quality of a car. When predicting the vibro-acoustic responses of interest (ROI) in high frequency ranges, the size of the finite element (FE) model grows increasingly large. To develop a reliable FE model, numerical analysts follow a standard procedure which controls the efficiency and accuracy of the numerical model in order to manage the computational costs. The standard modeling procedure is usually determined considering both the computational costs and the modeling technology of the company as accumulated during earlier development experiences. However, the vibro-acoustic FE model sometimes fails to predict the dynamic behaviors of a car. The main reason for these inaccurate predictions partly stems from the fact that vibro-acoustic systems, including various joints, are too complex to allow accurate descriptions of the dynamic behavior. Other reasons include intrinsic uncertainties of the physical systems, such as the randomness of excitations and manufacturing variabilities in the product. When experimental measurements are available, the vibro-acoustic FE model should be assessed and updated in a process known as model validation (Babuska and Oden 2004; Oberkampf and Roy 2010).

Computer model verification and validation (V&V) is a statistical assessment of model accuracy, which often requires numerous evaluations of the model. Thus, such a large vibro-acoustic FE model creates many challenges with regard to model validation. First, an efficient parameter prioritization scheme is necessary because the selection of important random variables among several thousands of input parameters incurs high computational costs. Once important random variables are selected, an additional high computational cost is required to propagate these variables to ascertain the uncertainty of system responses. In particular, the computational costs become higher when the uncertainty sources contain both aleatory and epistemic uncertainties. These high costs in turn require an efficient tool in the uncertainty propagation analysis. Another factor is that the ROIs of vibro-acoustic FE models, which are usually calculated in the frequency domain due to the many frequency-wise results to be compared. Thus, it is necessary to introduce a new validation metric which is suitable for frequency responses. In addition, after estimating the model accuracy, similar tasks, such as an efficient sensitivity analysis method and an effective selection scheme to update the parameters, must also be done.

Model updating involves refining earlier distributions of input parameters in order to maximize the agreement between the results of the numerical model and the experimental data (Campbell 2006; Youn et al. 2011). The validation and updating of a numerical model under uncertainties in data and in the model form are common and ongoing issues (Kennedy and O’Hagan 2001; Lee and Ahn 2014, 2015; Oberkampf et al. 2004; Xiong et al. 2009). The validation scheme can be adaptively changed depending on factors such as the problem principles and available data. In the automotive industry, statistical model validation is an emerging issue in spite of the large model sizes and the complexity of the structures. Recently, V&V and variability issues related to the windscreens of cars are investigated using a hierarchical approach (Lardeur et al. 2013; Scigliano et al. 2011) in which the variability of the components due to changes in the temperature is the main source of uncertainty. A nonparametric probabilistic model for a computational structural-acoustic car model was also proposed to estimate the response variability (Durand et al. 2008; Soize 2013). The variability of the vibrational responses due to elastomer uncertainties in a passenger car is also estimated using an uncertainty propagation analysis method (Kwon and Lee 2015; Lee and Hwang 2011). However, due to the large size of the vehicle model and the lack of efficient validation methods, there are many challenges to overcome before a fully statistical assessment of vibro-acoustic car models can be realized.

In this study, a model validation framework for a large numerical model is proposed using a vibro-acoustic FE model of a passenger car. The validation framework introduces the p-box (probability box) approach with an efficient quantification scheme for uncertainty sources and a new area metric, which is relevant to responses in the frequency domain. Four technical contributions of this study make the proposed model validation framework applicable to a huge vibro-acoustic FE model. These are 1) an efficient method to prioritize the uncertainty sources in input parameters which utilizes experts’ knowledge and variance-based sensitivity information with an orthogonal array; 2) an efficient p-box construction method, which uses a statistical-moment-based method for uncertainty propagation analyses and orthogonal combinations for interval-value uncertainty; 3) an effective metric for statistical assessments of a numerical model in the frequency domain, such as p-box color maps over the frequency band and a u-pooling p-box for frequency band of concern and for p-boxes at different frequencies; and 4) an efficient model-updating scheme which introduces the sensitivity analysis results and the experts’ knowledge pertaining to the components related to the hierarchical approach.

The paper is organized as follows. Section 2 explains the proposed model validation framework, including the classification of the uncertainty sources, related characterizations, the uncertainty propagation analysis method, and the validation metric. In Section 3, the validation framework is implemented for a large vibro-acoustic FE model. This section provides detailed descriptions of a real-model validation problem related to the prioritization method of the input parameters, the sensitivity analysis scheme based on the variance analysis, and the model updating scheme. Section 4 concludes the paper.

2 Model validation framework

Model validation is the process of determining the degree to which a numerical model is an accurate representation of the real world from the perspective of the intended uses of the model (Trucano et al. 2006). In the design stage, design engineers usually utilize commercial FE software to predict the vibro-acoustic performances of a passenger car. Computer model validation in this paper aims to quantitatively assess the accuracy of the vibro-acoustic performance of a passenger car in terms of the amount of errors in the numerical model. The main purpose of model validation is to identify the model form errors and influences of input uncertainties. In this section, the model validation framework serves to explain how the design engineer can reach these goals.

2.1 Validation framework for a numerical model

A numerical model represents the intended behavior of a physical system. The design engineer models the physical system considering the influences on the ROI. These include the system boundary, boundary conditions, governing equations and material models. The design engineer constructs a computational model of the physical system in order to predict the ROI. The design engineer assesses the numerical model as to whether or not it represents the physical system before the numerical model is used to compute the ROIs. Comparing the calculated ROIs with measured experiment data enables the design engineer to make an assessment of the numerical model.

The numerical model has many uncertainties in the input parameters and model errors. The measurement data also have uncertainties in the experimental setup and in the data processing steps and operation conditions. Thus, a statistical comparison between the calculated ROI and the measured value should be conducted in the validation procedure. Figure 1 shows the statistical validation framework of the numerical models. For statistical validation, the input parameters of the numerical model and the ROIs should be obtained through validation tests of the subsystem or full-scale system levels. Because both the input parameters and the model form contain uncertainties, probability models are necessary to represent them and to estimate their influence on the ROI statistically. For the input parameter uncertainties, measured experimental data or experts’ knowledge can provide the probability density function (PDF) or approximated values for the statistical information and/or the upper/lower bounds. The probability model gives the uncertainty information for the ROI. Generally, the calculated statistical information pertaining to the ROI differs from the measured data. The validation metric quantitatively defines the difference. The metric value satisfying a threshold results in a numerical model that can be used in the design or for trouble-shooting purposes. When the numerical model is not completely satisfactory, the input parameters of the model and their statistical information can initially be updated for another iteration of the validation metric. If the repeated updates do not enhance the accuracy of the computational model, the model refinement process provides a new computational model by modifying the mathematical or conceptual models (Youn et al. 2011).

2.2 Uncertainty sources

In general, there are two types of uncertainty in a numerical model: aleatory and epistemic uncertainties (Roy and Oberkampf 2011). Aleatory uncertainty arises from the inherent randomness in a quantity, while epistemic uncertainty is due to a lack of knowledge. Additional knowledge can eliminate the latter.

Uncertainties in the numerical model come from various sources. As well illustrated in literature (Oberkampf and Roy 2010; Roy and Oberkampf 2011). The sources of uncertainty in a numerical model include the following

-

model input parameters

-

model form

-

numerical approximations

The model input parameters are all variables or parameters in a numerical model, such as material constants, the geometry, the excitation and boundary conditions. Model form uncertainty refers to the uncertainty due to simplification or assumptions of a system model. Numerical approximation uncertainty includes discretization error in the spatial and time domains, round-off errors as well as software programming errors.

In most areas of the automotive industry, design engineers utilize commercial software in order to calculate the vibro-acoustic performances of passenger cars. Under this environment, code verification, which eliminates uncertainty in the numerical approximations, is not necessary because software-developing companies already conduct computer code verifications. Vibro-acoustic FE models for passenger cars discretize the geometry with a very fine mesh and usually have many degrees-of-freedom such that discretization error can be diminished. Thus, in this study, we assume that the uncertainties in the numerical approximations are negligible. This study focuses on the uncertainty in the model input parameters and their propagation to system responses.

2.3 Uncertainty characterization of input parameters

For the model validation process, all uncertainties in the input parameters should be quantitatively characterized. The PDF can be used to characterize aleatory uncertainty. Material properties, for example, can be measured for various manufacturing lots taken from different companies. Combining all of the measured data with a sufficient number of measurements, one can obtain a PDF for the material properties. A few parameters can usually represent the PDF with a prescribed type of distribution.

For epistemic uncertainties, obtaining the interval information for the input parameters is a typical uncertainty characterization method. Experimental data, a simulation model and experts’ knowledge can provide the interval information, including the upper and lower bounds. When the statistical information for an input parameter is imprecise, the distribution parameters can be either distributions or interval-valued quantities; i.e., an input parameter can be represented as a mixture of the aleatory and the epistemic uncertainty (Roy and Oberkampf 2011).

Model input parameters can be characterized as either deterministic values or as uncertain aleatory or epistemic random variables according to the amount of influence on the ROI, which can be determined from a sensitivity analysis. However, a sensitivity analysis of every input parameter for a large numerical model is impractical due to the high computational costs. Practically, experts’ knowledge is included when determining the characterization types. Thus, there is another type of uncertainty when characterizing input parameter uncertainties; in the validation process, this type of epistemic uncertainty will be included not in the variability of the ROI but in the model error (model form uncertainty).

2.4 Uncertainty estimation of response

Uncertainties in the input parameters of a numerical model are propagated into responses through the numerical model. Estimations of the uncertainties of the ROIs are necessary in order to quantify the uncertainty in the model form through comparisons with experimentally measured ROIs. Probability analysis methods such as the Monte Carlo simulation (MCS) method (Kroese et al. 2011) can provide the PDFs of the ROIs. With a sufficient number of random samples (typically millions of samples), the MCS method provides accurate probability information. However, the MCS method is impractical for very large numerical models such as those in this study due to the very high computational cost and the immense amounts of time required. Many researchers have developed approximation methods such as the dimension reduction method (Xu and Rahman 2004; Youn et al. 2008), the stochastic spectral method (Choi et al. 2004, 2007; Hu and Youn 2011a) and the stochastic collocation method (Barthelmann et al. 2000; Gerstner and Griebel 1998; Hu and Youn 2011b). Among them, the eigenvector dimension reduction (EDR) method (Youn et al. 2008) is one of the most efficient methods, as it does not include a sensitivity analysis as part of the probability analysis.

When all random variables are aleatory (i.e., all PDFs of the input parameters are available), the EDR method efficiently provides statistical information pertaining to the ROIs. However, a large vibro-acoustic car model generally has both aleatory and epistemic random variables. For a mixed case, the distribution of the ROIs is not a single function but an ensemble of the distributions of all possible combinations of the epistemic random variables whose values exist on intervals. The outer boundary of the ensemble of the cumulative distribution functions (CDF) is known as a p-box (Ferson and Ginzburg 1996; Roy and Oberkampf 2011).

2.4.1 EDR method

The EDR method approximates the statistical moments (mean, standard deviation, skewness, and kurtosis) of an ROI and its PDF. In general, the statistical moments of the ROI, Y(X), can be calculated as follows:

where Y is the ROI, E is the expectation operator, and f X(x) is the joint PDF of X. Multiple one-dimensional integrations using additive decomposition (Y a) can approximate the multi-dimensional integration in (1) as follows:

Here, N is the number of random variables and μ represents the mean of the random variables. The m th statistical moment for the ROI is approximated as follows:

Using a binomial formula, (3) can be evaluated by repeating the one-dimensional integration process recursively. In order to predict the probability of the ROI, the EDR method uses the following four sequential steps: 1) sampling of three or five responses along each eigenvector direction of the covariance matrix of the system input random parameters, 2) construction of a response surface with samples using the stepwise moving least-squares method, 3) calculation of the statistical moments by means of numerical integration, and 4) generation of the PDF of the ROI using the stabilized Pearson system.

For N random variables, the EDR method requires 2N + 1 or 4N + 1 samples. These small sampling processes make the EDR method very efficient when used for an uncertainty propagation analysis. In earlier work (Jung et al. 2011), it was demonstrated that the EDR method is sufficiently accurate to calculate the PDF and reliability in vibro-acoustic systems.

2.4.2 ROI uncertainty estimation

For passenger cars, a vibro-acoustic model has numerous uncertain input parameters. Some of them are aleatory, while others are epistemic. For these cases, a CDF of a ROI estimated using the EDR method for aleatory random variables represents only the uncertainty of the ROI for a realization of epistemic input parameters. Thus, the overall uncertainty of the ROI is all ensembles of the CDFs for all possible realizations of epistemic input parameters. The p-box can be obtained by taking the outer boundary of all CDFs. Figure 2a illustrates the method used to extract the p-box from the CDFs. The p-box represents the bounds of the CDFs for the ROI due to the lack of knowledge in the epistemic uncertainty. The variability of the ROI in the numerical model determines the shapes of the left- and right-hand bounds of the p-box. If there is no epistemic uncertainty, the area of the p-box vanishes; i.e., a single curve represents the variability of the ROI due to aleatory uncertainty. The greater the lack of knowledge of the input parameters is, the wider the distances between the bounds of the CDFs of the ROI become. Thus, with a considerable lack of knowledge of the input parameters, the p-box for the numerical model provides a probability range that consists of the minimums according to the left-hand bound (F L ) and the maximums according to the right-hand bound (F R ).

There are an infinite number of possible combinations of the set selected from the epistemic input parameters because the intervals are continuous. When generating the p-box in practical applications, the sampling of the CDFs is limited in terms of the computational cost and time. Thus, an efficient approximation for the p-box is required. This is described in Section 3 with a vibro-acoustic FE model.

2.5 Validation metric

The model form error in a numerical model is the amount of disagreement between the numerical model and the physical system due to all of the assumptions and idealizations in the model form. Our approach statistically estimates the model form error, as the uncertainties in the input parameter propagate into the simulation results through the numerical model.

2.5.1 Area metric

Comparisons of the simulation results with those of experimental measurements provide the validation metric. Among the validation metrics, the area metric (Ferson et al. 2008) is used in this study. The area metric requires the CDF of the experimental data (H n ) which is defined as

Here, y and n refer to the ROI and the number of experimental data, respectively. The area metric d can then be defined as

where F R and F L are the right- and left-hand bounds of the p-box, respectively. Figure 2b illustrates the calculation of the area metric for a p-box. When there is no epistemic uncertainty, the p-box becomes a line and the area metric is the area between the simulation and experimental CDFs.

The area metric quantitatively represents the difference in the ROI between the simulation and experimental results considering the uncertainties in the input parameters. The larger the area metric is, the greater the discrepancy between the numerical model and the physical system becomes. Thus, the area metric can be considered as the model form error of the numerical model. It is also noted that the area metric includes measurement errors typically in the form of bias error and which are inevitable during the measurement and data processing steps. The overall uncertainty during the simulation is the sum of ROI variability due to the input parameter uncertainties (as represented by the p-box) and the model form error (represented as the area metric) (Roy and Oberkampf 2011).

It should also be noted that in the automotive industry, test data for the validation metric does not exist when the computational model is used in the design stages. In other words, no physical system exists because computational models for passenger cars are typically used in the virtual design space. This situation is very common, but in this study we assume that some measurement data for the ROI exists. This time-lag situation between a numerical model and experimental measurements remains as a challenge to be addressed in future research by the authors.

2.5.2 U-pooling

The area metric focuses on the difference between ROIs from a numerical model and the experimentally measured value for a specific ROI. If there are different ROIs for a physical system, the area metrics for the ROIs provide the amount of difference for each ROI. However, different instances of the area metric cannot be directly compared because the distributions of the ROIs may differ. For example, the area metrics for an acceleration level and an interior noise level in a numerical model can be obtained with proper measurement data. However, the magnitudes of the area metrics cannot be compared to each other to obtain accuracy information pertaining to the numerical model. Therefore, a synthetic approach that unifies the metric scales is required in order to assess a numerical model for different ROIs simultaneously. Probability is a proper scale for comparing different ROIs (Ferson et al. 2008; Xiong et al. 2009). The cumulative probabilities of the experimental measurement responses for the p-box approach are defined as

Here, y e i and n e represents the experimental measurements and the number of experiments, respectively. Figure 3a illustrates the u-pooling method for two different ROIs.

By separately pooling the cumulative probability values (i.e., u i L and u i R ) for all of the experimental data, two cumulative distribution functions defined by (4) are generated because there are two u-values for each experiment. According to Ferson et al. (2008), the pooled u-values follow a standard uniform distribution over [0, 1] if the physical values are distributed according to their respective distributions. Thus, the area metric introduced by (5) for the p-box can be utilized to infer the degree of the overall agreement between all of the experimental data and their respective prediction distributions. Figure 3b shows the calculation method of the area metric from the u-pooling data, where the illustrative area metric for N e = 5 is plotted in gray. The larger the area metric is for the u-pooled data is, the less accurate the representation of the physical system becomes.

As shown in Fig. 3b, the u-pooled CDFs consist of two curves due to the epistemic uncertainties. When the numerical model contains only aleatory uncertainty, the two CDFs will be merged into one CDF. Less epistemic uncertainty leads to a shorter distance between the two CDF curves. The area metric considers only the propagated variability of the numerical model due to the uncertainties in the aleatory input. The influence of the epistemic uncertainty on the overall agreement is represented by the area between two CDFs. Figure 3b also depicts the area between two CDFs in the dotted area.

In the automotive industry, noise and vibration responses are generally investigated in the frequency domain. At each frequency, the noise and vibration responses have different distributions. Thus, u-pooling for all frequency responses over the frequency range of concern will provide a wealth of information pertaining to the validity of the numerical model.

2.6 Model updating

Statistical model validation for a numerical model can result in a more accurate representation of the ROIs by means of model updating or calibration involving modifications of the mathematical models and the input parameters. It was assumed that the geometry is discretized with sufficient accuracy due to fine mesh of the FE model. Mathematical model modifications include changes of all assumptions, such as the linear behavior of the materials and joints. Input parameter modifications are the updating of, for example, the coefficients of the material model, the boundary conditions and/or the magnitudes of the excitations.

After the assessment of the model accuracy, the numerical model can be updated in order to enhance its performance when calculating the ROIs. The most important step is to localize the modification region; i.e., it is necessary to minimize the number of modifications to the crucial mathematical model or the parameters on the ROIs. In this study, both the experts’ knowledge and the sensitivity information of the prioritization scheme determine which mathematical models and input parameters should be modified. These modification approaches are illustrated using the vibro-acoustic FE model in the next section. For an assessment of the accuracy of the updated numerical model, the model validation framework described in this section should be repeated.

3 Validation and updating of vibro-acoustic FE model

The passenger car industry is one of the most intensive areas to utilize numerical models due to the high manufacturing costs and the rapid product cycles. Vibro-acoustic quality for a passenger car is a key factor that design engineers must achieve. Automotive companies typically use finite element (FE) models to predict the vibro-acoustic ROIs of a passenger car. For the calculation of the interior noise, design engineers currently build an FE model with millions of degrees of freedom (DOF). Validation of vibro-acoustic FE models is very complicated due to their very numerous DOFs and given their structural complexity. Hierarchical approaches for complex systems can increase the efficiency of the validation process (Oberkampf and Roy 2010; Scigliano et al. 2011; Youn et al. 2011). Figure 4 illustrates an example of the validation hierarchy for a passenger car. For the model validation, the vehicle FE models are decomposed into subsystems with three or four levels as shown in Fig. 4. The validation process should be conducted on the lower level of the hierarchy (i.e., the component or part levels) because 1) the full-scale vibro-acoustic system of passenger car is very complex, 2) there are many common components in different passenger cars, 3) it is economical, and 4) in many cases, there are no experimental measurement data for an entire vibro-acoustic system due to the absence of a physical system (e.g., when it has not yet been manufactured). Thus, automotive companies undertake validations of components or part models. Based on the validation results, they establish standard procedures which must be followed when a vibro-acoustic system model is developed considering both the accuracy and the computational costs. The standard procedure usually regulates the solution methods, the material models, the finite element types and the sizes of the elements. For example, the modeling standard of a company for a spot-welded shell describes the element type, the thickness, and the spot size as well as the multi-point constraints. However, it should also be noted that all components in a vibro-acoustic FE model cannot be validated at the component or part levels, partly because typically in automotive systems many new components remain to be manufactured at early stages. A more inherent reason is the dependency of the responses of many components on the dynamic characteristics of the system. For example, many elastomer joints in passenger cars can be modeled using a linear spring, but the stiffness of the spring depends on the initial strain or the amplitude of the responses.

In the design stage of a passenger car, engineers build a vibro-acoustic FE model according to standard modeling procedures and predict vibro-acoustic ROIs such as the level of interior noise during, for example, wide-open throttle operation or idling states. When experimental measurement data are available for predicted ROIs after the proto manufacturing stage of a passenger car, the predictive FE model can be assessed through the validation framework prescribed in the previous section. There are certain challenges to be addressed before the validation framework can be successfully applied to a large vibro-acoustic FE model. The first of these is the selection of model parameters which have uncertainties and considerable influences on the ROIs. The FE model usually has several thousands of input parameters as well as millions of DOFs. It is impossible to consider all of the input parameters as uncertain variables due to the high computational costs. Therefore, an efficient parameter-selection scheme for statistical validation is required. Another challenge is to set the priority between the selected parameters according to the magnitude of the influences on the vibro-acoustic ROIs (i.e., the sensitivity of the selected model parameters with respect to the ROIs). Thus, an efficient sensitivity analysis method able to determine quantitative priority levels among the candidate model parameters is also required.

In this study, a parameter prioritization scheme for validation frameworks is proposed. Additionally, a new validation metric which is relevant to the p-box approach with vibro-acoustic ROIs is presented. This section will demonstrate the validation framework using the proposed approach through an illustrative vibro-acoustic FE model for a passenger car.

3.1 Vibro-acoustic model for a passenger car

During the design stage, the company built the FE model and used it to enhance the vibro-acoustic performance of a car. The FE model predicted a booming noise peak in the area of the front seats of the interior cavity for a wide-open throttle acceleration operation. After a few trade-offs, the FE model suggested a dynamic damper on the rear roof rail position and showed large abatement of the interior noise level without any deterioration at the other positions. However, in the prototype stage of the passenger car, experimental measurements showed that the dynamic damper on the rear roof rail cannot reduce the booming noise even slightly. Contrary to the results predicted by the FE model, further experimental modifications revealed that a dynamic damper on the front roof rail had very beneficial effect on reducing the booming noise in the interior cavity. Thus, the proposed validation framework was applied to the vibro-acoustic FE model in order to enhance the prediction capability of the FE model.

The vibro-acoustic model consists of a body-in-white structure, the doors, glass parts, seats, interior trim parts and interior cavities. There were approximately 1.93 million nodes and 1.91 million elements. The excitation forces through seven engine mounting points during operation with a wide-open throttle were measured and used to simulate the interior noise levels. The ROIs were the sound pressure level (SPL) in the cabin of the passenger car. Figure 5 shows the locations of the ROIs in the passenger cabin. The commercial software MSC/NASTRAN was used to simulate the ROIs using the modal superposition method (solution type 111). For the analysis, a PC workstation with two Intel Xeon QC CPUs and 24 GB RAM was used on the 64-bit Windows 7 operating system. The total time required to obtain the ROIs under the prescribed environment was approximately 9 h and 18 min.

3.2 Parameter prioritization

For the statistical validation of a full car model, the selection of the random variables is very difficult due to the large number of candidate model parameters in this model. For example, the vibro-acoustic FE model has 74 material properties and 2936 element properties. As explained in the previous section, the criterion that determines whether an input parameter is deterministic or random is the amount of influence of the parameter on the ROIs; i.e., a random input parameter can be treated as a deterministic value if the ROIs barely change according to the input uncertainty. The sensitivity analysis determines the degree of influence on the ROIs (Choi and Kim 2006; Choi et al. 1997; Kim et al. 2003). However, it is clear that for a large FE model, a sensitivity analysis of all of the input parameter incurs a considerable cost and requires much time such that such an analysis is not feasible in a practical engineering environment. Thus, an efficient parameter selection scheme and a prioritization method for the selected parameters are necessary for a large vibro-acoustic FE model.

In this study, the following two-step approach is proposed for parameter prioritization in the statistical validation framework:

-

Step 1: Selection of the candidate input parameters from the experts’ knowledge

-

Step 2: Running of a sensitivity analysis based on an analysis of variance

The next subsections illustrate each of the steps in the parameter prioritization process with the proposed FE model.

3.2.1 Candidate parameter selection from experts’ knowledge

Experts refer to any engineers who have knowledge about the physical system and the numerical model. They should be a group associated with the numerical model and can include experimentalists, computational analysts and designers. The experts’ group reviews the numerical model and discusses the possible parameters associated with the model. Experimental documents, the numerical modeling history and the behaviors of the numerical model provide the information needed for the discussions. Each expert adds a number of candidate model parameters which make the response uncertain from their knowledge. The group discussions based on their knowledge select the candidate input parameters from the gathered parameters. The selection of the candidate input parameters can be either objective or subjective; experimental results, the material behavior from other numerical simulations and physical principles, for instance, can support objective selections, whereas selections based on experience of experts, rational suspicion about the parameters and degree of uninformedness are subjective. Mutual agreement between the experts finalizes the set of candidate input parameters.

More experts may reduce the possibility of missing dominant parameters. The amounts of influence by the selected candidate parameters on the ROIs should be quantified, which limits the number of the selected candidate input parameters because the prioritization step also incurs a considerable computational cost.

In this study, an experts’ group selected the candidate input parameters for the large vibro-acoustic FE model. This group considered various types knowledge such as the experimental data, numerical simulation results, material models and joint models. Figure 6 illustrates the types of knowledge utilized as they determined the candidate input parameters for the vibro-acoustic FE model. First, the structural deformations and strain energy densities on the concerned frequency band were scrutinized using the FE model, especially for those near the roof rails, where the dynamic dampers were attached, resulting in a set of candidate input parameters associated with, for example, shell thicknesses, adhesive models and related material properties, and wind-shield models. Experimental results such as those from a transfer path analysis and an acoustic modal test were also investigated in order to review associated numerical models such as the interior cavity model, seat model and the measured excitation forces. Additionally, the experts’ group examined the boundary conditions and related joint models in detail. Table 1 lists the selected candidate input parameters for the FE model. In selecting the candidate input parameters, the total number was limited by the available computational resources for the prioritization scheme of the FE model.

3.2.2 Prioritization scheme based on variance analysis

The candidate input parameters selected by the experts’ group should be quantitatively sorted by the magnitude of their influences on the ROIs. The sensitivity analysis provides absolute criteria for the quantitative sorting of the candidate input parameters. It should be very efficient in order to apply it to very large vibro-acoustic FE models. In this study, the variance-based approach is used to obtain the sensitivity information of the candidate input parameters for the ROIs.

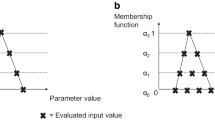

The variance-based method can be used to determine the global sensitivity information of a system model (Phadke 1989; Rao 1947; Saltelli et al. 2008). Most variance-based methods adopt a random sampling approach such as Monte Carlo simulation in order to obtain the variance information of the system model. However, for the very large vibro-acoustic model investigated here, this type of random sampling method incurs very high computational costs such that they are not affordable. Thus, in this study, efficient numerical experiments are conducted using an orthogonal array, which contains the balance levels of each parameter (Lee and Ahn 2015; Phadke 1989). For numerical experiments, the orthogonal array allocates two or three levels for each candidate input parameter. For an aleatory variable, the PDF provides good information pertaining to level allocation; i.e., using three levels of each input parameter set to 5, 50, and 95 % is a typical level allocation. For an epistemic variable, the upper and lower bounds and the median can serve as the levels. Numerical experiments according to the combinations of the candidate input parameters prescribed by the orthogonal array provide a set of ROIs. Using the numerical experiments, the variance is calculated using the sum of squares and the degrees of freedom. The variance ratio of the i-th input (F i ) can be defined as

where V i and V e are the variances of the i-th candidate input parameter and the error, respectively. By comparing the F values of the candidate input parameters, the statistical significance of the input parameters can be evaluated (Roy 1990). In addition, by normalizing the F values, the F-ratio can be defined as

The F-ratio provides quantitative priority information pertaining to the candidate input parameters on the ROI. The F-ratio can be integrated over a wide band for vibro-acoustic ROIs defined in the frequency domain as

where FR B i and f are the band FR of the i-th candidate input parameter and the frequency, respectively.

For the vibro-acoustic FE model, prioritization was performed using the proposed approach. Table 1 shows the estimated variability for the selected candidate input parameters. As listed in Table 1, the experts classified the candidate input parameters into two groups. The first group is normally distributed and the second group does not have probability distribution information. For the former group, the means and standard deviations (SD) of the candidate input parameters were approximated. For the remaining parameters in the latter group, the experts set the upper and lower bounds of the parameters. An orthogonal array (\( {2}^1\times {3}^{25} \)) which can allocate 25 three-level parameters and one two-level parameter was selected for the numerical experiments. Fifty-four numerical experiments in total were conducted for the parameter combinations that were determined according to the orthogonal array. Using (7)~(9), the variance-based sensitivity analyses were conducted for the candidate input parameters on the interior SPLs of the passenger car. Figures 7 and 8 show the calculated F-ratios and the band F-ratios over 38~48 Hz for the SPLs at the front and rear seat positions. In Fig. 7, the F-ratios of each parameter were stacked such that each contribution to the ROIs can be easily displayed. Thus, the area between two adjacent curves represents the amount of influence of each candidate input parameters. In Fig. 7, one can identify crucial candidate input parameters which considerably influence the ROIs at each frequency. Figure 8 shows the band F-ratios integrated over the frequency band of 38~48 Hz, where the booming noise peaks exist for the interior noise of a passenger car. In Fig. 8, the band F-ratios were also normalized by the sum of the band F-ratios and sorted in a descending order of magnitude. Thus, it is clear that the proposed prioritization method can provide priority information between candidate input parameters quantitatively even for the very large vibro-acoustic FE model. Based on the band F-ratios shown in Fig. 8, the input parameters that should treated as random variables during the model validation step can be selected. One simple rule when selecting the random input parameters is to examine the candidate input parameters until the stacked sum of the band F-ratios in a descending order reaches a given value, e.g., 90 %. However, it should also be stressed that the total number of random variables is determined considering the computational costs during the model validation step.

3.3 Model validation for interior noise responses

Using the model validation framework described in the previous section, the accuracy of the vibro-acoustic FE model was estimated. In order to select the random variables for which the uncertainties should be considered during the model validation step, the priority information in the previous subsection was used as the selection criterion. The candidate input parameters which are included within 92 % of the stacked sum of the band F-ratios in a descending order of the interior noise were selected as the uncertainty sources of the FE model. The prioritization scheme provided ten and twelve input parameters for the front and rear seat noise levels, respectively. It was revealed that all input parameters for the front seat noise level were also dominant for the rear seat noise level. Table 2 shows the input parameters selected as the uncertainty sources for the model validation step.

Among the selected input parameters, two material properties were modeled as aleatory variables: the distribution parameters of the mean and standard deviation were obtained from the measurement data. The other input parameters were modeled as epistemic variables. The experts carefully determined the lower and upper bounds of the input parameters. Table 2 lists the distribution parameters of the aleatory variables and the lower and upper bounds for the epistemic variables.

Experimental measurements for the ROIs were collected for the model validation step. For the front seat, four test datasets were available, whereas only two measurements were collected for the rear seat. Figure 9 shows the measured ROIs for a passenger car. Using (4), the experimental CDFs of the measured ROIs were generated. Because the ROIs are in the frequency domain, the generated CDFs are different at each frequency.

The uncertainty of the ROIs due to the input parameter uncertainties in Table 2 were also estimated using the p-box approach. The EDR method calculated the uncertainty in the ROIs due to the aleatory input parameter uncertainties for a combination of the epistemic input parameters. For the EDR method, three sampling points along the eigenvector direction were supplied in the calculation of the statistical information. In other words, the EDR method requests five simulations for the ROIs because there were only two aleatory input parameters. In order to determine the p-box accurately, the uncertainty propagation analysis should be repeated for the combinations of the epistemic input parameters in Table 2 as many as possible. However, the computational cost of the large vibro-acoustic FE model also limits the number of the combinations. In this study, an orthogonal array was introduced to generate effective combinations with small number of the simulations. Considering the total time for the simulations in the model validation, the L12(211) orthogonal array which have 11 parameters with two levels was selected to generate 12 combinations of the epistemic input parameters. The lower and upper bounds of the epistemic input parameters were set to the levels. Thus, 60 simulations were required to determine the p-box for the vibro-acoustic FE model.

The area metrics in (5) were calculated using the p-box and the measured CDF for the ROIs. At each frequency, the area metric has different values; i.e., both the area metric and the p-box depend on the frequency. Figure 10 depicts the calculated area metrics at a few typical frequencies. The area metric represents the area between the p-box and the measurement CDF on the ROIs as shown in Fig. 10. The area between the left- and the right-hand bounds on the p-box is due to the uncertainties of the epistemic input parameters. Thus, in the p-box approach, small area metric values does not always mean good agreement between the numerical model and the experimental measurements; i.e., large epistemic uncertainties in the input parameters can decrease the area metric value. As an extreme case, a wide p-box can make the area metric zero; i.e., the p-box includes the experimental CDF. Therefore, to assess the numerical model properly, both the area metric and the area of the p-box should be examined simultaneously. When the area of the p-box is large (i.e., the distance between the left- and right-hand CDFs is greater than the variation of the CDFs), the epistemic uncertainties may be reduced such that the area metric could play its proper role, i.e., indicating the accuracy of the numerical model. Figure 11 depicts the overall p-boxes for the ROIs on the frequency axis. The p-boxes in Fig. 11 were transformed into a color map in which the plotted values were obtained by adding the left-hand-bound CDF and the right-hand-bound CDF, and by subtracting the added value from the maximum(i.e., 2) if the added value is greater than one as

where h pbox (y, f) refers the transformed height of the p-box. In Fig. 10 the vertical length of the central value (i.e., represented in a bright hue) is the approximated width of the p-box which indicates the variability of the ROI due to the epistemic uncertainty at this frequency. The vertical lengths from zero to one and from one to zero also approximately represent the variability of the ROI due to the aleatory uncertainties. Therefore, this transformation enables us to assess the numerical model over the frequency range of concern while retaining the main characteristics of the p-box. Figure 11a clearly illustrates that the uncertainty of the ROIs over the frequency band is due to the epistemic input parameters while the aleatory uncertainties are dominant in the other frequency band. Figure 11 also shows the area metric calculated at each frequency. The area metrics show relatively large amounts of deviation between the simulation results and the experimental results beyond the 50 Hz frequency band. However, it should be noted that in this study, the frequency band of concern lies below 48 Hz. It is also noticeable in Fig. 11 that the vibro-acoustic responses in anti-resonance frequency band can have large variability than in resonance band, which enables to explain the relative large differences of the p-boxes between two close frequencies in Fig. 10.

Finally, the u-pooling method described in subsection 2.5.2 was applied to the vibro-acoustic FE model. In the u-pooling approach, all experimental measurements for the interior noise levels at the front and the rear seats were used over the frequency band of 38 ~ 48 Hz. Figure 12 shows the CDFs of the u-pooling data and the corresponding area metric for the vibro-acoustic FE model. The u-pooling CDFs provide the overall information pertaining to the accuracy of the numerical model. Similar to the p-box at a specific frequency, the area metric between the u-pooling CDFs and the reference uniform CDF represents the discrepancy between the numerical model and the experimental measurements in an overall sense. However, the area metric of the u-pooling CDFs does not include a portion of the discrepancy due to the epistemic input parameters which was hidden in the area between two CDFs, as shown in Fig. 12. Figure 12 shows the relatively large distance between two CDFs compared to the area metric, indicating that the vibro-acoustic FE model has more uncertainties due to the epistemic input parameters. These uncertainties are associated with models of various parts and with the lack of knowledge about its model parameters. Model updating can reduce these uncertainties, as explained in the next subsection.

3.4 Model updating

Model updating in a very large numerical model such as the vibro-acoustic FE model should utilize a hierarchical approach, as shown in Fig. 4, as the overall system is too complex to modify all of the parameters simultaneously. Model updating should occur at the lower level of the hierarchy (i.e., the component or unit problem levels). However, it is very difficult to localize the updating region or parameters of the numerical model at a low level because most low level components influence the ROIs. The sensitivity information of the input parameters is most important when determining the updating parameters of the numerical model. In this study, the validation framework provides the sensitivity information of the input parameters as shown in Figs. 7 and 8, indicating that the updating process does not request an additional sensitivity analysis. It should also be noted that the sensitivity information of the variance-based approach has more global characteristics than that in gradient-based approaches because the variance-based approach includes the variability of the input parameters.

For efficient updating, the additional knowledge by the experts’ group is also important because several types of knowledge are rarely included numerically. For example, new experimental results conducted in other departments or manufacturing processes of components which cause dynamic behaviors in the components may be crucial in the model-updating process. Therefore, the engineering insight supported by the sensitivity information and by the experts’ knowledge is required during the model-updating step of such a large vibro-acoustic FE model.

The vibro-acoustic FE model was updated using the proposed approach. Figure 13 illustrates the modifications of the component models and the input parameters. These processes were done according to both the sensitivity information and the experts’ knowledge. The input parameters associated with wind-shield glass showed considerable sensitivity with regard to the ROIs, leading to the modification of the model of the wind-shield glass. The glass model of a single-layer shell was modified to a three-layered composite shell, which is able to take into account the bonding adhesive between a pair of the glasses. The material properties of the three-layered composite shell referred to model validation reports on the wind-shield component, which was newly issued by the company. Additionally, according to the results of an experimental modal test of the interior cavity of a passenger car, the interior cavity FE model was refined by modifying the size of the air flow passages between the interior cavity and the trunk cavity. The input parameters of the bushes associated with the dynamic behaviors of the wind-shield, the roof rails, and the interior cavity (in this case the bush properties of the windshield adhesive and the roof sealers) were also updated, as depicted in Fig. 13. Figure 14 shows the ROIs of the updated FE model, where it is clear that the updated FE model shows dynamic damper effects consistent with those of the experimental measurement described in subsection 3.1; i.e., the dynamic damper on the front roof rail can effectively reduce the peak noise level in the cavity whereas the rear damper has negligible effect on the ROIs. In the updated model, it is noticeable that the peak of the front ROI became wider while the rear peak moved to higher frequency region due to the modifications.

In order to assess the accuracy of the updated FE model, the validation process was repeated. Table 3 lists the uncertainty sources in their re-estimated variability levels according to the model-updating step. Figures 15, 16 and 17 show the p-boxes at typical frequencies, the color map of the p-boxes over a wide band, and the u-pooling with the area metric, respectively. Figure 15 indicates that the variability of the ROIs due to the epistemic input parameters decreases at the important peak frequencies (i.e., the area of the p-box has decreased) while the area metric over the frequency range of interest increases slightly. One can also confirm these trends in Fig. 16 over the frequency band of concern (i.e., 38 ~ 48 Hz). The u-pooling results in Fig. 17 also show that the distance between the upper and lower bounds of the u-pooling CDF became closer than that of the initial FE model in Fig. 12, while the area metric value of the u-pooling p-box increased. In the updated FE model, the p-box area of the u-pooling decreased by 47.4 % and the area metric increased by 71.4 %, while the summation of the p-box area and the area metric decreased by 13 %. Thus, all information in Figs. 15, 16 and 17 indicates that in the updated vibro-acoustic FE model, the amount of uncertainty due to the epistemic input parameters (i.e., due to the lack of knowledge) was reduced and that a portion of the uncertainty was realized as the model error. However, it should be noted that the model-updating process recovered the dynamic behaviors associated with the dynamic dampers in spite of the slight increase in the model error due to the reduction in the lack of knowledge, thus illustrating the effectiveness of the proposed model validation framework for a large vibro-acoustic FE model.

4 Conclusion

In this paper, a model validation framework for a large vibro-acoustic FE model was proposed and applied to the FE model of a passenger car. The validation framework introduced the p-box approach with an efficient quantification scheme of uncertainty sources and a new area metric which is relevant to the responses in the frequency domain.

The prioritization method of the input uncertainties of the very large FE model utilized experts’ knowledge to select candidate input parameters which have large potential influences on the ROIs among the several thousand input parameters. Next, a variance-based sensitivity analysis which uses an orthogonal array was introduced in an effort to quantify the influence of the selected input parameters on the ROIs. The prioritization method applied to the very large FE model showed that the proposed procedure can provide important uncertain input parameters for the statistical model validation by effectively reducing the number of input parameters, and by efficiently quantifying the sensitivity information. As illustrated in the numerical application, it is stressed that the role of the experts’ group in the selection of the candidate input parameters and the estimation of their variability is crucial in the validation framework. The proposed sensitivity index also effectively provided the priority information pertaining to the ROIs defined over the frequency band on interest.

The p-box represented the variability of the ROIs due to the selected input parameters which consist of aleatory and epistemic random variables. The orthogonal array introduced for the p-box calculation minimized the number of combinations of the epistemic input parameters. The EDR method estimated the uncertainty which propagated to the ROIs due to the aleatory input parameters for each combination. The use of the EDR method and the orthogonal combinations provided the p-box of the ROI even for a very large vibro-acoustic FE model. The color map of the p-boxes over the frequency band, the u-pooling p-box for the frequency band of concern and the p-boxes at different frequencies were proven to be suitable for assessing the model error and for making quantitative contributions of the aleatory and epistemic input parameters to the overall variability of the ROIs in the frequency domain. Especially the color map keeps core probability information on the boundaries of the p-box, which enable to clearly understand the state of a numerical model pertaining to the uncertainties in the frequency domain.

The proposed validation framework was applied to a vibro-acoustic FE model for a passenger car. After assessing the model error with the proposed method, the FE model was updated. The sensitivity analysis results and the experts’ knowledge pertaining to the associated components determined the modifications of the component models and the input parameter values during the updating process. The color map of the p-box and the u-pooling p-box over the frequency band of concern showed that updating the component models reduced the variability of the ROIs due to the epistemic input parameters. In addition, some of the reduced variability of the ROIs was revealed as variability due to the aleatory input parameters.

d area metric, F i i-th variance ratio, F L , F R left- and right-hand bounds of p-box, h pbox height of p-box, H n experimental CDF, k number of candidate input parameters; u probability, N number of random variables, n e number of experimental measurements, μ mean

References

Babuska I, Oden JT (2004) Verification and validation in computational engineering and science: basic concepts. Comput Methods Appl Mech Eng 193:4057–4066. doi:10.1016/j.cma.2004.03.002

Barthelmann V, Novak E, Ritter K (2000) High dimensional polynomial interpolation on sparse grids. Adv Comput Math 12:273–288

Campbell K (2006) Statistical calibration of computer simulations. Reliab Eng Syst Saf 91:1358–1363. doi:10.1016/j.ress.2005.11.032

Choi KK, Kim N-H (2006) Structural sensitivity analysis and optimization 1: linear systems. Springer Science & Business Media

Choi KK, Shim I, Wang S (1997) Design sensitivity analysis of structure-induced noise and vibration. J Vib Acoust 119:173–179

Choi S-K, Grandhi RV, Canfield RA, Pettit CL (2004) Polynomial chaos expansion with latin hypercube sampling for estimating response variability. AIAA J 42:1191–1198

Choi S-K, Grandhi RV, Canfield RA (2007) Reliability-based structural design. Springer

Durand J-F, Soize C, Gagliardini L (2008) Structural-acoustic modeling of automotive vehicles in presence of uncertainties and experimental identification and validation. J Acoust Soc Am 124:1513–1525. doi:10.1121/1.2953316

Ferson S, Ginzburg LR (1996) Different methods are needed to propagate ignorance and variability. Reliab Eng Syst Saf 54:133–144. doi:10.1016/S0951-8320(96)00071-3

Ferson S, Oberkampf WL, Ginzburg L (2008) Model validation and predictive capability for the thermal challenge problem. Comput Methods Appl Mech Eng 197:2408–2430. doi:10.1016/j.cma.2007.07.030

Gerstner T, Griebel M (1998) Numerical integration using sparse grids. Numer Algorithm 18:209–232

Hu C, Youn BD (2011a) Adaptive-sparse polynomial chaos expansion for reliability analysis and design of complex engineering systems. Struct Multidiscip Optim 43:419–442

Hu C, Youn BD (2011b) An asymmetric dimension-adaptive tensor-product method for reliability analysis. Struct Saf 33:218–231

Jung BC, Lee D, Youn BD, Lee S (2011) A statistical characterization method for damping material properties and its application to structural-acoustic system design. J Mech Sci Technol 25:1893–1904

Kennedy MC, O’Hagan A (2001) Bayesian calibration of computer models. J R Stat Soc Ser B (Stat Methodol) 63:425–464

Kim NH, Dong J, Choi KK, Vlahopoulos N, Ma Z-D, Castanier M, Pierre C (2003) Design sensitivity analysis for sequential structural–acoustic problems. J Sound Vib 263:569–591

Kroese DP, Taimre T, Botev ZI (2011) Handbook of Monte Carlo methods vol 706. Wiley

Kwon J-H, Lee D (2015) Variability analysis of vibrational responses in a passenger car considering the uncertainties of elastomers. Proc Inst Mech Eng C J Mech Eng Sci. doi:10.1177/0954406215612816

Lardeur P, Scigliano R, Scionti M (2013) Verification and validation for the vibration study of automotive structures modelled by finite elements. J Strain Anal Eng Des 48:59–72. doi:10.1177/0309324712466508

Lee D, Ahn T-S (2014) A boundary element model for acoustic responses in the ear canal and its statistical validation and updating. J Mech Sci Technol 28:1203–1217

Lee D, Ahn T-S (2015) Statistical calibration of a finite element model for human middle ear. J Mech Sci Technol 29:2803–2815. doi:10.1007/s12206-015-0609-9

Lee D, Hwang I-S (2011) Analysis on the dynamic characteristics of a rubber mount considering temperature and material uncertainties. Trans Comput Struct Eng Inst Korea 24:383–389

Oberkampf WL, Roy CJ (2010) Verification and validation in scientific computing. Cambridge University Press, Cambridge

Oberkampf WL, Trucano TG, Hirsch C (2004) Verification, validation, and predictive capability in computational engineering and physics. Appl Mech Rev 57:345–384

Phadke MS (1989) Quality engineering using robust design. Prentice Hall, London

Rao CR (1947) Factorial experiments derivable from combinatorial arrangements of arrays. Suppl J R Stat Soc 9:128–139. doi:10.2307/2983576

Roy R (1990) A primer on the Taguchi method. Van Norstrand Reinhold, New York

Roy CJ, Oberkampf WL (2011) A comprehensive framework for verification, validation, and uncertainty quantification in scientific computing. Comput Methods Appl Mech Eng 200:2131–2144. doi:10.1016/j.cma.2011.03.016

Saltelli A et al. (2008) Global sensitivity analysis: the primer. John Wiley & Sons

Scigliano R, Scionti M, Lardeur P (2011) Verification, validation and variability for the vibration study of a car windscreen modeled by finite elements. Finite Elem Anal Des 47:17–29

Soize C (2013) Stochastic modeling of uncertainties in computational structural dynamics—recent theoretical advances. J Sound Vib 332:2379–2395. doi:10.1016/j.jsv.2011.10.010

Trucano TG, Swiler LP, Igusa T, Oberkampf WL, Pilch M (2006) Calibration, validation, and sensitivity analysis: what’s what. Reliab Eng Syst Saf 91:1331–1357. doi:10.1016/j.ress.2005.11.031

Xiong Y, Chen W, Tsui K-L, Apley DW (2009) A better understanding of model updating strategies in validating engineering models. Comput Methods Appl Mech Eng 198:1327–1337. doi:10.1016/j.cma.2008.11.023

Xu H, Rahman S (2004) A generalized dimension‐reduction method for multidimensional integration in stochastic mechanics. Int J Numer Methods Eng 61:1992–2019

Youn B, Xi Z, Wang P (2008) Eigenvector dimension reduction (EDR) method for sensitivity-free probability analysis. Struct Multidiscip Optim 37:13–28. doi:10.1007/s00158-007-0210-7

Youn BD, Jung BC, Xi Z, Kim SB, Lee WR (2011) A hierarchical framework for statistical model calibration in engineering product development. Comput Methods Appl Mech Eng 200:1421–1431. doi:10.1016/j.cma.2010.12.012

Acknowledgements

This work was supported by the Industrial Strategic Technology Development Program (Grant No. 10048305), funded by the Ministry of Trade, Industry & Energy (MI, Korea).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, D., Kim, N.H. & Kim, HS. Validation and updating in a large automotive vibro-acoustic model using a P-box in the frequency domain. Struct Multidisc Optim 54, 1485–1508 (2016). https://doi.org/10.1007/s00158-016-1427-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-016-1427-0