Abstract

The effect of soil-structure interaction on the optimum design of steel space frames is investigated using metaheuristic algorithms. Three-parameter elastic foundation model is used to incorporate soil-structure interaction. A computer program is developed in MATLAB interacting with SAP2000-OAPI for two way data flow in all optimization procedures. Optimum design of space frames is formulated according to LRFD-AISC (Load and Resistance Factor Design, American Institute of Steel Construction) specifications. The parameters of foundation model are obtained by using soil surface displacements. It is concluded that consideration of soil-structure interaction ends up with heavier frames, and method is applicable for practical purposes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Design of steel structures requires the selection of appropriate sections from a discrete set of standard section tables available in practice while satisfying the strength and serviceability limitations described by certain provisions. Applications of metaheuristic search methods are very convenient for the solution of discrete programming problems and being preferred by researchers in wide-range (Saka and Geem 2013). Genetic Algorithm (GA), Harmony Search Algorithm (HS), Ant Colony Algorithm (ACA), Particle Swarm Optimizer (PSO), Artificial Bee Colony Algorithm (ABC), Tabu Search Algorithm (TS), Simulated Annealing (SA) Algorithm, Teaching-Learning-Based Optimization Algorithm (TLBO) methods are some of the optimization algorithms used for the optimum design of structures effectively in recent years. Genetic Algorithm developed by Goldberg (1989) is one of the first stochastic search techniques which mimics the natural and biological phenomena. It was first used for the optimum design of truss system (Rajeev and Krishnamoorthy 1992; Daloglu and Aydın 1999). The method was later used for multi-element truss systems (Erbatur et al. 2000; Togan and Daloglu 2008) and planar frame systems (Daloglu and Armutcu 1998; Isenberg et al. 2002). Genetic Algorithm has successfully been used for the analysis of three dimensional frames (Hayalioglu and Degertekin 2004, 2005; Degertekin et al. 2006). The stress constraints are considered as indicated in TS 648 (Turkish Standard-Building Code for Steel Structures) (TS648 1980), LRFD-AISC Load and Resistance Factor Design or Allowable Stress Design (ASD) (ASD-AISC 2001) specifications in these papers.

There are other structural optimization studies available in literature in recent years based on other metaheuristic search techniques. Saka (2009) used Harmony Search algorithm to solve optimum design of steel sway frames under the limitations specified in BS5950. Aydogdu and Saka (2012) used Ant Colony Optimization for optimum design of irregular steel space frames. Togan (2012) studied optimum design of planar steel frames using Teaching–Learning Based Optimization. Kaveh and Talatahari (2012) proposed a hybrid CSS and PSO algorithm for optimal design of structures. Carbas et al. (2013) performed a comparative study of three different metaheuristic search techniques, Firefly Algorithm (FFA), Artificial Bee Colony (ABC), and Cuckoo Search (CS) algorithms for optimum design of engineering structures. Rafiee et al. (2013) applied Big Bang-Big Crunch method to obtain optimum design of steel frames with semi-rigid connections. Hadidi and Rafiee (2014) researched harmony search based, improved Particle Swarm Optimizer for minimum cost design of semi-rigid steel frames. Reliability based optimum design of reinforced concrete structures including soil-structure interaction are studied by Khatibinia et al. (2013, 2015) modelling the soil layer underneath the structure with isoperimetric four-node quadrilateral finite elements.

In recent years, the applicability and robustness of SAP2000 OAPI allows researchers to focus on specific structural problems. Wu et al. (2012) used SAP2000 OAPI for structural optimization of long span portal-rigid frames under wind action. Kaveh et al. (2014) focused on optimal design of single-layer barrel vault frames using improved magnetic charged system search. Hussein and Taysi (2013) studied genetic algorithm for optimization of space frame using MATLAB incorporated with SAP2000 OAPI.

In this study, the optimum design of steel space frames on elastic foundation is formulated according to LRFD-AISC by using OAPI features of SAP2000. Genetic Algorithm (GA) and Harmony Search (HS) algorithm are used for the optimization process of the steel space frame structures. Three-parameter foundation model is adopted in the study to incorporate the effect of soil foundation on the behavior of the frames in the optimum design process. The moduli of subgrade reaction k and soil shear parameter 2 t are calculated in terms of a third soil parameter γ that represents the vertical deformation profile within subsoil. A computer program is coded in MATLAB (2009) for optimization processes of space frames on three-parameter elastic foundation and connected to SAP2000 (2008) to perform the analysis of the frames interactively using OAPI feature. The members of steel space frames are to be selected from the list of W-section given in LRFD-AISC. A number of space frame examples are designed by the algorithms presented including and excluding the effect of soil-structure interaction in order to investigate the effect of soil-structure interaction on the optimum designs.

2 Optimum design problem

The discrete optimum design problem of steel space frames for minimum weight is defined as below

where W is the weight of the frame, Ak is cross-sectional area of group k, ρ i and L i are density and length of member i, ng is total number of groups, nk is the total number of members in group k. The steel space frames in the study are subjected to the strength constraints of LRFD-AISC specifications, geometric constraints and maximum lateral displacement constraints as being the top and inter-story drifts.

The strength constraints taken from LRFD-AISC (2001) are presented as

where nm is the total number of members, nl is the total number of loading conditions, Pu is the required axial strength, Pn is the nominal strength, Mux is the required flexural strength about major axis, Muy is the required flexural strength about minor axis, Mnx is the nominal flexural strength about major axis, Mny is the nominal flexural strength about minor axis, ϕ is resistance factor for compression (0.85) and for tension (0.90), ϕ b is resistance factor for flexure (0.90).

The nominal compressive strength is calculated as follows;

where A g is the cross-sectional area; K is the effective length factor; E is the elastic modulus; r is the governing radius of gyration; L is the member length; F y is the yield stress of steel, F cr is critical stress, λc is slenderness ratio.

The other constraints used in the optimum designs of the space frames are presented as below, (Aydogdu and Saka 2012).

-

Displacement constraints are expressed as

where δ jl is the displacement of jth degree of freedom under load case l, δ ju is the upper bound, m is the number of restricted displacements, nl is the total number of loading cases.

-

Inter-storey drift constraints are formulated by

where Δ jil is the inter-storey drift of ith column in the jth storey under load case l, Δ ju is the limit value (story height/300), ns is the number of storey, nsc is the number of columns in a storey.

-

Column-to-column geometric constraints (size constraints) can be defined by

where D un is the depth of upper floor column, D ln is the depth of lower floor column.

-

Beam-to-column geometric constraints are presented as below

where n bw is number of joints where beams are connected to web of column, b ′ fbk,i is flange width of beam, d c,i is depth of column, t fl,i is flange thickness of column.

where n bf is number of joints where beams are connected to the flange of column, b fbk,i and b fck,i are flange widths of the beam and column, respectively.

The objective function φ(x) is then determined as

where P is a penalty constant, φ(x) is penalized objective function, c i is constraint violations which are calculated as;

The minimum value of the objective function φ(x) is searched by GA and HS under the constraints described above. Best individuals are selected according to the fitness values in GA, and the fitness values are calculated as;

where F i is fitness function, φ(x)max and φ(x)min are maximum and minimum values of φ(x), φ(x) i is the value of ith individual. In HS, the solutions are sorted in ascending order by the objective function value, φ(x).

3 Three-parameter elastic foundation model

Subsoil reaction of a structure resting on elastic foundation is given by

where w is the displacement of subsoil surface, k and 2 t are first and second soil parameters; k is modulus of subgrade reaction and 2tis the soil shear parameter as defined below

in which E s , υ s and G s are modulus of elasticity, Poisson’s ratio and shear modulus of subsoil respectively Φ(z) is mode shape function as shown in Fig. 1 describing the variation of vertical displacement within the subsoil, and it can be expressed as

where H s is subsoil depth to the rigid base, Fig. 1, and γ is the third soil parameter and it can be evaluated as

The values of mode shape function Φ(z) in (20) are stipulated such that Φ(0) = 1 and Φ(H s ) = 0.

The important point here is that the modulus of subgrade reaction, k, and the soil shear parameter, 2 t, are both dependent on a mode shape function Φ(z) and the depth of the subsoil, H s , as can be seen in (18) and (19). Furthermore the third parameter of the soil, γ, describing the vertical deformation profile within the subsoil, varies with the subsoil surface displacement and the subsoil depth. Therefore, the solution of this complex soil-structure interaction problem can be performed using an iterative technique, (Vallabhan and Das 1991; Vallabhan and Daloglu 1999). The third soil parameter, γ, is set to be equal to 1 to start iterations. Then the two soil parameters, k and 2 t, are determined to analyze the frames on elastic foundation. New value of γ is obtained by using soil surface displacements obtained after the analysis of the structure. The iteration is repeated until the latest and previous values of γ within a prescribed tolerance.

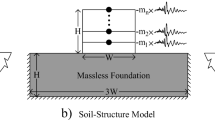

For this purpose, a computing tool is developed using MATLAB to model a space frame structure on elastic foundation in the optimum design process. SAP2000 software is used for the structural analysis part. The modulus of subgrade reaction, k, which is the only soil parameter used in one-parameter foundation model is represented by elastic area springs in SAP2000. However the interaction between springs is ignored due to the assumption that each spring acts independently. The interaction between springs is taken into account using subsoil shell elements connecting the top of the springs. Soil shear parameter, 2 t, is appointed as shear modulus material property of subsoil shear element.

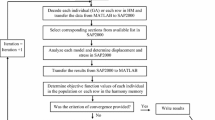

One of the main features of SAP2000-OAPI is to provide two-way data transfer to control structural model by different third-party applications simultaneously. The computing tool developed for the study is used to calculate the soil parameters k and 2 t in terms of the third parameter γ. The solution procedure is given in Fig. 2.

Therefore, the computing tool developed in the study enables SAP2000 to incorporate the soil-structure interaction according to a more realistic three-parameter elastic foundation model. SAP2000-OAPI is used interactively for the analysis of the structural system in the optimum design process by providing two-way data flow between MATLAB and SAP2000.

4 Genetic algorithm and analysis procedures

Genetic Algorithm (GA) which mimics natural biological procedures (reproduction, crossover and mutation) was developed by Goldberg (1989). The main purpose of the algorithm method is to minimize the objective function in the optimization. The analyses start with random initial population which includes individuals coded as binary digits. The binary codes of each individual in population are decoded and corresponding sections are selected from available standard steel section tables and assigned to frame members by the code developed in MATLAB. The frame matching each individual is analyzed by SAP2000 software with selected steel sections. The required results such as strength, displacement and geometric properties of sections are transferred to MATLAB from SAP2000 to determine the values of objective and fitness functions. The individuals are arranged according to their fitness values. To get a strong population, the weak individuals are replaced by fittest individuals. Then, double-point crossover and mutation operators are applied. A crossover probability of 0.90 and 0.01 mutation probability are used for the study. Thus, the initial population is replaced by a new stronger population. The procedures and iterations are repeated until convergence is obtained as presented in Fig. 2.

5 Harmony research and analysis procedures

One other recent meta-heuristic search techniques is Harmony Search (HS) method which is developed by using the improvisation process for a better musical harmony. This algorithm includes three basic steps which are mentioned as below. The detailed information about the algorithm can be obtained from (Lee and Geem 2004).

-

Step 1. Harmony memory matrix (HM) is initialized. It is filled with specified number of solutions as HMS (Harmony Memory Size). Each row of HM indicates the design variables. HMS is very similar to the total number of individuals in the population of GA. The form of HM matrix is as below,

$$ H=\left[\begin{array}{ccccc}\hfill {x}_1^1\hfill & \hfill {x}_2^1\hfill & \hfill ..\hfill & \hfill {x}_{n-1}^1\hfill & \hfill {x}_n^1\hfill \\ {}\hfill {x}_1^2\hfill & \hfill {x}_2^2\hfill & \hfill ..\hfill & \hfill {x}_{n-1}^2\hfill & \hfill {x}_n^2\hfill \\ {}\hfill ..\hfill & \hfill ..\hfill & \hfill ..\hfill & \hfill ..\hfill & \hfill ..\hfill \\ {}\hfill {x}_1^{HMS-1}\hfill & \hfill {x}_2^{HMS-1}\hfill & \hfill ..\hfill & \hfill {x}_{n-1}^{HMS-1}\hfill & \hfill {x}_n^{HMS-1}\hfill \\ {}\hfill {x}_1^{HMS}\hfill & \hfill {x}_2^{HMS}\hfill & \hfill ..\hfill & \hfill {x}_{n-1}^{HMS}\hfill & \hfill {x}_n^{HMS}\hfill \end{array}\right]\kern0.5em \begin{array}{c}\hfill \to \hfill \\ {}\hfill \to \hfill \\ {}\hfill \to \hfill \\ {}\hfill \to \hfill \\ {}\hfill \to \hfill \end{array}\kern0.5em \begin{array}{c}\hfill \varphi \left({x}^1\right)\hfill \\ {}\hfill \varphi \left({x}^2\right)\hfill \\ {}\hfill ..\hfill \\ {}\hfill \varphi \left({x}^{HMS-1}\right)\hfill \\ {}\hfill \varphi \left({x}^{HMS}\right)\hfill \end{array} $$(22)where, x j i is the ith design variable of j th solution vector, n is the total number of design variables, φ(x j) is j th objective function value.

-

Step 2. Harmony memory matrix is evaluated and their objective function values are calculated. The solutions in the harmony memory matrix are sorted according to the objective function values. φ(x 1) is the best solution in the matrix.

-

Step 3. New harmony memory matrix is improvised. A new solution x new i is carried out by selecting each design variable from either harmony memory matrix or the entire section list depending on Harmony Memory Considering Rate (HMCR) which is between 0 and 1. The new value of the design variable selected from harmony memory matrix is checked whether this value should be pitch-adjusted or not depending on Pitch Adjustment Ratio (PAR).

The application of Harmony Search Algorithm with SAP2000-OAPI is similar to the one of Genetic Algorithm. In the examples, HMS, HMCR and PAR are selected as 20, 0.9 and 0.3, respectively.

6 Design examples

The design algorithm presented is used for optimum design of three different space frames without and with consideration of soil-structure interaction. All three frame examples are taken from literature for comparison purposes. A two story, 21-member irregular space frame is solved in the first example to illustrate the effect of soil foundation as well as the effect of soil properties on the optimum design of frame. Then the optimum design of a 4-storey, 84-member space frame is presented for the frame without and with soil-structure interaction for three different subsoil depth. A 20-storey space frame systems is studied comparatively as the final example to illustrate the effect of soil foundation in optimization process. The appropriate cross sections are selected from a predefined list, containing 64 W discrete sections, for the first and second examples and 128 W sections for the third example. The modulus of elasticity, yield stress and the density of the steel material are taken as 200 GPa, 250 MPa, 7.85 ton/m3 respectively. Population size was selected as 20 in all three examples.

6.1 Example 1: two-storey, 21-member irregular space frame

The 21-member irregular space frame studied by Aydogdu (2010) using Ant Colony Optimization and Harmony Search Algorithm is considered to demonstrate the effect of elastic foundation in the optimum design. The space frame members are collected into 5 groups in total being two groups for beams and three groups for columns. Major and minor axes of columns and beams sections are placed as seen in Fig. 3. Maximum displacement and inter-storey drift constraints are taken as 4.0 and 1.02 cm, respectively. Vertical loads on each beam are applied as 20 kN/m and wind load of 50 kN is applied as seen in the figure.

Optimum design of steel space frames are performed for the cases without and with consideration of soil-structure interaction, and the results compared with the ones obtained by Aydogdu (2010). The analyses are carried out for three different soil types representing loose, medium dense and stiff soil by taking modulus of elasticity as 20,000 kN/m2 (Soil A), 68,950 kN/m2 (Soil B) and 120,000 kN/m2 (Soil C) respectively. The depth of the soil to the rigid base is taken as H s = 20 m, and Poisson’s ratio of the soil is equal to 0.25. Minimum weights, maximum top story and inter story drifts, steel sections of optimum designs are presented in Table 1 for comparison.

Design histories of all cases are shown in Fig. 4 using the best design of population for each iteration. Settlements of the soil surface are presented in Fig. 5 for the optimum design of the frames with soil-structure interaction. Six independent runs are performed for this example. Optimum solution for this example is obtained in 240 min for the frame with soil-structure interaction, whereas GA found it in 90 min without considering the effect of subsoil.

Final values of three parameters of elastic foundation are presented in Table 2 for each soil type used in the analysis.

It is shown in Table 1 that the minimum weight values and optimum cross sections obtained from this study are very close to the ones obtained by Aydogdu (2010) and Artar and Daloglu (2015) for the case of the frame without soil-structure interaction. Maximum lateral displacements are below the limit value. However inter storey drifts are very close to upper limit. This situation indicates that inter storey drift constraints are dominant in the optimal designs. It is also observed that minimum weights of the frames with soil-structure interaction determined by GA are 20.1, 5.78 and 4.28 % heavier for Soil types A, B and C respectively compare to the minimum weight of the frame without considering soil-structure interaction . The ones obtained from HS are parallel to the values of GA. As seen in Fig. 4, as the modulus of elasticity of the soil increases the minimum steel weight decreases. The settlements of the soil surface are presented in Fig. 5. It is observed that the maximum soil surface settlements for Soil A is about 0.5 cm while the maximum soil surface settlements for Soil Band Soil C are about 0.2 and 0.1 cm, respectively.

6.2 Example 2: four-storey, 84-member space frame

The 4-storey, 84-member space frame in Fig. 6 analyzed by Degertekin et al. (2008) using Tabu Search and Genetic Algorithm is considered next to demonstrate the effect of soil foundation and depth of soil stratum in the optimum design.

The 84 members of space frame are divided into 10 groups as follows: 1-st group: outer beams of 4-th storey; 2-nd group: outer beams of 3-rd, 2-nd and 1-st storeys; 3-rd group: inner beams of 4-th storey; 4-th group: inner beams of 3-rd, 2-nd and 1-st storeys; 5-th group: corner columns of 4-th storey; 6-st group: corner columns of 3-rd, 2-nd and 1-st storeys; 7-th group: outer columns of 4-th storey; 8-th group: outer columns of 3-rd, 2-nd and 1-st storeys; 9-th group: inner columns of 4-th storey; 10-th group: inner columns of 3-rd, 2-nd and 1-st storeys.

The space frame is subjected to dead load (D = 3.84 kN/m2), live load (L = 2.40 kN/m2), roof live load (Lr = 2.40 kN/m2 and wind pressure (p = CeCqqsIw, where p is design wind pressure; Ceis combined height, exposure and guest factor coefficient; Cqis pressure coefficient and equal to 0.8 and 0.5 for windward and leeward faces respectively, qsis wind stagnation pressure and equal to 0.785 kN/m2, the wind importance factor Iwis one). The design parameters are the same with the previous example. The wind loads are applied to structure in the x-direction. The maximum top and inter-story drifts are restricted to 3.50 and 1.17 cm respectively. Load combinations used in this example are as; I: 1.4D; II: 1.2D + 1.6 L + 0.5Lr; III:1.2D + 1.6Lr + 0.5 L; IV:1.2D + 1.3 W + 0.5Lr + 0.5 L (W: wind load).

The effect of subsoil depth to rigid base is investigated here and the analyses are carried out for three different subsoil depths, H s = 5 m, H s = 10 m and H s = 15 m, respectively. The modulus of elasticity of the soil is 68,950 kN/m2 and Poisson’s ratio of the soil is equal to 0.25. Minimum weights, maximum top storey and inter storey drifts, steel sections of optimum designs are presented in Table 3 for comparison.

Design histories of all cases are shown in Fig. 7 using the best design of the population for each iteration. And settlements of the soil surface are presented in Fig. 8 for the optimum design of the frames with soil-structure interaction.

It is observed from Table 3 that the minimum weight of 184.33 kN and optimum cross sections obtained from this study are very close to the results obtained by Degertekin et al. (2008) for the frame without soil-structure interaction. Top storey and inter storey drifts are very close to the upper limits. So, these constraints play active roles in the optimization. It is also seen that minimum weights of the frames with soil-structure interaction depending on the depths of the soil defined by GA are 2.2, 4.9 and 6.4 % heavier for three different values of soil depth compare to the optimum weight of frame without considering soil-structure interaction. The minimum weights obtained by HS are nearly 1.5 % lower than that of GA. It is observed from Fig. 8 that the maximum soil surface settlement for Hs = 15 m is about 0.3 cm while the maximum soil surface settlements for Hs = 10 m and Hs = 5 m are about 0.25 and 0.2 cm, respectively. Soil parameters according to different Hs values are presented in Table 4. Five independent runs are performed for the example. Optimum solutions for this example are obtained in 180 min for the frame without soil-structure interaction, and in 540 min for the frame with soil-structure interaction by GA.

6.3 Example 3: design of 20-storey, 460-member irregular space frame

The 20-storey, 460-member irregular space frame designed by Aydogdu (2010) and Aydogdu and Saka (2012) using Ant Colony Optimization (ACO) and Harmony Search Algorithm (HSA) is considered as the last example. Figure 9 shows the geometry, loading case and the groups of frame members. Vertical loads on all floors are 4.79 kN/m2 and wind load is 0.958 kN/m2 as shown in the figure. Maximum displacement and inter-storey drift constraints are 24.40 and 1.22 cm, respectively. Modulus of elasticity of the soil, E s , is taken to be equal to 68,950 kN/m2. The depth of the soil stratum to the rigid base is taken as H s = 30 m, and Poisson’s ratio of the soil is equal to 0.25.

Optimum design of steel space frames are performed for the cases of frames without and with consideration of soil-structure interaction and the results of the frame without soil effect are compared with the results reported by Aydogdu (2010). Minimum weights, maximum top story and inter story drifts, optimum values of cross sections for both the cases are presented in Table 5.

Figure 10 shows the variation of total steel weight with iterations for both cases. The curves are plotted using the best design of the population foreach iteration. The soil surface settlements obtained from the optimum design of the frame are shown in Fig. 11.

It is observed from Table 5 and Fig. 10 that the minimum weights of 3273.793 kN by GA and 3221.16 kN by HS and optimum cross sections for frame without considering soil effects are very close to the results reported by Aydogdu (2010) and Aydogdu and Saka (2012). In the solution by GA, the maximum lateral displacement of 21.45 cm is far below the limit value for the frame without soil effect while the value of 24.207 cm is quite close to the limit value. However the inter storey drift is 1.19 cm which is very close to upper limit of inter story drift. In the HS solution, these values are 23.45, 21.69 and 1.22 cm, respectively. This indicates that the inter storey drift constraints play an active role in the optimum design for the case without soil effects while top storey drift constraints are very important determinant of optimal design for the frame with soil-structure interaction.

Minimum weight of the frame on elastic sub soil is 3864.551 kN by GA and 3684.42 kN by HS, which are about 18.3 and 15.1 % heavier than the minimum weight of the frame without considering sub soil effect. Furthermore, larger cross sections are obtained for the columns. Modulus of subgrade reaction, k, is obtained as 3407.183 kN/m3, soil shear parameter, 2 t, and the third parameter γ are obtained as 174,299.186 kN/m and 2.15612 respectively. It is also observed that the maximum soil surface displacement is about 1.2 cm for this frame, Fig. 11. Eight independent runs are performed for the last example. Optimum solutions by GA are obtained in 480 min for the frame without soil-structure interaction, and in 1200 min for the frame with soil-structure interaction.

7 Summary and conclusions

The aim of this study is to investigate the effect of soil-structure interaction on the optimum designs of space frames using Genetic Algorithm and Harmony Search Algorithm. Three-parameter elastic foundation model is employed to determine the effect of the soil underneath the space frame structure. The strength constraints of LRFD-AISC specifications, the constraints of top and inter story drifts and geometric (column-to-column and beam to column) constraints are imposed on space frames with and without considering soil-structure interaction. A computer program is coded in MATLAB for the optimum design of steel space frames and to model three parameter elastic foundations. OAPI features of SAP2000 are used for the structural analysis of the frames interactively with the MATLAB code by accomplishing a two way data flow. The results obtained from MATLAB-SAP2000 OAPI based optimum design by using GA and HS are described below:

-

Optimum design of steel space frames on three-parameter elastic foundation is a very complex soil-structure interaction problem in civil and structural engineering. The proposed methodology is used to accomplish this without any difficulty because metaheuristic algorithms-based optimal design approaches are suitable and applicable to mathematically complex problems.

-

The computing tool proposed in the study enables SAP2000 to consider soil-structure interaction according to more realistic three-parameter foundation model. In fact, OAPI feature of SAP2000 is used along with MATLAB interactively to provide two-way data transfer to control and analyze structural model in the optimization process.

-

The minimum weights of optimum designs increase for all the examples when soil-structure interaction is considered. Furthermore, larger cross sections are obtained for the columns especially. The first example is solved for three different type of elastic subgrade representing loose, medium dense and stiff soil. Minimum weights increase depending on modulus of elasticity of the soil compare to the frame having fixed support at the bottom. It is observed that the difference decreases as the soil gets stiffer.

-

The optimum design of the second example is performed for three different values of subsoil depth to the rigid base. Heavier frames are obtained depending on the depths of the soil compare to the optimum weight of frames excluding soil-structure interaction. Minimum weights increase as the subsoil depth to the rigid base gets larger.

-

The soil surface displacements change according to the modulus of elasticity of the soil in the optimum designs of frames with soil-structure interaction. Hence it can be concluded that the soil surface displacements decrease as the soil gets stiffer.

-

The constraints of maximum lateral displacement and inter story drifts played very active roles in optimum designs for all the examples investigated in the study.

-

Results show that consideration of soil effects increases steel design weight of the frames. And the algorithm developed in the study can be used effectively for the optimum design of steel space frames including soil stratum at the bottom. Besides the computing tool developed in the study enables SAP2000 to incorporate the soil-structure interaction according to a more realistic foundation model and SAP2000-OAPI is used interactively for the analysis of the structural system in the optimum design process by providing two-way data flow between MATLAB and SAP2000.

References

Artar M, Daloglu AT (2015) Optimum design of steel space frames with composite beams using genetic algorithm. Steel and composite structures. Int J 19(2):503–519

ASD-AISC (2001) Manual of steel construction: allowable stress design. American Institute of Steel Construction, Chicago

Aydogdu I (2010) Optimum design of 3-d irregular steel frames using ant colony optimization and harmony search algorithms. Ph.D. Dissertation. Middle East Technical University, Ankara

Aydogdu I, Saka MP (2012) Ant colony optimization of irregular steel frames including elemental warping effect. Adv Eng Softw 44(1):150–169

Carbas S, Aydogdu I, Saka MP (2013) A comparative study of three metaheuristics for optimum design of engineering structures. 10th World Congress on Structural and Multidisciplinary Optimization, Orlando, Florida

Daloglu A, Armutcu M (1998) Optimum design of plane steel frames using genetic algorithm. Teknik Dergi 116:1601–1615

Daloglu A, Aydın Z (1999) Optimum design of trusses for practical applications. Pamukkale University Engineering College. J Eng Sci 5:951–957

Degertekin SO, Ulker M, Hayalioglu MS (2006) Optimum design of steel space frames using tabu search and genetic algorithm. Teknik Dergi 259:3917–3934

Degertekin SO, Saka MP, Hayalioglu MS (2008) Optimal load and resistance factor design of geometrically nonlinear steel space frames via tabu search and genetic algorithm. Eng Struct 30(1):197–205

Erbatur F, Hasancebi O, Tutuncu I, Kılıc H (2000) Optimal design of planar and space structures with genetic algorithms. Comput Struct 75(2):209–224

Goldberg DE (1989) Genetic algorithms in search. Optimization and machine learning. Addison-Wesley, Reading

Hadidi A, Rafiee A (2014) Harmony search based, improved Particle Swarm Optimizer for minimum cost design of semi-rigid steel frames. Struct Eng Mech 50(3):323–347

Hayalioglu MS, Degertekin SO (2004) Genetic algorithm based optimum design of non-linear steel frames with semi-rigid connections. Steel Compos Struct 4(6):453–469

Hayalioglu MS, Degertekin SO (2005) Minimum cost design of steel frames with semi-rigid connections and column bases via genetic optimization. ComputStruct 83(21-22):1849–1863

Hussein G, Taysi N (2013) Genetic algorithm optimization of space frame. 2nd International Balkans Conference on Challenges of Civil Engineering, BCCCE, Epoka University, Tirana, Albania

Isenberg J, Pereyra V, Lawver D (2002) Optimal design of steel frame structures. Appl Numer Math 40(1-2):59–71

Kaveh A, Talatahari S (2012) A hybrid CSS and PSO algorithm for optimal design of structures. Struct Eng Mech 42(6):783–797

Kaveh A, Mirzaei B, Jafarvand A (2014) Optimal desıgn of double layer barrel vaults using improved magnetic charged system search. Asian J Civil Eng (Bhrc) 15:135–154

Khatibinia M, Salajegheh E, Salajegheh J, Fadaee MJ (2013) Reliability-based design optimization of reinforced concrete structures including soil-structure interaction using a discrete gravitational search algorithm and proposed metamodel. Eng Optim 45(10):1147–1165

Khatibinia M, GharehbaghiS, Moustafa A, (2015) Seismic reliability-based design optimization of reinforced concrete structures including soil-structure interaction effects, Earthquake Engineering-From Engineering Seismology to Optimal Seismic Design of Engineering Structures. Chapter 11. InTech: 267–304

Lee KS, Geem ZW (2004) A new structural optimization method based on the harmony search algorithm. ComputStruct 82:781–798

LRFD-AISC (2001) Manual of steel construction-Load and resistance factor design. American Institute of Steel Construction, Chicago

MATLAB (2009) The language of technical computing. The Mathworks, Natick

Rafiee A, Talatahari S, Hadidi A (2013) Optimum design of steel frames with semi-rigid connections using Big Bang-Big Crunch method. Steel Compos Struct 14(5):431–451

Rajeev S, Krishnamoorthy CS (1992) Discrete optimization of structures using genetic algorithms. J Struct Eng ASCE 118(5):1233–1250

Saka MP (2009) Optimum design of steel sway frames to BS5950 using harmony search algorithm. J Constr Steel Res 65(1):36–43

Saka MP, Geem ZW (2013) Mathematical and Metaheuristic applications in design optimization of steel frame structures: an extensive review. Math Probl Eng 2013:1–33

SAP2000 (2008) Integrated finite elements analysis and design of structures. Computers and Structures, Inc, Berkeley

Togan V (2012) Design of planar steel frames using teaching–learning based optimization. Eng Struct 34:225–232

Togan V, Daloglu AT (2008) An improved genetic algorithm with initial population strategy and self-adaptive member grouping. Comput Struct 86(11-12):1204–1218

TS648 (1980) Turkish standard-building code for steel structures. Institution of Turkish Standards, Ankara

Vallabhan CVG, Daloglu AT (1999) Consistent FEM-Vlasov model for plates on layered soil. J Struct Eng ASCE 125(1):108–113

Vallabhan CVG, Das YC (1991) A refined model for beams on elastic foundations. Int J Solids Struct 27(5):629–637

Wu JR, Dong CC, Xu A, Fu JY (2012) Structural optimization of long span portal-rigid frames under wind action. The Seventh International Colloquium on Bluff Body Aerodynamics and Applications (BBAA7) Shanghai, China

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daloglu, A.T., Artar, M., Özgan, K. et al. Optimum design of steel space frames including soil-structure interaction. Struct Multidisc Optim 54, 117–131 (2016). https://doi.org/10.1007/s00158-016-1401-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-016-1401-x