Abstract

This study evaluated the effect of contact charring plus linseed oil submersion on wood chemistry and microstructure in Pinus taeda and Eucalyptus bosistoana wood specimens. Fourier-transform infrared spectroscopy (FT-IR), scanning electron microscope (SEM) and Raman spectroscopy analyses were performed to characterize charred wood in comparison to uncharred controls. Total lignin content increased to nearly 53% and 55% in the outer surfaces of the charred P. taeda and E. bosistoana specimens, respectively. The inner parts of the charred specimens also demonstrated increases higher than 50% in total lignin content. Total carbohydrate content of charred wood specimens decreased after the carbonization process. In the charred P. taeda specimens, the highest reductions in carbohydrate units observed were arabinan, xylan, and mannan. In the charred E. bosistoana specimens, arabinan, galactan and xylan showed the highest reductions in carbohydrate units. After charring, all wood specimens exhibited elevated contact angles when compared to control specimens due to increased hydrophobicity. The FTIR spectra analyses also indicated polysaccharide depolymerization and the formation of furans and alkylated aromatic compounds in charred specimens. Oil submersion led to saturation of cell lumens in both wood species used in this study. Charring led to sensitivity and homogeneity in cell walls although cells and pits retained their structural integrity and shape. Additionally, crack formation and separation occurred along the cell wall in some tracheid and fiber cells.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Charred wood has been used for centuries in Japan as a traditional method known as “yakisugi” to enhance the durability of wood against biodeterioration. Interest in the use of charred wood materials has been growing in recent years and has been introduced into the worldwide market as a sustainable and desirable aesthetic material for both exterior and interior applications. Surface charred wood is generally considered as a stylish, high-design structural material with good service-life (Sandberg and Kutnar 2021). In recent years, several studies have been done related to charring of wood surfaces focusing on water-sorption properties (Kymäläinen et al. 2018), surface characteristics and fire resistance (Machova et al. 2021), artificial weathering properties (Kymäläinen et al. 2022a), density profile and wettability (Šeda et al. 2021), weathering and surface functional groups (Kymäläinen et al. 2020), natural weathering characteristics (Kymäläinen et al. 2022b), water absorption and micromorphological analyses (Kymäläinen et al. 2017), moisture sorption and dimensional stability (Kymäläinen et al. 2022c), decay resistance (Kymäläinen et al. 2022d), fire performance (Buksans et al. 2021), cupping formation and charred layer thickness (Ebner et al. 2021), total carbohydrates, phenolic compounds, moisture and mechanical behavior (Čermák et al. 2019), durability and fire performance (Hasburgh et al. 2021), hydrophobicity, influence of inorganics on wood surface and organic acid effect on color (Morozovs et al. 2021), artificial weathering (Kampe and Pfriem 2018), and charring method development and structural evaluations (Ebner et al. 2022). In the above-mentioned studies, different charring techniques have been used such as flame charring, contact charring, one-sided or multi-sided charring, without oil application and most of these studies evaluated water sorption and wettability issues. However, there is little available research related to changes in micro-structure and wood chemistry after surface charring combined with oil treatment.

When wood is exposed to high temperatures, the chemical components begin to change, and the first signs of these changes can be observed in the cellular structure of the wood. This combined effect on chemical and microstructural alterations lead to changes in the macrostructure which eventually result in shifts in the physical and biological properties of the wood. The magnitude and impacts of these changes vary depending on the wood species as well as the process and parameters used during treatment (Fengel and Wegener 1984; Hill 2006). The varying effects of the same process on different species can be explained by the differences in underlying microstructure and chemical properties of different tree species (Sehlstedt-Persson et al. 2006; Boonstra 2008; Awoyemi 2011).

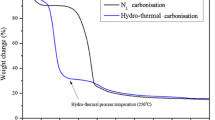

Different types of thermal modification techniques have been developed over the years. According to industry specifications for thermal modification, temperature does not usually exceed 250 °C (Hill 2006; Esteves and Pereira 2009; Boonstra 2008; Dubey 2010; ITWA 2021). In these methods, the entire material is treated, not just the outer surface/s. Surface modification chars the wood surface by subjecting it to high temperatures with flame or hot plate contact. However, studies on the effects of contact surface charring on wood microstructure are quite limited. Kymäläinen et al. (2017) revealed some changes in the microstructure of wood cells in one-sided charred spruce and pine sapwood, particularly on the lumen side of the tracheid cell, but no obvious crack formations were observed on the cell walls. Kymäläinen et al. (2018) examined the sorption-related characteristics of spruce wood and stated that although there was little effect on the overall cellular structure, a small number of crack formations were observed, and due to densification, the wood cells became flattened and plasticized. In addition to these limited number of studies related to surface charring, changes in the microstructure of carbonized wood have been the subject of some studies utilizing various tree species. In carbonization studies carried out at varying temperatures from 300 to 1000 °C, it has been demonstrated that changes in cell shapes, sizes, and frequency occur above 400 °C, and homogenization is observed with crack formations in the cell walls (Leme et al. 2010; Gonçalves et al. 2012; Gasson et al. 2017; Stange et al. 2018; Osterkamp et al. 2018; Li et al. 2022).

Hasburgh et al. (2021) states that as a thermochemical process, charring refers to incomplete combustion and results in removal of organic components and formation of a carbon layer that is generally devoid of surface carbohydrates. Kymäläinen et al. (2022b) studied chemical changes in charred and weathered wood surfaces by FTIR and Raman spectroscopy. Their results were indicative of degradation in the lignin components of contact charred wood; however, more resistant carbon structures in flame charred wood were shown even after weathering. Another study by Kymäläinen et al. (2018) evaluated the changes in the microstructure and surface functional groups of surface charred spruce wood by SEM and photoacoustic FTIR spectroscopy. They found increases in aromatic structures on the wood surface after charring; however, little effect was observed on the cellular structure of charred wood. Kymäläinen et al. (2022d) found decreases in the overall carbohydrate content of one-sided charred wood by contact and flame methods. Their study indicated that in the contact charred wood, hemicelluloses were almost entirely depleted, while the flame method resulted in complete degradation of all carbohydrates. Šeda et al. (2021) studied the relationships between wettability/water absorption and chemical properties in one-sided charred beech wood and their results revealed decreases in the number of OH groups in the celluloses and hemicelluloses and increases in cellulose crystallinity and cross-linking of lignin. Machová et al. (2021) also showed significant decreases in total carbohydrates in one-sided charred wood. Čermák et al. (2019) found that reductions in equilibrium moisture content levels and decreased water absorption properties in one-sided surface charred wood specimens were correlated with the decreases in OH groups and cross-linking of lignin as well as increases in soluble carbohydrates and phenolic compounds.

Published literature has repeatedly demonstrated the effects of temperature modification on changes in wood properties. Therefore, understanding microstructural changes associated with temperature treatment methods and wood species can be important for material characterization. In this study, the wood surface of two wood species was carbonized by surface contact charring. During carbonization, the water in the cell structures is removed and macro cracks may form due to the collective effect of the shrinkage of cells and decomposition of chemical components. To prevent the formation of macro cracks, samples were dipped in linseed oil after charring and crack formation was relatively controlled. In our previous study (Soytürk et al. 2023), we examined biological performance of multi-side charred Pinus taeda and Eucalyptus bosistoana woods by contact charring method with linseed oil application. The overall goal of the current study was to examine alterations in wood microstructure as well as changes in wood chemistry associated with contact charring plus linseed oil treatment.

2 Materials and methods

2.1 Wood specimens

Three 50-year-old Eucalyptus bosistoana (F. Muell.) and two 22-year-old Pinus taeda (L.) trees were harvested from Bernardo Rosengurtt Experimental Station of the Faculty of Agronomy of Universidad de la República, Cerro Largo, Uruguay. Sapwood of the harvested trees was utilized in this study since it is susceptible to deterioration and thus would benefit from charring protection. The harvested trees were cut into 2-meter-long boards and then air dried for 16 weeks. The sapwood boards were then cut into specimens (15 × 25 × 50 mm); half of the specimens were charred while the other half remained uncharred and was used as controls.

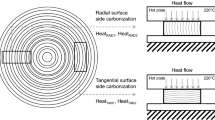

2.2 Charring process

The prepared wood specimens were first oven dried at 80 °C for two days and then charred on a hot metallic surface at an initial temperature of 120 °C. The surface was heated with electric resistance monitoring the temperature via an HI 99550-00 infrared thermometer (Hanna Inst. Mexico City, MX) every 15 min. During charring, a 5 kg weight was placed on top of the specimens to ensure homogenous contact throughout the entire surface and to avoid deformations. In addition, temperature was continuously maintained below 150 °C to prevent cracking on wood surfaces. The charring conditions were selected based on preliminary attempts to minimize surface cracking while forming a thick and uniform charred layer beneath the surface. Contact time with the hot surface was determined by monitoring the char depth with a caliper to obtain homogeneous specimens with a char layer no thicker than 3 mm. Each surface of a given specimen was exposed to heat for 10 min and all surfaces of each specimen were exposed to the same charring conditions. Once the charring process was finished, the specimens were immediately dipped in linseed oil for 5 s to homogenize the char layer and prevent further cracking. Excess oil and loose char were then gently removed with a wire brush and charred specimens were subjected to air drying for 96 h at room temperature.

2.3 Chemical analyses

Chemical analysis was done on three replicate blocks from each of the specimen test groups. In charred samples, outer sections (approximately 3 mm) were analyzed separately from inner portions, which were prepared by sectioning off the outer portion of the block using a blade so that analyses could be used to determine differences between the charred surface layer versus the inner core. All samples for chemical analysis were prepared by grinding in a Wiley mill to pass size 20 mesh and approximately 200 mg was collected from each sample. Chemical analysis was run in duplicate and included evaluation of total carbohydrates based on the NREL/TP-510-42618 procedure, “Determination of Structural Carbohydrates and Lignin in Biomass” (NREL 2012). The analytical procedure included quantification of lignin (soluble and insoluble) and carbohydrates. Briefly, the procedure consisted of a two-stage acid hydrolysis followed by a filtration step to remove the insoluble fraction. The hydrolysates were then diluted and injected into an ion chromatography system (DIONEX ICS 3000) to quantify soluble sugars. Chemical analysis data for wood sugars is presented as quantities of each sugar monomer (glucan, arabinan, rhamnan, galactan, xylan, mannan) as a fraction of dry weight material which can be used to estimate the amount of the hemicelluloses.

2.4 Characterization

To determine surface wettability, contact angle (CA) was measured with an optical tensiometer (Attension, Theta Lite). The CA was measured by placing a droplet (5 µL) of de-ionized water on the surface of the specimens. The surface morphology of the wood specimens was then characterized using a scanning electron microscope (SEM) instrument (Zeiss EVO LS10) at 25 kV. Before SEM characterization, the wood samples from charred and control specimens were sputter coated with a thin layer of gold. The chemical composition of wood samples was characterized via FTIR using the ATR (Attenuated Total Reflection) mode (LUMOS II, Bruker). The Raman spectra were obtained by a Raman microscope (Alpha 300 M+, WITec, Germany) using an excitation laser at a wavelength of 532 nm and a power of 22.8 mW. Raman spectra were measured using a 100X objective for an integration time of 0.5 s. The measurements of Raman on each wood specimen were repeated on ten different locations, and the average value was reported.

2.5 Microstructure

Changes in the microstructure of the specimens before and after charring were examined from 5 to 10 mm cubes prepared from specimens with 3 sectional surfaces (transverse, radial, tangential). To remove the emerging linseed oil that came to the surface during vacuum in the electron microscope, the specimens were kept in turpentine for 24 h, then washed with distilled water and air-dried for 24 h. Prior to imaging with SEM (Zeiss EVO LS10) at 25 kV, the surfaces of the samples were smoothed with a sliding microtome (Leica SM2010R) and then sputter coated with a thin layer of gold.

2.6 Data analysis

For chemical analyses, statistical significance was determined by Duncan’s multiple range test (p ≤ 0.05) using the InerSTAT-a V1.3 program (Vargas 1999).

3 Results and discussion

3.1 Chemical analysis

Table 1 shows acid insoluble lignin (AIL), acid soluble lignin (ASL), and total lignin content as well as ash content of the test specimens. In charred P. taeda specimens, no statistically significant differences were observed between the inner and outer sections of the charred specimens for AIL or total lignin content, however, the inner and outer section did show significantly higher AIL and total lignin content compared to control P. taeda. There was significantly higher ASL content formed in the outer section compared to the inner section of charred P. taeda specimens. In E. bosistoana specimens, significantly higher AIL and total lignin content was obtained in the outer section. Additionally, there was significantly higher AIL and total lignin content in both outer and inner sections when compared to control E. bosistoana. The inner section of E. bosistoana contained significantly higher ASL content when compared to the outer section; however, the higher ASL in the inner section was comparable to control E. bosistoana.

Ash content (Table 1) was different between the two species tested. In charred P. taeda, ash content was not statistically different between in the inner and outer sections of the specimens. There also does not appear to be much difference between inner and outer samples for E. bosistoana; however, there was significantly lower ash content in the outer section compared to the E. bosistoana control. According to Vassilev et al. (2010), chemical compositions of biomass (especially ash) are highly variable due to moisture variations and genetic material. Additionally, ash content of firewood residues range between 0.1 and 16.5% (Smolka-Danielowska and Jablonska 2022).

Carbohydrate contents of the test specimens are given in Table 2. Control specimens of P. taeda had higher amounts of arabinan, galactan, mannan, and ash (Table 1) compared to E. bosistoana controls which had higher amounts of rhamnan, glucan, and xylan. Charring in both species resulted in a significant reduction in all carbohydrates with the exception of the inner section of E. bosistoana which showed a significant increase in mannan. In general, the inner section of charred P. taeda had significantly higher carbohydrates in comparison with the outer sections with the exceptions of rhamnan (no change) and glucan (significantly higher). Carbohydrate production was significantly higher in the inner section of charred E. bosistoana when compared to the outer sections for all carbohydrates with the exception of glucan (no significance between inner and outer sections).

The percent change in the chemical properties of charred specimens compared to control specimens is given in Fig. 1. In P. taeda, AIL and total lignin content in charred wood increased upwards of 40% while ASL in charred wood increased by at least 30% (Fig. 1a). In E. bosistoana, AIL and total lignin content in charred wood increased at least 40% while AIL in charred wood decreased by approximately 10% (Fig. 1c). Ash content from both charred species decreased by at least 30% when compared to control specimens (Fig. 1a and c). Arabinan content decreased by more than 60% in P. taeda (Fig. 1b) and decreased by more than 40% in E. bosistoana (Fig. 1d). Galactan content decreased by 30% in both P. taeda (Fig. 1b) and E. bosistoana (Fig. 1d) inner sections while the outer sections of both species showed decreases of approximately 50%. Rhamnan content decreased by at least 25% in both species while glucan content decreased by around 20%. Xylan content decreased upwards of 50% in P. taeda while E. bosistoana showed decreases above 35% (inner section) and 50% (outer section). In P. taeda, mannan content decreased more than 45%; however, E. bosistoana showed almost a 10% increase in the inner section and a 20% decrease in the outer section.

While lignin is considered the most thermally stable component of wood, it can be subjected to degradation below 200 °C (Fengel and Wegener 1984). Condensation and repolymerization reactions are also readily occurring during thermal degradation. These reactions generally result in new lignin-based polymers or increased cross-linking of the lignin network (Boonstra 2008). In this study, increases in lignin content are likely due, at least in part, to the loss of the hemicelluloses as well as the condensation and repolymerization of lignin. Boonstra and Tjeerdsma (2006) evaluated the effects of heat treatment on Scots pine wood and their results indicated that acid insoluble lignin content increased from 27.7% in control specimens to 36% in heat-treated specimens while acid soluble lignin content increased from 0.37% (control) to 0.56% (heat-treated). Esteves et al. (2021) found similar results in acid insoluble content in thermally modified Paulownia wood; however, thermally modified wood contained less soluble lignin compared to controls. The overall reduction in carbohydrates associated with charring indicates decomposition of the hemicelluloses which is expected after thermal treatment. Kymäläinen et al. (2022d) evaluated the properties of one-sided charred spruce and birch by contact and flame methods. They found the contact charred surfaces of the test specimens were nearly completely depleted of hemicelluloses while the flame charred specimens were almost entirely devoid of all carbohydrates (mainly contained Klason lignin). The total lignin content in birch wood increased from 21 to 50% and 96% associated with contact and flame-charring, respectively. In contact and flame charred spruce wood specimens, total lignin content increased from 27 to 61% and 93%, respectively. They showed that as the relative amount of carbohydrates is reduced following the thermal degradation process, lignin content rises (Kymäläinen et al. 2022d), which agrees with the results of the present study. Raveendran et al. (1996) and Antal and Gronli (2003) state that in pyrolysis reactions, lignin preferentially forms a char layer; however, other lignin-like aromatic compounds are also formed and those are also responsible for the increases in relative total lignin content (also correlated to the present study). In one-sided charred beech wood, total carbohydrates were found to be significantly changed at various wood depths after surface carbonization (Machova et al. 2021).

Aside from surface charring, other thermal treatments help to improve wood durability, and have been well studied across several wood species and treatment parameters (Candelier et al. 2016; Presley et al. 2022). The increased durability of wood exposed to thermal modifications is generally attributed to increased hydrophobicity, formation of toxic compounds, chemical modifications of wood cell components (i.e., degradation of carbohydrates) and / or the loss of hydroxyl groups (Kamdem et al. 2000, 2002; Weiland and Guyonnet 2003; Hakkou et al. 2006; Hill 2006; Kartal 2006; Kartal et al. 2007, 2008; Del Menezzi et al. 2008). Kamdem et al. (2002) found Klason lignin content in heat-treated wood to be higher than that of the control wood and attributed increases in lignin content (7, 15 and 23% in pine, spruce, and beech wood, respectively) to the loss of hemicelluloses or fragile pentoses and hexoses during thermal modifications. Piernik et al. (2022) showed that heat-treated pine sapwood (220 °C) had reduced amounts of extractives, holocellulose and hemicelluloses, and higher amounts of cellulose and lignin in comparison to unmodified wood. Additionally, increases in the duration of thermal treatment resulted in increases in the amount of cellulose and lignin, as well as decreases in hemicellulose and holocellulose content (Piernik et al. 2022). Boonstra and Tjeerdsma (2006) provide a thorough explanation of the chemical changes in heat treated softwoods (165–185 °C), under aqueous environment at super-atmospheric pressure depolymerization of hemicelluloses and the cleavage of acetyl groups of carbohydrates occurred. However dry and atmospheric conditions were limited to the depolymerization of hemicelluloses and the cleavage of the acetyl groups. Eventually the increases in lignin content of heat-treated wood were linked to the depolymerization of the carbohydrates; however, polycondensation reactions creating cross-linking of the lignin network and/or the formation of other aromatic structures were also demonstrated to be important factors. Chemical changes during the production of heat-treated beech wood were also studied by Windeisen et al. (2007) and their findings indicated that the decomposition of polysaccharides can be almost completely attributed to polyoses. The degradation of sugar units was also linked to the decrease of acetyl groups and aliphatic hydroxyl groups (Windeisen et al. 2007). The hemicelluloses are the least thermally stable wood components regarding their branched structure with acetyl side chains. Depolymerization of hemicelluloses is caused by cleavage of acetic acid from acetyl side chains and leads to reduction in the acetyl content of wood. Thus, these reactions act as an autocatalysis in the mechanism of thermolysis reactions (Hill 2006; Boonstra 2008; Dubey 2010) and the degradation of the hemicelluloses reduces hydroxyl groups resulting in less hygroscopic wood (Dubey et al. 2012).

3.2 Characterization

The IR spectra of the charred and control wood samples are shown in Fig. 2 (a-b). Vibrations associated with aliphatic C–O–C and alcohol–OH in the range of 1060–1030 cm− 1 are present in the uncharred P. taeda and E. bosistoana wood (Guo et al. 1998). These oxygenated functional groups were mostly eliminated after charring in wood species. The reductions in these bands which correspond to C-O stretching in celluloses and hemicelluloses, are indicative of polysaccharide depolymerization (Dubey et al. 2012). The band at 3350 cm− 1 represents the OH stretching vibration of water. The intensity of this band decreased significantly after charring in both P. taeda and E. bosistoana. The reduction at this hydroxyl peak is suggestive of a decrease in wood hygroscopicity (Boonstra 2008).

The band at 2850–2920 cm− 1 represents aliphatic C-H stretching vibrations. In both P. taeda and E. bosistoana, the FTIR spectrum shows an increase in the C–H stretching band due to the formation of alkylated furans and alkylated aromatic compounds after charring (Oudemans et al. 2007). The bands at 2855 to 2928 cm− 1 are also characteristic for C-H stretching vibration with linseed oil (Kose Demirel et al. 2018). Therefore, the increase in these bands can be attributed to alterations in the wood structure by charring and from the presence of the linseed oil. Peaks at 1740 cm− 1 are associated with C–O stretching of carbonyl groups in hemicelluloses and ester groups present in linseed oil, respectively (Pandey 1999; Dubey 2010; Boonstra 2008; Calvo-Correas et al. 2015; Kose Demirel et al. 2018). The FTIR spectrum shows an increase in the C–O stretching band after charring in both P. taeda and E. bosistoana. A decrease in this peak is expected with the decomposition of carbonyl groups in the structure of hemicelluloses at high temperatures (Dubey 2010). According to Tjeerdsma and Militz (2005), an increase in this peak is associated with formation of new carbonyl groups by esterification reactions which can be linked to the lignin complex. Boonstra (2008) also related this increase to the formation of ester, ketone and carbonyl groups in the lignin network.

The molecule size of linseed oil is too large to penetrate in the cell wall, thus any absorbed oil remained in the cell lumens (Hill 2006; Dubey et al. 2012) which is thought to result in the increase at 1740 cm− 1 due to the presence of carbonyl groups. This increase has also been attributed to lignin condensation reactions at the C = C double bonds in conjugated carbonyl groups with a vibration band positioned at 1654 cm− 1 (Esteves et al. 2013). The band at 1510 cm− 1 represents the aromatic ring structure and C = C stretching vibration of lignin. After charring, both species showed a slight increase in this band which indicates alterations in lignin content apart from the degradation of hemicellulose (Pandey 1999; Dubey 2010; Boonstra 2008).

Raman spectroscopy is a well-known effective technique for characterizing the bonding structure of carbon materials and was used to examine the effect of surface charring on wood structure in P. taeda and E. bosistoana (Fig. 2c-d). Bands D (∼1350 cm− 1) and G (~ 1580 cm− 1) are the most prominent signals in carbon materials using this technique (Bengtsson et al. 2020). D-band arose from out of plane vibrations of sp2 bonded carbon atoms and is assigned to the disordered or distorted graphitic structure at the edge of microcrystalline carbon (Yamauchi and Kurimoto 2003, Roslan et al. 2017, Kymalainen et al. 2022b). The presence of D-band indicates defect occurrence in carbon material (Bokobza et al. 2015; Bengtsson et al. 2020), which can be seen in Fig. 2 for P. taeda (c) and E. bosistoana (d). Band G arose from plane vibration of C-C bond associated with amorphous carbon materials indicating graphitic structure (Roslan et al. 2017, Kymalainen et al. 2022b). The intensity ratio of these bands (ID/IG) is a measure of the defects present on carbon materials and related to graphitization and pyrolysis state (Ferrari and Robertson 2000). Intensity of D/G ratio was 0.37 and 0.68 for charred P. taeda and E. bosistoana, respectively. Occurrences and shifts of D-bands and intensity of D/G ratios indicate the defects on charred wood related to crystallite size of amorphous carbon.

As shown in the SEM and contact angle images (Fig. 3), P. taeda exhibited contact angles of 56° and 23° in control specimens, which then increased to 76° and 74° after charring on radial and tangential surfaces, respectively. This increase in the water contact angle can be attributed to charring on the specimen surface. Previous literature has demonstrated the creation of a hydrophobic / superhydrophobic coating after flame burning of hydrocarbon-based materials (Celik et al. 2021; Seo and Kim 2014); thought to arise from unburned long chain carbon compounds (Yang et al. 2019).

SEM and contact angle images of charred and control E. bosistoana specimens are shown in Fig. 4. Uncharred E. bosistoana wood was more hydrophilic with higher contact angles of 70° and 52° compared to uncharred P. taeda wood (56° and 23°) for radial and tangential surfaces, respectively. This observation is likely due to different surface roughness of these tree species. After E. bosistoana specimens were charred, the contact angle increased to 80° on radial surface, and 72° on tangential surface (Fig. 4). Kymäläinen et al. (2017) evaluated contact angle properties of one-sided charred spruce and pine wood using a hot plate method. Their results showed the contact angles of both wood species were increased compared to uncharred wood. However, elevated temperatures of up to 400 °C that were used for charring resulted in diminished contact angles in both species as a result of surface cracking and increased porosity. Similarly, Seda et al. (2021) measured the highest contact angle for one-sided charred beech at 200 °C, and that contact angle measurements decreased at elevated temperatures up to 400 °C. In a more recent study by Kymäläinen et al. (2018), one-sided charred spruce specimens showed decreased water sorption capacity as a result of increased surface hydrophobicity. Cross-linking mechanism during thermal degradation (Tjeerdsma et al. 1998; Wannapeera et al. 2011), migration of extractives on the wood surface (Rautkari et al. 2010), and softening of lignin (Nuopponen et al. 2003; Kymäläinen et al. 2018) have all been identified as potential factors associated with decreased water absorption in charred wood. Čermák et al. (2019) suggested that increases in soluble carbohydrates and phenolic compounds significantly diminish the water absorption properties of charred wood specimens. Results from the present study agree with published literature in that specimens of both tree species examined showed increased surface hydrophobicity with increasing contact angles in conjunction with changes in the chemical structure of wood after surface charring. Overall, these changes have the potential to result in enhanced dimensional stability in multi-sided charred wood specimens.

3.3 Microstructure

In charred specimens of both species, the linseed oil covered the wood cells, serving as a protective layer against cracking. In the charred cross-sections, the wood cell lumens were saturated with oil, especially in charred P. taeda (Fig. 5). Charred P. taeda samples showed increased homogeneity and sensitivity in the tracheid cell walls while maintaining their cellular structure. Tracheid cells became fragile after charring which leads to microcracks along the cell walls (Fig. 6). Ray cells also maintained their shape, although thin-walled ray parenchyma cell walls were ruptured and the bordered pits on the radial walls became more porous (Fig. 7). The bordered pits at ray tracheid and cross-field pits at the contact points of tracheid and ray parenchyma cell walls damaged but retained their shapes (Fig. 6).

Similar to our results, it was stated that as a result of hydrothermal processes (200 °C) the wood structure became more open, different stress areas induced crack formations, and also pits were intact (Boonstra et al. 2006; Tuncer and Dogu 2018). However, Dubey (2010) found that hot oil treatment did not induce crack formation in the microstructure of the wood because of uniform heat transfer in the oil medium. In wood samples impregnated with oil heated at 60–70 °C, it was observed that latewood tracheids were clogged with oil, while the majority of earlywood tracheid lumens were empty (Jebrane et al. 2015; Köse Demirel et al. 2018). Dubey (2010) also observed linseed oil deposition in the lumen in specimens treated in oil heated to 160 °C, but not in those treated at 180 or 210 °C. This suggests that the oil moves away from the cell lumen at temperatures above 180 °C. In this study, oil treatment was applied without heating which caused the linseed oil to remain within the cell lumen.

After 300 °C, the tracheid cell walls became increasingly homogeneous, the cell walls coalesced into one, and the middle lamella was no longer distinguishable, indicating that the charcoalification of softwoods begins at around 300 °C (Li et al. 2022). Similarly, it was reported that cell wall layers and middle lamella were filled with polymerized oil and homogenized in pine samples impregnated with epoxy linseed oil at 70 °C (Jebrane et al. 2015). This suggests that the homogenization and filling of cells are related.

Studies have shown there to be minimal effect on cellular structure at temperatures of 250–400 °C, but some fibers can become plasticized and flattened around 400 °C (Kymäläinen et al. 2018). At high temperatures, Kymäläinen et al. (2017) and Kymäläinen et al. (2018) showed damage to tracheid cell walls without the formation of cracks; however, cellular structure became brittle above 600 °C (Osterkamp et al. 2018). They observed that as temperature increased, tracheid cell wall thickness and lumen dimensions decreased (Meincken et al. 2010; Osterkamp et al. 2018; Li et al. 2022), while crack formation and ray width increased (Osterkamp et al. 2018). Eventually these types of alterations are likely to cause wood shrinkage which can lead to defects such as cupping.

In charred E. bosistoana specimens, cells (vessels, fibers and rays) and pits retained their structural integrity and shape, even thin-walled ray parenchyma cells (Fig. 8). However, it was observed that cell walls became sensitive and brittle, which resulted in the formation of cracks and separation along cell walls in some fibers (Fig. 9). In addition, the cell wall layers could not be detected due to the absence of the compound middle lamella (Fig. 9). Instead, a more homogeneous structure was observed, similar to observations in previous studies on different hardwood species (Leme et al. 2010; Gasson et al. 2017; Perdigão et al. 2020; Neto et al. 2021). However, it is not clear whether this change is due to thermal degradation, the utilization of linseed oil, or a combination.

Results from published literature provide support for the hypothesis that high temperature treatments can alter the physical, microstructural, and chemical composition of wood. Several studies on hardwoods have shown that the overall qualitative characteristics of the wood microstructure do not change substantially at temperatures below 400 °C (Leme et al. 2010; Gonçalves et al. 2012; Stange et al. 2018; Perdigão et al. 2020; Barauna et al. 2021). Although, some studies have demonstrated that between 350 and 400 °C fiber cells are homogenized in a way that the middle lamella becomes indistinguishable and fiber wall thicknesses and widths decrease (Leme et al. 2010; Gasson et al. 2017; Arantes et al. 2020; Perdigão et al. 2020; Tamburini et al. 2020; Neto et al. 2021). Above 400 °C, cracks begin forming and vessels lose their circular shape, instead becoming more angular which results in collapse and rupture (Leme et al. 2010; Gasson et al. 2017; Perdigão et al. 2020; Tamburini et al. 2020). In general, ray cells remain intact under increasing temperature conditions, but localized cracks and intercellular separations do occur due to minor degrees of shrinkage (Leme et al. 2010; Gasson et al. 2017; Stange et al. 2018; Perdigão et al. 2020). Areas of different densities in wood (such as axial parenchyma and fibers) have been suggested as initiation points for crack formation.

Pyrolysis and gasification of wood begins after 270 and 500 °C, respectively, and damages in wood structure and wood chemical composition have been noted at or above 200 °C. However, thermal decomposition can be observed after exposure to temperatures as low as 100 °C, depending on additional factors (e.g., processing time, environment) (Fengel and Wegener 1984). Changes in wood cell structure were observed in this study even though treatment temperatures did not exceed 200 °C. Specifically, P. taeda tracheid walls and E. bosistoana fiber walls showed formation of a homogeneous structure after charring due to thermal decomposition, clogging of cells with oil, or the combination. However, most charred cells remained intact and preserved their structural integrity. When comparing our results with that from published literature there appears to be a consensus that the qualitative features of wood are preserved but that certain quantitative properties change (Gonçalves et al. 2012; Stange et al. 2018; Osterkamp et al. 2018; Perdigão et al. 2020; Barauna et al. 2021).

4 Conclusion

Surface carbonization of P. taeda and E. bosistoana wood was achieved using a temperature controlled hot plate and resulted in changes to the chemical and microstructural properties of the wood. In both wood species, total lignin content increased, and total carbohydrates decreased, associated with charring. The degradation of wood carbohydrates in the charred wood specimens is an important contributor towards increased surface wettability and increased contact angles due to decreased hydrophilic OH groups. In this study, the immersion of wood in linseed oil after charring served to prevent formation of large and/or extended cracks on the wood surface. Although the cells and pits remained mostly intact after charring, minor cracks in the cell walls of some tracheid and fiber cells were observed. Further studies are in progress to evaluate the effect of accelerated and natural weathering exposure on the microstructure of charred wood surfaces.

References

Antal MJJ, Grønli M (2003) The art, science, and technology of charcoal production. Ind Eng Chem Res 42:1619–1640. https://doi.org/10.1021/ie0207919

Arantes MD, Trugilho PF, Moulin JC, Goulart SP, Baraúna EEP, Neto RA (2020) Anatomy of charcoal and carbonization effect under Eucalyptus fibers’ dimensions. Floresta E Ambiente 27(1). https://doi.org/10.1590/2179-8087.064317

Awoyemi L, Jones IP (2011) Anatomical explanations for the changes in properties of western red cedar (Thuja plicata) wood during heat treatment. Wood Sci Technol 45:261–267. https://doi.org/10.1007/s00226-010-0315-9

Baraúna EEP, Stallbaun PH, Monteiro TC, Silva TC, Baldin T, Colen F, Arantes MDC (2021) The effect of carbonization on the wood anatomy of Sclerolobium Paniculatum Vogel. BioResources 16(4):7846–7854. https://doi.org/10.15376/biores.16.4.7846-7854

Bengtsson A, Hecht P, Sommertune J, Ek M, Sedin M, Sjöholm E (2020) Carbon fibers from lignin–cellulose precursors: Effect of carbonization conditions. ACS Sustain Chem Eng 8(17):6826–6833. https://doi.org/10.1021/acssuschemeng.9b00108

Bokobza L, Bruneel JL, Couzi M (2015) Raman Spectra of carbon-based materials (from graphite to carbon black) and of some silicone composites. Carbon 1:77–94. https://doi.org/10.3390/c1010077

Boonstra MJ (2008) A Two-Stage Thermal modification of wood. Dissertation in Co-supervision Ghent University and Université Henry Poincaré.

Boonstra MJ, Tjeerdsma B (2006) Chemical analysis of heat-treated softwoods. Holz als Roh-und Werkstoff 64:204–211. https://doi.org/10.1007/s00107-005-0078-4

Boonstra M, Pizzi A, Zomers F, Ohlmeyer M, Paul W (2006) The effects of a two-stage heat treatment process on the properties of particleboard. Holz Werkst 64:157–164. https://doi.org/10.1007/s00107-005-0055-y

Buksans E, Laiveniece L, Lubinskis V (2021) Solid wood surface modification by charring and its impact on reaction to fire performance. In: 20th International scientific conference “Engineering for rural development”: proceedings, Jelgava, Latvia, 20, 1899 – 905. https://doi.org/10.22616/ERDev.2021.20.TF203

Calvo-Correas T, Mosiewicki MA, Corcuera MA, Eceiza A, Aranguren MI (2015) Linseed oil-based polyurethane rigid foams: synthesis and characterization. J Renew Mater 3:3–13. https://doi.org/10.7569/JRM.2014.634132

Candelier K, Thevenon MF, Petrissans A, Dumarcay S, Gerardin P, Petrissans M (2016) Control of wood thermal treatment and its effects on decay resistance: a review. Ann for Sci 73:571–583. https://doi.org/10.1007/s13595-016-0541-x

Celik N, Kiremitler NB, Ruzi M, Onses MS (2021) Waxing the soot: practical fabrication of all-organic superhydrophobic coatings from candle soot and carnauba wax. Prog Org Coat 153:106169. https://doi.org/10.1016/j.porgcoat.2021.106169

Čermák P, Dejmal A, Paschová Z, Kymäläinen M, Dömény J, Brabec M, Hess D, Rautkari L (2019) One-sided surface charring of beech wood. J Mater Sci 54(13):9497–9506. https://doi.org/10.1007/s10853-019-03589-3

Del Menezzi CHS, de Souza QR, Thompson RM, Teixeira DE, Okino EYA, da Costa AF (2008) Properties after weathering and decay resistance of a thermally modified wood structural board. Int Biodeterior Biodegrad 62:448–454. https://doi.org/10.1016/j.ibiod.2007.11.010

Dubey MK (2010) Improvements in stability, durability and mechanical properties of Radiata pine wood after heat-treatment in a vegetable oil. Dissertation, University of Canterbury

Dubey MK, Pang S, Walker J (2012) Changes in chemistry, color, dimensional stability and fungal resistance of Pinus radiata D. Don wood with oil heat-treatment. Holzforschung 66:49–57. https://doi.org/10.1515/HF.2011.117

Ebner DH, Barbu MC, Klaushofer J, Čermák P (2021) Surface modification of spruce and fir sawn-timber by charring in the traditional Japanese method—Yakisugi. Polymers 13(10):1662. https://doi.org/10.3390/polym13101662

Ebner DH, Barbu MC, Gryc V, Čermák P (2022) Surface charring of silver fir wood cladding using an enhanced traditional Japanese yakisugi method. BioResources 17(2):2031. https://doi.org/10.15376/biores.17.2.2031-2042

Esteves B, Pereira HM (2009) Wood modification by heat treatment. Rev BioResources 4(1):370–404. https://doi.org/10.15376/biores.4.1.370-404

Esteves B, Velez Marques A, Domingos I, Pereira H (2013) Chemical changes of heat-treated pine and eucalypt wood monitored by FTIR. Maderas Ciencia Y tecnología 15(2):245–258. https://doi.org/10.4067/S0718-221X2013005000020

Esteves B, Ferreira H, Viana H, Ferreira J, Domingos I, Cruz-Lopes L, Jones D, Nunes L (2021) Termite resistance, chemical and mechanical characterization of Paulownia tomentosa wood before and after heat treatment. Forests 12(8):1114. https://doi.org/10.3390/f12081114

Fengel D, Wegener G (1984) Wood, Chemistry, Ultrastructure, reactions. Walter de Gruyter & Co., Berlin. ISBN 3-11-008481-3

Ferrari AC, Robertson J (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Am Phys Soc 61(20):14095–140107

Gasson P, Cartwright C, Leme CLD (2017) Anatomical changes to the wood of Croton Sonderianus (Euphorbiaceae) when charred at different temperatures. IAWA J 38(1):117–123. https://doi.org/10.1163/22941932-20170161

Gonçalves TAP, Marcati CR, Scheel-Ybert R (2012) The effect of carbonization on wood structure of Dalbergia Violacea, Stryphnodendron Polyphyllum, Tapirira Guianensis, Vochysia tucanorum, and Pouteria torta from the Brazilian cerrado. IAWA J 33(1):73–90. https://doi.org/10.1163/22941932-90000081

Guo Y, Bustin RM (1998) FTIR spectroscopy and reflectance of modern charcoals and fungal decayed woods: implications for studies of inertinite in coals. Int J Coal Geol 37(1–2):29–53. https://doi.org/10.1016/S0166-5162(98)00019-6

Hakkou M, Petrissans M, Gerardin P, Zoulalian A (2006) Investigations of the reasons for fungal durability of heat-treated beech wood. Polym Degrad Stab 91(2):393–397. https://doi.org/10.1016/j.polymdegradstab.2005.04.042

Hasburgh LE, Zelinka SL, Bishell AB, Kirker GT (2021) Durability and Fire performance of charred wood siding (Shou Sugi Ban). Forests 12(9):1262. https://doi.org/10.3390/f12091262

Hill CAS (2006) Wood modification: Chemical, Thermal and other processes. John Wiley &Sons, Chichester. ISBN 0-470-02172-1

ITWA (2021) Thermowood Handbook. International Thermowood Association. https://www.thermowood.fi/thermowood-handbook-published

Jebrane M, Fernandez-Cano V, Panov D, Terziev N, Daniel G (2015) Novel hydrophobization of wood by epoxidized linseed oil. Part 2. Characterization by FTIR spectroscopy and SEM, and determination of mechanical properties and field test performance. Holzforschung 69(2):179–186. https://doi.org/10.1515/hf-2014-0030

Kamdem DP, Pizzi A, Triboulot MC (2000) Heat-treated timber: potentially toxic byproducts presence and extent of wood cell wall degradation. Holz Roh- Werkst 58:253–257. https://doi.org/10.1007/s001070050420

Kamdem DP, Pizzi A, Jermennaud A (2002) Durability of heat-treated wood. Holz als Roh- Werkst 60:1–6. https://doi.org/10.1007/s00107-001-0261-1

Kampe A, Pfriem A (2018) A note on artificial weathering of spruce (Picea abies) with a carbonised layer. Int Wood Prod J 9(2):86–89. https://doi.org/10.1080/20426445.2018.1493841

Kartal SN (2006) Combined effect of boron compounds and heat treatments on wood properties: boron release and decay and termite resistance. Holzforschung 60:455–458. https://doi.org/10.1515/HF.2006.072

Kartal SN, Hwang WJ, Imamura Y (2007) Water absorption of boron-treated and heat-modified wood. J Wood Sci 53:454–457. https://doi.org/10.1007/s10086-007-0877-9

Kartal SN, Hwang WJ, Imamura Y (2008) Combined effect of boron compounds and heat treatments on wood properties: Chemical and strength properties of wood. J Mater Process Technol 198:234–240. https://doi.org/10.1016/j.jmatprotec.2007.07.001

Kose Demirel G, Temiz A, Jebrane M, Terziev N, Gezer ED (2018) Micro-distribution, water absorption, and dimensional stability of wood treated with epoxidized plant oils. BioResources 13(3):5124–5138. https://doi.org/10.15376/biores.13.3.5124-5138

Kymäläinen M, Hautamäki S, Lillqvist K, Segerholm K, Rautkari L (2017) Surface modification of solid wood by charring. J Mater Sci 52:6111–6119. https://doi.org/10.1007/s10853-017-0850-y

Kymäläinen M, Turunen H, Čermák P, Hautamäki S, Rautkari L (2018) Sorption-related characteristics of surface charred spruce wood. Materials 11(11):2083. https://doi.org/10.3390/ma11112083

Kymäläinen M, Turunen H, Rautkari L (2020) Effect of weathering on surface functional groups of charred Norway spruce cladding panels. Forests 11(12):1373. https://doi.org/10.3390/f11121373

Kymäläinen M, Sjökvist T, Dömény J, Rautkari L (2022a) Artificial weathering of contact-charred wood—the effect of modification duration, wood species and material density. Materials 15:3951. https://doi.org/10.3390/ma15113951

Kymäläinen M, Lourençon TV, Lillqvist K (2022b) Natural weathering of soft-and hardwoods modified by contact and flame charring methods. Eur J Wood Product 80(6):1309–1320. https://doi.org/10.1007/s00107-022-01864-w

Kymäläinen M, Dömény J, Rautkari L (2022c) Moisture sorption of wood surfaces modified by one-sided carbonization as an alternative to traditional façade coatings. Coatings 12:1273. https://doi.org/10.3390/coatings12091273

Kymäläinen M, Belt T, Seppäläinen H, Rautkari L (2022d) Decay resistance of surface carbonized wood. Materials 15:8410. https://doi.org/10.3390/ma15238410

Leme CLD, Cartwright C, Gasson P (2010) Anatomical changes to the wood of Mimosa Ophthalmocentra and Mimosa tenuiflora when charred at different temperatures. IAWA J 31(3):333–351. https://doi.org/10.1163/22941932-90000027

Li G, Gao L, Liu F, Giu M, Dong G (2022) Quantitative studies on charcoalification: physical and chemical changes of charring wood. Fundamental Res. https://doi.org/10.1016/j.fmre.2022.05.014

Machová D, Oberle A, Zárybnická L, Dohnal J, Šeda V, Dömény J, Vacenovská V, Kloiber M, Pencík J, Tippner J (2021) Surface characteristics of one-sided charred beech wood. Polymers 13:1551. https://doi.org/10.3390/polym13101551

Meincken M, Smit NH, Steinmann D (2010) Physical properties of burnt timber, with special focus on the drying performance. Eur J Wood Prod 68:455–461. https://doi.org/10.1007/s00107-009-0388-z

Morozovs A, Laiveniece L, Lubinskis V (2021) Wood one-side surface charring of timber for claddings or recycled wood. Latvia Univ of Life Sciences and Technologies Jelgava (Latvia). https://doi.org/10.22616/ERDev.2021.20.TF221

Neto RA, Lima JT, Takarada LM, Trugilho PF (2021) Effect of thermal treatment on fiber morphology in wood pyrolysis. Wood Sci Technol 55:95–108. https://doi.org/10.1007/s00226-020-01238-6

NREL (National Renewable Energy Laboratory) (2012) NREL/TP-510-42618-Determination of Structural Carbohydrates and Lignin in Biomass. National Renewable Energy Laboratory Technical Report Issue, Date: April 2008, Revision Date: August 2012, Contract No. DE-AC36-08GO28308

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2003) The effects of a heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic measurements. Wood Sci Technol 37:109–115. https://doi.org/10.1007/s00226-003-0178-4

Osterkamp IC, Müller de Lara D, Gonçalves TAP, Kauffmann M, Périco E, Stülp S, Machado NTG, Uhl D, Jasper A (2018) Changes of wood anatomical characters of selected species of Araucaria during artificial charring: implications for palaeontology. Acta Bot Brasilica 32(2):198–211. https://doi.org/10.1590/0102-33062017abb0360

Oudemans TFM, Boon JJ, Botto RE (2007) FTIR and solid-state 13 C CP/MAS NMR spectroscopy of charred and non‐charred solid organic residues preserved in Roman Iron Age vessels from the Netherlands. Archaeometry 49(3):571–294. https://doi.org/10.1111/j.1475-4754.2007.00321.x

Pandey KK (1999) Study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J Appl Polym Sci 71:1969–1975

Perdigão CRV, Júnior MMB, Gonçalves TAP, Araujo CS, Mori FA, Barbosa ACMC, Souza FIBd, Motta JP, Melo FEL (2020) Forestry control in the Brazilian Amazon I: Wood and charcoal anatomy of three endangered species. IAWA J 41(4):1–20. https://doi.org/10.1163/22941932-bja10016

Piernik M, Woźniak M, Pinkowski G, Szentner K, Ratajczak I, Krauss A (2022) Impact of the heat treatment duration on color and selected mechanical and chemical properties of scots pine wood. Materials 15:5425. https://doi.org/10.3390/ma15155425

Presley G, Cappellazzi J, Eastin I (2022) Durability of thermally modified western hemlock lumber against wood decay fungi. Front for Global Change 5:813080. https://doi.org/10.3389/ffgc.2022.813080

Rautkari L, Kutnar A, Kamke FA, Hughes M (2010) Wood surface densification using different methods. In: Proceedings of the 11th World Conference on Timber Engineering, Riva del Garda, Italy, 20–24 June 2010

Raveendran K, Ganesh A, Khilar KC (1996) Pyrolysis characteristics of biomass and biomass components. Fuel 75:987–998. https://doi.org/10.1016/0016-2361(96)00030-0

Roslan MS, Chaudary KT, Haider Z, Zin AFM, Ali J (2017) Effect of magnetic field on carbon nanotubes and graphene structure synthesized at low pressure via arc discharge process. AIP Conference Proceedings 1824, 030025. https://doi.org/10.1063/1.4978843

Sandberg D, Kutnar A, Karlsson O, Jones D (2021) Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation (1st ed.). CRC Press. ISBN 978-1-138-49177-9

Šeda V, Machová D, Dohnal J, Dömény J, Zárybnická L, Oberle A, Vacenovská V, Cermák P (2021) Effect of one-sided surface charring of Beech Wood on Density Profile and Surface Wettability. Appl Sci 11(9):4086. https://doi.org/10.3390/app11094086

Sehlstedt-Persson M, Johansson D, Moren T (2006) Effect of heat treatment on the microstructure of pine, spruce and birch and the influence on capillary absorption. In: Proceedings of the 5th IUFRO Symposium “Wood Structure and Properties ‘06”, Sliac – Sielnica, Slovakia, Sep 3–6 2006, ISBN 80-968869-4–3, 251–255

Seo K, Kim M (2014) Candle-based process for creating a stable superhydrophobic surface. Carbon 68:583–596. https://doi.org/10.1016/j.carbon.2013.11.038

Smołka-Danielowska D, Jabłońska M (2022) Chemical and mineral composition of ashes from wood biomass combustion in domestic wood-fired furnaces. Int J Environ Sci Technol 19:5359–5372. https://doi.org/10.1007/s13762-021-03506-9

Soytürk EE, Kartal SN, Arango RA, Ohno KM, Solhan E, Çağlayan İ, Ibanez CM (2023) Surface carbonization of wood: comparison of the biological performance of Pinus taeda and Eucalyptus bosistoana woods modified by contact charring method. Wood Material Science and Technology. https://doi.org/10.1080/17480272.2023.2198993

Stange R, Vieira HC, Rios PD, Nisgoski S (2018) Wood and charcoal anatomy of four Myrtaceae species. Cerne 24(3):190–200. https://doi.org/10.1590/01047760201824032552

Tamburini D, Cartwright CR, Gasson P, Łucejko JJ, Leme CLD (2020) Using analytical pyrolysis and scanning electron microscopy to evaluate charcoal formation of four wood taxa from the caatinga of north-east Brazil. J Anal Appl Pyrol 151. https://doi.org/10.1016/j.jaap.2020.104909

Tjeerdsma BF, Militz H (2005) Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz Roh- Werkst 63:102–111. https://doi.org/10.1007/s00107-004-0532-8

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh-Werkst 56:149–153. https://doi.org/10.1007/s001070050287

Tuncer FD, Dogu AD (2018) Effects of heat treatment on some macroscopic and physical properties of scots pine sapwood and heartwood. Forestist 68(2):93–100. https://doi.org/10.26650/forestist.2018.343295

Vargas MH (1999) InerSTAT-a v1.3. Instituto Nacacional de Respiratorias, Mexico

Vassiley S, Baxter D, Andersen L, Vassileva C (2010) An overview of the chemical composition of biomass. Fuel 89(5):913–933. https://doi.org/10.1016/j.fuel.2009.10.022

Wannapeera J, Fungtammasan B, Worasuwannarak N (2011) Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass. J Anal Appl Pyrol 92:99–105. https://doi.org/10.1016/j.jaap.2011.04.010

Weiland JJ, Guyonnet R (2003) Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy. Holz als Roh- und Werkstoff 61:216–220. https://doi.org/10.1007/s00107-003-0364-y

Windeisen E, Strobel C, Wegener G (2007) Chemical changes during the production of thermo-treated beech wood. Wood Sci Technol 41:523–536. https://doi.org/10.1007/s00226-007-0146-5

Yamauchi S, Kurimoto Y (2003) Raman spectroscopic study on pyrolyzed wood and bark of Japanese cedar: temperature dependence of Raman parameters. The Japan Wood Research Society 49: 235–240.

Yang L, Fu H, Yang C, Tian W, Wu P, Jiang W (2019) Carbon soot with arbitrary wettability deposited on solid surface by ethanol flame method. Colloids Surf a 578:123576. https://doi.org/10.1016/j.colsurfa.2019.123576

Acknowledgements

The authors wish to acknowledge Amy Bishell (USDA Forest Products Laboratory (FPL), Madison, WI, USA) for help preparing wood samples and Carlos Baez (USDA FPL, Madison, WI, USA) for performing chemical analyses.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

F.D.T.: Investigation, Data Curation, Writing-Original Draft, Writing - Reviewing and EditingS.N.K.: Supervision, Conceptualization, Methodology, Writing- Original DraftE.E.S.: Investigation, Data Curation, Visualization, Writing-Reviewing and EditingR.A. A.: Investigation, Data Curation, Writing - Reviewing and EditingK.M.O.: Investigation, Data Curation, Writing - Reviewing and EditingM.S.Ö.: Investigation, Data Curation, Writing - Reviewing and EditingN.Ç.: Investigation, Data Curation, Writing - Reviewing and EditingC.M.I: Conceptualization, Methodology, Resources.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tuncer, F.D., Kartal, S.N., Soytürk, E.E. et al. Changes in chemical properties and microstructure of Pinus taeda and Eucalyptus bosistoana woods modified by contact charring. Eur. J. Wood Prod. 82, 107–121 (2024). https://doi.org/10.1007/s00107-023-02011-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-023-02011-9