Abstract

The purpose of this study was to predict the color change of heat-treated wood during artificial weathering by an artificial neural network (ANN) model. Chemical component analysis was used to analyze the origin of color change of the heat-treated wood. The network included an input layer consisting of three input nodes, namely, the weathering exposure time, heat treatment temperature, and heat-treated wood species, a hidden layer using six neurons and an output layer consisting of one output node, namely heat-treated wood color. A hyperbolic tangent sigmoid transfer function was used in the hidden layer, and the training algorithm was the Levenberg–Marquardt backpropagation. According to the results, the mean absolute percentage errors (MAPE) were 8.17, 9.70, and 9.85% for the prediction of color change (ΔE) for training, validation and testing data sets, respectively. Determination coefficients (R2) above 0.92 were obtained with the proposed ANN model for all data sets. These results showed that the ANN model can be successfully used for predicting the color change of heat-treated wood during artificial weathering. FTIR results showed that the color change of heat-treated wood during artificial weathering is due to the change in the chemical composition, especially the photodegradation of lignin and wood extractives.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The use of wood and heat-treated wood (HTW) as industrial product for outdoor applications is increasing. It is well known that the natural untreated wood is susceptible to environmental degradation induced by weathering factors, such as solar radiation (ultraviolet, visible, and infrared light), moisture (dew, rain, snow, and humidity), temperature, and oxygen (Feist et al. 1990). The colors of untreated wood vary rapidly when exposed to weathering. It is well acknowledged that wood changes the color due to the photodegradation of lignin and wood extractives (Feist et al. 1990). The advantages of HTW are related to the dimensional stability, durability, and attractive dark color (Nuopponen et al. 2003; Icel et al. 2015; Nguyen et al. 2018a). In addition, the HTW shows better color stability when exposed to UV radiation and moisture than the untreated wood, which is probably attributed to the thermally induced changes of lignin-cellulose and structural modification of chromophoric groups on lignin (Ayadi et al. 2003; Peng et al. 2015). Although the chemical composition of wood varies depending on the species, the main compounds are cellulose, hemicellulose, lignin, and extractives. As a result of weathering treatment, the color of wood changes appearing darker, which is usually explained by the formation of colored degradation products from hemicelluloses (Sehlstedt-Persson 2003; Sundqvist 2004) and extractives, the latter being likely also the origin of the color of the hydrothermally treated wood (Armondo 1997; Sundqvist and Morén 2002). The formation of oxidation products, such as quinones, is also referred to as a color change factor (Mitsui et al. 2001; Bekhta and Niemz 2003). During the artificial weathering, different wood species undergo different color changes due to the different chemical composition, i.e., cellulose, hemicellulose, lignin, and extractives (Bekhta and Niemz 2003; Tuong and Li 2010).

Knowing the color change of HTW during weathering helps to better apply environmentally-friendly HTW products. However, many experiments are needed to identify the optimum values, which is time-consuming, expensive, and difficult to do. Thus, a model that predicts the relationship between the process parameters of weathering time and color properties of HTW is necessary. The artificial neural network (ANN) has been applied in the field of wood science to aim for better use of wood materials, reduce the number of experiments, and optimize the process.

Artificial neural networks are an information processing system built on the generalization of a mathematical model of biological neurons adapted from the human brain. An ANN is based on a collection of connected units or nodes called artificial neurons, which loosely model the neurons in a biological brain. Each connection, like the synapses in a biological brain, can transmit a signal from one artificial neuron to another. ANN learns the relationship between input and output variables through previously recorded data (Kalogirou 2001). To achieve this, the network is trained with the data related to the problem under consideration using a training algorithm. The training consists of a process of adjusting the connection weights that allow the ANN to produce outputs that are equal or close to desired targets (Hamed et al. 2004). ANN has been successfully used in several studies for predictions in the field of wood science. Fernandez et al. (2008) used the ANN approach for modeling the internal bond strength of particleboards. Tiryaki and Coşkun (2014) employed the ANN for predicting the modulus of rupture (MOR) and modulus of elasticity (MOE) of heat-treated wood. Demirkir et al. (2013) employed the same approach for modelling the plywood bonding strength. In a previous study, Nguyen et al. (2018b) employed the ANN for predicting color change in wood during heat treatment.

The aim of this study was to investigate the color change of heat-treated larch (HTL) and heat-treated poplar (HTP) during exposure to artificial weathering for 0, 240, 480, 720, 960, 1200, 1440, 1680, 1920, 2160, 2400, 2700, and 3000 h, and to identify the relationship between wood discolorations and degradation of wood components. Then, based on these results, an ANN model was used to predict the color change of HTW during artificial weathering with different time variables without the need of conducting expensive and time-consuming experiments.

2 Materials and methods

2.1 Materials

In this study, heat-treated larch (Larix gmelinii), a softwood species, and heat-treated poplar (Populus alba), a hardwood species, were used. Heat-treated larch (HTL) and heat-treated poplar (HTP) were provided by the Material Science and Engineering College of the Northeast Forestry University. Both types of wood were heat-treated at temperatures of 180, 190, 200, 210, and 220 °C, with a processing time of 4 h. 105 HTL and 105 HTP wood blocks measuring 80 × 30 × 3 mm3 (l × t × r) were randomly divided into 10 treatment groups, each of them having 21 samples. The samples were conditioned at a room temperature of 20 ± 2 °C and 65 ± 5% relative humidity to a moisture content of about 12%.

2.2 Experimental procedure

2.2.1 Color measurement

The color of the samples was measured at 0, 240, 480, 720, 960, 1200, 1440, 1680, 1920, 2160, 2400, 2700, and 3000 h. For each period of exposure to weathering, three samples were used for color measurement. Four measurements were taken for each sample, two of which were taken on early wood, and the other two on late wood.

The measurements of the HTW surface color were taken with a CM- 2300d spectrophotometer (D5003908, Konica Minolta Sensing, Inc., Japan) in a holder with a diameter of 8 mm. The overall color change, ΔE*, was measured using the CIE 1976 L*a*b* color measuring system. Accordingly, there are three important color parameters, L*, a*, and b*, to be calculated. The overall color change, ΔE*, was calculated using the following formulas:

where ΔL*, Δa*, and Δb* represent the color change before and after exposure to artificial weathering.

2.2.2 Weathering tests

Artificial weathering tests were conducted at the Key Laboratory of Bio-Based Material Science and Technology, Northeast Forestry University, Harbin, Heilong Jiang, China. Accelerated weathering test was conducted in a Q-panel QUV weathering tester (Q-Lab Corporation USA) equipped with UVA-340 lamps. The tester can reproduce the damage that may occur to wood over months or years of outdoor exposure. Each 12-hour weathering cycle consisted of 8 h of UV exposure at 60 °C followed by 4 h water spraying at 50 °C. The UV irradiance was 0.89 W/m2 at 340 nm. The changes in the surface color of the samples were evaluated after weathering exposure for 0, 240, 480, 720, 960, 1200, 1440, 1680, 1920, 2160, 2400, 2700, and 3000 h.

2.2.3 Chemical analysis

The effect of the artificial weathering on the transformation induced to chemical compositions in heat-treated woods was studied by Fourier transform infrared (FTIR) spectroscopy. The FTIR spectra were recorded by a Magna-IR 560 FTIR instrument provided by Nicolet Co. Ltd (32 scans between 650 and 4000 cm−1 were collected with a resolution of 4 cm−1).

2.2.4 Artificial neural network

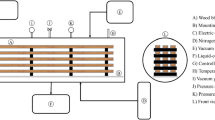

In this study, a proposed ANN model was designed using the MATLAB Neural Network Toolbox and a multi-layer perception (MLP) model for prediction. The MLP architecture consists of an input layer, one or more hidden layers, and an output layer, the last one being the result of the network, as shown in Fig. 1 (Hamzaçebi et al. 2009). The training was carried out by trying to establish different ANN models with different network architecture and learning parameters. The models were tested using a test data set, which was not utilized for the training processes in order to test the performance of networks. Thus, the ANN models producing the closest values to the actual values were chosen as the prediction models (Tiryaki and Coşkun 2014).

The ANN structure selected as a prediction model included an input layer consisting of three input nodes, namely, the weathering exposure time, heat treatment temperature, and heat-treated wood species, a hidden layer using six neurons and an output layer consisting of one output node, namely heat-treated wood color (Fig. 2). A hyperbolic tangent sigmoid transfer function was used in the hidden layer, and the training algorithm was the Levenberg–Marquardt backpropagation.

In Fig. 1, Xi is the input value of ith independent variable; Wij is the weight of connection between the ith input neuron and jth hidden neuron; βj is the bias value of the jth hidden neuron; θ is the bias value of output neuron; Y is the prediction value of dependent variable.

To examine the effects of the exposure time to artificial weathering on the color change of heat-treated woods, the data were divided into training, validation, and testing sets (Zhang et al. 1998). The average values obtained for the color of the heat-treated wood were used in the ANN model with a total of data points. The data generated by these experiments were randomly divided into three groups, i.e., 84 data points (70% of total data) were used for the ANN training process group, 18 data points (15% of total data) for the validation group, and 18 data points (15% of all data) for the testing process group (Table 1).

The performance of each prediction model was evaluated and compared using statistical and graphical comparisons. The parameters considered to assess the prediction performance of the ANN models are the mean absolute percentage error (MAPE), root mean square error (RMSE), and coefficients of determination (R2). The MAPE, RMSE, and R2 values were calculated using Eqs. (5) (6), and (7), respectively. If RMSE and MAPE approach 0 and R2 approaches 1, then the ANN predictions are optimum (Haghbakhsh et al. 2013).

where ti represents the experimental output, tdi represents the predicted output, N represents the total number of samples and \(\bar{t}\) represents the mean of predicted outputs.

3 Results and discussion

3.1 Effects of artificial weathering on overall color change of heat-treated wood (ΔE)

Figure 3 shows that the ΔE of the untreated larch and poplar wood was more sensitive at an earlier stage in comparison with the heat-treated specimens. In Fig. 3a, it can be seen that the ΔE of the untreated larch increased from the beginning of the exposure to weathering for up to 1680 h, whereas from 1680 to 3000 h, the ΔE decreased. For the untreated poplar (Fig. 3b), the ΔE increased from the time 0 of the weathering exposure to 1200 h of exposure, then it decreases as the time further increases to 3000 h, which is in accordance with previous research (Xing et al. 2015). Regarding the heat-treated wood, the ΔE values for the HTL and HTP slowly increased with the exposure time, then slightly decreased and continued to increase up to 2160 h of exposure. From 2160 to 3000 h, the color of the wood reduced. This result indicates a better color stability of heat-treated wood exposed to UV radiation and moisture spray, which is in line with previously reported data (Yildiz et al. 2013; Xing et al. 2015).

The effects of the exposure time to weathering on the change in HTW color was studied by variance analysis. With the aim to establish homogenous groups, the Duncan test (Duncan's Multiple Range Test) was applied to the results displayed in Fig. 4. As can be noticed, the change in ΔE value of HTP is higher than that of HTL. It was shown that the wood species has a considerable effect on the color change. At 240 h, the average value of color change of the two species of heat-treated wood was 9.14. This value dropped to 7.5 after 480 h of weathering exposure time and increased to 8.87 at 720 h, then decreased again for 960 and 1200 h. However, a constant increase was noticed as the time increased from 1440 to 2160 h. From 2160 to 3000 h, the color of the HTW decreased slightly. Therefore, the results clearly show that the weathering exposure time has a considerable effect on the color change of the heat-treated wood.

According to these results, the effect of weathering exposure time on the heat-treated wood color was statistically significant with 5% error margin. In addition, the average values for all parameters generally increased with increasing weathering exposure time.

3.2 Chemical analysis of heat-treated wood

FTIR spectroscopy is a very useful technique for analyzing the chemical components of wood. In this study, the FTIR analysis of wood heat-treated at 200 °C (without artificial weathering) and wood, which was first heat-treated at 200 °C and then suffered artificial weathering was performed to investigate the changes in the chemical composition of the specimens.

The specimens before and after 3000 h of weathering exposure were considered for analysis. The characteristic bands identified in the corresponding FTIR spectra (Fig. 5) recorded from 650 to 2750 cm−1 are listed in Table 2. On the basis of the obtained results, the color change of HTW was related to the changes in the chemical composition of wood.

The absorption bands at around 1605, 1510, 1465, 1425 and 809 cm−1 (Colom et al. 2003; Temiz et al. 2007; Yildiz et al. 2013; Xing et al. 2015), assigned to lignin in heat-treated specimens, significantly decreased compared with that of the untreated specimens, indicating that lignin is the component of heat-treated wood which was degraded during weathering. This result is in accordance with the results of the chemical component analysis of heat-treated wood after weathering reported in previous studies (Huang et al. 2012; Vartanian et al. 2015).

Besides the changes of lignin reflected in the FTIR spectra, according to other researches, the color change of the heat-treated wood during artificial weathering was also due to the movement of the extractives from inside to the wood surface (Huang et al. 2012) and the photodegradation of wood extractives (Hon and Minemura 2000; Kishino and Nakano 2004a, b), with the formation of chromophoric groups as carbonyl and carboxyl groups, which resulted from the degradation of α-carbonyl, biphenyl, and ring-conjugated double bond structures in lignin. The above phenomena regarding the extractives were not reflected in the FTIR spectra in this paper and will be further explored in future studies.

3.3 Predicting color change (ΔE) of heat-treated wood during artificial weathering by ANN

To predict the color change of HTL and HTP during artificial weathering, the experimental data were grouped into training, validation, and testing sets, which are shown in Table 3. The training was carried out by making attempts to establish different ANN models with different network architecture and learning parameters. The models were tested using a test data set, which was not utilized for the training processes in order to test the performance of networks. Thus, the ANN models producing the closest values to the actual values were chosen as the prediction models (Tiryaki and Coşkun 2014). Table 3 shows that the prediction values obtained by ANN model were determined with very low percentage errors (1.84 - 0.01%) for color change in HTL and HTP. As seen from Table 3, in most cases, the neural network prediction is very close to the measured values. This indicates that predicting the color change of heat-treated wood during weathering via the ANN model is feasible.

The predictability of the established models was evaluated by performance indicators, such as MAPE, RMSE, and R2, the first two being the most important performance criteria (Sagıroglu et al. 2003; Canakci et al. 2012). It was reported that if RMSE and MAPE approach 0 and R2 approaches 1, then the ANN predictions are optimum (Haghbakhsh et al. 2013). Table 4 summarizes the values of the criteria used in predicting the color change values of HTL and HTP. As can be seen, the values for MAPE are 8.17, 9.70, and 9.85% for training, validation, and testing, respectively. These values of MAPE are considered as satisfactory if the heterogeneity of the wood material is taken into account. In previous studies, 10% < MAPE ≤ 20% was considered as a good prediction (Aydin et al. 2014; Sofuoglu 2015). Thus, it can be affirmed that the values of MAPE obtained in this study are suitable. The values for RMSE are 0.69, 0.61 and 0.77% for training, validation, and testing, respectively. In addition, the R2 values are 0.925, 0.964, and 0.977 for training, validation, and testing data sets, respectively, which indicates that the obtained network explains at least 0.92% of the observed data. The values of R2 obtained by ANN in this study are higher compared to those obtained by other ANN applications for modeling in the field of research on wood materials. Some studies on R2 value are summarized as follows: Samarasinghe et al. (2007) obtained R2 value of 0.62 in the determination of fracture toughness of solid wood; Fernandez et al. (2012) found R2 values of 0.73 and 0.66 for MOR and MOE in prediction of MOR and MOE of structural plywood board, respectively; Luis et al. (2009) predicted a value for R2 of 0.75 in modeling the MOE of solid wood. Therefore, this ANN model obtained reliable values to predict the color change of heat-treated wood during artificial weathering.

Figure 6 shows the relationship between real and predicted values for HTW color in training, validation, and testing. The R values were found as 0.976, 0.918, and 0.985 for training validation, and testing, respectively. The obtained values of R2 listed in Table 4 confirm the excellent fit between measured results and model prediction. These results indicate that the ANN approach is quite accurate to predict the color change of heat-treated wood during artificial weathering.

Figure 7 illustrates a comparison between the real and predicted values for color change of HTW, and it is obvious that the real values match well the predicted ones. Thus, the proposed model was properly trained and showed an acceptable accuracy in predicting the color change of HTW during artificial weathering. Therefore, well-trained ANN models can predict the color change of HTW using different inputs.

4 Conclusion

In this study, the effects of artificial weathering on color change in heat-treated wood were modeled by an artificial neural network. The data used for the modeling were those obtained experimentally for the color values of the heat-treated wood. The RMSE values for all data sets were less than 0.776%. Because the MAPE values were less than 10%, the prediction can be regarded as good. The value of the determination coefficients (R2) in all data sets was higher than 0.92. The predicted color change of the heat-treated wood from the model and expressed as ΔE is close to the values measured experimentally. Therefore, the ANN model has proven to be an effective and successful tool to accurately predict the color change in HTW during artificial weathering. Chemical component analysis showed that the color change of heat-treated wood during artificial weathering is due to the photodegradation of lignin and wood extractives and the formation of the chromophoric groups, such as carbonyl and carboxyl groups, mainly resulting from the degradation of α-carbonyl, biphenyl, and ring-conjugated double bond structures in lignin. The results provided by the modeling studies using an artificial neural network model demonstrated the color change of heat-treated wood during artificial weathering can be successfully predicted without the need of conducting expensive and time-consuming experimental studies.

References

Armondo G (1997) Chemical and UV–Vis spectroscopic study on kiln brown stain formation in Radiata pine. In: Proceedings of the 9th international symposium of wood and pulping chemistry. Montreal, Canada, June 9–12, 1997. pp 70.1–70.5

Ayadi N, Lejeune F, Charrier F, Charrier B, Merlin A (2003) Color stability of heat-treated wood during artificial weathering. Holz Roh- Werkst 61:221–226

Aydin G, Karakurt I, Hamzacebi C (2014) Artificial neural network and regression models for performance prediction of abrasive waterjet in rock cutting. Int J Adv Manuf Tech 75:1321–1330

Bekhta P, Niemz P (2003) Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 57:539–546

Canakci A, Ozsahin S, Varol T (2012) Modeling the influence of a process control agent on the properties of metal matrix composite powders using artificial neural networks. Powder Technol 228:26–35

Colom X, Carrillo F, Nogués F, Garriga P (2003) Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym Degrad Stabil 80:543–549

Demirkir C, Ozsahin S, Aydin I, Colakoglu G (2013) Optimization of some panel manufacturing parameters for the best bonding strength of plywood. Int J Adhes Adhes 46:14–20

Vartanian E, Barres O, Roque C (2015) FTIR spectroscopy of woods: a new approach to study the weathering of the carving face of a sculpture. Spectrochim Acta A 136:1255–1259

Fernandez FG, Esteban LG, DePalacios P, Navarro M, Conde M (2008) Prediction of standard particleboard mechanical properties utilizing an artificial neural network and subsequent comparison with a multivariate regression model. Forest Syst 17:178–187

Fernandez FG, Palacios P, Esteban LG, Garcia-Iruela A, Rodrigo BG, Menasalvas E (2012) Prediction of MOR and MOE of structural plywood board using an artificial neural network and comparison with a multivariate regression model. Compos Part B-Eng 43:3528–3533

Feist WC, Rowell RM, Barbour RJ (1990) Outdoor wood weathering and protection. Am Chem Soc 255:263–289

Haghbakhsh R, Adib H, Keshavarz P, Koolivand M, Keshtkari S (2013) Development of an artificial neural network model for the prediction of hydrocarbon density at high-pressure, high-temperature conditions. Thermochim Acta 551:124–130

Hamed MM, Khalafallah MG, Hassanien EA (2004) Prediction of wastewater treatment plant performance using artificial neural networks. Environ Modell Softw 19:919–928

Hamzaçebi C, Akay D, Kutay F (2009) Comparison of direct and iterative artificial neural network forecast approaches in multi-periodic time series forecasting. Expert Syst Appl 36:3839–3844

Hon DN-S, Minemura N (2000) Color and discoloration. Wood Cell Chem 385–442

Huang X, Kocaefe D, Kocaefe Y, Boluk Y, Pichette A (2012) A spectrocolorimetric and chemical study on color modification of heat-treated wood during artificial weathering. Appl Surf Sci 258:5360–5369

Icel B, Guler G, Isleyen O, Beram A, Mutlubas M (2015) Effects of industrial heat treatment on the properties of spruce and pine woods. BioResources 10:5159–5173

Kalogirou SA (2001) Artificial neural networks in renewable energy systems applications: a review. Renew Sust Energ Rev 5:373–401

Kishino M, Nakano T (2004) Artificial weathering of tropical woods. Part 1: Changes in wettability. Holzforschung 58(5):552–557

Kishino M, Nakano T (2004) Artificial weathering of tropical woods. Part 2: Color change. Holzforschung 58(5):558–565

Kotilainen R, Toivanen T, Alén N (2000) FTIR monitoring of chemical changes in softwood during heating. J Wood Chem Technol 20:307–320

Luis G, Francisco G, Palacios P (2009) MOE prediction in Abies pinsapo Boiss. timber: application of an artificial neural network using non-destructive testing. Comput Struct 87:1360–1365

Mitsui K, Takada H, Sugiyama M, Hasegawa R (2001) Changes in the properties of light-irradiated wood with heat treatment. Part 1. Effect of treatment conditions on the change in color. Holzforschung 55:601–605

Nguyen THV, Nguyen TT, Ji XD, Nguyen VD, Gui M (2018) Enhanced bonding strength of heat-treated wood using a cold atmospheric-pressure nitrogen plasma jet. Eur J Wood Prod 76:1697–1705

Nguyen THV, Nguyen TT, Ji XD, Guo M (2018) Predicting color change in wood during heat treatment using an artificial neural network model. BioResources 13:6250–6264

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2003) The effects of a heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci Technol 37:109–115

Nuopponen M, Wikberg H, Vuorinen T et al (2004) Heat-treated softwood exposed to weathering. J Appl Polym Sci 91:2128–2134

Peng Y, Liu R, Cao J (2015) Characterization of surface chemistry and crystallization behavior of polypropylene composites reinforced with wood flour, cellulose, and lignin during accelerated weathering. Appl Surf Sci 332:253–259

Sagıroglu S, Besdok E, Erler M (2003) Artificial intelligence applications in engineering-1: Artificial neural networks. Ufuk Books Stationery, Kayseri

Sehlstedt-Persson M (2003) Colour responses to heat-treatment of extractives and sap from pine and spruce. In: International IUFRO Wood Drying Conference 459–464

Samarasinghe S, Kulasiri D, Jamieson T (2007) Neural networks for predicting fracture toughness of individual wood samples. Silva Fennica 41:105–122

Sofuoglu SD (2015) using artificial neural networks to model the surface roughness of massive wooden edge-glued panels made of Scotch Pine (Pinus sylvestris L.) in a machining process with computer numerical control. BioResources 10:6797–6808

Sundqvist B (2004) Colour changes and acid formation in wood during heating, Luleå tekniska universitet

Sundqvist B, Morén T (2002) The influence of wood polymers and extractives on wood colour induced by hydrothermal treatment. Eur J Wood Prod 60:375–376

Temiz A, Terziev N, Eikenes M, Hafren J (2007) Effect of accelerated weathering on surface chemistry of modified wood. Appl Surf Sci 253:5355–5362

Tiryaki S, Coşkun H (2014) Predicting modulus of rupture (MOR) and modulus of elasticity (MOE) of heat treated woods by artificial neural networks. Measurement 49:266–274

Tuong VM, Li J (2010) Effect of heat treatment on the change in color. BioResources 5:1257–1267

Xing D, Wang S, Li J (2015) Effect of artificial weathering on the properties of industrial-scale thermally modified wood. BioResour 10:8238–8252

Yildiz S, Tomak ED, Yildiz UC, Ustaomer D (2013) Effect of artificial weathering on the properties of heat treated wood. Polym Degrad Stabil 98:1419–1427

Zhang G, Patuwo BE, Hu MY (1998) Forecasting with artificial neural networks: the state of the art. Int J Forecast 14:35–62

Acknowledgements

This work is financially supported by Applied Technology Research and Development Program of Heilongjiang Province (GX16A002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen, T.T., Van Nguyen, T.H., Ji, X. et al. Prediction of the color change of heat-treated wood during artificial weathering by artificial neural network. Eur. J. Wood Prod. 77, 1107–1116 (2019). https://doi.org/10.1007/s00107-019-01449-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01449-0