Abstract

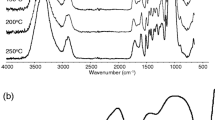

The viscoelastic properties of glycerol-impregnated poplar wood after heat treatments at various temperatures were examined by dynamic-mechanical analysis. The spectra of storage modulus (E′) and loss tangent (tgδ) in the frequency at 10 Hz were measured in the temperature range from −100 to 300 °C. Compared to no peak in E′ spectra and two relaxation processes in tgδ spectra of non-impregnated wood, two peaks in E′ spectra and two new relaxation processes in tgδ spectra were observed in the glycerol-impregnated wood. The magnitudes of the peaks decreased with the heat treatment temperatures. Both the peaks in E′ spectra and the new relaxation processes in tgδ spectra disappeared at the heat treatment temperature above 180 °C. The analysis results suggested that there are special interactions between glycerol and wood polymer and the interactions completed at the higher temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Wood is a natural polymer consisting of cellulose, hemicellulose and lignin (Placet et al. 2008). The mechanical behaviour of polymers, which is intermediate between that of solid and liquid, is termed viscoelasticity (Ferry 1980). Viscoelastic and amorphous polymers exhibit a range of mechanical properties from linear elasticity to viscous behaviour depending on temperature, diluents concentration and duration of the test (Ward 1983).

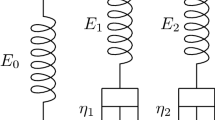

The dynamic mechanical analysis (DMA) is commonly used to decouple thermal activation from the time effect. In DMA, a harmonic force (or a displacement) is applied to the sample, and displacement (or the force) is measured. A phase difference, dependent on the properties of the polymer sample, can be observed between the resulting response and the applied stimulus. Thus, the storage modulus E′ is defined as the in-phase or elastic response, proportional to the recoverable or stored energy. The loss factor modulus E″ is the imaginary or viscous response, proportional to the irrecoverable or dissipated energy. The loss factor tgδ is the ratio E″/E′, representing the ratio of dissipated to stored energy. Its value varies dramatically throughout polymer transition (Jiang et al. 2010).

DMA has been used to characterize the mechanical behaviour of wood and wood products for more than decades. Birkinshaw et al. (1986, 1987) conducted the dynamic mechanical analysis of ten wood species including both hardwoods and softwoods that have different densities and microstructural morphology. Their results have shown that the dynamic mechanical behaviour of wood was non-species-specific. Wood has been examined in the temperature range −100 to 200 °C, and there are two peaks in tgδ spectra labeled as α relaxation process and β relaxation, respectively (Birkinshaw et al. 1986, 1989; Sugiyama 1998; Furuta et al. 2001; Bao et al. 2015). The β relaxation process occurring at around −50 °C was interpreted as movement of side chain such as adsorbed water or CH2OH groups (Sugiyama 1998; Birkinshaw et al.1989; Furuta et al. 2001) and the α relaxation process occurred at around 100 °C and was interpreted as the micro-Brownian motions of cell wall polymers in the non-crystalline region (Sugiyama 1998).

Effect of treatments on the viscoelastic properties of wood has been investigated with DMA methods (Sugiyama 1998; Ebrahimzadeh et al. 1996; Furuta et al. 2001; Obataya et al. 2003; Jiang et al. 2010; Bao et al. 2015; Chang et al. 2016). Sugiyama (1998) calculated the storage modulus E′ and loss tg δ of the modified Sitka spruce (Picea sitchensis Carrr.). Two relaxation processes due to micro-Brownian motion and the motion of CH2OH groups were observed in untreated wood. In the paraformaldehyde formalized wood, the micro-Brownian motion was restricted by the formation of OCH2 bridges between the main chains and the relaxation process due to the motion of OCH2 groups was observed. The two relaxation processes due to the micro-Brownian motion and the motion of the OCOCH3 groups were recognized in the acetylated wood. Two relaxation processes due to the micro-Brownian motion and the motion of the OCH2 groups were detected in the propylene oxide treated wood. Three relaxation processed were ascribed to the micro-Brownian motion of the matrix substance plasticized with PEG molecules, the micro-Brownian motion of PEG molecules in the cell wall and the motion of the CH2OH groups. Obataya et al. (2003) studied the dynamic viscoelastic properties of acetylated Sitka spruce (Picea sitchensis Carrr.) wood. The treated wood exhibited a marked drop in E′ and a clear tgδ peak above 150 °C, whereas the E′ and tgδ of the untreated wood were relatively stable up to 200 °C. A β′ relaxation process of plasticized cellulose acetate sample was observed which was different from β relaxation process of unplasticized cellulose acetate sample. The β′ relaxation process showed a different molecular origin to that of the β′ relaxation process (Obataya et al. 2003).

Glycerol has been successfully impregnated into wood to improve dimensional stability of compressed wood and heat-treated wood. The high dimensional stability of compressed wood was obtained when wood was pre-treated with 40% glycerol solution prior to compression (Inoue et al. 2000). The compressive deformation of poplar (Populus cathayana) wood can be properly stabilized with 50% glycerol impregnation and compression at 160 °C for 60 min (Yan et al. 2010). Douglas-fir (Pseudotsuga menziesii) that was impregnated with 20% glycerol solution prior to heat treatment at 200 °C for 6 h showed higher anti-swelling efficiency (48%) than normally heat-treated wood (26%) (Yan and Morrell 2014).

The objective of this study is to analyse the viscoelastic properties of the glycerol-impregnated wood heat-treated at various temperatures. The result of this study can provide a better understanding of the reaction or interaction between glycerol and wood polymer at elevated temperatures.

2 Materials and methods

2.1 Materials

The testing samples were prepared from a 33 year-old poplar tree (Populus cathayana Rehd.). The samples were prepared from a mature tree to minimize the variability of density. The 200 mm × 30 mm × 500 mm blocks of sapwood wood were taken at the breast height of the tree. The average growth ring width was 7.18 mm. After air-drying, the blocks were sawn into samples of 2 mm (R) × 5 mm (T) × 50 mm (L). The average air-dried density of the samples was 0.498 g/cm3. The samples were free of visible defects, such as, knots, checks, stain and decay.

2.2 Glycerol treatment

The samples were impregnated with glycerol (concentration of 99.0% A.P) for about 30 min under vacuum condition of 0.09 MPa. Samples were then immersed in glycerol at room temperature for 48 h prior to heat treatment. The average air-dried density of glycerol-impregnated samples was 0.839 g/cm3. The retention of the glycerol was 0.341 (±0.018) g/cm3.

2.3 Heat treatment

The glycerol-impregnated samples and non-impregnated samples were heated to 120, 140, 160, 180 and 200 °C for 4 h in an oven. Three samples were treated at each temperature. After samples were cooled to 20 °C, they were stored in a chamber with desiccant of phosphorus pentoxide.

2.4 DMA measurements

DMA measurements were carried out using DMA242 (NETZSCH). Three-point bending mode (amplitude: 50 μm, load: 4 N, static force: 0 N) at a frequency of 10 Hz can determine storage modulus (E′) and loss tangent (tgδ) of glycerol-impregnated wood. The test was done with the temperature sweep mode from −100 to 300 °C at a heating rate of 3 °C/min. The scale factor was 1:3. The values of E′ and tgδ were normalized with formula 1.

where x* is the normalized value, x is the original value, minA is minimum data, maxA is maximum data.

3 Results and discussion

3.1 Storage modulus (E′)

The spectra of three replicates at each condition were similar. The intermediate spectrum of the three was analyzed.

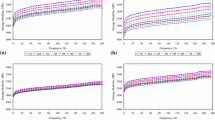

The variation of storage modulus (E′) for heat-treated wood with or without glycerol impregnation are compared in Fig. 1. For non-impregnated wood, E’s of both the heat-treated wood and untreated wood decreased with the treatment temperature. This result was in agreement with previous studies (Indira et al. 2014; Ling et al. 2008; Bao et al. 2015). In general, the magnitudes E′ decrease because of the softening of the wood components at higher temperature. This is also caused by the thermal expansion of polymers at higher temperature that results in reduced inter molecular forces (Indira et al. 2014).

However, the spectra of E′ of heat-treated glycerol-impregnated poplar samples were different compared to those of untreated wood. Two peaks were observed in spectra of E′ of untreated wood and heat-treated wood at the treatment temperature of 120 °C respectively. Peak I appeared at 70–100 °C and peak II appeared at around 270 °C. Peak II was also observed in E′ spectra of 140 and 160 °C heat-treated wood samples. However, no clear peak was observed in E′ spectra of samples heat-treated at 180 and 200 °C. The temperatures and values of maximum E′ minus to minimum E′ (E′max − E′min) of the peaks are presented in Table 1. Similar peaks at the E′ spectra were also observed in the DMA spectra for incompletely cured isocyanate adhesives (Taki et al. 1982) and isocyanate treated wood (Ling et al. 2008). The peaks were interpreted as the crosslink of isocyanate reaction (Ling et al. 2008). In the glycerol-impregnated wood, the peaks in the E′ spectrum can be interpreted with special links existing between glycerol and wood. Peak I at the lower temperature corresponded to the links between short molecular chains and peak II at the higher temperature corresponded to the links among long molecular chains. The magnitudes of peaks decreased with the heat treatment temperature. Peak I is not so distinguished for the wood samples that were heat-treated at temperatures higher than 140 °C. At the same time, the magnitudes at peak II decreased when wood was heat-treated at higher temperature and the peak was not distinguished for those samples treated at the temperature higher than 180 °C. The magnitude of peak I of 120 °C heat-treated sample is higher compared with that of untreated sample. This indicated that there was the special interaction forming during heat treatment at 120 °C. After heat treatment at 120 °C, the special interaction between glycerol and wood was initiated and not completed and it continued to form during DMA test in a gradually increasing temperature until peak I started to decline. Peak I was not observed when the heat-treated temperature reached 140 °C which indicated that the initial special interaction no longer took place at temperature higher than 140 °C. For the same reason, peak II was not observed at temperatures above 180 °C which indicated that the following special interaction revealed by peak II has completed at 180 °C. These observations revealed that the first special interaction between glycerol and wood polymer took place and was completed at a temperature less than or at 140 °C and the second interactions at a temperature less than or at 180 °C.

3.2 Loss tangent (tgδ)

The variation of loss tangent (tgδ) at 10 Hz with temperature of heat-treated glycerol-impregnated and non-impregnated wood are compared in Fig. 2. The peak temperatures of relaxation processes are shown in Table 2. The relaxation temperatures varied with heat treatment temperature. Two relaxation processes of non-impregnated wood (α1 and β1) were observed. β1 relaxation process was due to the movement of side chain of wood molecule (Sugiyama 1998, Birkinshaw et al.1989; Furuta et al. 2001) and α1 relaxation process was due to the softening of polymers (Sugiyama 1998).

The effects of heat treatment on peak temperatures at β1 relaxation processes were greater than those at α1 relaxation processes. The β1 relaxation process occurred at higher temperature with increasing heat treatment temperatures. The peak temperature at α1 relaxation process appeared between 246 and 267 °C and there is no correlation with the heat treatment temperatures. This indicated that heat treatment has affected the molecule movement of side chain more than that of main chain of those non-impregnated samples.

The relaxation processes of glycerol-impregnated wood differed at various heat treatment temperatures. Four relaxation processes of untreated, 120 and 140 °C heat-treated glycerol-impregnated wood were observed and labelled α2′, α2, β2′ and β2, respectively. Then the β2′ and α2′ relaxation processes began to disappear when heating temperature reached 160 and 180 °C, respectively.

The plasticization in wood can reduce the requirement of energy to initiate chain mobility (Schaffer 1980). The presence of low molecular weight materials in wood often serves to plasticize the amorphous polymer. Water molecule plasticises cell wall components and the peak temperature of α1 relaxation process declined at the higher moisture content shown in the tgδ spectra of wood (Kelley et al. 1987). Glycerol is a low molecular weight material and can plasticise the polymer (Mekonnen et al. 2013). As the result, the temperature of relaxation peak (α2 and α2′) of glycerol-impregnated wood was lower than that of untreated one (α1) in non-heating, 120,140, and 160 °C conditions.

At heat treatment temperatures of 120, 140 and 160 °C, the temperatures corresponding to the peaks of α2 and α2′ relaxation process were lower at the higher heat treatment temperatures. In contrast, the temperatures corresponding to β2 and β2′ relaxation processes were higher at the higher heat treatment temperatures. The β2′ relaxation process began to disappear when heat treatment temperature was 160 °C. When the heat treatment temperature was 180 °C, the temperatures at the peaks of α2 and β2 relaxation processes were higher about 234.4 and −11.7 °C, respectively. At the higher treatment temperatures, the α2′ and β2′ relaxation processes disappeared.

The α2′, α2 relaxation process were related to the motion of main chain of wood polymer and the β2′, β2 relaxation process were related to the motion of the side chain of wood polymer or the small radical groups absorbed on the side chain of wood polymer. It can be concluded that the glycerol has interacted with both main chain and side chain of wood polymers on the relaxation processes. The effects of glycerol on the relaxation processes varied with heat treatment temperature.

4 Conclusion

The glycerol has been impregnated into wood to improve dimensional stability of the compressed and heat-treated wood materials. The viscoelastic properties of heat-treated glycerol-impregnation poplar wood were analyzed in DMA spectra to study the interaction between the glycerol and wood polymer at the various heat treatment temperatures. There is no significant effect of heat treatment on E′ of non-impregnated wood. Two peaks were observed in E′ spectra of glycerol-impregnated wood heat-treated at low temperatures and both peaks were not observed in the DMA spectra at heat treatment temperature above180 °C. Two peaks suggested that there are special interactions between glycerol and wood polymers. These interactions were completed at a treatment temperature of about 180 °C.

From the analysis of the relaxation processes in tgδ spectra of glycerol-impregnated wood, glycerol that was impregnated into wood polymer had an effect on the relaxation processes and the molecular movement of both main chain and side chain of wood polymers.

References

Bao CY, Long DR, Vergelati C (2015) Miscibility and dynamical properties of cellulose acetate/plasticizer systems. Carbohydr Polym 116(1):95–102

Birkinshaw C, Buggy M, Henn C (1986) Dynamic mechnaical analysis of wood. J Mater Sci Lett 5(9):898–900

Birkinshaw C, Buggy M, Henn C (1987) Dynamic mechanical analysis of fibreboard. J Mater Sci Lett 6(1):113–114

Birkinshaw C, Buggy M, Carew A (1989) Thermo-mechanical behavior of wood and wood products. J Mater Sci Lett 24(1):359–362

Chang FC, Kadla JF, Lam F (2016) The effects of wood flour content and coupling agent on the dynamic mechanical and relaxation properties of wood-plastic composites. Eur J Wood Prod 74(1):23–30

Ebrahimzadeh PR, Kubát J, McQueen D H (1996): Dynamic mechanical characterization of mechanosorptive effects in wood and paper. Holz Roh-Werkst 54(4): 263–271

Ferry JD (1980) Viscoelastic properties of polymers. 3rd Ed. Wiley, New York

Furuta Y, Obata Y, Kanayama K (2001) Thermal-softening properties of water-swollen wood: the relaxation process due to water soluble polysaccharides. J Mater Sci 36(4):887–890

Indira KN, Jyotishkumar P, Thomas S (2014) Viscoelastic behavior of untreated and chemically treated banana fiber/PF composites. Fiber Polym 15(1):91–100

Inoue M, Hamaguchi T, Morooka T, Higashihara T, Norimoto M, Tsunoda T (2000) Fixation of compressive deformation of wood by wet heating under atmospheric pressure. Mokuzai Gakkaishi 46(4):298–304

Jiang J, Lu J, Zhao Y, Wu Y (2010) Influence of frequency on wood viscoelasticity under two types of heating conditions. Drying Technol 28(6):823–829

Kelley SS, Rials TG, Glasser WG (1987) Relaxation behaviour of the amorphous components of wood. J Mater Sci 22(2):617–624

Ling N, Hori N, Takemura A (2008) Effect of Postcure Conditions on the Dynamic Mechanical Behavior of Water-based Polymer-isocyanate Adhesive for Wood. J Wood Sci 54(5):377–382

Mekonnen T, Mussone P, Khalil H, Bressler D (2013) Progress in bio-based plastics and plasticizing modifications. J Mater Chem A 1(43):13379–13398

Obataya E, Furuta Y, Gril J (2003) Dynamic viscoelastic properties of wood acetylated with acetic anhydride solution of glucose pentaacetate. J Wood Sci 49(2):152–157

Placet V, Passard J, Perre P (2008) Viscoelastic properties of wood across the grain measured under water-saturated conditions up to 135 °C: evidence of thermal degradation. J Mater Sci 43(9):3210–3217

Schaffer EL (1980) General constitutive relations for wood and wood-based materials. Syracuse University Press, NY, p 361

Sugiyama M (1998) Viscoelastic properties of the matrix substance of chemically treated wood. J Mater Sci 33(4):3503–3510

Taki K, Tomita B, Mizumachi H (1982) Studies on aqueous vinyl polymer solution-isocyanate adhesives I. Mechanical properties of base polymers and bond strength over a vide temperature range. Mokuzai Gakkaishi 28(3):143–149

Ward IM (1983) Mechanical properties of solid polymers, 2nd Ed. Wiley-Interscience, New York

Yan L, Morrell JJ (2014) Effects of thermal modification on physical and mechanical properties of douglas-fir heartwood. Bioresources 9(4):7152–7161

Yan L, Cao JZ, Jin XJ (2010) Deformation fixation, mechanical properties and chemical analysis of compressed Populus Cathayana wood pretreated by glycerin. Forest Stud China 12(4):213–217

Acknowledgements

The authors are grateful for the support of National Natural Science Foundation of China (NSFC) No. 31400500.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, L., Chen, Z. Dynamic viscoelastic properties of heat-treated glycerol-impregnated poplar wood. Eur. J. Wood Prod. 76, 611–616 (2018). https://doi.org/10.1007/s00107-017-1210-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1210-y