Abstract

Purpose

Torque control in lingual orthodontics is key to obtain optimal esthetic results. The aim of this in vitro experimental study was to verify the efficiency of the ligature–archwire–slot system in torque control using a customized lingual appliance.

Methods

An idealized cast with eight extracted human teeth was created and a set of customized lingual brackets was obtained. Tests were performed with the following wires: 0.016″ × 0.022″ nickel-titanium (NiTi), 0.016″ × 0.024″ stainless steel (SS), 0.017″ × 0.025″ βIII titanium (βIIITi), 0.0182″ × 0.0182″ βIIITi, 0.018″ × 0.025″ SS, 0.018″ × 0.025″ NiTi, 0.018″ × 0.025″ βIIITi, and three types of ligatures were tested using a universal testing machine to calculate the efficiency in torque control. A blind statistical analysis was performed.

Results

Based on post hoc multiple comparisons, differences were found for two of the three ligatures when using the 0.016″ × 0.022″ NiTi wires (p < 0.001 for both ligatures). When considering all ligatures, 0.018″ × 0.025″ SS and 0.018″ × 0.025″ βIIITi were significantly different from all other wires (p < 0.001 in all cases). With a moment of 5 Nmm, the 0.016″ × 0.022″ NiTi wire developed median angles of 26.7, 29.8, and 38.7° with the three ligatures, respectively, while the 0.018″ × 0.025″ SS developed median angles of 12.9, 10.7, and 12.7°, respectively.

Conclusions

The ligature type and geometry did not affect the efficiency of torque control, except for the 0.016″ × 0.022″ NiTi wire. The wires generating the greatest moments were the 0.018″ × 0.025″ SS and 0.018″ × 0.025″ βIIITi.

Zusammenfassung

Zweck

Die Torquekontrolle in der lingualen Kieferorthopädie ist ein Schlüsselfaktor, um optimale ästhetische Ergebnisse zu erzielen. Ziel dieser experimentellen In-vitro-Studie war es, die Effizienz des Ligatur-Bogen-Slot Systems bei der Torquekontrolle mit einer individualisierten Lingualapparatur zu überprüfen.

Methoden

Ein idealisiertes Modell mit 8 extrahierten menschlichen Zähnen wurde erstellt und ein Satz individualisierter lingualer Brackets wurde angefertigt. Es wurden Tests mit den folgenden Drähten durchgeführt: 0,016″ × 0,022″ Nickel-Titan (NiTi), 0,016″ × 0,024″ Edelstahl (SS), 0,017″ × 0,025″ βIII-Titan (βIIITi), 0,0182″ × 0,0182″ βIIITi, 0,018″ × 0,025″ SS, 0,018″ × 0,025″ NiTi, 0,018″ × 0,025″ βIIITi. Drei Arten von Ligaturen wurden mit einer Universalprüfmaschine getestet, um das Ausmaß der Torquekontrolle zu berechnen. Eine blinde statistische Analyse wurde durchgeführt.

Ergebnisse

Basierend auf post hoc durchgeführten Mehrfachvergleichen wurden bei der Verwendung der 0,016″ × 0,022″ NiTi-Drähte (p < 0,001 für beide Ligaturen) Unterschiede für 2 der 3 Ligaturen nachgewiesen. Bei Betrachtung aller Ligaturen unterschieden sich 0,018″ × 0,025″ SS und 0,018″ × 0,025″ βIIITi signifikant von allen anderen Drähten (p < 0,001 in allen Fällen). Bei einem Drehmoment von 5 Nmm entwickelte der 0,016″ × 0,022″ NiTi-Draht Medianwinkel von 26,7, 29,8 bzw. 38,7° mit den 3 Ligaturen, der 0,018″ × 0,025″ SS-Draht erzielte dagegen Medianwinkel von 12,9, 10,7 bzw. 12,7°.

Schlussfolgerungen

Ligaturtyp und Geometrie hatten – mit Ausnahme des 0,016″ × 0,022″ NiTi-Drahts – keinen Einfluss auf die Effizienz der Torqueübertragung. Die Drähte, welche die größten Drehmomente erzeugten, waren 0,018″ × 0,025″ SS und 0,018″ × 0,025″ βIIITi.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lingual orthodontics is a reliable alternative both for the clinicians who want to fully accomplish therapeutic treatment and for patients who require an esthetic or “invisible” treatment. The advantage of this solution is the possibility of treating any malocclusion the same as labial orthodontics, including extraction, nonextraction, and orthognatic cases [6, 11, 26, 27].

Three-dimensional control of each tooth is important during all the phases of treatment in order to achieve a functional and esthetic outcome. In lingual orthodontics, tooth control is managed differently when compared to labial orthodontics; the geometries of the biomechanics change because of the different point of force application, mainly on the vertical plane. This difference has clinical consequences. In extraction cases, bracket-related space closure mechanics can seriously affect maxillary incisors’ torque control. Many factors affect torque expression, including both the materials and the bracket position in addition to the procedures that clinicians adopt to manage third order movements [7, 12, 17,18,19, 24].

The arch wire–bracket system is fundamental for precisely controlling torque expression since a solid engagement of the wire into the slot is needed to generate the right moment.

This concept is extremely important in customized lingual systems for providing full size wires in order to fine-tune third order movements.

The expression of an “optimal” force system is a weak concept that should be related to force/tooth movement efficiency, expressed as the moment required to generate a precise third order movement (torque). A thorough literature analysis on the optimum force values for torque movement led to studies describing the way in which materials with different rigidities perform when wires of the same size are considered or the way in which the torquing moment changes when different brackets systems are considered. Torque values between 5 and 20 Nmm were described as ideal [2, 3, 25], and the minimum torque value to obtain movement of an upper incisor would be 5 Nmm [8, 9, 12, 15] even if it is necessary to consider that this value may differ for each tooth and each patient.

As the clinical discussion on orthodontic materials underlines the influence of different ligatures and ligation modes in enhancing the performance of the bracket–wire system, we prepared an experimental set-up to compare different appliance configurations. The aim of the present study was to evaluate the way in which different ligatures affect torque control in a customized lingual bracket appliance using different wire sizes and materials. The null hypothesis used in this study stated that there were no differences between different ligation modes.

Materials and methods

Idealized cast

Eight extracted human teeth were used: (1) one central upper right incisor; (2) two upper lateral incisors (right and left); (3) two upper canines (right and left); (4) two upper first bicuspids (right and left); and (5) one upper second bicuspid (left). All of the teeth were carefully cleaned with ultrasonic and manual instruments, disinfected with hydrogen peroxide, and stored in physiological saline sodium chloride 0.9% at pH 5.5 in order to avoid dehydration and elasticity loss and to prevent the risk of fractures.

Transparent methyl methacrylate components (Orthojet, Lang, Wheeling, IL, USA) were carefully mixed so as not to produce air bubbles and then poured into a 100 mm × 35 mm × 25 wax box (Tenatex Red, Kemdent, Purton, Swindon Wiltshire, UK) to create a resin base in which the collected teeth could be accommodated. The resin was cured in a curing water machine (30 °C, 6.08 × 105 Pa).

The lateral surface of the resin block was then dug out with a denture bur contained in a straight handpiece, and once enough space had been created, the teeth’s roots were set along a straight line in the pit in such a way to reproduce the mutual contact points and encased up to the cementoenamel junction in fluid transparent resin (methyl methacrylate). Test teeth were not positioned along the natural shape of the arch but were in a straight line in order to study the system’s mechanical properties. The crowns emerged from the resin and presented a contact point with each adjacent tooth; one empty space was left for the missing tooth (upper left incisor). The block was cured again in order to achieve teeth stability.

A silicone biphasic impression of the resulting idealized cast was taken (Hydrorise, Zhermack, Badia Polesine (RO), Italy) and sent to the Incognito lab. A set of customized brackets, an indirect bonding tray, and straight sectional wires consisting of different materials and dimensions were obtained.

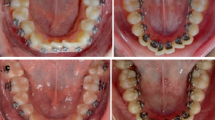

All of the teeth were sand blasted with aluminum oxide (50 µm), then etched for 30 s with 32% orthophosphoric acid (Scotchbond, 3M Unitek, Monrovia, CA, USA), rinsed with water for 30 s, and dried for 20 s. Test brackets (Customized Incognito lingual brackets slot size 0.018″ × 0.025″) were indirectly bonded using the provided tray with an orthodontic composite (RelyX Unicem 2 Automix; 3M Unitek). After the composite was cured, all samples were extracted from the resin block and tied to the Incognito 0.018″ × 0.025″ stainless steel (SS) arch wire one by one. The tooth crowns were then included in a block of soft wax to remain stable in relation to each other. Once more, the lateral surface of the resin block was dug out with a denture bur contained in a straight handpiece, and the tooth roots were placed in a straight line in the pit and encased in transparent fluid resin (methyl methacrylate). The resin was cured, and the wax was removed from the crowns. The resulting teeth position in the idealized cast allowed slots to be passively engaged by the arch wire (Fig. 1a).

a Custom-made idealized cast; b bonded lingual brackets with a wire; c idealized cast fixed to the machine; d experimental setting; e enarthrosis connection between the screw and the machine; f perforated screw

a Das maßgefertigte idealisierte Modell; b geklebte linguale Brackets mit Bogen; c an der Maschine befestigtes idealisiertes Modell; d experimentelles Setting; e kugelgelenkige Verbindung zwischen Schraube und Maschine; f perforierte Schraube

Wires

The tested Incognito arch wires were 0.016″ × 0.022″ and 0.018″ × 0.025″ nickel–titanium (NiTi), 0.016″ × 0.024″ and 0.018″ × 0.025″ stainless steel (SS), and 0.017″ × 0.025″, 0.0182″ × 0.0182″, and 0.018″ × 0.025″ βIIITi (βIII titanium, 3M Unitek). All of the wires were first measured with a digital calliper in order to verify if the nominal dimension corresponded with the real one (Table 1).

Ligatures

AlastiK lingual ligatures (L1), AlastiK Easy-to-tie (L2), AlastiK Easy-to-tie in over-tie were tested (L3) (Alastik, 3M Unitek) (Fig. 2).

Testing machine

The bracket matching the missing incisor was tied to the wire and represented the test bracket on which the measurements were performed. An extension was laser-welded to the bonding surface of the bracket in order to apply the forces to be tested. The extension was a large round steel wire of 1.5 mm in diameter. At a distance of 10 mm, a bottleneck was shaped on the extension in order to create a detectable force application point for all of the tests. The extension was laser welded to the back of the bracket.

The Zwick/Roell Z0.5 machine (sensibility: <1%, displacement sensibility 1 µm, full scale range 500 N) was used to apply controlled traction and thrust forces to the system using forces from 0 to 0.5 N. The idealised cast was fixed to the Zwick/Roell Z0.5 machine with bolts and screws that engaged with the grooves on the horizontal bar (Fig. 1c), so that the model was solidly fixed to the machine in order to create a system suitable to the application of forces (Figs. 1 and 3).

The model was positioned by placing the side with the largest area on the horizontal bar, so that the lingual side of each tooth was above, the vestibular side below, the coronal portion of the teeth on the right, and the roots housed in the resin on the left.

The traction/compression system was hooked to the bottleneck extension of the test bracket via a rigid metallic perforated screw. The extension of the test bracket was placed into the screw drill (Fig. 1f).

A connection similar to an enarthrosis joint was used between the screw and the machine in order to prevent the force decomposition in the horizontal components and maintain constant vertical traction. In order to eliminate the play between the screw hole and the extension rod, a pretest adjustment was applied by moving the enarthrosis connection in such a position that the rod was in contact with the screw. The torque moment (Nmm) was calculated by multiplying the force by the arm (i.e., the distance between the axis of rotation and the point of force application), which was fixed to 10 mm throughout the whole experiment. The torque angle (°) was algebraically calculated: since the Zwick/Roell Z0.5 machine is able to measure the displacement induced by the extension, when the displacement (δ) and the arm (b) are known (Fig. 3) the following holds:

The value of the torque angle (ϑ), which is a measure of the torsion produced on the wire by the applied moment, was then obtained by applying the arcsine function. When the angle between the extension and the machine changes, the arm of the force also changes; thus, the error was corrected for the arm inclination angle cosine after data collection. The torsion angle of the center bracket at an applied moment from neutral to one side was used for the descriptive statistics and data analysis (a lower angle represents better torque control of the bracket–wire system).

The sample size estimation calculated that four elastomeric ligatures per group achieved a power of 0.80 and was used to detect a difference of 10° in torque values with a significance level (α) of 0.05 and a standard deviation (SD) of 5°. For each type of ligature, a sample of five ligatures was tested for every wire.

Software

The TestXpert II Zwick-Roell software was used to collect data and to represent the torque moment on the ordinate with the torque angle on the abscissa on a Cartesian graph (Fig. 4).

Angle/moment graph of different wires with AlastiK™ Easy-to-tie in overtie. In this graph both positive and negative angle values are represented. Positive values are associated with tension forces (root towards lingual); negative angle values are associated with compression forces

Winkel‑/Drehmomentgrafik verschiedener Drähte mit AlastiK™ Easy-to-tie in Overtie. Im Diagramm werden sowohl positive als auch negative Winkelwerte dargestellt. Positive Werte sind mit Zugkräften assoziiert (Wurzel nach lingual), negative Winkelwerte mit Druckkräften

Statistical analysis

A blinded statistical analysis was performed. Data were tested for normality, and Levene’s test was used for the homogeneity of variances assessment. Differences among groups for wires were evaluated using the Kruskal–Wallis rank sum test, and multiple post hoc comparisons were carried out with the Steel–Dwass test. Results are expressed as median and interquartile ranges, and differences with a p-value <0.01 were selected as significant. Data were acquired and analyzed using the R v3.2.3 software environment [21].

Repeatability of wire measurements was evaluated by means of the intraclass correlation coefficient (ICC) and was >0.91 for all measurements.

Results

Descriptive statistics for torque angle absolute values are reported in Table 2 and Fig. 5. Continuous variables are given as median with range, whereas categorical variables are presented as numbers (for all abbreviations see Table 3).

Medians and interquartile ranges graph of angle absolute values for each reading group: a all types of ligatures and ligation modes; b AlastiK™ lingual ligatures; c AlastiK™ Easy-to-tie; d AlastiK™ Easy-to-tie in overtie

Median- und Interquartilbereichsdiagramm der Winkelabsolutwerte für jede Prüfgruppe: a alle Ligaturtypen und Ligaturmodi; b AlastiK™ linguale Ligaturen; c AlastiK™ Easy-to-tie; d AlastiK™ Easy-to-tie in Overtie

No significant differences were found in angle values between ligatures when the complete set of data was tested (p > 0.01).

Differences between ligatures were found when using the 0.016″ × 0.022″ NiTi wire. By using post hoc multiple comparisons for the 0.016″ × 0.022″ NiTi wire, ligature L3 produced a significantly higher angle with respect to the other ligatures (28°, p < 0.001 for both ligatures).

A significant difference was found among all wires with respect to angle values (p < 0.001). By using post hoc comparisons, 0.018″ × 0.025″ SS and 0.018″ × 0.025″ βIIITi showed significantly lower angles compared to all the other wires (11° and 12°, respectively; p = 0.00049 between them and p < 0.001 in all other pairwise comparisons, Table 4). More differences were found between 0.018″ × 0.025″ NiTi, 0.017″ × 0.025″ βTi, and 0.016″ × 0.022″ NiTi wires (p < 0.001 in both cases). The result for the 0.018″ × 0.018″ βIIITi wire was significantly different from the 0.017″ × 0.025″ βIIITi and 0.016″ × 0.022″ NiTi wires (p < 0.001 for both wires).

A separate ligature-associated analysis was performed while setting the force level at 0.5 N (Table 5). Differences between ligatures were found when using the 0.016″ × 0.022″ NiTi and the 0.017″ × 0.025″ βTi wires. Based on post hoc multiple comparisons for the 0.016″ × 0.022″ NiTi wire, ligature L3 showed a significant difference compared to the others (p < 0.001 for both ligatures). The same ligature showed a significant difference with respect to the other two for the 0.017″ × 0.025″ βIIITi wire (p < 0.001).

When the system generated a moment of 5 Nmm, the 0.016″ × 0.022″ NiTi wire developed median angles of 26.7, 29.8, and 38.6° with L1, L2, and L3, respectively, while the 0.018″ × 0.025″ SS developed median angles of 12.9, 10.7, and 12.7° with L1, L2, and L3, respectively.

Discussion

In lingual orthodontics, torque control of the anterior area is one of the main points that should be subject to strict control during the whole treatment. A review of the literature on this subject shows an increase in interest in this procedure in the last several years; lingual orthodontics is living a new renaissance, due principally to the recent customized or self-ligating brackets [5, 13, 16, 20].

On the other hand, the demand for esthetic or invisible orthodontic treatments has increased among patients; thus, clinicians should be able to use these kinds of systems for treatment and esthetic purposes.

Studies concerning torque control with buccal brackets are much easier to find, and generally they are focused in order to verify the way in which the play between the wire size and slot dimension affects torque control. In lingual orthodontics, especially with customized brackets, the final arch wire is full sized with no or almost zero play. Therefore, in these systems, it is more relevant to verify the effect of the type of ligature, if any, in the three-dimensional control of the anterior teeth using different wire sizes, especially for undersized wires. Material characteristics (such as materials exhibiting different characteristics with regard to rigidity) may influence torque control and could lead to different results. In fact, the capacity to generate adequate torque movement is related to the interactions of multivariate parameters, including three main elements: (1) the wire (material and dimension); (2) the bracket/slot (material and dimension); and (3) the ligature (material, dimension, and type of ligation); this system changes its expression (torque expression) when any single component modification occurs [1, 4, 10, 23].

One of the first studies concerning lingual torque analysis with a completely customized appliance was performed by Lossdörfer et al. [14]. In that study, the authors conducted an in vitro experiment using a customized appliance bonded on an idealized cast and tested different finishing wires. The present study basically retraced that setup, improving data acquisition and registration; movement variation with a continuous acquisition in the present experiment was possible using a mathematical elaboration of the movement analysis. The brackets were bonded on extracted human teeth using the standard clinical procedure; furthermore, in the present study it was decided to put the wires in a straight line in order to eliminate any kind of distortion due to the wire configuration. All of these decisions were used in order to isolate any kind of interference on the wire–bracket–ligature system as much as possible.

In order to understand the results of the present study, it is important to emphasize that the angle calculated by the Zwick/Roell apparatus does not represent the wire–bracket torque play. Instead, it is a measure of torque expression and efficiency since it represents the torsion produced on the wire by the applied moment. On the other hand, it is the geometrical configuration that will produce the same moment once the wire is set into the slot. The lower the angle, the greater the efficiency of the slot–wire–ligation system (because less twisting produces the same moment).

Performance of different ligation systems

Generally, studies on torque efficiency focus on the wire–bracket system without considering the effects of ligature type on the system. However, from a clinical point of view, this variable should be evaluated because emphasis is given to different ligature methods in order to obtain better three-dimensional control of the teeth. Daratsianos et al. [5] compared several lingual brackets using the same ligature in an O‑ring configuration; the study was performed using a single bracket and testing wires of various sizes. They found interesting data concerning torque play (degrees) among different systems. The overall idea is that the customized brackets result in the most precise system. Sifakakis et al. [25] compared different lingual brackets and used a traditional O‑ring configuration in order to compare the variations in torque. They concluded that customized brackets produced the highest moments even though they assumed that the moment is dependent on the ligation model. Our results showed that the dependency on ligature is relevant only for one wire (0.016″ × 0.022″ NiTi), and the ligature did not affect the result when using larger wires. The present study focused on three specific ligatures. In particular, L1 was specifically developed to create a ligature that could better set the wire into the slot for a better tip and torque control. In our study, this result was only relevant for the 0.016″ × 0.022″ NiTi wire even if this difference could be clinically relevant since this could lead to a better control of the anterior teeth even in the earliest alignment stage. Quite surprisingly, the over-tie configuration resulted in a less efficient system when compared with the other two; this could be associated with the partial plastic deformation that could occur when the over-tie configuration is used.

Moments

Table 5 showed the analysis of the movement of the wires into the slot when the system reached the value of 5 Nmm. Even though there is no general consensus concerning the ideal force value to generate a moment, based on the literature evaluations, 5 Nmm was the most reliable value for obtaining dental movement [2, 3, 8, 12, 15, 19, 22].

The table confirmed that stainless steel wire performed better when compared to beta-titanium or NiTi materials of the same dimensions (0.018″ × 0.025″), on larger wires the ligation type effect on torque control was negligible.

It would be interesting to observe the behavior of the ligature–wire–bracket system with smaller wires; efficiency information of the system could result in some useful information for daily use.

Fig. 4 shows an angle/moment graph with ligature L3, which is useful to depict moment and angles values according to the selected wire.

After considering only the lingual ligature L1, it was observed that it did not present any advantages with respect to torque control except for the 0.016″ × 0.022″ NiTi wire. This wire’s use resulted in a statistically significant better control compared to the over-tie and a better control (even if not statistically significant) than the conventional ligature. Similarly, the lingual ligature showed better results for the 0.016″ × 0.024″ SS wire (not statistically significant) when compared to the conventional type. For this wire the over-tie resulted in the best performance (not statistically significant). With respect to the 0.016″ × 0.022″ NiTi, both L1 and L2 gave better results for the L3 over-tie (P < 0.001).

Limits

The results of this study have to be prudently used when reported to clinical practice. Other factors could play a role in an in vivo situation even though this set up has been appositely studied in order to evaluate the ligation efficiency in a customized lingual bracket. The decision to use a straight wire instead of an arch wire could also affect the results, considering that this appliance has a different wire insertion mode in the posterior area (horizontal, while it is vertical in the anterior), but the overall effects should be limited and are typical of this experimental configuration. Moreover, the interbracket distance in a straight configuration appears to be larger than in the mouth. This is likely to have an impact on the torque moment to angular displacement ratio. Other limits of this study concern the selected ligature types; it may be possible that ligatures from other companies would perform differently.

Conclusions

-

In this in vitro study a complete torque expression record using three ligature systems and seven wires was obtained for a customized lingual appliance.

-

The ligature type and geometry did not affect the torque efficiency, except for the 0.016″ × 0.022″ NiTi wire.

-

The best performance was found with the 0.018″ × 0.025″ SS and 0.018″ × 0.025″ βIIITi wires.

-

The lingual ligature allowed significantly better control with the 0.016″ × 0.022″ NiTi wire.

-

The analysis at 5 Nmm showed that a ligature in the over-tie configuration resulted in significantly better control with the 0.017″ × 0.025″ βIIITi wire, and better performance for the lingual and conventional ligatures was found with the 0.016″ × 0.022″ wire.

References

Archambault A, Major TW, Carey JP, Heo G, Badawi H, Major PW (2010) A comparison of torque expression between stainless steel, titanium molybdenum alloy, and copper nickel titanium wires in metallic self-ligating brackets. Angle Orthod 80:884–889

Bantleon HP, Droschl H (1988) Front torque using a partial arch technic. J Orofac Orthop 49:203–212

Burstone CJ (1966) The mechanics of the segmented arch techniques. Angle Orthod 36:99–120

Creekmore TDTD (1979) Creekmore on torque. J Clin Orthod 13:305–310

Daratsianos N, Bourauel C, Fimmers R, Jäger A, Schwestka-Polly R (2016) In vitro biomechanical analysis of torque capabilities of various 0.018″ lingual bracket-wire systems: total torque play and slot size. Eur J Orthod 38:459–469

Fulmer DT, Kuftinec MM (1989) Cephalometric appraisal of patients treated with fixed lingual orthodontic appliances: historic review and analysis of cases. Am J Orthod Dentofacial Orthop 95:514–520

Germane N, Bentley BE Jr, Isaacson RJ (1989) Three biologic variables modifying faciolingual tooth angulation by straight-wire appliances. Am J Orthod Dentofacial Orthop 96:312–319

Gmyrek H, Bourauel C, Richter G, Harzer W (2002) Torque capacity of metal and plastic brackets with reference to materials, application, technology and biomechanics. J Orofac Orthop 63:113–128

Harzer W, Bourauel C, Gmyrek H (2004) Torque capacity of metal and polycarbonate brackets with and without a metal slot. Eur J Orthod 26:435–441

Hemingway R, Williams RL, Hunt JA, Rudge SJ (2001) The influence of bracket type on the force delivery of Ni-Ti archwires. Eur J Orthod 23:233–241

Hong RK, Lee JG, Sunwoo J, Lim SM (2000) Lingual orthodontics combined with orthognathic surgery in a skeletal Class III patient. J Clin Orthod 34:403–408

Huang Y, Keilig L, Rahimi A, Reimann S, Eliades T, Jäger A (2009) Numeric modeling of torque capabilities of self-ligating and conventional brackets. Am J Orthod Dentofacial Orthop 136:638–643

Inami T, Nakano Y, Miyazawa K, Tabuchi M, Goto S (2016) Adult skeletal Class II high-angle case treated with a fully customized lingual bracket appliance. Am J Orthod Dentofacial Orthop 150:679–691

Lossdörfer S, Bieber C, Schwestka-Polly R, Wiechmann D (2014) Analysis of the torque capacity of a completely customized lingual appliance of the next generation. Head Face Med 10:4

Major TW, Carey JP, Nobes DS, Heo G, Major PW (2011) Mechanical effects of third-order movement in self-ligated brackets by the measurement of torque expression. Am J Orthod Dentofacial Orthop 139:e31–44

Mathew RN, Katyal A, Shetty A, Nayak KUS (2016) Effect of increasing the vertical intrusive force to obtain torque control in lingual orthodontics: a three-dimensional finite element method study. Indian J Dent Res 27:163–167

Miethke RR, Melsen B (1999) Effect of variation in tooth morphology and bracket position on first and third order correction with preadjusted appliances. Am J Orthod 116:329–335

Morina E, Eliades T, Pandis N, Jäger A, Bourauel C (2008) Torque expression of self-ligating brackets compared with conventional metallic, ceramic, and plastic brackets. Eur J Orthod 30:233–238

Papageorgiou SN, Sifakakis I, Doulis I, Eliades TT, Bourauel C (2016) Torque efficiency of square and rectangular archwires into 0.018 and 0.022 in conventional brackets. Prog Orthod 17:5

Pauls A, Nienkemper M, Schwestka-Polly R, Wiechmann D (2017) Therapeutic accuracy of completely customized lingual appliance WIN: A retrospective cohort study. J Orofac Orthop 78:52–61

R Core Team (2018) A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna (http://www.R-project.org/)

Reitan K (1964) Effects of force magnitude and direction of tooth movement on different alveolar bone types. Angle Orthod 34:244–255

Schudy GF, Schudy FF (1989) Intrabracket space and interbracket distance: critical factors in clinical orthodontics. Am J Orthod Dentofacial Orthop 96:281–294

Sebanc J, Brantley WA, Pincsak JJ, Conover JP (1984) Variability of effective torque as a function of edge bevel on orthodontic arch wires. Am J Orthod 86:43–51

Sifakakis I, Pandis N, Makou M, Eliades T, Katsaros C, Bourauel C (2013) A comparative assessment of torque generated by lingual and conventional brackets. Eur J Orthod 35:375–380

Smith JR, Gorman JC, Kurz C, Dunn RM (1986) Keys to success in lingual therapy. Part 1. J Clin Orthod 20:252–261

Wei L, Qiguo R, Jiuxiang L, Baohua X (2009) Torque control of the maxillary incisors in lingual and labial orthodontics: a 3‑dimensional finite element analysis. Am J Orthod Dentofacial Orthop 135:316–322

Acknowledgements

We would like to thank and remember Professor Marco Capurro: his great contribution as a man, a teacher and a researcher will last in our hearts. We also would like to thank 3M Oral Care for the kind support, assistance and the materials provided for the experiments.

Funding

This research did not receive any specific grant from funding agencies in public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

R. Stradi has a consultancy agreement with 3M Unitek. M. Migliorati, D. Poggio, S. Drago, A. Lagazzo, F. Barberis and A. Silvestrini-Biavati declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Migliorati, M., Poggio, D., Drago, S. et al. Torque efficiency of a customized lingual appliance. J Orofac Orthop 80, 304–314 (2019). https://doi.org/10.1007/s00056-019-00190-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00056-019-00190-w