Abstract

The inhibition of nitric oxide and prostaglandin E2 productions is a very interesting research topic in the field of anti-inflammatory drug development. In the current study, a new series of 1,3,4-triarylpyrazole derivatives was synthesized and evaluated for their capabilities to inhibit nitric oxide and prostaglandin E2 productions in lipopolysaccharide-induced RAW 264.7 macrophages. Among all the target analogs, the diarylurea hydroxyl compounds 1f and 1h possessing phenyl and 3-(trifluoromethyl)phenyl terminal moiety, respectively, showed the highest inhibitory effect on the production of prostaglandin E2. Both compounds exerted equal activity to the reference compound NS-398 at 3 µM concentration. This effect was due to inhibition cyclooxygenase-2 enzyme activity not inhibition of cyclooxygenase-2 protein expression. The IC50 value of compound 1f against lipopolysaccharide-induced prostaglandin E2 production in the macrophages was 1.12 μM. In addition, compound 1j with urea linker, hydroxyl group, and 3,5-bis(trifluoromethyl)phenyl terminal ring was the strongest nitric oxide inhibitor. Western blot study showed that it exerted that effect through inhibition of inducible nitric oxide synthase protein expression.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Inflammation is a complex physiological and pathological process associated with activation of the local vascular system, the immune system, and various cells within the damaged tissue (Coussens and Werb 2002). It is a normal protective response to tissue injury caused by physical trauma (cut, burn, or bruise), microbiological agents, noxious chemicals, or even autoimmune disorders. Acute inflammation is a part of the defense response by the organisms to remove injurious stimuli, such as pathogens, irritants, or physical injury, from tissues and to initiate the healing process. However, persistent and excessive immune response can promote tissue damage, resulting in chronic inflammation. This chronic inflammation is a part of many human diseases including arteriosclerosis (Qui et al. 2006), inflammatory bowel disease (Lee et al. 2010), arthritis (Hochberg 1990), cancer (Sung et al. 2011), and Alzheimer’s disease (Sastre et al. 2011). In the inflammatory state, the activated immune cells such as macrophages, secrete large amounts of proinflammatory cytokines, nitric oxide (NO), and prostaglandin E2 (PGE2). However, high levels of NO and PGE2 in a chronic inflammation state can result in various pathological conditions (Yun et al. 1996; Hinz and Brune 2002). Accordingly, control of the production of NO and PGE2 in macrophages are currently interesting research topics for the development of new anti-inflammatory drugs.

In this study, we have synthesized a series of new compounds possessing 1,3,4-triarylpyrazole scaffold for the purpose of anticancer screening (will be carried out later and the results will be published in due course). Due to the presence of a vicinal diaryl heterocycle moiety which has been reported in selective cyclooxygenase (COX)-2 inhibitors such as celecoxib (Fig. 1), we decided to test their anti-inflammatory activity. Several pyrazole derivatives including celecoxib have been reported as anti-inflammatory agents (Norgard et al. 2004; Keche et al. 2012; El-Sayed et al. 2012; Ragab et al. 2013; Malvar et al. 2014; Kurumbail et al. 1996). The anti-inflammatory activities of our target compounds 1a–k were evaluated through measuring their effects as inhibitors of lipopolysaccharide (LPS)-induced NO and PGE2 productions in RAW 264.7 macrophages.

Experimental

General

Mass spectra (MS) were determined by liquid chromatography–mass spectrometry (LC-MS) analysis using the following system: Waters 2998 photodiode array detector, Waters 3100 mass detector, Waters SFO system fluidics organizer, Waters 2545 binary gradient module, Waters reagent manager, Waters 2767 sample manager, SunfireTM C18 column (4.6 × 50 mm, 5 μm particle size); Solvent gradient = 95% A at 0 min, 1% A at 5 min; solvent A: 0.035% trifluoroacetic acid (TFA) in water; solvent B: 0.035% TFA in CH3OH; flow rate of 3.0 mL/min. 1H-nuclear magnetic resonance (NMR) and 13C-NMR analyses were carried out using a Bruker ARX-300, 300 MHz (Bruker Bioscience, Billerica, MA, USA) and a Bruker ARX-400, 400 MHz (Bruker Bioscience, Billerica, MA, USA) in NMR solvents containing tetramethylsilane as an internal standard. All the solvents and reagents were commercially available and used as such without further purification.

Synthesis of 4-(3-(3-chloro-5-methoxyphenyl)-1H-pyrazol-4-yl)pyridine (6)

It was synthesized by the previously reported 4-step method (Bennett et al. 2007; Choi and Oh 2009; El-Gamal et al. 2011). It was obtained as a white to off-white solid.

4-[3-(3-Chloro-5-methoxyphenyl)-1-(3-nitrophenyl)-1H-pyrazol-4-yl]pyridine (7)

A mixture of compound 6 (0.5 g, 1.7 mmol), 1-iodo-3-nitrobenzene (0.9 g, 3.5 mmol), K2CO3 (0.7 g, 5.2 mmol), CuI (0.033 g, 0.2 mmol), and l-proline (0.04 g, 0.2 mmol) in DMSO (7 mL) was heated at 90 °C under nitrogen atmosphere for 8 h. The reaction mixture was cooled and then extracted between ethyl acetate (15 mL) and saturated saline (15 mL). The organic phase was washed with saturated saline solution (three times) and dried using anhydrous sodium sulfate. After evaporation of the organic solvent, the residue was purified by column chromatography (silica gel, hexane-ethyl acetate 1:2 v/v) to yield compound 7 (0.55 g, 59%) as a yellow solid. 1H NMR (300 MHz, DMSO-d6) δ 9.28 (s, 1H), 8.79 (d, 1H, J = 2.0 Hz), 8.60 (d, 2H, J = 4.4 Hz), 8.46 (d, 1H, J = 8.2 Hz), 8.24 (d, 1H, J = 8.2 Hz), 7.87 (t, 1H, J = 8.2 Hz), 7.39 (d, 2H, J = 4.2 Hz), 7.16–7.14 (m, 2H), 6.99 (s, 1H), 3.75 (s, 3H).

4-[3-(3-Chloro-5-methoxyphenyl)-1-(3-aminophenyl)-1H-pyrazol-4-yl]pyridine (8)

A mixture of the nitro compound 7 (0.5 g, 1.2 mmol) and palladium over carbon 5% (0.5 g) in anhydrous tetrahydrofuran (5 mL) under hydrogen (50 psi) was stirred at room temperature for 2 h. The mixture was filtered through celite and the filtrate was evaporated under reduced pressure to give compound 8 (0.4 g, 87%) as an oil. 1H NMR (300 MHz, CDCl3) δ 8.56 (d, 2H, J = 4.6 Hz), 8.07 (s, 1H), 7.26–7.18 (m, 5H), 7.05 (d, 1H, J = 6.7 Hz), 6.92 (d, 2H, J = 1.9 Hz), 6.64 (d, 1H, J = 6.4 Hz), 3.72 (s, 3H); 13C NMR (75 MHz, CDCl3) δ 160.3 (C=O), 150.0, 149.2, 147.8, 140.5, 140.4, 135.1, 135.0, 130.4, 127.3, 122.9, 121.0, 120.0, 114.6, 113.8, 112.6, 108.8, 106.0, 55.6 (OMe); LC-MS: 378.89 (M+ + 2), 377.90 (M+ +1), 376.91 (M+).

General procedure for synthesis of diarylurea derivatives 1a–e

To a solution of compound 8 (50 mg, 0.1 mmol) in anhydrous tetrahydrofuran (THF) (1 mL), a solution of the appropriate aryl isocyanate (0.1 mmol) in THF (1 mL) was added dropwise at room temperature under N2. The reaction mixture was stirred at room temperature for 12 h. After completion of the reaction, the mixture was evaporated under reduced pressure, and the residue was purified by column chromatography (silica gel, hexane-ethyl acetate 2:1 v/v then switching to 1:5 v/v) to yield the target compound 1a–e.

1-(3-(3-(3-Chloro-5-methoxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)-3-phenylurea (1a)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 8.99 (s, 1H), 8.96 (s, 1H), 8.73 (s, 1H), 8.57 (d, 2H, J = 6.0 Hz), 8.17 (s, 1H), 7.53 (d, 1H, J = 7.6 Hz), 7.49–7.46 (m, 3H), 7.43 (d, 1H, J = 4.8 Hz), 7.38 (dd, 2H, J = 4.8 Hz, 1.2 Hz), 7.30 (t, 2H, J = 7.8 Hz), 7.11 (s, 1H), 7.11 (t, 1H, J = 2.0 Hz), 6.99 (d, 1H, J = 7.2 Hz), 6.97–6.96 (m, 1H), 3.75 (s, 3H); 13C NMR (100 MHz, DMSO-d 6 ) δ 160.6 (C=O), 153.0 (C–OMe), 150.4 (pyridyl C–N–C), 148.7 (pyrazolyl C-3′), 141.5 (pyridyl C-4′), 140.2 (central phenyl Ar–C), 139.9 (C–Cl), 135.7 (Cl, OMe-phenyl Ar–C), 134.5 (terminal phenyl Ar–C), 130.4 (terminal phenyl Ar–C), 129.7 (pyrazolyl C-5′), 129.3 (central phenyl Ar–C), 123.2 (terminal phenyl Ar–C), 122.5 (terminal phenyl Ar–C), 120.6 (terminal phenyl Ar–C), 120.1 (central phenyl Ar–C), 118.9 (central phenyl Ar–C), 117.1 (Cl, OMe-phenyl Ar–C), 114.4 (Cl, OMe-phenyl Ar–C), 113.5 (Cl, OMe-phenyl Ar–C), 112.3 (pyrazolyl C-4′), 109.1 (central phenyl Ar–C), 56.1 (OMe); LC-MS: 496.0 (M+ + 1).

1-(3-(3-(3-Chloro-5-methoxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)-3-(3,4-dichlorophenyl)urea (1b)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 9.14 (s, 1H), 9.06 (s, 1H), 8.95 (s, 1H), 8.56 (d, 2H, J = 6.0 Hz), 8.16 (s, 1H), 7.90 (d, 1H, J = 2.4 Hz), 7.57–7.51 (m, 2H), 7.48–7.40 (m, 2H), 7.38–7.35 (m, 3H), 7.13–7.10 (m, 2H), 6.95 (dd, 1H, J = 2.0 Hz, 1.2 Hz), 3.74 (s, 3H); 13C NMR (100 MHz, DMSO-d6) δ 160.6 (C=O), 152.8 (C–OMe), 150.4 (pyridyl C–N–C), 148.7 (pyrazolyl C-3′), 141.1 (pyridyl C-4′), 140.3 (central phenyl Ar–C), 140.2 (Cl, OMe-phenyl Ar–C), 139.9 (Cl, OMe-phenyl Ar–C), 135.6 (terminal phenyl Ar–C), 134.5 (terminal phenyl Ar–C), 131.5 (pyrazolyl C-5′), 131.0 (central phenyl Ar–C), 130.5 (terminal phenyl Ar–C), 129.7 (terminal phenyl Ar–C), 123.8 (terminal phenyl Ar–C), 123.2 (central phenyl Ar–C), 120.6 (central phenyl Ar–C), 120.2 (terminal phenyl Ar–C), 120.0 (central phenyl Ar–C), 119.0 (Cl, OMe-phenyl Ar–C), 117.4 (Cl, OMe-phenyl Ar–C), 114.4 (Cl, OMe-phenyl Ar–C), 113.6 (Cl, OMe-phenyl Ar–C), 112.7 (pyrazolyl C-4′), 109.4 (central phenyl Ar–C), 56.1 (OMe); LC-MS: 564.9 (M+ + 2), 563.9 (M+ + 1).

1-(3-(3-(3-Chloro-5-methoxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)-3-(3-(trifluoromethyl)phenyl)urea (1c)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 9.16 (brs, 2H), 8.97 (s, 1H), 8.57 (d, 2H, J = 6.0 Hz), 8.17 (s, 1H), 8.03 (s, 1H), 7.62 (d, 1H, J = 8.0 Hz), 7.57–7.47 (m, 3H), 7.45 (s, 1H), 7.38 (d, 2H, 5.6 Hz), 7.32 (d, 1H, J = 7.6 Hz), 7.14 (s, 1H), 7.11 (t, 1H, J = 1.8 Hz), 6.96 (s, 1H), 3.75 (s, 3H); 13C NMR (100 MHz, DMSO-d6) δ 160.6 (C=O), 153.0 (C–OMe), 150.4 (pyridyl C–N–C), 148.7 (pyrazolyl C-3′), 141.1 (pyridyl C-4′), 140.9 (central phenyl Ar–C), 140.2 (Cl, OMe-phenyl Ar–C), 139.9 (terminal phenyl Ar–C), 135.7 (pyrazolyl C-5′), 134.5 (central phenyl Ar–C), 130.5 (terminal phenyl Ar–C), 130.4 (terminal phenyl Ar–C), 129.7 (terminal phenyl Ar–C), 123.2 (central phenyl Ar–C), 122.5 (Cl, OMe-phenyl Ar–C), 120.6 (terminal phenyl Ar–C), 120.1 (central phenyl Ar–C), 117.4 (CF3), 114.8 (Cl, OMe-phenyl Ar–C), 114.4 (Cl, OMe-phenyl Ar–C), 113.5 (Cl, OMe-phenyl Ar–C), 112.7 (pyrazolyl C-4′), 109.4 (central phenyl Ar–C), 56.1 (OMe); LC-MS: 564.0 (M+ + 1).

1-(4-Chloro-3-(trifluoromethyl)phenyl)-3-(3-(3-(3-chloro-5-methoxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)urea (1d)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 9.68 (brs, 2H), 8.95 (s, 1H), 8.56 (d, 2H, J = 5.6 Hz), 8.18 (s, 1H), 8.13 (d, 1H, J = 2.4 Hz), 7.71 (dd, 1H, J = 8.4 Hz, 1.6 Hz), 7.61 (d, 1H, J = 8.8 Hz), 7.55 (d, 1H, J = 4.0 Hz), 7.45 (d, 2H, J = 4.4 Hz), 7.38 (d, 2H, J = 6.0 Hz), 7.13–7.11 (m, 2H), 6.96 (s, 1H), 3.75 (s, 3H); 13C NMR (100 MHz, DMSO-d6) δ 160.6 (C=O), 153.1 (C–OMe), 150.4 (pyridyl C–N–C), 148.7 (pyrazolyl C-3′), 141.2 (pyridyl C-4′), 140.2 (Cl, OMe-phenyl Ar–C), 139.9 (terminal phenyl Ar–C), 135.7 (pyrazolyl C-5′), 134.5 (central phenyl Ar–C), 132.4 (central phenyl Ar–C), 130.4 (terminal phenyl Ar–C), 129.7 (terminal phenyl Ar–C), 123.7 (central phenyl Ar–C), 123.2 (central phenyl Ar–C), 120.6 (terminal phenyl Ar–C), 120.1 (central phenyl Ar–C), 117.5 (CF3), 117.4 (Cl, OMe-phenyl Ar–C), 114.4 (Cl, OMe-phenyl Ar–C), 113.5 (Cl, OMe-phenyl Ar–C), 112.7 (pyrazolyl C-4′), 109.5 (central phenyl Ar–C), 56.1 (OMe); LC-MS: 598.8 (M+ + 2), 597.8 (M+ + 1).

1-(3,5-Bis(trifluoromethyl)phenyl)-3-(3-(3-(3-chloro-5-methoxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)urea (1e)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 10.53 (brs, 2H), 8.90 (s, 1H), 8.56 (d, 2H, J = 6.0 Hz), 8.22–8.20 (m, 3H), 7.58 (s, 1H), 7.51 (d, 2H, J = 6.4 Hz), 7.43 (d, 1H, J = 8.0 Hz), 7.38 (d, 2H, J = 5.6 Hz), 7.13–7.10 (m, 2H), 6.96 (s, 1H), 3.74 (s, 3H); 13C NMR (100 MHz, DMSO-d6) δ 160.6 (C=O), 153.4 (C–OMe), 150.3 (pyridyl C–N–C), 148.7 (central phenyl Ar–C), 141.4 (pyrazolyl C-3′), 140.2 (pyridyl C-4′), 139.8 (Cl, OMe-phenyl Ar–C), 135.7 (Cl, OMe-phenyl Ar–C), 134.5 (terminal phenyl Ar–C), 131.2 (pyrazolyl C-5′), 130.9 (central phenyl Ar–C), 130.2 (central phenyl Ar–C), 129.6 (terminal phenyl Ar–C), 125.2 (terminal phenyl Ar–C), 123.1 (central phenyl Ar–C), 122.5 (central phenyl Ar–C), 120.6 (terminal phenyl Ar–C), 120.1 (central phenyl Ar–C), 118.3 (2 CF3), 117.6 (Cl, OMe-phenyl Ar–C), 114.4 (Cl, OMe-phenyl Ar–C), 113.5 (Cl, OMe-phenyl Ar–C), 112.7 (pyrazolyl C-4′), 109.6 (central phenyl Ar–C), 56.1 (OMe); LC-MS: 632.9 (M+ + 2), 631.9 (M+ + 1).

General procedure for demethylation to the target hydroxyl derivatives 1f–j

Compound 1a–e (0.1 mmol) was dissolved in anhydrous dichloromethane (1 mL), and boron tribromide (0.08 mL of a 1 M solution in methylene chloride, 1.2 mmol) was added thereto dropwise at −78 °C under nitrogen atmosphere. The reaction mixture was stirred at the same temperature for 30 min. The temperature was raised to room temperature, and the mixture was stirred overnight at room temperature. The mixture was quenched with saturated aqueous sodium carbonate. Ethyl acetate (15 mL) was added, the mixture was stirred, and the organic layer was separated. The aqueous layer was extracted again with ethyl acetate (2 × 10 mL). The combined ethyl acetate extracts were washed with saturated saline solution, and then dried with anhydrous Na2SO4. The organic solvent was evaporated under reduced pressure, and the remained crude product was purified by short column chromatography (silica gel, hexane-ethyl acetate 1:1 v/v then switching to 1:5 v/v) to yield the target compound 1f–j.

1-(3-(3-(3-Chloro-5-hydroxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)-3-phenylurea (1f)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 10.10 (s, 1H), 8.98 (s, 1H), 8.95 (s, 1H), 8.71 (s, 1H), 8.57 (s, 2H), 8.18 (t, 1H, J = 2.0 Hz), 7.54–7.49 (m, 1H), 7.48 (d, 1H, J = 1.2 Hz), 7.46 (d, 1H, J = 0.8 Hz), 7.43 (d, 1H, J = 8.0 Hz), 7.39–7.37 (m, 3H), 7.30 (t, 2H, J = 8.0 Hz), 6.99–6.98 (m, 2H), 6.87–6.85 (m, 2H); 13C NMR (100 MHz, DMSO-d 6 ) δ 159.0 (C=O), 153.0 (C–OH), 150.2 (pyridyl C–N–C), 149.0 (central phenyl Ar–C), 141.5 (pyrazolyl C-3′), 140.4 (pyridyl C-4′), 140.0 (Cl, OH-phenyl Ar–C), 135.6 (Cl, OH-phenyl Ar–C), 134.2 (terminal phenyl Ar–C), 130.4 (pyrazolyl C-5′), 129.7 (central phenyl Ar–C), 129.3 (central phenyl Ar–C), 123.2 (terminal phenyl Ar–C), 122.5 (terminal phenyl Ar–C), 120.0 (central phenyl Ar–C), 119.0 (central phenyl Ar–C), 118.9 (terminal phenyl Ar–C), 117.0 (central phenyl Ar–C), 115.8 (Cl, OH-phenyl Ar–C), 114.5 (Cl, OH-phenyl Ar–C), 112.3 (pyrazolyl C-4′), 109.0 (central phenyl Ar–C); LC-MS: 482.0 (M+ + 1).

1-(3-(3-(3-Chloro-5-hydroxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)-3-(3,4-dichlorophenyl)urea (1g)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 10.11 (s, 1H), 9.18 (s, 1H), 9.10 (s, 1H), 8.94 (s, 1H), 8.56 (dd, 2H, J = 4.4 Hz, 1.6 Hz), 8.18 (t, 1H, J = 2.0 Hz), 7.91 (d, 1H J = 2.4 Hz), 7.56–7.52 (m, 2H), 7.46 (t, 1H, J = 8.0 Hz), 7.40–7.36 (m, 4 H), 6.98 (t, 1H, J = 1.6 Hz), 6.87 (dt, 2H, J = 6.8 Hz, 1.9 Hz); 13C NMR (100 MHz, DMSO-d6) δ 159.0 (C=O), 152.8 (C–OH), 150.4 (pyridyl C–N–C), 149.0 (central phenyl Ar–C), 141.1 (pyrazolyl C-3′), 140.3 (pyridyl C-4′), 140.2 (central phenyl Ar–C), 140.0 (Cl, OH-phenyl Ar–C), 135.6 (Cl, OH-phenyl Ar–C), 134.1 (terminal phenyl Ar–C), 131.5 (terminal phenyl Ar–C), 131.0 (pyrazolyl C-5′), 130.4 (central phenyl Ar–C), 129.7 (terminal phenyl Ar–C), 123.8 (terminal phenyl Ar–C), 123.1 (terminal phenyl Ar–C), 120.0 (central phenyl Ar–C), 119.9 (central phenyl Ar–C), 119.0 (terminal phenyl Ar–C), 118.9 (central phenyl Ar–C), 117.3 (Cl, OH-phenyl Ar–C), 115.8 (Cl, OH-phenyl Ar–C), 114.5 (Cl, OH-phenyl Ar–C), 112.6 (pyrazolyl C-4′), 109.3 (central phenyl Ar–C); LC-MS: 551.6 (M+ + 2), 550.6 (M+ + 1).

1-(3-(3-(3-Chloro-5-hydroxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)-3-(3-(trifluoromethyl)phenyl)urea (1h)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 10.10 (brs, 1H), 9.15 (d, 2H, J = 6.8 Hz), 8.95 (s, 1H), 8.57 (d, 2H, J = 5.6 Hz), 8.18 (s, 1H), 8.03 (s, 1H), 7.62 (d, 1H, J = 8.0 Hz), 7.55 (t 1H, J = 6.4 Hz), 7.51–7.40 (m, 3H), 7.38 (d, 2H, J = 5.6 Hz), 7.33 (d, 1H, J = 7.6 Hz), 6.98 (s, 1H), 6.86 (dd, 2H, J = 4.8 Hz, 2.0 Hz); 13C NMR (100 MHz, DMSO-d6) δ 159.0 (C=O), 153.0 (C–OH), 150.4 (pyridyl C–N–C), 149.0 (pyrazolyl C-3′), 141.1 (pyridyl C-4′), 140.9 (central phenyl Ar–C), 140.2 (Cl, OH-phenyl Ar–C), 140.0 (terminal phenyl Ar–C), 135.6 (pyrazolyl C-5′), 134.2 (central phenyl Ar–C), 130.5 (terminal phenyl Ar–C), 130.4 (terminal phenyl Ar–C), 129.7 (terminal phenyl Ar–C), 123.1 (central phenyl Ar–C), 122.5 (Cl, OH-phenyl Ar–C), 120.0 (Cl, OH-phenyl Ar–C), 119.0 (CF3), 118.8 (Cl, OH-phenyl Ar–C), 117.4 (Cl, OH-phenyl Ar–C), 115.8 (Cl, OH-phenyl Ar–C), 114.8 (central phenyl Ar–C), 114.5 (Cl, OH-phenyl Ar–C), 112.6 (pyrazolyl C-4′), 109.3 (central phenyl Ar–C); LC-MS: 550.1 (M+ + 1).

1-(4-Chloro-3-(trifluoromethyl)phenyl)-3-(3-(3-(3-chloro-5-hydroxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)urea (1i)

White solid; 1H NMR (400 MHz, DMSO-d 6 ) δ 10.32–10.28 (m, 3H), 8.90 (s, 1H), 8.53 (dd, 2H, J = 4.6 Hz, 1.4 Hz), 8.18–8.15 (m, 2H), 7.74 (d, 1H, J = 8.8 Hz), 7.59 (d, 1H, J = 8.8 Hz), 7.52–7.46 (m, 3H), 7.43 (d, 1H, J = 8.0 Hz), 7.38 (dd, 2H, J = 4.4 Hz, 1.6 Hz), 6.75–6.74 (m, 3H); LC-MS: 585.1 (M+ + 2), 584.1 (M+ + 1).

1-(3,5-Bis(trifluoromethyl)phenyl)-3-(3-(3-(3-chloro-5-hydroxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)urea (1j)

White solid; 1H NMR (400 MHz, DMSO-d6) δ 10.09 (brs, 1H), 9.49 (brs, 1H), 9.36 (brs, 1H), 8.96 (s, 1H), 8.57 (d, 2H, J = 4.8 Hz), 8.17 (brs, 2H), 7.67 (s, 1H), 7.58 (d, 1H, J = 7.2 Hz), 7.50–7.44 (m, 2H), 7.38 (d, 2H, J = 5.6 Hz), 6.98 (s, 1H), 6.87–6.84 (m, 2H); 13C NMR (100 MHz, DMSO-d6) δ 159.0 (C=O), 152.9 (C–OH), 150.4 (pyridyl C–N–C), 149.0 (pyrazolyl C-3′), 142.2 (pyridyl C-4′), 140.8 (Cl, OH-phenyl Ar–C), 140.2 (Cl, OH-phenyl Ar–C), 140.0 (terminal phenyl Ar–C), 135.6 (pyrazolyl C-5′), 134.2 (central phenyl Ar–C), 131.4 (central phenyl Ar–C), 130.5 (terminal phenyl Ar–C), 129.7 (terminal phenyl Ar–C), 123.1 (central phenyl Ar–C), 122.4 (central phenyl Ar–C), 120.0 (terminal phenyl Ar–C), 119.0 (central phenyl Ar–C), 118.7 (2 CF3), 117.8 (Cl, OH-phenyl Ar–C), 115.8 (Cl, OH-phenyl Ar–C), 114.5 (Cl, OH-phenyl Ar–C), 113.0 (pyrazolyl C-4′), 109.7 (central phenyl Ar–C); LC-MS: 618.1 (M+ + 1).

Synthesis of N-(3-(3-(3-chloro-5-methoxyphenyl)-4-(pyridin-4-yl)-1H-pyrazol-1-yl)phenyl)benzamide (1k)

A mixture of the amine compound 8 (50 mg, 0.1 mmol), benzoic acid (25 mg, 0.2 mmol), HOBt (36 mg, 0.3 mmol), and EDCI (38 mg, 0.2 mmol) in DMF (1.0 mL) was cooled to 0 °C under nitrogen atmosphere. Triethylamine (0.03 mL, 0.2 mmol) was added to the reaction mixture at the same temperature. The mixture was then stirred at 80 °C for 12 h. The reaction mixture was cooled and then partitioned between saturated saline (10 mL) and ethyl acetate (10 mL). The organic layer was separated, and the aqueous layer was extracted again with ethyl acetate (3 × 5 mL). The organic extract was washed with saturated saline (3 × 15 mL), and dried using anhydrous sodium sulfate. The organic solvent was evaporated, and the crude residue was purified by column chromatography (silica gel, hexane-ethyl acetate 1:1 v/v) to yield the target compound as a white solid;. 1H NMR (400 MHz, DMSO-d 6 ) δ 10.48 (brs, 1H), 8.97 (s, 1H), 8.55 (dd, 2H, J = 4.4 Hz, 1.6 Hz), 8.45 (t, 1H, J = 2.0 Hz), 7.99 (d, 2H, J = 6.8 Hz), 7.83 (dd, 1H, J = 8.0 Hz, 1.2 Hz), 7.65 (dd, 1H, J = 8.0 Hz, 1.6 Hz), 7.62–7.58 (m, 1H), 7.55–7.51 (m, 3H), 7.36 (dd, 2H, J = 4.4 Hz, 1.6 Hz), 6.94 (s, 1H), 3.72 (s, 3H); 13C NMR (100 MHz, DMSO-d6) δ 166.2 (C=O), 160.6 (C–OMe), 150.4 (pyridyl C–N–C), 148.8 (pyrazolyl C-3′), 140.9 (pyridyl C-4′), 140.2 (C–Cl), 139.7 (Cl, OMe-phenyl Ar–C), 135.6 (terminal phenyl Ar–C), 135.1 (terminal phenyl Ar–C), 134.5 (pyrazolyl C-5′), 132.3 (central phenyl Ar–C), 130.3 (central phenyl Ar–C), 129.7 (terminal phenyl Ar–C), 128.9 (terminal phenyl Ar–C), 128.2 (central phenyl Ar–C), 123.1 (central phenyl Ar–C), 120.6 (terminal phenyl Ar–C), 120.2 (central phenyl Ar–C), 119.1 (Cl, OMe-phenyl Ar–C), 114.4 (Cl, OMe-phenyl Ar–C), 114.0 (Cl, OMe-phenyl Ar–C), 113.6 (pyrazolyl C-4′), 111.3 (central phenyl Ar–C), 56.1 (OMe).

Biological evaluation

Cell culture and sample treatment, nitrite determination, PGE2 assay, and MTT assay of cell viability were carried out following the procedure reported in the literature (Jang et al. 2014).

Western blot

RAW 264.7 cells were resuspended in PRO-PREPTM protein extraction solution (Intron Biotechnology, Seoul, Korea) and incubated for 20 min at 4 °C. The cell debris was removed by microcentrifugation, and the supernatants were quickly frozen. The protein concentration was determined using the Bio-Rad protein assay reagent according to the manufacture’s instruction. The cell proteins were electroblotted onto a PVDF membrane after separation on 8–12% SDS-polyacrylamide gel electrophoresis. The immunoblot was incubated with a blocking solution (5% skim milk) at room temperature for 1 h, followed by incubation overnight with a primary antibody at 4 °C. The blots were washed four times with a Tween 20/Tris-buffered saline (T/TBS) and incubated with a 1:2000 dilution of horseradish peroxidase-conjugated secondary antibody at room temperature for 2 h. The blots were again washed three times with T/TBS, and then developed by enhanced chemiluminescence (GE healthcare, WI, USA).

COX-2 enzyme activity assay

Compounds 1f and 1h were evaluated for potency and selectivity of inhibition in vitro using COX Inhibitor Screening Assay (Cayman, MI, USA). Recombinant COX-2 proteins were pre-incubated with compounds 1f or 1h for 10 min in 37 °C. The reaction was started by the addition of 100 μM arachidonic acid and allowed to proceed for 2 min. The reaction was terminated by addition of HCl solution containing SnCl2. The COX activity assay directly measures PGF2α produced by SnCl2 reduction of COX-derived PGH2. The prostanoid product concentration was analyzed using EIA. Dup-697 (10 μM) was used as a reference COX-2 inhibitor.

Results and discussion

Chemistry

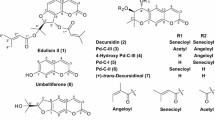

The target compounds 1a–k were synthesized through the pathway illustrated in Scheme 1. Heating 3,5-dichlorobenzoic acid (2) with sodium methoxide (3 eq.) in hexamethylphosphoramide (HMPA) followed by acidification with HCl produced 3- chloro-5-methoxybenzoic acid (3). The acid 3 was esterified using methanol in the presence of acetyl chloride to produce the corresponding methyl ester 4 (Takahashi et al. 1985). Treatment of the ester 4 with 4-picoline in THF in the presence of lithium bis(trimethylsilyl)amide yielded the pyridyl ketide derivative 5. Treatment of compound 5 with dimethylformamide dimethyl acetal (DMF-DMA) followed by treatment with hydrazine monohydrate led to formation of the cyclized 3,4-diarylpyrazole intermediate 6 (Bennett et al. 2007; Choi and Oh 2009; El-Gamal et al. 2011). N-Arylation of compound 6 using 1-iodo-3-nitrobenzene in the presence of potassium carbonate, copper(I)iodide, and L-proline as catalysts produced the m-nitrophenyl compound 7. The nitro group of compound 7 was reduced to amino using Pd/C in H2 atmosphere. The amine compound 8 was reacted with the appropriate aryl isocyanate to produce compounds 1a–e. The methoxy group of compounds 1a–e was demethylated in using boron tribromide to obtain the corresponding hydroxyl analogs 1f–j. Compound 1k was synthesized through condensation of the amino compound 8 with benzoic acid in presence of 1-hydroxybenzotriazole (HOBt), 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDCI), and triethylamine (TEA). The structures of the target compounds and their yield percentages are illustrated in Table 1.

Reagents and conditions: a sodium methoxide, HMPA, 115–120 °C, 15 h, 54%; b acetyl chloride, CH3OH, rt, 15 h, 89%; c 4-picoline, LHMDS, THF, rt, overnight, 77%; d DMF-DMA, rt, 18 h; e hydrazine monohydrate, C2H5OH, rt, overnight, 72%; f 1-iodo-3-nitrobenzene, K2CO3, CuI, l-proline, DMSO, 90 °C, 8 h, 59%; g H2, 10% Pd/C, THF, rt, 2 h, 87%; h appropriate aryl isocyanate, THF, rt, 12 h, 24~85%; i BBr3, CH2Cl2, −78 °C, 30 min; rt, 1 h, 24–89%; j benzoic acid, HOBt, EDCI, TEA, DMF, 80 °C, 12 h, 65%

Biological screening

Inflammation is a normal protective immune response against tissue damages that occur due to external factors in the body (Qui et al. 2006). But the inflammatory response can also cause considerable damage to the host. The microbial components such as LPS can induce the production of COX-2, inducible nitric oxide synthase (iNOS), and pro-inflammatory cytokines in the macrophages. In particular, if large amounts of NO and PGE2 secreted by activated immune cells in the inflammatory condition, they can induce several pathological conditions. So inhibition of the production of inflammatory mediators is a potential avenue for treatment of acute and chronic inflammations. The target compounds 1a–k were assessed for their abilities to inhibit the production of inflammatory mediators, NO and PGE2, in LPS-induced RAW 264.7 macrophages (Moncada et al. 1991; Kim et al. 2008; Shin et al. 2014). N 6-(1-Iminoethyl)-L-lysine (L-NIL) and N-(2-cyclohexyloxy-4-nitrophenyl)methanesulfonamide (NS-398) were utilized as reference compounds for screening of NO and PGE2 production inhibitions, respectively. The cytotoxic effects of the triarylpyrazoles 1a–k on RAW 264.7 macrophages were also evaluated using the MTT assay to test whether the inhibitory effects on the productions of NO and PGE2 were caused by non-specific cytotoxicity (Table 2). All the target compounds showed IC50 values ≥5.86 µM. Compounds 1b and 1e did not inhibit 50% of RAW 264.7 macrophages growth up to 100 µM. After that, the target compounds were tested for NO and PGE2 production inhibitions at 5 and 3 µM, respectively.

The target pyrazole compounds 1a–k exerted varying inhibitory effects on the LPS-induced NO and PGE2 productions (Table 3). Compounds 1h–j possessing m-hydroxyl group on the aromatic ring on position 3 of the pyrazole ring showed higher inhibitory effect on NO production than the corresponding methoxy analogs 1c–e. Similarly, the phenolic derivatives 1f, 1h, and 1i were more active as PGE2 production inhibitors than the corresponding methoxy compounds 1a, 1c, and 1d. So the phenolic OH group could be essential for anti-inflammatory activity of this series of compounds. It may act as hydrogen bond donor at the receptor site. Or its steric and/or electronic properties, which are different from those of the methoxy group, can strengthen the affinity at the receptor site. In addition, the increased lipophilicity seems to be unfavorable for PGE2 production inhibitory activity.

Compound 1k with amide linker was synthesized and biologically tested in order to compare the effect of the linker on the biological activity. It was found that the urea compound 1a was more active than the amide analog 1k in terms of NO production inhibition. This can be rationalized that the longer urea linker may help the compound fit appropriately at the receptor site. Or the extra terminal NH group of the urea linker can make additional hydrogen bond(s) at the receptor site. Any or both of these effects can help enhance the compound affinity at the receptor site, and hence higher activity. Due to the non-promising results of compound 1k as NO production inhibitor, it was not tested for PGE2 production inhibition.

The effect of the terminal aryl moiety on the biological activity was also investigated. Upon comparing the results of the methoxy compounds 1a–e on NO production inhibitions, the mono-substituted phenylurea derivative 1a was the most active than the other di- or tri-substituted phenyl derivatives 1b–e. So the steric/electronic factor(s) may play a role in these activity differences. But upon comparing the hydroxyl derivatives 1f–j, compound 1j possessing 3,5-bis(trifluoromethyl)phenyl terminal moiety showed the best activity. Its IC50 value over NO production was 4.35 µM. So that bulky terminal moiety may be optimal for activity. Since it is well-known that iNOS catalyzes the oxidative deamination of l-arginine to produce NO (Moncada et al. 1991), we determined the effect of compound 1j on LPS-induced iNOS protein expression using Western blot. Compound 1j significantly inhibited LPS-induced iNOS expression, suggesting the inhibitory action of compound 1j on NO was due to inhibition on iNOS protein expression (Fig. 2).

The inhibitory effect of compound 1j on LPS-induced iNOS expression in RAW 264.7 cells. Total cellular proteins were obtained from cells stimulated with LPS (1 μg/mL) for 24 h in presence or absence of 1j (a) or L -NIL (b). iNOS was detected by Western blot using specific antibody. β-actin was used as an internal control. The experiments were repeated three times, and similar results were obtained

Regarding the effect on PGE2 production inhibition, the best results were obtained with compounds 1a and 1f with phenyl ring, and compound 1h possessing 3-(trifluoromethyl)phenyl terminal moiety. Compounds 1f and 1h showed almost the same inhibition percentage as NS-398 and Celecoxib against PGE2 at 3 µM concentration. So both phenyl and m-(trifluoromethyl)phenyl terminal rings are the optimum for PGE2 production inhibitory effect of this series of compounds. During the inflammatory process, biosynthesis of PGE2 requires transformation of arachidonic acid by COX-2 to PGH2, which is subsequently converted by microsomal PGE synthases (mPGES-1) (Shin et al. 2014). To determine the mechanisms by which compound 1f and 1h blocked the PGE2 production in macrophages, we first examined expression of both COX-2 and mPGES-1 by Western blot. As shown in Fig. 3a, compounds 1f and 1h had no effect on LPS-induced COX-2 and mPGES-1 protein expression. The COX-2 enzyme activity is extremely important for PGE2 production, hence we next studied the effects of compounds 1f and 1h on COX-2 enzyme activities by performing screening assays using purified COX-2 enzymes. We found that compounds 1f and 1h exhibited inhibitory effect to COX-2 activity in a dose-dependent pattern. Compound 1f was more potent than compound 1h. Dup697 was used as a positive control for inhibition of COX-2 enzyme activity (Fig. 3b). These result indicated that compounds 1f and 1h reduced LPS-induced PGE2 production through inhibition of COX-2 enzyme activity.

Effect of compounds 1f and 1h on LPS-induced iNOS and mPGES expression in RAW 264.7 cells and COX-2 enzyme activities. a Total cellular proteins were obtained from cells stimulated with LPS (1 μg/mL) for 24 h in presence or absence of 1f or 1h. COX-2 and mPGES-1 were detected by Western blot using specific antibodies. β-actin was used as an internal control. The experiments were repeated three times, respectively, and similar results were obtained. b Recombinant COX-2 enzyme was in vitro treated with the indicated concentrations of 1f or 1h for 10 min. Dup-697 (10 μM) was used as a positive COX-2 inhibitor controls. Values shown are means ± SD of three independent experiments; ***p < 0.001 vs. the 100% activity group

Conclusion

A series of 1,3,4-triarylpyrazole derivatives was synthesized and studied in order to explore the relationship between their structures and their antiinflammatory activity. The hydroxyl compounds were generally more active than the corresponding methoxy derivatives. The urea moiety was found optimum linker for activity. The phenyl, m-(trifluoromethyl)phenyl, and 3,5-bis(trifluoromethyl)phenyl rings were the best terminal moieties. These together can represent the pharmacophore of this series of compounds. The highest PGE2 production inhibition activities were obtained by compounds 1f and 1h. Both of them exerted that effect due to inhibition of COX-2 enzyme activity not COX-2 protein expression. Both compounds possess phenolic hydroxyl group and urea linker. Their terminal moieties are phenyl and m-(trifluoromethyl)phenyl rings, respectively. They showed almost equal inhibitory effect on PGE2 production as NS-398 at the same concentration, 3 µM. In addition, the urea derivative 1j containing hydroxyl group and 3,5-bis(trifluoromethyl)phenyl terminal ring showed the highest inhibitory effect on NO production, and this was due to inhibition of iNOS protein expression as concluded from the Western blot study. Further lead optimization is required for development of more active and more potent analogs based on the structure–activity relationship study.

References

Bennett MJ, Cho-Schultz S, Deal JG, King SJ, Marrone TJ, Palmer CL, Romines WH, Rui EY, Sutton SC, Zehnder LR (2007) Pyrazole compounds. WO 2007/105058

Choi W-K, Oh C-H (2009) Synthesis and antiproliferative activities of 1-substituted-3-(3-chloro-5-methoxyphenyl)-4-pyridinylpyrazole derivatives against melanoma cell line. Bull Korean Chem Soc 30:2027–2031

Coussens LM, Werb Z (2002) Inflammation and cancer. Nature 420:860–867

El-Gamal MI, Sim TB, Hong JH, Cho J-H, Yoo KH, Oh C-H (2011) Synthesis of 1H-pyrazole-1-carboxamide derivatives and their antiproliferative activity against melanoma cell line. Arch Pharm Chem Life Sci 11:197–204

El-Sayed MA-A, Abdel-Aziz NI, Abdel-Aziz AA-M, El-Azab AS, ElTahir KEH (2012) Synthesis, biological evaluation and molecular modeling study of pyrazole and pyrazoline derivatives as selective COX-2 inhibitors and anti-inflammatory agents. Part 2. Bioorg Med Chem 20:3306–3316

Hinz B, Brune KJ (2002) Cyclooxygenase-2–10 years later. Pharmacol Exp Ther 300:367–375

Hochberg MC (1990) Changes in the incidence and prevalence of rheumatoid arthritis in England and Wales, 1970–1982. Semin Arthritis Rheum 19:294–302

Jang H-L, El-Gamal MI, Choi H-E, Cho H-Y, Lee K-T, Oh C-H (2014) Synthesis of tricyclic fused coumarin sulfonates and their inhibitory effects on LPS-induced nitric oxide and PGE2 productions in RAW 264.7 macrophages. Bioorg Med Chem Lett 24:571–575

Keche AP, Hatnapure GD, Tale RH, Rodge AH, Kamble VM (2012) Synthesis, anti-inflammatory and antimicrobial evaluation of novel 1-acetyl-3,5-diaryl-4,5-dihydro (1H) pyrazole derivatives bearing urea, thiourea and sulfonamide moieties. Bioorg Med Chem Lett 22:6611–6615

Kim JY, Park SJ, Yun KJ, Cho YW, Park HJ, Lee KT (2008) Isoliquiritigenin isolated from the roots of Glycyrrhiza uralensis inhibits LPS-induced iNOS and COX-2 expression via the attenuation of NF-kB in RAW 264.7 macrophages. Eur J Pharmacol 584:175–184

Kurumbail RG, Stevens AM, Gierse JK, McDonald JJ, Stegeman RA, Pak JY, Gildehaus D, Miyashiro JM, Penning TD, Seibert K, Isakson PC, Stallings WC (1996) Structural basis for selective inhibition of cyclooxygenase-2 by anti-inflammatory agents. Nature 384:644–648

Lee I-A, Bae E-A, Hyun Y-J, Kim D-H (2010) Dextran sulfate sodium and 2,4,6-trinitrobenzene sulfonic acid induce lipid peroxidation by the proliferation of intestinal gram-negative bacteria in mice. J Inflamm 7:7

Malvar DDC, Ferreira RT, de Castro RA, dr Castro LL, Freitas ACC, Costa EA, Florentino IF (2014) Antinociceptive, anti-inflammatory and antipyretic effects of 1.5-diphenyl-1H-Pyrazole-3-carbohydrazide, a new heterocyclic pyrazole derivative. Life Sci 95:81–88

Moncada S, Palmer RM, Higgs EA (1991) Nitric oxide: physiology, pathophysiology, and pharmacology. Pharmacol Rev 43:109–142

Norgard B, Pedersen L, Johnsen SP, Tarone RE, McLaughlin JK, Friis S, Sorensen HT (2004) COX-2-selective inhibitors and the risk of upper gastrointestinal bleeding in high-risk patients with previous gastrointestinal diseases: a population-based casecontrol study. Aliment Pharmacol Ther 19:817–825

Qui H, Johansson A-S, Sjostrom M, Wan M, Schroder O, Palmblad J, Haeggstrom JZ (2006) Differential induction of BLT receptor expression on human endothelial cells by lipopolysacharide, cytokines, and leukotriene B4. Proc Natl Acad Sci USA 103:6913–6918

Ragab FA, Abdel Gawad NM, Georgey HH, Said MF (2013) Synthesis of novel 1,3,4-trisubstituted pyrazoles as anti-inflammatory and analgesic agents. Eur J Med Chem 63:645–654

Sastre M, Richardson JC, Gentleman SM, Brooks DJ (2011) Inflammatory risk factors and pathologies associated with Alzheimer’s disease. Curr Alzheimer Res 8:132–141

Shin JS, Choi HE, Kim SD, Lee YS, Cho YW, Lee K-T (2014) Anti-inflammatory effects of 7-hydroxyl-1-methylindole-3-acetonitrile, a synthetic arvelexin derivative, on the macrophages through destabilizing mPGES-1 mRNA and suppressing NF-κB activation. Chem Biol Interact 224C:68–77

Sung B, Prasad S, Yadav VR, Lavasanifar A, Aggarwal BB (2011) Cancer and diet: How are they related? Free Radic Res 45:864–879

Takahashi K, Shimizu S, Ogata M (1985) Synthesis of phenolic metabolites of an antifugal imidazole derivatives (cloconazole hydrochloride). Heterocycles 23:1483–1491

Yun HY, Dawson VL, Dawson TM (1996) Neurobiology of nitric oxide. Crit Rev Neurobiol 10:291–316

Acknowledgements

This work was supported by Korea Institute of Science and Technology (KIST), KIST Project (2E24680).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Byung-Jun Park and Mohammed I. El-Gamal have contributed equally to this work.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Park, BJ., El-Gamal, M.I., Lee, WS. et al. Synthesis and inhibitory effects of triarylpyrazoles on LPS-induced NO and PGE2 productions in RAW 264.7 macrophages. Med Chem Res 26, 2161–2171 (2017). https://doi.org/10.1007/s00044-017-1923-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00044-017-1923-9