Abstract

This paper compares four systems of deployable scissor-like structures (also known as double layer grid-articulated joint systems). Its aim is to understand which of these require fewer elements to cover/span a given area. The results are assessed for five cases of the same area but with different geometry. As part of the research, two different methods have been used, contrasting the precision and convenience of each one simultaneously. On the one hand, we have used mathematical equations that allow us to quantify the amount of rods and joints needed in each system. On the other hand, in carrying out these evaluations, we have also used several digital models made with Grasshopper, a software that offers us tools to create algorithms. To conclude, we then evaluate the results obtained via both procedures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

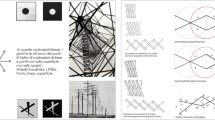

In the second half of the twentieth Century, architects, such as Buckminster Fuller, Frei Otto or Charles Hoberman, developed an interest in deployable structures. Enthusiasm for these types of structures reached a peak during the 1960s and 1970s. In addition to their application in the field of architecture, research was dedicated to how they might be used for the construction of space vehicles and satellites.

The Spanish architect Emilio Pérez Piñero was one of the first to patent some of these structures and is regarded as a pioneer in this field. A little later, another Spanish architect, Félix Escrig, was awarded another patent that capitalised and built on Piñero’s research.

The findings we present here compare in a parametric way four geometric modules that can be used to configure deployable structures. Two of these modules were developed by Emilio Pérez Piñero, while the other two modules were pioneered by Félix Escrig, who continued the research initiated by Piñero in Spain.

Emilio Pérez Piñero was born in Valencia in 1935, almost a year before the start of the Spanish Civil War that was to take place during his infancy. While he was still a young child, his family moved to Calasparra (Murcia), a place that was to significantly influence the development of Piñero’s work. He initially tested all his projects using prototypes built here, aided by local workers he trained himself, and using materials that he came across in his everyday surroundings, such as bicycle parts or umbrellas. This extraordinary hands-on approach is an aspect of his work that has been fêted by some of the writers who have researched Pérez Piñero’s life. They highlight his innate skills, such as the first-class spatial vision he displayed as a child, that went on to serve him extremely well as an adult, when he embarked on the study of deployable structures (Pérez-Almagro 2013).

Later on, in the 4th year of his university studies, he won first prize in a student competition organised by the International Union of Architects (UIA). This also marked the beginning of his professional career, as the event placed him directly on the international scene. The UIA conference held in London in July 1961 promoted this competition among architecture students from participant countries. Félix Candela and Buckminster Fuller were part of the jury that awarded him first prize. He had a close relationship with Candela both personally and professionally—they had a contractual agreement, and Candela helped him to land clients for architectural projects in the US (Pérez-Almagro 2013). They collaborated on design projects, including plans for a structure for accommodating a greenhouse on the surface of the moon, as required by NASA and better known as a lunar module or automatic deployable module, that could deploy autonomously (Peña and Calvo 2013). Thanks to Félix Candela, the first ‘Mobile Theatre’ project was published in the journal Progressive Architecture, under the title ‘Expandable Space Framing’ in 1962 (Fig. 1). The two inventions that register as patents in the U.S. office serve as proof of Pérez Piñero’s ambition in accessing the American architectural scene.

The first of these, the ‘Three-dimensional structural frame’ (Pérez Piñero 1965), included all of the knowledge developed in the first system derived from the ‘Mobile Theatre’ project. The second, which was awarded posthumously in 1976, is called the ‘System of articulated planes’ (Pérez and Belda 1976), and it encapsulates some of the research work from the Salvador Dalí project ‘Hypercubic stained glass’ (Vidriera hipercúbica), which was carried out in order to cover the proscenium arch of the theatre at Dalí’s museum (Fig. 2).

To illustrate the leading-edge and international level at which Pérez Piñero was working, according to Candela, Buckminster Fuller was surprised when he saw the prototype that Piñero presented in London and told him that he had patented a similar deployable structure system. In fact, Buckminster Fuller had developed a similar system at the University of Washington in 1953, known as the ‘Flying Seedpod’, which was a deployable dome made up of tetrahedral modules that folded in the upper and lower nodes, although he never got to patent it (Krausse and Lichtenstein 2000).

The ground-breaking significance of the mechanism encouraged Pérez Piñero to embark on the patent application process even before he attended the UIA conference, using the name ‘Estructura reticular esterea plegable’, (literally, ‘Folding mesh retractable structure’), in 1961 (Pérez Piñero 1961), which was later introduced in the US under the name ‘Three-dimensional reticular structure’, the patent application process for which also began the same year (Fig. 3), which he ultimately obtained in 1965. Securing this patent further proved the originality of his crossing three-rod system that enabled the folding of the spatial or double-layered dome. This system is similar to (but not the same as) Fuller’s system referred to above. However, Fuller did not get round to patenting this invention.

The first project, which Pérez Piñero developed in an intuitive way, is based on the three-rods module referred to in this paper as EP1 (Fig. 6). The rods do not cross in the geometrical centre, and therefore they form a curvature radius that allows Pérez Piñero to provide a dome built with same-sized metallic rods, and with deployable functionality. The thinking behind this is compiled and thoroughly detailed as part of his first patent, elevating it into a genuinely intellectual document that not only protects but also conveys the knowledge and expertise that went into it.

In 1963, Pérez Piñero became professor of the ‘Estructuras II’ course at the ETSAM School of Architecture in Madrid. During his tenure, he continued to develop and improve his deployable and detachable mechanisms, pursuing a line of research that would continue for the duration of his professional career. The first work he built appeared after he won the limited-entry competition to make a ‘Transportable Pavilion for Exhibitions’, to commemorate 25 years of peace under the Franco regime (Pérez Belda and Pérez Almagro 2016). Architectural teams such as Corrales y Molezún, Rafael de La Hoz and the aforementioned Pérez Piñero took part in this competition. The latter won the competition and built the pavilion using the module referred to in this paper as EP2, formed by four rods crossing at their geometrical centre (Fig. 6).

Most of the deployable structures built by Piñero are now lost or dispersed across various locations, including property owned by Spain’s Ministry of Defence. His only surviving work is represented by a few non-deployable systems, such as his dome for the Dalí Museum in Figueres.

On the other hand, Félix Escrig, who is often regarded as an acolyte of Piñero, was linked to university teaching throughout his professional life (in the interest of brevity, we have not provided background on Escrig’s childhood or formative years in this paper). As Full Professor of Structures at the ETSAS School of Architecture in Seville, he founded the research group ‘Mechanics of continuous media and theory of structures’, as part of which he researched deployable prototypes using scale models. In 1992, he organised the inaugural International Convention of Large-Span Domes in Seville, which was attended by various top-level global players, such as Frei Otto, Heinz Isler and Minoru Kawaguchi. The convention garnered a lot of interest and it resulted in a book being published, Arquitectura Transformable, which remains a key reference point in the field of deployable structures to this day.

Félix Escrig has a successful time participating at Expo’92, in which he played an important role. He acted as a consultant on The Palenque and on the Venezuela and Extremadura pavilions, in addition to creating an incredibly interesting proposal involving plant-based pergolas to provide shade and create a microclimate to help counter the effect of Seville’s summertime temperatures. Félix Escrig therefore leaves an important body of architectural work, linked intrinsically to the three concepts published in his last book, Modular, Ligero, Transformable (Escrig 2012).

Just as Piñero did, he compiled and safeguarded his knowledge through his acquisition of patents. His patent for a ‘Modular system for construction of spatial deployable structures of rods’ has become the ‘go-to’ guide for the provision of this kind of system. Escrig arranged and codified the information already started by Piñero, in addition to making his own contributions. By means of the so-called ‘Plane cross modules’ and its additions, he managed to design and build almost all of his deployable systems using same-sized rods only.

Among the modules described by Escrig, we have included the following in this paper: FE1 and FE2 (Fig. 6). The second one “illustrates schematically the relative position of the rods that forms the structure joining all the opposite vertices of the sides of a regular quadrangular prismatic module” (Escrig-Pallarés 1984). This is the module that he uses in different built works, such as the deployable cover of the San Pablo Olympic Swimming Pool in Seville.

Similarly, the module called FE1 is defined as a regular triangular prism, in which three crosses are placed on each side. As seen in the image, when the length of the semi-rods are not the same, the system can fold and unfold generating curves, domes and spheres (Fig. 4).

It is important to appreciate the analogical work of these two architects, who, in an empirical way, always built scale-size prototypes of their models. In those days, research into these types of structures relied fundamentally on working with physical models. The challenges of representing the trajectories of the different points and components through 2-D drawings relegated these graphical tools to a more secondary role.

More recently, a series of research initiatives have focused on deployable structures, carrying out several widely applicable studies that aim to establish a classification system for them, such as in the case of Evaluation of Deployable Structures for Space Enclosures. Fenci and Currie (2017) conclude in their paper “Deployable structures classification: A review” that a clear, complete, consistent and unified classification for deployable structures does not exist currently. To arrive at that conclusion, they analyse the classifications and reviews made by Merchan (1987), Gantes et al. (1989), Pellegrino (2001), Hanaor and Levy (2001), Korkmaz (2004), Stevenson (2011), and Del Grosso and Basso (2013), among others.

Current advances in architectural and engineering software better enable the study of these systems, as well as for their optimisation using parametric design tools, such as Grasshopper, and producing a comparative analysis of several systems. The arrival of 3-D modelling and printing have also been useful for designing joints and nodes, and for testing systems.Footnote 1 The present paper explores these possibilities in order to obtain results that help research initiatives to advance and in the fulfilment of new deployable systems.

Aim of the Research

As we have already seen, patents on deployable structures are essentially descriptive documents. They define systems that can be folded, which is basically a property of their geometry.

As stated previously, the systems in the study are all structures composed of joints and rods. These nodes are articulated joints that permit the bars to turn and, consequently, for the structure to fold or unfold. The joints of each system are different, as they correlate with the specific geometry of each one. They are probably the most sophisticated elements of these structures and the hardest to produce. We therefore consider it relevant to have information about the quantities of each element for its manufacture, whether by industrial means or via digital manufacturing methods.

Recently, algorithm-aided design has been applied to the study and development of these types of structures, adapting them to more complex geometries (González and Carrasco 2015). However, there are very few studies comparing different deployable systems to each other.

The main aim of this paper is precisely that, namely to compare four deployable structures systems (double layer grid (DLG)-articulated joint systems), according to the Hanaor and Levy (2001) classification, and to obtain conclusions about their effectiveness in covering flat surfaces that, although having the same area, vary in terms of their boundary shapes as follows: square (case 1), circular (case 2), triangular (case3), rectangular (proportions 1:2, case 4) and hexagonal (case 5). The effectiveness of these structural systems will be compared using parameters such as the number of rods, nodes and modules used by each of these structures in covering the aforementioned areas. Such amounts are variables depending on θ, which is the angle comprised between the rods of these structures and the horizontal plane, and which shows the extent to which they are unfolded at any one time. This will allow us to obtain conclusions on the effect of different dimensional variables when it comes to designing structures based on these kinds of systems.

The area in all five cases is always the same—100 square units—with the length unit taken as reference being the same as the length of the used rods (L), which remains constant for all of the evaluated systems and cases (Fig. 5).

We will also study if mathematical equations can be used as a reliable means for anticipating results obtained graphically.

Description of the Compared Systems

The systems being researched here are relatively simple, with rigid rods and articulated joints. Two of them come from Emilio Pérez Piñero’s patents (which we refer to using the prefix ‘EP’), while the other two come from the Félix Escrig’s patents (which we refer to using the prefix ‘FE’). We have called them EP1, EP2, FE1 and FE2 respectively (Fig. 6).

As can be seen in Fig. 6, the base module of the EP1 system consists of three bars articulated in a central joint. The entire volume can be inscribed in a straight antiprism whose bases are equilateral triangles.Footnote 2

The basic module of the EP2 system is similar to the previous one, but includes four rods, which are contained in a straight square-based prism (Fig. 6). This is the module used in the aforementioned Pavilion for Commemoration of 25 Years of Peace in Spain, under Franco’s regime.

In the Félix Escrig patents that form part of this study, rods are placed on the prism sides, articulating in pairs of two at their midpoint, forming crosses or scissors on each side4. In this case, the basic module of the FE1 system is contained in a straight prism whose base is an equilateral triangle, while the FE2 system is defined by a straight square-based prism (Fig. 6).Footnote 3

Naming the nodes:

In all of the studied examples, the rods are joined in knots. However, we can differentiate those nodes by the systems they belong to, by their position along the rod, and by the number of rods that converge into them. In relation to this, a notation system has been defined in order to identify each and every joint in a straightforward way.

Firstly, the aforementioned naming convention (EP1, EP2, FE1 and FE2) is used to identify the system to which the node belongs. Next, separated by a hyphen, a number indicates its position along the rod. So position 1 is a lower-end node, position 2 is a central node, and position 3 is an upper-end node. Finally, another number shows the number of rods that are joining at this particular knot. For instance, code EP2-2-4 indicates a joint from Piñero’s second system, placed in a central position of the rod (2) in which four rods are joined (4).

The number of bars converging at each knot corresponds with the module within the system—that is to say, the module is surrounded by other modules with similar features, so that all of the possible rods converge in the knot according to the configuration of that system.

Definition of the Unfolding Level of the Structure

In our study, the variable that lets us evaluate the unfolding state of the structure is the theta angle (θ) (Fig. 6). This angle is the one formed by the bars of each system and the horizontal plane defined by the X and Y axes. In the ideal modelling conditions for this study, we consider 0 thickness for rods and knots. When θ adopts the value 0° in relation to the XY plane, the structure is considered to be unfolded and the bars are contained in the XY plane. When θ adopts the value 90° \(\left( {\frac{\pi }{2}} \right)\) in relation to the XY plane, the structure is considered to be completely folded and the bars remain contained in the Z axis (Fig. 7).

Methodology and Modelling Criteria

As indicated above, we will use two different methods for modelling the structural systems analysed and for evaluating their efficiency according to the terms that we have previously defined.

Firstly, we will use some mathematical equations that will enable us to arrive at an estimation of the number of modules, nodes and rods that are included in the aforementioned surface areas for each system. We will call this method “mathematical estimation”.

Secondly, using Grasshopper, we will model the structural systems previously described and the surface areas being considered. A counter component introduced into the algorithm will provide data about the number of modules, bars and knots necessary to cover the areas in the different cases. We will refer to this method as “digital (or algorithmical) estimation”.

Whether we are working with mathematical equations or using Grasshopper algorithms, the modelling has been carried out by regarding the rods and joints of each structural system as ideal geometrical elements—lines and points respectively—which allows us to obtain, through mathematical estimation, a first verification of the results obtained by the aforementioned mathematical equations. In the same way, when using both methodologies (mathematical or digital), the independent variable will be the theta angle (θ), which, as outlined above, enables us to quantify the unfolding degree of the structure at every instance. This will affect the number of modules that cover the area in each case-study (1, 2, 3, 4 and 5).

Mathematical Estimation

For each system, a series of mathematical equations has been deduced, which lets us obtain the number of modules (M), rods (R) and knots (K) for each of the systems being studied, according to the theta (θ) value, within an area of 100 L2.

The resulting equations are, essentially, quotients that show the relation between the total area to be covered on the XY plane, and the area on this same plane that is occupied by the projection of each module. All of the equations are summarised in Table 1.

Where:

EP1, EP2, FE1 and FE2; represent the deployable systems considered for each one of them.

M: describes the number of Modules that each system occupies within a generic area S of 100 L2, where L is the unit length of the rods.

R: represents the number of Rods that each system needs within a generic area S of 100 L2.

Ks-p-r: denotes the number of Knots each system needs within a generic area S of 100 L2. The subscript (s) denotes the considered system. The values of the subscript (p) from 1 to 3 indicates the position which the considered Knot holds within the system, and the subscript (r) represents the number of rods that converge in the described Knot (2, 3, 4 or 6).

E[f]: is the floor function for the integral part of a real number given by the function f, and gives as output the greatest integer less than or equal to x

θ: Shows the value of the angle between the rods and the XY plane (horizontal plane), and, therefore, the state of deployability of the system considered.

Looking at these formulae, we can see that:

In all of the equations the floor function is involved, as what we are seeking to obtain is the whole number of elements (modules, rods or knots) found within the surface area being considered in each case, and not a fractional representation of these.

Furthermore, in all cases, the content of this floor function is formed by a rational function, in which a scalar is divided by cos2 θ. Such a formula yields clear results, because at first glance it allows us to figure out which functions will have a more accelerated growth.

As has already been explained, such equations are obtained when considering the number of modules M to be the quotient between the area to be covered (100 L2) and the projection area of the basic module of each system on the XY plane, or, in more architectural jargon, the area that such a module occupies from a top view. The number of rods and knots is simply arrived at by proportionality.

However, we should not forget that this reasoning does not offer anything more than an approximation to solving the problem, since despite the fact that the shape of the basic module of each system has been taken into consideration, the shape of the perimeter of the area to be covered has been omitted, as we have considered only the value of this area. The greater the relation between the considered area and the bar length, the more accurate this estimation will be.

When looking at our findings later on, we will be able to compare the data obtained by both methods and verify the effectiveness of this estimation.

Digital (or Algorithmical) Approximation

Grasshopper is a graphical interface that allows users to create algorithms in order to obtain parametric geometries that, in some cases, are impossible to generate with other CAD applications. It is integrated into Rhinoceros 3D and enables us to design in a parametric way, starting with the combination of geometries and parameters (Gómez González and Torner Ribé 2016).

Specifically, Grasshopper’s interface can create visual diagrams, based on nodes that control, edit or generate the aforementioned geometries (Tedeschi and Wirz 2015: 27). In our case, we have used the three-dimensional parametric model controlled by algorithms to generate four algorithms that reproduce the geometries of the structural systems studied (EP1, EP2, FE1 and FE2). Through these, it is possible to observe how such systems fold and unfold (when varying θ), as well as the elements (modules, bars or knots) that remain within the perimeter of the five different shapes studied in each case.

The four algorithms are somewhat similar, as in each of them we can differentiate parts that accomplish the same function (Fig. 8).

As we can see in Fig. 9, the part called A functions to introduce and manage the variables included in the algorithm. Such variables enable the geometry of the basic module to be defined and its spatial reproduction to generate the system.

In Fig. 9, the controller labelled A1 enables the management of the θ variable value (folding level of the structure), allowing the folding and unfolding of the structure. For this purpose, polar coordinates have been used to define the position of the points Ks−p−r. Starting from the origin point O of the XY cartesian system, this is assigned the position of point Ks−2−r of the system’s first module. Once the θ angle and the bar length L that forms the system are known, it is possible to determine the position of the knots Ks−1−r and Ks−3−r.

Looking at Fig. 10, within zone B of the diagram is an area referred to as B1, which consists of the components that reproduce the base module according to the geometrical pattern specific to each system.

In the EP1 system’s case, we can note that its pattern is hexagonal, triangular in the FE1′s case, and squared for EP2 and FE2. When focusing on such patterns (Fig. 11), we can verify that in the EP systems, modules are placed in an adjacent way, one beside another. However, with the FE systems, we can always detect a void or empty space inserted between every two modules (this has been also taken in consideration when formulating the mathematical equations in the previous section).

Meanwhile, in zone C we find the controllers in charge of representing the different perimeter shapes containing an area of 100L2 in each of the cases studied (Fig. 12).

The counter component, placed in zone D, is one of the most important elements of the diagram, as it enables us to ascertain a quantification of the obtained results (Fig. 13).

This component determines how many modules are comprised within the studied area in each case when varying the values of θ between 0° and 90° \(\left( {\frac{\pi }{2}} \right).\) In reality, this model is also prone to a certain level of inaccuracy. For the calculation of the number of modules M, the algorithm considers the relative position of each module (within the area) condensed to one auxiliar point placed on its geometrical centre. This auxiliar point is linked to the point Ks−2−r of the modules of systems EP1 and EP2, as well as to the geometrical centre of the FE1 and FE2 systems’ modules.

The counter component works as follows. On the one hand, when that geometrical centre of a module is on the perimeter or inside the boundary, the algorithm adopts a true value and that module is added to the total amount. In this way, the module is considered to be completely contained within the perimeter. On the other hand, when the geometrical centre of a module is completely outside of the boundary and the area of study, the counter algorithm adopts a false value and that module is not included in the total amount. In this case the module is supposed to remain completely excluded from the perimeter.

This way of working means that for some positions of the geometrical centre included in the interval ½ ≤ (x·L·cos θ − E[x·L·cos θ]) (Fig. 14b) in which it is verified E[x·L·cos θ] < x·L·cos θ, (where x is the dimension of the analysed area in a certain direction), some modules can be partially inside the perimeter and can therefore be included by the counter. On the other hand, modules whose geometrical centres’ positions are included in the interval ½ ≤ (x·L·cos θ − E[x·L·cos θ]) (Fig. 14c) will not be taken into consideration.

For that reason, the mechanism in the study is a simplified approach to solving the problem. This is due to the fact that the modules, simplified to a point as equations, have dimensions in the orthogonal directions X and Y of the cartesian system being studied. The counting mechanism introduces some variations with regard to the anticipated result. It considers as complete modules those whose fractions are partially included within the perimeter depending on the position of their geometrical centres. Such variations are to do with the inclusion or exclusion of the complete modules within the perimeter, but they tend to offset themselves by having opposite signs.

The system variable θ can accept values up to 90 sexagesimal degrees. The number of modules contained within the considered area tends to be infinite when θ gets closer to 90°. The computational cost from 80 sexagesimal degrees increases exponentially, making the counter algorithm inoperative, independently of the system being studied.

Appraisal of Findings

The two methods used to model the studied structural systems lead us to two sets of differentiated results. In order to be able to analyse and compare them, different graphs have been produced. These obviously render more visually expressive results than a mere list of data.

When observing all of these together, we can identify some common traits. Essentially, they are characteristics that are unrelated to the modelling method, the system, the elements in the study (modules, rods or knots), as well as to the shape of the boundary to be covered (Fig. 15).

Looking at Fig. 15, first of all we can see that all graphs are increasing in the studied interval and are concave.

The use of absolute values makes them discontinuous, rendering finite gaps.

We can also note that all graphs display a horizontal asymptote, the closer θ gets to 0° (structure completely unfolded/open).

Similarly, a vertical asymptote appears in all graphs when θ approaches 90° (structure completely folded/closed). The appearance of this asymptote is due to the fact that, whether in the mathematical or digital model, the structure has been represented as lines and points, i.e. as elements lacking in thickness. When all of these structural elements are concentrated in one point, the number of them tends theoretically to be infinite. In reality, the physical thickness of these constructive elements would impose a limit for such values.

Next we will focus on the particularities of the results obtained when working with the mathematical model, before looking at those obtained with the digital model.

Results of the Mathematical Model

As has been already outlined, the mathematical equations obtained do not take into account the shape of the perimeter, so we can only produce sixteen graphs, i.e. four (M, R, Ks−1−r = Ks−3−r and Ks−2−r) for each of the four systems.

If we focus on the number of modules (M), we can see that the system that involves fewer modules is FE2, followed by FE1, EP1 and EP2. This characteristic does not vary according to the area being studied (Fig. 15).

We can also note that the system that requires fewer rods is FE1, followed by FE2, EP1 and EP2 (Fig. 15).

Taking into account the number of knots in the central position Ks−2−r, we can observe that the system that needs fewer joints is EP1, followed by EP2, FE2 and last by FE1.

However, when considering the number of knots in the end position Ks−1−r and Ks−3−r, we find that the system that requires a smaller number of knots is FE2, followed by FE1, EP1 and EP2.

Results of the Ideal Three-Dimensional Parametric Model Controlled by Algorithms

Generally, an initial glance leads us to ascertain that the results obtained via this method are similar to those acquired previously. Nevertheless, the model generated with Grasshopper, unlike the mathematical model, does let us take into account the boundary shape of the area to be covered and to evaluate the influence that it exerts.

If we focus on the degree to which the number of each system’s modules varies according to the shape of the aforementioned boundary, we can note that this variation is relatively small and that it represents a random dispersal of results for all of the cases and perimeters being studied. The distribution of these results for each of the systems can be seen in the graphs shown below (Fig. 16). It is important to note that in almost every case, the shapes with fewer dispersed results are the circle and hexagon, contrary to what might be deduced a priori.

However, we could conclude that the influence of the boundary shape on the number of elements involved for the purpose of the system is rather minimal. The results obtained by this method merely confirm those acquired by means of mathematical formulae, as can be observed when comparing, for instance, the M graphs for all systems EP1, EP2, FE1 and FE2 (Fig. 17)—FE2 continues to use fewer modules to cover the surface area, followed by FE1, EP1 and EP2.

In any case, in comparing the graphs acquired from formulae with those obtained from the digital model, we are able to see that the values represented in the latter are more accurate than those obtained from the equations, as the digital model takes into account the boundary characteristics created by the shape of the perimeter in question as part of the studied analysis.

Conclusions

In summary, based on what we have discussed above, we can assert that:

The estimation obtained using the Grasshopper software is quite precise and does not differ noticeably from what we have observed by producing mathematical equations. We would presume that such differences would become more apparent if we were to take into account a smaller proportion between the surface area to be covered and the bar length of each system (L).

The shape of the surface area to cover exerts, in the conditions deployed as part of this study, a limited influence on the number of system modules and components required for each of the areas studied, and this influence is proportional to the size of the rod length (L).

For this very reason, choosing one of the studied systems to cover an area of similar dimensions to the one we have studied here, is not necessarily an issue relating to the quantity of materials but one of constructive simplicity. It would be recommendable, therefore, to opt for systems that resolve the boundary challenges in a more straightforward way. A subsequent phase of the study will seek to determine how modelling by means of parametric algorithms can resolve the boundary challenges in characterising these foldable systems.

In addition, system FE2 was also found to be the more efficient systematically, in terms of number of modules, rods and joints. It is also worth mentioning that its graphs do not cross in the studied domain. This fact leads us to determine that system FE2 needs fewer modules to cover the surface areas studied, followed by FE1, EP1 and EP2. This reveals that Félix Escrig’s systems end up being more efficient from this perspective. At the other extreme, EP2 is deemed to be the least efficient system in terms of number of modules, rods and joints.

Notes

This module was initially introduced by Buckminster Fuller in his 1954 ‘Building Construction’ patent, where it was referred to as “tripod” (Fuller 1954).

Scissor-hinged mechanisms (Merchan’s classification) are typically referred to as pantographs in other classifications (see Fenci and Currie 2017). Hanaor and Levy (2001: 215) classify the systems by Piñero and Escrig in “pantographic grids”; Gantes, who refers to pioneers such as Piñero and Zeigler, does not provide an additional classification of these particular foldable structures. However, they do highlight the contribution of Escrig et al. in his attempt for classifying the pantographs and spherical two-way foldable grids (Fenci and Currie 2017: 115).

References

Alegria Mira, L., Filomeno Coelho, R., Thrall, A. P. and N. de Temmerman. 2015. Parametric evaluation of deployable scissor arches. Engineering Structures (99): 479–491.

Alegria Mira, L., Filomeno Coelho, R., Thrall, A. P. and N. de Temmerman. 2014. Deployable scissor arch for transitional shelters. Automation in Construction (43): 123–131.

Del Grosso A. E. and P. Basso. 2013. Deployable structures. Adv Sci Tech (83): 122–131.

Escrig-Pallarés, F. 1984. Sistema modular para la construcción de estructuras espaciales desplegables de barras. Spain patent application.

Escrig, F. 2012. Modular, Ligero y Transformable. Un paseo por la arquitectura ligera móvil. Sevilla: Secretariado de Publicaciones. Universidad de Sevilla.

Fenci, G. E. and N. G. Currie. 2017. Deployable structures classification: A review. International Journal of Space Structures 32 (2): 112–131.

Fuller, R. B. 1954. Building Construction. United States patent application.

Gantes C. J., J. J. Connor and R. D. Logcher. 1989. Structural analysis and design of deployable structures. Comput Struct (32): 661–669.

Gómez González, S. and Torner Ribé, J. 2016. Grasshopper para Rhinoceros e impresión 3D, Barcelona, Marcombo

González Meca, S. and J. Carrasco Hortal. 2015. Trasladar desplegables de tijeras (Pérez-Piñero) a contornos libres, ¿ejemplo de competencia gráfica de último nivel formativo?. EGA Expresión Gráfica Arquitectónica 20(25): 200–207.

Hanaor, A. and R. Levy. 2001. Evaluation of Deployable Structures for Space Enclosures. International Journal of Space Structures 16(4): 211–229.

Korkmaz K. 2004. An analytical study of the design potentials in kinetic architecture. İzmir: İzmir Institute of Technology.

Krausse, J. and L. Claudia. 2000. Your Private Sky. R. Buckminster Fuller Design als Kunst einer Wissenschaft. Baden: Lars Müller.

Merchan, C. H. H. 1987. Deployable structures. Cambridge: Department of Architecture, Massachusetts Institute of Technology.

Pellegrino, S. and J. F. V. Vincent. 2001. How to fold a membrane. In: Deployable structures, ed. S. Pellegrino, 59–75. Vienna: Springer.

Peña Fdez-Serrano, M. and Calvo López, J. 2013. From the first planetarium to the conquest of the moon. New proposals for transformable architecture, engineering and design. p. 393–398

Pérez-Almagro, M. C. (2013). Estudio y normalización de la colección museográfica y del archivo de la Fundación Emilio Pérez Piñero. Ph.D. thesis, Universidad de Murcia.

Pérez Belda, E. and M. C. Pérez Almagro. 2016. La arquitectura desplegable conmemora los XXV años de paz. 50 Aniversario del Pabellón de Emilio Pérez Piñero. EGA Expresión Gráfica Arquitectónica 21(28): 146–155.

Pérez Piñero, E. 1961. Estructura Reticular Esterea Plegable. Spain patent application.

Pérez Piñero, E. 1965. Three dimensional reticular structure. U S. Patent. United States of America.

Pérez Piñero, E. and C. Belda Aroca. 1976. System of articulated planes. U. S. Patent. United States of America.

Sánchez Sánchez, J., F. Escrig Pallarés and Mª T. Rodríguez-León. 2014. Reciprocal Tree-Like Fractal Structures. Nexus Network Journal 16(1): 135–150.

Stevenson, C. M. 2011. Morphological principles: current kinetic architectural structures. London: Adaptive Architecture, The Building Centre: 1–12.

Tedeschi, A. and F. Wirz. 2015. AAD Algorithms-Aided Design: parametric strategies using Grasshopper. Brienza: Le Penseur.

Acknowledgements

This paper is embedded within the work of a broader study, which is part of a research project entitled “Application of Parametric and Generative Design for the Analysis and Optimisation of Deployable Spatial Structures”, financed with public funds obtained as part of a competitive tender within the 2017–2019 period at UPCT. In subsequent phases of this research, we plan to include the material and constructive properties of elements, such as thickness, profile type, opening angle limits, collision points of the rods, etc., when modelling different structural systems. Funding was provided by Universidad Politécnica de Cartagena (Grant no. PRIPRO_2017_2453).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Ródenas-López, M.A., Peña Fernández-Serrano, M., Jiménez-Vicario, P.M. et al. Geometric Evaluation of Deployable Structures Using Parametric Modelling. Nexus Netw J 22, 247–270 (2020). https://doi.org/10.1007/s00004-019-00432-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00004-019-00432-9