Abstract

The objective of this study was to extend the shelf life of sliced sourdough bread by active packaging using oxygen absorbers of different capacity in combination with a modified atmosphere. The sourdough bread slices were packaged using biaxially oriented polypropylene/polyvinylidene chloride (BOPP/PVDC) bags with two oxygen absorbers of different capacity (100 and 300 cc) under different atmospheres (air, 50% carbon dioxide [CO2]:50% nitrogen [N2], 100% N2) and stored at 22 °C for 18 days. The high capacity absorbers kept the O2% concentration < 1% in 100% N2 atmosphere during the entire storage. In the headspace containing the high capacity absorber, the initial oxygen (21%) decreased below 1% in six days, and in nine days in the packages with the low capacity absorber. Whiteness index decreased and browning index increased during storage, but the highest whiteness index, lowest browning index and hardness were obtained for 100% N2 combined with the high capacity absorber. The chemical properties were affected by the storage time but not by the packaging treatments. The microbial growth was kept at a lower level in bags with 100% N2 and high capacity absorbers. The study indicated that modified atmosphere packaging (50% CO2 and 50% N2) with no initial oxygen was not sufficient to preserve microbial quality, possibly due to transfer of trapped oxygen from the pores of the sliced bread to the headspace during the storage period. The product packaged with 100% N2 and the high capacity absorber received the highest sensory scores and had the longest shelf life (12 days) among all treatments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Bread is one of the main and widely consumed foods in Turkey and worldwide due to its nutritional and sensory characteristics (Galic et al. 2009). Bread is mostly consumed fresh, and preservation of freshness is still a major challenge for the bakery industry due to fast staling which reduces consumer acceptability (Fik et al. 2012). Thus, bread is one of the most wasted foods (FAO 2011). Melini and Melini (2018) reported that spoilage of bread results in 5–10% losses in world bread production and economic losses for the bakery industry and the consumer besides health risks from mycotoxin contamination. The average shelf life of bread is about 3–4 days at room temperature for genuine bread made of flour, yeast, water and salt without any preservatives and enzymes (Nielsen and Rios 2000; Fik 2004; Galic et al. 2009; Khoshakhlagh et al. 2014). Enzymes such as amylases and lipases, emulsifiers and lipids are often included in bread formulations to retard staling (Pasqualone 2019). Sourdough lowers the pH and reduces mold growth. However, the pH drop and the acidification can extend bread shelf life only to a limited extent and/or do not extensively inhibit mold growth (Melini and Melini 2018). Apparently, the formulation has an influence on bread shelf life.

The main limiting factors on shelf life are staling and microbial spoilage mostly due to fungal activity (Nielsen and Rios 2000; Rodriguez et al. 2000; Kotsianis et al. 2002; Galic et al. 2009; Khoshakhlagh et al. 2014). There has been a growing interest in packaging and preservation technologies to retard staling and microbial spoilage and thus, increase the shelf life for whole and sliced bread (Nielsen and Rios 2000; Gutierrez et al. 2009); e.g. active packaging with absorbing and/or releasing compounds effective against bread staling and/or antimicrobials preventing the growth of undesirable microorganisms (Melini and Melini 2018). Pasqualone (2019) reviewed various packaging solutions to extend the shelf life of bread including all types of potential packaging materials and innovative packaging solutions from active and intelligent packaging to edible coating and nanomaterials coupled with modified atmosphere packaging (MAP). The author reported that active packaging in the form of active sachets could be less expensive than MAP as it does not need high-barrier films and special packaging machines for displacing atmospheric air from the headspace. The most widely used preservation methods are MAP technologies and the use of antimicrobials, basically chemical additives based on propionates and sorbates, especially for sliced products (Pasqualone 2019). However, consumers prefer additive free foods, especially when they are frequently and daily consumed (Melini and Melini 2018). MAP is reported to prevent the microbial spoilage and bread staling during storage (Rasmussen and Hansen 2001; Degirmencioglu et al. 2011; Khoshakhlagh et al. 2014). MAP aims to remove the atmospheric air by a gas mixture commonly composed by CO2 and N2 (Pasqualone 2019). CO2 is mostly used with MAP packaging of bakery products due to its bacteriostatic and fungistatic effects (Sivertsvik et al. 2002). It is also challenging to reduce the oxygen (O2) content in the package headspace to a very low concentration due to a large number of pores in the bread crumb which tend to trap O2 (Galic et al. 2009; Fik et al. 2012). Molds could grow in the headspace with an O2 concentration as low as 1–2% (Tabak and Cook 1978). However, a high CO2-MAP combined with nitrogen may not be sufficient to remove the trapped O2 in the pores.

Oxygen absorbers are proposed as an alternative to overcome this drawback of MAP packaging (Berenzon and Saguy 1998; Del Nobile et al. 2003; Melini and Melini 2018).

There are some researches concentrated on combination of the MAP and active packaging techniques to extend the shelf life of different types of bread (Fernandez et al. 2006; Degirmencioglu et al. 2011; Suhr and Nielsen 2013).

It was reported that no microbial growth was observed in sliced rye bread packaged with oxygen absorbers during 42 days of storage (Salminen et al. 1996). Del Nobile et al. (2003) prolonged the shelf life of the bread from three days to approximately 18 days in 80% CO2 + 20% N2 atmosphere using oxygen absorbers.

MAP technologies in combination with oxygen absorbers can be used more effectively to remove the O2 remaining in the pores of the sliced product and thus, retard the microbial spoilage and extend the shelf life. There is limited literature on a combination of MAP and oxygen absorbers as called active modified atmosphere for packaging of bakery products (Nielsen and Rios 2000; Guynot et al. 2003). Exploring active packaging applications as an alternative to chemical additives in frequently consumed products such as sliced bread could be an alternative for both industry and consumers who prefer a clean label.

Upasen and Wattanachai (2018) demonstrated that the combination of active packaging using oxygen scavengers and MAP has a high potential for bakery product industries. However, they reported that if the packaging film possesses a high barrier for O2 transmission, the use of oxygen scavenger and MAP is almost unnecessary. However, this is not valid for the sliced bread with pores trapping O2 which will eventually transfer into the package headspace even if the O2 transmission is prevented by the high barrier material. This study aimed to improve the quality indices and extend the shelf life of sliced sourdough bread using different capacity oxygen absorbers combined with MAP. The novelty of this study is to explore the combination of different capacity oxygen absorbers under 100% N2 for low cost active MAP packaging, and also different capacity oxygen absorbers under air atmosphere to investigate whether active packaging without using special MAP gases and packaging machines is possible.

2 Material and methods

2.1 Material

Sourdough bread slices consisting of wheat flour, water, sourdough starter, yeast and salt were freshly supplied from a local bakery. The packaging material was supplied by Polinas Packaging Company (Manisa, Turkey). The packaging material is of corona treated printable layer/transparent BOPP film/PVDC coating with a thickness of 31 µm. The O2 transmission rate (OTR) and water vapor transmission rate (WVTR) are 30.0 cm3/m2/24 h (at 23 °C and 0% relative humidity [RH]) and 3.5 g/m2/24 h (at 38 °C and 90% RH), respectively. Two different concentrations of oxygen absorbers (Fresh Life®) were provided by CML Food Company (Istanbul, Turkey): a low capacity absorber of 100 cc and a high capacity absorber of 300 cc.

The oxygen absorbers used in this study are iron based oxygen absorbers. In iron based O2, the reduced iron is oxidized to the non-toxic ferric oxide trihydrate complex under appropriate moisture conditions [4Fe (OH)2 + O2 + 2H2O → 4Fe (OH)3]. Thus, it consumes the O2 in the package headspace (Galic et al. 2009; Prasad and Kochhar 2014; Yildirim et al. 2018).

2.2 Packaging operation and shelf life study

The packaging film provided by the company was cut into sizes of 30 cm × 37 cm, and sealed with a constant heat sealer (ME-400 CFN, Mercier Corporation, Taiwan) at 125 °C to produce a pouch. The heat seal was tested for leaks according to dye penetration test method of Food and Drug Administration-Bacteriological Analytical Manual (FDA-BAM) (Arndt 2001).

Ten slices of bread (approx. 350 ± 30 g and each slice in 12 × 11 cm size) were placed in BOPP/PVDC bags hygenically and packaged with a single chamber packaging machine (Reepack, RV 300, Germany) combined with a triple gas mixer (KM60-3, Witt, Germany). Six different packaging applications were prepared (Table 1). Triplicate packages were prepared for each application and were stored at 22 °C for 18 days and analyzed on 0, 3, 6, 9, 12, 15 and 18 days for headspace gas, physical, chemical, microbiological and sensory attributes. 21 packages for each packaging application and a total of 126 packages for six packaging applications were prepared. Three packages on each analysis day were tested for each application.

2.3 Analyses

2.3.1 Headspace analysis

The headspace O2 (%v/v) and CO2 (%v/v) concentrations were determined using a gas analyzer (Witt, Oxybaby, Hamburg, Germany) before opening the packages. Gas analysis was performed by inserting the needle attached to the gas analyzer through an impermeable rubber seal attached to the outer surface of the packaging film. The results are expressed as O2% and CO2%. The measurements were taken twice from each bag and averages of six measurements were calculated for each application (Nalçabasmaz et al. 2017).

2.3.2 Physical analyses

The color of sliced bread samples was analyzed by a color analyzer (PCE-CSM 7, PCE Instruments, Meschede, Germany), using the CIE L*a* and b* scale. Five slices were taken from each bag, and the color measurements were performed on both sides of each slice. Averages of 30 measurements were taken for each application (Khoshakhlagh et al. 2014). Whiteness index (WI) and browning index (BI) were calculated based on the color values (L*, a* and b*) of sourdough bread with Eqs. 1–3.

Texture analysis was performed by TA-TX Plus (Stable Micro System, Surrey, UK) with the texture analyzer using a 50 mm diameter cylinder probe with 1 mm/s test speed and 30 kg load cell under compression mode. The samples were cut into 8 × 8 cm dimensions. Five slices were taken from each bag, and 15 measurements were taken for each application (Rasmussen and Hansen 2001). The results were expressed as compressive force (N) and bread firmness was measured according to the American Association of Cereals Chemists (AACC) method 74–09 (AACC 1999).

2.3.3 Chemical analyses

A total of 10 g was taken from five different slices of each bag and homogenized with 100 ml of distilled water for 1 min and the pH was measured with a calibrated pH meter (WTW-315, Germany). Two measurements were performed for each bag and averages of six measurements were taken for each application (American Association of Cereal Chemists International [AACCI], 2010). Analysis of water activity was performed on crust and crumb of the bread samples with a water activity meter (AquaLab®, Model Series 3, Decagon Devices, Inc., Pullman, WA., USA). Two measurements were made per crumb and crust for each bag and averages of six measurements were taken for each application.

2.3.4 Microbiological analyses

Total mesophilic aerobic bacterial count were measured. Total mesophilic aerobic bacteria were determined using plate count agar (PCA, Merck) with incubation at 37 ºC for 48 h. Microbial counts were expressed as log cfu/g. The microbiological quality (visible mold growth) of the bread slices was also observed visually and was calculated by dividing the number of slices having visible mold growth to the total number of slices per package on each analysis day.

2.3.5 Sensory evaluation

Sensory evaluation was performed with a panelist group of six experienced panelists. Crust and crumb color, smell and general acceptability properties were evaluated on a five points hedonic scale with the score of three and above indicating acceptability (Certel et al. 2009). Table 2 shows the evaluation criteria for each attribute.

2.3.6 Statistical analysis

Effects of experimental factors (packaging application and storage time) were evaluated by using a two-way analysis of variance (ANOVA) and Duncan multiple comparison range tests at 95% confidence level. SPSS 20.0 (SPSS Inc., Chicago, Illinois, USA) for Windows was used as the statistical software. All results are presented by mean values ± standard deviation.

3 Results and discussion

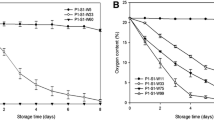

3.1 Headspace gas concentration (O2% and CO2%)

The headspace evolution of O2 and CO2 is shown in Fig. 1 and 2, respectively. The high capacity oxygen absorbers (300 cc) were able to keep the O2% concentration below 1% in 100% N2-MAP for the entire storage. However, with the low capacity absorbers (100 cc) the O2 level reached up to 2.1% on the 3rd day of storage possibly to the transfer of O2 from the pores of the bread. After the 3rd day the low capacity absorbers kept the O2% concentration below 1%. The initial O2 concentration (21%) of air atmosphere significantly decreased below 1% in six days in the headspace containing high capacity oxygen absorbers, while it took nine days for the packages with low capacity absorbers. This indicates that air atmosphere combined with the oxygen absorbers did not effectively lower the O2 content in a short time causing a higher microbial count during storage. Janjarasskul et al. (2016) reported that using an oxygen absorber (400 cc) combined with a high barrier pouch is a useful solution for eliminating the O2 remaining in the pores of sponge cake.

The effect of oxygen absorbers and MAP on headspace oxygen content (%) of sliced bread during the storage period (MAP1-OA1: 100% N2 + low capacity oxygen absorber, MAP1-OA2: 100% N2 + high capacity oxygen absorber, Air atmosphere-OA1: 21% O2 + 79% N2 + low capacity oxygen absorber, Air atmosphere-OA2: 21% O2 + 79% N2 + high capacity oxygen absorber, MAP2: 50% CO2 + 50% N2, Air atmosphere: (Control) 21% O2 + 79% N2)

The effect of oxygen absorbers and MAP on headspace carbon dioxide content (%) of sliced bread during the storage period (MAP1-OA1: 100% N2 + low capacity oxygen absorber, MAP1-OA2: 100% N2 + high capacity oxygen absorber, Air atmosphere-OS1: 21% O2 + 79% N2 + low capacity oxygen absorber, Air atmosphere-OA2: 21% O2 + 79% N2 + high capacity oxygen absorber, MAP2: 50% CO2 + 50% N2, Air atmosphere: (Control) 21% O2 + 79% N2)

Although there is no initial O2 in the application of 50% CO2 + 50% N2, the O2 increased up to 5% possibly due to transfer of trapped O2 from the sliced bread pores to the headspace on 6th day. This concentration of O2 decreased below 1% after 9 days of storage possibly due to aerobic microbial growth. Although 50–60% CO2 combined with N2 is widely suggested for bread packaging, it was not effective to remove the trapped O2 from the pores of the sliced bread. Similar results obtained by Öz et al. (2006) indicating that the headspace of packaged bread samples with MAP (30% CO2 + 70% N2) had no O2 initially, but O2 was detected between 2–3% due to the transfer of trapped O2 from the pores of bread slices during storage.

CO2 concentrations remained below 1% in the applications with high capacity oxygen absorbers for 15 days. CO2% levels increased up to 31.5% at the end of the storage with air atmosphere with low capacity oxygen absorbers, whereas the application of 100% N2 with the low capacity oxygen absorbers reached 13.1%. The released O2 from the pores possibly provided suitable growth conditions for aerobic microorganisms which produce CO2, resulting in CO2 increase for applications without oxygen absorbers.

Modified gas compositions without O2 are generally reported to be successful in slowing down the microbial growth. However, the negative effect of the trapped O2 in bread pores could only be eliminated by the use of oxygen absorbers (Piergiovanni and Fava 1997; Janjarasskul et al. 2016).

3.2 Physical properties

The WI decreased and BI increased in all treatments during increased storage (Table 3). Considering the recommended longest shelf life of sliced bread as 12 days, 100% N2 atmosphere with both oxygen absorbers had a higher WI than the air atmosphere. However, there was no significant difference in WI between products packaged under air atmosphere (control) and air atmopshere with both oxygen absorbers.

The bread slices packaged under 100% N2 atmosphere with both high and low capacity oxygen absorbers had lower browning index than the air application with both high and low capacity oxygen absorbers on 12th day of storage. The decrease in WI and increase in BI in bread could be explained by starch retrogradation and staling. Majzoobi et al. (2011) reported a time-dependent decrease in the L* value of the bread samples which was attributed to retrogradation of starch. In a study conducted on Sangak bread, color changes of bread were attributed to the bread staling rather than a moisture loss since there were negligible changes in moisture content during storage (Khoshakhlagh et al. 2014).

The effects of oxygen absorbers and MAP on the textural property of sliced bread are given in Table 4. The results are expressed in Newton (N) as the compressive force, and the increasing values refer to the hardening in texture. The hardness of bread slices increased for all applications during storage (p ≤ 0.05). Although there was no significant difference among packaging applications on the 18th day in terms of product hardness, the bread slices packaged under 100% N2 with high capacity oxygen absorbers had the highest softness on the 12th day of storage. Some studies indicated that packaging under CO2 atmosphere reduced the hardness of bread during storage (Knorr and Tomlins 1985; Cencic et al. 1996). On the other hand, it is also reported that hardness of bread is not affected by the atmosphere (Black et al. 1993; Rasmussen and Hansen 2001; Khoshakhlagh et al. 2014).

Increase in hardness is mostly attributed to the transfer of moisture through the bread crumb to the crust (Baik and Chinachoti 2000), moisture loss or retrogradation of starch in bread (Certel et al. 2009). Water acts like a plasticizer in the structure of bread. When the moisture content decreases, hydrogen bonds are formed between starch polymers or between starch and proteins, increasing the hardness (Schiraldi and Fessas 2001; Majzoobi et al. 2011).

3.3 Chemical properties

The pH increased slightly with increasing storage period at all treatments, but there was no apparent effect of any packaging treatment on pH (Table 5). Gerçekaslan (2006) and Kotancılar et al. (2009) reported that the pH values of sliced bread increased during storage. There was a positive correlation reported between pH and softness of the bread (Kotancılar et al. 2009).

There was gradual increase in water activity of the crust and very slight changes in water activity of the crumb for all applications during storage (p ≤ 0.05) (Table 6). On the 12th day of storage, there were no significant differences among packaging treatments in terms of water activity of the crust. As a result, chemical properties are mostly affected by the storage time but slightly by the packaging treatments with different capacity oxygen absorbers and modified atmosphere. Licciardello et al. (2014) and Ertugay (2006) reported similar results.

3.4 Microbiological quality

Bread slices packaged under 100% N2 and air atmosphere with the high capacity oxygen absorbers had the lowest bacterial growth during storage (Table 7). The total aerobic mesophilic bacterial growth in air atmosphere (control) reached up to 7.03 log cfu/g on the 18th day. Similar results were reported for sponge cake packaged with oxygen absorbers, suggesting that active packaging systems show great potential for delaying microbial growth (Janjarasskul et al. 2016).

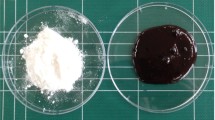

The effects of oxygen absorbers and MAP on visual microbial (mold) growth during storage time are shown in Table 8, and the photograph of the bread slices taken on 12th day of storage can be seen in Fig. 3. There was no visual mold growth until 6 days for all applications. However, bread slices packaged with 50% CO2 + 50% N2 atmosphere had 10%, a low capacity oxygen absorber combined with air atmosphere had 30%, and the air atmosphere group (control) had 40% of visible microbial growth on the 6th day. There was no visual mold growth on the slices packaged with high capacity oxygen absorbers under 100% N2 for 12 days and under air atmosphere for 9 days. Nevertheless, the visual mold growth was observed in all applications on 15th and 18th days. High CO2 (50%) with no oxygen absorbers was not enough to control the mold growth.

The use of low and high capacity oxygen absorbers with 100% N2 and high capacity O2oxygen absorbers with air atmosphere applications resulted in lowest mold growth throughout the entire storage. Black et al. (1993) showed that MAP (100% CO2) with oxygen absorbent sachets was the best technique for slowing down the yeast and mold growth for pita bread compared to MAP (15% CO2) without the sachets. Brasava et al. (2012) indicated that packages with oxygen absorbers were effective in slowing down mold growth until the 14th day.

Upasen and Wattanachai (2018) tested linear low-density polyethylene (LDPE) based materials with an oxygen scavenger and also sachets on bread and reported that although the scavenging capability of the oxygen absorber sachet lasted for only four days, the fungi and mold development thereafter was still lower compared to the package without the sachet. Combined applications of oxygen sensors as smart packaging technology and ethanol emitters as active packaging with MA (10% CO2 and 90% N2) were applied to Ciabatta bread (consisting of wheat flour, yeast, milk, water, sugar, salt and butter). oxygen sensors demonstrated that O2 was utilized by yeasts/moulds within the packs over time while the use of ethanol emitters prevented mycological growth, thereby extending the product shelf life (Hempel et al. 2013). However, the ethanol may have an adverse effect on taste and may not be acceptable by the consumer.

Results indicated that the most effective packaging technique was the use of high capacity oxygen absorbers to control the microbial growth for sliced bread where the low capacity oxygen absorbers were insufficient. N2 replaces the O2 in the headspace initially and then the O2 trapped in the pores (which could not be removed initially) and also possibly transmitted through the packaging material was absorbed by the high capacity oxygen absorbers providing low level of O2 (< 1%) in the headspace through the entire storage and preventing the mold growth for 12 days of storage.

3.5 Sensory evaluation

The panelist’s scores for crust and crumb color decreased during storage (Table 9). Products packaged with 100% N2 with high and low capacity oxygen absorbers were acceptable on the 12th day in terms of crust color. However, the products packaged only with 100% N2 and high capacity oxygen absorbers were acceptable on the 12th day of storage in terms of crumb color and odor. The acceptability for crust and crumb colors of the bread slices packaged with high CO2 application and air atmosphere (control) was limited to six days.

In terms of overall product acceptability, the bread slices packaged with 100% N2 and high capacity oxygen absorbers, and air atmosphere with high capacity oxygen absorbers were acceptable on the 12th day of storage. However, this period was nine days for air atmosphere with high capacity oxygen absorber due to visible mold growth on the 12th day.

It has been demonstrated that oxygen absorbers had no negative effects on the sensory quality of the packaged bread (Salminen et al. 1996; Latou et al. 2010). Freshly prepared bread slices packaged with oxygen absorbers were acceptable for longer time compared to bread slices packaged without oxygen absorbers (Matche et al. 2011).

4 Conclusions

In conclusion, the most effective application was the high capacity oxygen absorber combined with 100% N2. The O2 concentration (%) was below the critical concentration in 100% N2 with high capacity oxygen absorbers for the entire storage. However, in air atmosphere the high capacity oxygen absorbers reduced the O2 concentration in the headspace below the critical concentration within six days. Although there was no initial O2 in 50% CO2 + 50% N2 MAP application, the O2 concentration increased above 2% due to the trapped O2 in the pores of bread which caused aerobic microbial growth accordingly, and the shelf life was limited to three days. The product packaged with 100% N2 in combination with high capacity oxygen absorber received highest sensory scores among all applications and was acceptable for 12 days, and the shelf life was suggested as 12 days at 22 °C. MAP technologies in combination with the use of sufficient capacity oxygen absorbers can be used more effectively to remove the O2 trapped in the product and thus, retard microbial spoilage and extend the shelf life. Exploring oxygen absorbers as an active packaging application instead of using chemical additives in frequently consumed products like bread will be a good commercial alternative for the industry and consumers.

References

AACC (1999) Measurement of bread firmness by universal testing machine. In: Approved methods of the AACC (74–09). American Association of Cereals Chemists, St. Paul

AACCI (2010) American association of cereal chemists international, approved methods of analysis, method, 11th edn. AACCI International, St. Paul

Arndt GW (2001) Examination of flexible package for integrity: chapter 22C. In: Jackson GJ, Merker RI, Bander R (eds) Bacteriological analytical manual, 8th edn. AOAC International, Gaithersburg, MD, pp 16–17

Baik MY, Chinachoti P (2000) Moisture redistribution and phase transitions during bread staling. Am Associ Cereal Chem 77(4):484–488. https://doi.org/10.1094/CCHEM.2000.77.4.484

Berenzon S, Saguy IS (1998) Oxygen absorbers for extension of crackers shelf-life. LWT 31:1–5. https://doi.org/10.1006/fstl.1997.0286

Black RG, Quail KJ, Reyes V, Kuzyk M, Ruddick L (1993) Shelf-life extension of Pita bread by modified atmosphere packaging. Food Aust 45(8):387–391. https://doi.org/10.21608/jfds.2014.52739

Brasava SM, Dukalska L, Murniece I, Bicka ID, Kozlinskis A et al (2012) Active packaging influence on shelf life extension of sliced wheat bread. Int J Nutr Food Eng 6(7):480–486. https://doi.org/10.5281/zenodo.1333016

Cencic L, Bressa F, DallaRosa M (1996) Influence of modified atmosphere on bread staling during storage. Ital Food Bev Technol 71:20–24

Certel M, Erem F, Konak Üİ, Karakaş B (2009) Dondurulmuş hamur ile kısmi olarak pişirilip dondurulmuş hamurlardan üretilen beyaz ekmeklerin fiziksel tekstürel ve duyusal özellikleri. Akdeniz Üni Ziraat Fak Dergisi 22(1):91–102 (In Turkish)

Degirmencioglu N, Göcmen D, Inkaya AN, Aydin E, Guldas M et al (2011) Influence of modified atmosphere packaging and potassium sorbate on microbiological characteristics of sliced bread. J Food Sci Technol 48(2):236–241. https://doi.org/10.1007/s13197-010-0156-4

Del Nobile MA, Martoriello T, Cavella S, Giudici P, Masi P (2003) Shelf life extension of durum wheat bread. Ital J Food Sci 15:383–393

Ertugay MF (2006) The effect of packaging on water activity of bread. Food 31(1):43–47 (Article in Turkish with an abstract in English)

FAO (2011) Global food losses and food waste. FAO, Rome

Fernandez U, Vodovotz Y, Courtney P, Pascal MA (2006) Extended shelf life of soy bread using modified atmosphere packaging. J Food Prot 69(3):693–698. https://doi.org/10.4315/0362-028X-69.3.693

Fik M (2004) Bread staling and methods of prolonging its freshness. Zywnosc Nauka Technol Jakosc 2:5–22

Fik M, Surowka K, Maciejaszek İ, Macura M, Michalczyk M (2012) Quality and shelf life of calcium-enriched whole meal bread stored in a modified atmosphere. J Cereal Sci 56:418–424. https://doi.org/10.1016/j.jcs.2012.06.006

Galic K, Curic D, Gabric D (2009) Shelf life of packaged bakery goods. A review. Food Sci Nutr 49(5):405–426. https://doi.org/10.1080/10408390802067878

Gerçekaslan KE (2006) Trabzon Vakfıkebir ekmeğinin bayatlamasının çeşitli yöntemlerle takibi ve Francala ekmeği ile mukayesesi. Atatürk Üniversitesi, Fen Bilimleri Enstitüsü, Gıda Mühendisliği Bölümü, Yüksek Lisans Tezi (Master Thesis in Turkish)

Gutierrez L, Sanchez C, Batlle R, Nerin C (2009) New antimicrobial active package for bakery products. Trends Food Sci Technol 20:92–99. https://doi.org/10.1016/j.tifs.2008.11.003

Guynot ME, Sanchis V, Ramos AJ, Marin S (2003) Mold-free shelf-life extension of bakery products by active packaging. J Food Sci 68(8):2547–2552. https://doi.org/10.1111/j.1365-2621.2003.tb07059.x

Hempel AW, O’Sullivan MG, Papkovsky DB, Kerry JP (2013) Use of smart packaging technologies for monitoring and extending the shelf-life quality of modified atmosphere packaged (MAP) bread: application of intelligent oxygen sensors and active ethanol emitters. Eur Food Res Technol 237:117–124. https://doi.org/10.1007/s00217-013-1968-z

Janjarasskul T, Tananuwong K, Kongpensook V, Tantratian S, Kokpol S (2016) Shelf life extension of sponge cake by active packaging as an alternative to direct addition of chemical preservatives. LWT-Food Sci Technol 72:166–174. https://doi.org/10.1016/j.lwt.2016.04.049

Khoshakhlagh K, Hamdami N, Shahedi M, Le-Bail A (2014) Quality and microbial characteristics of part-baked Sangak bread packaged in modified atmosphere during storage. J Cereal Sci 60(1):42–47. https://doi.org/10.1016/j.jcs.2014.01.014

Knorr D, Tomlins RI (1985) Effect of carbon dioxide modified atmosphere on the compressibility of stored baked goods. J Food Sci 50(4):1172–1173. https://doi.org/10.1111/j.1365-2621.1985.tb13037.x

Kotancılar HG, Gerçekaslan KE, Karaoğlu MM (2009) Crumb pasting and staling properties of white and traditional Vakfıkebir breads. Turk J Agric for 33:435–443. https://doi.org/10.3906/tar-0901-28

Kotsianis IS, Giannou V, Tzia C (2002) Production and packaging of bakery products using MAP technology. Trends Food Sci Technol 13:319–324. https://doi.org/10.1016/S0924-2244(02)00162-0

Latou E, Mexis SF, Badeka AV, Kontaminas MG (2010) Shelf life extension of sliced wheat bread using either an ethanol emitter or an ethanol emitter combined with an oxygen absorber as alternatives to chemical preservatives. J Cereal Sci 52:457–465. https://doi.org/10.1016/j.jcs.2010.07.011

Licciardello F, Cipri L, Muratore G (2014) Influence of packaging on the quality maintenance of industrial bread by comparative shelf life testing. Food Packag Shelf Life 1(1):19–24. https://doi.org/10.1016/j.fpsl.2013.10.001

Majzoobi M, Farahnaky A, Agah S (2011) Properties and shelf-life of part-and full-baked flat bread (Barbari) at ambient and frozen storage. J Agric Sci Technol 13(7):1077–1090

Matche RS, Sreekumar RK, Raj B (2011) Modification of linear low-density polyethylene film using oxygen scavengers for its application in storage of bun and bread. J Appl Polym Sci 122(1):55–63. https://doi.org/10.1002/app.33718

Melini V, Melini F (2018) Strategies to extend bread and GF bread shelf-life: from sourdough to antimicrobial active packaging and nanotechnology—review. Fermentation 4:1–18. https://doi.org/10.3390/fermentation4010009

Nalçabasmaz S, Ayhan Z, Cimmino S, Silvestre C, Duraccio D (2017) Effects of PP-based nanopackaging on the overall quality and shelf life of ready-to-eat salami. Packag Technol Sci 30(10):663–679. https://doi.org/10.1002/pts.2309

Nielsen PV, Rios R (2000) Inhibition of fungal growth on bread by volatile components from spices and herbs, and the possible application in active packaging, with special emphasis on mustard essential oil. Int J Food Microbiol 60:219–229. https://doi.org/10.1016/S0168-1605(00)00343-3

Öz S, Özdemir M, Çevik T (2006) Oksijen emici ve farklı ambalaj malzemeleri kullanımının tost ekmeği özelliklerine etkisinin incelenmesi. In: Seventh National Chemical Engineering Conference, 5–8 September, Anadolu University, Eskişehir (in Turkish)

Pasqualone A (2019) Bread packaging: features and functions. In: Preedy VR, Watson RR (eds) Flour and breads and their fortification in health and disease prevention. Academic Press, London, pp 211–222

Piergiovanni L, Fava P (1997) Minimizing the residual oxygen in modified atmosphere packaging of bakery products. Food Addit Contam 14(6–7):765–773. https://doi.org/10.1080/02652039709374587

Prasad P, Kochhar A (2014) Active packaging in food industry: a review. IOSR-JESTFT 8:01–07. https://doi.org/10.9790/2402-08530107

Rasmussen PH, Hansen A (2001) Staling of wheat bread stored in modified atmosphere. LWT 34:487–491. https://doi.org/10.1006/fstl.2001.0793

Rodriguez M, Medin LM, Jordano R (2000) Effect of modified atmosphere packaging on shelf life of sliced wheat flour bread. Nahrung 44(4):247–252. https://doi.org/10.1002/1521-3803(20000701)44:4%3c247:AID-FOOD247%3e3.0.CO;2-I

Salminen A, Kala KL, Randell K, Hurme E, Linko P et al (1996) The effect of ethanol and oxygen absorption on the shelf-life of packed sliced rye bread. Packag Technol Sci 9:29–42. https://doi.org/10.1002/(SICI)1099-1522(199601)9:1%3c29::AID-PTS351%3e3.0.CO;2-K

Schiraldi A, Fessas D (2001) Mechanism of staling: An overview. In: Chinachoti P, Vodovotz Y (eds) Bread staling. CRC Press, USA, pp 1–17

Sivertsvik M, Rosnes JT, Bergslien H (2002) Modified atmosphere packaging. In: Ohlsson T, Bengtsson N (eds) Minimal processing technologies in the food industry. CRC Woodhead Publishing Limited, Cambridge, pp 61–86

Suhr KI, Nielsen PV (2013) Antifungal activity of essential oils evaluated by two different application techniques against rye bread spoilage fungi. J Appl Microbiol 94(4):665–674. https://doi.org/10.1046/j.1365-2672.2003.01896.x

Tabak HH, Cook WB (1978) The effects of gaseous environments on the growth and metabolism of fungi. Bot Rev 34:126–252

Upasen S, Wattanachai P (2018) Packaging to prolong shelf life of preservative-free white bread. Heliyon 4:1–21. https://doi.org/10.1016/j.heliyon.2018

Xie F, Dowell FE, Sun XS (2003) Comparison of near-infrared reflectance spectroscopy and texture analyzer for measuring wheat bread changes in storage. Cereal Chem 80(1):25–29. https://doi.org/10.1094/CCHEM.2003.80.1.25

Yildirim S, Röcker B, Pettersen MK, Nilsen-Nygaard J, Ayhan Z et al (2018) Active packaging applications for food. Compr Rev Food Sci Food Saf 17:165–199. https://doi.org/10.1111/1541-4337.12322

Acknowledgements

This work was supported by Scientific Research Projects Commission of Sakarya University (Project No. 2017-50-01-019, 2017-2018) as a part of a master thesis. The authors thank Polinas (Manisa, Turkey) for providing the packaging film.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kütahneci, E., Ayhan, Z. Applications of different oxygen scavenging systems as an active packaging to improve freshness and shelf life of sliced bread. J Consum Prot Food Saf 16, 247–259 (2021). https://doi.org/10.1007/s00003-021-01331-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00003-021-01331-3