Abstract

A refinery processes crude oils to manufacture a broad range of useful products, such as jet fuel, gasoline, petrochemicals, diesel, and asphalt constituents. In addition to being manufactured via hydro methods, kerosene can also be produced as a direct run product, particularly from heavier crude oil feedstocks. Hydrocarbon fuels like kerosene jet fuel are virtually exclusively made of carbon and hydrogen atoms. Aromatic compounds, cycloparaffins (naphthenes), and paraffins (iso and normal) make up the majority of the hydrocarbon composition. The ratios of these hydrocarbon components will vary in aviation jet fuel made from various feedstocks and processing methods. The burning of aviation turbine fuel has been linked to “global warming,” which is why “biojet” has been suggested as a way to blend fuel to lessen carbon emissions. The maximum percentage of biojet to conventional jet fuel blend permitted by the standard is 50%. While bioethanol and biobutanol, which have been shown to be effective as automotive fuels, were determined to be inappropriate for use in aircraft because they did not meet ASTM D7566-09 requirements. Many technological solutions have surfaced as a result of extensive global R&D activities. These systems generated renewable hydrocarbon fraction as drop-in fuel known as “biojet” using feedstock like animal fat, leftover agricultural products, municipal solid waste (MSW), waste cooking oil, plant seed oil, and waste cooking oil. Reduced carbon emissions in aviation fuel are the main advantage of using feedstock made from plants or agricultural waste in place of crude oil. To ensure that biojet is a sustainable, affordable, and environmentally friendly aviation fuel, a number of obstacles have to be overcome in order to meet the strict requirements of aviation fuel.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

2.1 Introduction

Our society has changed for the better because of air travel, which has improved community relations, fueled trade, and made it possible for things that were unavailable to earlier generations to be exchanged. Even though air travel makes the globe smaller and better, the energy necessary for flying comes at a significant cost. Highly specialized jet fuel (Jet-A-1), produced from crude oil, is used extensively in air transportation for people, cargo, and the military. The aviation industry has a significant need for 200 million tons of jet fuel annually due to the 5% annual increase in flight traffic worldwide (Davidson et al. 2014). Air carriers are a hazard to high-altitude propagation since they consume a lot of traditional fossil fuel (Jet-A), which is responsible for 2% of all greenhouse gas emissions from the transportation industry. To mitigate the effects of “global warming,” certain nations have suggested levying a “carbon tax” on airlines that utilize aviation fuel derived from fossil fuels, such as Jet A-1. The following objectives have been committed to by International Air Transport Association (IATA) members:

-

Increase fuel efficiency by 1.5% annually for the next 10 years

-

Attain growth that is carbon-neutral for the aviation industry as a whole

-

Achieve a 50% net reduction in CO2 emissions by 2050

2.1.1 Aviation Industry Growth

India has one of the highest fuel prices and taxes in the world, if not the highest overall, which negatively impacts the bottom line of smaller airlines. Over the last 5 years, India’s civil aviation sector has seen a 20% rise in both domestic and international air travel. Nitrogen oxides (NOX), carbon dioxide (CO2), water vapor (H2O), and particulate matter (PM) are the primary greenhouse gas (GHG) emissions from aviation during flight, and they all contribute to global air pollution (Martin et al. 2003). In order to replace fossil fuel-based Jet A-1 fuel, the aviation sector urgently needs green fuel. Second-generation biofuels could be a competitive alternative to Jet A-1, which is based on fossil fuels, and helps partially meet the demand for aviation fuel. This would help reduce the environmental impact of water vapor (H2O), nitrogen oxides (NOX), particulate matter (PM), and net carbon dioxide (CO2) (Özaydın et al. 2013).

The present refueling infrastructure may be used to partially mix these fuels with aviation gasoline, enabling the creation of a straightforward global supply chain system. Nevertheless, compared to other modes of transportation like cars, the use of biofuels in aviation is fraught with difficulties. One of the most difficult issues of using biofuels is in autos (Adhikari 2018).

The main prerequisites for environmentally friendly alternative jet fuels are as follows:

-

It can be combined with regular jet fuel.

-

Drop-in fuel is compatible with existing supply infrastructure and does not require engine or aircraft change.

-

I can meet the same standards as traditional jet fuel, especially those pertaining to temperature resistance.

-

It requires a lot of energy (minimum 42.8 MJ/kg).

-

It can meet environmental criteria such as lowering freshwater requirements, minimizing lifecycle carbon emissions, without affecting food production, and preventing deforestation.

The current aircraft industry’s strict requirements for aviation fuel must undoubtedly be met by any alternative fuel.

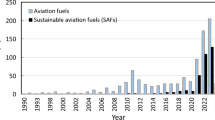

2.1.2 Biofuels That Are Sustainable for Aviation

The two most sustainable biofuels currently being produced for use in cars for surface transportation are bioethanol and biodiesel. While traditional automobiles in the EU, the United States, and India use a mixture of 5–10% (E5–E10) bioethanol in gasoline, Flexi cars in Brazil utilize an 85% bioethanol mixture in gasoline (E85) (Sinha et al. 2013). Table 2.1 shows compliance with aviation fuel specifications (Jet A-1). Diesel vehicles that use 20% biodiesel in place of petroleum diesel (B20) perform well all around the world. Nonedible oils derived from plant seeds and lignocellulosic biomass are the most sustainable feedstocks for large-scale bioethanol and biodiesel production, respectively.

These two biofuels have a significantly lower carbon footprint than gasoline and diesel, according to their life cycle analysis (LCA) (Tirado et al. 2021). Consequently, the most environmentally friendly biofuels for cars are now bioethanol and biodiesel. The limitations of employing bioethanol and biodiesel as aviation biofuels are shown in Table 2.2.

Although biodiesel and bioethanol are utilized with great success in road transport vehicles, their intrinsic qualities have limited their usage as sustainable aviation fuel. The best solution is an alternative fuel that satisfies all necessary fuel criteria, ideally derived from renewable sources. As a result, the primary requirements for aviation biofuel, also known as biojet, are synthetic fuels that meet the fundamental requirements of aviation turbine fuel (ATF), whether they are hydrocarbon or nonhydrocarbon kinds and have “drop-in” qualities (Zhu et al. 2014). These biofuels have no net carbon footprint and need less capital for supply chain infrastructure management and refining operations.

-

1.

They concentrated on creating a method that effectively creates jet propellant 8, or JP-8, an alternative to petroleum-based military jet fuel from oil-rich crops grown through aquaculture or agriculture. In the end, this method may provide an inexpensive substitute for JP-8 made from petroleum.

-

2.

Alternative fuels in airplanes have unique challenges (safety, logistics, temperature, etc.). The only options available to consider, considering the amount of money invested in aviation, are drop-in fuels or fuels having kerosene-like qualities that do not require major modifications to infrastructure or equipment architecture.

2.1.3 Bio-Aviation Fuel

Bio-aviation fuel is a mixture of synthetic paraffinic kerosene (SPK) made from biomass and jet fuel derived from petroleum. The manufacturing platforms, as well as a brief process description, for these is SPK. Oil-to-jet production platform hydroprocessed esters and fatty acids production method (HEFA) generates HEFASPK by hydroprocessing deoxygenated oils and fats. Other oil-to-jet platforms include fast pyrolysis of cellulose and hydrothermal liquefaction of plant or algal oil. These platforms are then followed by jet fuel upgrading (Abdullah et al. 2019). The gas-to-jet platform converts biomass into syngas through the Fischer–Tropsch production pathway (FT), which is then hydroprocessed to create FTSPK. Alcohols are created by fermenting the fermentable sugars that are produced after the biomass is hydrolyzed (Behrendt et al. 2018). The process of converting fermentable sugars from biomass into farnesene through fermentation, hydroprocessing, and fractionation is known as the “sugar-to-jet production platform” or “direct sugar-to-hydrocarbon jet fuel synthesis” (DSCH). Aqueous-phase reforming is followed by direct sugar to hydrocarbons and sugar catalytic reforming as other sugar-to-jet platforms. Chemical or biochemical intermediates are another option (Anderson et al. 2012). Additional potential advantages include job creation, price stability, and energy security. The usage of bio-aviation fuel may lead to rural development, which may include a rise in employment in production and agriculture, as well as a higher productivity of marginal nonarable land. Deployment has not got enough support despite its economic advantages. The production pathways must receive investments in the form of subsidies and legislative support in order to become economically competitive with the output of oil refineries (Campbell 2018).

2.2 Feedstocks for Biomass-Derived

2.2.1 Synthetic Paraffinic Kerosene

The four generations that feedstocks are divided into are the first, second, third, and fourth generations. Table 2.3 shows feedstocks for bio-aviation fuel production (Azwan et al. 2016). When choosing a feedstock, availability is an important factor to take into account. There is a connection between the availability of cultivated feedstocks and their potential yield. With a production of 19.2 t/ha/year, oil palm was the most productive of these feedstocks. Since algae culture is mostly done at the lab- to pilot scale, the potential output for microalgae for 3-G feedstocks has been estimated to be substantially bigger at 91 t/ha/year; however, this number is questionable (Couto et al. 2017).

2.2.2 Renewable Feedstocks

Nonetheless, developing sustainable biojet fuel necessitates a continuous, quantitative, and qualitative supply of renewable feedstocks. To guarantee a consistent supply of fuel for international flights, such feedstocks must to be accessible on all continents of the planet (Domínguez-García et al. 2017). Commercial flights have already used biojet fuels made from plant seed oils in modest amounts (Dzięgielewski et al. 2014). These flights, which were run by United, Lufthansa, JAL, and other airlines, all combined Jet A with biofuel made from the nonedible evergreen shrub Jatropha (Giudicianni et al. 2017). British Airways and Solena have partnered to begin manufacturing a synthetic paraffin product made from agricultural and urban waste (Fischer et al. 2018).

Three different kinds of raw materials could be used to produce carbon-free and affordable biojet fuel:

-

(a)

Lipids – camelina, rapeseed, karanjia, maize (corn), palm oil, jatropha, and used cooking oil are all types of oils derived from seeds. Certain procedures seek to employ both algal and animal fats.

-

(b)

Wood, agricultural wastes, and forest residues are examples of lignocellulosic biomass.

Energy crops include grasses and plants that grow quickly, such as giant reed, bamboo, and miscanthus.

-

(c)

Sugars

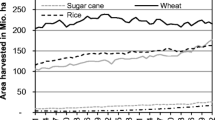

Malaysia, Indonesia, China, India, the United States, Brazil, and Argentina account for a sizable portion of global plant oil production, rapeseed, palm, soybean, and jatropha, serving as the primary feedstock oils (Gutiérrez-Antonio et al. 2013). Plant oils have the potential to be sustainably available worldwide, but some nations, like India, have limited supply of some of them, especially edible oils (He et al. 2017). Table 2.4 shows a summary of supply chain model for bio-aviation fuel provision. Aquatic algae, which might be grown in offshore or marine water, is another alternative source. Yeast lipids, for example, are being researched as potential nonplant sources of microbial lipids. The future of biojet generation from fats and oils, on the other hand, is about creating sustainability in big quantities at a fair cost (Karmee 2017).

Producing high-yielding nonfood grade oil feedstocks in areas with extremely wide production spaces, avoiding rivalry with (or displacement of) existing food production, and having enough water and other inputs are the only clear answers to these three key issues (Howe et al. 2015). Every year, India uses about 4.5 million tons of biojet fuel (Klein et al. 2018). Table 2.5 shows oil output from various oil plants per hectare (ha). Three million hectares of wasteland are available in India that might be planted with pongamia or jatropha, which would produce about nine million tons of oil annually, enough to produce biojets. Table 2.6 shows fuel properties and the role of fatty acid structure. Also, 70% of the world’s biomass supply is produced by regions of tropical Asia and Africa.

2.3 Technologies for Biojet Fuel Processing

2.3.1 Hydroprocessed Ester and Fatty Acids (HEFA)

A company’s renewable jet fuel process is an excellent illustration of cutting-edge technological techniques that could be used in the manufacturing of aviation biofuels (Jacobson et al. 2016). Tallow, algal oils, and a range of refined natural oils and fats, both edible and inedible, can all be converted using this procedure. Through the use of a selective cracking stage, the carbon chain lengths of natural oil, which range from C16–C18, are reduced to C10–C14 for jet fuel in the renewable jet process (Doliente et al. 2020). The aim of this novel technique is to achieve a 50–70% Bio-SPK (bio-kerosene) yield (Molefe et al. 2019). The catalytic processes of deoxygenation, isomerization, and selective cracking of the hydrocarbons found in natural fats and oils must be optimized in order to produce high-quality, ultralow sulfur jet fuel that satisfies Jet A-1 specifications, such as a freeze point of −47 °C and a flash point of 38 °C (Fig. 2.1). This innovative technique yields diesel and naphtha range fuels as by-products (Newes et al. 2015).

The procedure can be changed to create the Bio-SPK at a particular freeze point or it can be run in diesel mode instead. The Indian Institute of Petroleum Dehradun, a part of CSIR, has developed another cutting-edge catalytic technique for producing biofuels for the aviation and transportation sectors by hydroprocessing nonedible vegetable oils like jatropha seed oil (Fontes and Freires 2018). A demonstration facility processing 100 kg of jatropha oil per day successfully proved the process, yielding 33–40% of biojet fuel and 99% conversion, with the remaining liquid products being used as diesel and gaseous fuel (Mohseni and Pishvaee 2016). The CSIR-IIP fuel processing plan for transportation and aviation is shown in Fig. 2.2. A 40% maximum yield and a superior conversion rate of 99% for biojet may be achieved by using hierarchical mesoporous zeolites, silica–alumina, and mesoporous alumina as selective catalysts for the hydroconversion of waste cooking oil, seed oil, and algal oil (Pham et al. 2010). Table 2.7 shows a comparison of the characteristics of the biojet generated by CSIR-IIP. Using oil with different FFA contents is one advantage of the technique. A scheme for synthesized bio- kerosene production is illustrated in Fig. 2.3 (Pirker et al. 2016).

2.3.2 Synthetic Bio-Kerosene Process

In order to create synthetic fuels like biojet fuel and biodiesel, the process is primarily based on the concept of converting biomass into liquid (BtL), employing feedstocks including lignocellulosic biomass, wheat straw wood debris, and forest leftovers. There are five steps in this process: (a) pretreatment of biomass, (b) gasification or pyrolysis, (c) syn-gas purification, (d) Fischer–Tropsch (FT) synthesis, and (e) hydroisomerization of FT-wax to biojet, naphtha, and biodiesel, depending on needs. Sulfur and other contaminants are absent from the very high-quality kerosene fraction that is produced by the BtL process (Sannan et al. 2017).

2.3.3 Alcohol Oligomerization Process

Numerous businesses have announced the discovery of methods to turn alcohols into jet fuel; however, the viability of these procedures depends on the source of the alcohols. According to the American renewable chemicals and biofuels business Gevo, fermentable sugars obtained from cellulosic biomass have been successfully used to produce isobutanol, which is then transformed into paraffinic kerosene (jet fuel) and isobutylene (Raje and Davis 1997). It is also claimed that Lanzatech, a different business, produces alcohol from “clean” carbon monoxide-containing industrial waste gases and uses oligomerization and hydrogenation to turn the alcohol into jet fuel as illustrated in Fig. 2.4.

2.3.4 Direct Sugar to Hydrocarbons (DSHC)

To complete conversion, a sophisticated fermentation technique is used in the procedure. This biological conversion, in contrast to “traditional” sugar-to-ethanol fermentation, occurs under aerobic circumstances (Schmitt et al. 2019). Then, this passes through one further conversion process, producing the saturated and hydrogenated hydrocarbon farnesane. The authorized route was created through an alliance between Amyris, an industrial bioscience business located in California, and Total, a French petroleum distribution and refining corporation (Seber et al. 2014). Most eukaryotes and higher bacteria include farnesene, a terpenoid olefin (1,6,10-dodecatrienes, C15H24), which is biochemically generated through the mevalonate or isoprenoid pathway (Samsatli and Samsatli 2019). It dissolves well in alcohols but not in water. Pour point is −76 °C, boiling point is 250 °C, and density is 0.83 (15 °C).

Because farnesene and its isomers are non-hygroscopic, have very low pour points, densities, and have flash points that meet aviation fuel criteria, they offer an advantage over butanol and ethanol as biofuels.

2.3.4.1 Mevalonate Pathway

Actyl-CoA + Acetoacetyl-CoA 3-Hydroxy-3-methylglutaryl CoA (HMG-CoA) Mavelonate Isopentyl-PP Geranyl-PP Farnasyl-PP Farnesene

The principal enzymes connected to the route of terpenoid biosynthesis include

(a) acetyl-CoA acetyltransferase, (b) 3-hydroxy-3-methylglutarylcoenzyme A synthase, (c) HMG-CoA reductase, (d) mevalonate kinase, (e) phosphomevalonate kinase, (f) mevalonate pyrophosphate decarboxylase, (g) isopentenyl diphosphate (IPP) isomerase, (h) isoprene synthase, (i) farnesyl pyrophosphate (FPP) synthase, and (j) a-farnesene synthase.

Both aerobic and anaerobic microorganisms use glycolysis to produce the 2 mol of NADPH and the 3 mol of ATP needed for the process (Sinha et al. 2015). The ability to overproduce terpenoids through microbial fermentation instead of plant-based production has been made possible by recent advancements in synthetic biology and metabolic engineering. This has produced a number of significant discoveries, such as bulk chemicals and biofuels, as well as complicated natural products like artemisinin and taxol precursors. A scheme for the direct conversion of sugar to biojet is shown in Fig. 2.5.

2.3.5 Hydroprocessing Bio-Oil to Produce Biojet Fuel

The method is predicated on the hydrotreatment of bio-oil, which is made from wood and lignocellulosic biomass by fast and catalytic pyrolysis. Table 2.8 shows the status of development of the biojet fuel process. Co-processing heavy vacuum petrol oil (HVGO) and bio-oil in an oil refinery’s hydrotreatment unit is an additional method of producing Jet-A1 fuel as shown in Fig. 2.6.

A few large businesses, including BTG, Ensene, and UOP, are pushing the process, which is still in the developmental stage, to be demonstrated in a demo plant. Numerous chemicals, catalytic, and biocatalytic techniques have been demonstrated to be effective in converting various renewable feedstocks, including biomass, plant oilseeds, and sugars, into biojet fuel (Wang et al. 2021). However, in order to utilize such “biojet fuel” in commercial aircraft, it must be certified by the ASTM and be technologically and economically viable.

2.4 Feedstock Storage and Transportation, as well as Bio-Aviation Fuel

Planning and executing BAF provision present extra difficulties for the aviation sector due to the storage and supply chain mobility of intermediates, raw materials, and/or completed goods (Vasquez et al. 2017). Long-distance fuel and feedstock transportation dramatically raises supply chain expenses and greenhouse gas emissions. Therefore, it is necessary to reduce the associated effects in order to make BAF a more affordable and environmentally responsible substitute for CJF. The supply chain is generally not significantly affected by feedstock storage (Tao et al. 2017). However, across the supply chain, energy-intensive facilities that require a medium to long period to preserve and dry feedstocks may result in higher costs and emissions. Fortunately, storage becomes less of a problem after the final BAF products leave the biorefinery since sophisticated technologies, such as carrier tanks with particle settling and removal capabilities to preserve fuel, are already in place to support them during transport. However, the related effects of storage must be taken into account for its thorough planning, construction, and operation if they are to be taken into account within a supply chain for BAF provision (Wei et al. 2019).

A number of models have been put out to optimize the placement of industrial sites within BAF supply networks. The suggested models, however, only took the supply networks’ transportation component into account. In order to account for the storage required to fulfill short-term future demand, as well as the consequences of biodiversity and the energy, food, water, and environment, supply chain models for BAF need to be more detailed (Taylor et al. 2010). To guarantee that the outcomes are trustworthy and pertinent, they should be conducted with as much recent data as feasible.

2.5 Economic and Environmental Analyses

The most popular ways to transport feedstocks are by truck, rail, and ship; pipelines are the least used method at the moment, but they could be important in the future. According to a recent analysis of feedstock logistics, the impact of transportation costs and distances on feedstock usage will lead to a rise in interest in multimodal movement, or the combination of modes. The cost of transportation is made up of a set cost and a variable cost that varies according to distance and is usually lower for both rail and ship than for vehicle. Geographical variations, feedstock composition and type, and transport capacities all affect how much transportation costs vary between nations (Woytiuk et al. 2017). The high cost of transportation makes biomass transport impractical for distances greater than 150–200 km. In a similar vein, long-distance feedstock transportation can result in higher emissions over the course of the life cycle.

In a BAF supply chain, feedstock storage serves primarily to handle the temporal unpredictability of demand, particularly in seasons of poor productivity (Trivedi et al. 2015). The problem of storing lignocellulosic feedstocks without experiencing large dry matter losses (DML) needs to be solved. The location and climate of storage have an impact on the quality of the lignocellulosic feedstocks being held. There are also reported costs for every storage infrastructure.

2.6 Issues Restricting the Use of Biojet Fuels Worldwide

Many obstacles prevent the widespread use of inexpensive biojet fuels, including lack of regulatory incentives, manufacturing capacity, high production costs, competing feedstock applications, technological restrictions, and the possibility of waste and residues (Yan et al. 2018).

2.6.1 High Production Costs

Biojet fuel is now more expensive than petro Jet-A1 fuel because of the unpredictable and poor feedstock supply chain on the global market, including pogoma, camellia, and jatropha oil. In general, the price of biojet fuel depends on (a) input cost and composition of feedstock, (b) process technologies, (c) conversion efficiency and product yield, (d) value-added coproducts, and (e) process energy efficiency (Zhang et al. 2018a). It was found that between 50% and 70% of the cost of biojet fuel is made up of feedstock and hydrogen (Zhang et al. 2018b). As a result, the important determinant for cost reduction is a steady supply of prospective feedstock.

2.6.2 Technology and Plant Capacity

Pilot or demonstration stages are reached by several biojet fuel processes. Some of them still require technological development (Zhu et al. 2018). The utilization of trash and residues as feedstock offers the most net greenhouse gas reduction when compared to other alternative feedstocks; nevertheless, supply and its availability chain strategy have not yet been recognized worldwide (Agusdinata and DeLaurentis 2015). High-capacity stand-alone production units require a large investment as well as a high running cost. Biojet fuel might be used as a drop-in fuel in the aviation sector in the near future. As a result, such plants should be built near a petroleum refinery or another biofuel facility (Agusdinata et al. 2011).

2.6.3 Absence of Policy Motivation

To bring fuels closer to parity with fossil fuels, a number of countries have set up incentives for mixing bioethanol and biodiesel with gasoline or diesel. On the other hand, the aviation industry has not implemented any similar measures concerning the utilization of biojet fuel (Bailis and Baka 2010). This circumstance may result in global pricing and availability of discrepancies for feedstock and biojet fuel (Ball et al. 2005).

2.7 Conclusion

Given that there will likely be a rise in demand for aviation services in the near future, the challenge will be to meet this request while also adhering to global initiatives to reduce emissions (Eller et al. 2016). A crucial step in decarbonizing the sector and separating it from the finite supply of fossil fuels is the use of alternate jet fuel. This chapter has examined the possibilities for the bio-aviation fuel industry by carefully examining the feedstocks, manufacturing methods, storage alternatives, and modes of transportation (Elsoragaby et al. 2019). The following are the main conclusions:

-

1.

There are numerous feedstocks for the production of bio-aviation fuel that each have their own advantages in terms of the economy and the environment. Short- to medium-term inexpensive, high-yielding feedstocks with a high oil content might be a good interim option. While waste sources with uncertainty and variability, such used cooking oil and municipal solid waste, may limit their application, land-based crops with adverse environmental effects, like jatropha and oil palm, may also do the same.

-

2.

There are production paths, but they are not all equally prepared. Due to its established nature, HEFA presents a potential solution for the quick and affordable usage of bio-aviation fuel. It is crucial to look at other production techniques more, especially FT, which has higher capital expenditures than other approaches but is closer to commercial maturity and produces superior greenhouse gas reductions.

-

3.

Either centralized or dispersed, the transportation structure of refined petroleum products and biomass feedstock needs to be carefully designed to produce efficient supply chains. It has been found that using a variety of transportation modes throughout the chain can lower GHG emissions and transportation costs when traveling long distances.

-

4.

Supply chains for biofuels may be planned and designed with the use of optimization models, which are helpful tools for decision-making. Decisions made in the supply chain are influenced by temporal and spatial factors.

-

5.

These regulations must be simplified for every link in the supply chain in order to coordinate their growth and expansion and meet environmental and socioeconomic sustainability goals. Since the aviation industry is international, certain regulations must be harmonized worldwide while also providing sufficient flexibility to meet the diverse national goals of different countries.

References

Abdullah B, Muhammad SAFAS, Shokravi Z, Ismail S, Kassim KA, Mahmood AN, Aziz MMA (2019) Fourth generation biofuel: a review on risks and mitigation strategies. Renew Sust Energ Rev 107:37–50

Adhikari DK (2018) Bio-jet fuel. In: Biorefining of biomass to biofuels: opportunities and perception. Springer, pp 187–201

Agusdinata DB, DeLaurentis D (2015) Multi-actor life-cycle assessment of algal biofuels for the US airline industry. In: Algal biorefineries: volume 2: products and refinery design. Springer, pp 537–551

Agusdinata DB, Zhao F, Ileleji K, DeLaurentis D (2011) Life cycle assessment of potential biojet fuel production in the United States. Environ Sci Technol 45(21):9133–9143

Anderson S, Cooper J, Gudde N, Howes J (2012) Aviation renewable fuels: technical status and challenges for commercialisation. Aeronaut J 116(1185):1103–1122

Azwan MB, Norasikin AL, Abd Rahim S, Norman K, Salmah J (2016) Analysis of energy utilisation in Malaysian oil palm mechanisation operation. J Oil Palm Res 28(4):485–495

Bailis RE, Baka JE (2010) Greenhouse gas emissions and land use change from Jatropha curcas-based jet fuel in Brazil. Environ Sci Technol 44(22):8684–8691

Ball J, Carle J, Del Lungo A (2005) Contribution of poplars and willows to sustainable forestry and rural development. Unasylva 56(2):3

Behrendt D, Schreiber C, Pfaff C, Müller A, Grobbelaar J, Nedbal L (2018) Algae as a potential source of biokerosene and diesel–opportunities and challenges. In: Kaltschmitt M, Neuling U (eds) Biokerosene: status and prospects. Springer, Berlin/Heidelberg, pp 303–324

Campbell M (2018) Camelina–an alternative oil crop. In: Biokerosene: status and prospects. Springer, Berlin, pp 259–275

Couto ND, Silva VB, Monteiro E, Rouboa A, Brito P (2017) An experimental and numerical study on the Miscanthus gasification by using a pilot scale gasifier. Renew Energy 109:248–261

Davidson C, Newes E, Schwab A, Vimmerstedt L (2014) Overview of aviation fuel markets for biofuels stakeholders

Doliente SS, Narayan A, Tapia JFD, Samsatli NJ, Zhao Y, Samsatli S (2020) Bio-aviation fuel: a comprehensive review and analysis of the supply chain components. Front Energy Res 8:110

Domínguez-García S, Gutiérrez-Antonio C, De Lira-Flores JA, Ponce-Ortega JM, El-Halwagi MM (2017) Strategic planning for the supply chain of aviation biofuel with consideration of hydrogen production. Ind Eng Chem Res 56(46):13812–13830

Dzięgielewski W, Gawron W, Kaźmierczak U, Kulczycki A (2014) Butanol/biobutanol as a component of an aviation and diesel fuel. J Kones 21

Eller Z, Varga Z, Hancsók J (2016) Advanced production process of jet fuel components from technical grade coconut oil with special hydrocracking. Fuel 182:713–720

Elsoragaby S, Yahya A, Mahadi MR, Nawi NM, Mairghany M (2019) Energy utilization in major crop cultivation. Energy 173:1285–1303

Fischer M, Zenone T, Trnka M, Orság M, Montagnani L, Ward EJ, Ceulemans R (2018) Water requirements of short rotation poplar coppice: experimental and modelling analyses across Europe. Agric For Meteorol 250:343–360

Fontes CHDO, Freires FGM (2018) Sustainable and renewable energy supply chain: a system dynamics overview. Renew Sust Energ Rev 82:247–259

Giudicianni P, Pindozzi S, Grottola CM, Stanzione F, Faugno S, Fagnano M, Ragucci R (2017) Pyrolysis for exploitation of biomasses selected for soil phytoremediation: characterization of gaseous and solid products. Waste Manag 61:288–299

Gutiérrez-Antonio C, Gómez-Castro FI, Segovia-Hernández JG, Briones-Ramírez A (2013) Simulation and optimization of a biojet fuel production process. In: Computer aided chemical engineering, vol 32. Elsevier, pp 13–18

He CR, Kuo YY, Li SY (2017) Lignocellulosic butanol production from Napier grass using semi-simultaneous saccharification fermentation. Bioresour Technol 231:101–108

Howe D, Westover T, Carpenter D, Santosa D, Emerson R, Deutch S, Lukins C (2015) Field-to-fuel performance testing of lignocellulosic feedstocks: an integrated study of the fast pyrolysis–hydrotreating pathway. Energy Fuel 29(5):3188–3197

Jacobson RA, Keefe RF, Smith AM, Metlen S, Saul DA, Newman SM, Inman D (2016) Multi-spatial analysis of forest residue utilization for bioenergy. Biofuels Bioprod Biorefin 10(5):560–575

Karmee SK (2017) Fuel not food—towards sustainable utilization of gutter oil. Biofuels 8(3):339–346

Klein BC, Chagas MF, Junqueira TL, Rezende MCAF, de Fátima Cardoso T, Cavalett O, Bonomi A (2018) Techno-economic and environmental assessment of renewable jet fuel production in integrated Brazilian sugarcane biorefineries. Appl Energy 209:290–305

Martin VJ, Pitera DJ, Withers ST, Newman JD, Keasling JD (2003) Engineering a mevalonate pathway in Escherichia coli for production of terpenoids. Nat Biotechnol 21(7):796–802

Mohseni S, Pishvaee MS (2016) A robust programming approach towards design and optimization of microalgae-based biofuel supply chain. Comput Ind Eng 100:58–71

Molefe M, Nkazi D, Mukaya HE (2019) Method selection for biojet and biogasoline fuel production from castor oil: a review. Energy Fuel 33(7):5918–5932

Newes EK, Bush BW, Peck CT, Peterson SO (2015) Potential leverage points for development of the cellulosic ethanol industry supply chain. Biofuels 6(1–2):21–29

Özaydın B, Burd H, Lee TS, Keasling JD (2013) Carotenoid-based phenotypic screen of the yeast deletion collection reveals new genes with roles in isoprenoid production. Metab Eng 15:174–183

Pham V, Holtzapple M, El-Halwagi M (2010) Techno-economic analysis of biomass to fuel conversion via the MixAlco process. J Ind Microbiol Biotechnol 37(11):1157–1168

Pirker J, Mosnier A, Kraxner F, Havlík P, Obersteiner M (2016) What are the limits to oil palm expansion? Glob Environ Chang 40:73–81

Raje AP, Davis BH (1997) Fischer-Tropsch synthesis over iron-based catalysts in a slurry reactor. Reaction rates, selectivities and implications for improving hydrocarbon productivity. Catal Today 36(3):335–345

Samsatli S, Samsatli NJ (2019) The role of renewable hydrogen and inter-seasonal storage in decarbonising heat–comprehensive optimisation of future renewable energy value chains. Appl Energy 233:854–893

Sannan S, Jordal ABK, Roussanaly S, Giraldi C, Clapis A (2017) Understanding the cost of retrofitting CO2 capture in an integrated oil refinery: reference base case plants: economic evaluation. SINTEF Rapport

Schmitt N, Apfelbacher A, Jäger N, Daschner R, Stenzel F, Hornung A (2019) Thermo-chemical conversion of biomass and upgrading to biofuel: the Thermo-catalytic reforming process–a review. Biofuels Bioprod Biorefin 13(3):822–837

Seber G, Malina R, Pearlson MN, Olcay H, Hileman JI, Barrett SR (2014) Environmental and economic assessment of producing hydroprocessed jet and diesel fuel from waste oils and tallow. Biomass Bioenergy 67:108–118

Sinha AK, Anand M, Rana BS, Kumar R, Farooqui SA, Sibi MG, Joshi RK (2013) Development of hydroprocessing route to transportation fuels from non-edible plant-oils. Catal Surv Jpn 17:1–13

Sinha M, Sørensen A, Ahamed A, Ahring BK (2015) Production of hydrocarbons by aspergillus carbonarius ITEM 5010. Fungal Biol 119(4):274–282

Tao L, Milbrandt A, Zhang Y, Wang WC (2017) Techno-economic and resource analysis of hydroprocessed renewable jet fuel. Biotechnol Biofuels 10:1–16

Taylor JD, Jenni MM, Peters MW (2010) Dehydration of fermented isobutanol for the production of renewable chemicals and fuels. Top Catal 53:1224–1230

Tirado A, Trejo F, Ancheyta J (2021) Prediction of temperature profiles for catalytic hydrotreating of vegetable oil with a robust dynamic reactor model. Ind Eng Chem Res 60(38):13812–13821

Trivedi P, Malina R, Barrett SR (2015) Environmental and economic tradeoffs of using corn Stover for liquid fuels and power production. Energy Environ Sci 8(5):1428–1437

Vasquez MC, Silva EE, Castillo EF (2017) Hydrotreatment of vegetable oils: a review of the technologies and its developments for jet biofuel production. Biomass Bioenergy 105:197–206

Wang ZJ, Staples MD, Tyner WE, Zhao X, Malina R, Olcay H et al (2021) Quantitative policy analysis for sustainable aviation fuel production technologies. Front Energy Res 9:751722

Wei H, Liu W, Chen X, Yang Q, Li J, Chen H (2019) Renewable bio-jet fuel production for aviation: a review. Fuel 254:115599

Woytiuk K, Campbell W, Gerspacher R, Evitts RW, Phoenix A (2017) The effect of torrefaction on syngas quality metrics from fluidized bed gasification of SRC willow. Renew Energy 101:409–416

Yan X, Jiang D, Fu J, Hao M (2018) Assessment of sweet sorghum-based ethanol potential in China within the water–energy–food nexus framework. Sustainability 10(4):1046

Zhang Z, Wang Q, Chen H, Zhang X (2018a) Hydroconversion of waste cooking oil into bio-jet fuel over a hierarchical NiMo/USY@ Al-SBA-15 zeolite. Chem Eng Technol 41(3):590–597

Zhang B, Wu J, Yang C, Qiu Q, Yan Q, Li R et al (2018b) Recent developments in commercial processes for refining bio-feedstocks to renewable diesel. Bioenergy Res 11:689–702

Zhu F, Zhong X, Hu M, Lu L, Deng Z, Liu T (2014) In vitro reconstitution of mevalonate pathway and targeted engineering of farnesene overproduction in Escherichia coli. Biotechnol Bioeng 111(7):1396–1405

Zhu Z, Chu F, Dolgui A, Chu C, Zhou W, Piramuthu S (2018) Recent advances and opportunities in sustainable food supply chain: a model-oriented review. Int J Prod Res 56(17):5700–5722

Acknowledgment

It is my proud privilege and special appreciation toward the Department of Chemistry, Vigyan Mandir, Banasthali Vidyapith, Rajasthan.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Kumari, A., Kumar, D., Sati, P., Kumar, S., Yadav, A.K., Verma, A.S. (2024). Overview of Aviation Sector, Feedstock, and Supply Chain. In: Kuila, A. (eds) Biojet Fuel: Current Technology and Future Prospect. Clean Energy Production Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-99-8783-2_2

Download citation

DOI: https://doi.org/10.1007/978-981-99-8783-2_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-8782-5

Online ISBN: 978-981-99-8783-2

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)